Patents

Literature

43results about How to "Good thermosetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

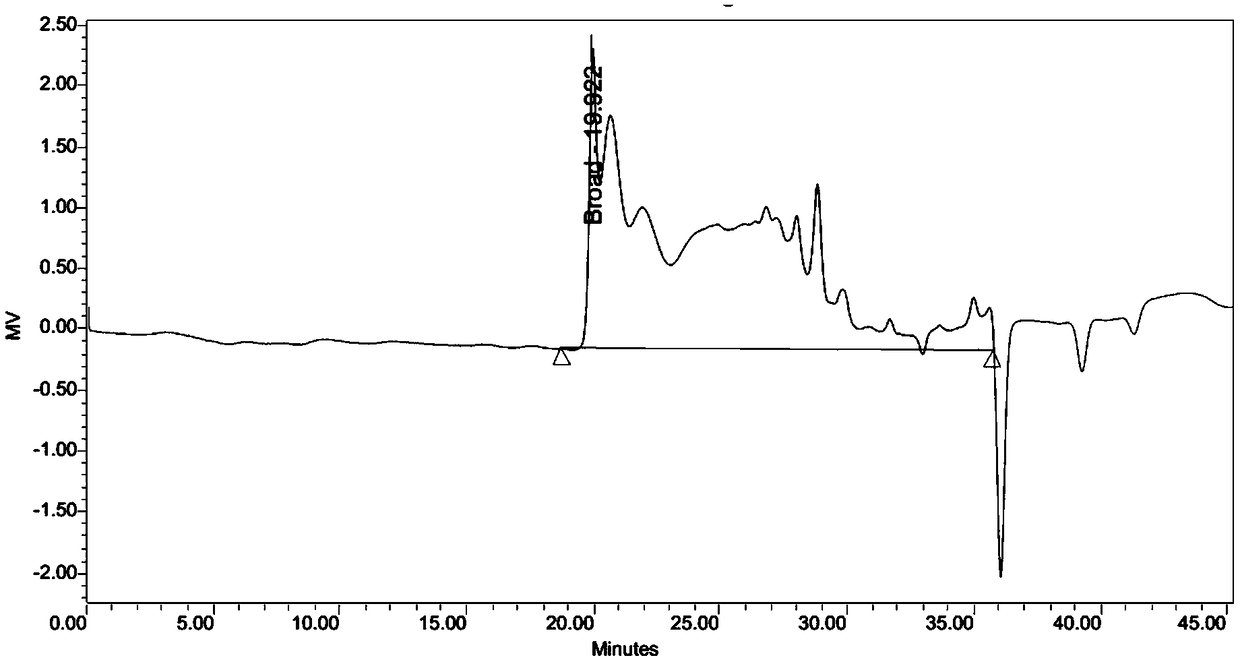

Process for the manufacture of elastic polyurethane fiber and the elastic polyurethane fiber made thereby

ActiveUS7255820B2Excellent set propertyImprove propertiesMonocomponent polyurethanes artificial filamentMelt spinning methodsFiberPolymer science

Disclosed is a process for the manufacture of an elastic polyurethane fiber, including mixing one component selected from among polystyrene polymers or polystyrene copolymers having a number average molecular weight of 50,000–500,000 with polyurethane having a number average molecular weight of 15,000–100,000, to prepare a polymer mixture, which is then spun. The polyurethane elastic fiber made by the method is also provided, which is greatly increased in heat set properties, with a very low rate of change of fundamental properties as the results compared with conventional elastic polyurethane fibers. Hence, the elastic polyurethane fiber can be directly applied for preparation of end products requiring superior heat set properties with no change of conventional conditions of the process.

Owner:HYOSUNG CORP

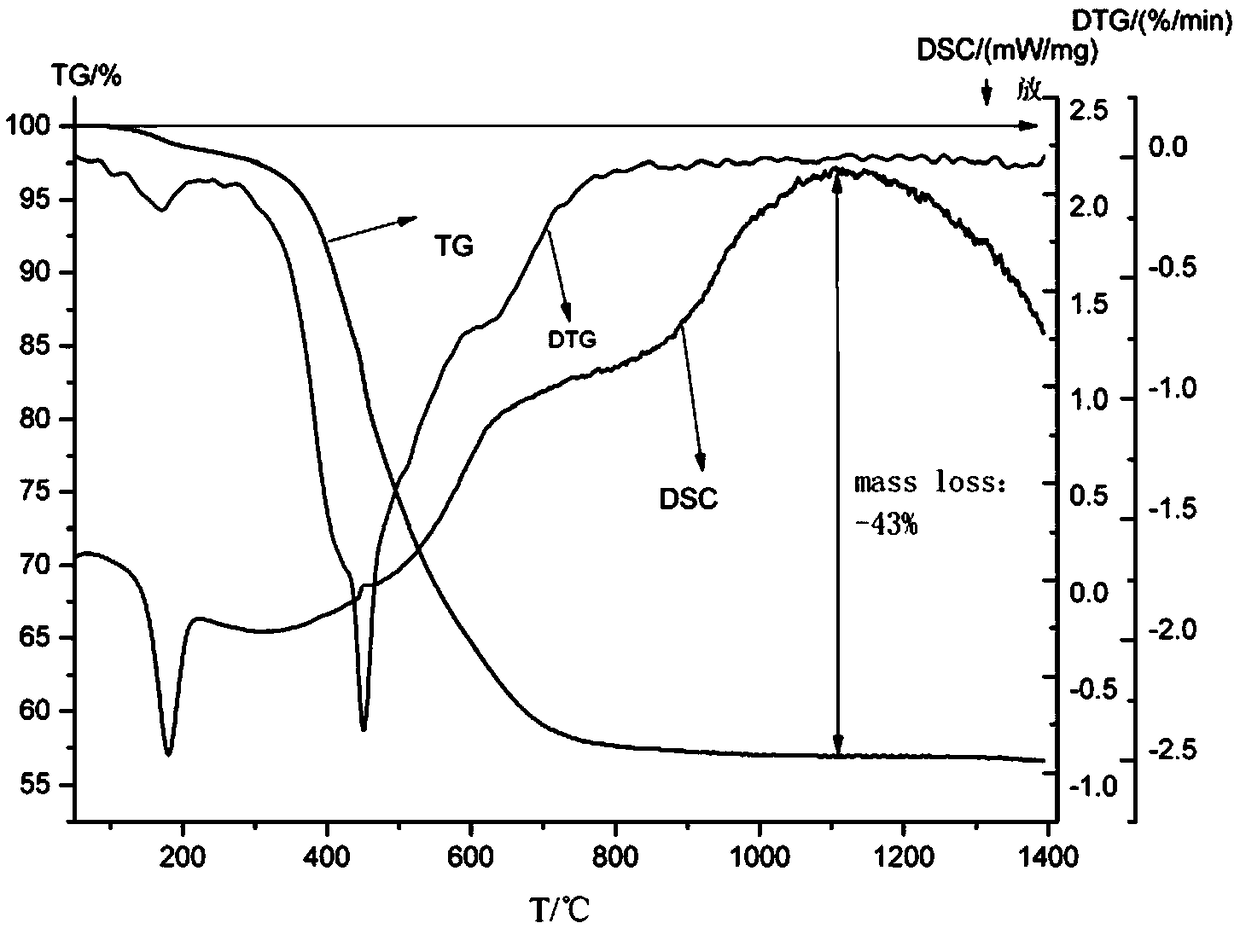

High-boron content silicon-boron-carbon-nitrogen precursor and preparation method thereof

InactiveCN109369918AAvoid over-crosslinkingIncreased boron contentViscous liquidElemental composition

The invention relates to a high-boron content silicon-boron-carbon-nitrogen precursor and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing functional, bifunctional and trifunctional chlorosilane containing unsaturated groups and hexamethyl-disilazane at a low temperature according to a certain ratio, raising the temperature and completely reacting, dropping 1,3-diethyl cycloborazane under low temperature conditions according to a certain ratio, fully reacting the reactants, and finally performing reduced pressure distillation to obtain the solvent and by-products produced by the reaction, thereby obtaining faint yellow viscous liquid or a solid product, namely the SiBCN ceramic precursor. According to the synthetic method disclosed by theinvention, a novel Polyborosilicate resin is prepared by adopting a 'double boron source', the boron content of the prepared SiBCN ceramic can reach 20%, and the problems that the boron content is low and improvement of high temperature resistance and oxidation resistance of the ceramic is not obvious can be solved. The elementary composition regulation range of the precursor disclosed by the invention is wide, and resins which are suitable to serve as a high-temperature-resistant coating, a fiber reinforcement or a ceramic-based composite material matrix and have different elementary compositions can be prepared.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method of aldehyde-free adhesive and application of aldehyde-free adhesive

InactiveCN108504320AHigh bonding strengthImprove water resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesBond strengthPollution

The invention relates to an aldehyde-free adhesive. The aldehyde-free adhesive comprises the following components in percentage by weight: 80% of component A and 20% of component B, wherein the component A comprises the following ingredients in percentage by weight: 30% of polyvinyl alcohol, 30% of xanthan gum, 30% of vinyl acetate-acrylic emulsion, 5% of starch and 5% of plant protein, and the component B comprises the following ingredients in percentage by weight: 40% of DBP, 40% of DOP and 20% of MDI. A bonded artificial sheet material is high in bonding strength, good in water resistance and free of off odors, is non-toxic and pollution-free, is free of formaldehyde pollution of commonly-used adhesives, is applicable to continuous production of shaving boards and medium-density fiberboards and has the characteristics of good initial viscosity and thermosetting property, good adhesion with wood, zero formaldehyde and the like.

Owner:广东始兴县华洲木业有限公司

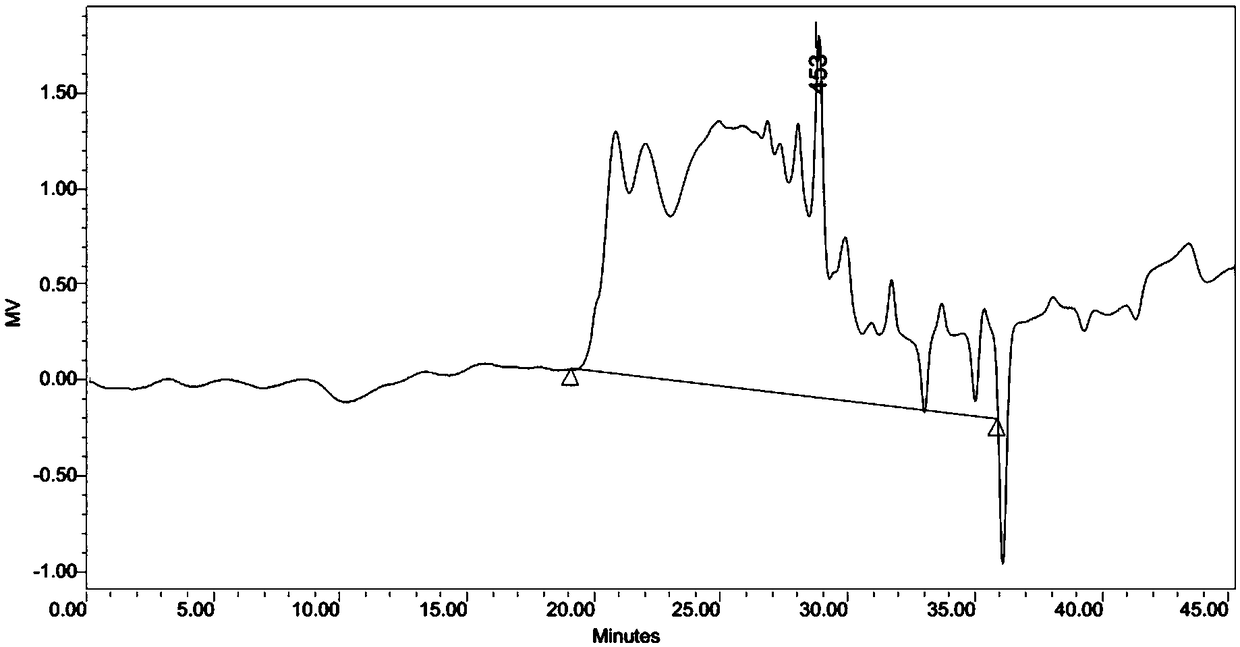

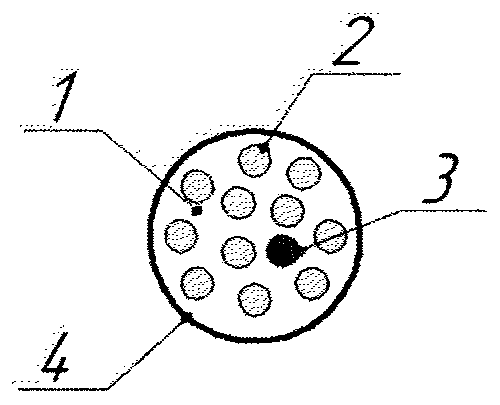

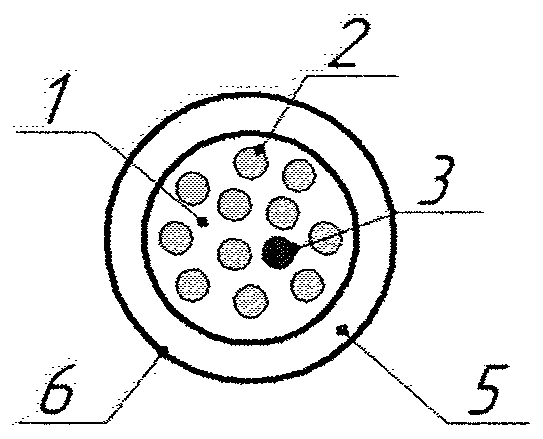

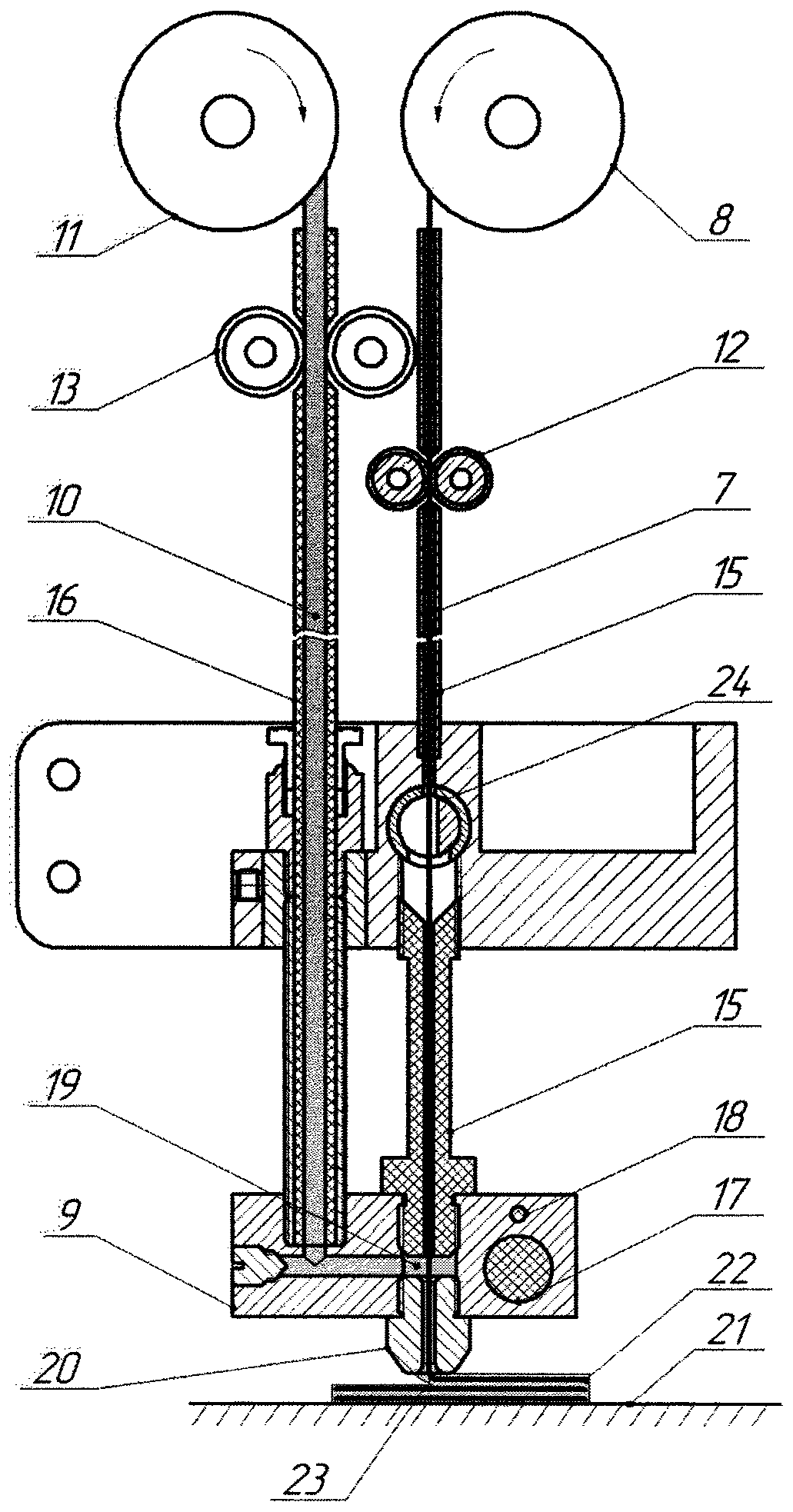

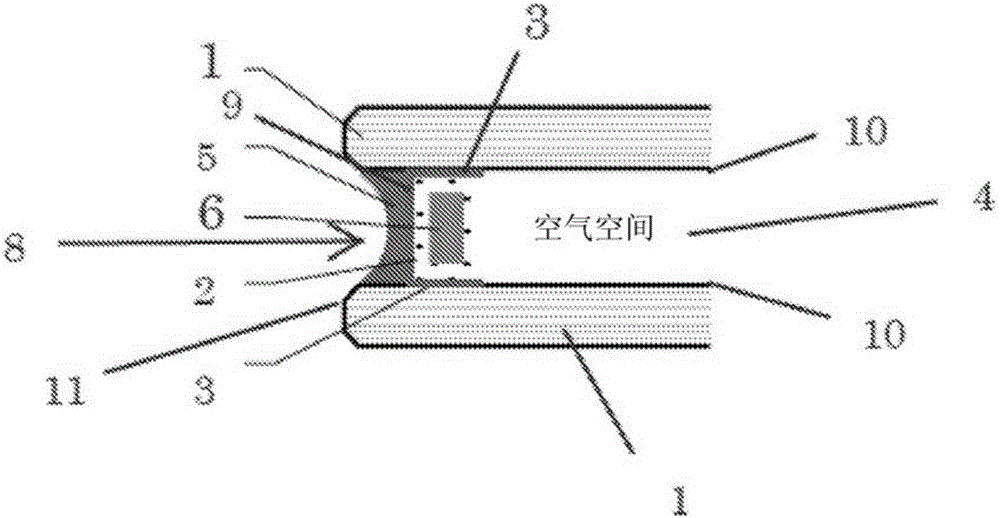

Production of articles made of composite materials by 3d-printing method

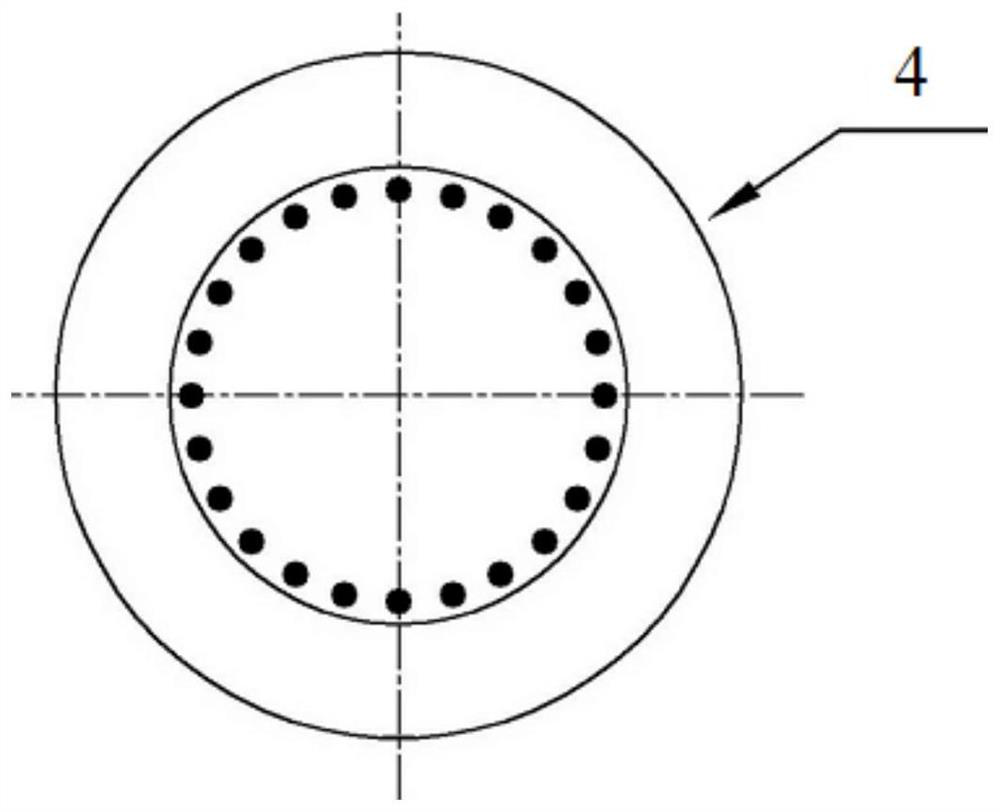

ActiveCN111163921AGood thermosettingImprove technical performanceManufacturing heating elements3D object support structuresFiberPolymer science

The invention relates to the field of additive technologies and can be used for manufacturing components and structures made of composite materials. A device comprises an extruder having inlet channels, a heater, a camera, a temperature sensor, a nozzle for material discharge, mechanisms for feeding material and composite fibre in the form of thread, a thread-cutting mechanism, a table and a three-dimensional displacement mechanism. A method comprises manufacturing composite fibre, feeding same and thermoplastic material into the extruder, and heating up the extruder, wherein the thermoplasticmaterial is combined with the composite fibre. The composite material is then extruded onto the surface of the table, where the composite fibre cools and hardens, and the melt of thermoplastic material solidifies, bonding the composite fibres to one another and forming the article. In addition, in the process of forming the article, the composite fibre is cut and the extruder moves on to the nextsection of the trajectory thereof.

Owner:阿奈索三维打印科技(苏州)有限公司

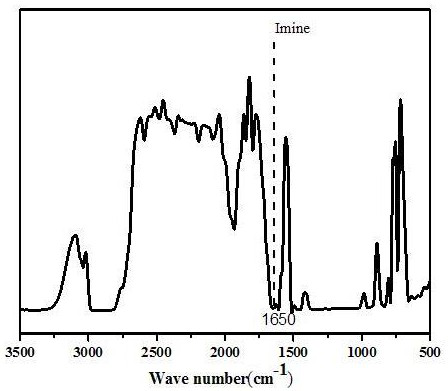

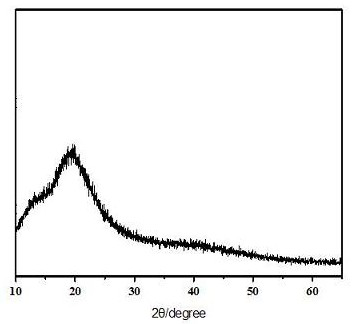

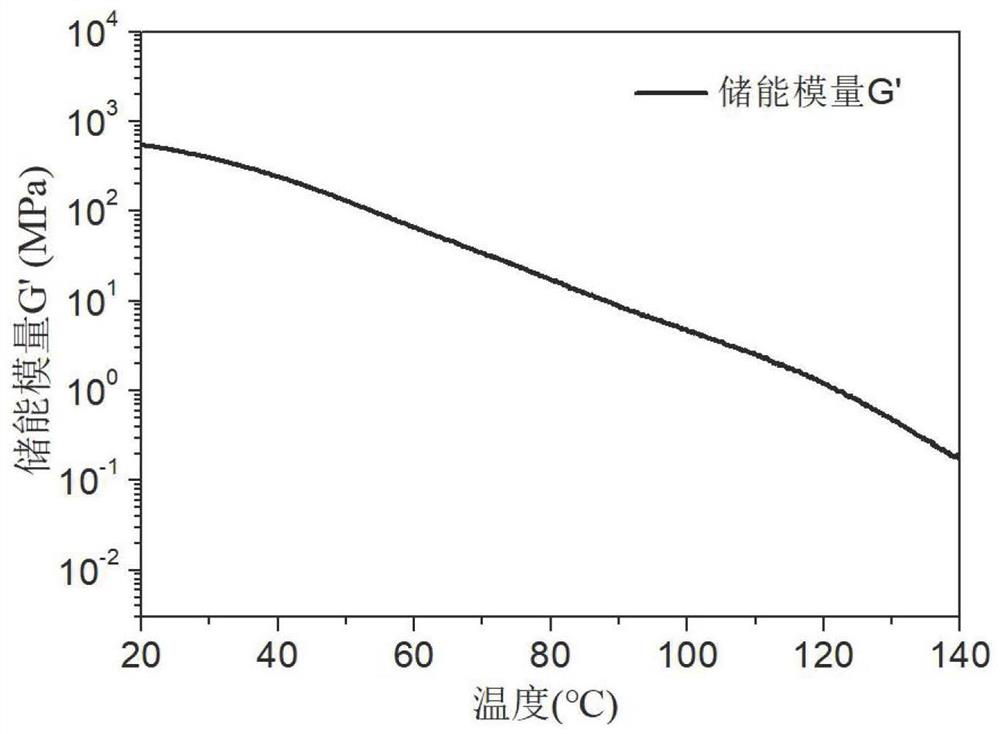

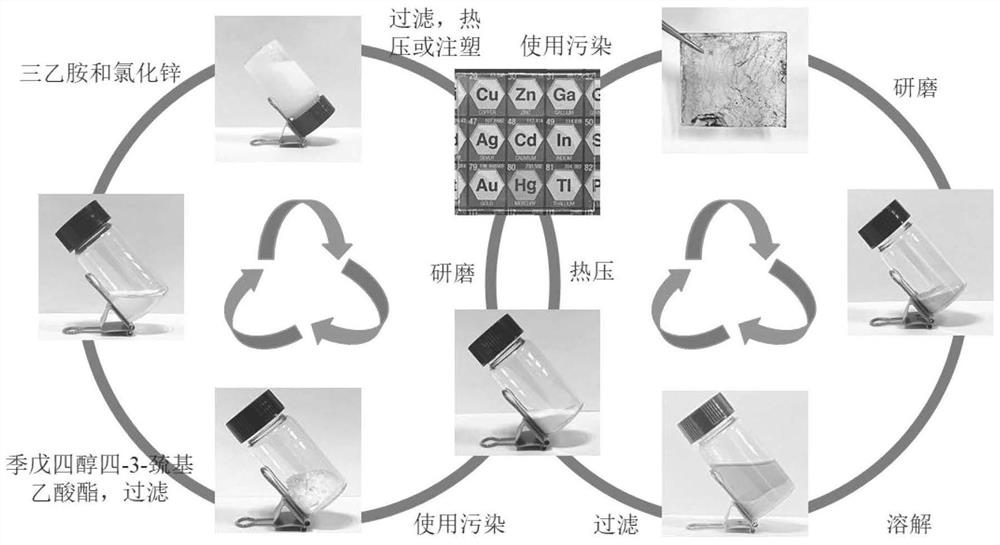

Repairable cross-linked solid polymer electrolyte as well as preparation method and application thereof

ActiveCN111682261AGood thermosettingGuaranteed ionic conductivityLi-accumulatorsElectrolyte immobilisation/gelificationPolymer sciencePolythylene glycol

The invention provides a repairable cross-linked solid polymer electrolyte as well as a preparation method and application thereof, and the repairable cross-linked solid polymer electrolyte is prepared by the following method: dispersing and dissolving terephthalaldehyde, bisphenol A diglycidyl ether, polyethylene glycol diamine and a lithium salt in an acetonitrile solvent, and carrying out stirring for 2-6 hours to obtain a transparent and uniform mixed solution A; dropwise adding the mixed solution A onto a polytetrafluoroethylene mold, and volatilizing acetonitrile at room temperature to obtain a sol-like substance B; and putting the sol-like substance B into a vacuum drying oven, carrying out polymerization reaction to completely crosslink and solidify the sol-like substance B, and continuously heating to dry the sol-like substance B to prepare the polymer electrolyte. According to the invention, a dynamic imine covalent bond is introduced into the polymer electrolyte to form thesolid network-shaped polymer electrolyte, so that the solid network-shaped polymer electrolyte can be repaired in time when fracture occurs in the use process; the prepared network-like polymer electrolyte has high thermal stability and dendritic-crystal-free morphology, and has excellent electrochemical properties such as ionic conductivity and lithium ion migration number.

Owner:NANCHANG HANGKONG UNIVERSITY

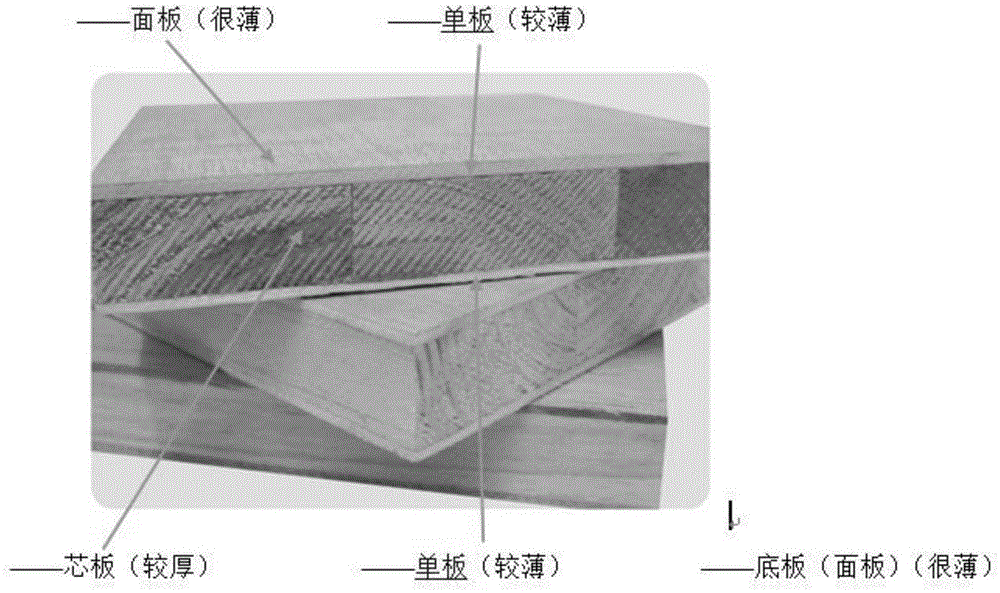

Ecological decorative paper and production method thereof

The invention provides ecological decorative paper and a production method thereof. The ecological decorative paper is prepared from the following raw materials in parts by weight: 15-20 parts of softwood pulp fiber, 15-20 parts of hardwood pulp fiber, 10-20 parts of polyester fiber, and 40-50 parts of modified thermoset resin. The ecological decorative paper is produced through steps of size degradation, beating, molding, drying, gluing, drying in a baking oven, sheeting and packaging by a fourdrinier machine. The product possesses the following advantages: 1, the product is good in eveness, stable in quality and stable in thickness, does not contain formaldehyde, melamine and other harmful substances, and is healthy and friendly to environment; 2, the product possesses good thermosetting performance, and therefore the product and a single plate and a decoration layer can be directly subjected to hot pressing for preparing a decoration sheet material, operations of sanding, glue preparation, glue blending, glue coating and the like of a single plate and a surface plate are saved, and production time, raw material cost and labor cost are saved. The product is a truly environment-friendly health product. The method of using the ecological paper for replacing the surface layer of a lumber core board is initially created in household sheet material industry, and the excellent performances of the product surly will bring revolutionary change for household sheet material industry.

Owner:SHANDONG LUNAN NEW MATERIALS

Thermosetting acrylic coating used on surface of metal

The invention provides a thermosetting coating, and more particularly adopts a thermosetting acrylic coating used on the surface of metal. The thermosetting acrylic coating mainly includes thermosetting acrylic resin, nano pigment and other necessary components. The coating adopting the components has good thermosetting property, requires lower thermosetting temperature, can effectively reduce the deformation of sheet metal caused by high temperature, prolongs the service life of the pigment, and improves the quality of the produced board; furthermore, the thermosetting acrylic coating also has good weatherability, can be used for a long time, is lower in production cost and is widely popularized and applied.

Owner:赵庆利

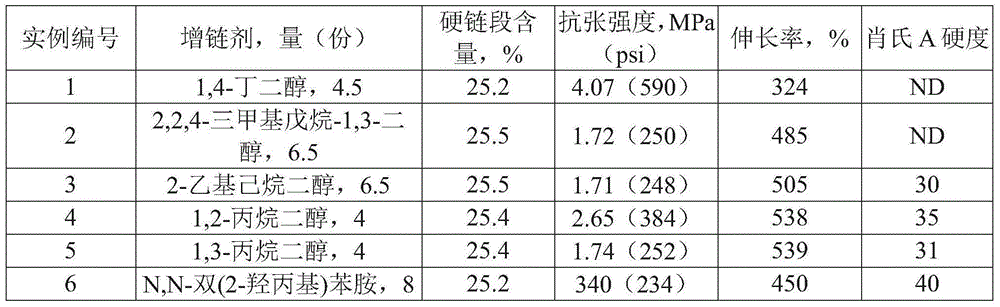

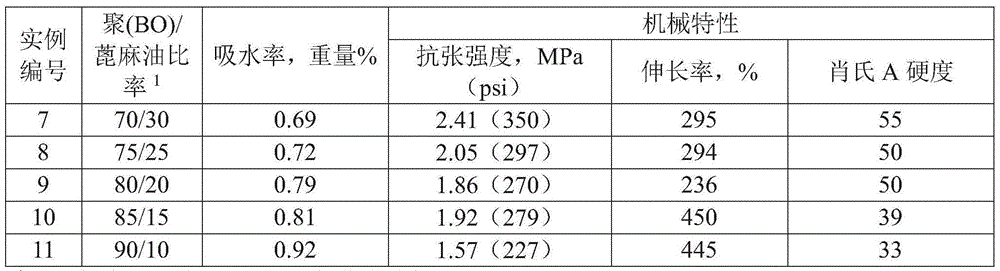

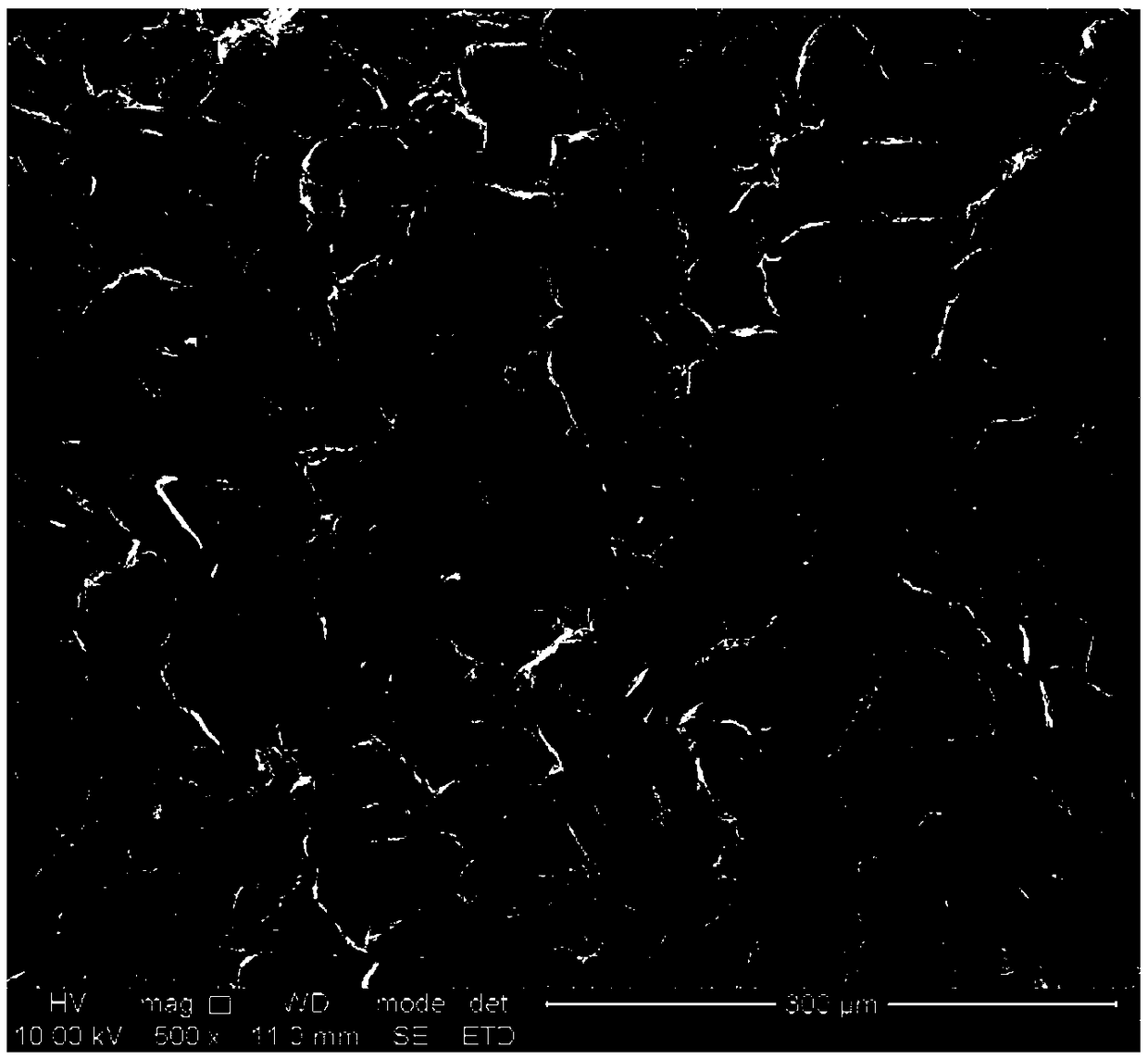

Polyurethane sealant based on poly (butylene oxide) polyols for glass sealing

ActiveCN105189398AReduce penetrationEasy to processDoors/windowsPolyureas/polyurethane adhesivesPolymer sciencePolyol

A polyurethane glass sealant is made by reacting a poly(l,2-butylene oxide) polymer with a chain extender and a polyisocyanate. The poly(l,2-butylene oxide) polymer may be used as a mixture with up to 50% by weight of other polyols, including castor oil. The sealant is especially useful as a secondary sealant for an insulated glass unit (IGU).

Owner:DOW GLOBAL TECH LLC

Novel glass adhesive and preparation method therefor

InactiveCN107353846AImprove adhesionNot easy to fall offNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses a novel glass adhesive. The novel glass adhesive is prepared from the following raw materials in parts by weight: 20-40 parts of styrene-butadiene rubber, 13-22 parts of polyacrylic acid, 15-27 parts of epoxy resin, 7-14 parts of methyl methacrylate, 8-17 parts of starch, 11-18 parts of polyurethane, 15-26 parts of acetone, 2-5 parts of Chinese herbal medicine mixture, 17-28 parts of filler, 3-6 parts of modifier, 1-3 parts of oxide additives and 4-7 parts of curing agent. The novel glass adhesive is good in adhesiveness and long in service life, is not prone to spalling and is not prone to chemical residue generation and environmental pollution causing.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

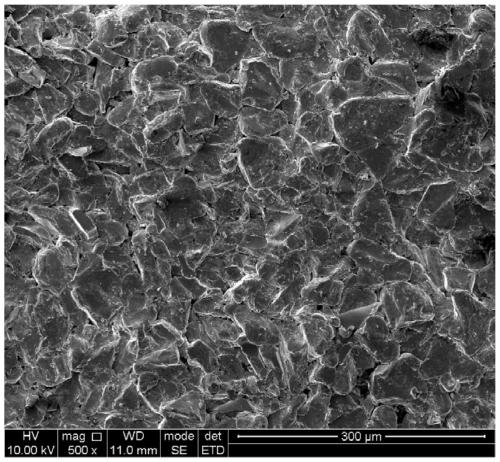

An amorphous nanocrystalline composite magnetic powder core and a preparation method thereof

ActiveCN109036753AImprove densification performanceImprove uniformityInductances/transformers/magnets manufactureMagnetic materialsHigh densityInductor

The invention discloses an amorphous nanocrystalline composite magnetic powder core and a preparation method thereof, and the amorphous nanocrystalline composite magnetic powder core is prepared fromFe-based amorphous nanocrystalline magnetic powder and nano-grade glass powder / micron-grade glass powder through spark plasma sintering. The amorphous nanocrystalline composite magnetic powder core has high permeability, high density, low magnetic loss and low coercivity, so the amorphous nanocrystalline composite magnetic powder core has excellent soft magnetic and mechanical properties, and canbe widely used for manufacturing high-power switching power supplies, high-power inductors and high-efficiency energy-saving motors and other equipment.

Owner:SICHUAN UNIV

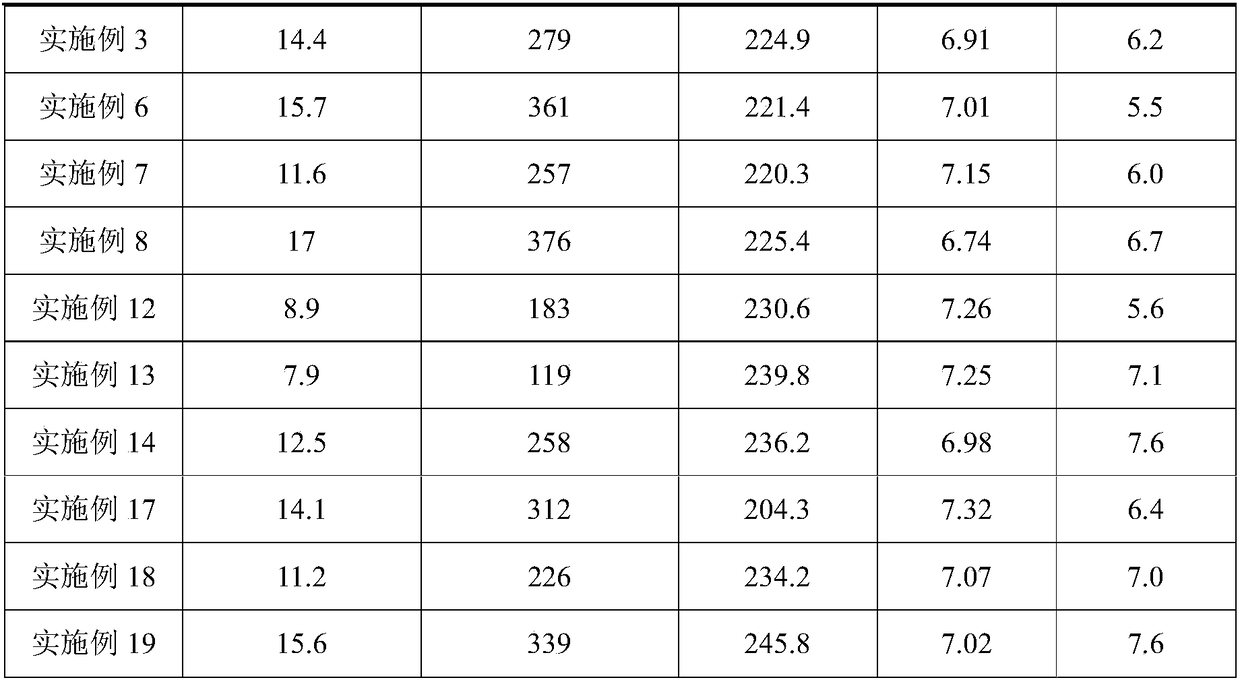

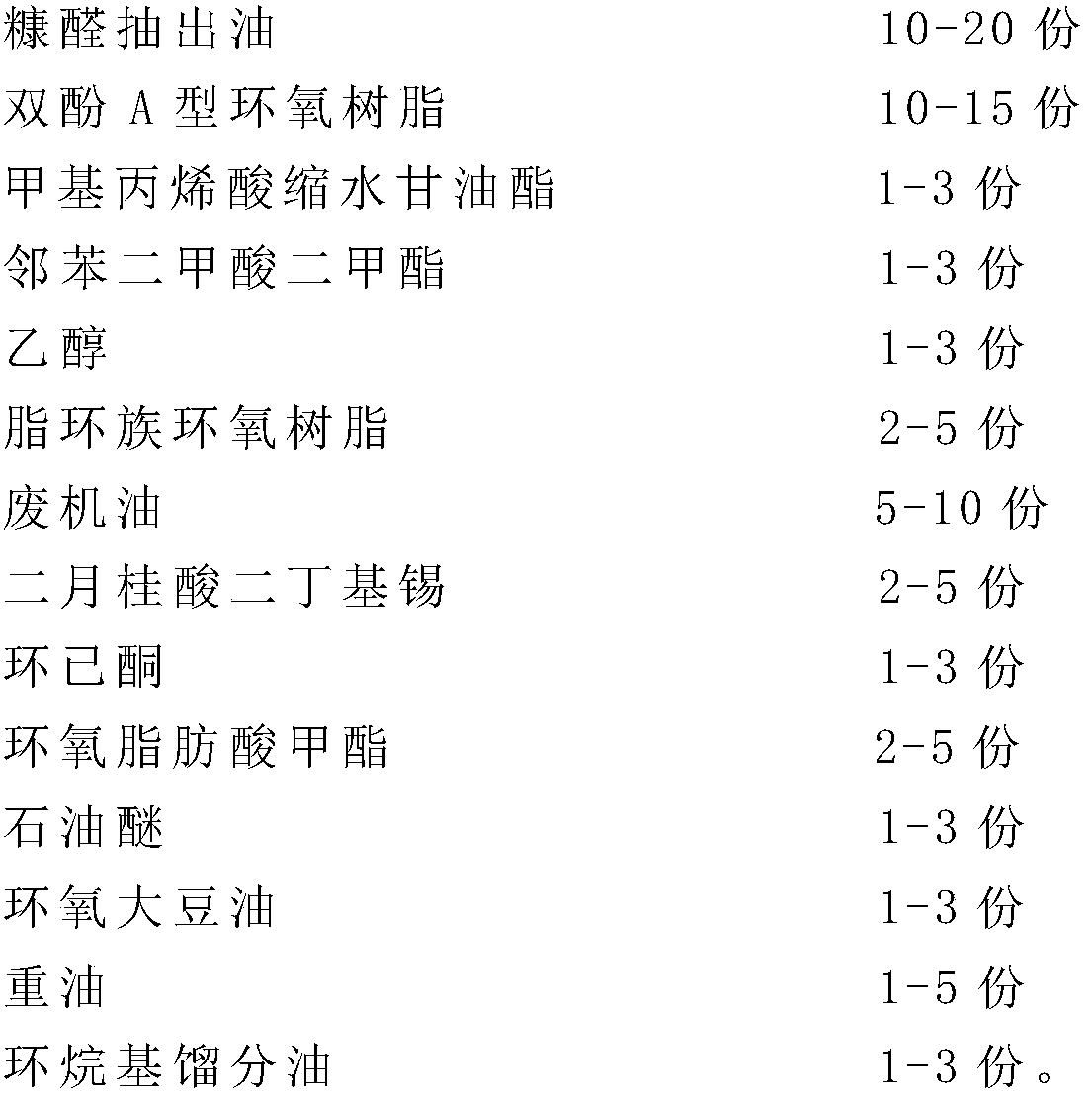

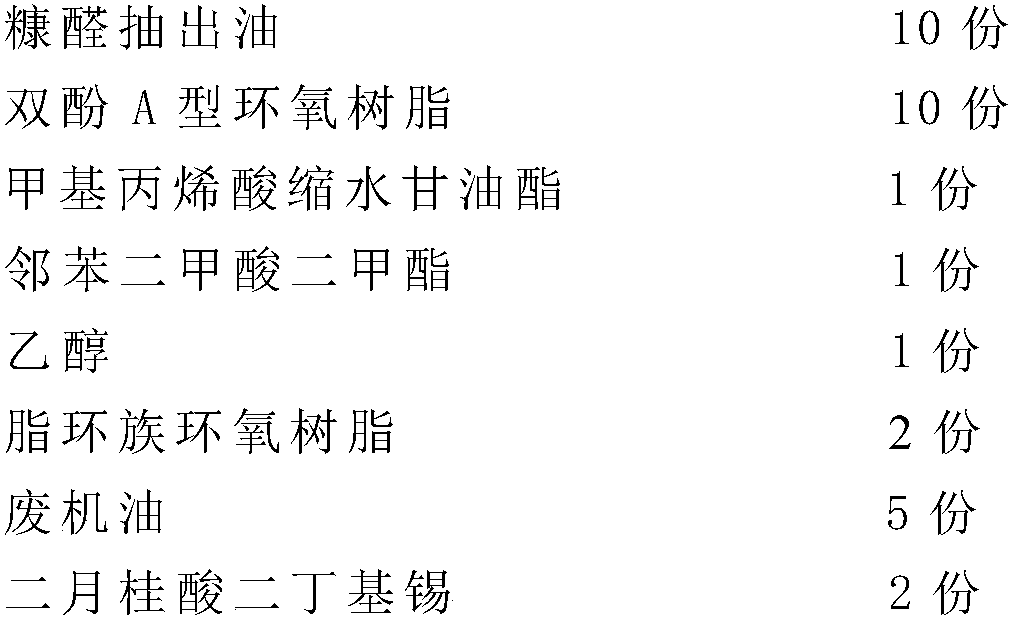

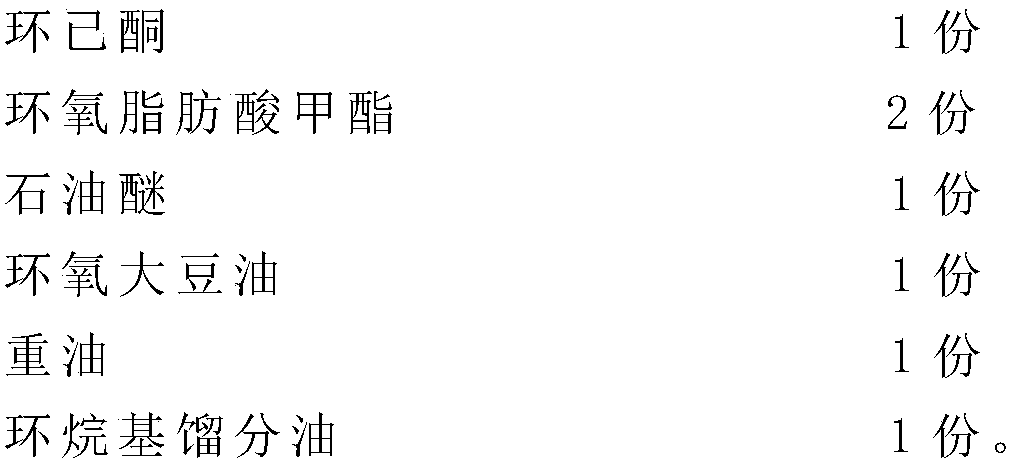

Regenerant for aged asphalt and preparation method thereof

InactiveCN109021599AImprove solubilityImprove softening effectPlastic/resin/waxes insulatorsBuilding insulationsCyclohexanoneGlycidyl methacrylate

The invention discloses a regenerant for aged asphalt and a preparation method thereof, and belongs to the field of road engineering. The asphalt regenerant of the invention is composed of the following ingredients (by weight): 10-20 parts of furfural extract oil, 10-15 parts of bisphenol A epoxy resin, 1-3 parts of glycidyl methacrylate, 1-3 parts of dimethyl phthalate, 1-3 parts of ethanol, 2-5parts of alicyclic epoxy resin, 5-10 parts of used oil, 2-5 parts of dibutyltin dilaurate, 1-3 part of cyclohexanone, 2-5 parts of epoxidized fatty acid methyl ester, 1-3 parts of petroleum ether, 1-3parts of epoxidized soybean oil, 1-5 parts of heavy oil and 1-3 parts of cycloalkyl distillate. The regenerant has characteristics of high temperature performance, excellent low-temperature crack resistance and strong ageing resistance and weather resistance, and is suitable for large-scale promotion and application.

Owner:四川高路远长集团有限公司

Coating material for titanium alloy fastener of aircraft and preparation method of coating material

The invention discloses a coating material for aircraft titanium alloy fasteners and a preparation method thereof. 5-10 parts of aluminum powder, 3-5 parts of anti-corrosion filler, 1-3 parts of lubricant, 3-6 parts of thixotropic agent, 1-3 parts of plasticizer, 1.5-2.5 parts of dispersant, 2-8 parts of solvent, The invention relates to a coating material for aircraft titanium alloy fasteners. The aircraft titanium alloy fastener coating can have good strength, toughness and lubricating performance, meet the requirements of the fastener use environment, and have good stability.

Owner:青岛爱飞客航空科技有限公司

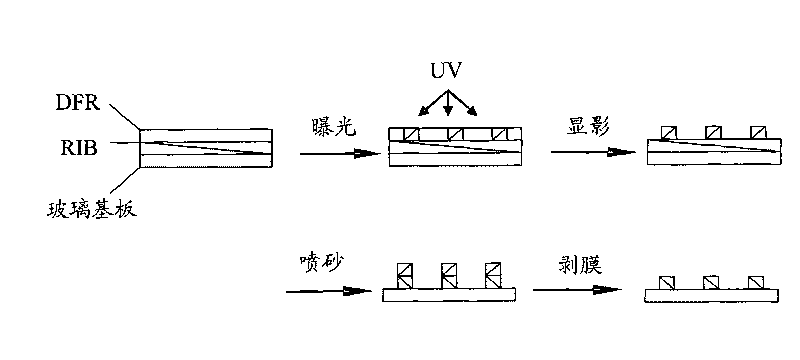

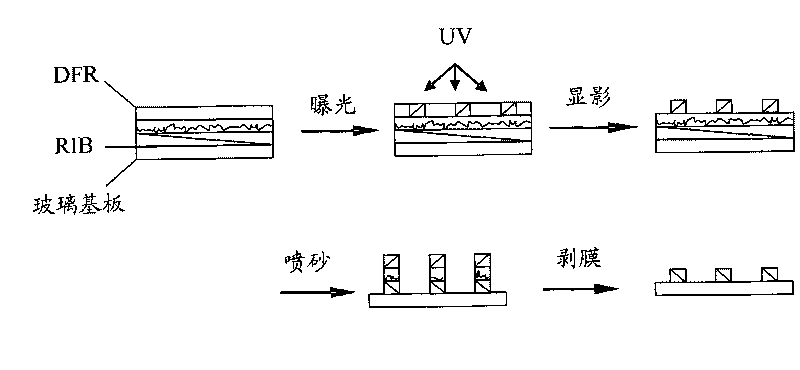

Composite for improving interfacial effect of photoresist dry film and barrier and preparation and usage method thereof

InactiveCN101728149AGood thermosettingReduce surface tensionVessels or leading-in conductors manufactureCold cathode manufactureSolventPhotoresist

The invention provides a composite for improving interfacial effect of a photoresist dry film and a barrier and a preparation and usage method thereof, and a method for manufacturing a barrier of a plasma display panel by utilizing the composite; the composite comprises glass powder, plasticizer, alkali solubility adhesive low polymer, dispersing agent, inorganic filler and solvent; by utilizing the composite and method of the invention, the combinability of the barrier and the photoresist dry film can be improved, so as to reduce the disadvantage that the barrier is easy to incline and collapse after sand blasting is carried out, and improve the finished product ratio.

Owner:SICHUAN COC DISPLAY DEVICES

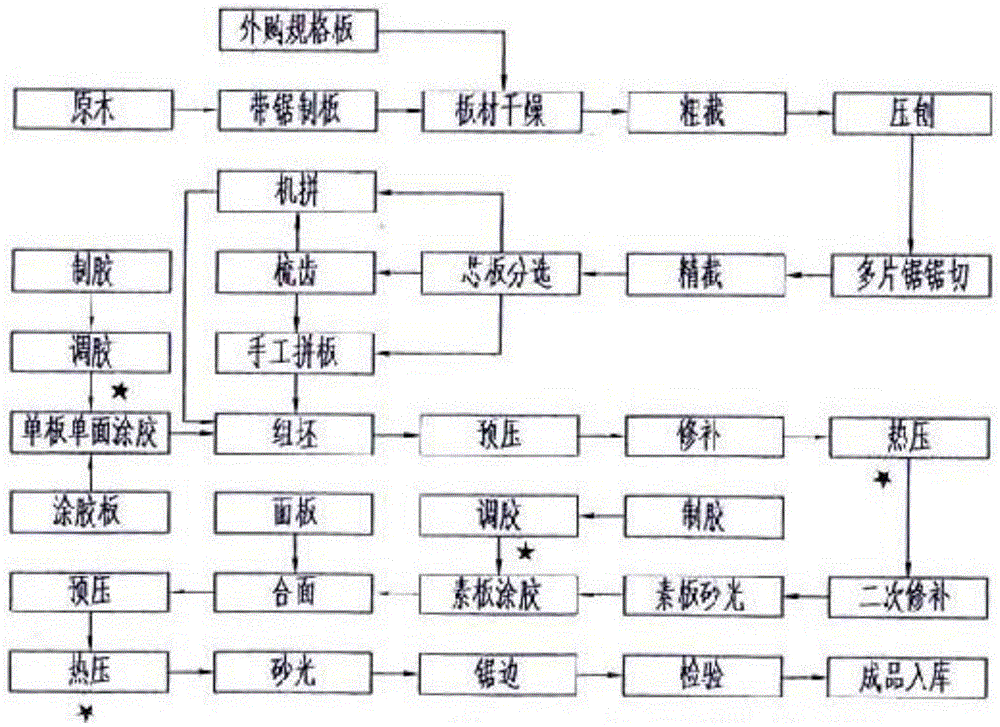

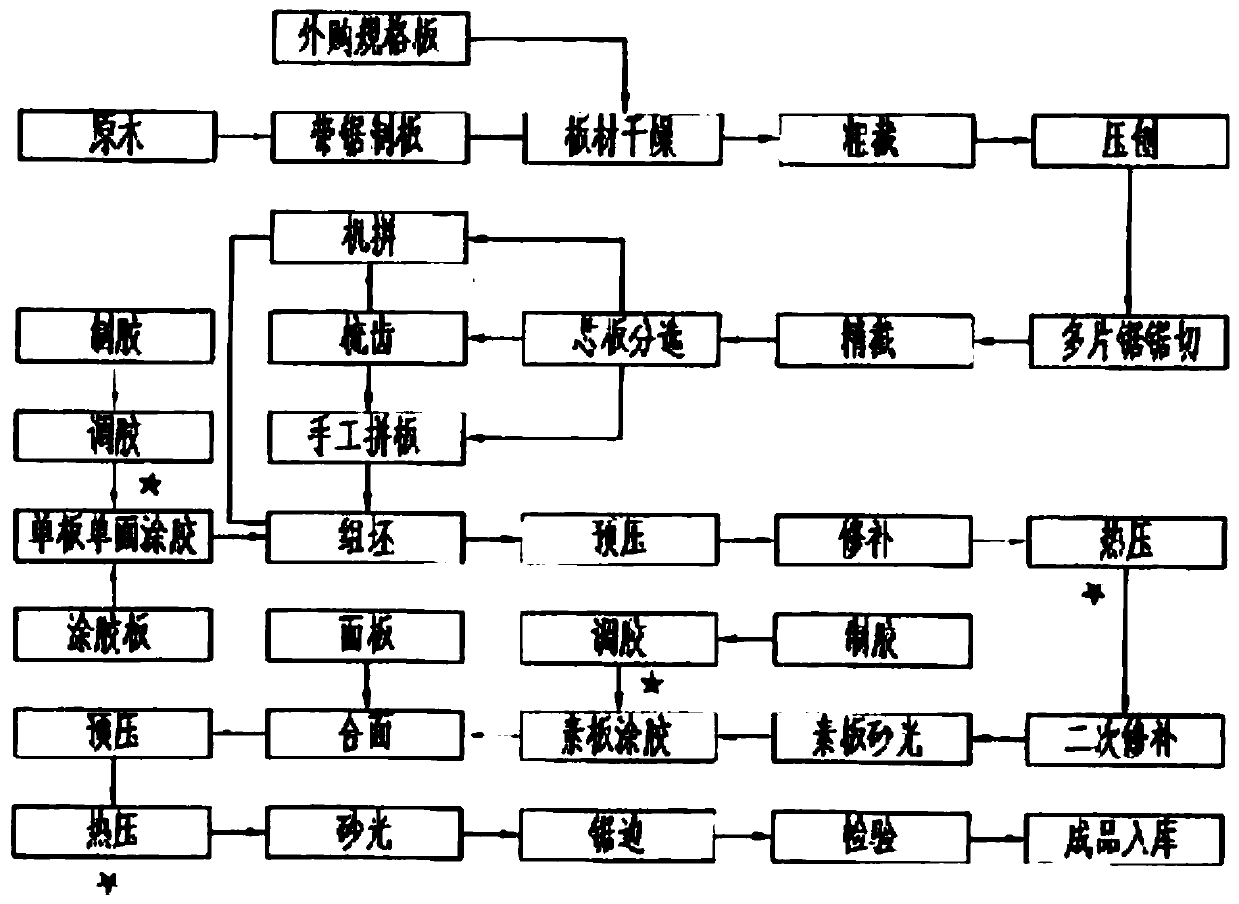

Production process for plywood

InactiveCN106182220AImprove uniformityConvenient ArrangementOther plywood/veneer working apparatusWood veneer joiningAdhesiveSulfide

A production process of plywood, which relates to the technical field of plywood production, comprising the following steps: peeling a log, cutting it into chips, and then drying it in the sun; gluing, and applying an adhesive to the wood chips, and the adhesive consists of the following in parts by weight: 80-100 parts of urea-formaldehyde resin, 20-40 parts of nitrocellulose, 10-20 parts of polyphenylene sulfide, 6-10 parts of curing agent, 30-50 parts of filler, 5-9 parts of modifier and 80-100 parts of water; keep the wood chips on the conveyor belt, heat and soften the wood chips through the heating device, the heating temperature is 60-80 ℃, and then flatten the wood chips by pressing rollers; glue repair; billet formation; pre-pressing; trimming And hot pressing; filling putty; sawing edge forming, get plywood. The present invention has short pre-pressing and hot-pressing time, fast production speed, small internal stress, and is not easy to unglue and deform. The adhesive has the advantages of good thermosetting, high viscosity, high strength, good endurance and not easy to deteriorate.

Owner:和县薛氏木制品制造有限公司

Thermosetting amino-acid resin coating

InactiveCN103773221AEasy to prepareGood storage stabilityPolyamide coatingsSolventComposite material

The invention discloses a thermosetting amino-acid resin coating. Raw materials of the thermosetting amino-acid resin coating comprise, by weight, 100 parts of a thermosetting amino-acid resin composition, 35-50 parts of an aluminum-magnesium-zinc alloy pigment, 10-12 parts of an amino acid salt, 3-5 parts of an auxiliary solvent, 0.5-2 parts of an auxiliary agent, 0-1 part of a curing agent and 30-35 parts of water, wherein the thermosetting amino-acid resin composition comprises, by weight, 50 parts of methanol, 35-50 parts of hexamethylolmelamine, 15-18 parts of sodium glutamate or sodium aspartate, 3-5 parts of ammonium sulfamate, ammonium p-toluenesulfonate or ammonium tartrate, 40 parts of a mixture obtained by mixing wollastonite and talcum powder according to a ratio of 3:1, 50-65 parts of propyleneglycol monomethyl ether and 1.5 parts of diethanolaniline. The thermosetting amino-acid resin coating has good storage stability, good thermosetting property and good water resistance; a reaction temperature is low; and a reaction time is short.

Owner:NANJING HENGAN RESIN CHEM

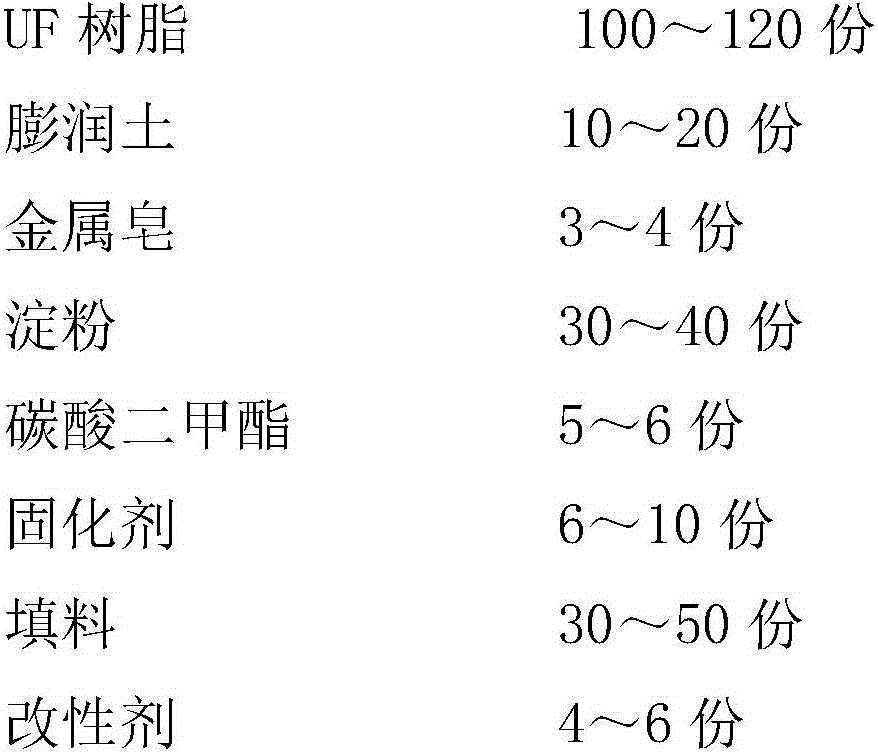

Glass adhesive and preparation method thereof

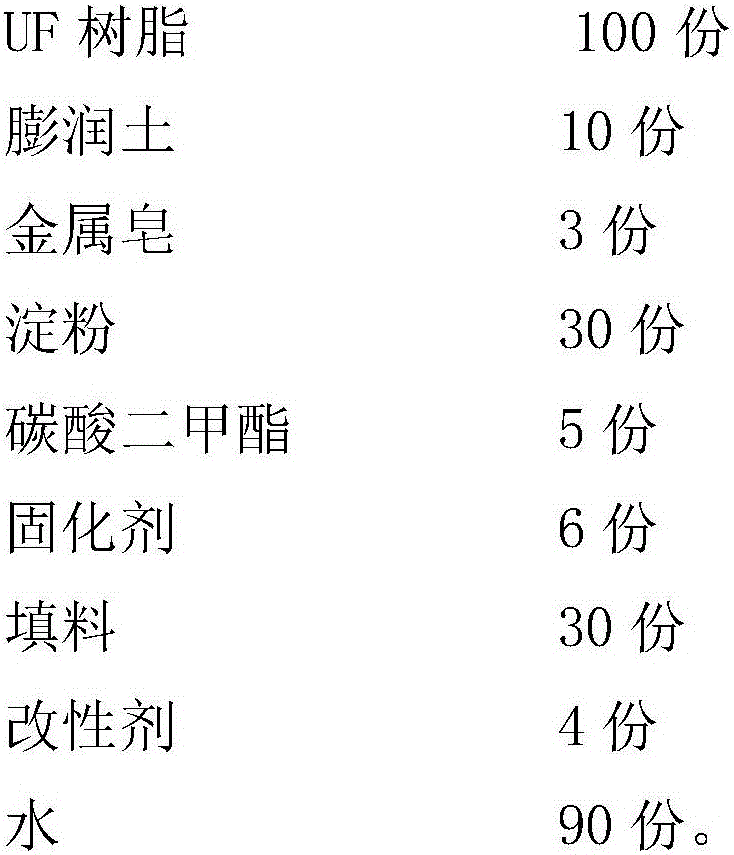

InactiveCN106590490AImprove waterproof performanceGood adhesivenessNon-macromolecular adhesive additivesStarch adhesivesSodium BentoniteMethyl carbonate

The invention provides a glass adhesive and a preparation method thereof and relates to the technical field of adhesives. The glass adhesive is prepared from the following raw material components in parts by weight: 100-120 parts of UF (urea-formaldehyde) resin, 10-20 parts of bentonite, 3-4 parts of metallic soap, 30-40 parts of starch, 5-6 parts of dimethyl carbonate, 6-10 parts of a curing agent, 30-50 parts of filler, 4-6 parts of a modifier and 90-110 parts of water. The preparation method comprises the following steps: 1) adding UF resin, coal tar, metallic soap, alkanolamide and water to a mixer for sufficient stirring and adhesive mixing; 2) adding the starch and the filler for stirring until no air mass is left in the mixer; 3) adding the curing agent to be stirred for 5-10 minutes, and then leaving the mixture to stand for 15 minutes; 4) adding the modifier for mixing finally. The glass adhesive has the advantages of good thermosetting property, high viscosity, high strength, good endurance, good waterproof effect and long service life, and is not easy to degenerate or crack.

Owner:TIANHAO GLASSWARE GRP CO LTD

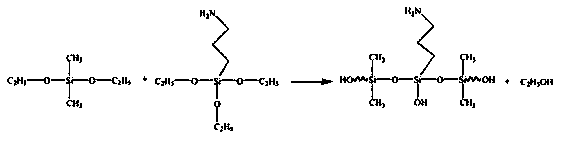

Aqueous high-temperature-resistant thermosetting methylphenyl silicone resin and preparation method thereof

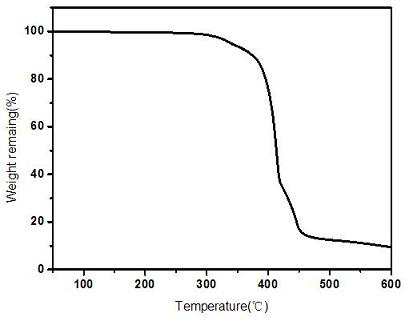

InactiveCN110684198ASlow down the rate of thermal decompositionPlay a capping rolePolymer scienceMethylphenylsilicone

The invention discloses aqueous high-temperature-resistant thermosetting methylphenyl silicone resin and a preparation method thereof. The aqueous high-temperature-resistant thermosetting methylphenylsilicone resin is characterized in that the structural formula of the aqueous high-temperature-resistant thermosetting methylphenyl silicone resin is shown in a formula (I). (Please see the specification for the formula I). The preparation method comprises the following steps that (1) a sol-gel method is adopted to obtain a hydrophilic silane prepolymer; and (2) the hydrophilic silane prepolymeris grafted onto organic silicone resin to obtain the aqueous high-temperature-resistant thermosetting methylphenyl silicone resin, a reaction formula is shown in a formula (II): (Please see the specification for the formula II). The aqueous high-temperature-resistant thermosetting methylphenyl silicone resin and the preparation method have the beneficial effects that a controllable hydrophilic group can be given to the silicone resin without changing the properties of the silicone resin, the self-emulsifying of the silicone resin is achieved, and the prepared methylphenyl silicone resin is hydrophilic, resistant to high temperature and good in thermosetting performance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

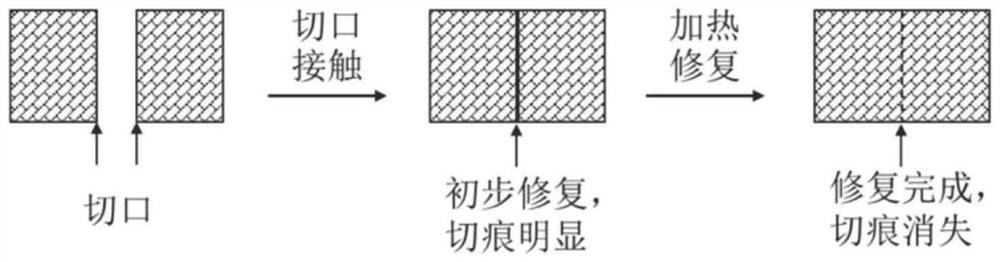

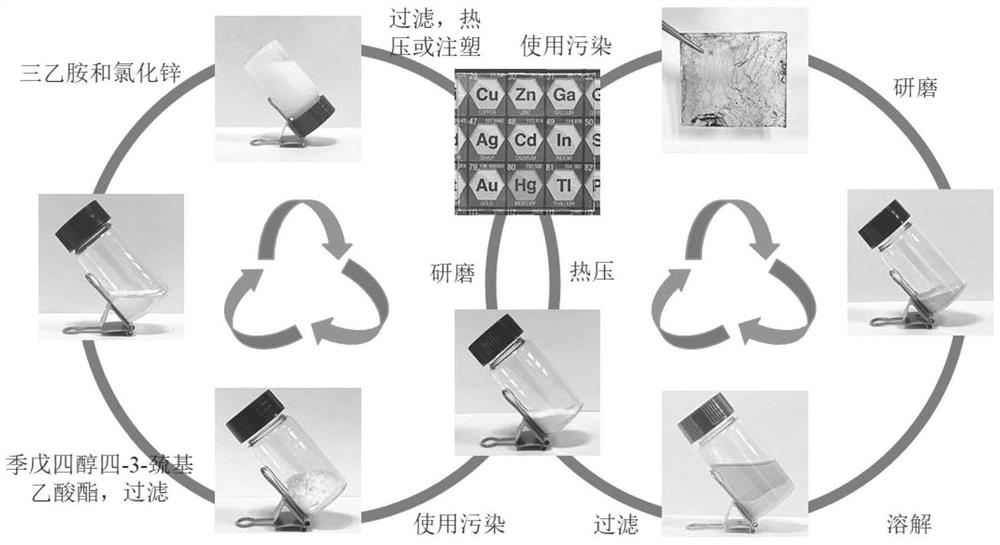

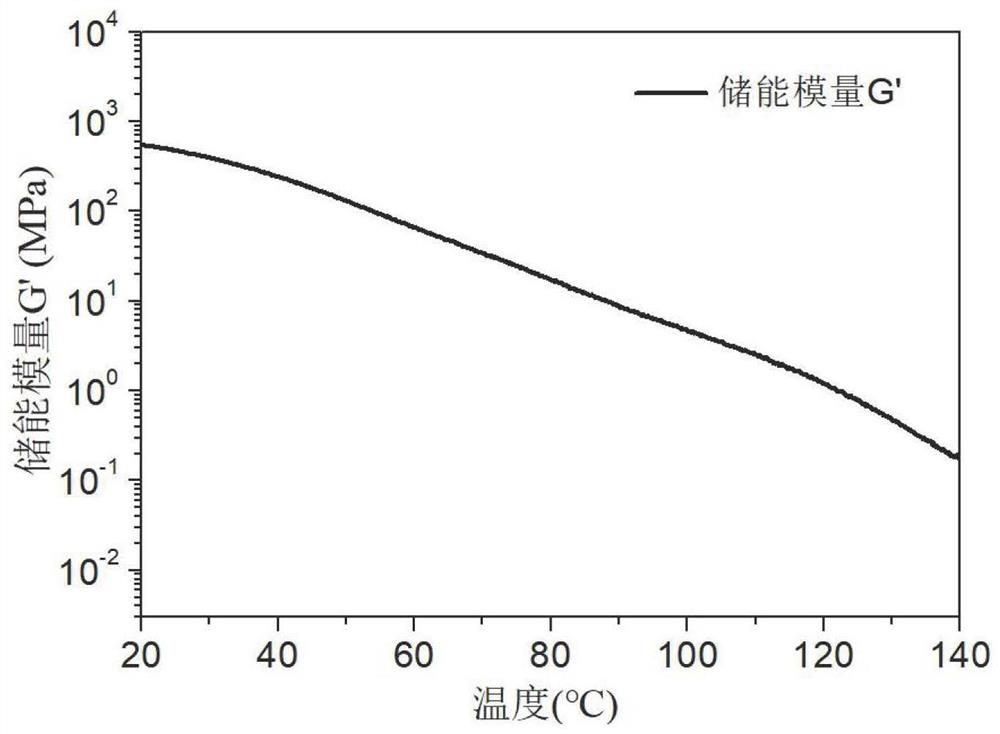

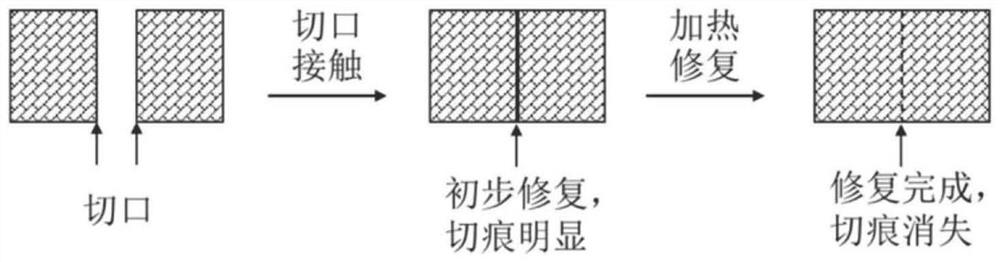

Variable-stiffness self-repairing material containing metal-sulfydryl coordinate bond as well as preparation and application thereof

ActiveCN113817173AMild reaction conditionsSimple stepsAdditive manufacturing apparatusAdhesivesSolventCompositermes

The invention relates to a variable stiffness self-repairing material containing a metal-sulfydryl coordination bond. The variable stiffness self-repairing material is prepared from a sulfydryl-terminated small molecule compound, sulfydryl-terminated liquid polysulfide resin, a cross-linking agent, zinc salt, other metal salts, an alkaline regulator and a solvent. The structure of the material contains a large number of metal-sulfydryl coordination bonds, and the coordination bonds have good thermodynamic stability, so that the material has higher rigidity and mechanical strength; the good dynamic activity of the coordination bond ensures that the material has good self-repairing performance; due to the high temperature sensitivity of the coordination bond, the variable stiffness of the material in a wide temperature range is ensured; the coordination bond is insensitive to water, so that the environmental use stability of the material is ensured; meanwhile, the material has the characteristics of high transparency and adjustable refractive index. The variable stiffness self-repairing material containing the metal-sulfydryl coordinate bond can be applied to the fields of sealants, self-repairing coatings, temperature-sensitive variable stiffness self-repairing engineering materials, additive manufacturing, composite materials, optical transparent adhesives and the like.

Owner:NANJING UNIV

Preparation method for producing nano composite PVC (polyvinyl chloride) sheet by using waste PVC

InactiveCN105860331AImprove heat resistanceImprove flame retardant performanceFlat articlesHeat resistancePolyvinyl chloride

The invention discloses a preparation method for producing a nano composite PVC (polyvinyl chloride) sheet by using waste PVC. The preparation method is characterized by comprising the following steps: (1) preparing a waste PVC material; (2) plastifying and internally mixing; (3) mixing and extruding the material plastified and internally mixed in the step (2) via a screw extruder; and (4) molding, carrying out operations of calendering the sheet and cutting the material mixed and extruded in the step (3) via a silk roller calendar; and taking a lifter and a conveying belt as intermediate connection structures to form a complete nano composite PVC sheet produced by the waste PVC. Through the preparation method for producing the nano composite PVC sheet by using waste PVC, the product has excellent heat resistance and flame resistance, free of release of micro molecules in the curing process, nearly free of curing shrinkage ratio, large in modulus, high in strength, rich in raw materials, low in cost, easy to process and mold and excellent in overall performance; and the product produced by the method has nano-sized multifunctional modification, so that the product has a better thermocuring effect.

Owner:GUANGDE TIANYUN NEW TECH

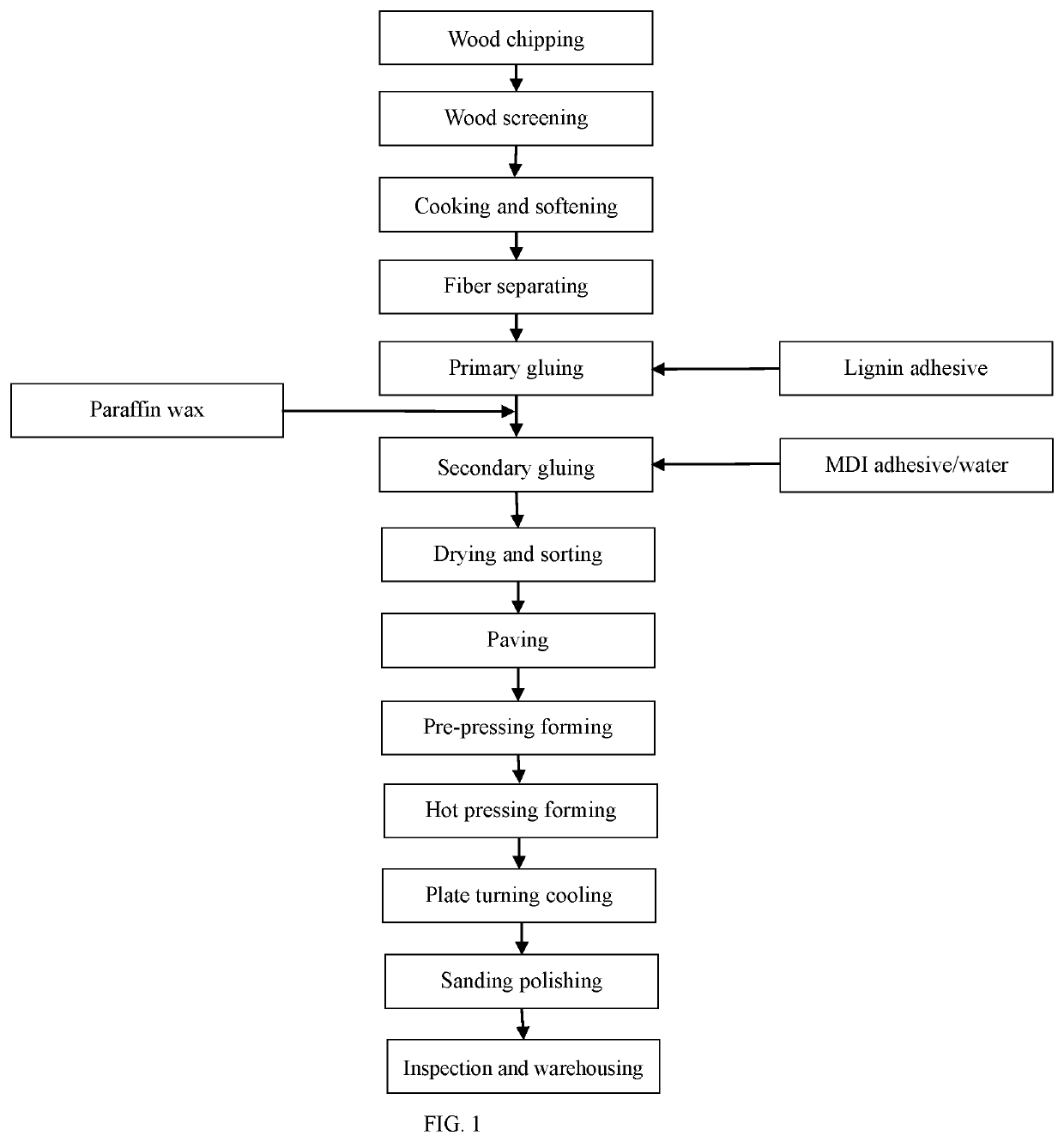

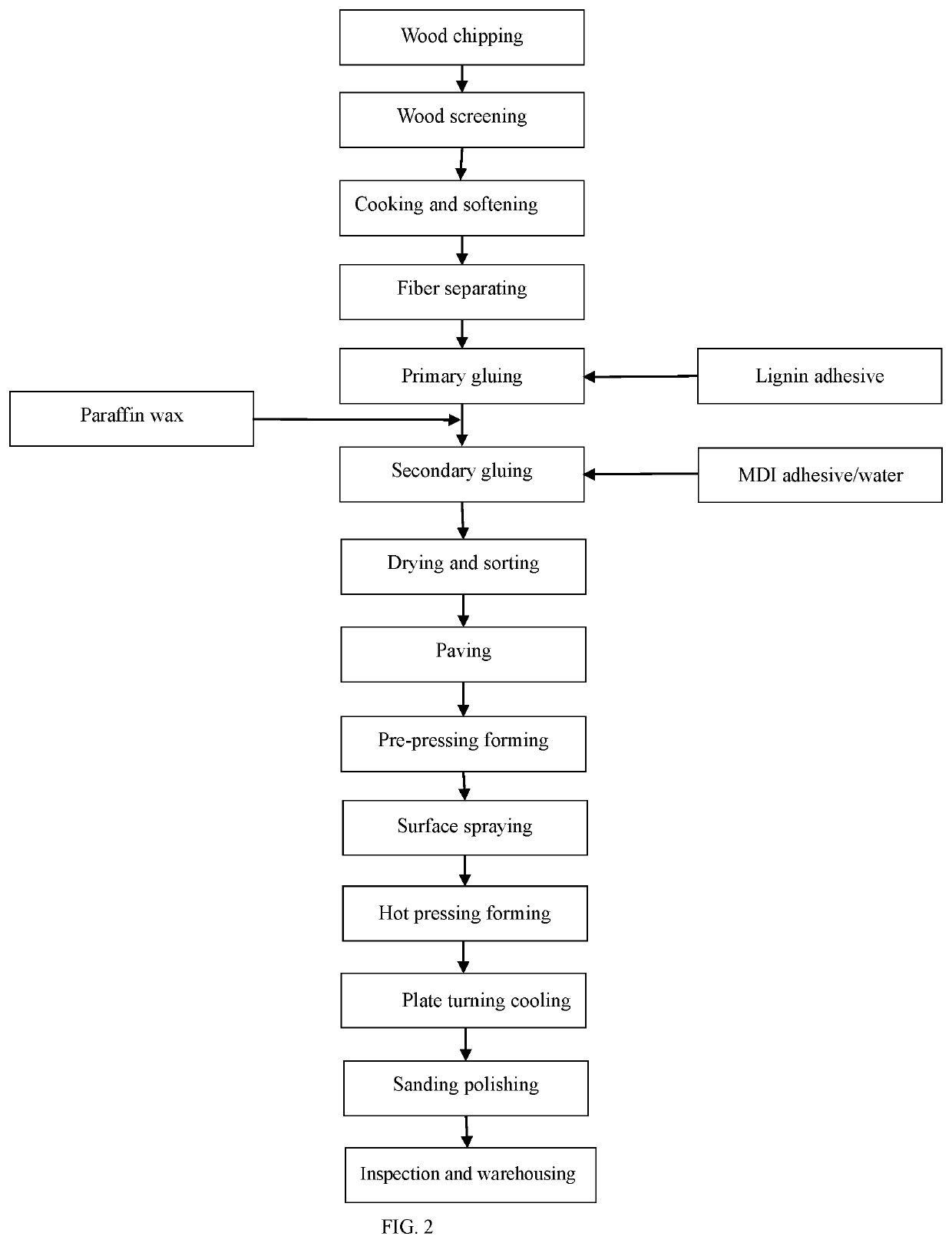

Formaldehyde-free medium-high-density board capable of meeting deep facing requirements and method for manufacturing same

PendingUS20220032494A1Suitable for productionImprove permeabilityPolyureas/polyurethane adhesivesFlat articlesFiberHigh density

The present invention relates to a formaldehyde-free medium-high-density board capable of meeting deep facing requirements, and a method for manufacturing same. The method includes: wood chipping, screening, cooking and softening, fiber separating, gluing, drying and sorting, paving, pre-pressing, hot pressing, cooling, sanding, and inspection and warehousing, where the gluing is two-step gluing, including: first performing gluing once by using a lignin adhesive, and then performing secondary gluing by using an MDI adhesive after waterproof treatment. According to the manufacturing method of the present invention, by using biomass adhesives and formaldehyde-free adhesives without adding additives such as a curing agent and an anti-mildew agent, formaldehyde pollution is eliminated from the source by using a two-step gluing method, so that production is formaldehyde-free, and the product is formaldehyde-free. Through the sequential control of the gluing process and the grasp of the gluing type and ratio, surface hardness of the product is improved, and the final product is capable of deep facing to reach 20 to 80 filaments.

Owner:BEIJING FORESTRY UNIVERSITY +2

Flame-retardant high-temperature socket

The invention discloses a flame-retardant high-temperature socket. The flame-retardant high-temperature socket is produced by using the following materials in parts by weight: 40 to 60 parts of nitrile rubber, 80 to 100 parts of polyphenyl ether, 12 to 16 parts of a compound flame retardant synergist, 10 to 20 parts of carbon black, 30 to 40 parts of acrylonitrile-phenylacetonitrile, 21 to 33 parts of asbestos fiber, 10 to 17 parts of clay, 6 to 14 parts of a graphite powder, 5 to 8 parts of an antiager, 8 to 10 parts of sulfide, 11 to 15 parts of organic clay, 7 to 9 parts of a dispersing agent, 6 to 8 parts of silicon dioxide and 8 to 12 parts of a leveling agent; the flame-retardant high-temperature socket has the advantages of durability, good flame-retardant performance and good thermosetting performance.

Owner:YUYAO JIEFEI ELECTRIC APPLIANCE CO LTD

Thermosetting epoxy-asphalt pavement material and preparation method thereof

InactiveCN103773038AHigh thermosetting propertiesGood thermosettingBuilding insulationsGlutaric anhydridePolymer science

The invention relates to a thermosetting epoxy-asphalt pavement material and a preparation method thereof. The thermosetting epoxy-asphalt pavement material comprises the following components in parts by weight: 13-16 parts of petroleum asphalt, 8-13 parts of polybutadiene resin, 11-14 parts of bisphenol F-type epoxy resin, 5-7 parts of polyazelaic polyanhydride, 2-3 parts of glutaric anhydride, 6-9 parts of palmitic acid and 3-5 parts of sodium hexametaphosphate. The preparation method of the thermosetting epoxy-asphalt pavement material comprises the steps of: high-temperature dissolving, mixing, stirring, reaction and thermal insulation. The prepared epoxy-asphalt pavement material has good thermosetting property and high hardness.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Production technology of waterproof plywood

InactiveCN106217575AImprove uniformityConvenient ArrangementNon-macromolecular adhesive additivesWood working apparatusAdhesiveConveyor belt

The invention provides a production technology of a waterproof plywood and relates to the technical field of plywood production. The production technology comprises the following steps: peeling barks from logs, annularly cutting the logs into wood sheets, and then air-drying; applying an adhesive, and coating the wood sheets with the adhesive which comprises the following components in parts by weight: 100-120 parts of UF resin, 10-20 parts of coking coal oil, 10-20 parts of metallic soap, 10-20 parts of alkanolamide, 6-10 parts of a curing agent, 30-50 parts of filler, 5-9 parts of a modifier and 90-110 parts of water; conveying the wood sheets onto a conveyor belt, softening the wood sheets by using a heating device to heat the wood sheets to 60-80DEG C, and then, planishing the wood sheets through compression rollers; replenishing the adhesive; assembling a blank; pre-pressing; trimming and hot-pressing; filling putty; and sawing edges and molding so as to obtain the polywood. The production technology is short in pre-pressing and hot-pressing time and high in production speed. The waterproof plywood is small in internal stress, cannot easily come apart or deform as the adhesive is good in thermosetting property, high in viscosity, high in strength, good in durability and is not prone to going bad, and is good in waterproof effect.

Owner:和县薛氏木制品制造有限公司

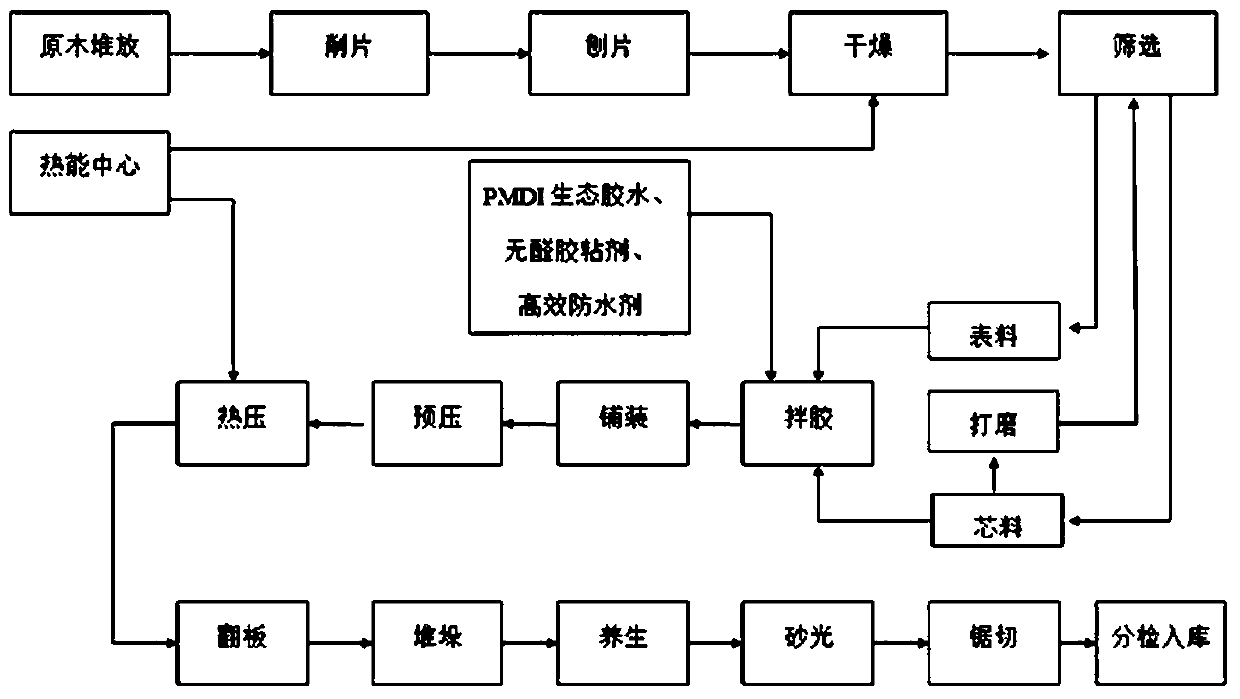

Preparation technology for zero-formaldehyde light particle board

InactiveCN110434954AZero formaldehyde contentImprove securityPolyureas/polyurethane adhesivesWood veneer joiningAfter treatmentSurface layer

The invention relates to a preparation technology for a zero-formaldehyde light particle board. According to the technical scheme, the preparation technology for the zero-formaldehyde light particle board is characterized by comprising the production steps that logs are subjected to chipping, flaking, drying and screening, two shaving particles of surface-layer raw materials and core-layer raw materials are prepared, MDI glue, a formaldehyde-free adhesion agent and light packing are added to be mixed, paving, pre-pressing, hot-pressing and after-treatment are conducted, a finished product particle board is prepared, and then sorting and warehousing are conducted. According to the preparation technology for the zero-formaldehyde light particle board, the prepared shaving board finished product has the advantages that the formaldehyde content is zero, green and environmental protection are achieved, the using safety is high, the thermosetting property is good, the waterproof capability is high, the service life is long, and the strength is high.

Owner:广东始兴县华洲木业有限公司

Production process of high-strength environment-friendly particle board

PendingCN113021559AFormaldehyde freeGood thermosettingWood working apparatusFlat articlesProcess engineeringFormaldehyde free

The invention relates to a production process of a high-strength environment-friendly particle board. Raw materials are subjected to slicing, flaking, drying, screening, adhesive mixing, laying, pre-pressing, hot-pressing, after-treatment and the like. According to the production process of the high-strength environment-friendly particle board, the prepared environment-friendly particle board finished product has the advantages of being free of formaldehyde, environmentally friendly, good in thermosetting performance, high in waterproofing and fireproofing performance, long in service life, high in strength, not prone to deformation and the like.

Owner:澳森木业孝感有限责任公司

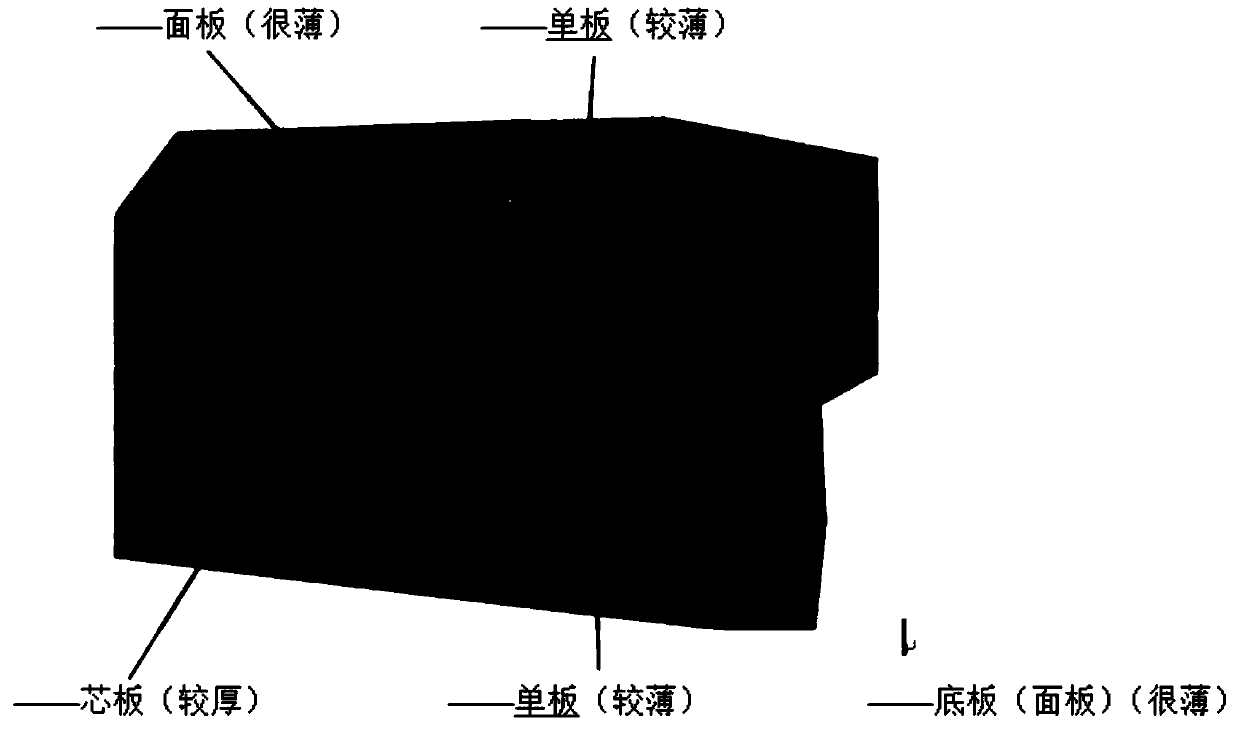

A kind of ecological decorative paper and its production method

The invention provides ecological decorative paper and a production method thereof. The ecological decorative paper is prepared from the following raw materials in parts by weight: 15-20 parts of softwood pulp fiber, 15-20 parts of hardwood pulp fiber, 10-20 parts of polyester fiber, and 40-50 parts of modified thermoset resin. The ecological decorative paper is produced through steps of size degradation, beating, molding, drying, gluing, drying in a baking oven, sheeting and packaging by a fourdrinier machine. The product possesses the following advantages: 1, the product is good in eveness, stable in quality and stable in thickness, does not contain formaldehyde, melamine and other harmful substances, and is healthy and friendly to environment; 2, the product possesses good thermosetting performance, and therefore the product and a single plate and a decoration layer can be directly subjected to hot pressing for preparing a decoration sheet material, operations of sanding, glue preparation, glue blending, glue coating and the like of a single plate and a surface plate are saved, and production time, raw material cost and labor cost are saved. The product is a truly environment-friendly health product. The method of using the ecological paper for replacing the surface layer of a lumber core board is initially created in household sheet material industry, and the excellent performances of the product surly will bring revolutionary change for household sheet material industry.

Owner:SHANDONG LUNAN NEW MATERIALS

Curable composition

PendingCN112745770AExcellent photocurabilityGood thermosettingTelevision system detailsNon-macromolecular adhesive additivesPolymer scienceMeth-

The invention provides a curable composition having both excellent photo-curability and excellent thermosetting properties. The curable composition comprises: (1) a compound that has a (meth)acryloyl group, (2) an epoxy compound that has two or more epoxy groups in one molecule and is solid at 25 DEG C, (3) a polythiol compound that has two or more mercapto groups in one molecule, (4) a photo-radical generator, and (5) a latent curing agent, wherein the amount of the component (3) is from 15% by weight to 50% by weight with respect to the entire curable composition.

Owner:AJINOMOTO CO INC

Variable stiffness self-healing material containing metal-mercapto coordination bond and its preparation and application

ActiveCN113817173BImprove thermal stabilityAdjustable dynamicsAdditive manufacturing apparatusAdhesivesAdhesive cementRepair material

The invention relates to a variable-stiffness self-repairing material containing a metal-mercapto coordination bond, which is composed of a mercapto-terminated small molecule compound, a mercapto-terminated liquid polysulfide resin, a crosslinking agent, a zinc salt, other metal salts, an alkaline regulator and a solvent composition. The material structure contains a large number of metal-mercapto coordination bonds. The good thermodynamic stability of the coordination bonds ensures that the material has greater rigidity and mechanical strength; Repair performance; the high temperature sensitivity of the coordination bond ensures the variable stiffness of the material under a wide temperature range; the insensitivity of the coordination bond to water ensures the environmental stability of the material; at the same time, the material has a transparent It has the characteristics of high performance and adjustable refractive index. The variable-stiffness self-healing material containing metal-mercapto coordination bonds of the present invention can be applied to the fields of sealants, self-healing coatings, temperature-sensitive variable-stiffness self-repairing engineering materials, additive manufacturing, composite materials, optically transparent adhesives and the like.

Owner:NANJING UNIV

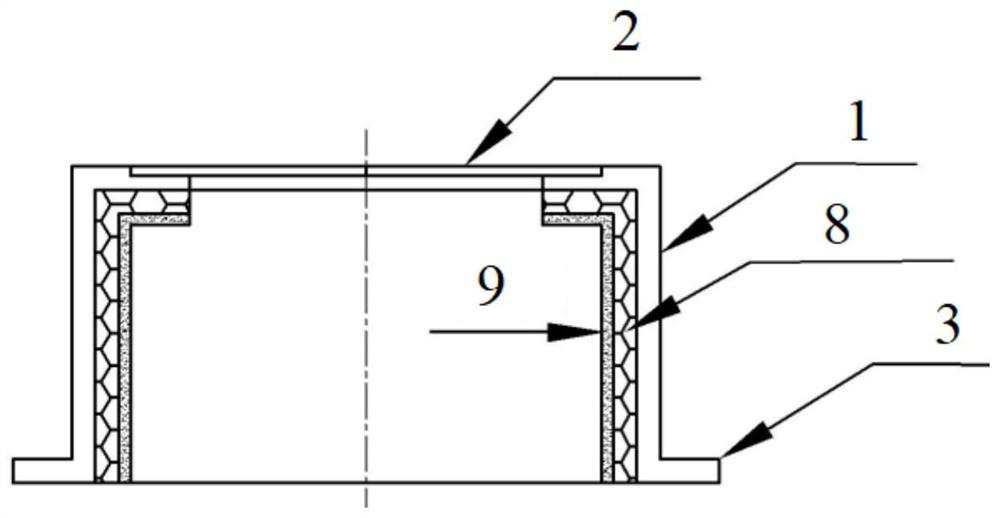

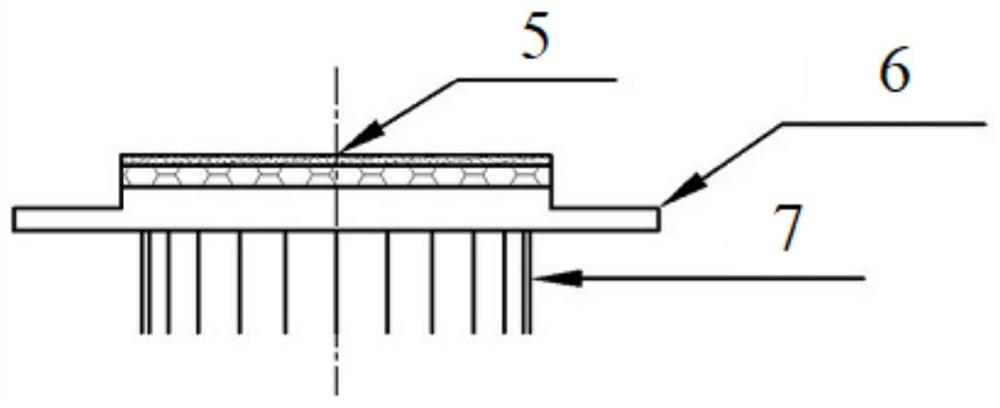

Packaging method of low-temperature vacuum infrared detector

PendingCN113964233AReduce gas outputIncrease roughnessLaser beam welding apparatusSemiconductor devicesFiberSilicon dioxide

The invention relates to a packaging method of a low-temperature vacuum infrared detector, and belongs to the technical field of semiconductors. The method comprises the following steps: polishing the inner surface of a vacuum tube metal shell except a germanium window and a base loading surface; preparing a heat insulation film layer composed of a polyimide layer and an alumina fiber cloth layer on the inner surface and the loading surface; plating a passivation film made of a silicon dioxide or aluminum oxide material on the surface of the heat insulation film layer to form a passivation film layer; and installing an infrared detector chip and a refrigerator on the loading surface, and after electrodes and pins are bonded, carrying out vacuum exhaust and laser fusion welding in a cavity of a vacuum welding workbench so that vacuum sealing packaging is achieved. According to the packaging method, the vacuum sealing of the infrared detector can be realized while the temperature impact on the infrared detector chip caused by a high temperature in the packaging and welding process is avoided; and according to the packaging method, the air output of the inner wall of the vacuum tube after packaging can be effectively reduced, leakage holes in the packaging position of the vacuum tube are effectively reduced, and therefore the vacuum holding time of the low-temperature vacuum infrared detector is prolonged.

Owner:云南昆物新跃光电科技有限公司

A kind of amorphous nanocrystalline composite magnetic powder core and preparation method thereof

ActiveCN109036753BImprove densification performanceImprove uniformityInductances/transformers/magnets manufactureMagnetic materialsNanocrystalline compositesSwitching power

The invention discloses an amorphous nanocrystalline composite magnetic powder core and a preparation method thereof, and the amorphous nanocrystalline composite magnetic powder core is prepared fromFe-based amorphous nanocrystalline magnetic powder and nano-grade glass powder / micron-grade glass powder through spark plasma sintering. The amorphous nanocrystalline composite magnetic powder core has high permeability, high density, low magnetic loss and low coercivity, so the amorphous nanocrystalline composite magnetic powder core has excellent soft magnetic and mechanical properties, and canbe widely used for manufacturing high-power switching power supplies, high-power inductors and high-efficiency energy-saving motors and other equipment.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com