Packaging method of low-temperature vacuum infrared detector

A technology of infrared detectors and packaging methods, which is applied in the direction of semiconductor devices, laser welding equipment, electrical components, etc., to achieve the effects of avoiding temperature shock, prolonging vacuum holding time, and reducing leakage holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A packaging method for a vacuum low-temperature infrared detector, the method is suitable for unit HgCdTe infrared detectors.

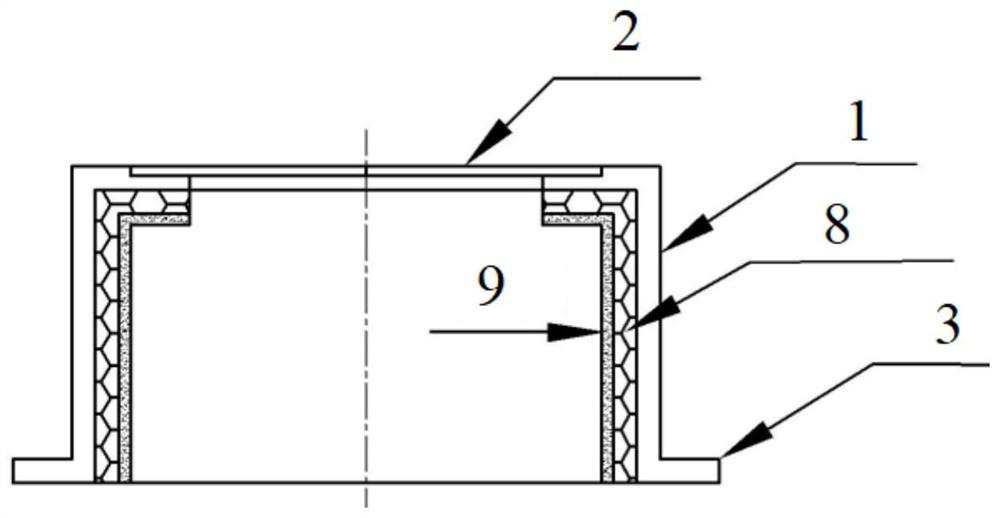

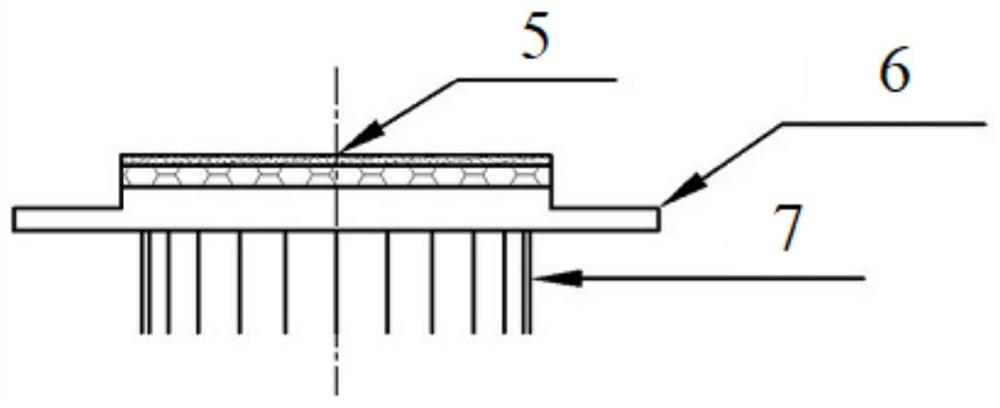

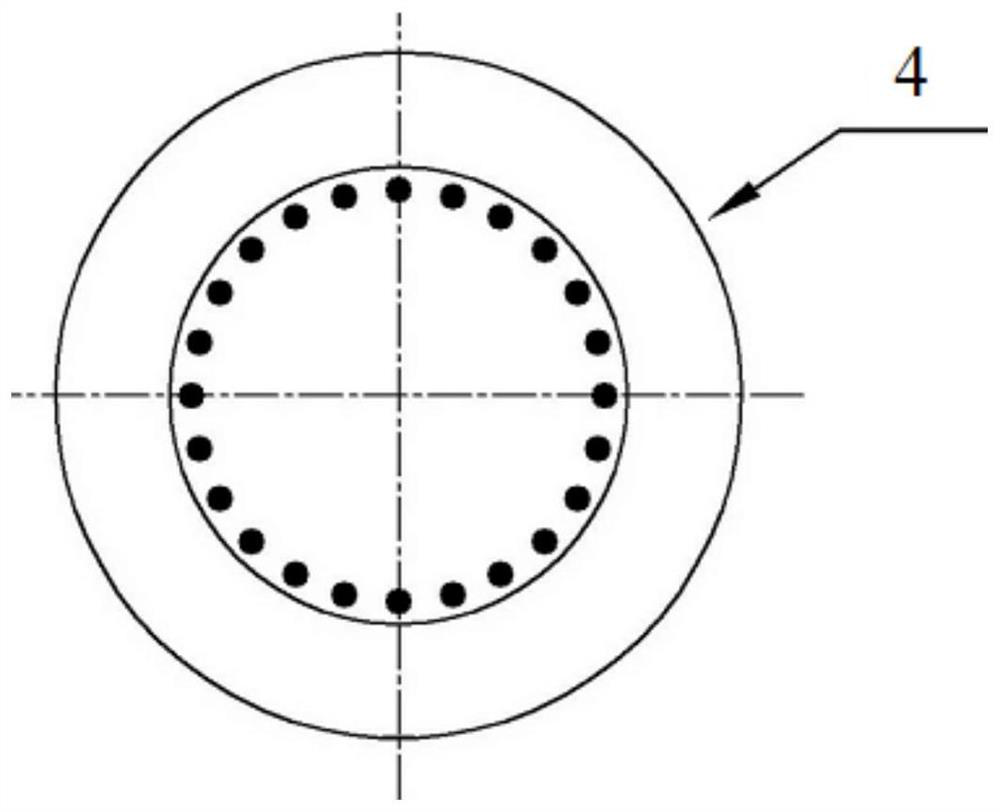

[0042] The method adopts that the vacuum tube encapsulating the infrared detector chip is a cylindrical vacuum tube composed of a stainless steel casing 1 and a Kovar (4J29) base 4 . Such as figure 1 As shown, the housing 1 is a cylinder with a germanium window 2, the outer periphery of the bottom edge of the housing 1 is provided with a housing outer edge 3, the inner space of the housing 1 is used to load an infrared detector chip, and the outer surface of the housing 1 The diameter is 13mm, the wall thickness of the shell 1 is 0.5mm, the height of the shell 1 is 10mm, the diameter of the germanium window 2 is 4.5mm, and the diameter of the outer edge 3 of the shell is 15mm. Such as figure 2 and 3 As shown, the upper surface of the base 4 protrudes as a loading surface 5, and the outer periphery of the bottom of the loading surface 5 of t...

Embodiment 2

[0052] A packaging method for a vacuum low-temperature infrared detector, the method is suitable for unit HgCdTe infrared detectors.

[0053] In the method, the heat-insulating film layer 8 on the inner wall of the vacuum tube shell of the infrared detector chip and the loading surface 5 of the base 4 is replaced with a polyimide film for the aluminum oxide fiber cloth in Example 1, that is, with a polyimide film. The imide solution is bonded with a layer of polyimide film, and is cured by heating according to the curing of polyimide. The polyimide film is DuPont Kapton high temperature resistant PI film with a film thickness of 400 μm. The rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com