A viscosity modifying material specially used for self-compacting concrete for CRTSIII type plates

A technology of self-compacting concrete and modified materials, which is applied in the field of new concrete materials, can solve the problems of poor passability of gaps, high sensitivity to water consumption, and poor system stability, so as to avoid laitance and buoyant layers and improve durability , Constant thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The ratio of viscosity-modified materials for new self-compacting concrete of CRTSⅢ type slab is shown in Table 1:

[0028] Table 1 Proportion of viscosity-modified materials for new self-compacting concrete of CRTSⅢ type slab

[0029] components Proportion(%) components Proportion(%) fumed silica 47 Low Viscosity Hydroxyethyl Cellulose 0.3 Nano Calcium Carbonate 49.1 High Viscosity Hydroxyethyl Cellulose 0.4 Polyamide 1.2 Water-soluble polymer rubber powder 2

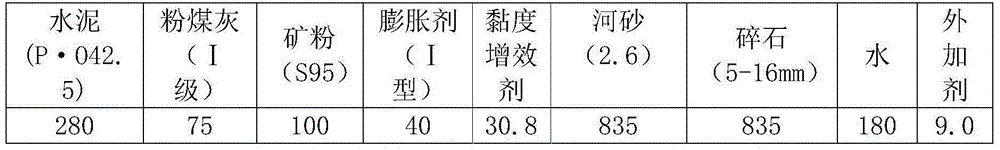

[0030] Mixed self-compacting concrete uses the mix as shown in Table 2.

[0031] Table 2 The proportion of self-compacting concrete used in the test (unit: kg / m 3 )

[0032]

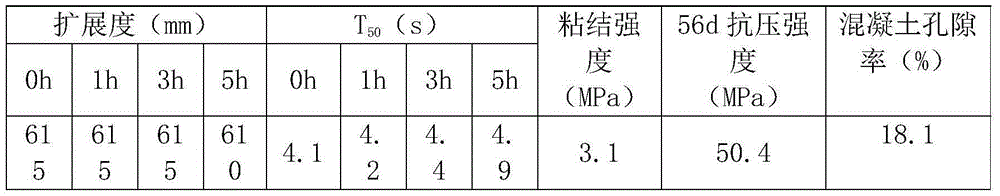

[0033] The properties of the self-compacting concrete prepared by mixing the viscosity-modified material in Example 1 and the concrete proportion in Table 1 are shown in Table 3.

[0034] Table 3 Properties of self-compacting concrete using viscosity-modified materials in Example 1

[003...

Embodiment 2

[0038] The ratio of viscosity-modified materials for new self-compacting concrete of CRTSⅢ type slab is shown in Table 4:

[0039] Table 4 Proportion of viscosity-modified materials for new self-compacting concrete of CRTSⅢ type slab

[0040] components Proportion(%) components Proportion(%) fumed silica 46.1 Low Viscosity Hydroxyethyl Cellulose 0.2 Nano Calcium Carbonate 50 High Viscosity Hydroxyethyl Cellulose 0.2 Polyamide 1.5 Water-soluble polymer rubber powder 2

[0041] The viscosity-modified material in Example 2 and the concrete ratio in Table 2 were used to mix and prepare self-compacting concrete, and the properties are shown in Table 5.

[0042] Table 5 Properties of self-compacting concrete using viscosity-modified materials in Example 1

[0043]

Embodiment 3

[0045] The ratio of viscosity-modified materials for new self-compacting concrete for CRTSⅢ type slabs is shown in Table 6:

[0046] Table 6 Proportion of viscosity-modified materials for new self-compacting concrete of CRTSⅢ type slab

[0047] components Proportion(%) components Proportion(%) fumed silica 48.6 Low Viscosity Hydroxyethyl Cellulose 0.2 Nano Calcium Carbonate 47 High Viscosity Hydroxyethyl Cellulose 0.2 Diureas 2 Water-soluble polymer rubber powder 2

[0048] The viscosity-modified material in Example 3 and the concrete ratio in Table 2 were used to mix and prepare self-compacting concrete, and the properties are shown in Table 7.

[0049] Table 7 Properties of self-compacting concrete using viscosity-modified materials in Example 1

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com