Long-carbon-chain heat-conducting nylon composite material and preparation method thereof

A nylon composite material and long carbon chain technology, which is applied in the field of long carbon chain heat-conducting nylon composite materials and its preparation, can solve the problems of whitening of air marks, poor fluidity, unfavorable assembly, etc., and achieve reduced consumption, environmental friendliness, and reduction row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

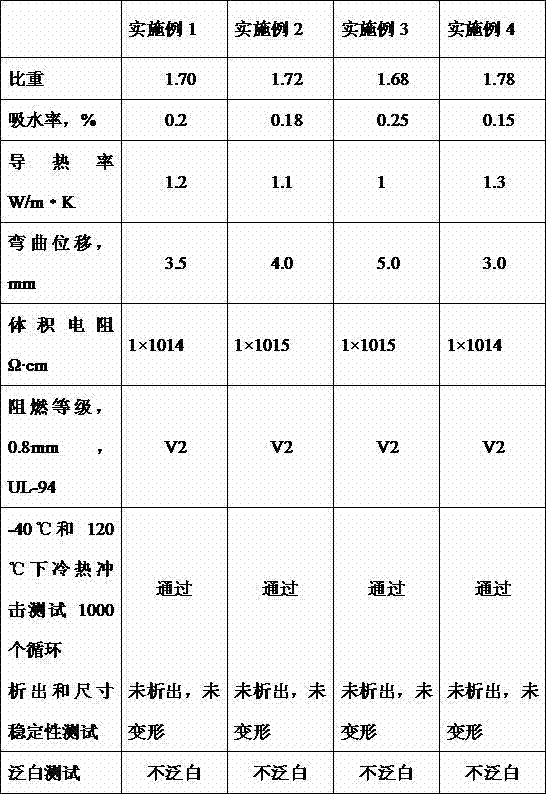

Examples

Embodiment 1

[0063] According to the mass percentage of raw material formula: long carbon chain nylon resin 25.0%, thermal conductive filler 45%, reinforcing filler 10%, halogen-free flame retardant 18%, coupling agent 0.4%, lubricant 1%, antioxidant 0.3%, color Powder 0.3%. Mix the weighed long carbon chain nylon resin and coupling agent in a mixing tank at a speed of 100 rpm for 30 seconds, then add antioxidant, mix for another 30 seconds, then add thermally conductive filler, halogen-free flame retardant , lubricant, toner and mix for 3 minutes. The mixed raw materials are melted, kneaded and extruded through the meshing co-rotating twin-screw extruder, and at the same time, the reinforcing filler is fed into the barrel of section 6 using the side feeding device.

[0064] The temperature control of the twin-screw extruder is as follows: the first section is 160℃~180℃, the second section is 180℃~200℃, the third section is 200℃~220℃, the fourth section is 200℃~220℃, and the fifth section...

Embodiment 2

[0067] According to the mass percentage of raw material formula: long carbon chain nylon resin 30.0%, thermal conductive filler 40%, reinforcing filler 13%, halogen-free flame retardant 15.5%, coupling agent 0.3%, lubricant 0.8%, antioxidant 0.2%, color Powder 0.2%. Mix the weighed long carbon chain nylon resin and coupling agent in a mixing tank at a speed of 100 rpm for 30 seconds, then add antioxidant, mix for another 30 seconds, then add thermally conductive filler, halogen-free flame retardant , lubricant, toner and mix for 3 minutes. The mixed raw materials are melted, kneaded and extruded through the meshing co-rotating twin-screw extruder, and at the same time, the reinforcing filler is fed into the barrel of section 6 using the side feeding device.

[0068] The temperature control of the twin-screw extruder is as follows: the first section is 160℃~180℃, the second section is 180℃~200℃, the third section is 200℃~220℃, the fourth section is 200℃~220℃, and the fifth sec...

Embodiment 3

[0071] According to the mass percentage of raw material formula: long carbon chain nylon resin 33.7%, thermal conductive filler 35%, reinforcing filler 16%, halogen-free flame retardant 14%, coupling agent 0.2%, lubricant 0.6%, antioxidant 0.4%, color Powder 0.1%. Mix the weighed long carbon chain nylon resin and coupling agent in a mixing tank at a speed of 100 rpm for 30 seconds, then add antioxidant, mix for another 30 seconds, then add thermally conductive filler, halogen-free flame retardant , lubricant, toner and mix for 3 minutes. The mixed raw materials are melted, kneaded and extruded through the meshing co-rotating twin-screw extruder, and at the same time, the reinforcing filler is fed into the barrel of section 6 using the side feeding device.

[0072] The temperature control of the twin-screw extruder is as follows: the first section is 160℃~180℃, the second section is 180℃~200℃, the third section is 200℃~220℃, the fourth section is 200℃~220℃, and the fifth secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com