Process for producing a crosslinked cellulose ether

A technology of cellulose ether and cellulose, which is applied in the field of production of cross-linked cellulose ether, can solve problems such as excessive cross-linking affecting the process, achieve uniform distribution, and enhance the effect of the process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

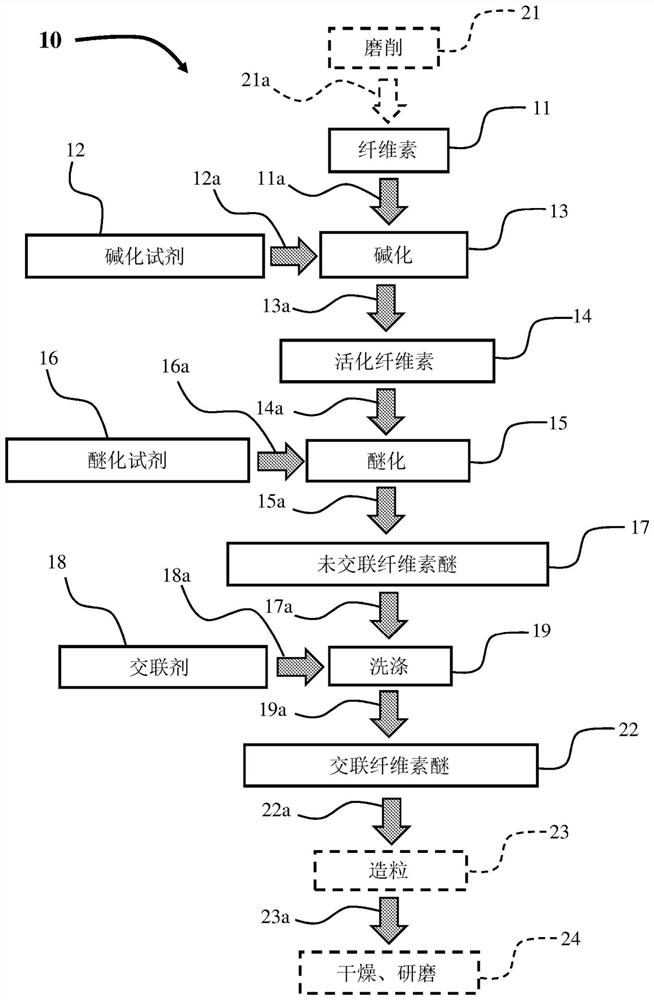

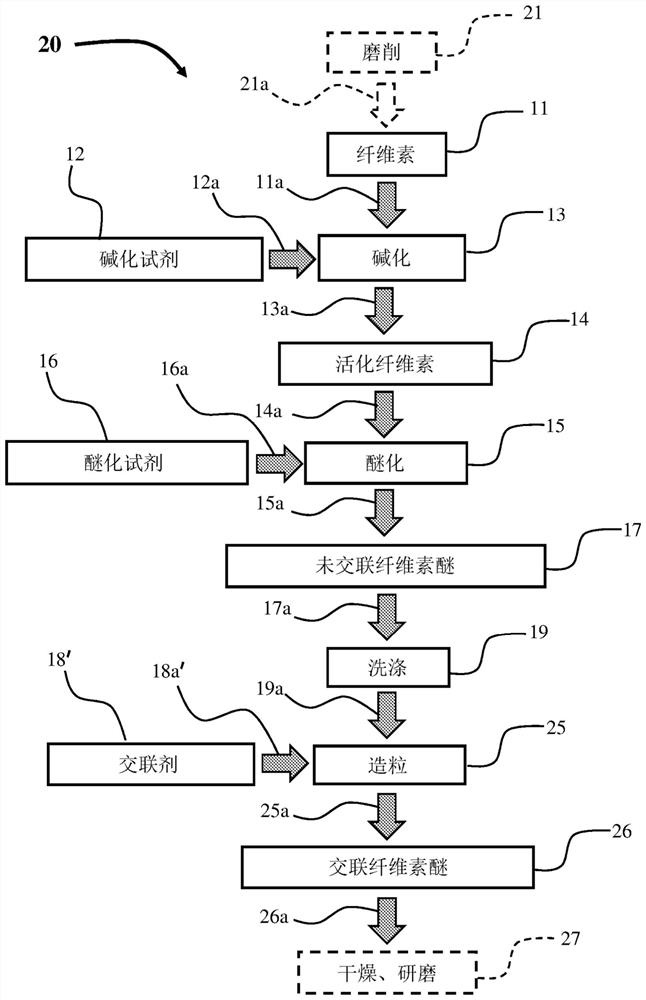

Method used

Image

Examples

example

[0099] The following examples are provided to illustrate the invention in additional detail, but should not be construed as limiting the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

[0100] Various terms and designations used in the following Inventive Examples (Inv. Ex.) and Comparative Examples (Comp. Ex.) are explained below and in Tables II to VI.

[0101] "HEMC" stands for hydroxyethylmethylcellulose.

[0102] "AGU" stands for anhydroglucose unit of cellulose ether.

[0103] "LVN" stands for the Intrinsic Viscosity Number of pulp as measured according to the procedure described in ISO 5351 (2010).

[0104] The various raw materials or ingredients used in the examples are explained below:

[0105] Epilox M 985 and Epilox P13-42 are poly(propylene glycol) diglycidyl ethers available from Leuna Harze AG.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com