Water-based drilling fluid for stabilizing shale

A water-based drilling fluid and shale technology, applied in the field of water-based drilling fluid, can solve the problems of high cost and environmental pollution, and achieve the effects of low cost, high viscosity and shear force, and improved plugging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

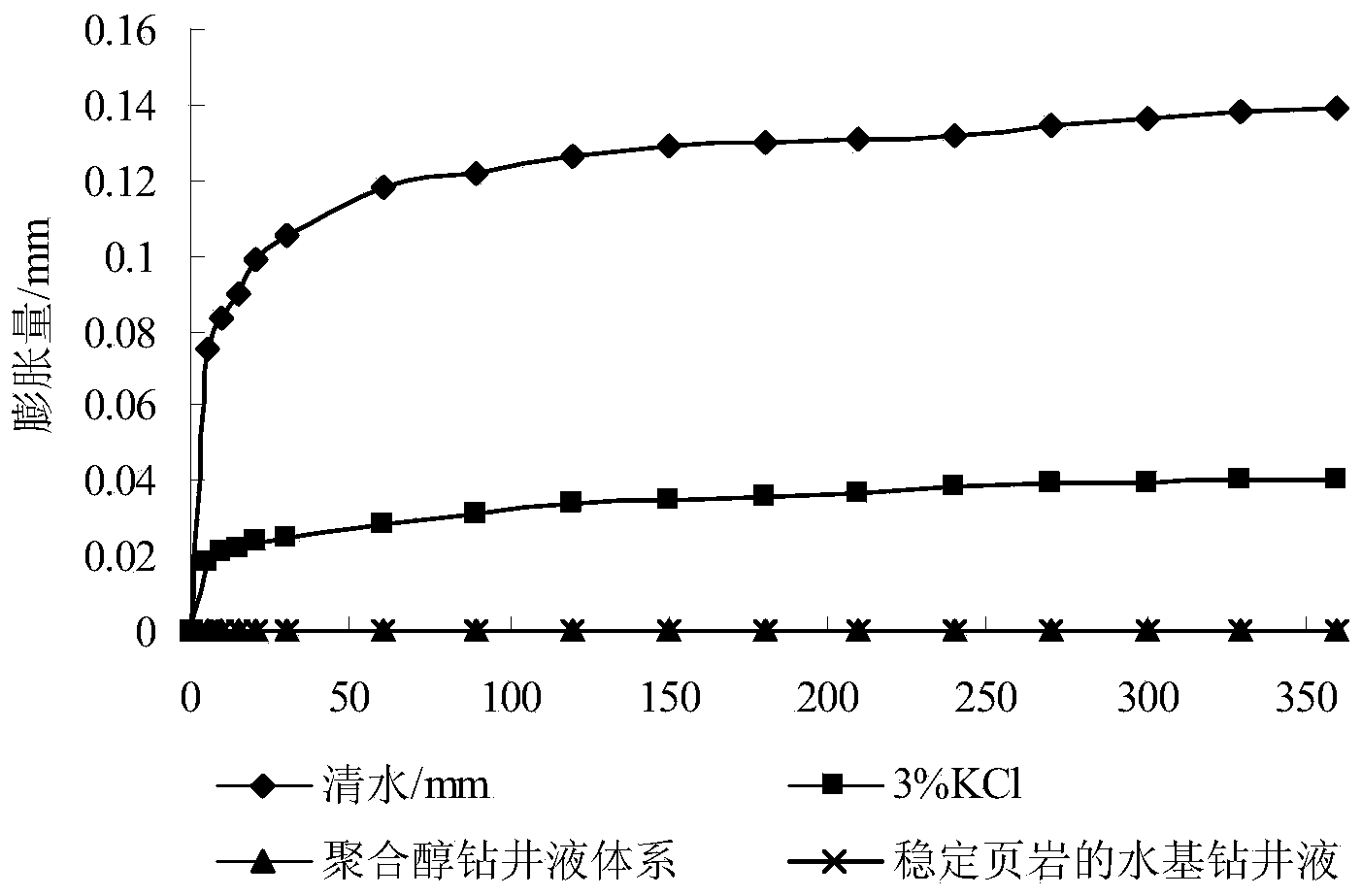

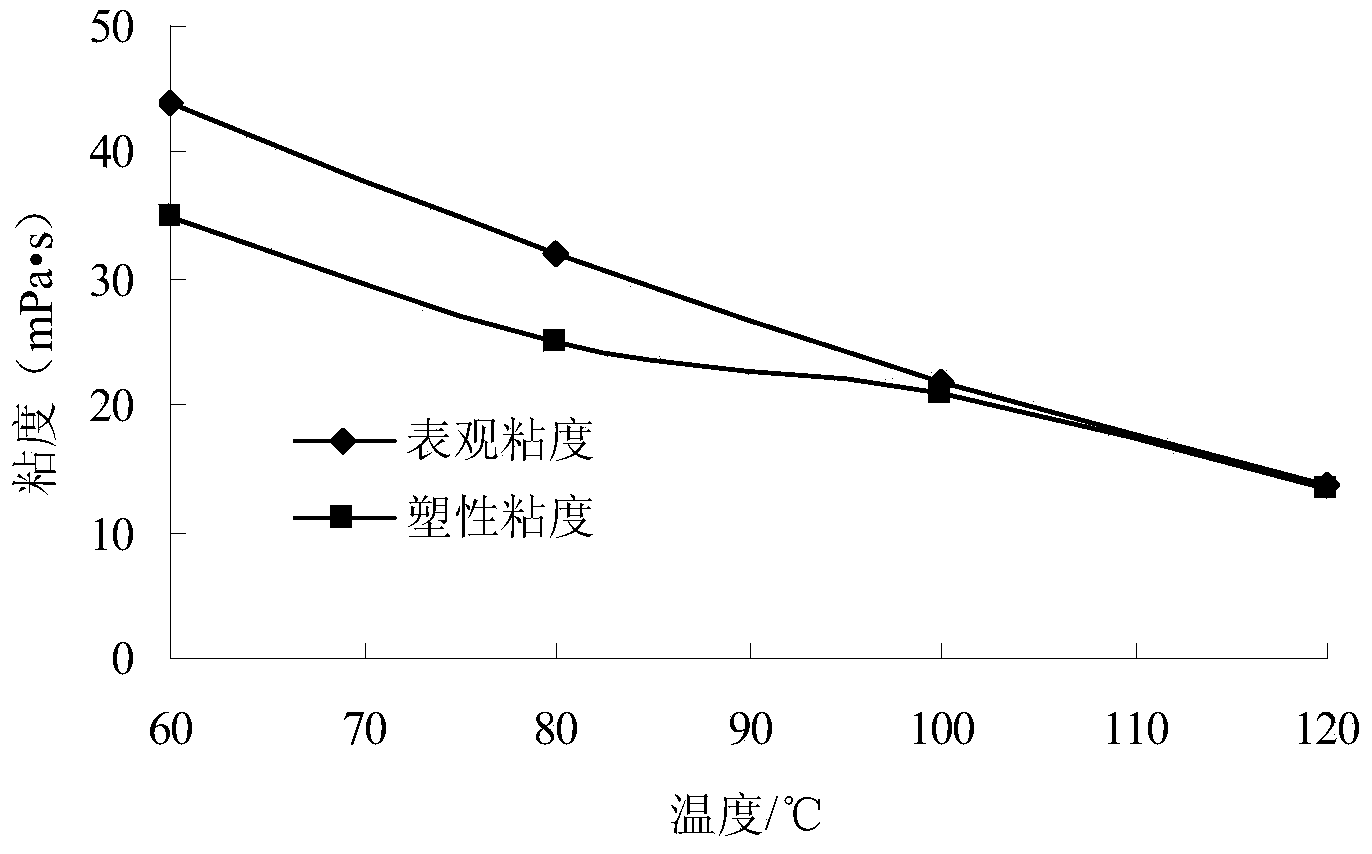

[0026] This Example 1 mainly reflects: (1) the preparation method and basic performance parameters (rheology and fluid loss) of water-based drilling fluid for stabilizing shale; (2) thermal stability evaluation of water-based drilling fluid for stabilizing shale ; (3) XRD analysis results of shale rock samples in Yanchang Oilfield; (4) Changes in expansion of shale rock samples in Yanchang Oilfield after contact with water-based drilling fluid for stable shale; (5) Shale rock samples in Yanchang Oilfield Rolling recovery rate results after contact with water-based drilling fluid for stable shale; (6) Changes of rheological parameters (apparent viscosity and plastic viscosity) of water-based drilling fluid for stable shale under high temperature and high pressure conditions; (7 ) Analysis of filtration performance of water-based drilling fluid for stable shale under high temperature and high pressure conditions; (8) Lubrication performance of water-based drilling fluid for stabl...

Embodiment 2

[0095] This example mainly reflects: (1) The preparation and basic performance parameters (rheology and fluid loss) of the water-based drilling fluid system for stable shale; (2) The water-based drilling fluid for stable shale was heated at 120°C for 16 hours The basic performance parameters in the future.

[0096] The water-based drilling fluid for stabilizing shale prepared in this example, the parts by mass of each component in the drilling fluid are: calculated by the addition amount per 100 milliliters of water, 5 grams of sodium bentonite, 1.5 grams of shale inhibitor gram, 0.5 gram of tackifier, 0.2 gram of flow regulator, 0.9 gram of fluid loss control agent, 2.5 grams of anti-high temperature treatment agent, 9.33 grams of bridging agent, 2.2 grams of plugging agent, and 1.3 grams of anti-slumping agent. Wherein: the shale inhibitor is sulfonated asphalt sodium salt. The thickener is polyanionic cellulose. The flow regulator is xanthan gum. The fluid loss control a...

Embodiment 3

[0110] The water-based drilling fluid for stabilizing shale prepared in this example, the parts by mass of each component in the drilling fluid are: calculated by the addition amount per 100 milliliters of water, 5 grams of sodium bentonite, 1.6 grams of shale inhibitor gram, 0.7 gram of tackifier, 0.1 gram of flow regulator, 0.7 gram of fluid loss reducer, 2.3 gram of anti-high temperature treatment agent, 10.67 gram of bridging agent, 1.8 gram of plugging agent, 1.1 gram of anti-slump agent. Wherein: the shale inhibitor is sulfonated asphalt sodium salt. The thickener is polyanionic cellulose. The flow regulator is xanthan gum. The fluid loss control agent is modified starch. The high temperature resistant treatment agent is lignite resin. The bridging agent is a nano-silica dispersion liquid with a mass concentration of 30%, and the particle diameter of the nano-silica particles in the dispersion liquid is 10-20 nm. The leak-stopping agent is nano-calcium carbonate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com