Patents

Literature

49results about How to "Avoid over-crosslinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MRI and PTT diagnosis and treatment integration functional microsphere with core-shell structure and preparation method thereof

InactiveCN105920624AImprove stabilityWith photothermal effectEnergy modified materialsEmulsion deliveryMicrospherePolypyrrole

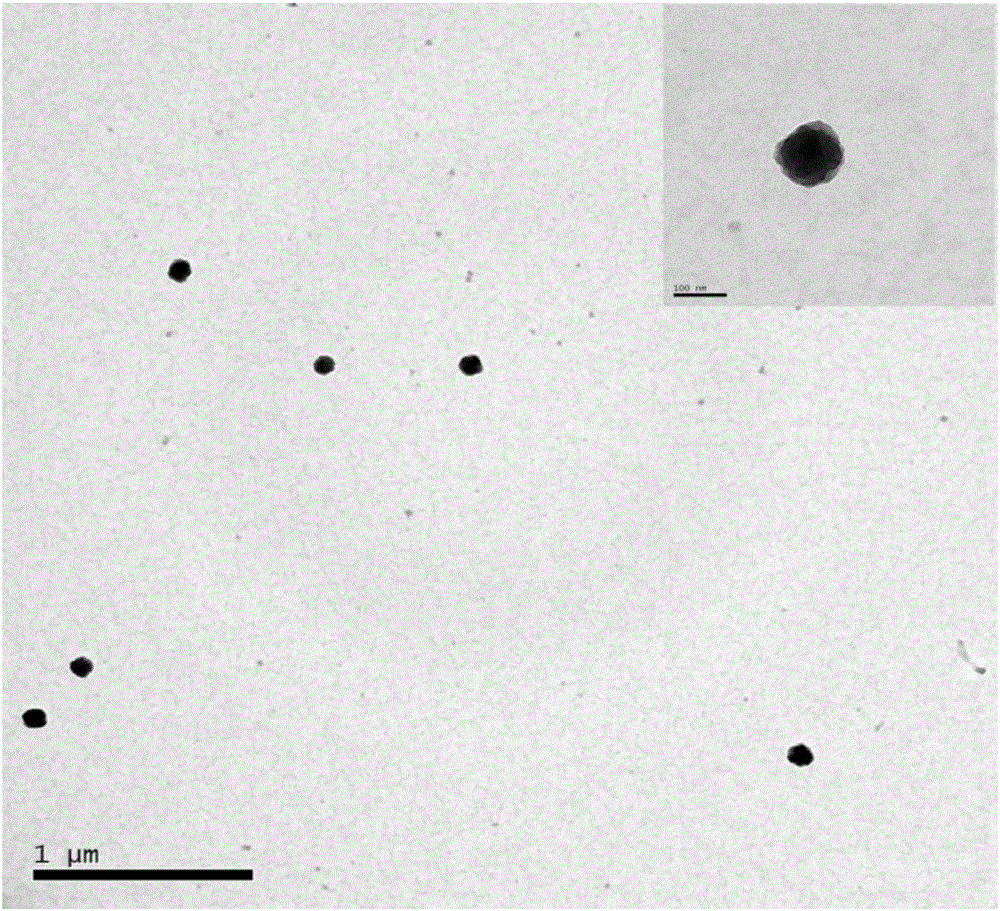

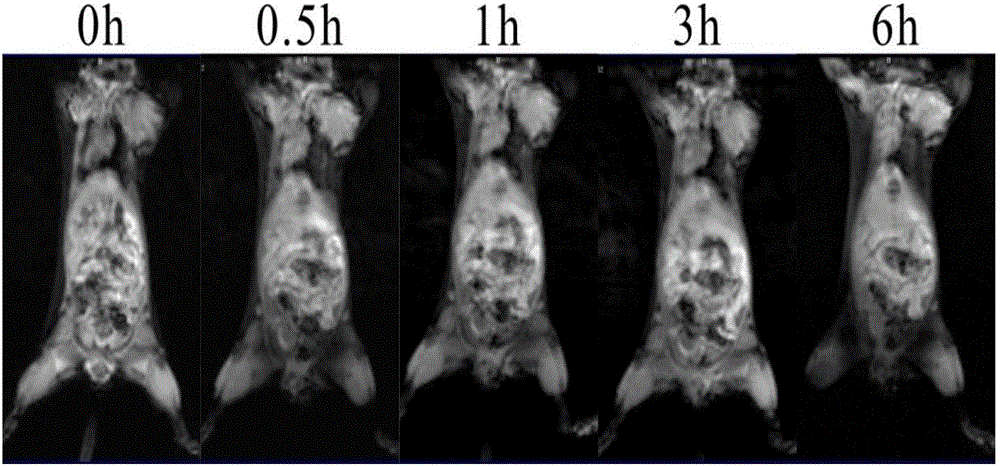

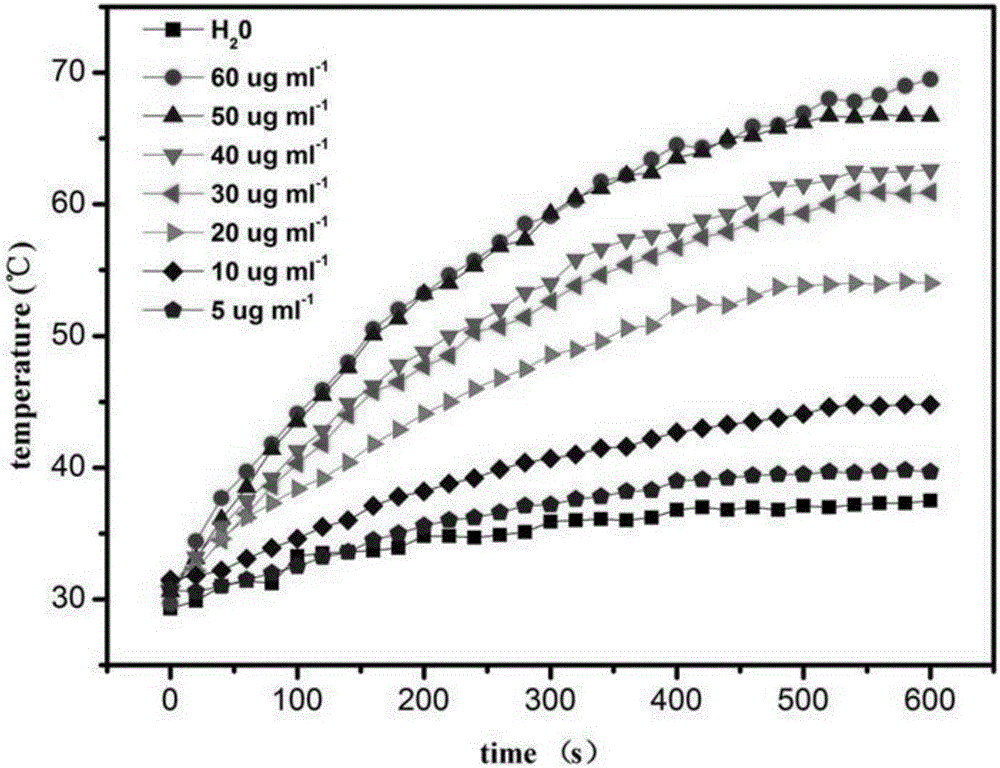

The invention belongs to the fields of material science and biomedical application, and in particular relates to an MRI and PTT diagnosis and treatment integration functional microsphere with a core-shell structure and a preparation method thereof. The functional microsphere comprises a polypyrrole nano particle core and a polydopamine shell coated on the outer surface of the core, Fe3+ particles are arranged on the polydopamine shell in a complexing manner, the weight ratio of polypyrrole nano particles to polydopamine is 1: (3.1-10.2), and the weight ratio of the Fe3+ particles to the polydopamine is 1: (9.3-11.2). The preparation method comprises the following three steps: S1, preparation of the polypyrrole nano particles; S2, preparation of the nano microsphere with the core-shell structure; and S3, preparation of the MRI and PTT diagnosis and treatment integration functional microsphere. The functional microsphere is prepared by using the nontoxic polypyrrole and polydopamine with excellent biocompatibility, and is high in stability in blood of human bodies; moreover, the functional microsphere has T1 radiography effect and optothermal effect, can be used for magnetic resonance imaging (MRI) and photothermal therapy (PTT), and is a diagnosis and treatment integration functional material with great potential value.

Owner:HUBEI UNIV

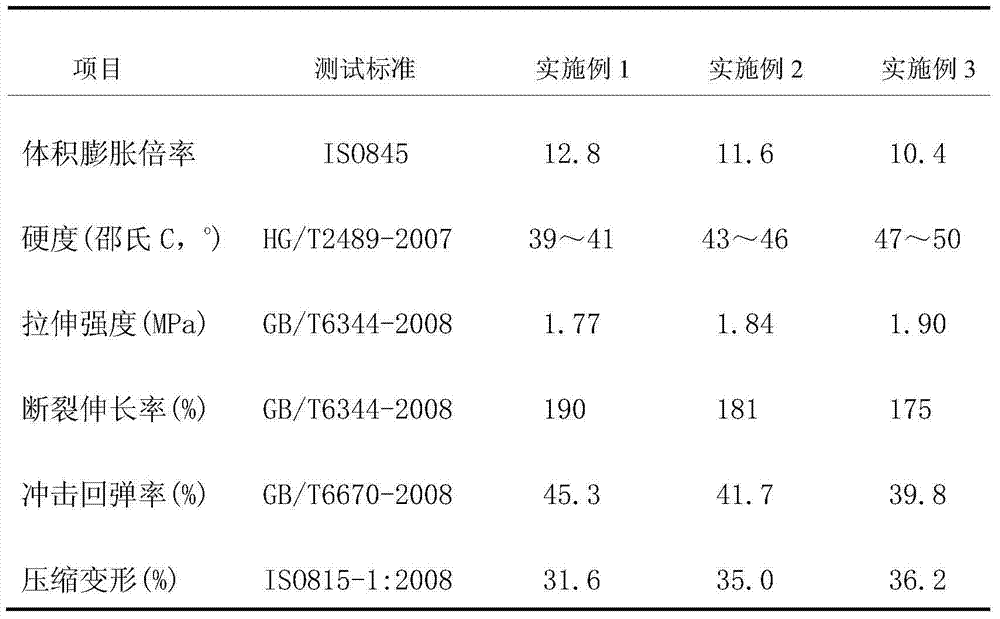

Polyethylene foam material prepared by utilizing recycled foam material and production method thereof

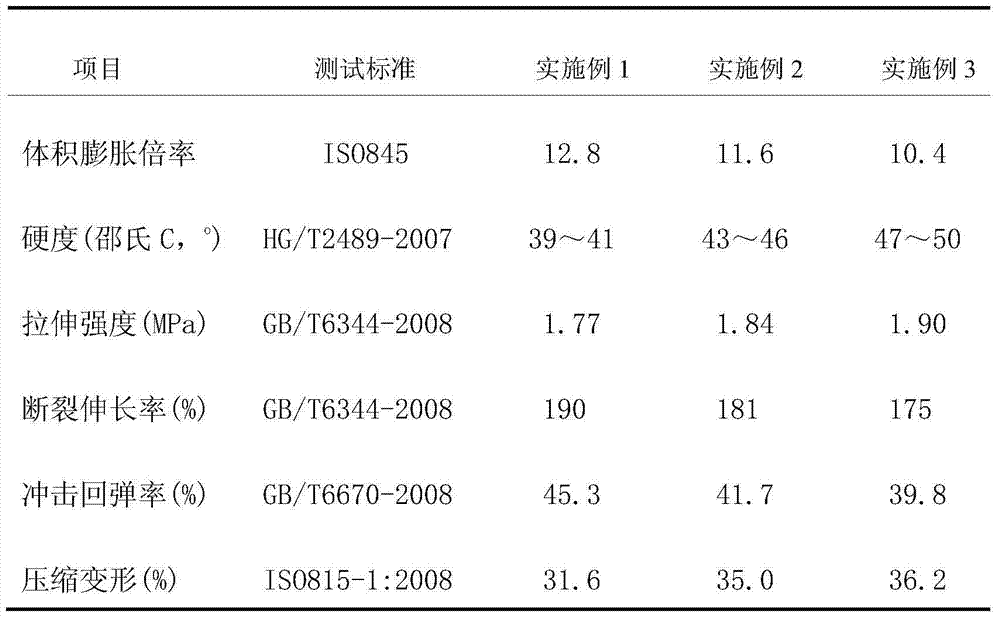

The invention relates to a polyethylene foam material prepared by utilizing a recycled foam material. The polyethylene foam material sequentially comprises the following components in parts by weight: cross-linked polyethylene foam material waste, composite filling agent, compound cross-linking agent, compound foaming agent and foaming auxiliary agent and is sequentially processed and produced through the cross-linked polyethylene foam material waste, the composite filling agent, the compound cross-linking agent, the compound foaming agent and the foaming auxiliary agent. The polyethylene foam material with excellent property disclosed by the invention is produced by sequentially carrying out cross-linked polyethylene foam material waste processing, raw material mixing, raw material retreatment, slice cutting, compression moulding and cooling shaping on the cross-linked polyethylene foam material waste, the composite filling agent, the compound cross-linking agent, the compound foaming agent and the foaming auxiliary agent which are in certain parts by weight, thereby reducing the production cost, protecting the environment and recycling the resources.

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

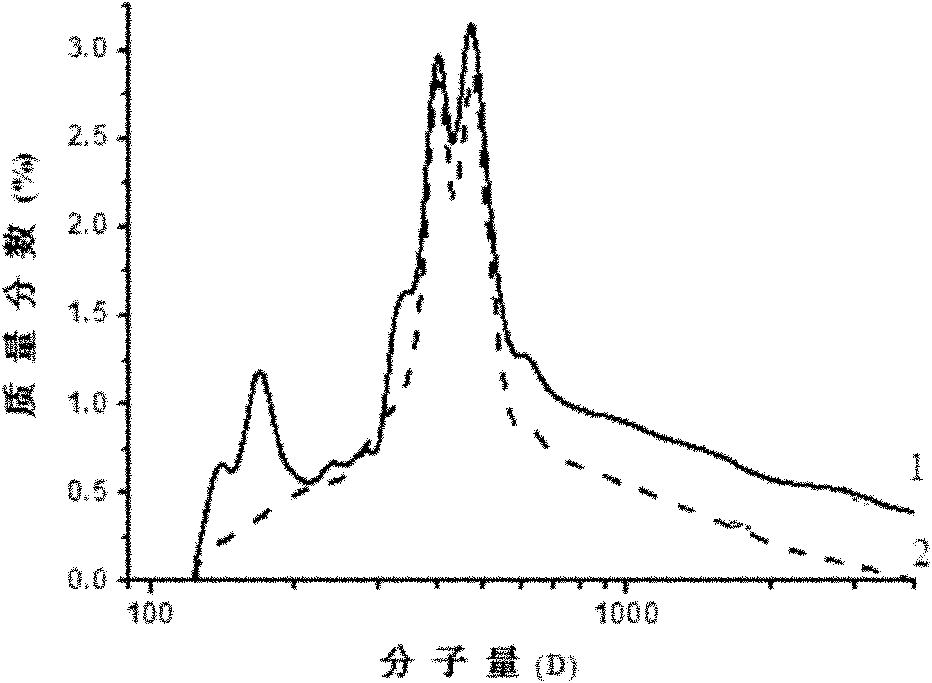

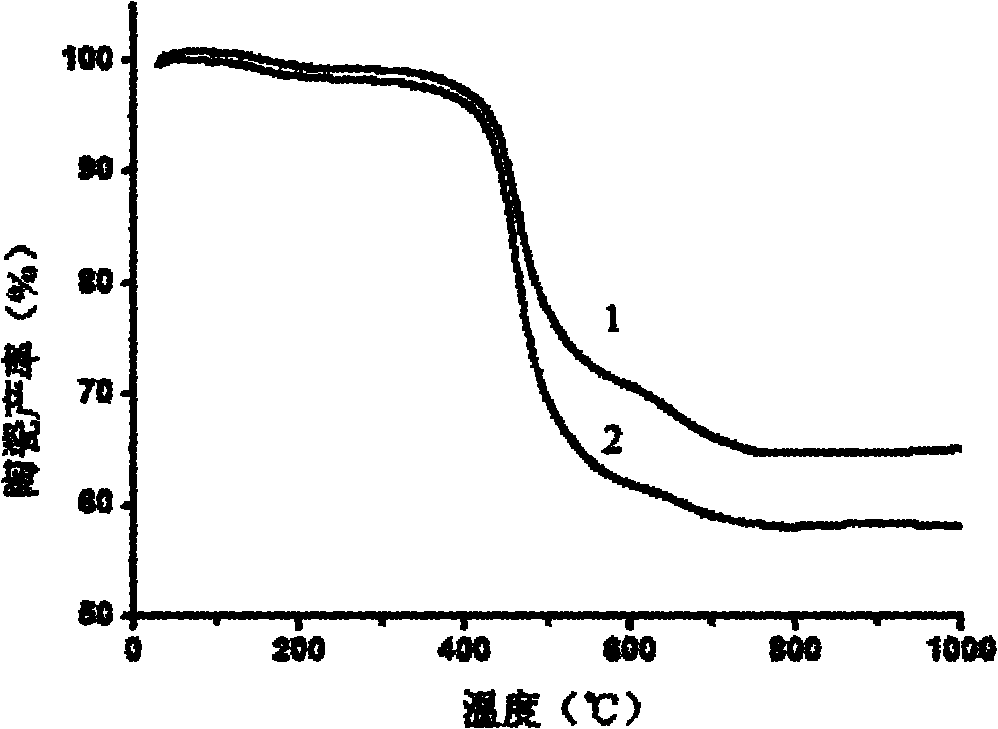

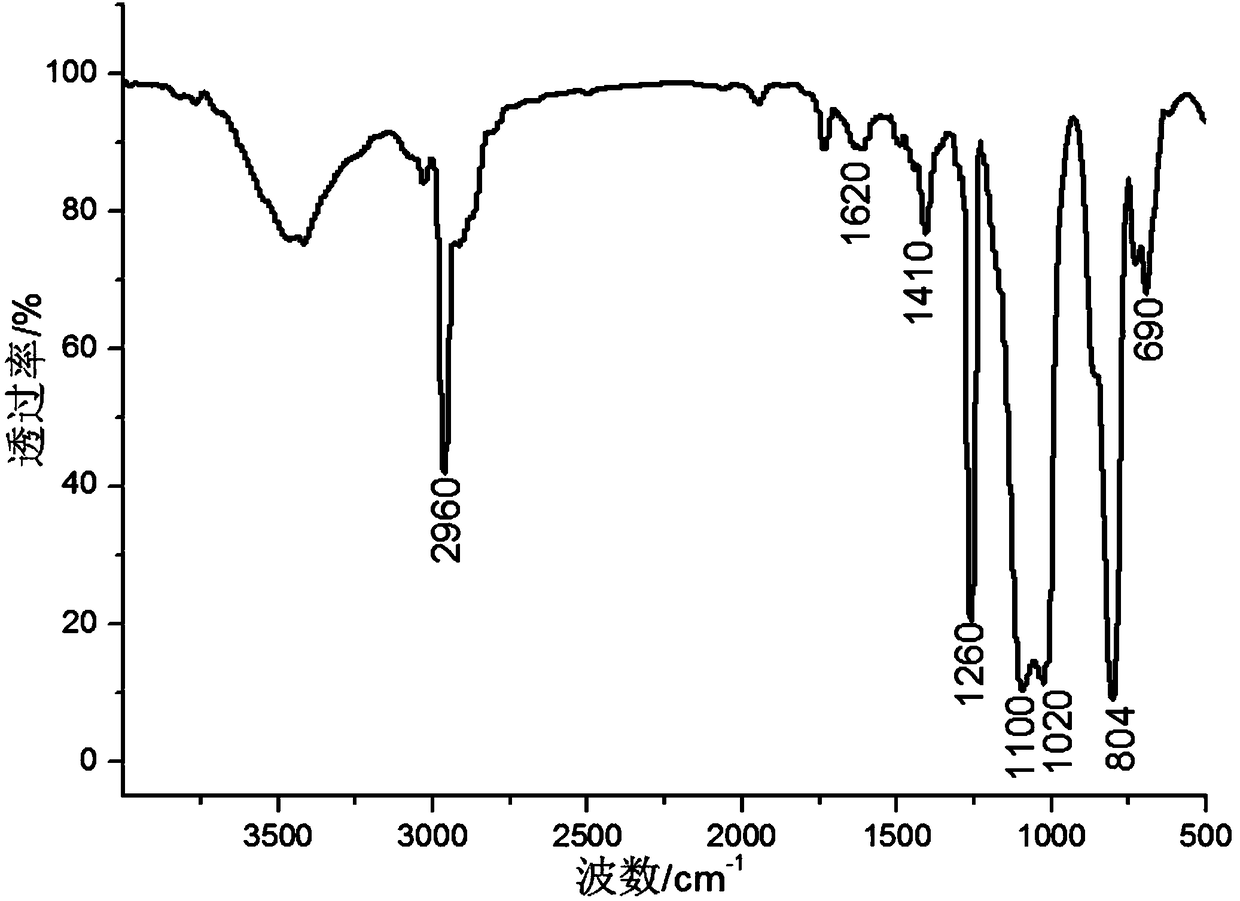

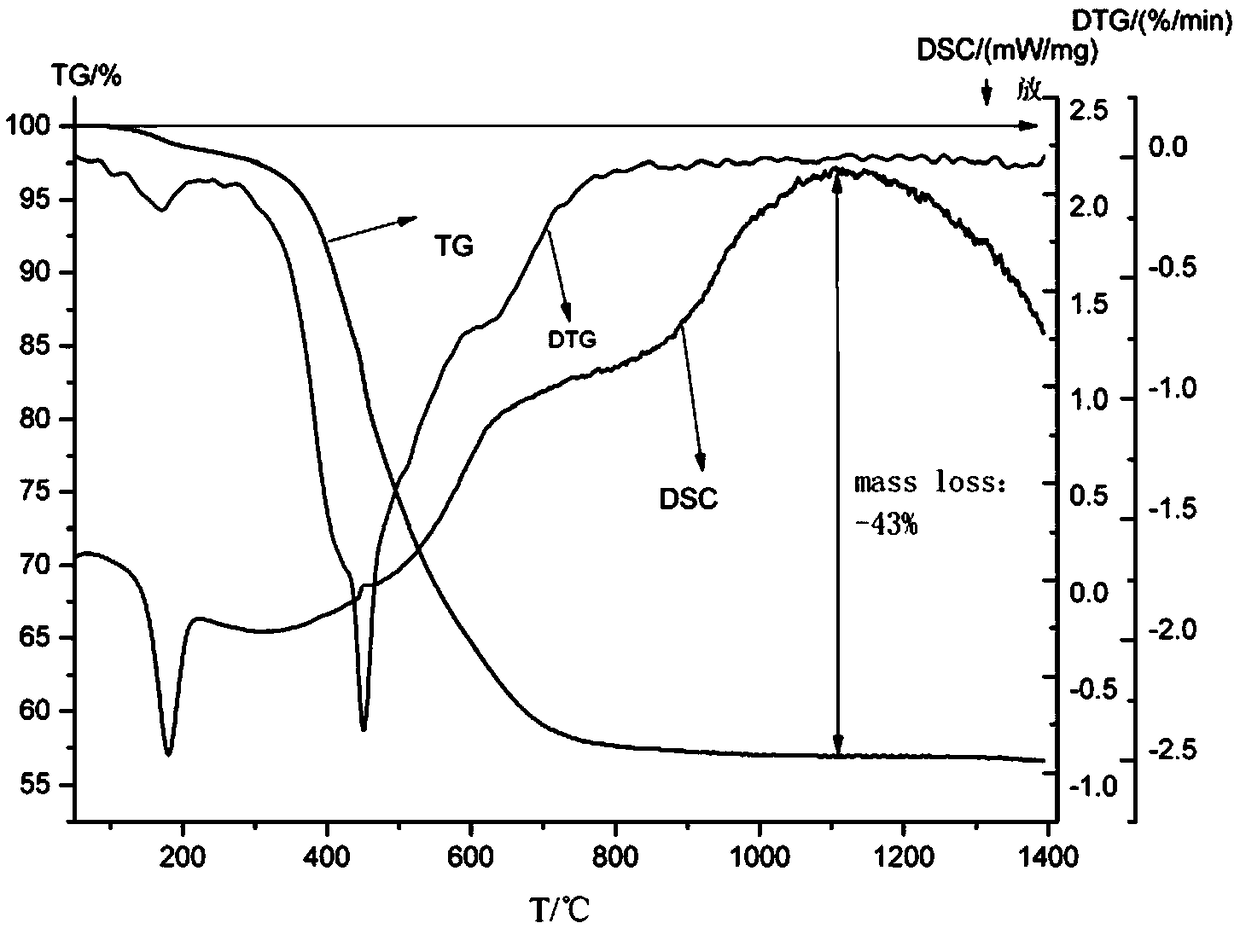

Preparation method for liquid polyborosilazane

The invention relates to a preparation method for liquid polyborosilazane and belongs to the field of inorganic nonmetallic materials. The preparation method comprises the following steps: liquid polyborosilazane and 9-borabicyclo [3,3,1]-nonane are added in a solvent in inert atmosphere to obtain mixed solution, then the obtained mixed solution is hydroborated under the stirring condition, and then the solvent is removed after completion of hydroboration to obtain the liquid polyborosilazane. The preparation method solves the problems in the traditional polymer route that excessive cross-linking is easily caused in the hydroboration addition reaction, and solid polyborosilazane has poorer fluidity. The prepared liquid polyborosilazane has good fluidity and high ceramic yield and can be directly used for the high polymer infiltration and pyrolysis method for preparing SiBCN ceramic matrix composites.

Owner:XIAMEN UNIV

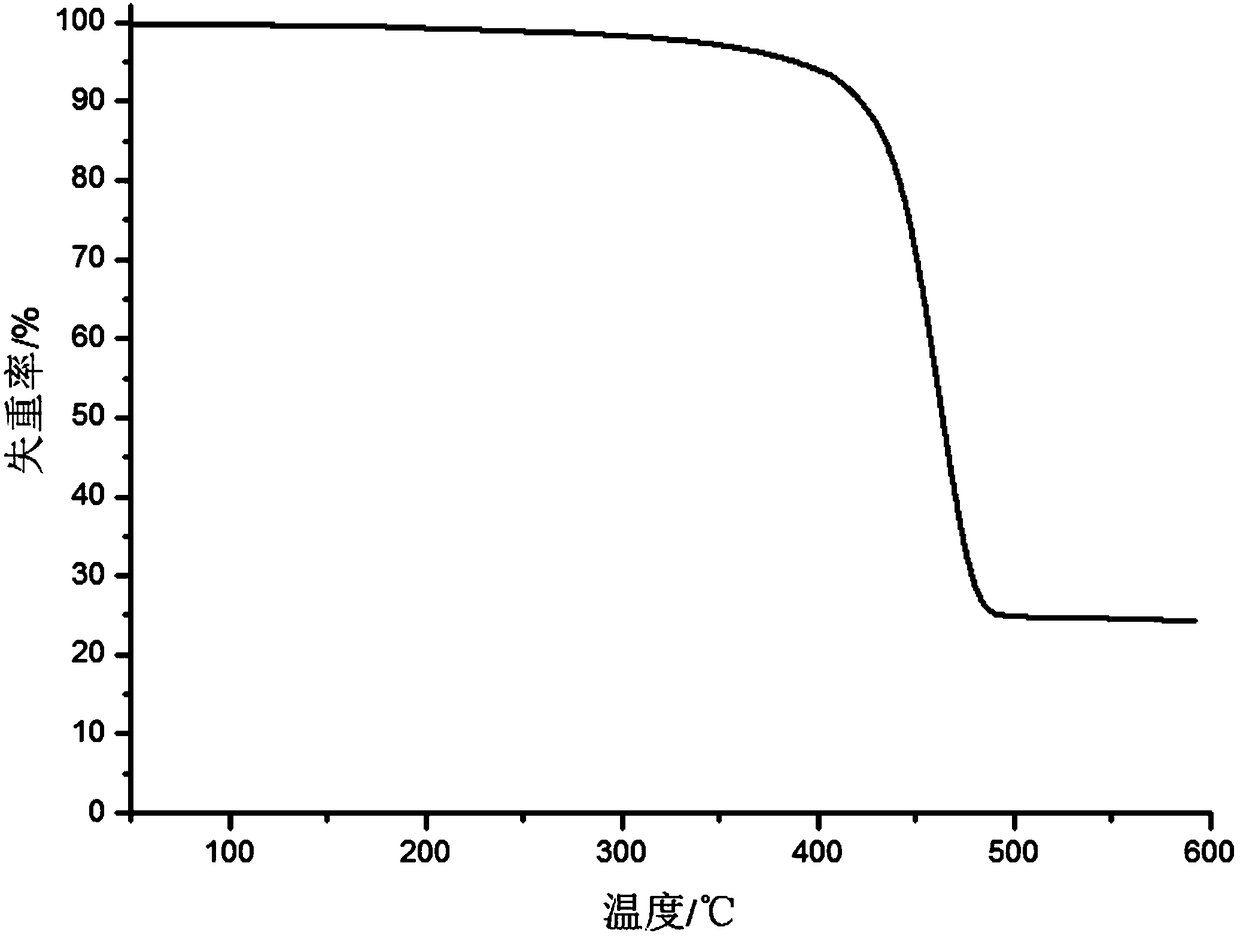

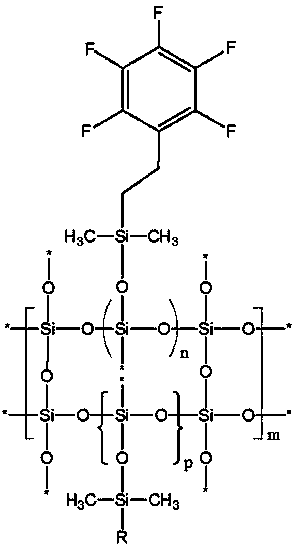

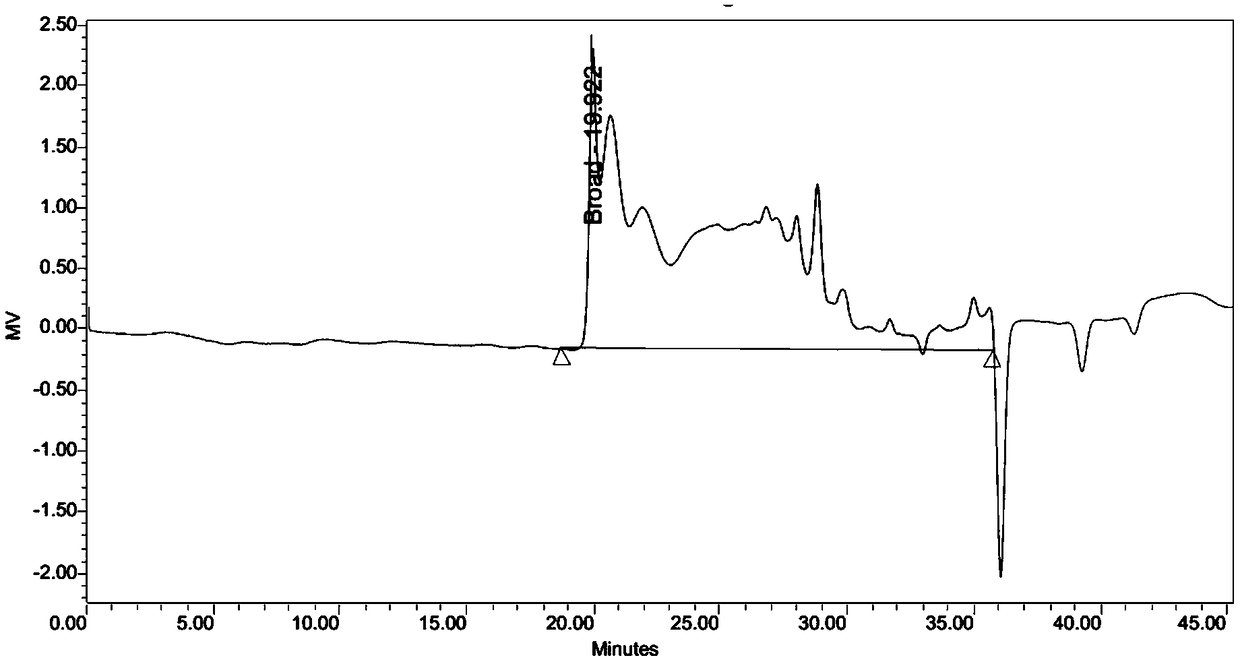

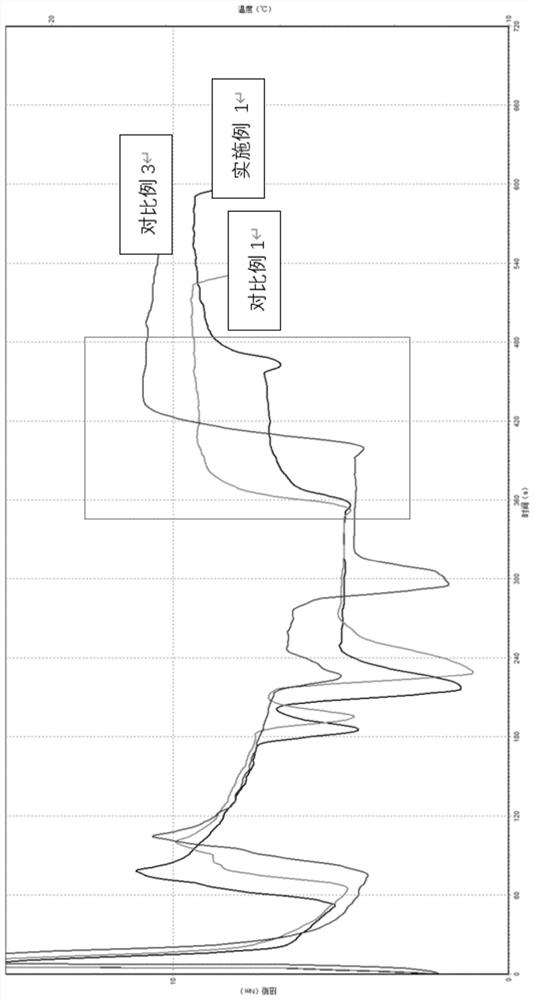

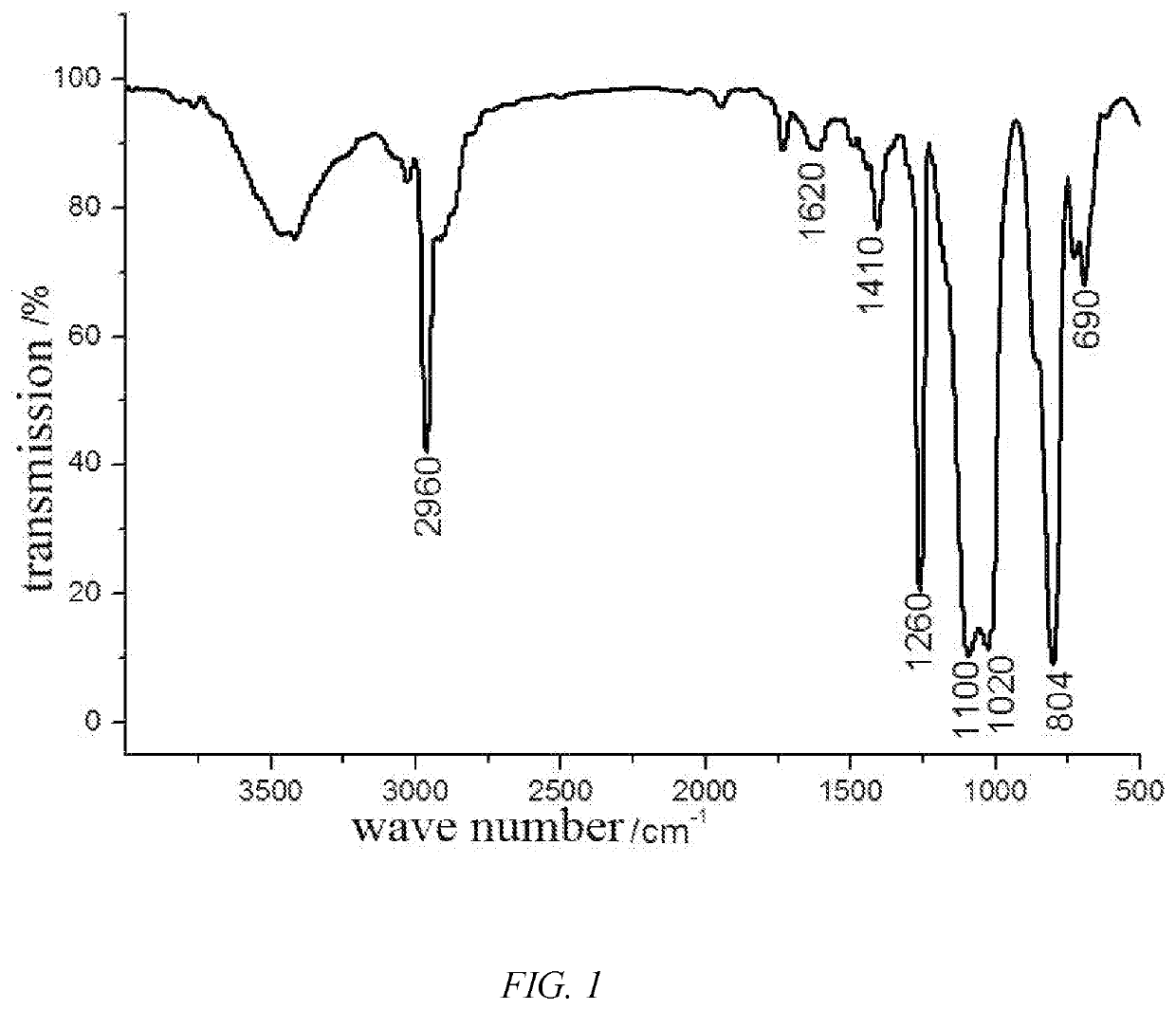

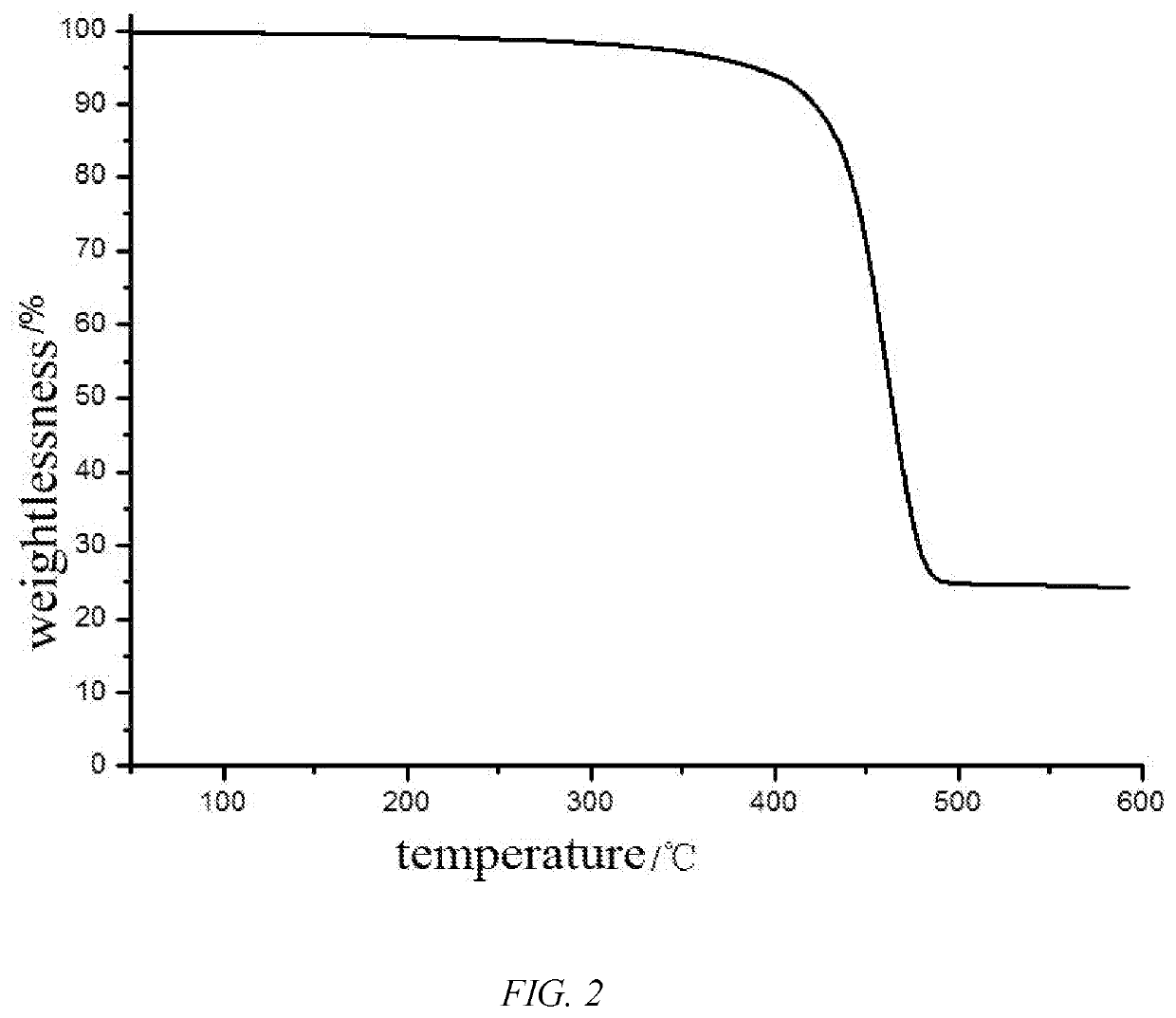

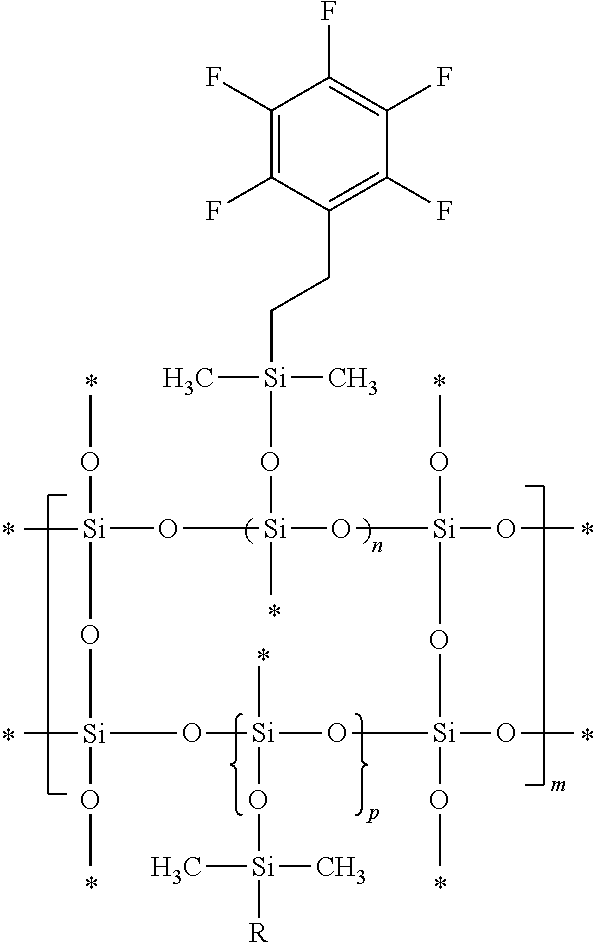

Fluorosilicone resin and preparation method thereof

ActiveCN108484914AImprove thermal stabilityHigh carbon-fluorine bond energyTrimethylsilyl chlorideAdhesive

The invention discloses fluorosilicone resin and a preparation method thereof. The method comprises the following steps: pentafluorostyrene is used as a raw material, and pentafluorophenethyldimethylchlorosilane is obtained by a hydrosilylation reaction; and the pentafluorophenethyldimethylchlorosilane, trimethylchlorosilane and ethyl orthosilicate are subjected to a polycondensation reaction to prepare the pentafluorophenyl silicon resin. When the resin disclosed by the invention is prepared, a secondary polycondensation process is adopted, so that the defect of a larger difference of hydrolysis reactivity of the pentafluorophenethyldimethylchlorosilane and copolymerized trialkylmonochlorosilane is overcome, and a preparation yield is high; the obtained pentafluorophenyl silicone resin has superior heat resistance; the method has the advantages of a simple preparation process, low requirements on equipment and raw materials easy to obtain, and is suitable for industrialized enlarged production; and the heat-resistant fluorosilicone resin can be applied to high-molecular materials such as heat-resistant adhesives.

Owner:SHENZHEN TAIKE TECH

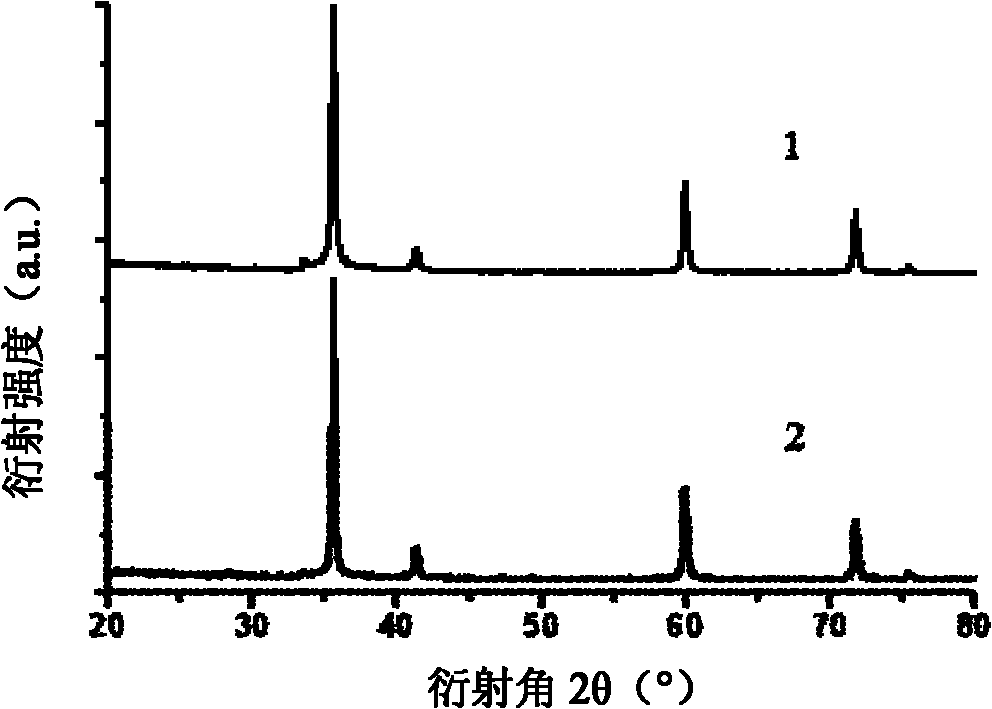

High-boron content silicon-boron-carbon-nitrogen precursor and preparation method thereof

InactiveCN109369918AAvoid over-crosslinkingIncreased boron contentViscous liquidElemental composition

The invention relates to a high-boron content silicon-boron-carbon-nitrogen precursor and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing functional, bifunctional and trifunctional chlorosilane containing unsaturated groups and hexamethyl-disilazane at a low temperature according to a certain ratio, raising the temperature and completely reacting, dropping 1,3-diethyl cycloborazane under low temperature conditions according to a certain ratio, fully reacting the reactants, and finally performing reduced pressure distillation to obtain the solvent and by-products produced by the reaction, thereby obtaining faint yellow viscous liquid or a solid product, namely the SiBCN ceramic precursor. According to the synthetic method disclosed by theinvention, a novel Polyborosilicate resin is prepared by adopting a 'double boron source', the boron content of the prepared SiBCN ceramic can reach 20%, and the problems that the boron content is low and improvement of high temperature resistance and oxidation resistance of the ceramic is not obvious can be solved. The elementary composition regulation range of the precursor disclosed by the invention is wide, and resins which are suitable to serve as a high-temperature-resistant coating, a fiber reinforcement or a ceramic-based composite material matrix and have different elementary compositions can be prepared.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for preparing saururus chinensis whitening emulsion

InactiveCN107095820AImprove performancePrevent proliferationCosmetic preparationsToilet preparationsOil phaseSaururus chinensis

The invention relates to a method for preparing saururus chinensis whitening emulsion, which belongs to the technical field of emulsion preparation. The method comprises the following steps: preparation of a saururus chinensis extract, preparation of aqueous phase liquid, preparation of oil phase liquid and emulsification. The emulsion has no chemical addition, and has excellent whitening and skin caring functions, long term usage can make skin smooth and bright, and the emulsion is suitable for allergic people.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

High-adhesion wear-resistant antifouling paint

InactiveCN104559673AStrong coveringGood dispersionAntifouling/underwater paintsPaints with biocidesEpoxyWear resistant

The invention discloses a high-adhesion wear-resistant antifouling paint which is prepared from the following raw materials in parts by weight: 32-35 parts of dicyclopentadiene phenol epoxy resin, 25-28 parts of terpene resin, 10-13 parts of phenol formaldehyde resin, 17-20 parts of iron-titanium dioxide composite modified polystyrene microsphere, 10-13 parts of light calcium carbonate, 4-8 parts of nano attapulgite, 1-3 parts of mica powder, 0.8-1.2 parts of silane coupling agent KH-550, 1.2-1.5 parts of curing agent, 0.6-0.9 part of defoaming agent, 1.5-1.8 parts of leveling agent, 1.2-1.5 parts of pigment and 50-53 parts of solvent.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

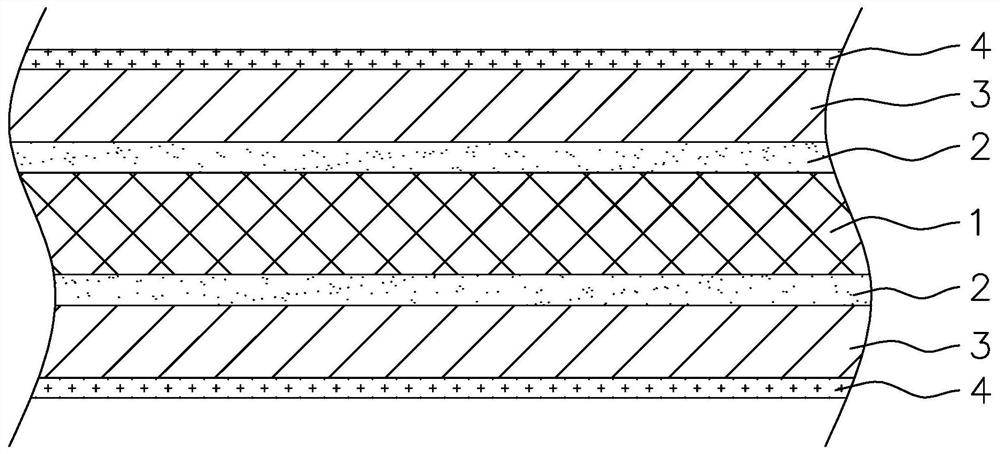

Double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smoke flame-retardant power cable with long service life

ActiveCN110534249APromote environmental protectionImprove high temperature resistanceInsulated cablesPower cablesPolymer scienceInsulation layer

The invention discloses a double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smoke flame-retardant power cable with a long service life. The power cable comprises a conductor, a fireproof layer wrapping the conductor, a double-layer co-extrusion insulation layer wrapping the fireproof layer and an outer protection layer wrapping the double-layer co-extrusion insulationlayer. The outer protection layer is prepared from an ethylene propylene diene monomer composite material; the ethylene propylene diene monomer composite material is prepared from the following raw materials: ethylene propylene diene monomer, silicone rubber, white carbon black, bentonite, talcum powder, zinc oxide, stearic acid, a vulcanizing agent, ammonium polyphosphate, aluminum hydroxide, microencapsulated red phosphorus, melamine pyrophosphate, pentaerythritol, an accelerant and an anti-aging agent. The double-layer co-extrusion insulation irradiation crosslinking halogen-free low-smokeflame-retardant power cable with a long service life provided by the invention is good in flame retardance and smoke suppression, excellent in heat resistance and aging resistance and long in servicelife.

Owner:ANHUI CABLE

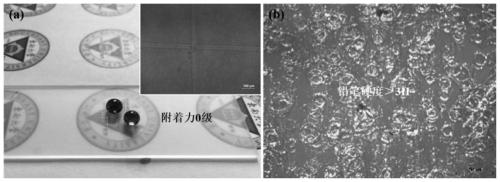

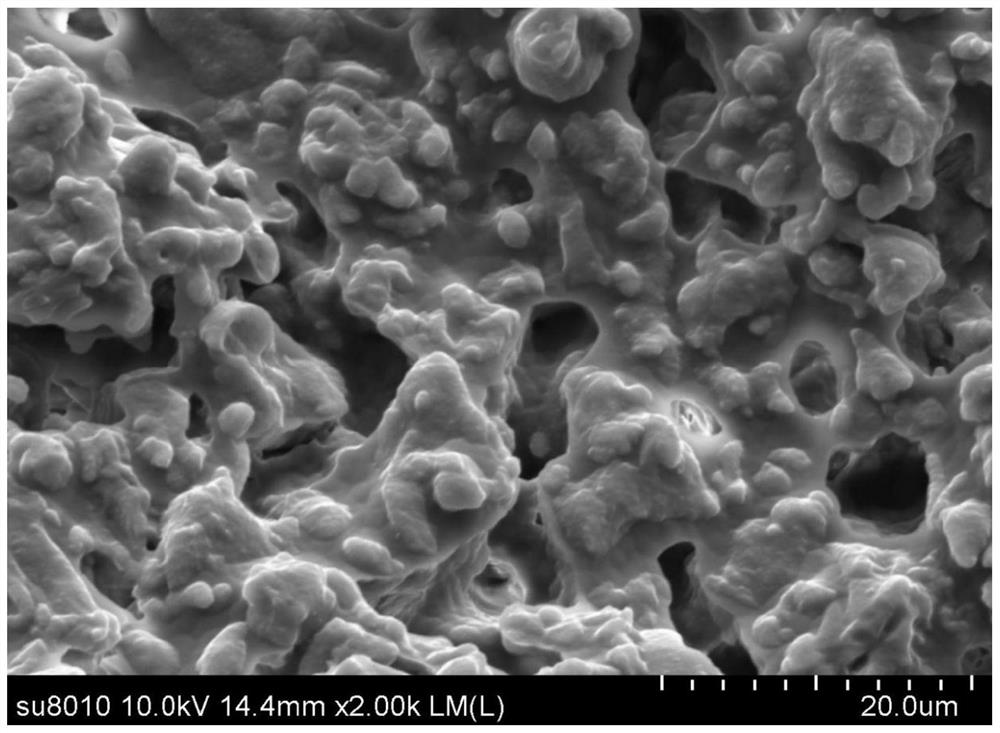

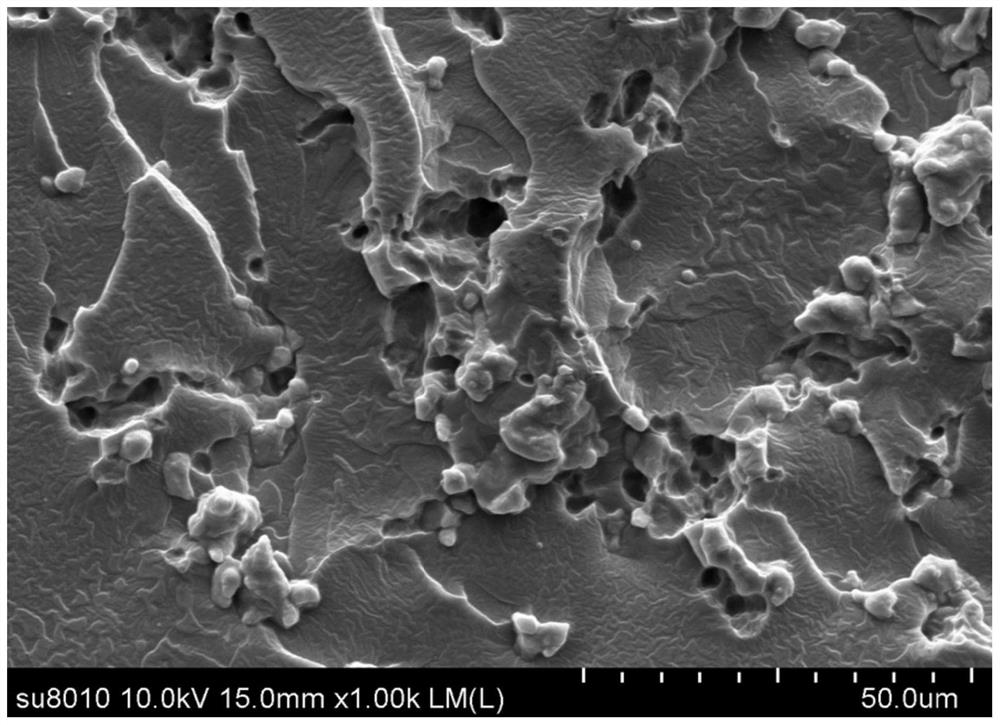

Long-acting self-repairing super-hydrophobic ceramic coating as well as preparation method and application thereof

The invention relates to a long-acting self-repairing super-hydrophobic ceramic coating as well as a preparation method and application thereof. Inorganic nanoparticles, an acidic pH regulating solution, tetraethyl orthosilicate and a siloxane monomer are dispersed in a volatile organic solvent to prepare a ceramic coating; acidic nano silica sol, ammonia water, deionized water, tetraethyl orthosilicate and a hydrophobic treatment agent are dispersed into a volatile organic solvent to prepare a super-hydrophobic nano coating; the volatile organic solvent is removed from the super-hydrophobic nano coating to obtain a dry super-hydrophobic aggregate; the super-hydrophobic aggregate is put into a ball milling tank for ball milling to obtain super-hydrophobic nano powder; and the super-hydrophobic nano-powder is ultrasonically dispersed in the ceramic coating, an acrylate copolymer is added as a dispersing agent, an adhesion promoter and propylene glycol methyl ether acetate are then added, and stirring is performed to obtain the long-acting transparent self-repairing super-hydrophobic ceramic coating. The method is simple in process, easy to operate and suitable for large-scale preparation and production.

Owner:SOUTHEAST UNIV

High-resilience polyurethane/organic silicon thermoplastic elastomer and preparation method thereof

ActiveCN113004682AReduce vulcanization rateProlong vulcanization timePlastic recyclingThermoplasticOrganosilicon

The invention relates to the technical field of dynamically vulcanized thermoplastic elastomers, and discloses a high-resilience polyurethane / organic silicon thermoplastic elastomer and a preparation method thereof.The preparation method comprises the steps that blending thermoplastic polyurethane, vinyl silicone rubber, a compatilizer and reinforcing filler, placing a product in an internal mixer to be premixed, adding a cross-linking agent, uniform mixing continuesly to obtain rubber and plastic blend; adding the rubber and plastic blend into a twin-screw extruder, adding a prepolymerization catalyst, and carrying out prevulcanization and shear dispersion treatment; when a pre-vulcanized cross-linked product passes through the screw middle section of the double-screw extruder, adding a dynamic vulcanization catalyst, and carrying out shearing dispersion treatment to obtain the polyurethane / organic silicon thermoplastic elastomer; wherein the prepolymerization catalyst and the dynamic vulcanization catalyst are both rubber compounds formed by mixing a catalyst and vinyl silicone rubber. The catalyst is added in batches, so that the silicon rubber can be dispersed in the polyurethane, and the vulcanization rate can be reduced; by adopting the catalyst masterbatch, the uniform particle size of the silicon rubber can be ensured, so that the prepared TPSiV is silky in hand feeling.

Owner:CHENGDU SILIKE TECH

A kind of polyethylene foam material prepared by foaming recycled material and its production method

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

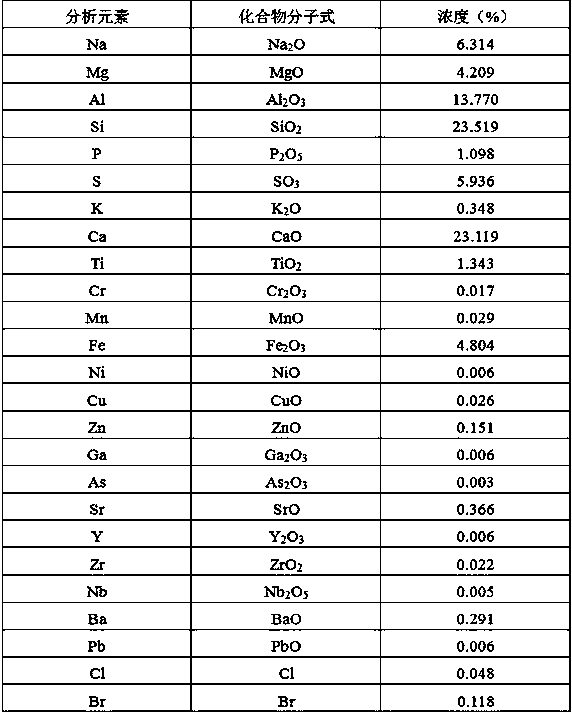

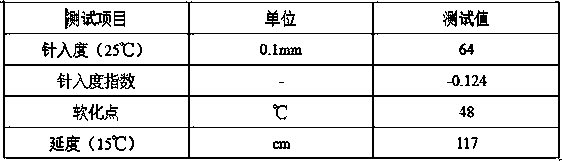

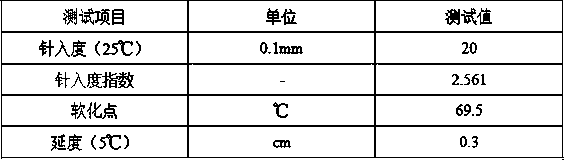

Biomass material-based recycled asphalt and preparation method thereof

The invention discloses biomass material-based recycled asphalt which comprises, by weight, 30-40 parts of waste asphalt, 10-20 parts of new asphalt, 10-20 parts of wood tar oil, 3-6 parts of biopolymer fibers, 3-5 parts of plasticizers, 0.5-1.5 parts of stabilizers and 0.2-0.5 part of compatibilizers. The invention further discloses a preparation method of the biomass material-based recycled asphalt and preparation method. The method includes the steps: preparing a recycled asphalt prototype sample; preparing recycled asphalt. The biomass material-based recycled asphalt can effectively restore pavement performances of waste asphalt, antioxidant aging and low-temperature anti-cracking performances of the waste asphalt are remarkably improved, and a preparation process is simple, easy to operate and low in preparation cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

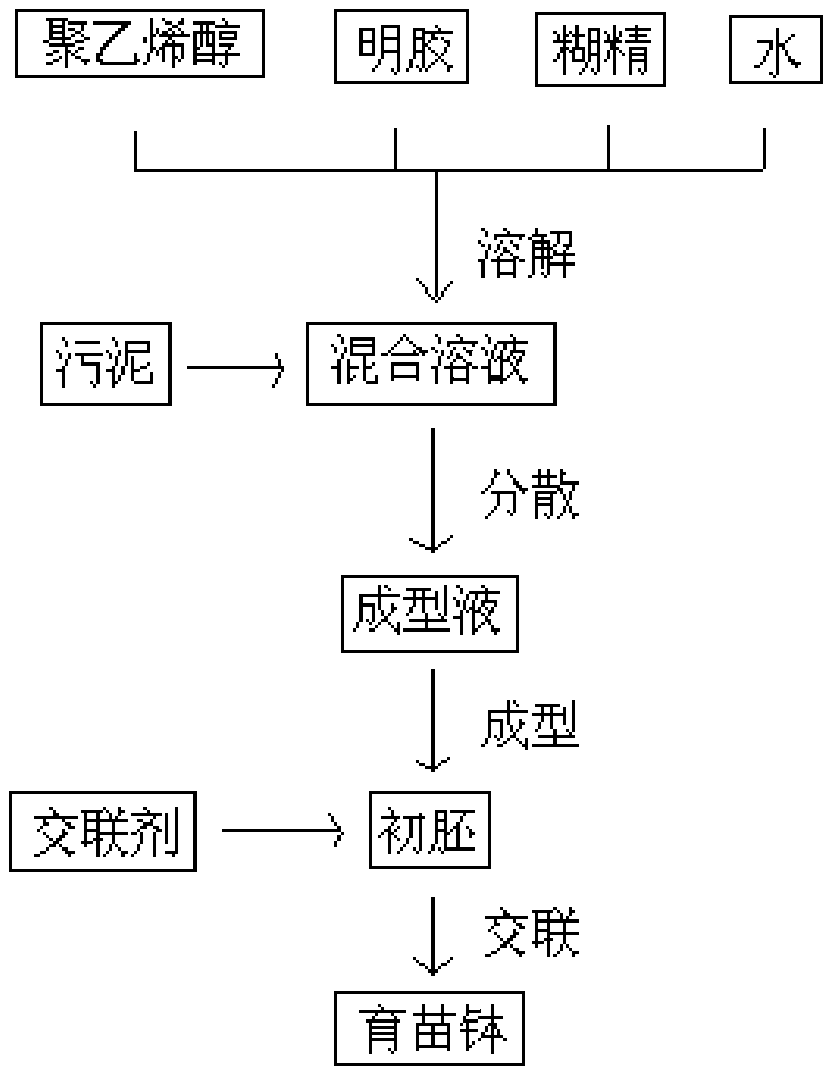

Degradable sludge-based seedling pot and preparation method thereof

InactiveCN108476804AImprove mechanical propertiesShorten degradation timeGrowth substratesCulture mediaCross-linkPlant roots

The invention relates to a degradable sludge-based seedling pot and a preparation method thereof. The seedling pot is prepared from, by weight, 2-5 parts of polyvinyl alcohol, 80-100 parts of water, 5-10 parts of gelatin, 5-10 parts of dextrin, 5-20 parts of sludge and 0.5-1 part of cross-linking agent. In the preparation process of the seedling pot, the forming treatment is conducted before the cross-linking treatment. The seedling pot has high mechanical properties and can meet the requirements of use performance of the seedling pot in seedling cultivation; the seedling pot can also be rapidly degraded in soil, so that the rapid growth and extension of plant roots after transplanting or planting are not limited, which has a positive effect in improvement of the survival rate of seedlingsand the growth rate of plants.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

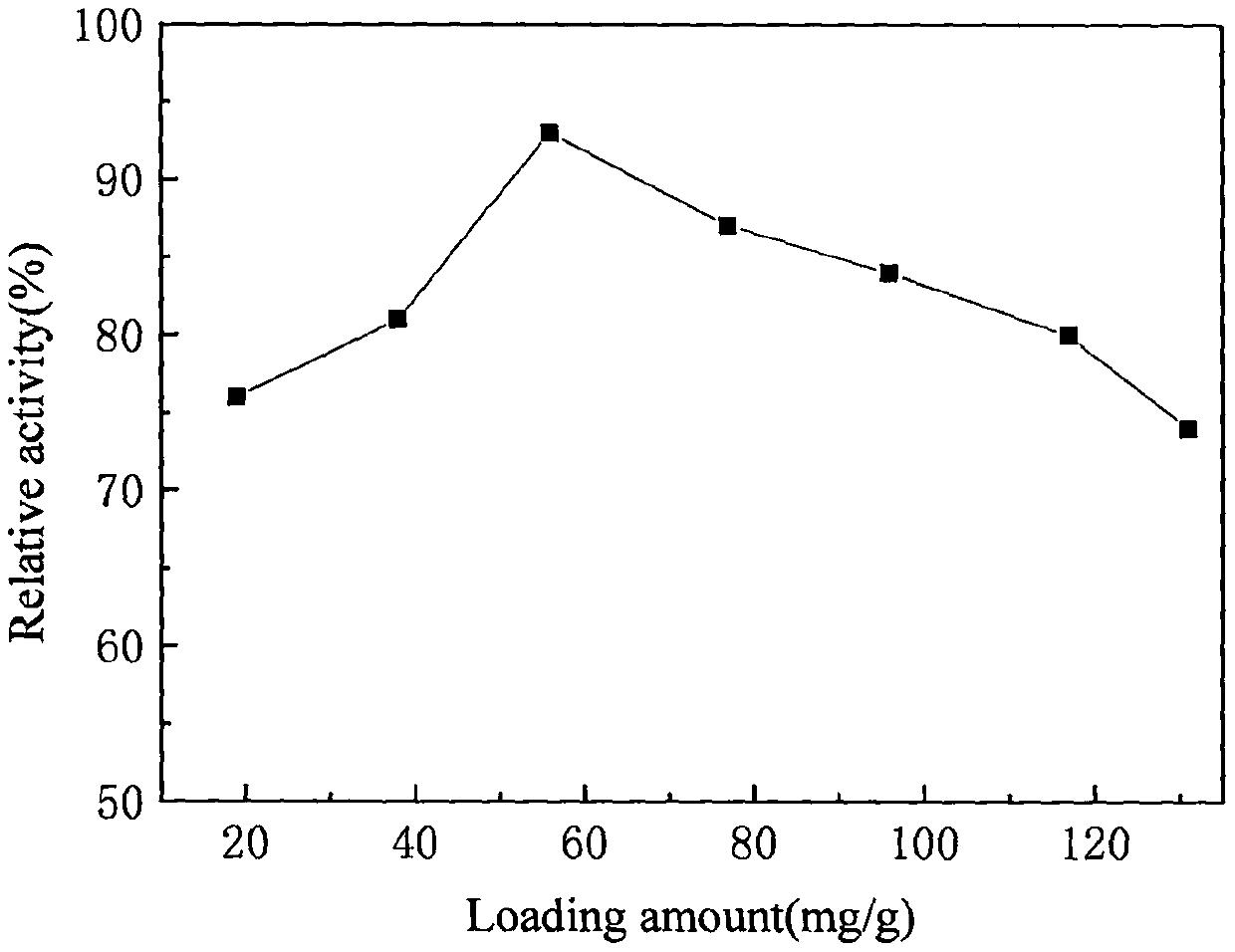

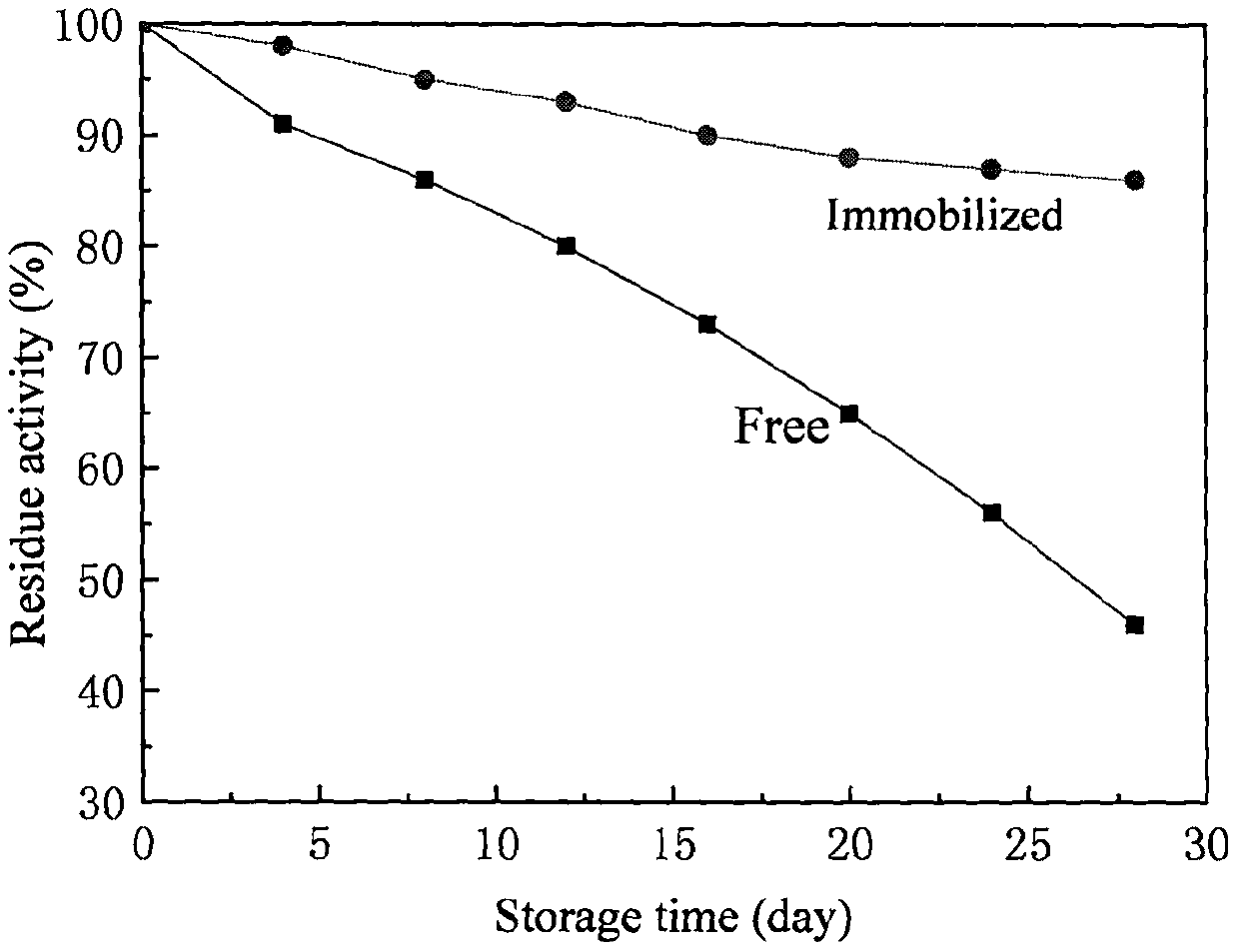

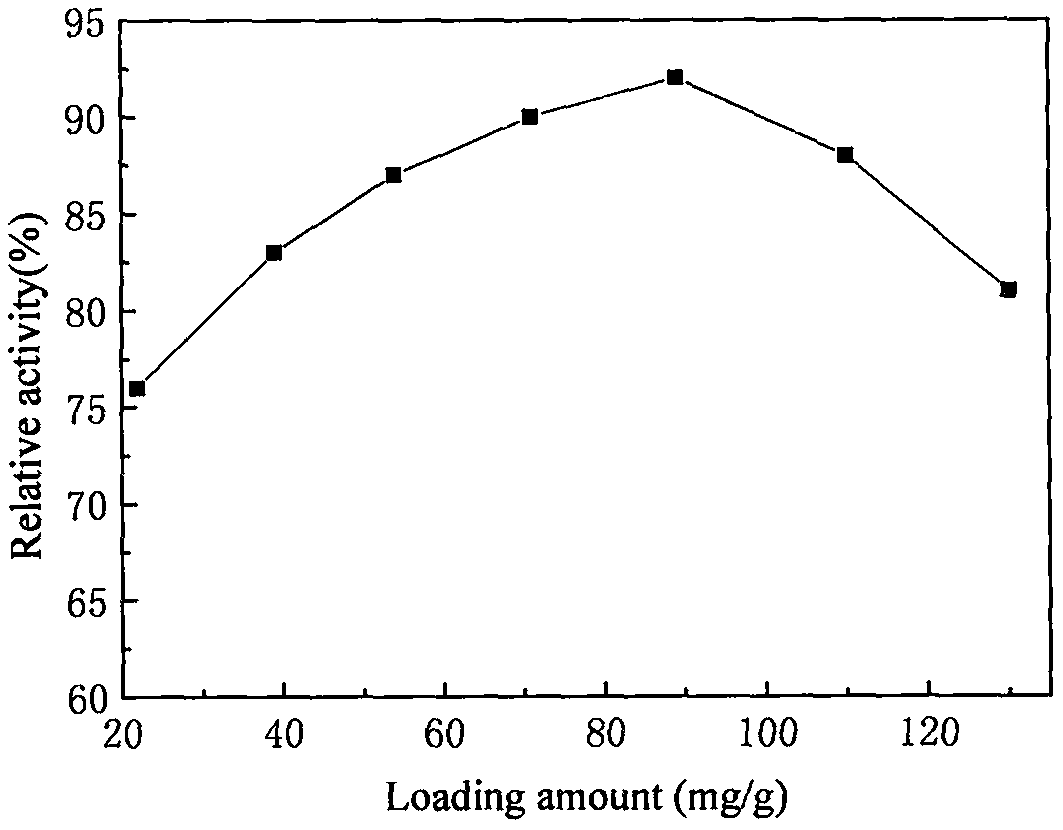

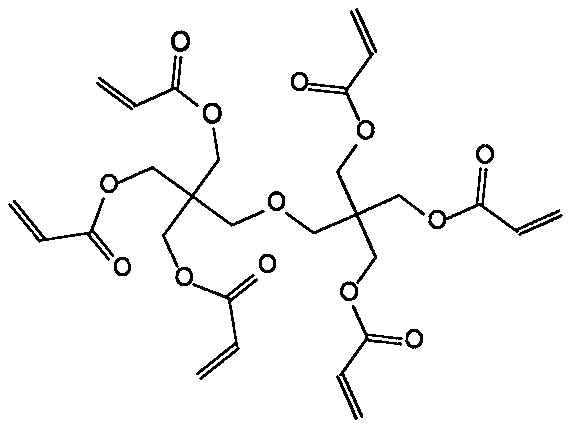

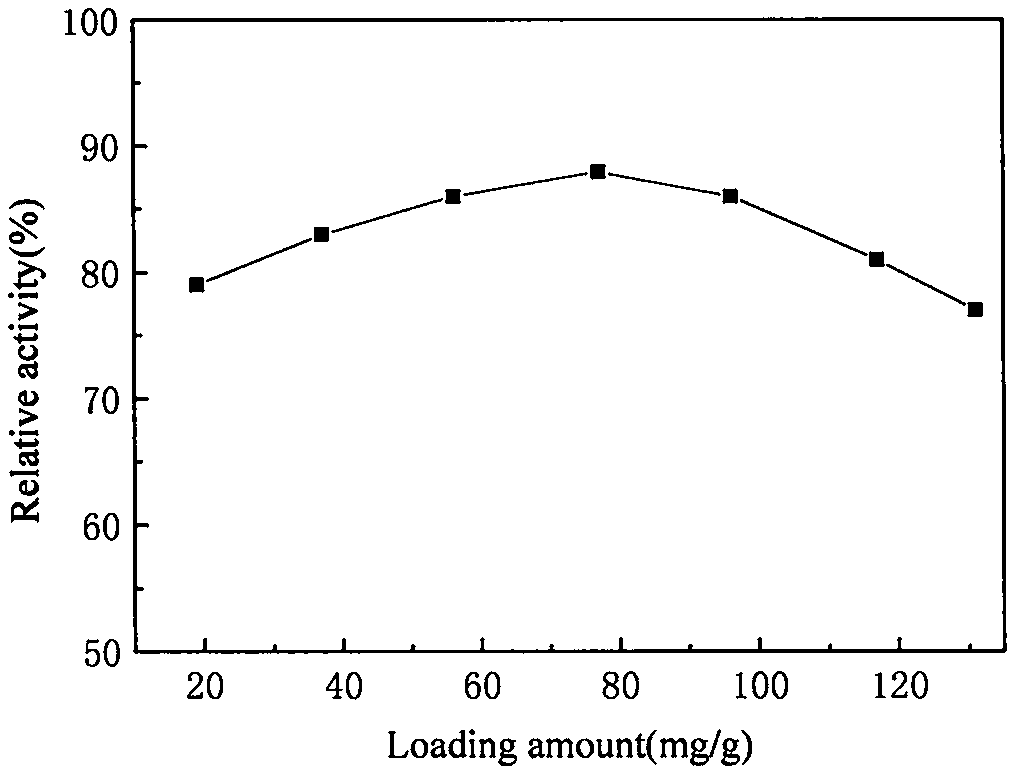

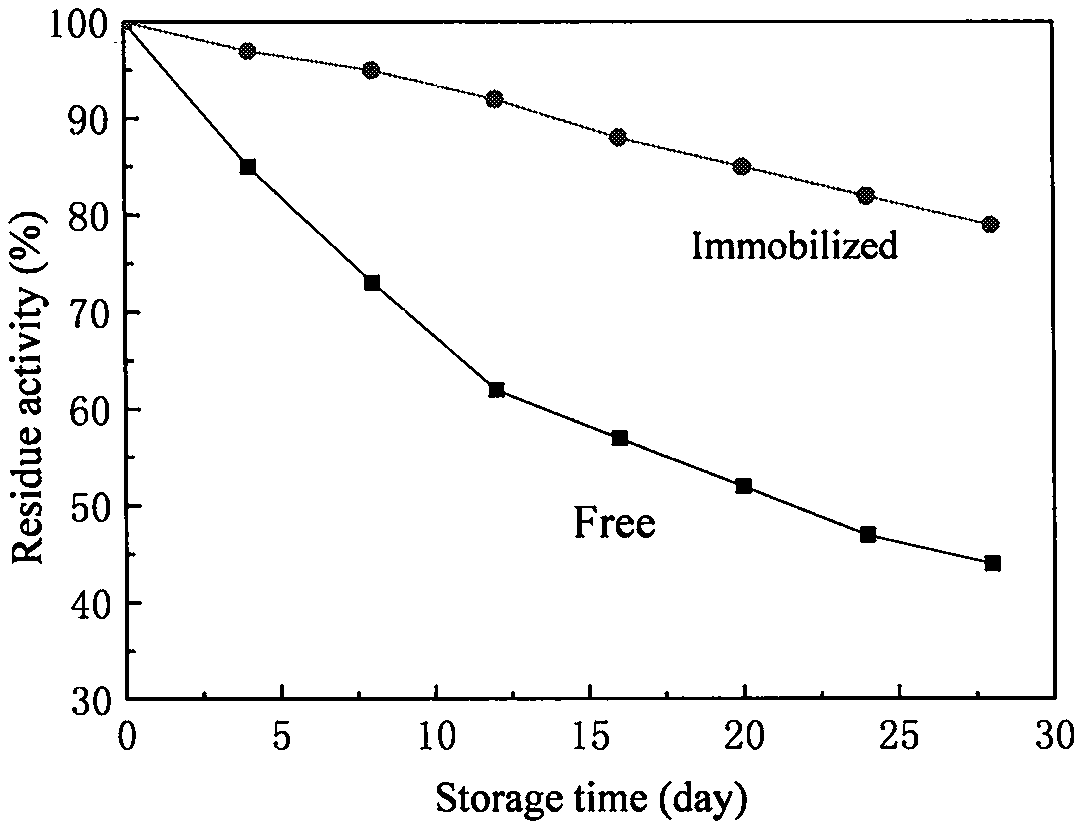

Co-crosslinking immobilization method of beta-galactosidase

ActiveCN110804603AImprove microenvironmentHigh catalytic activityChemical industryOn/in organic carrierEpoxyPolymer science

The invention relates to a co-crosslinking immobilization method of beta-galactosidase. Oil-soluble diethylene glycol diacrylate is used as a cross-linking agent, a reactant in an aqueous phase is a molecule compound prepared from amino containing beta-galactosidase, aminated epoxy resin and beta-cyclodextrin, through a Michael addition reaction of dual bonds and amino, the co-crosslinking polyreaction is generated at low temperature, and the immobilization beta-galactosidase of different loading quantities can be prepared. The cross-linking degree is controlled, so that the dispersibility isimproved, and internal mass transfer microenvironment can be improved. An immobilized enzyme has high catalytic activity, and when the loading quantity is 56mg of enzymes / 1g of carriers, the relativeactivity can achieve the highest value, and is 93% of that of free enzymes.

Owner:NINGBO UNIV

Non-greasy hand cream and preparation method thereof

InactiveCN107970148ASoft textureImprove stabilityCosmetic preparationsToilet preparationsXylitolGeranium

The invention discloses a non-greasy hand cream and a preparation method thereof. The non-greasy hand cream is prepared from the following components by weight: 20 to 30 parts of grape seed oil, 30 to50 parts of mint essential oil, 20 to 40 parts of geranium essential oil, 10 to 20 parts of arnica extract, 10 to 30 parts of organic beeswax, 15 to 20 parts of urea, 10 to 30 parts of vitamin E, 10to 20 parts of xylitol, 5 to 10 parts of ethylparaben and 10 to 30 parts of deionized water. The non-greasy hand cream has dual effects on the hand; i.e., on the one hand, the cream can promote appropriate cross-linking of collagen, and on the other hand, the cream, functioning as an effective free radical scavenger, can prevent excess cross-linking of skin, so wrinkles and vesicae on the skin areprevented and the skin is allowed to maintain soft, moist and smooth. Meanwhile, the cream is soft, mild, moist, non-greasy and non-sticking. Moreover, the cream is good in stability and suitable forstorage and can be used for a long time.

Owner:赖婷婷

Method for modifying polarity of elastomer resin

The invention relates to a method for modifying the polarity of elastomer resin, which is characterized in that: the elastomer resin is subjected to melt grafting modification by using sorbic acid as a grafting agent on the premise that an initiator is not added. The method comprises the following steps of: putting the elastomer resin and the sorbic acid (2,4-hexadienoic acid) into processing equipment at one time, and uniformly mixing at the temperature of between 20 and 80 DEG C to obtain composite glue; and feeding the composite glue into reaction equipment, making the composite glue become a melt at the temperature of between 135 and 200 DEG C, maintaining reaction of various components in the melt for 5 to 60 minutes, discharging, and cooling to obtain the elastomer resin subjected to polarity grafting modification. The method effectively solves the problem that the elastomer resin is over-crosslinked easily by the conventional modification technology, and the obtained polarity grafting modification product has thermoplasticity and a bright application prospect in the field of thermoplastic elastomers.

Owner:FUJIAN NORMAL UNIV

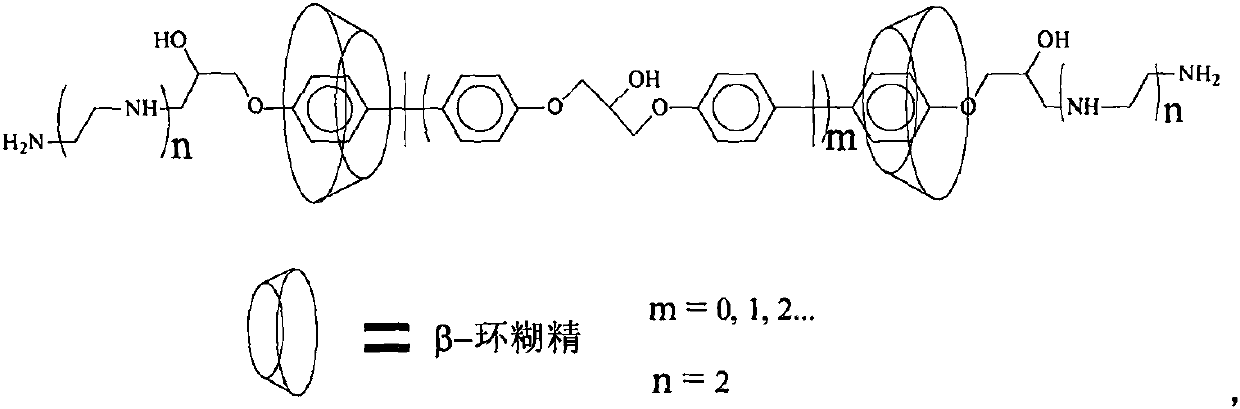

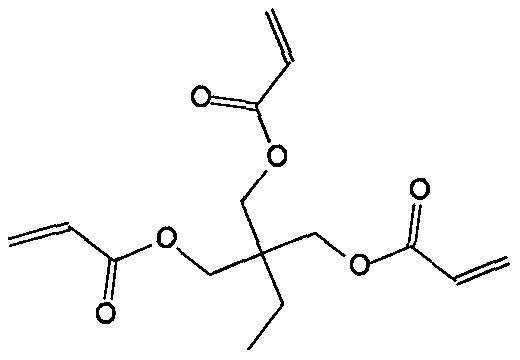

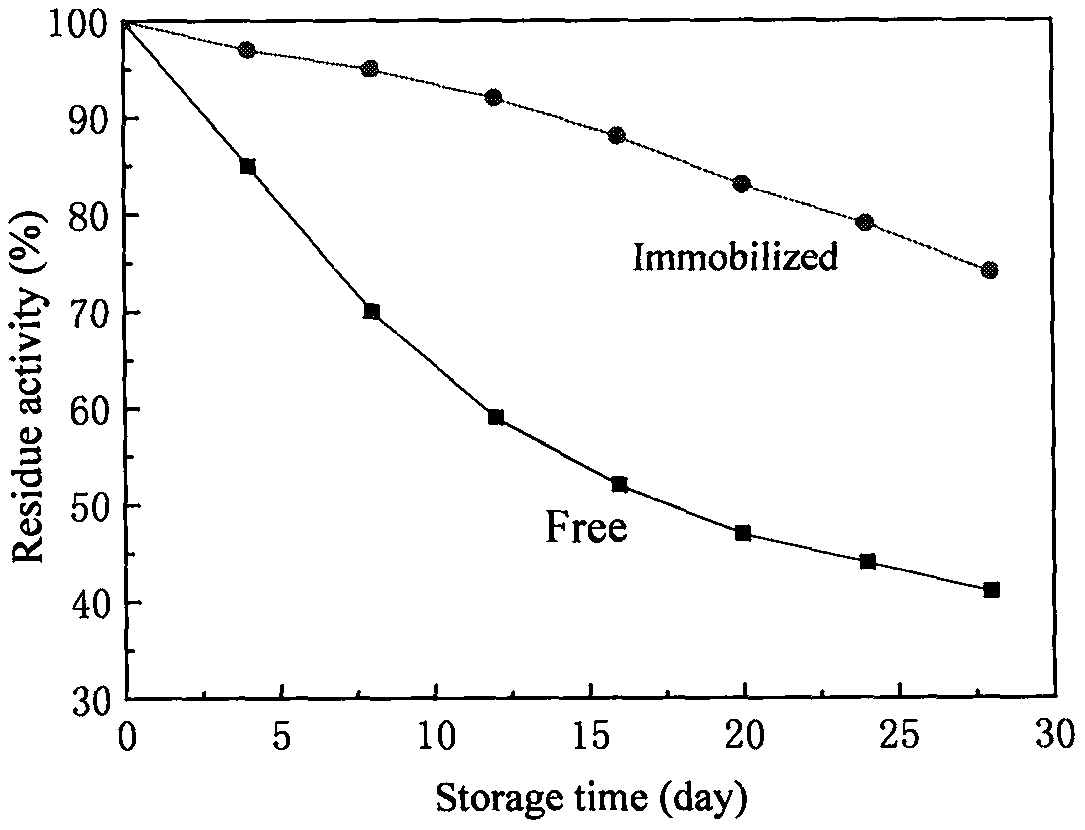

Co-crosslinking immobilization method of tannase

ActiveCN110777129AHigh catalytic activityInhibit aggregationHydrolasesClimate change adaptationEpoxyPolymer science

The invention relates to a co-crosslinking immobilization method of tannase. Oil-soluble trimethylolpropane triacrylate is used as a crosslinking agent, reactants in a water phase are the tannase containing amino and a supramolecular complex formed by aminated epoxy resin and beta-cyclodextrin, through a Michael addition reaction of double bonds and the amino, a co-crosslinking polymerization reaction occurs at the low temperature, and immobilized tannase with different loading capacities is prepared. By controlling the cross-linking degree, dispersity is improved, the mass transfer microenvironment inside the tannase is improved, the immobilized tannase has high catalytic activity and has the highest activity when the loading capacity is 89 mg of an enzyme per gram of a carrier, and the activity reaches 92% of a free enzyme.

Owner:NINGBO UNIV

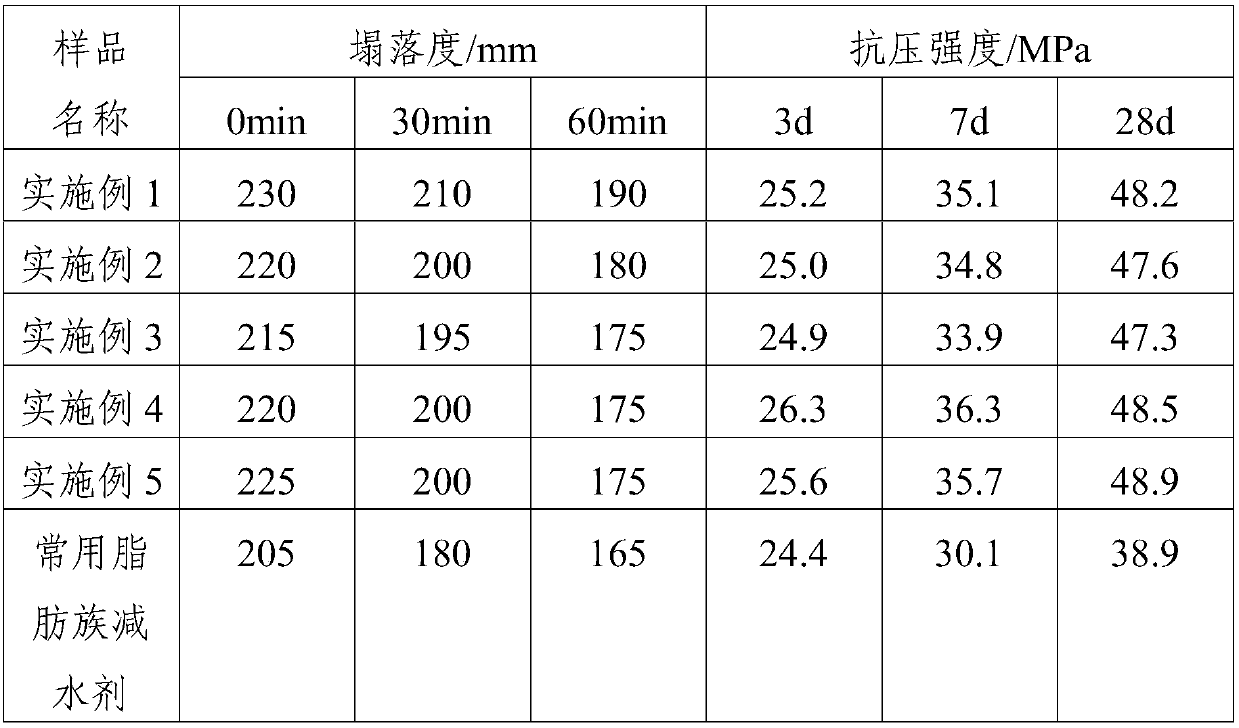

Aliphatic efficient water reducing agent modified with 2-naphthol waste fluid and preparation method of aliphatic efficient water reducing agent

The invention provides an aliphatic efficient water reducing agent modified with 2-naphthol waste fluid and a preparation method of the aliphatic efficient water reducing agent, and relates to the technical field of waste fluid treatment. The aliphatic efficient water reducing agent is prepared from, by weight, 35-90 parts of 2-naphthol waste fluid, 60-80 parts of ketone compound, 260-380 parts ofaldehyde compound, 80-180 parts of sodium sulfite, 5-15 parts of initiator, 3-12 parts of cellulose xanthate, 1-10 parts of sodium p-styrenesulfonate, 30-90 parts of calcium chloride and 110-160 parts of water; in the preparation process, cellulose xanthate and sodium p-styrenesulfonate are mixed to obtain a solution A, sodium sulfite, the initiator, the ketone compound, the aldehyde compound, the solution A and calcium chloride are added in the 2-naphthol waste fluid in sequence, all reaction temperatures are controlled, and the water reducing agent is obtained. The prepared modified water reducing agent can obviously reduce collapsbillity loss; compared with frequently-used aliphatic water reducing agent, better collapse resistance and freezing resistance are achieved.

Owner:萧县沃德化工科技有限公司

Preparation method of tilapia skin collagen beautifying skin-care emulsion

InactiveCN107157796AGood moisturizing effectAvoid over-crosslinkingCosmetic preparationsConnective tissue peptidesTilapiaAllergy

The invention relates to a preparation method of tilapia skin collagen beautifying skin-care emulsion, and belongs to the technical field of emulsion preparation, and the method comprises preparation of tilapia skin collagen, preparation of an aqueous phase material liquid, preparation of an oil phase liquid material liquid and emulsification. The tilapia skin collagen beautifying skin-care emulsion prepared by the method has no chemical addition, has excellent moisturizing and whitening functions, can make the skin smooth and bright by long-term use, and is suitable for people susceptible to allergies.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

Camellia-powder composition with functions of beauty face-whitening-nourishing, anti-radiation and improving sub-health condition

InactiveCN1850213AInhibit peroxidation reactionPrevent agingPharmaceutical delivery mechanismDermatological disorderOrganic acidPollen

The present invention relates to a natural nutrient preparation, in particular, it relates to a tea pollen composition with the effect of whitening skin, nourishing face, resisting radiation and improving subhealth and its preparation method and application. Said tea pollen contains natural organic acids such as catechinic acid and epicatechin, etc. so that it can promote absorption of OPC and possess obvious synergistic antioxidation action.

Owner:XINSHIJI HAILUN MEDICINE SCI TECH BEIJING

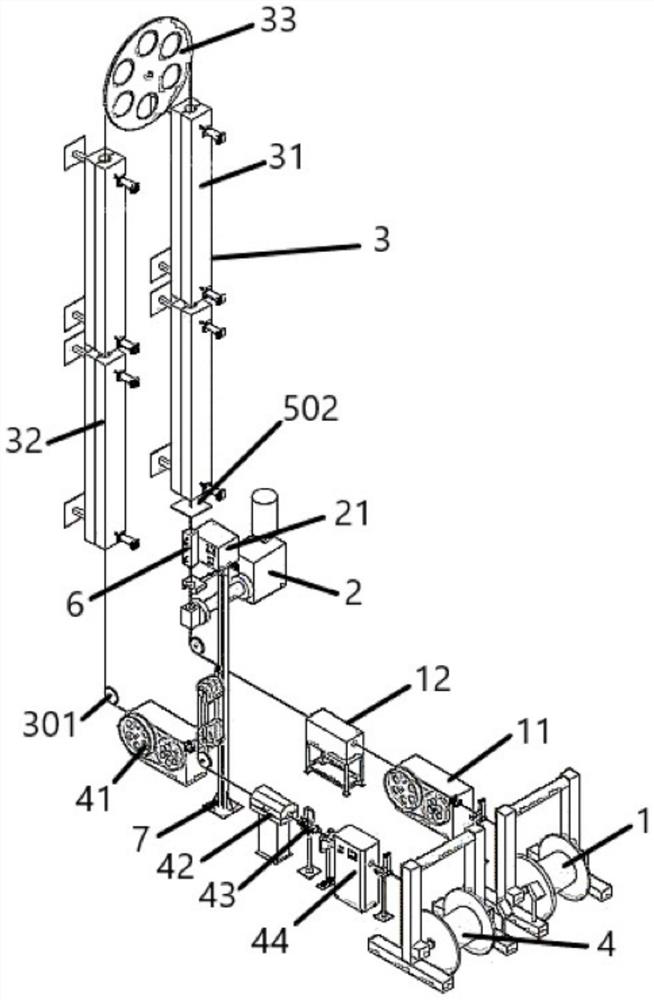

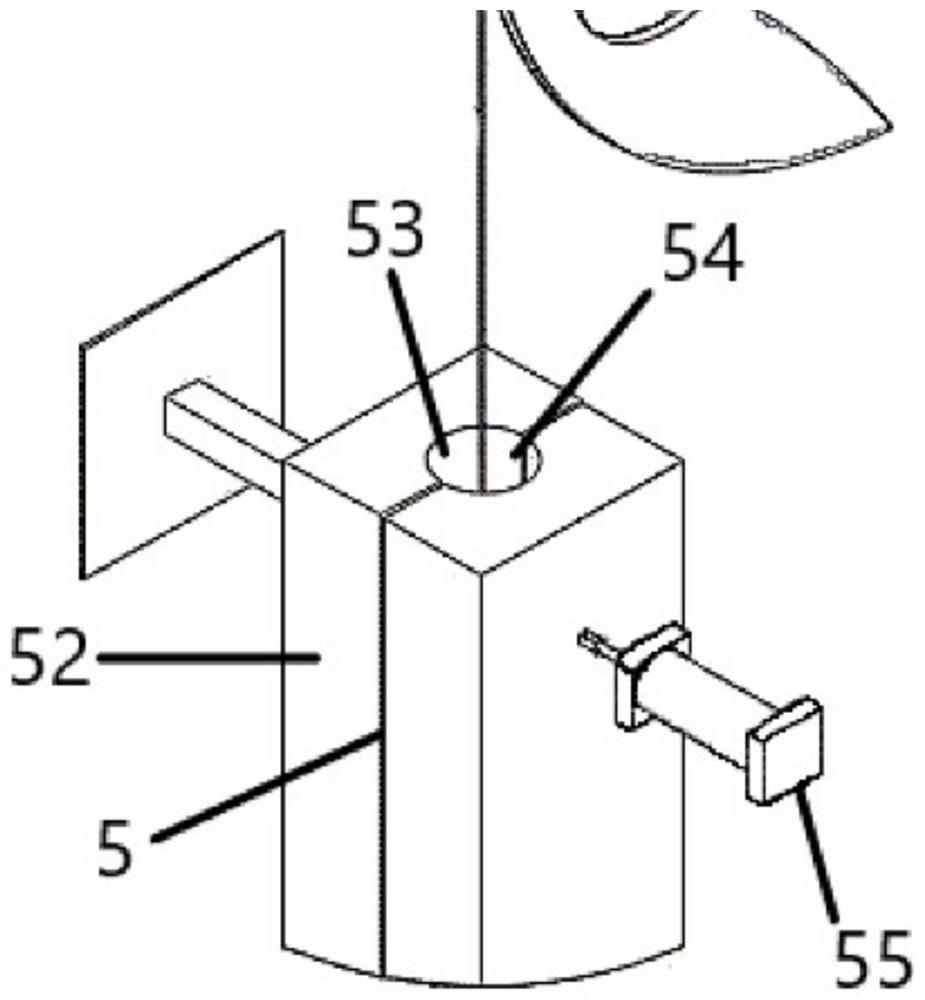

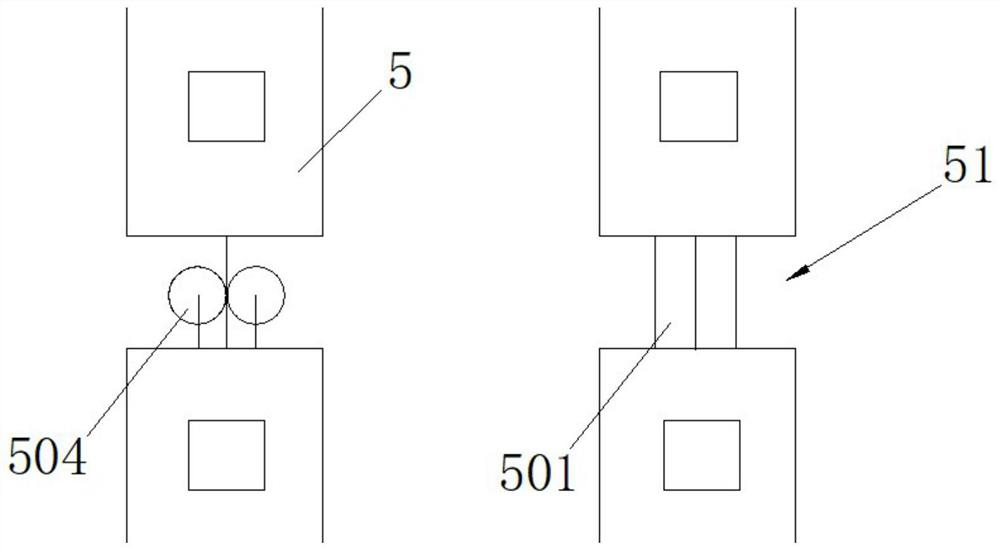

Vertical production line for cables for new energy electric vehicles

ActiveCN112309647BQuality improvementReduce stressApparatus for heat treatmentInsulating conductors/cablesProduction lineElectrical conductor

The invention discloses a vertical production line for electric cables for new energy electric vehicles, which includes a pay-off reel, a first tractor, an extruder, a vulcanizing device, a second tractor and a take-up reel, which are installed in sequence. The vulcanizing device includes an uplink The vulcanization section, the descending vulcanization section and the reversing wheel, the up vulcanization section and the down vulcanization section all include at least two vulcanization pipes, the vulcanization pipes further include two vulcanization pipe units, and a pre-set is installed between the up vulcanization section and the extruder heater. In the present invention, the vulcanization device is divided into an upward vulcanization section and a downward vulcanization section arranged vertically, so that the rubber on the conductor will not have an eccentric effect on the conductor under the action of gravity. Split into multiple vulcanization tubes set at intervals, by controlling the heating temperature of different vulcanization tubes, adjust according to different vulcanization states at different parts, so as to improve the overall vulcanization quality and vulcanization efficiency of the cable, and then improve the molding quality of the cable .

Owner:鑫宏业科技(湖南)有限公司

Method for preparing stichopus japonicus collagen emulsion

InactiveCN107115227AInhibitory activityInhibit synthesisCosmetic preparationsToilet preparationsStichopusOil phase

The invention relates to a method for preparing an stichopus japonicus collagen emulsion and belongs to the technical field of emulsion preparation. The method comprises the procedures of preparing stichopus japonicus collagen, preparing an aqueous-phase feed solution, preparing an oil-phase feed solution and carrying out emulsification. The stichopus japonicus collagen emulsion prepared by the method is free of chemical addition, has excellent moisture-preserving, whitening and skin care effects, can be used for smoothing and brightening skin in long-term usage and is applicable to allergic people.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

Preparation method of golden camellia whitening emulsion

InactiveCN107213057AInhibitory activityInhibit synthesisCosmetic preparationsToilet preparationsOil phaseAqueous extract

The invention provides a preparation method of a golden camellia whitening emulsion and belongs to the technical field of emulsion preparation. The preparation method comprises the following steps of: golden camellia aqueous extract preparation, aqueous phase material liquid preparation, oil phase material liquid preparation and emulsion. The prepared golden camellia whitening emulsion is free of chemical additive, has excellent whitening and skin-protecting functions, can smoothen and brighten the skin if being used for a long time, and is suitable for easily allergic people.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

Fluorosilicone resin and preparation method thereof

ActiveUS11299593B2Improve heat resistanceSteric hindrance is largeGroup 4/14 element organic compoundsAdhesivesPolymer scienceAdhesive

Provided is a fluorosilicone resin and a preparation method thereof. Using pentafluorostyrene as raw material, pentafluorophenethyldimethylchlorosilane is prepared by a hydrosilylation reaction. By means of a polycondensation reaction of the pentafluorophenethyldimethylchlorosilane, trimethylchlorosilane and tetraethyl orthosilicate, a pentafluorophenyl silicone resin is prepared. The preparation method adopts a two-step polycondensation process, which overcomes the disadvantages of a large difference in hydrolysis reactivity between pentafluorophenyldimethylchlorosilane and a copolymerized trialkyl-chlorosilane, and achieves a high yield. The obtained pentafluorophenyl silicone resin has the advantages of superior heat resistance, simple preparation process, low equipment requirements, high availability of raw material, and suitability for mass production. The heat-resistant fluorosilicone resin can be applied in a polymer material, such as a heat-resistant adhesive.

Owner:SUZHOU UNIV

Co-crosslinking immobilization method of laccase

ActiveCN110760502AImprove microenvironmentImprove catalytic activityOxidoreductasesOn/in organic carrierComposite materialDouble bond

The invention relates to a co-crosslinking immobilization method of laccase. Oil-soluble dipentaerythritol hexaacrylate is used as a cross-linking agent, reactants in a water phase are amino-containing laccase and a supermolecular complex formed by aminated epoxy resin and beta-cyclodextrin, a Michael addition reaction of double bonds and amino is utilized, a co-crosslinking polymerization reaction is carried out at a low temperature, and immobilized laccase with different loading capacities is prepared. By controlling the crosslinking degree, the dispersity is improved and the internal mass transfer microenvironment is improved. The immobilized enzyme has higher catalytic activity, and has the highest activity when the loading capacity is 77mg enzyme / g carrier, and the loading capacity reaches 88% of that of a free enzyme.

Owner:NINGBO UNIV

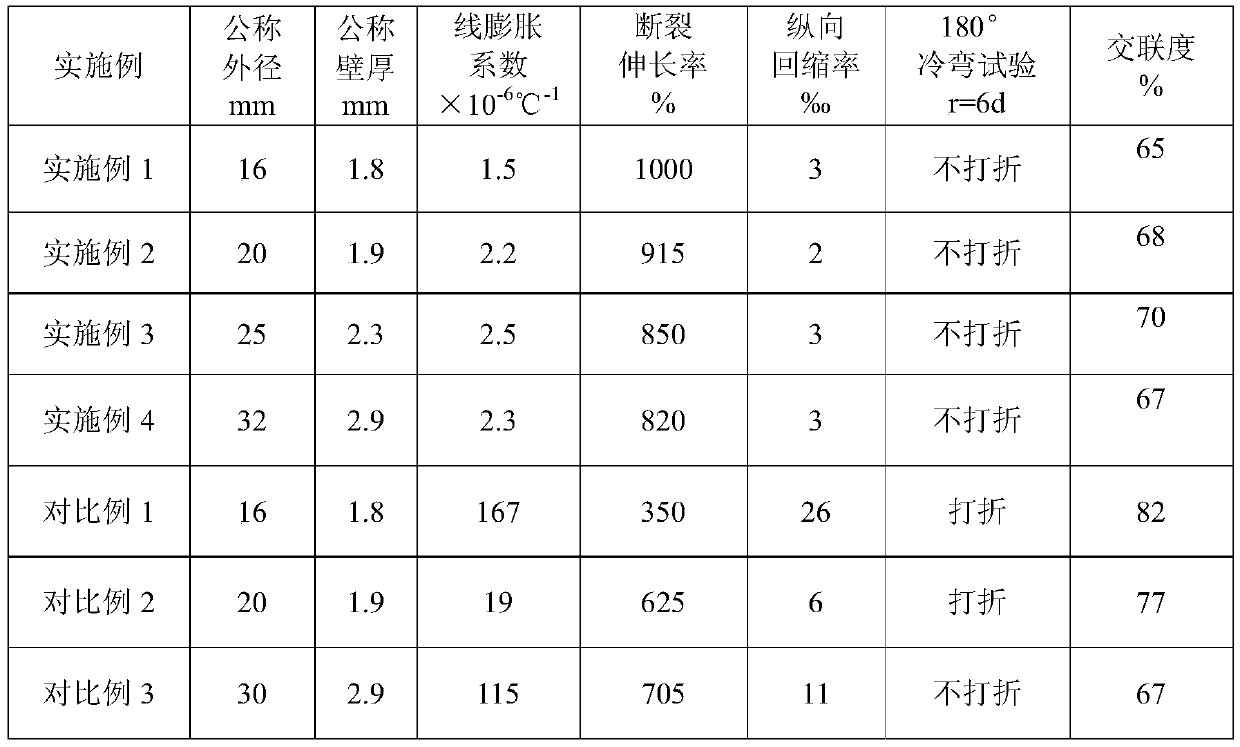

Floor heating heating pipe with low linear expansion coefficient and preparation method thereof

ActiveCN107987353BGood high temperature creep propertiesSmall expansion coefficientTubular articlesPolymer scienceDibutyl tin dilaurate

The invention discloses a floor heating system heating pipe with a low linear expansion coefficient and a preparation method thereof. The heating pipe is prepared by performing matrix resin drying, feeding, blending, four-section single screw extrusion forming, argon vacuum sizing, water tank cooling, compressed air purging, traction, cut-to-length cutting, and coiling and crosslinking on matrix resin and an auxiliary agent with the mass ratio being 100: (0.76-1.08), wherein the matrix resin adopts HDPE, LDPE and PPR; the auxiliary agent adopts vinyl trimethoxy silane, dicumyl peroxide, dibutyltin dilaurate and an antioxidant. The heating pipe has the advantages that three types of matrix resin is adopted to be blended to obtain the best performance matching, and the adding of a small amount of auxiliary agent restrains the excessive crosslinking of pipes; through the adoption of a four-section single screw extruder with a large ratio of length to diameter, the grafting reaction efficiency is improved, and through the controlling of temperature, humidity and time, hydrolizing and crosslinking is more sufficient. The pipe has high tenacity and plasticity, and low expansion coefficient, is convenient for construction, and can be widely applied to the floor radiation heating field.

Owner:济南能源工程集团有限公司

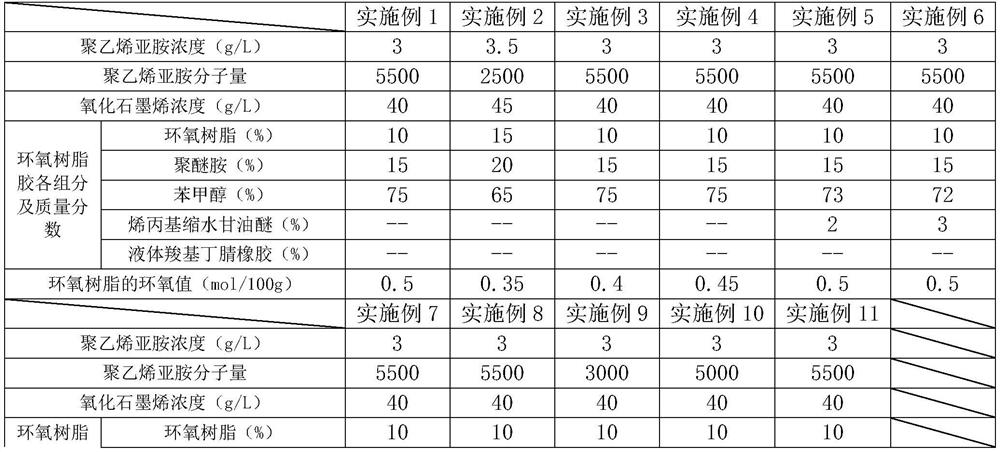

Graphene-based antibacterial fabric and production process thereof

The invention relates to the field of fabrics, and particularly discloses a graphene-based antibacterial fabric and a production process thereof. The fabric sequentially comprises a fabric layer, a bonding layer, a graphene layer and a protective layer from inside to outside; the fabric layer is formed by tatting cotton fibers; the bonding layer is a structural layer which is formed after the surface of the fabric layer is finished by polyethyleneimine and plays a role in bonding transition; the graphene layer is a structural layer which is formed by hot-press finishing of graphene oxide on the surface of the bonding layer and plays a main antibacterial role; the protective layer is a structural layer which is formed by crosslinking epoxy resin glue on the surface of the bonding layer and mainly has a protective effect; and the epoxy resin glue is mainly formed by mixing epoxy resin, polyether amine and benzyl alcohol. The graphene antibacterial fabric prepared by the process has good wear resistance on the surface and can be used for a long time, and the graphene layer is not easy to wear or not prone to falling off, so that the graphene antibacterial fabric has more durable antibacterial performance.

Owner:HANGZHOU KELIDA HOME TEXTILE CO LTD

Preparation method of ginseng beautifying and skin caring lotion

InactiveCN107095821AImprove antioxidant enzyme activitySuppress generationCosmetic preparationsToilet preparationsMedicineOil phase

The invention relates to a preparation method of a ginseng beautifying and skin caring lotion, which belongs to the technical field of emulsion preparation. The method comprises the following steps: preparation of a ginseng aqueous extract, preparation of aqueous phase liquid, preparation of oil phase liquid and emulsification, the ginseng beautifying and skin caring lotion prepared by the method has no chemical addition, and has excellent cosmetic and skin care functions, long term usage can make skin smooth and bright, and the lotion is suitable for allergic people.

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

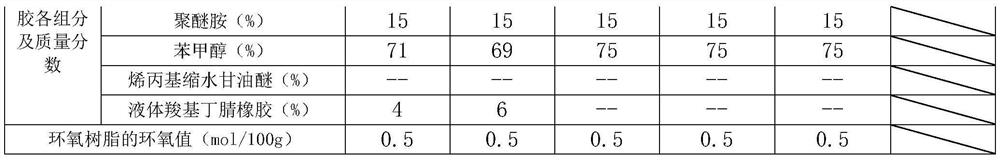

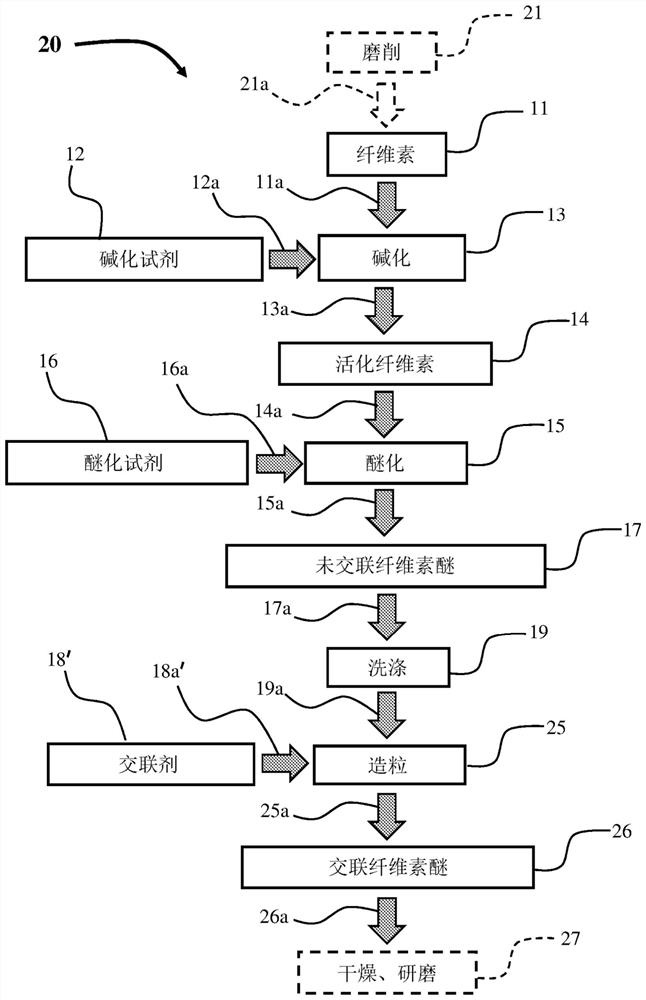

Process for producing a crosslinked cellulose ether

A process for producing a crosslinked cellulose ether including the steps of: (a) contacting at least one cellulose material with at least one alkalization reagent to form an activated cellulose material; (b) contacting the activated cellulose material of step (a) with at least one etherification reagent to form an uncrosslinked cellulose ether; (c) subjecting the cellulose ether of step (b) to a simultaneous or stepwise washing and / or granulating step; (d) adding at least one crosslinking agent to the uncrosslinked cellulose ether during the washing and / or granulating of step (c) to form a crosslinked cellulose ether; and (e) any other optional components desired; and a crosslinked cellulose ether produced by the above process.

Owner:DOW GLOBAL TECH LLC

Method for modifying polarity of elastomer resin

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com