Refining device for preparing high-pure isobutene by cracking methyl tertiary butyl ether and technique thereof

A technology of methyl tertiary butyl ether and refining device, applied in the field of rectification, can solve the problems of incomplete absorption of methanol, inability to produce high purity, affecting purity, etc., to reduce energy consumption and production cost, and reduce the pressure drop of the whole tower , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

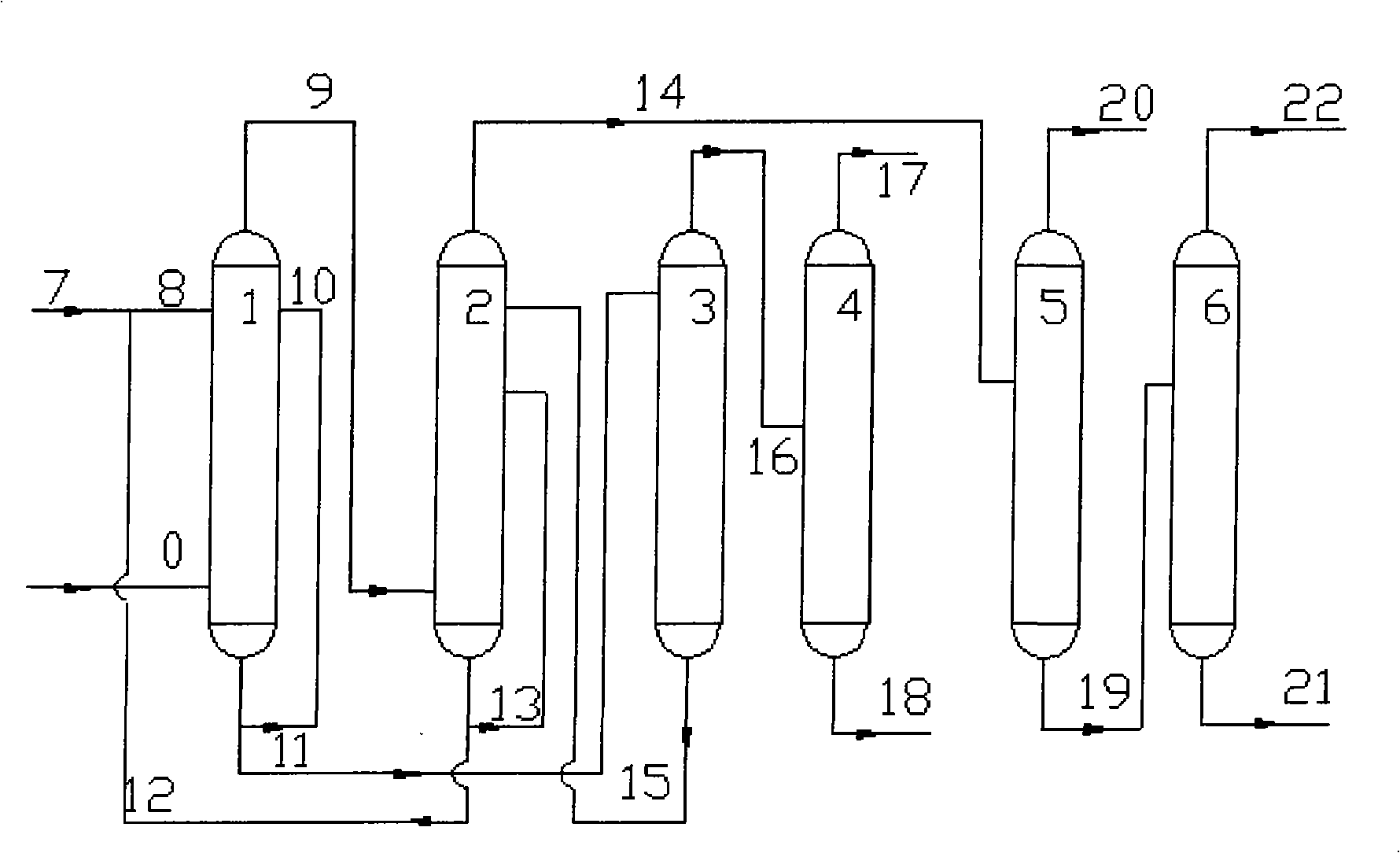

[0019]After cracking of methyl tert-butyl ether (MTBE), it contains 58.75% (wt) of isobutylene, 34.52% (wt) of methanol, 4.92% (wt) of MTBE, 0.51% (wt) of dimethyl ether, and 0.15% (wt) of tert-butanol , water 0.25% (wt) and C80.9% (wt) cracked gas 0 enters the described cooling absorption double tower system from the tower still of cooling absorption tower 1 and starts cooling absorption operation, and cooling absorption tower 2 tower stills distillate water 8( Fresh water 7) enters the cooling absorption tower 1 from the top of the tower when just driving. Cooling absorption tower 1 is operated under normal pressure or slightly positive pressure, with 16 theoretical plates, and the internals of the tower adopt high-efficiency structured packing and multi-row hole distribution internals. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com