High-boron content silicon-boron-carbon-nitrogen precursor and preparation method thereof

A silicon boron carbon nitrogen and element content technology is applied in the field of high boron element content silicon boron carbon nitrogen precursor and its preparation, which can solve the problems of complex synthesis steps, low content of ceramic B element, difficult to remove by-products and the like, and achieves high temperature Good stability and oxidation resistance, increasing boron content and avoiding excessive cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the silicon-boron-carbon-nitrogen precursor with high boron element content of the present invention specifically comprises the following steps:

[0042]Step (1), add a certain amount of solvent into the Schlenk reactor filled with an inert gas atmosphere in advance, and put chlorosilane and boron trichloride containing unsaturated groups into the reactor at a certain ratio at -40 ~ 0°C , under magnetic stirring, slowly drop hexamethyldisilazane into the system, after the dropwise addition, raise the temperature to 0-40°C, preferably 0-25°C, stir and react for 4-24h.

[0043] The molar ratio of the chlorosilane, boron trichloride and hexamethyldisilazane added above is 1-5:1-5:4-10; the inert gas can be argon, helium, nitrogen or the like.

[0044] The dropping rate of the above-mentioned hexamethyldisilazane is 2-5 seconds per drop, preferably: add dropwise at a rate of 2-5 seconds per drop in the early stage of the reaction, and quickly add t...

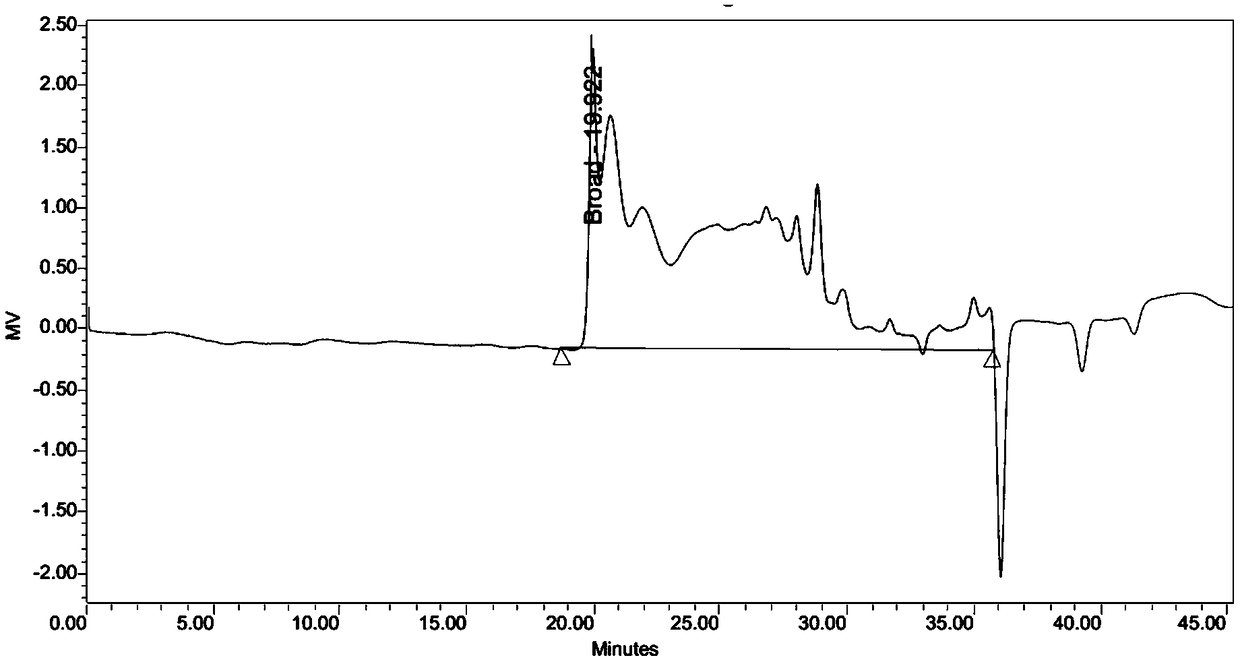

Embodiment 1

[0054] 1) At -40~0°C, add 400ml of 1mol / L boron trichloride n-hexane solution and 52ml of methylvinyldichlorosilane into a Schlenk reactor filled with an inert gas atmosphere in advance, and mix 360ml of six Methyldisilazane is slowly added dropwise to the system at a rate of 3 seconds per drop in the early stage of the reaction. After the reaction system becomes clear and transparent, the remaining liquid can be quickly added. After the dropwise addition is completed, the temperature is raised to 25°C ; Stir and react for 12h.

[0055] 2) Fully stir the reactants obtained above, raise the temperature to 200° C. and react for 8 hours.

[0056] 3) Slowly add 54 g of 1,3-diethylborazine (DEB-H) dropwise into the reaction system of step 2) at a rate of 1 second / drop at 0°C, raise the temperature to 20°C and react for 10 h.

[0057] 4) Distill the prepared SiBCN precursor under reduced pressure at a pressure of -0.1MPa and a distillation temperature of 180°C to remove the solvent...

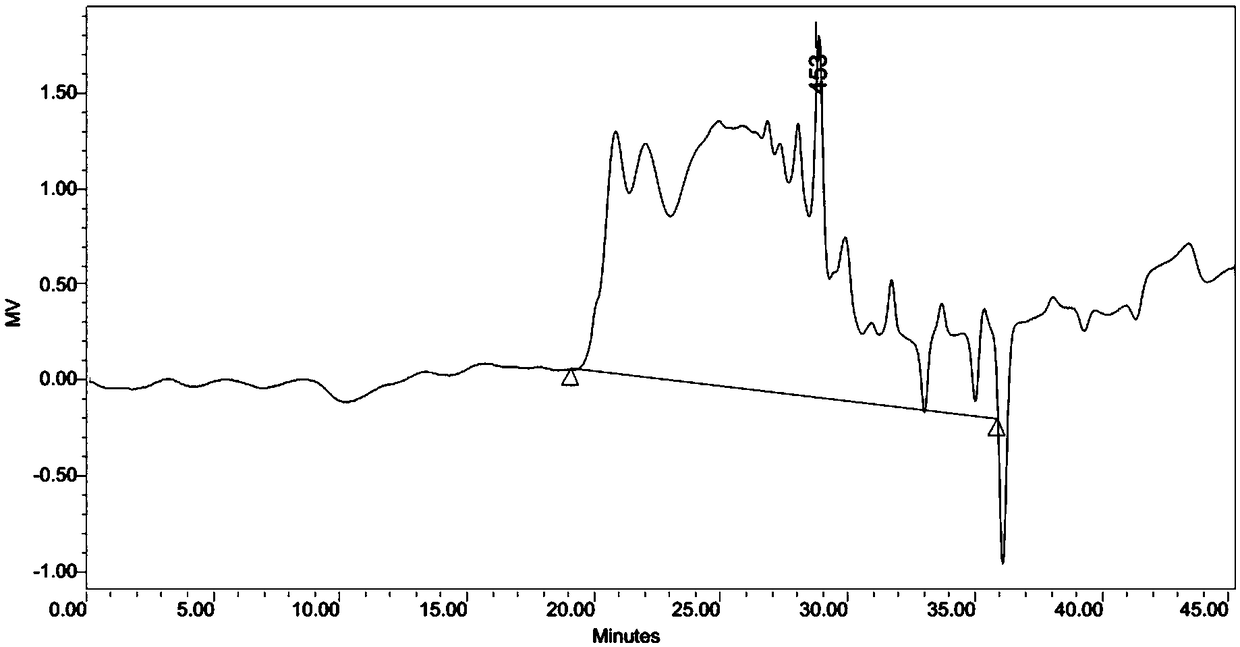

Embodiment 2

[0060] 1) At -40~0°C, add 400ml of 1mol / L boron trichloride n-hexane solution, 52ml of methylvinyldichlorosilane, and 42ml of methylhydrogendichlorosilane into a Schlenk reactor filled with inert gas atmosphere in advance , slowly drop 500ml of hexamethyldisilazane into the system under magnetic stirring, the rate of addition is: in the early stage of the reaction, drop at a rate of 2 seconds per drop, and the remaining liquid can be quickly added after the reaction system becomes clear and transparent, After the dropwise addition, the temperature was raised to 25°C; stirred and reacted for 8h.

[0061] 2) Fully stir the product obtained above, raise the temperature to 200° C. and react for 10 h.

[0062] 3) At 0°C, 54 g of 1,3-diethylborazine (DEB-H) was slowly added dropwise into the system at a rate of 1 second / drop, and the temperature was raised to 20°C for 10 hours of reaction.

[0063] 4) Distill the prepared SiBCN precursor under reduced pressure at a pressure of -0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com