Lithium manganese ferric phosphate-ternary material composite positive electrode material and preparation method therefor

A composite cathode material, lithium iron manganese phosphate technology, applied in electrical components, battery electrodes, structural parts, etc., can solve the problems of component segregation, reduced energy density of mixed electrodes, and difficulty in uniform distribution of particles, preventing deterioration and improving stability. Sexuality and Circulation, Effects of Reducing Contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also discloses a preparation method of lithium manganese iron phosphate-ternary material composite positive electrode material, comprising the following steps:

[0049] S1, mix lithium manganese iron phosphate material with ternary material in a certain proportion, the quality of lithium manganese iron phosphate material is M1, the quality of ternary material is M2, M1:M2 is between 1:99 and 4:6, and ferromanganese phosphate The sum of the mass of lithium and the mass of the ternary material is the mass of the active material of the lithium battery, which is Ma=M1+M2; preferably, M1:M2 is between 5:95 and 15:85;

[0050] S2, adding a certain mass ratio of binder and conductive agent, wherein the quality of the solid binder is M3; the quality of the conductive agent is M4, wherein: M3: Ma is between 0:100 and 5:100, M4: Ma between 0:100 and 5:100;

[0051] S3, using a mechanical fusion machine to perform high-speed mechanical fusion to obtain lithi...

Embodiment 1

[0058] Lithium manganese iron phosphate particles and ternary material NCM523 are mixed according to the mass ratio of 1:9 and then mechanically fused and coated:

[0059] 1. Use a mechanical fusion machine with a cabin volume of 0.3 liters, and load 180 grams of ternary material NCM523 and 20 grams of lithium manganese iron phosphate material;

[0060] 2. The product was obtained after the equipment was operated at a speed of 4600 rpm for 4 minutes, which was named product 1;

[0061] 3. The electron microscope photo of product 1 is shown in the attachment figure 1 - attached image 3 ;

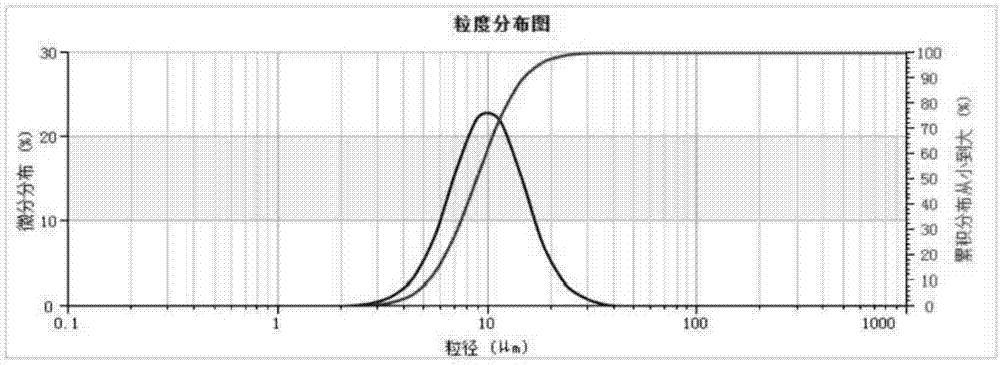

[0062] 4. Product 1 was measured with a laser particle size analyzer, using water as the medium, and the refractive index of the ternary material and product 1 were both set to 2.6. The results are described in Table 1. The particle size distribution of the ternary material is shown in the appendix Figure 5 , the particle size distribution of product 1 is shown in the attached Figure 6...

Embodiment 2

[0068] The lithium manganese iron phosphate particles and the ternary material NCM523 are mixed according to the mass ratio of 3:7 and then mechanically fused and coated:

[0069] 1. Use a mechanical fusion machine with a cabin volume of 0.3 liters, and load 140 grams of ternary material NCM523 and 60 grams of lithium manganese iron phosphate material;

[0070] 2. The product was obtained after the equipment was operated at a speed of 4600 rpm for 4 minutes, which was named product 2;

[0071] 3. The electron microscope photo of product 2 is shown in Figure 1-Figure 3 ;

[0072]4. Product 2 is measured with a laser particle size analyzer, using water as the medium, and setting the refractive index of the ternary material and product 2 to 2.6. The results are described in Table 1. The particle size distribution diagram of the ternary material is shown in Figure 5 , the particle size distribution of product 2 is shown in Figure 7 ;

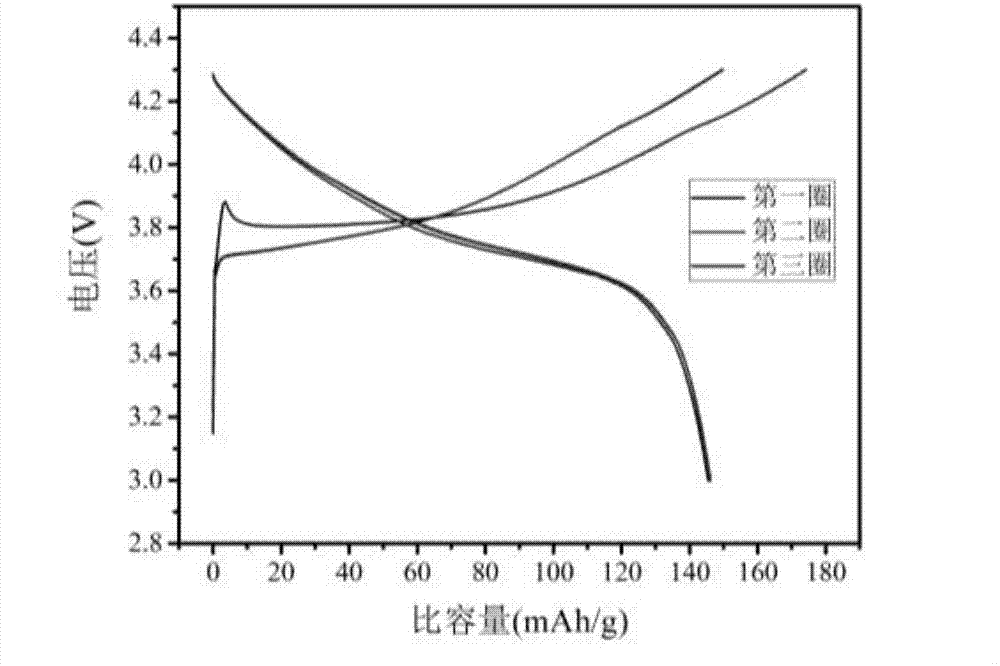

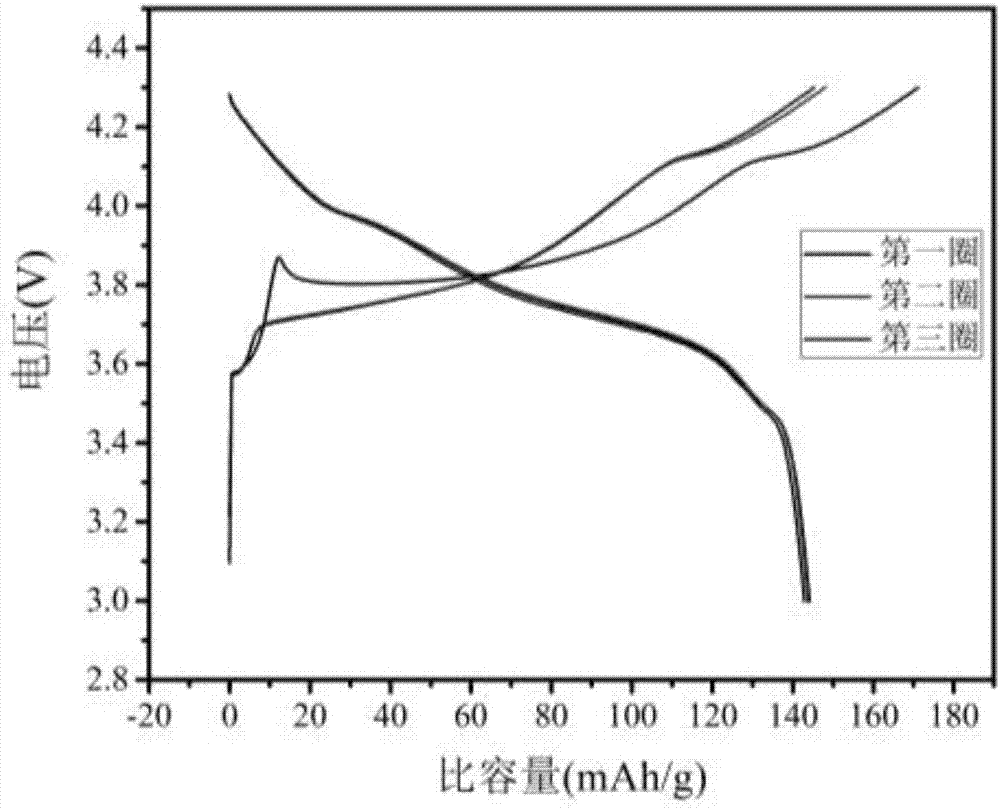

[0073] 5. The charge and discharge cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com