Coriolis Mass Flow Meter

a mass flow meter and coriolis technology, applied in the field of can solve the problems of affecting the measurement, affecting the accuracy of measurement, and the desire for smaller coriolis mass flow meter, and achieves the effect of simple construction of vibration pickups and favorable effect on the robustness of vibration pickups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

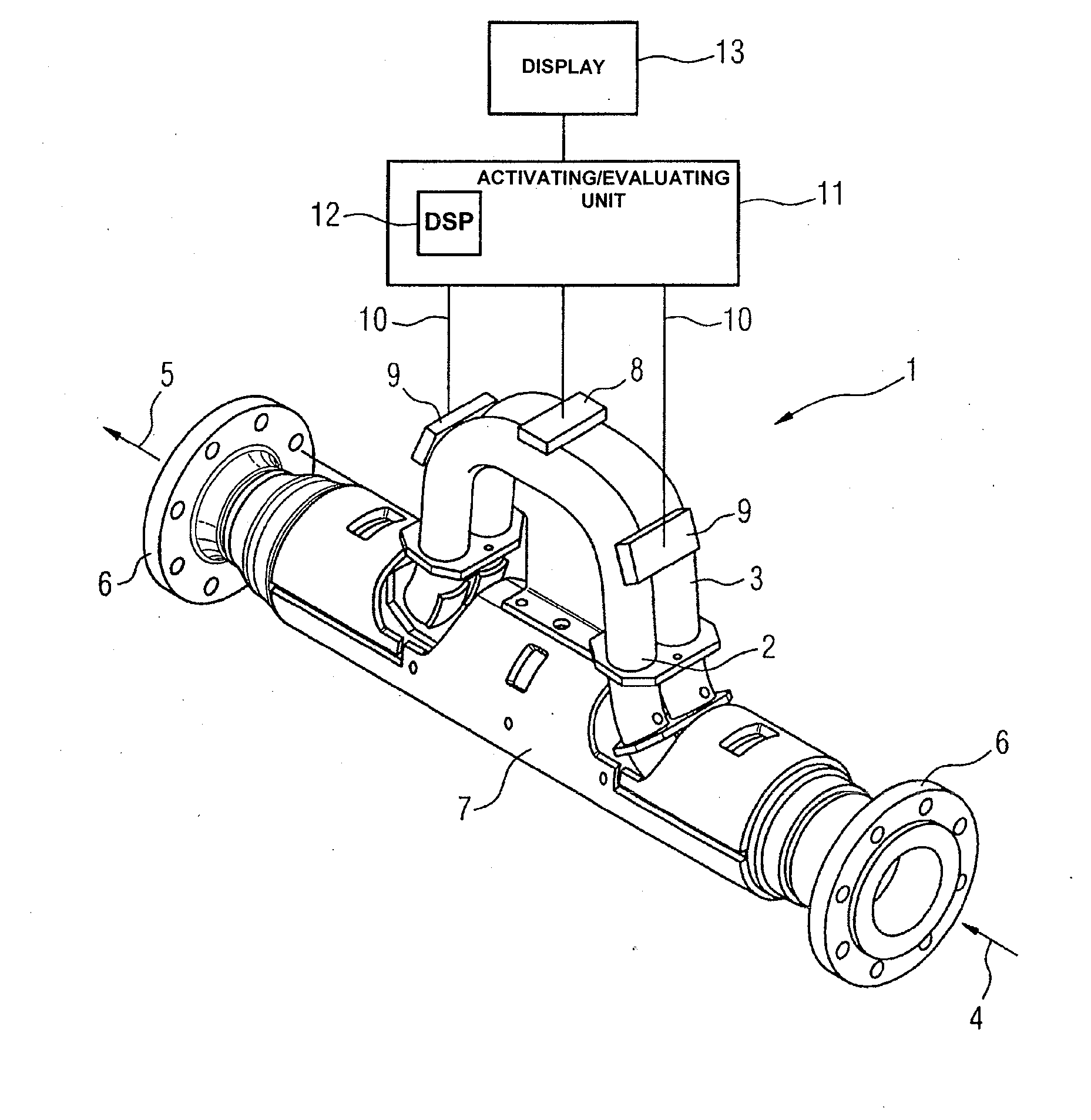

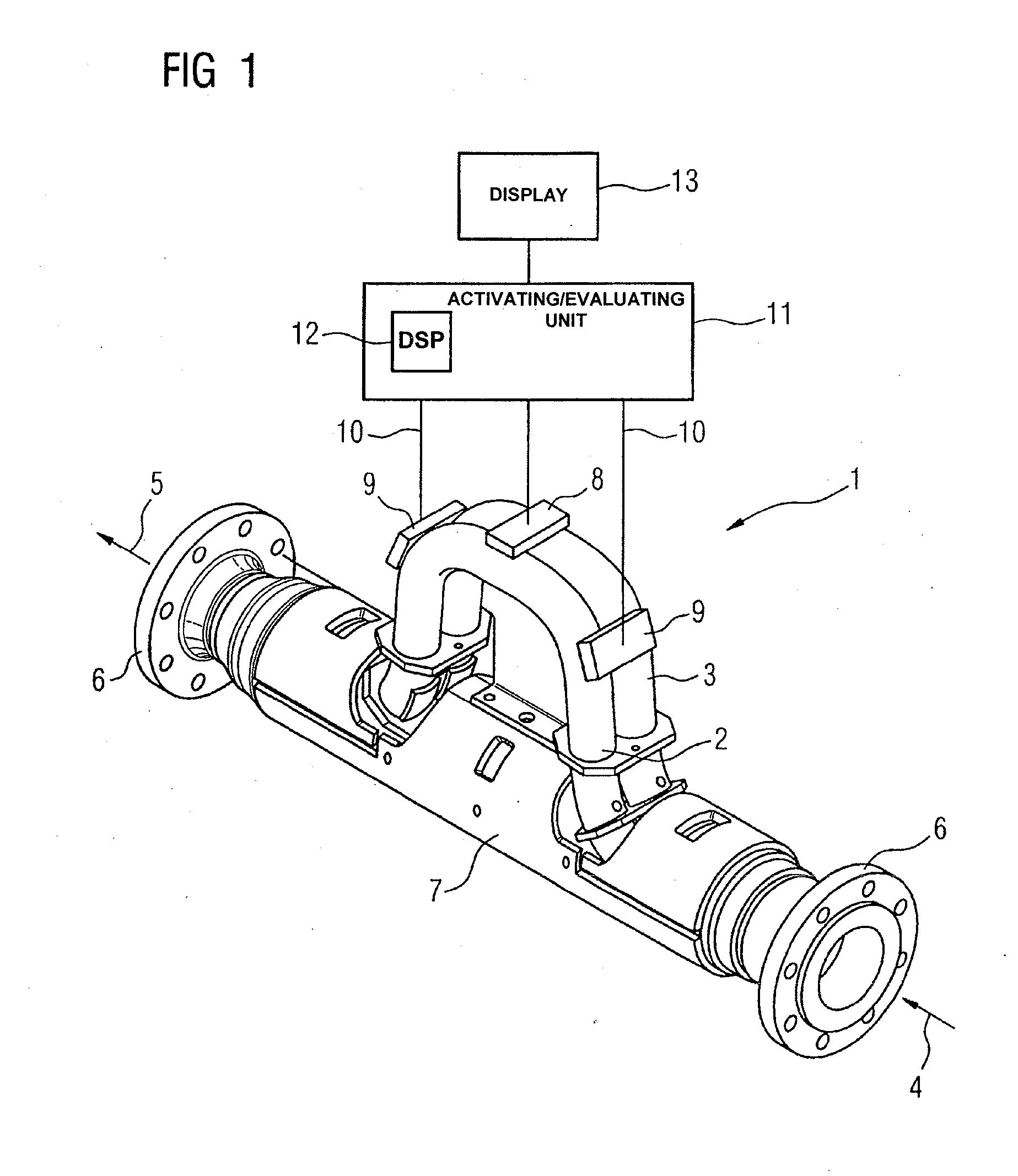

[0027]FIG. 1 shows a Coriolis mass flow meter 1 according to a preferred exemplary embodiment of the present invention. The mass flow meter 1 has a first measuring tube 2 and a second measuring tube 3, which are arranged substantially parallel to one another. These are usually made from one piece by bending. The path followed by the measuring tubes 2 and 3 is substantially U-shaped. A flowable medium flows according to an arrow 4 into the mass flow meter 1, and thereby into the two inlet portions of the measuring tubes 2 and 3 located downstream of an inlet splitter, which cannot be seen in FIG. 1, and according to an arrow 5 out again from the outlet portions and the outlet splitter located downstream thereof, which likewise cannot be seen in FIG. 1. Flanges 6, which are fixedly connected to the inlet splitter and the outlet splitter, serve for securing the mass flow meter 1 in a pipeline not represented in FIG. 1. The geometry of the measuring tubes 2 and 3 is kept largely constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com