Patents

Literature

47results about How to "Reduce gas output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing ferric phosphate material

The invention relates to a method for synthesizing a ferric phosphate material, belonging to the technical field of lithium ion cathode materials. The method for synthesizing the ferric phosphate material comprises the following steps of: (1) manufacturing a hollow spherical template: stirring oil with carbon hydrogen bonds and a water-soluble surfactant free of metal ions for 0.1-10 h in a water solution to form an emulsion, wherein the weight ratio of the oil to the surfactant is 1:(1-9), and the total weight of the oil and the surfactant accounts for 0.1-5% of the solution; (2) precipitating ferric phosphate: adjusting the pH value of an acid solution containing phosphates and ferric salts by using the emulsion to form ferric phosphate precipitate, wherein the precipitate is adhered to an emulsion microsphere to form a structure of which the exterior is ferric phosphate and the kernel is the emulsion microsphere; and (3) processing the ferric phosphate microsphere: filtering and drying the ferric phosphate microsphere, calcining the ferric phosphate microsphere at high temperature to form a hollow / shell structure microsphere ferric phosphate material. The method provided by the invention has the advantages of simple process, operation convenience, stable ferric phosphate microsphere, large rate discharge capacity and low temperature capacity and the like.

Owner:天津恒普科技发展有限公司

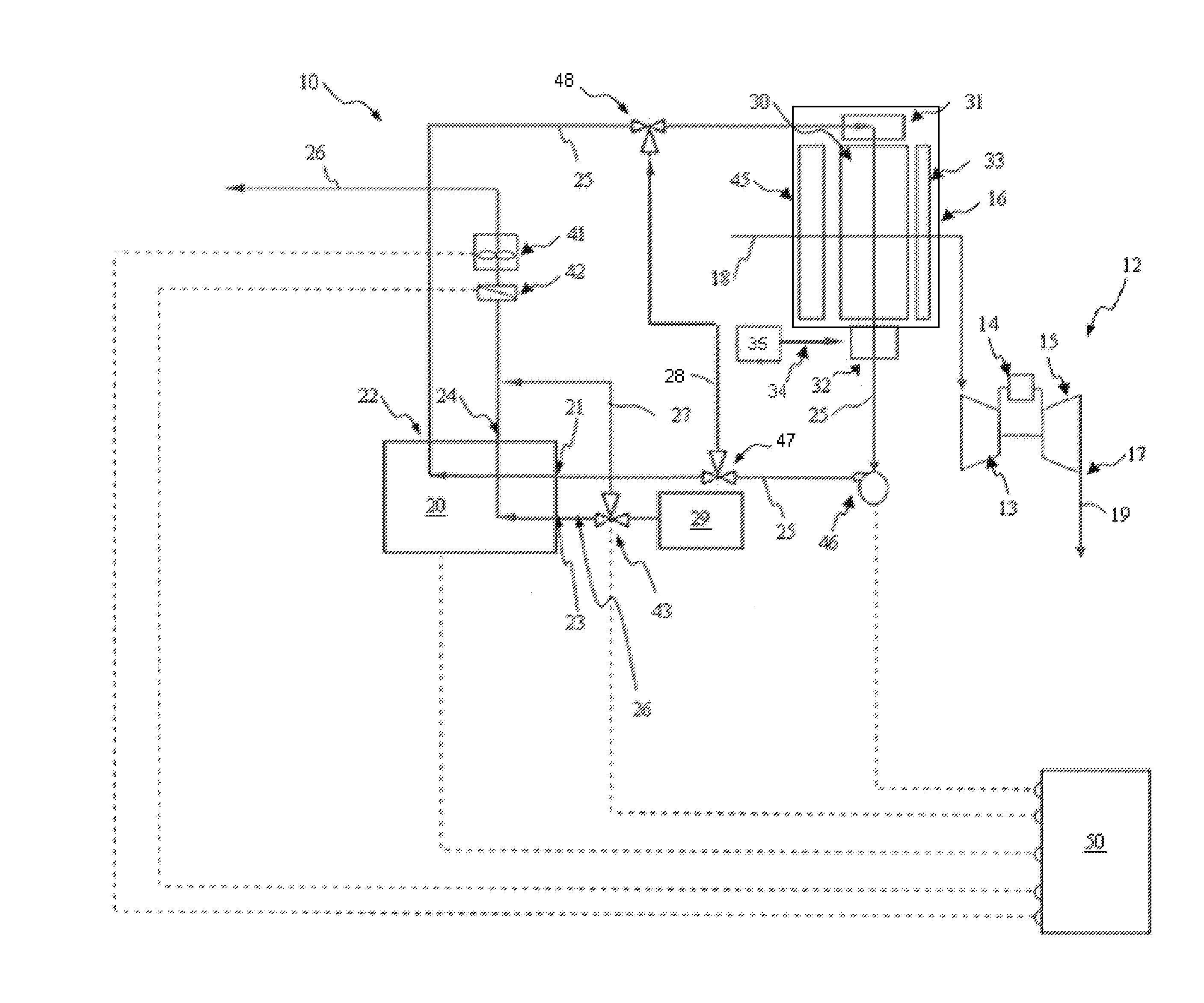

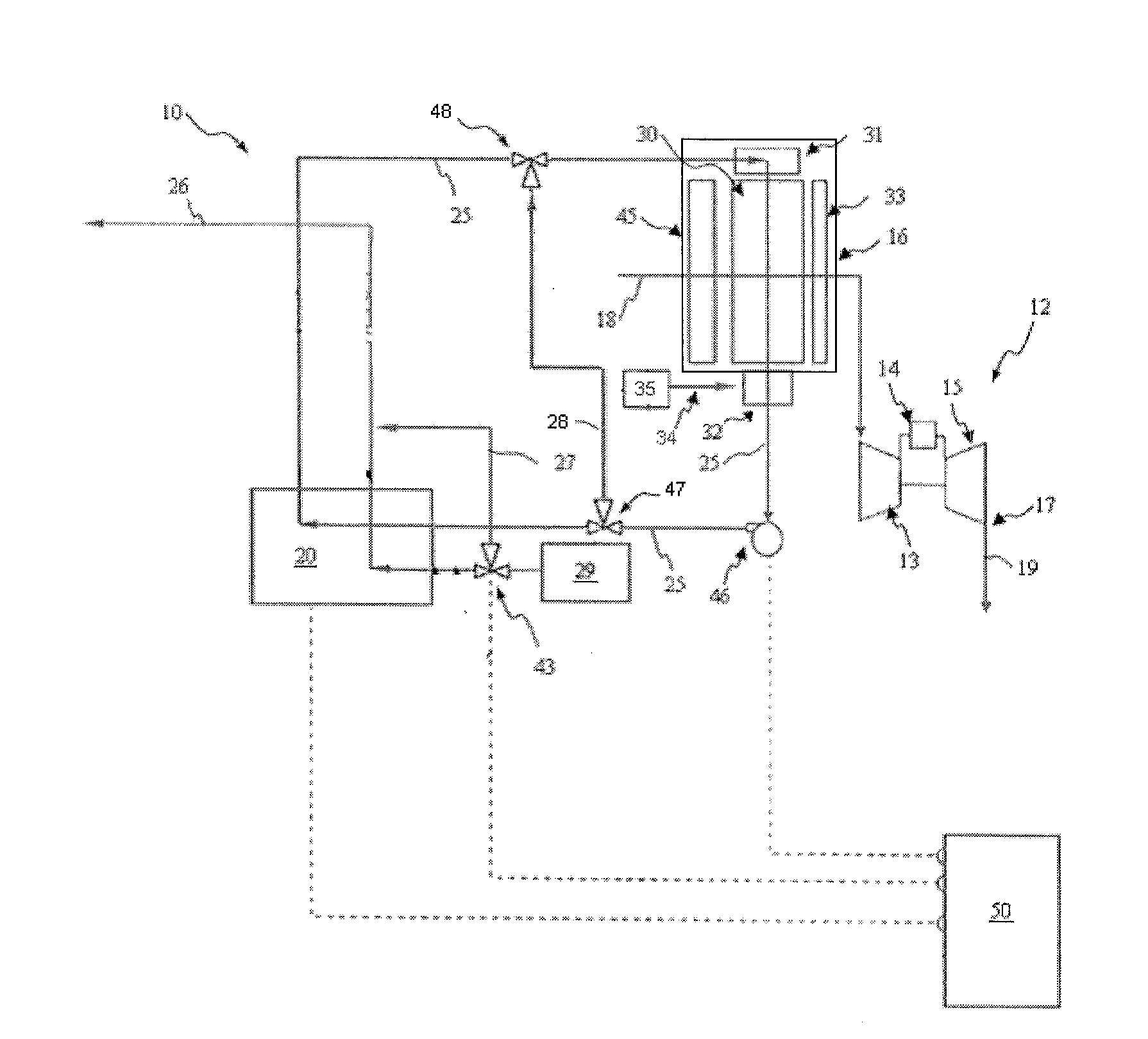

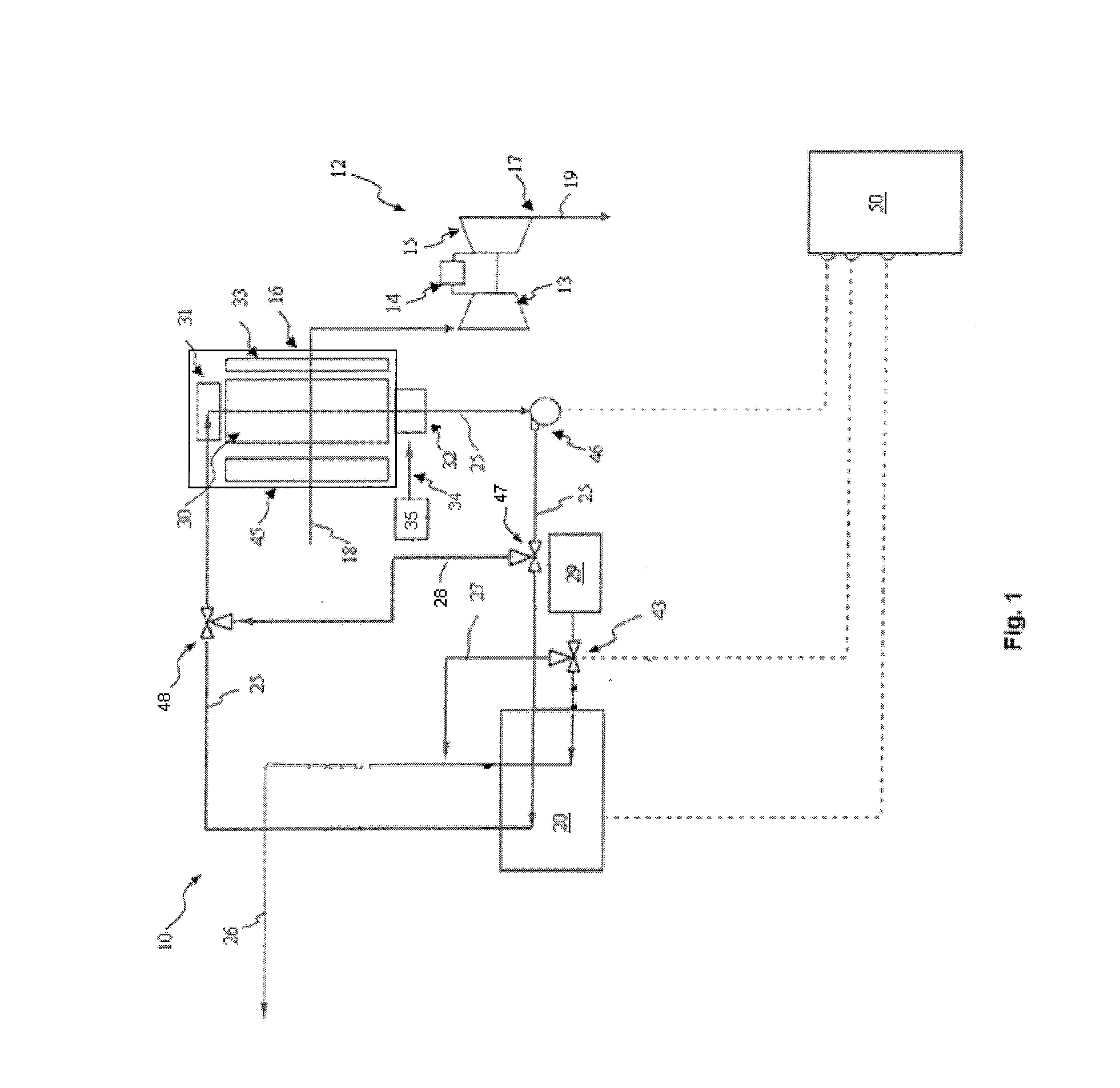

System and method for gas turbine inlet air heating

InactiveUS20130199202A1Low outputExtend turndown rangeGas turbine plantsTurbine/propulsion fuel controlEvaporative coolerChiller

In one embodiment of the present disclosure, a gas turbine system for part load efficiency improvement and anti-icing within the inlet and at the compressor inlet is described. The system includes a gas turbine having a compressor which receives inlet-air. A direct-contact heat exchanger heats the inlet-air before the inlet-air flows through the inlet and to the compressor. Heating the inlet-air reduces an output of the gas turbine and extends the turndown range, and avoids ice-forming conditions within the inlet and at the compressor inlet bellmouth. The direct-contact heat exchanger may also be configured to act as an evaporative cooler, air chiller, or use liquid dessicant.

Owner:GENERAL ELECTRIC CO

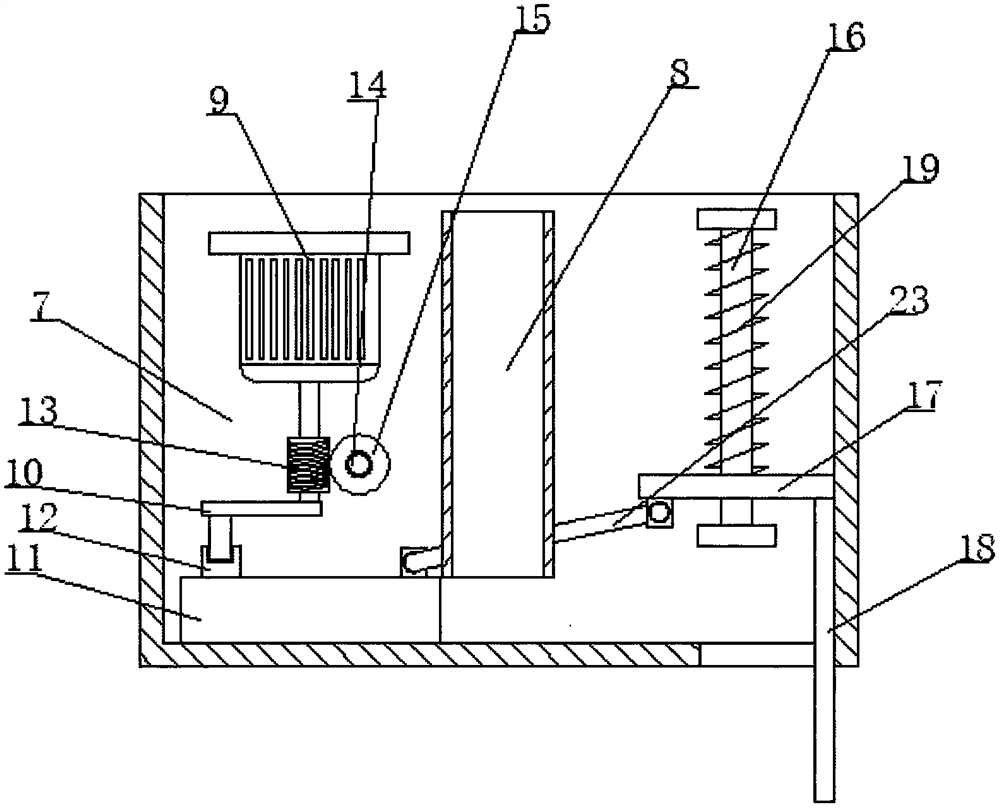

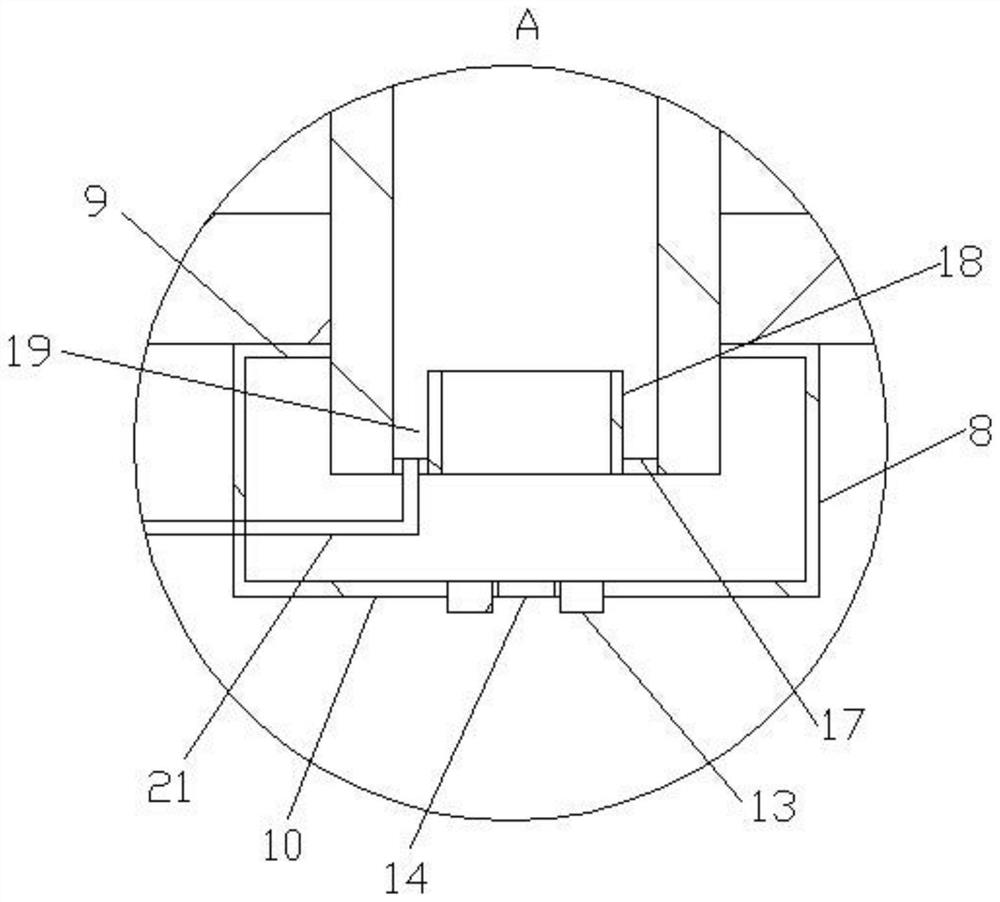

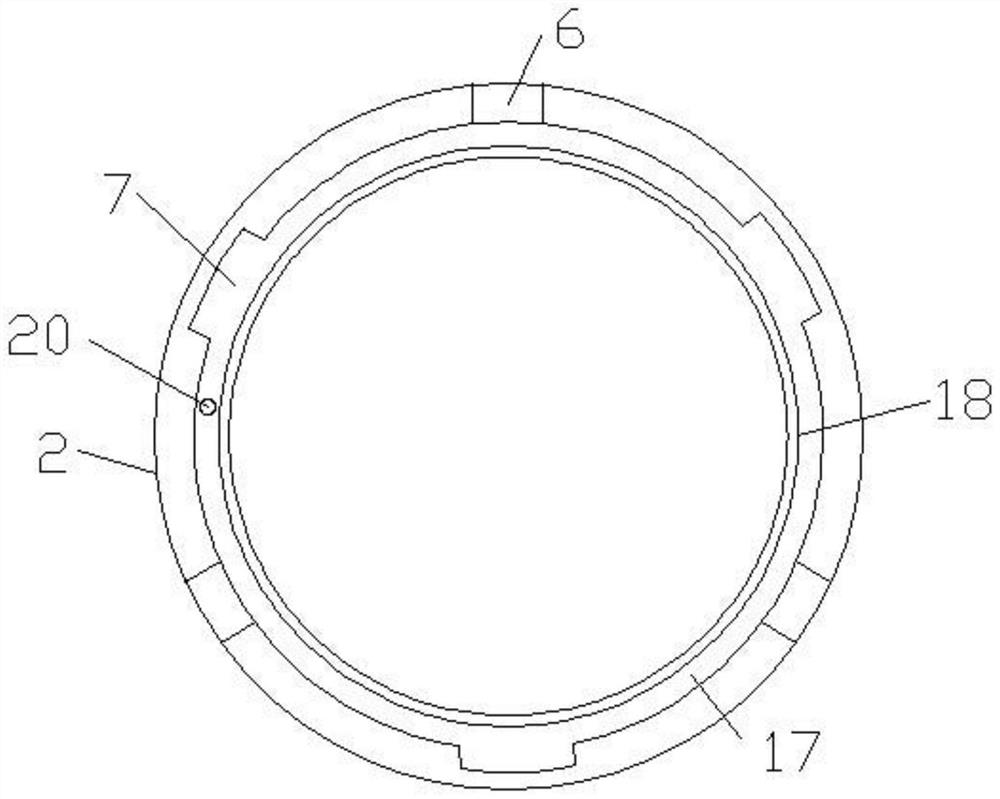

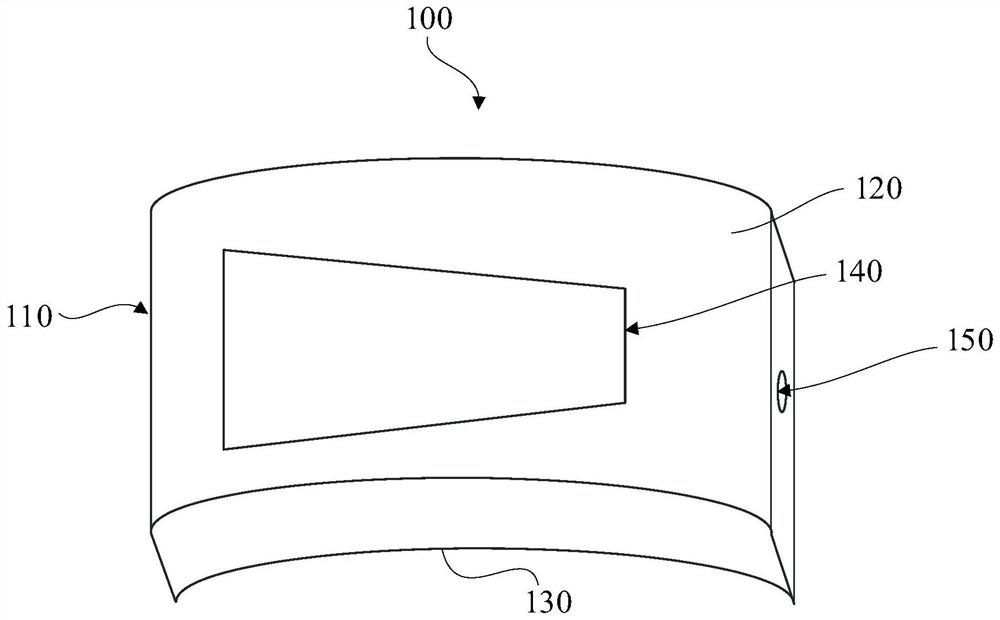

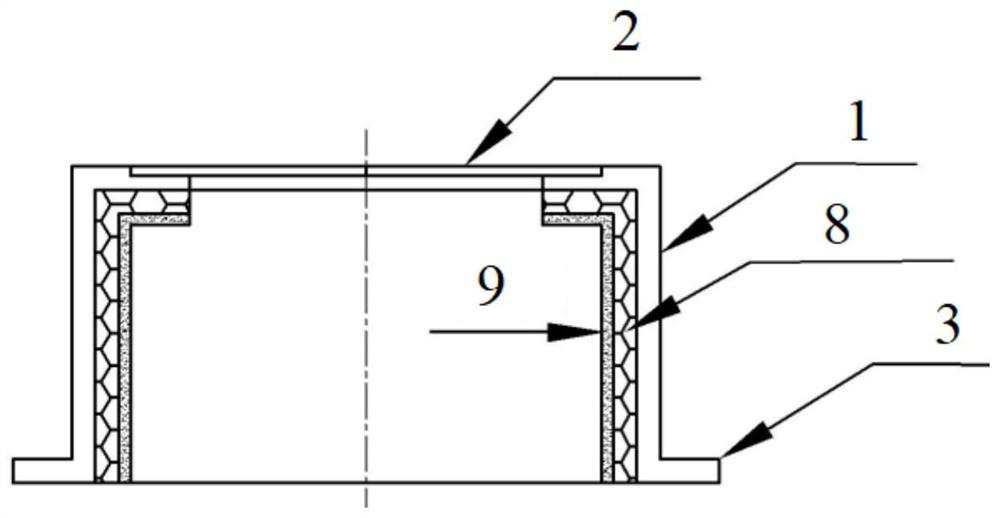

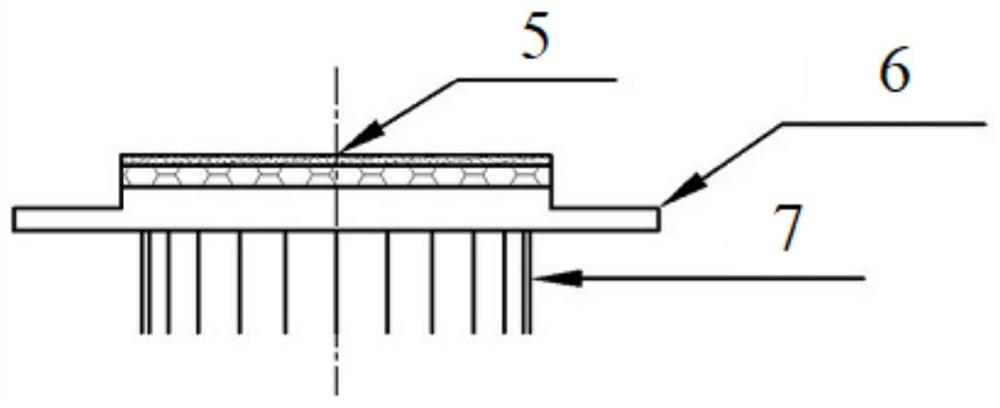

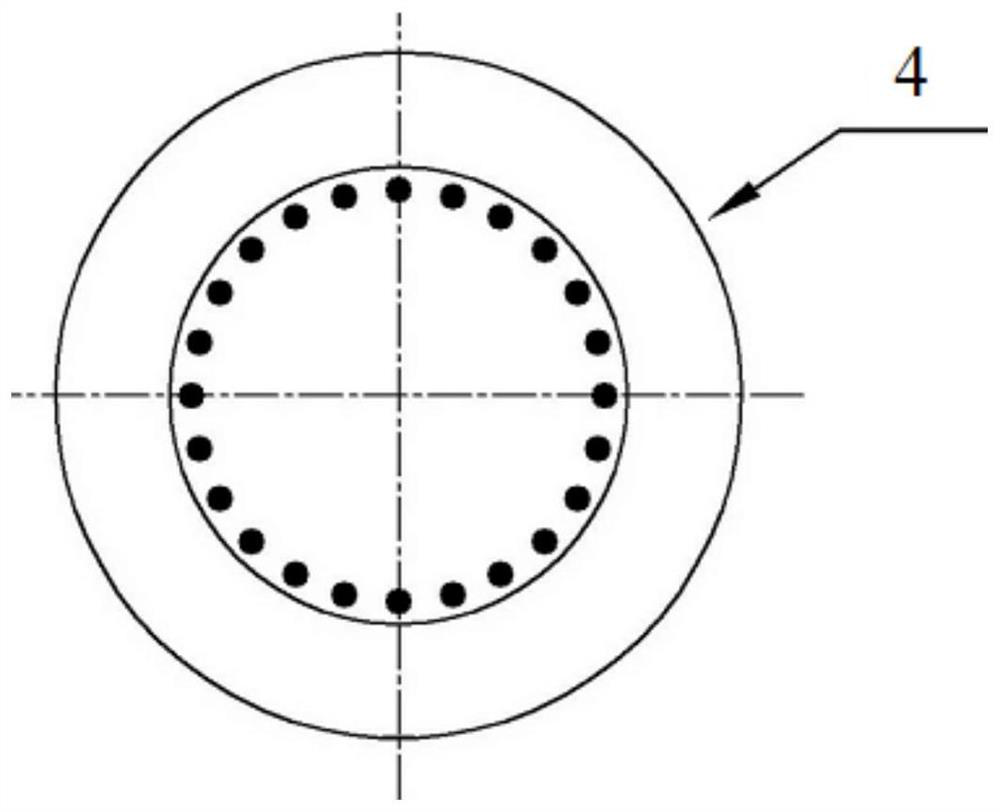

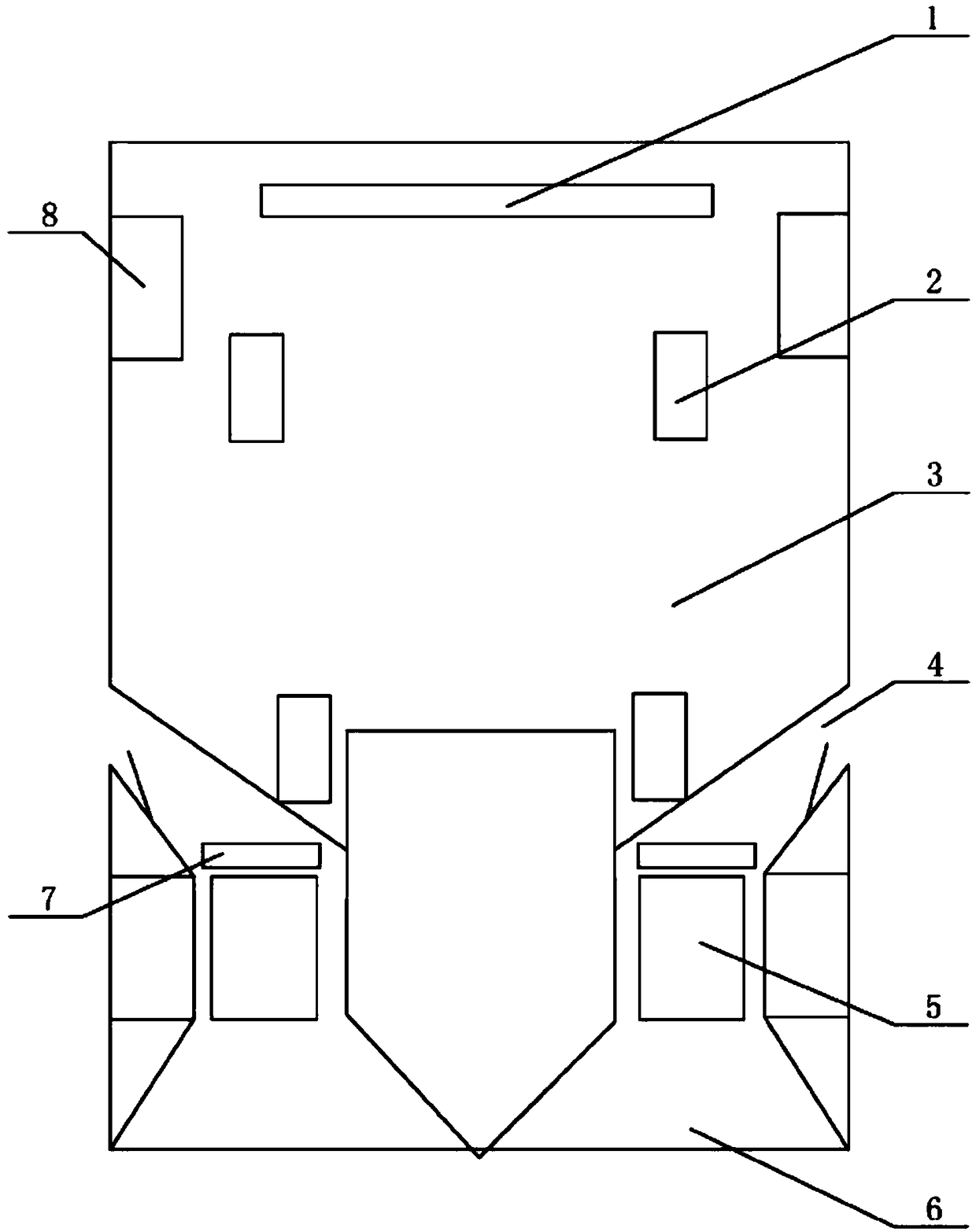

Coal mine camera protection system with automatic lens replacing, cleaning, dust removing and dust falling functions and application thereof

ActiveCN112714242ARealize automatic replacementShorten the timeTelevision system detailsFouling preventionDust controlEnvironmental engineering

The invention relates to a coal mine camera protection system with automatic lens replacing, cleaning, dust removing and dust falling functions and application thereof, and belongs to the technical field of mining equipment, which comprises a lens cleaning device, a lens drying device, an internal pressurizing device, an external lens cover, a lens bracket, a shell and a controller. When the lens is replaced, the underground use safety performance of the system is improved through the external lens cover and the internal pressurizing device, the camera window can be cleaned instead of manual work after the system is applied to the site, the labor intensity is reduced, the life safety of personnel is guaranteed, and the system is externally provided with a device capable of sprinkling water to reduce dust and is started when the external dust concentration is too high. The dust concentration around the camera system is rapidly reduced, and the lens cleaning frequency can be reduced. Unmanned cleaning of the camera window is achieved, meanwhile, cleaning and drying work is carried out in the shell, cleaning and drying equipment is isolated from flammable and explosive gas, and explosion-proof design of system equipment is better facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

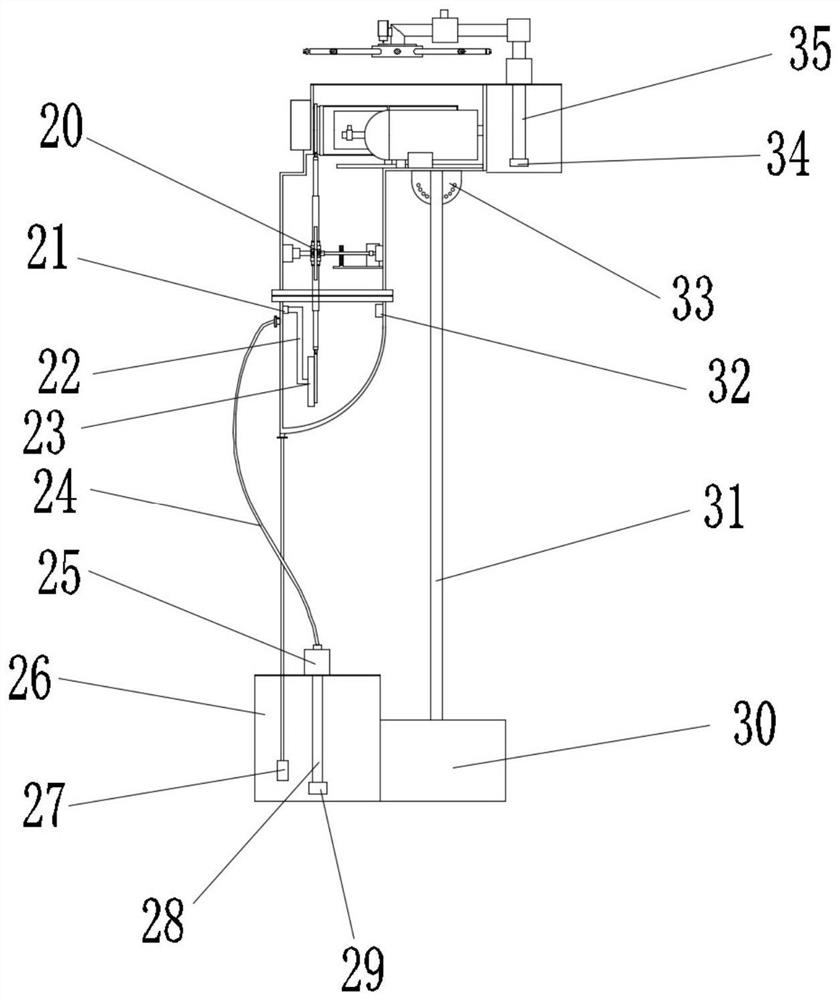

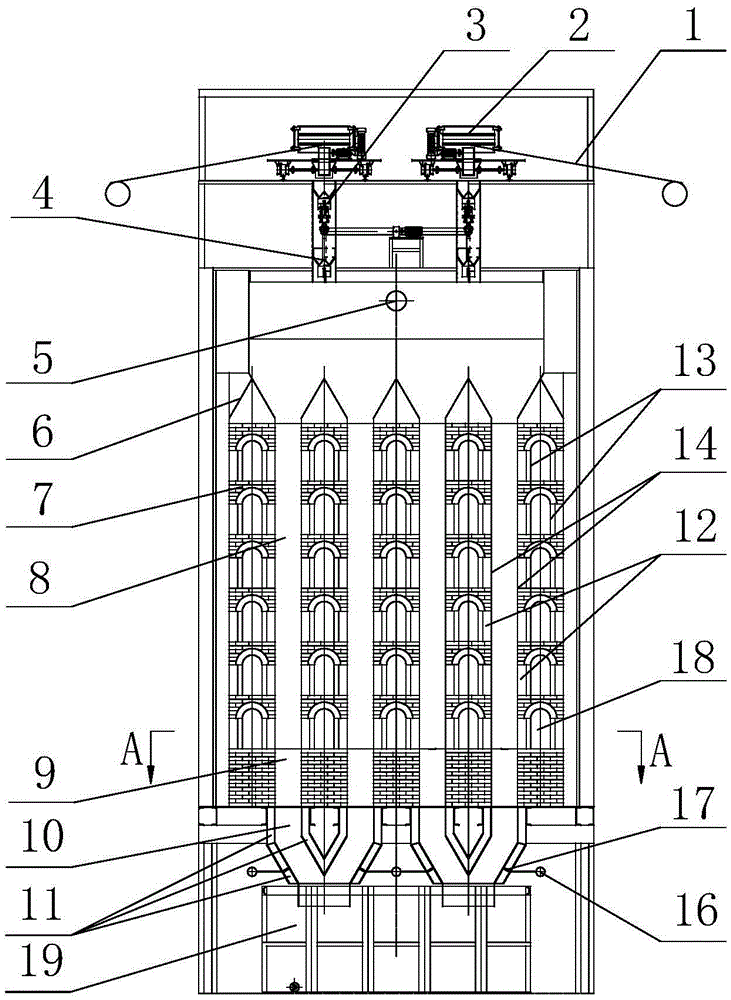

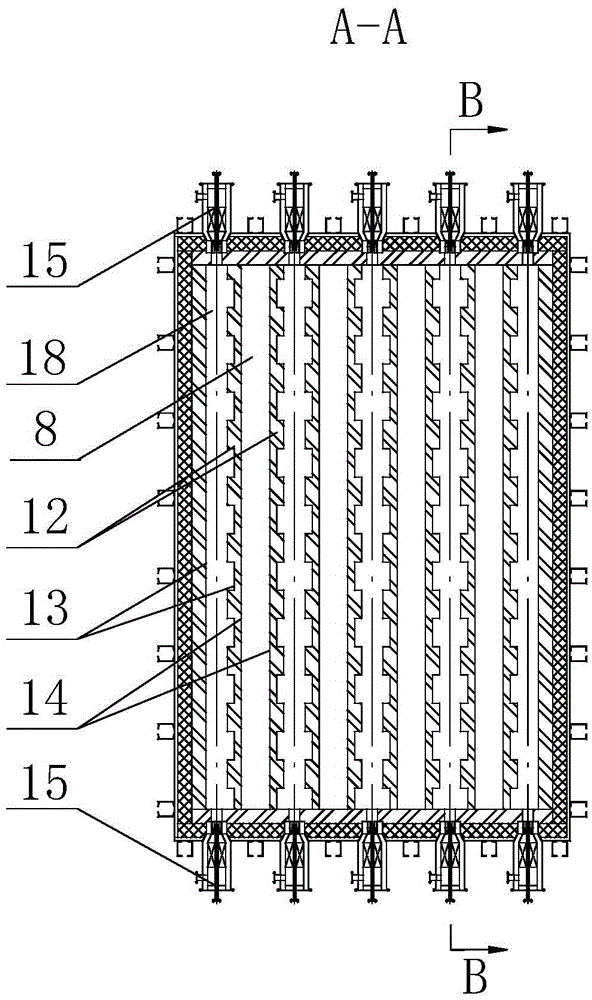

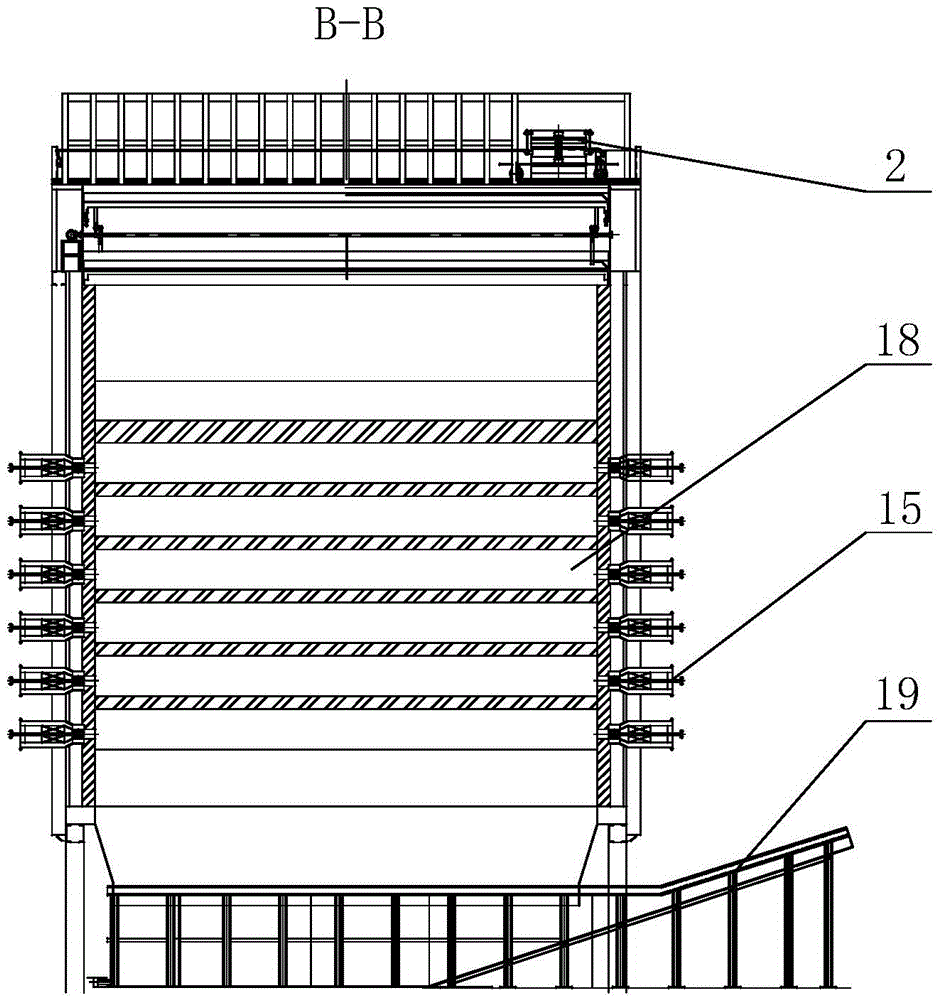

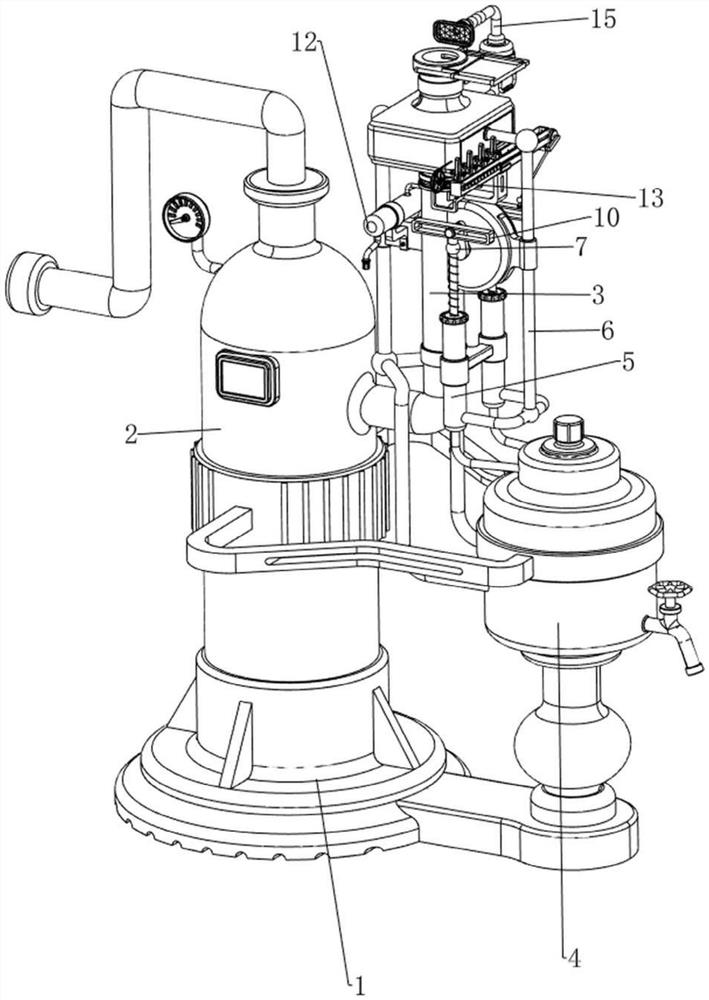

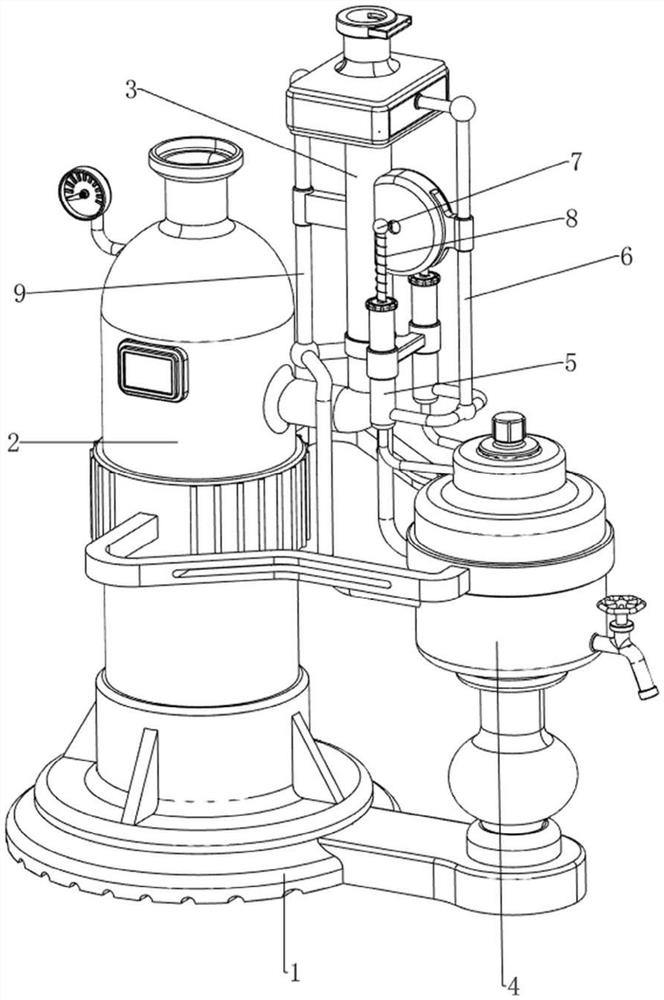

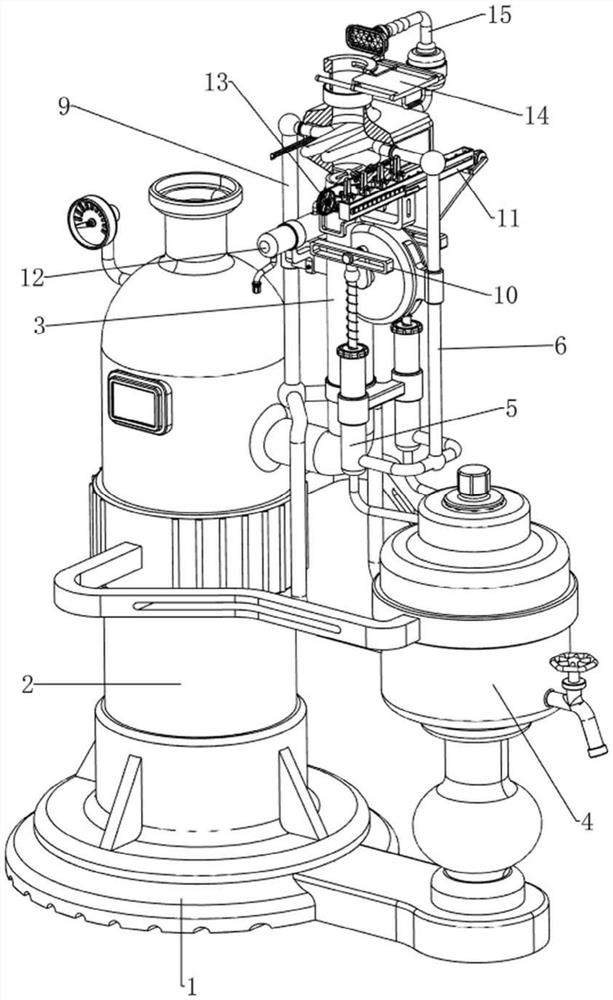

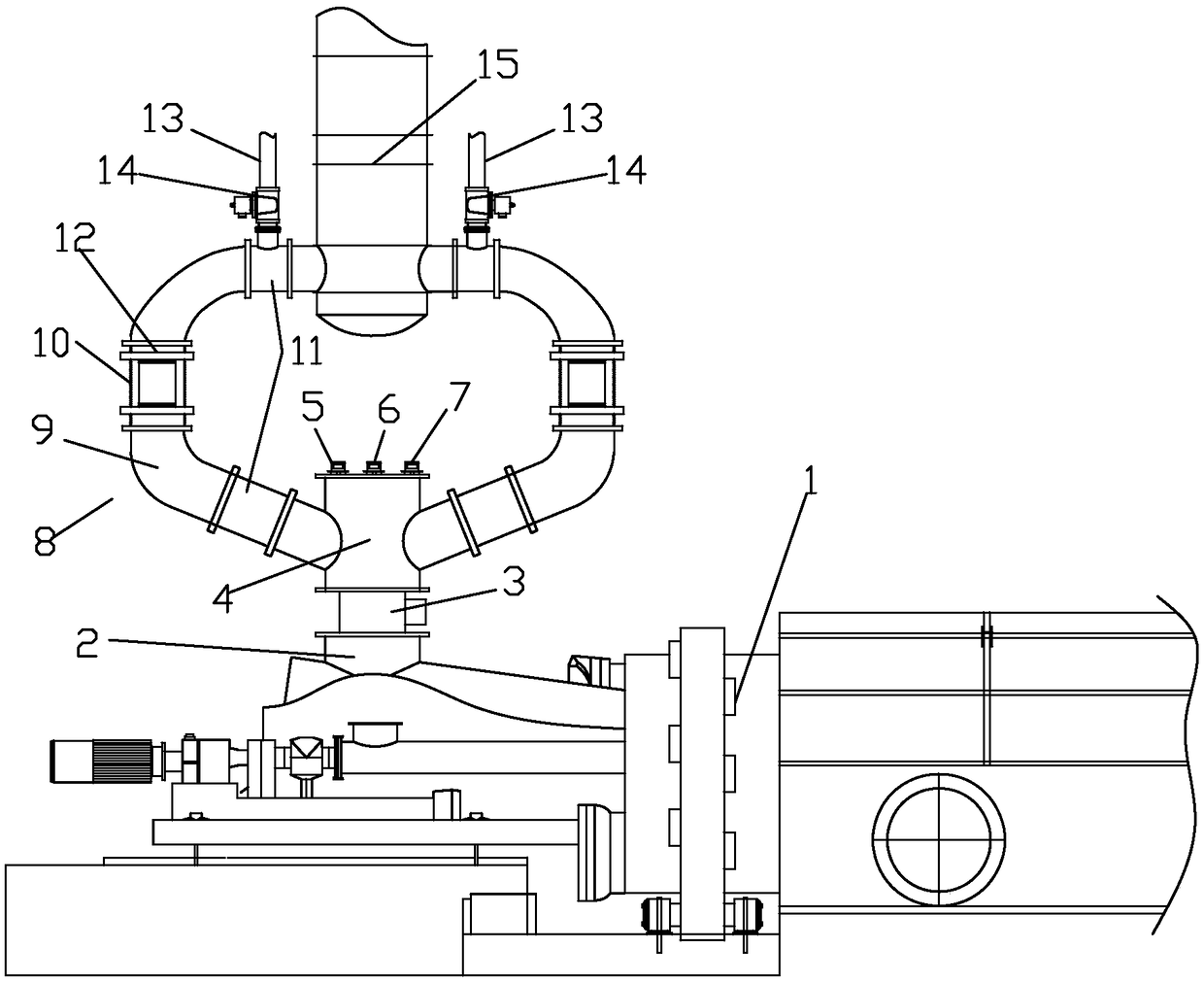

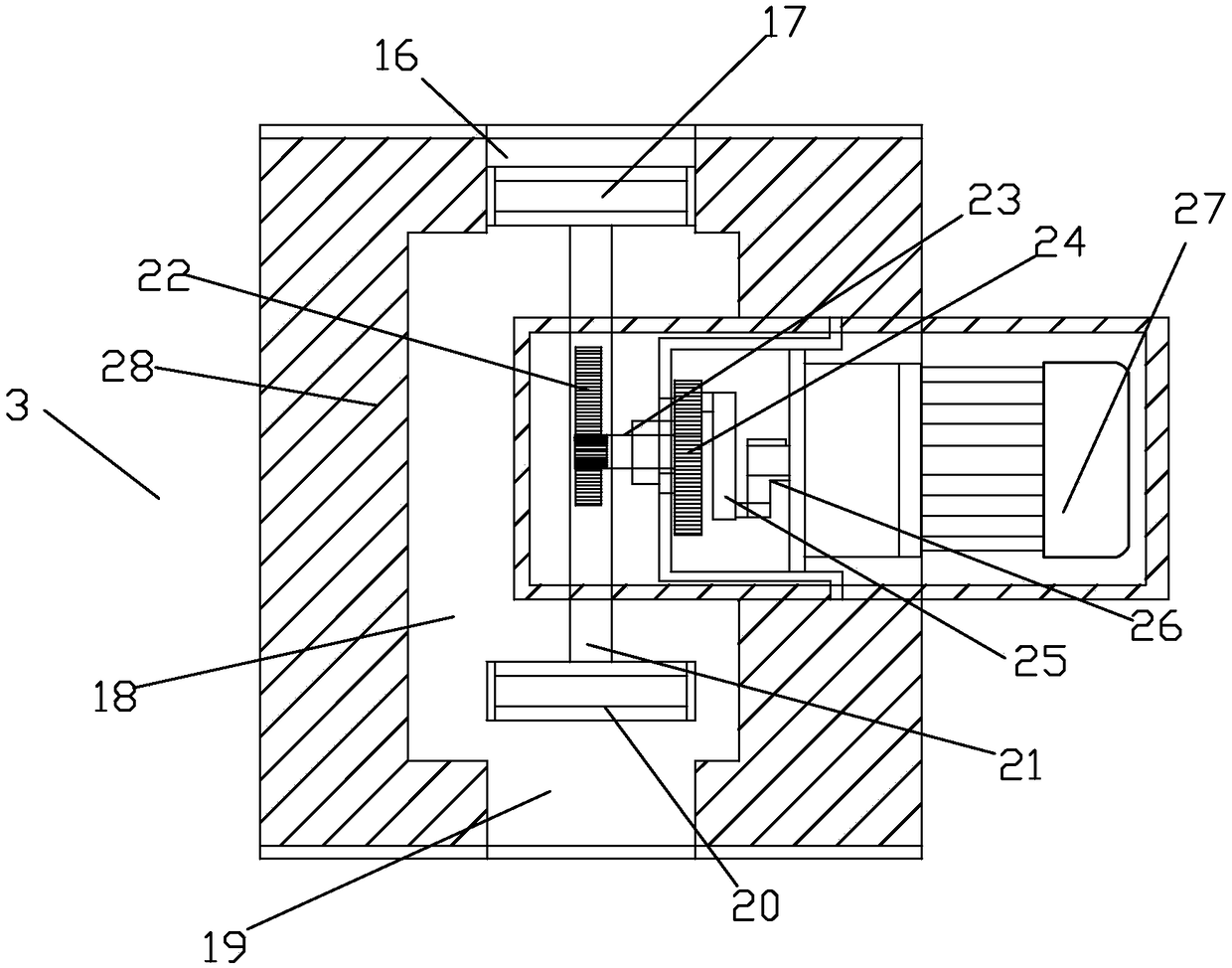

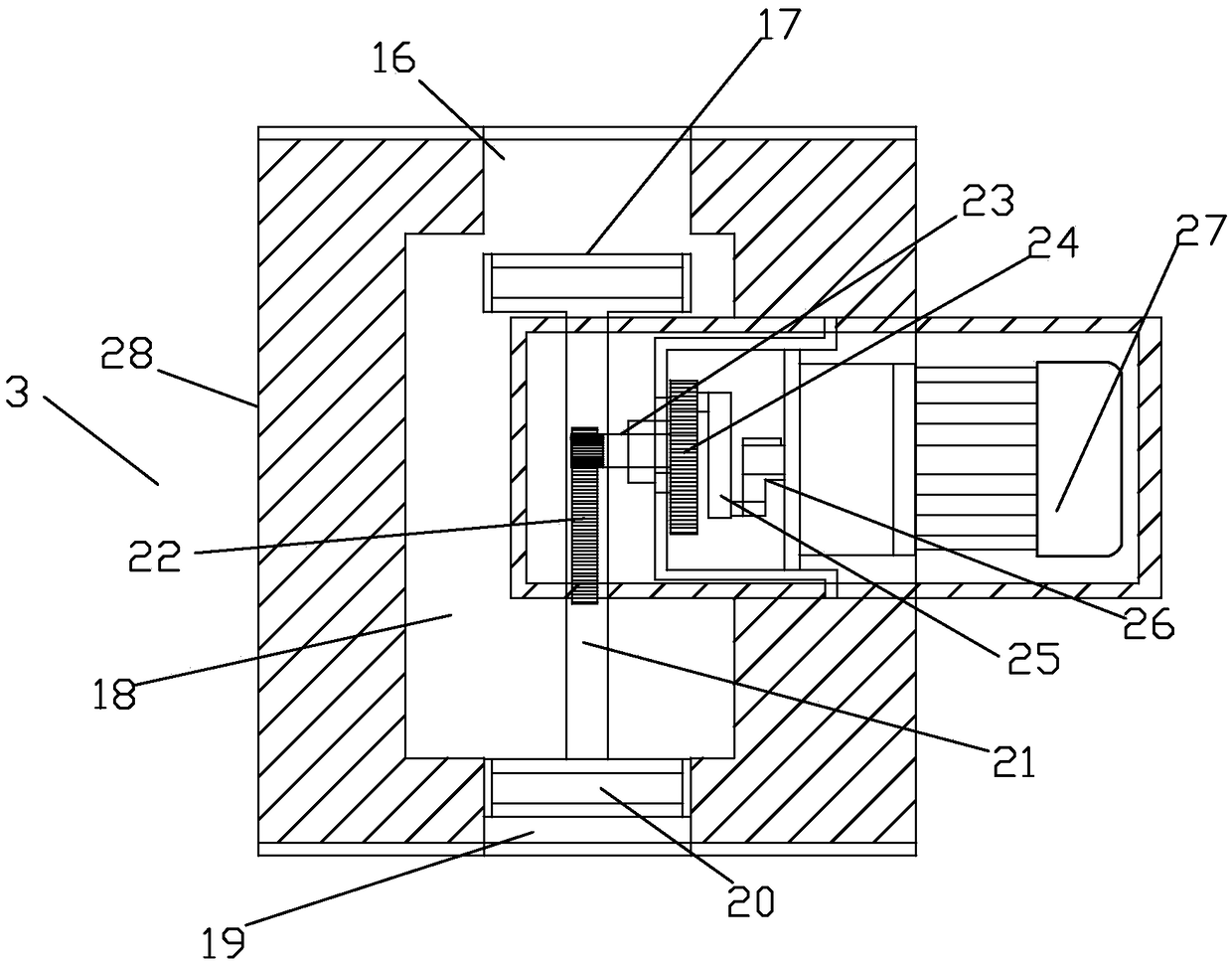

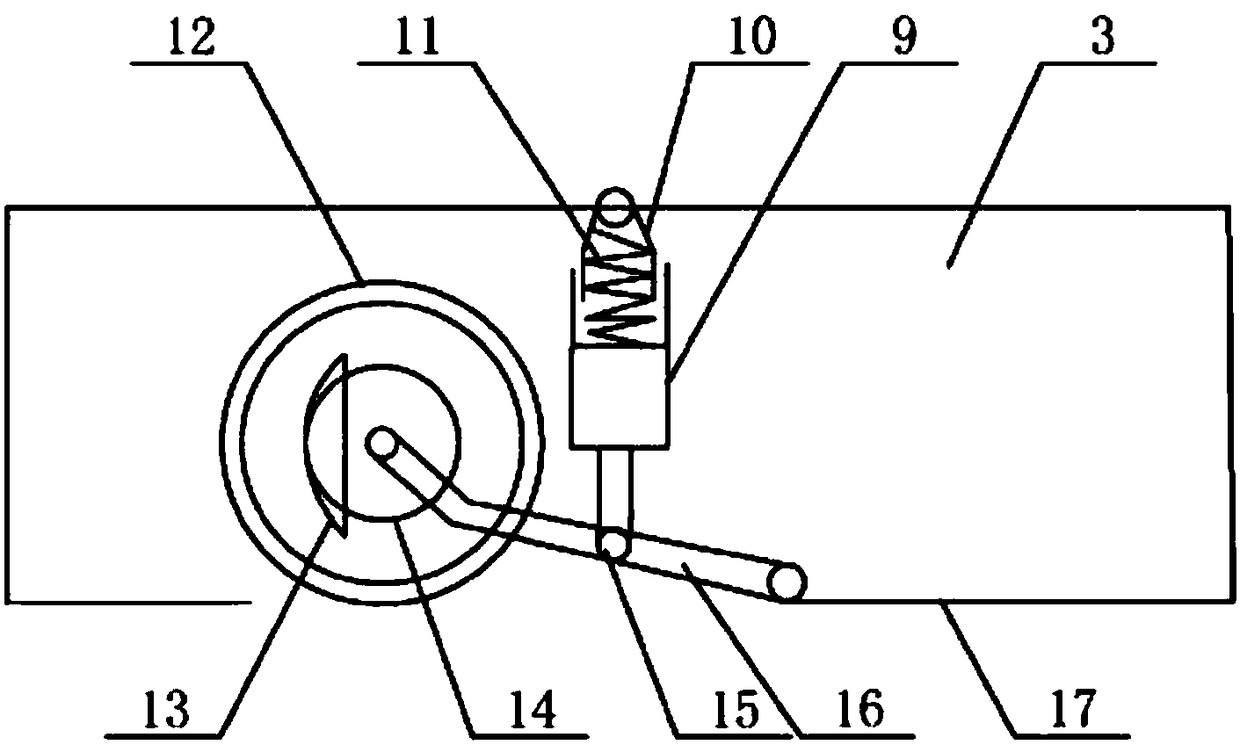

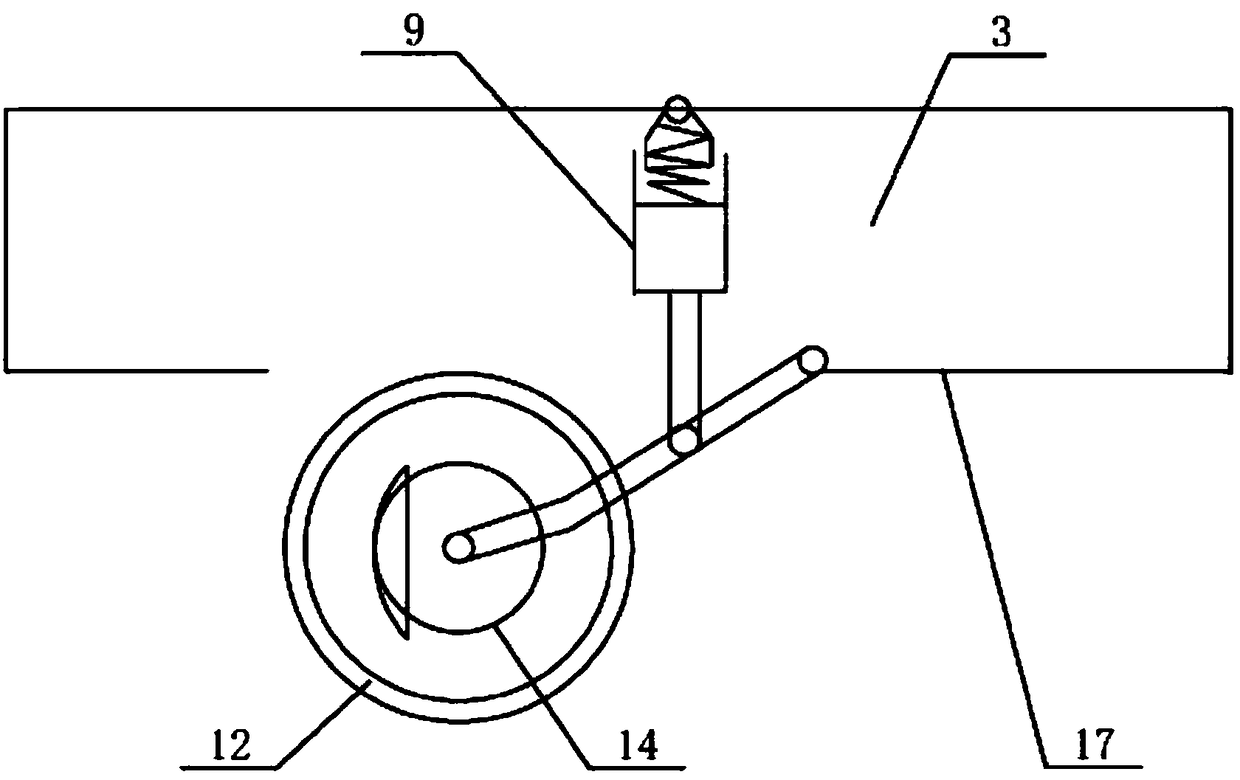

External heat radiation regenerative oil shale dry distillation furnace

ActiveCN105542863AHigh strengthRun smoothlyGasification processes detailsCombustible gas productionCombustion chamberThermal efficiency

The invention relates to an external heat radiation regenerative oil shale dry distillation furnace. The furnace is provided with a plurality rows of alternately arranged dry distillation chambers and combustion chambers; each row of combustion chambers is formed by a plurality layers of independent combustion channels; heat generated by combustion is transferred to oil shale in the dry distillation chambers with heat radiation and heat conduction manners with lattice-wall-structured heat conduction walls. With a gasification section, a cooling section, cooling water jackets and steam nozzle devices on the lower part of the dry distillation furnace, carbon residue in semicoke can be fully recycled, and semicoke and ash residual heat can be recycled. Water gas generated by the reaction of semicoke and steam is used as a medium for bringing out oil shale pyrolysis oil gas, such that outlet gas amount is low, dry distillation gas purity is high, and dry distillation gas heat value is high. The daily processing capacity of the dry distillation furnace can by higher tan 500t, and an oil yield can be higher than 90%. Water and electricity consumptions are low, and an auxiliary recovery system is small. With existing external heat dry distillation technologies, semicoke carbon residue cannot be utilized, thermal efficiency is low, maintenance is difficult, and yield is low. With the dry distillation furnace, the above problems are solved. The dry distillation furnace is especially suitable for water-deficient areas.

Owner:WUHAN UNIV OF SCI & TECH

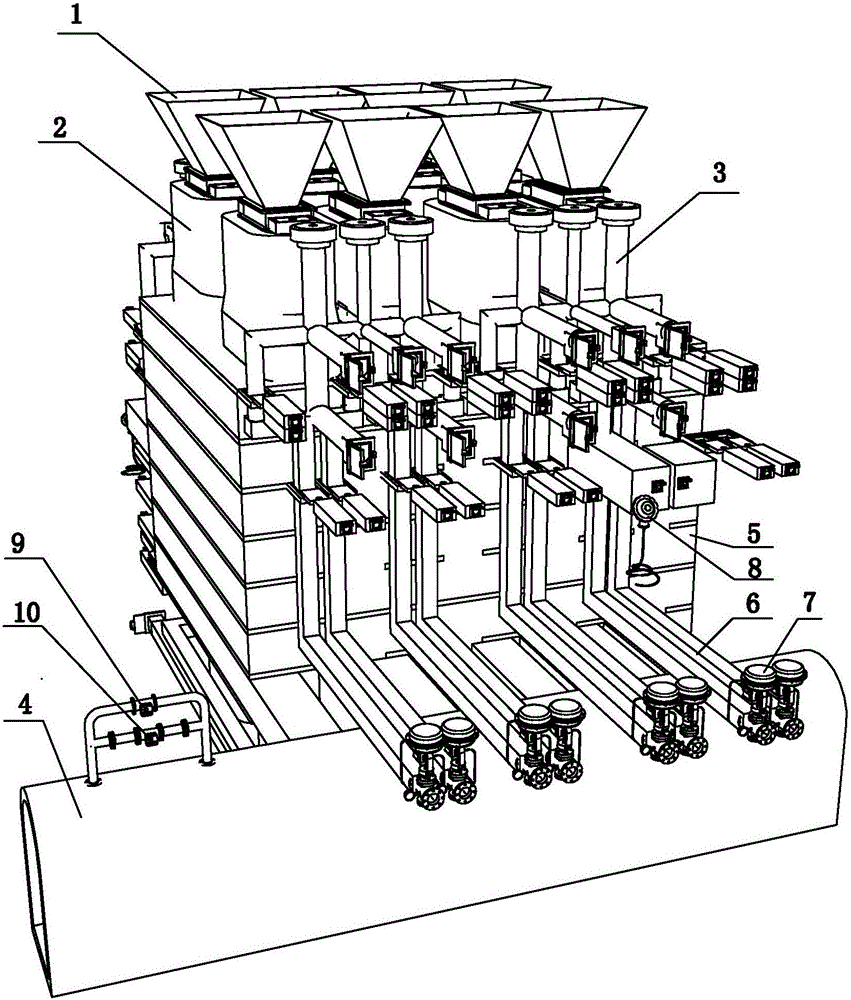

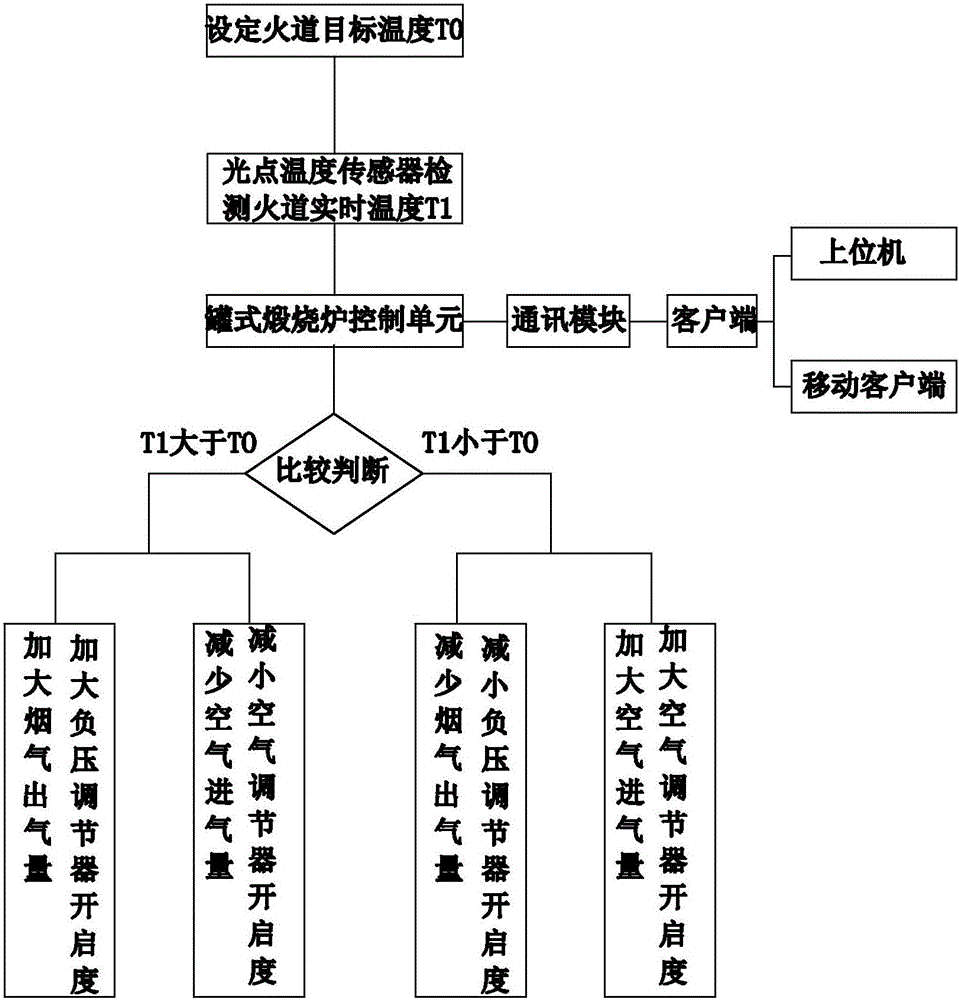

Pot calciner thermoregulation control device and method

ActiveCN106044746ARealize precise automatic controlHigh degree of automationCrucible furnacesElectricityCombustion

The invention discloses a pot calciner thermoregulation control device and method. The device comprises a photoelectric temperature sensor installed on a flame channel of a pot calciner, air conditioners installed on inlets of air channels of the pot calciner and a negative pressure regulator installed on an outlet of a gathering flue of the pot calciner, the photoelectric temperature sensor, the air conditioners and the negative pressure regulator are electrically connected with a control unit of the pot calciner, and the control unit of the pot calciner is in communication with a remote client side. When real-time temperature, detected by the photoelectric temperature sensor, of the flame channel is not within the target temperature range, the control unit of the pot calciner directly sends an instruction, or the remote client side sends an instruction to the control unit of the pot calciner, then the control unit of the pot calciner sends the instruction to the air conditioners and the negative pressure regulator to regulate respective opening degrees and then regulate the combustion degree of volatile matter in the flame channel, the real-time temperature of the flame channel is automatically and accurately regulated to be within the target temperature range, and the automation degree of the pot calciner is improved.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

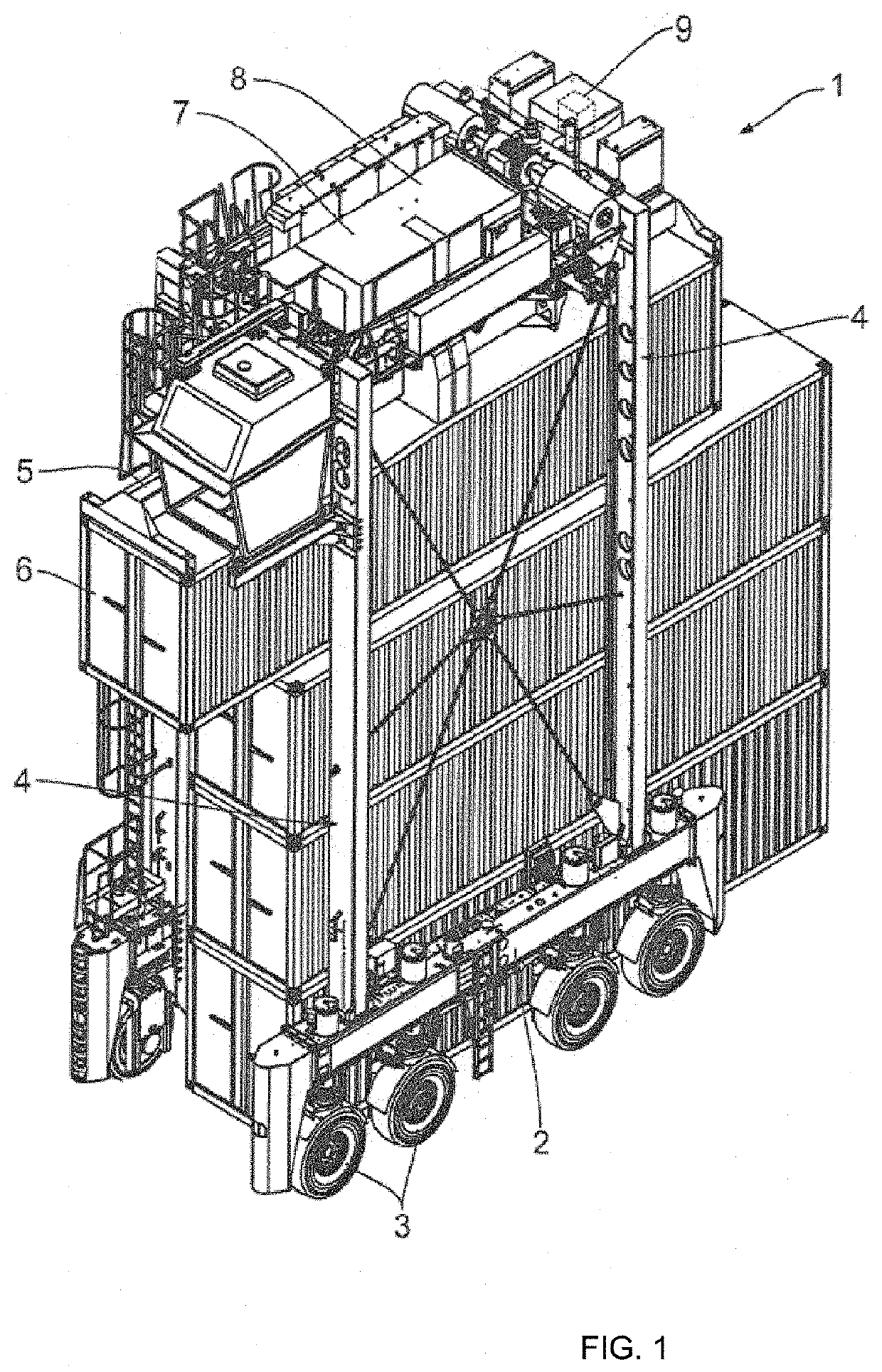

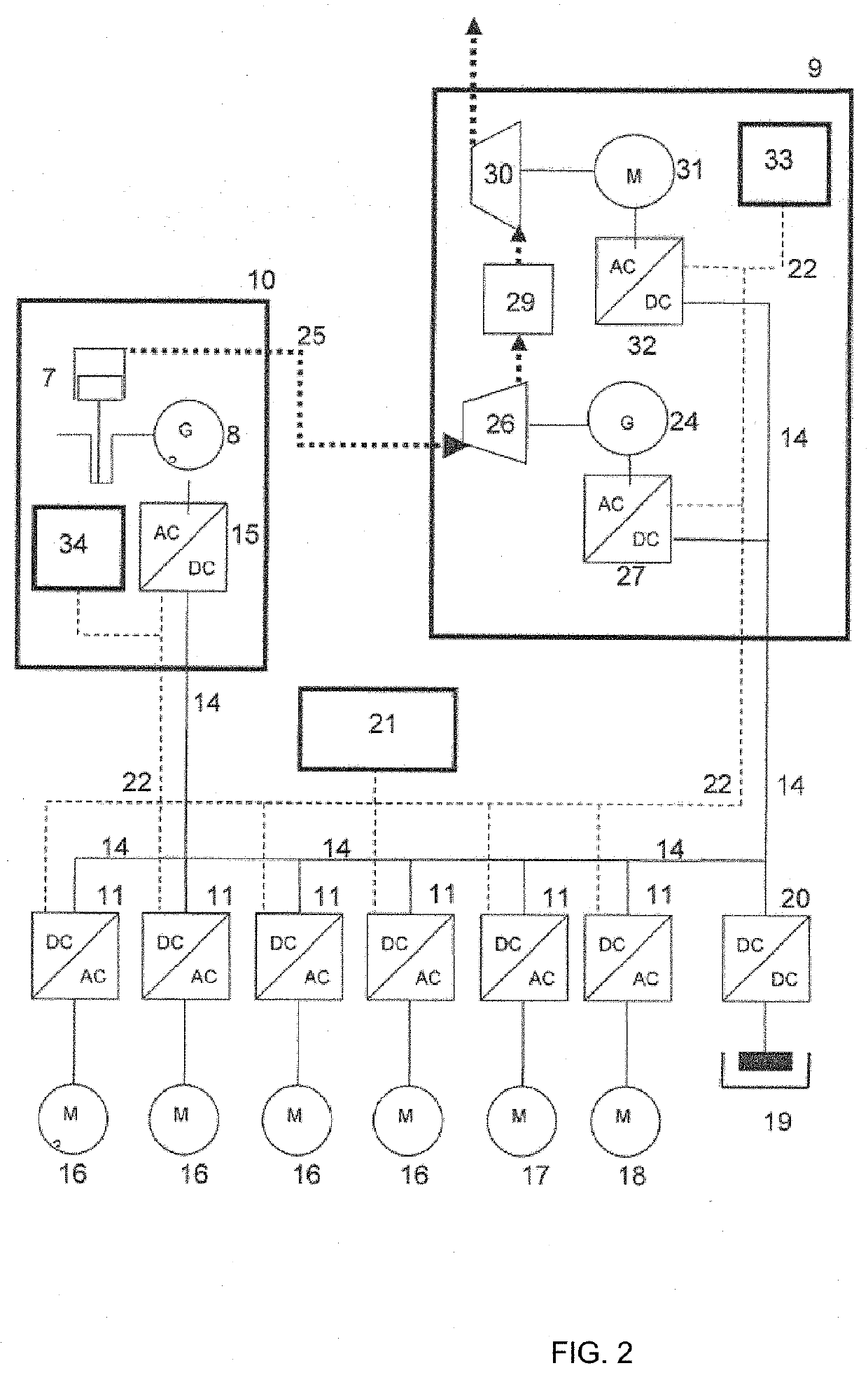

System having a secondary current generating assembly for the secondary conversion into electricity of exhaust gas heat from a primary current generating assembly

ActiveUS20200056564A1Improve efficiencyReduce fuel consumptionInternal combustion piston enginesExhaust apparatusControl systemExhaust fumes

A system having a primary current generating assembly includes a primary thermal engine and a secondary current generating assembly, in particular an electric turbo compound installation, for the secondary conversion into electricity of exhaust gas heat from the primary current generating assembly. The secondary current generating assembly includes an exhaust gas turbine arranged in an exhaust gas stream of the primary thermal engine, and the exhaust gas turbine drives an electric secondary generator. In order to improve efficiency, and in particular to reduce fuel consumption, it is proposed that an exhaust gas cooler followed by a compressor are arranged in the exhaust gas stream downstream of the exhaust gas turbine, the compressor being driven by an electric motor and the rotational speeds of the compressor and the exhaust gas turbine are controlled by a process control system. The disclosed invention also relates to a vehicle equipped therewith.

Owner:KONECRANES GLOBAL

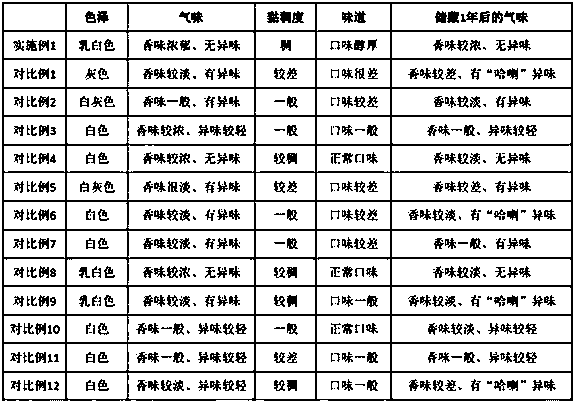

Preparation method for strong-flavor clear ox bone soup

InactiveCN110074373AIncrease the fragranceIncrease umamiSugar food ingredientsFood thermal treatmentFlavorWarm water

The invention provides a preparation method for a strong-flavor clear ox bone soup. The preparation method comprises the following steps: smashing ox bone, cleaning, soaking in warm water, cooking, filtering, centrifugally separating, emulsifying, blending, degassing, sterilizing and filling, thereby acquiring a clear ox bone soup product. On the basis of original technology, the invention improves the processes of soaking in warm water, cooking, filtering, emulsifying and degassing. Compared with the original bone soup, the clear ox bone soup produced by the invention has the advantages of milk white, strong flavor, mellow taste, rich nutrition and high stability of bone soup.

Owner:泰安市海之润食品有限公司 +1

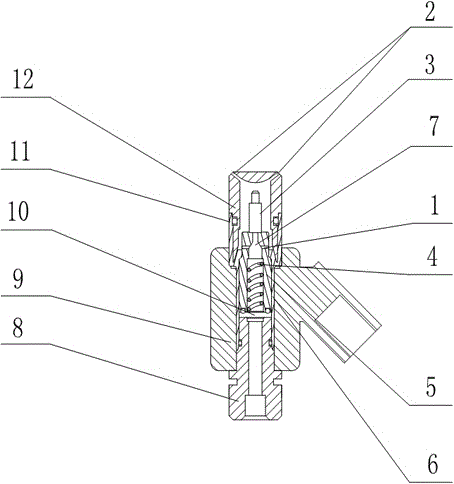

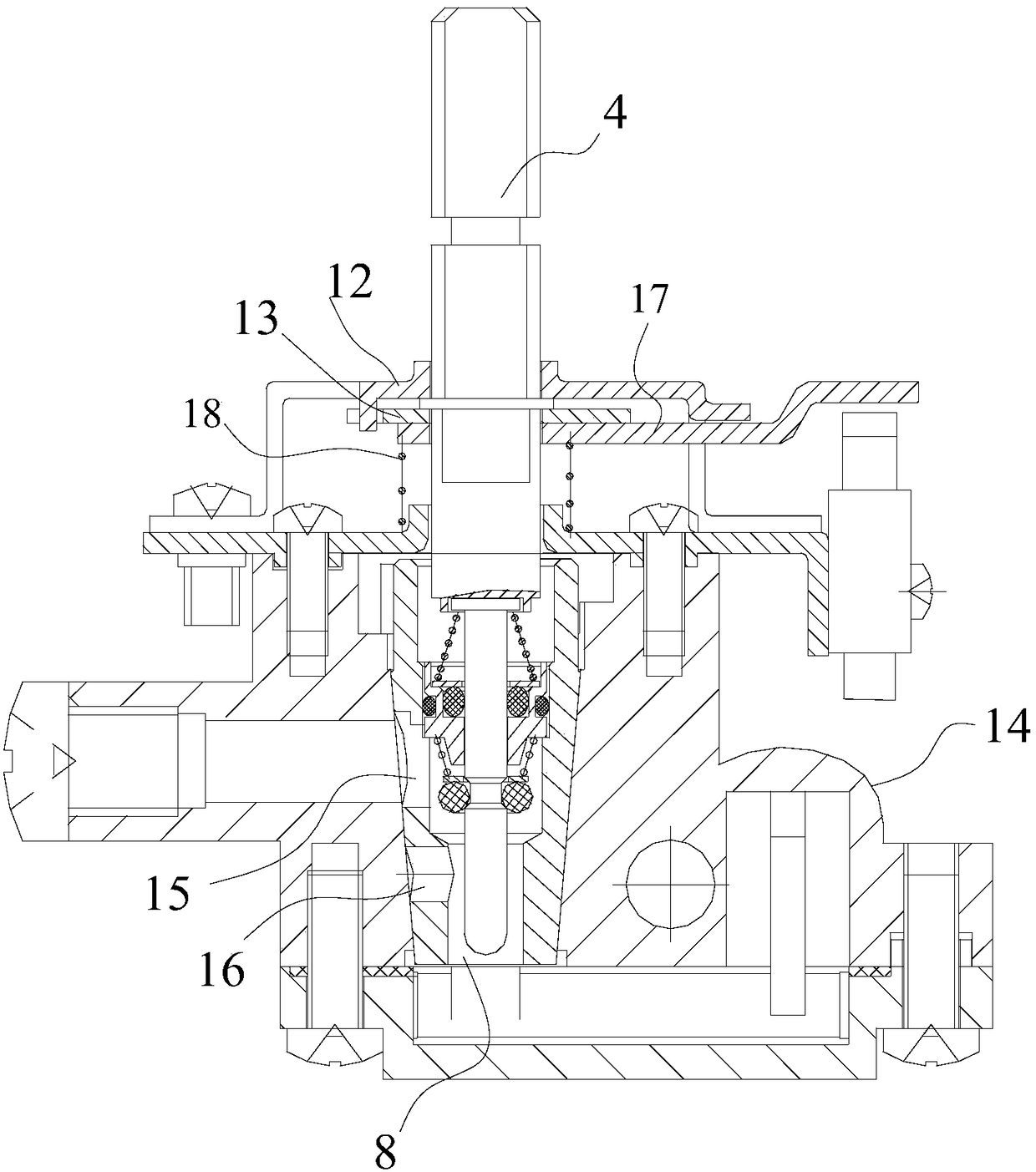

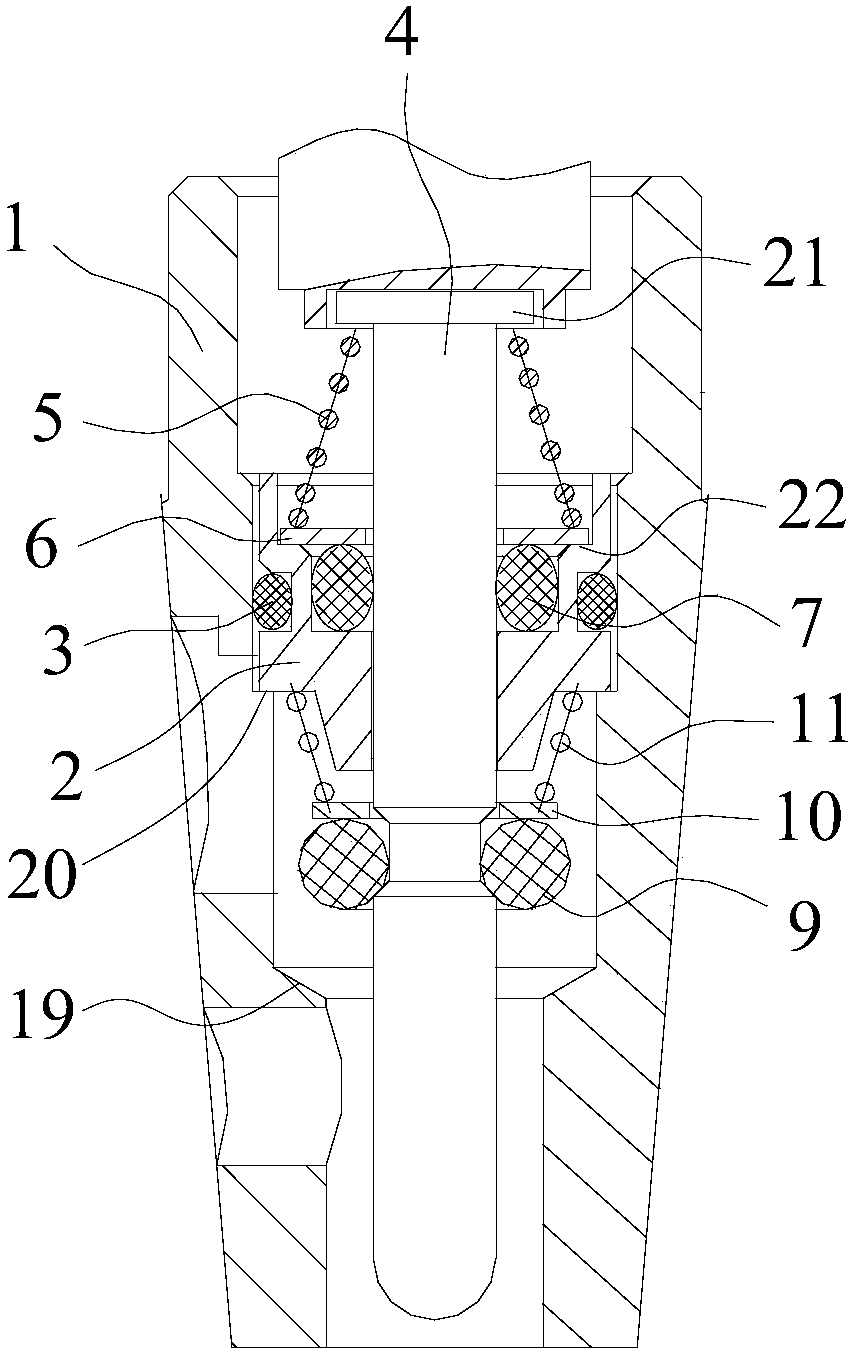

Electromagnetic valve for regulating gas flow

ActiveCN105485397AQuick changeAvoid replacementOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringGas supply

The invention discloses an electromagnetic valve for regulating gas flow. The electromagnetic valve comprises an electromagnetic valve seat, wherein a movable valve body and a casing are sequentially arranged in the electromagnetic valve seat from inside to outside, the upper end of the casing extends outwards, a connecting piece with a hollow inner part is arranged at the lower end of the casing, a gap is reserved between the upper end of the connecting piece and the lower end of the movable valve body, a valve mouth is in threaded connection with the extending end of the casing, a gas channel communicated with the middle part of the connecting piece is formed in the movable valve body, a spring is arranged in the gas channel, two through holes communicated with the gas channel are formed in the side wall of the movable valve body, the upper end of the movable valve body is communicated with the inside of the valve mouth, and multiple blowholes are formed in the circumference of the top end of the valve mouth. Compared with the prior art, under the premise of the same increase of gas input, the output of a single gas transmission channel is far lower than that of double gas transmission channels, then the change rate of gas supply quantity of a spray rail car is realized, and the gas flow is flexibly regulated and controlled.

Owner:四川省诚德蓝天环保科技有限公司

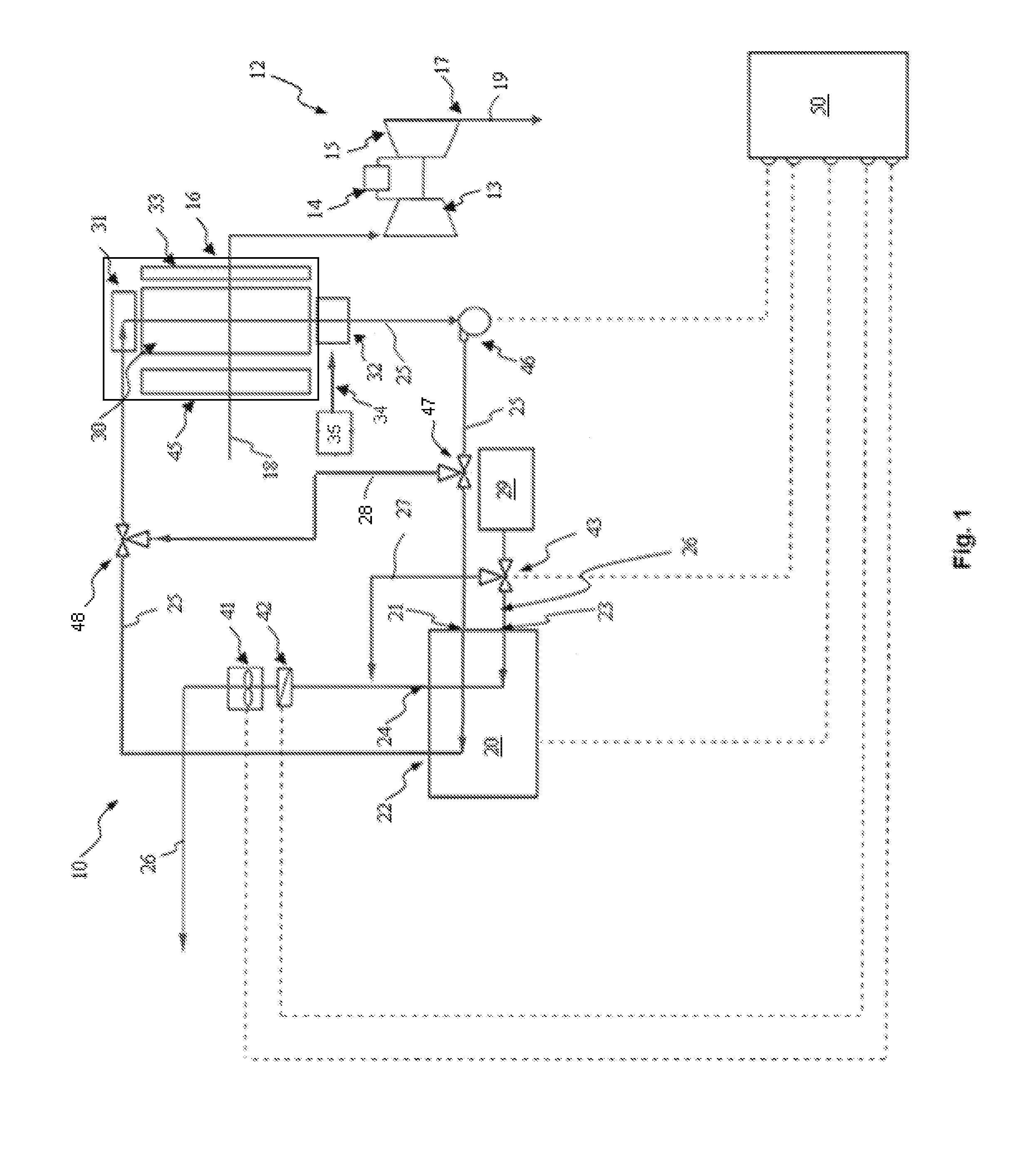

System and method for gas turbine NOX emission improvement

InactiveUS20130199192A1Reduce emissionExtend turndown rangeGas turbine plantsEngineering emergency devicesAutomotive engineeringGas turbines

In one embodiment of the present disclosure, a gas turbine system for NOx emission reduction and part load efficiency improvement is described. The system includes a gas turbine having a compressor which receives inlet-air. A direct-contact heat exchanger heats and humidifies the inlet-air before the inlet-air flows to the compressor. Heating the inlet-air reduces an output of the gas turbine and extends the turndown range. Humidifying the inlet-air can lower NOx emissions from the gas turbine unit.

Owner:GENERAL ELECTRIC CO

Flue gas waste heat recovery system for industrial gas boiler

ActiveCN114278957AEfficient recyclingIncrease profitCombustion technology mitigationFeed-water heatersIndustrial gasThermodynamics

The invention relates to a flue gas waste heat recovery system, in particular to a flue gas waste heat recovery system for an industrial gas boiler. According to the flue gas waste heat recovery system for the industrial gas boiler, the heat energy utilization rate is increased. A flue gas waste heat recovery system for an industrial gas-fired boiler comprises a base, a boiler, a discharge flue, an energy saver, a pressurization box, a water inlet pipe, a pressurization rod and the like. A boiler is arranged on the left side of the top of the base, a discharge flue is arranged on the right upper portion of the boiler, an energy saver is arranged on the right side of the top of the base and connected with the boiler, pressurizing boxes are connected between the front side and the rear side of the lower portion of the discharge flue and the energy saver, water inlet pipes are connected between the right upper portion of the discharge flue and the lower portions of the pressurizing boxes, and pressurizing rods are arranged on the upper portions of the pressurizing boxes in a sliding mode. When the driving mechanism operates, the four first shifting blocks are driven to intermittently flap the water inlet pipe, so that water drops condensed and attached to the outer wall of the coiled pipe drop downwards, and flue gas waste heat recovery is prevented from being affected.

Owner:江西方德能源环境工程有限公司

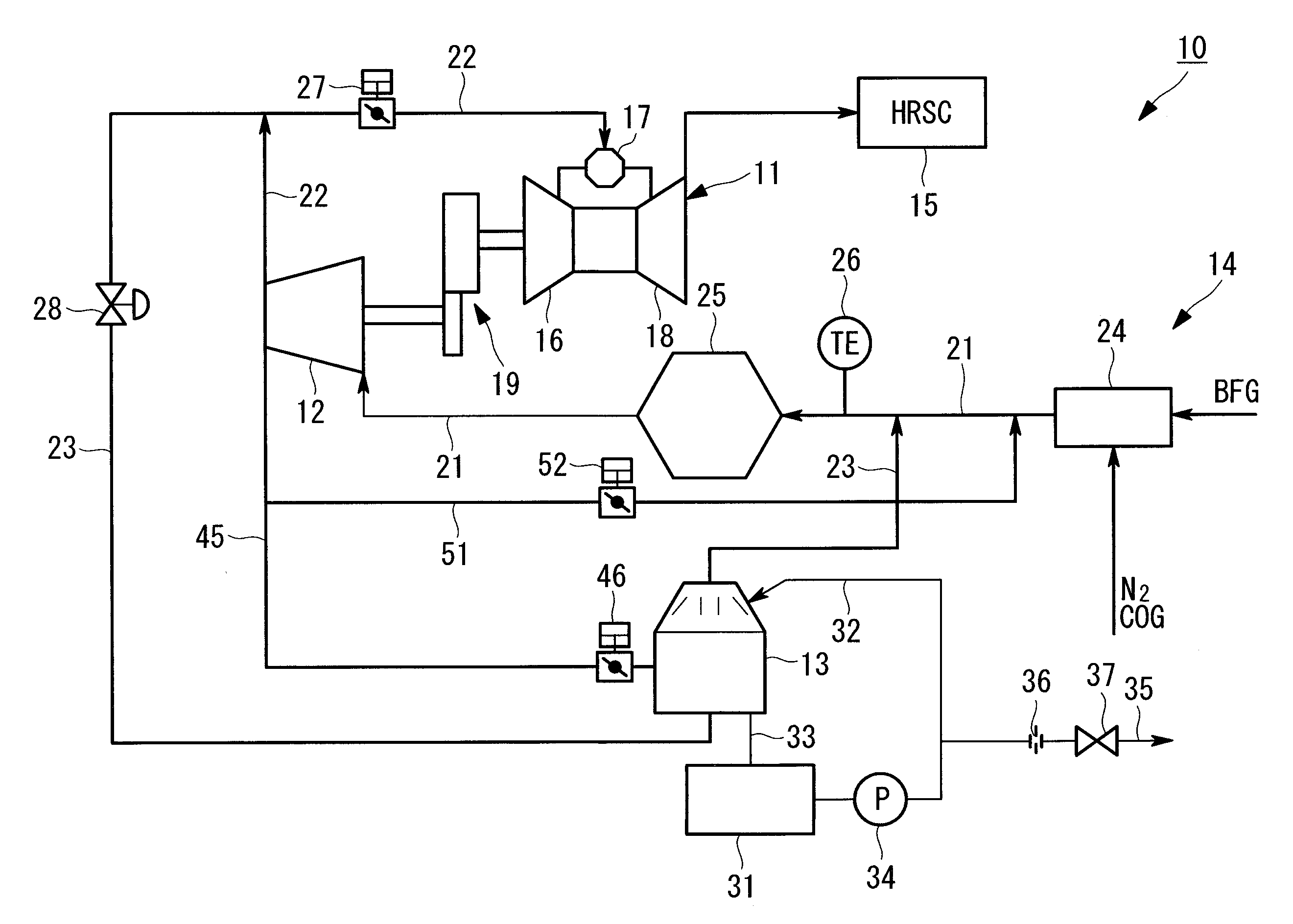

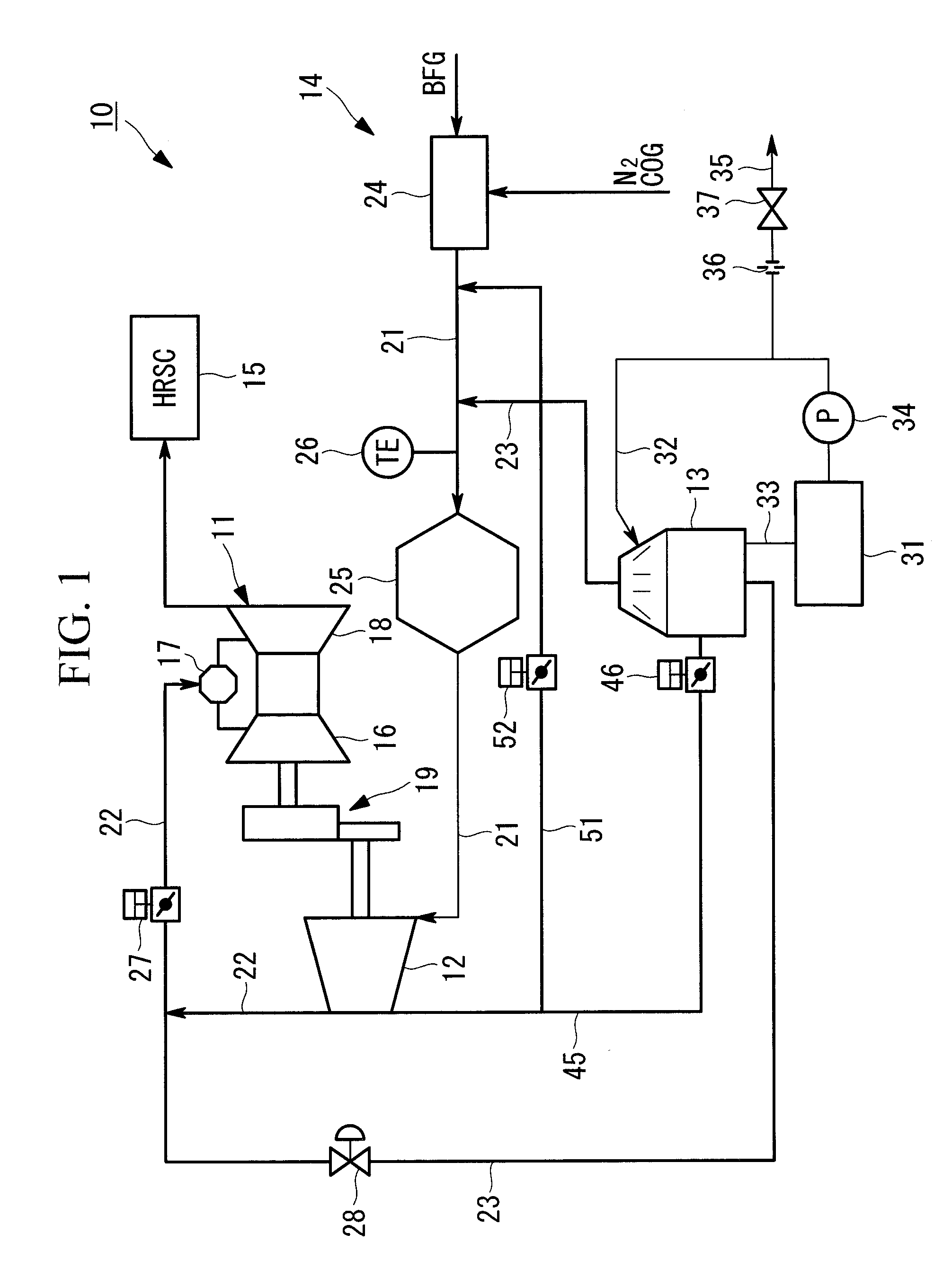

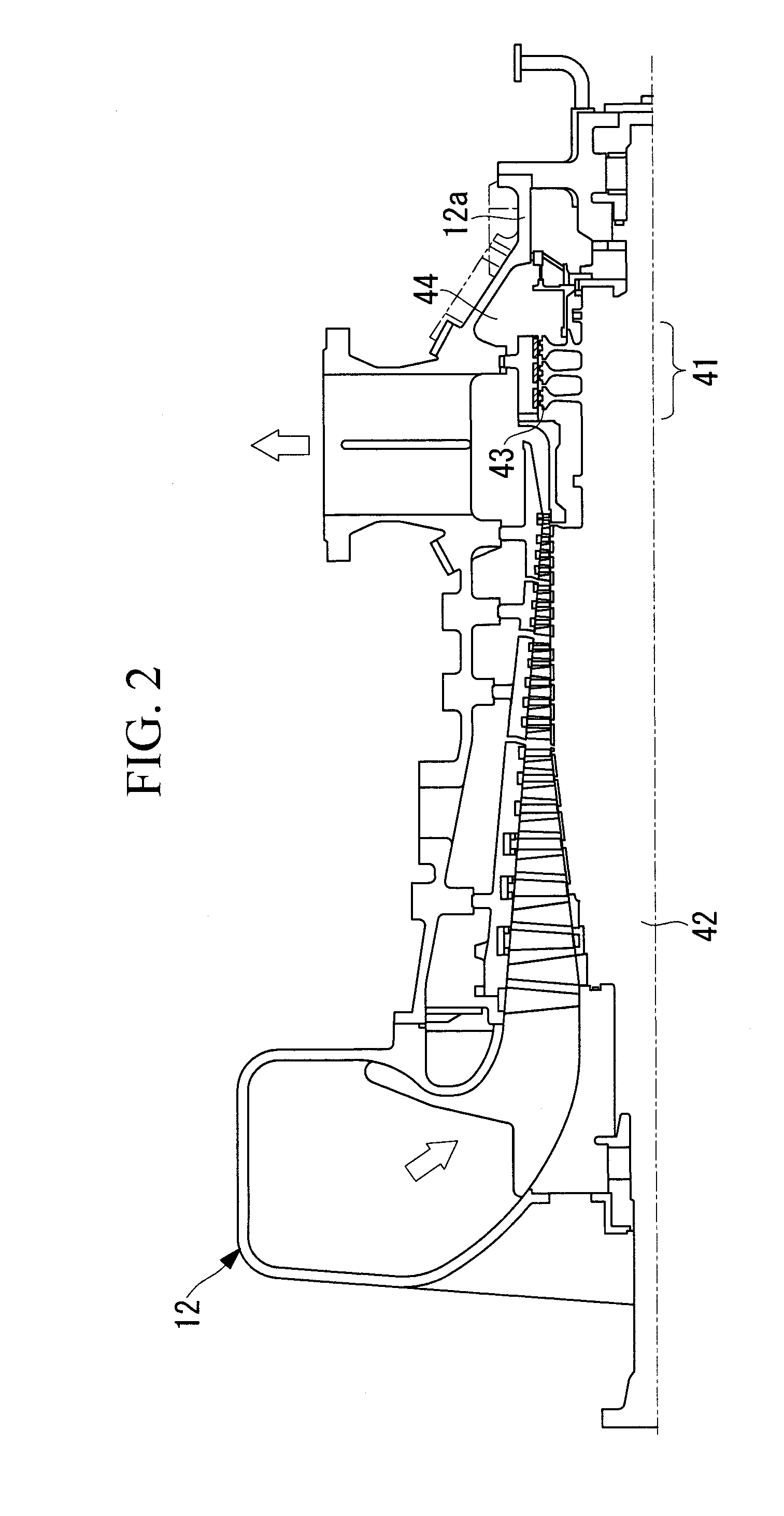

Power plant

ActiveUS20120137693A1Increase temperatureReduce gas outputEngine fuctionsTurbine/propulsion fuel heatingPower stationNuclear engineering

Provided is a power plant including a gas turbine that uses a fuel gas as a fuel; a fuel gas cooler that cools the fuel gas, which is to be pressurized in a fuel gas compressor and re-circulated, using cooling water; and a dust collection device that separates / removes impurities from the fuel gas that is to be guided to the fuel gas compressor; wherein the power plant further includes heating means that heats the fuel gas that is to be guided to the dust collection device using the fuel gas that has been used to generate an anti-thrust force acting on a rotor of the fuel gas compressor.

Owner:MITSUBISHI POWER LTD

A gas cock valve

ActiveCN106051200BReasonable range of motionReduce gas outputSpindle sealingsPlug valvesDetonationGas supply

Owner:ZHEJIANG XINTAO ELECTRONICS MACHINERY

Aircraft propulsion system

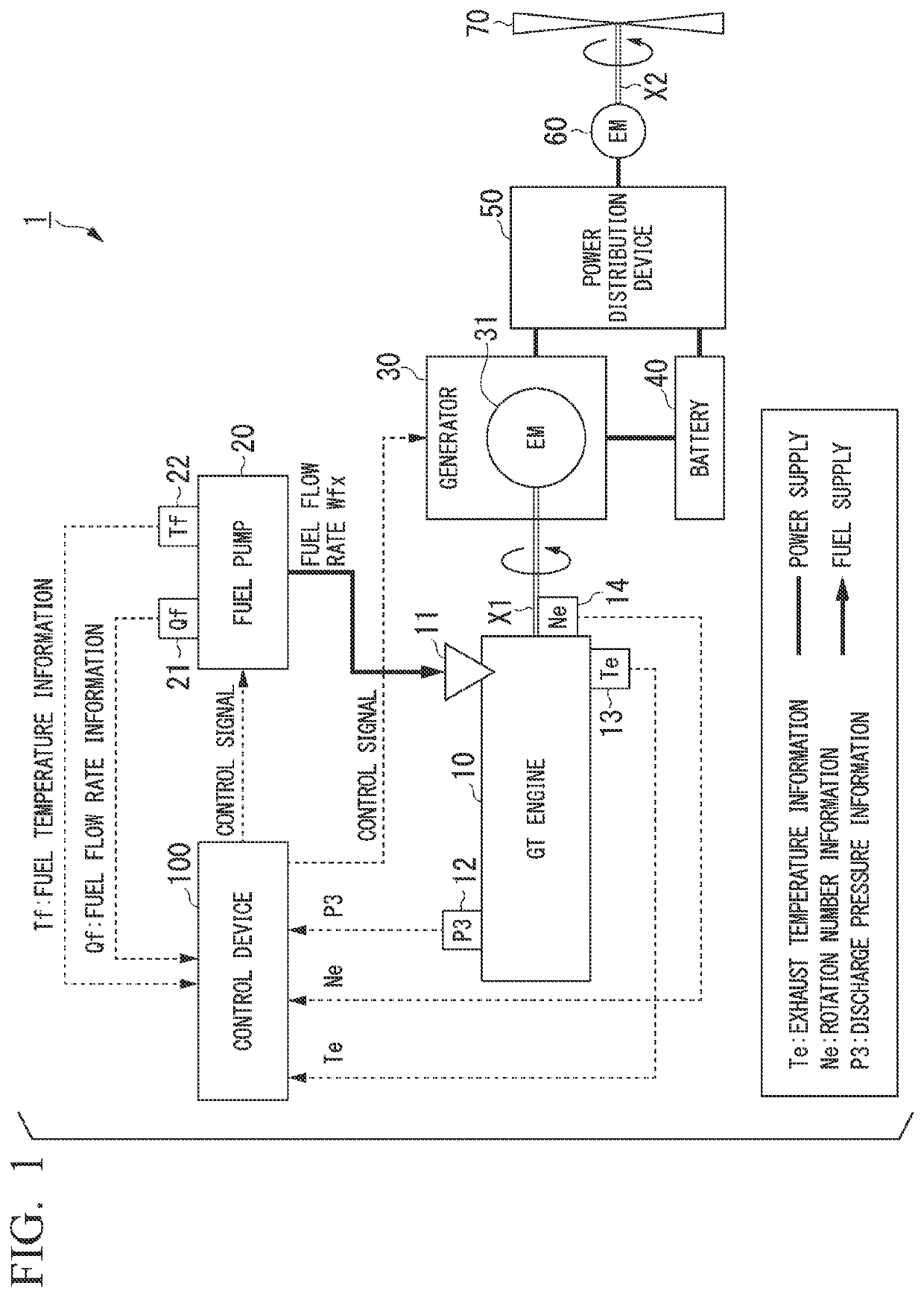

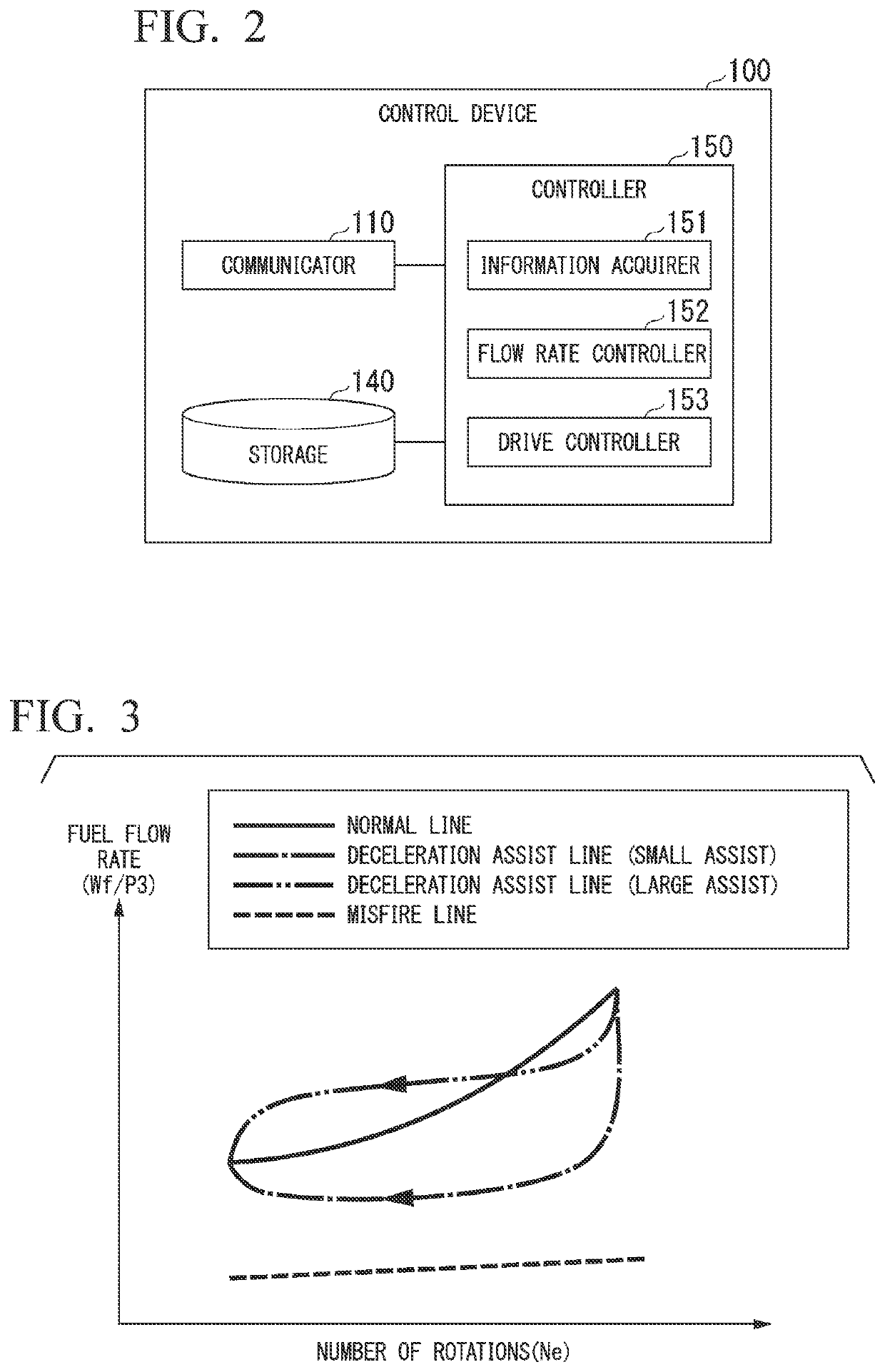

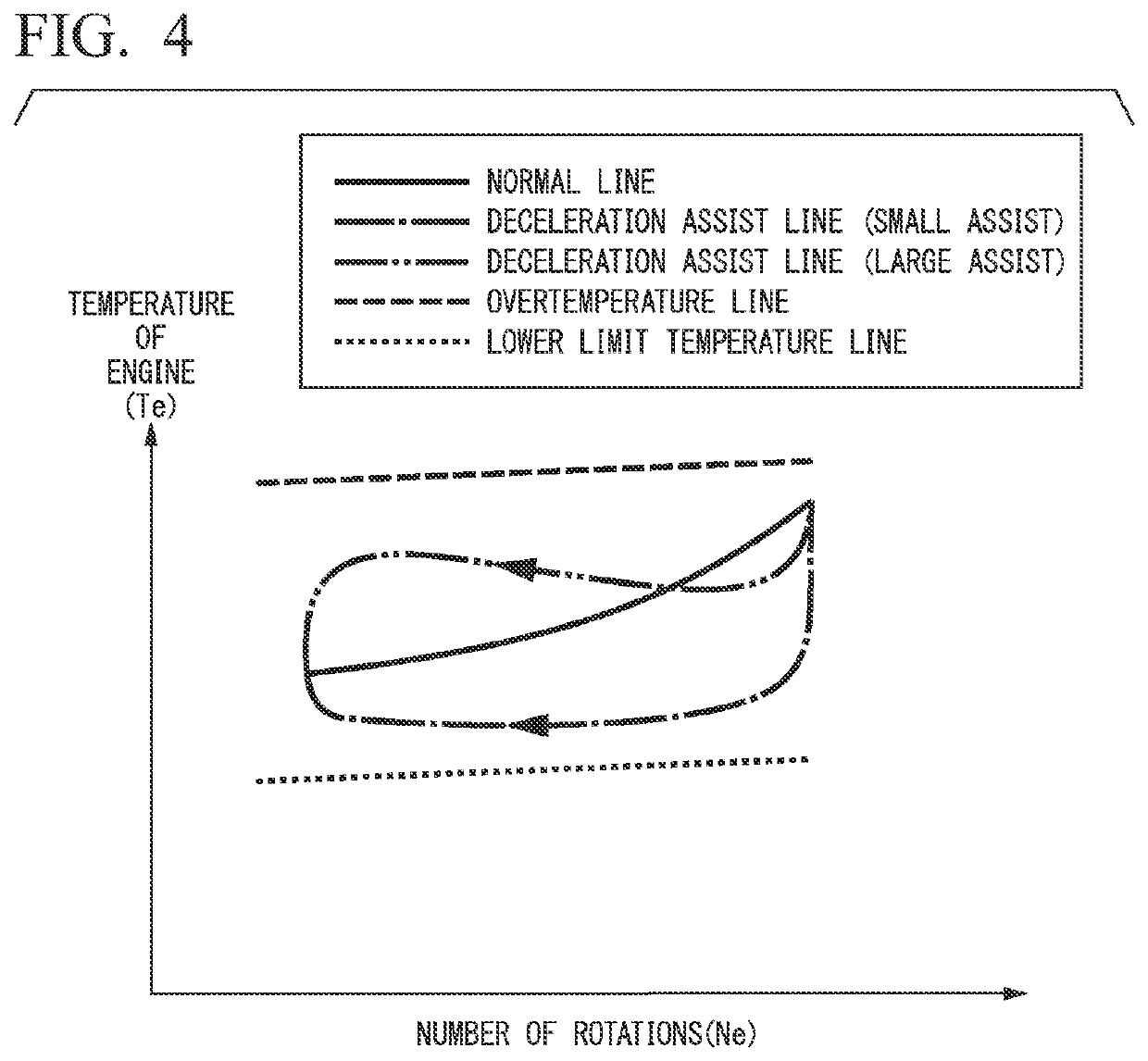

PendingUS20220290576A1Reduce gas outputReduce outputGas turbine type power plantsTurbine/propulsion fuel controlFlight vehicleRotor (electric)

An aircraft propulsion system includes: a gas turbine engine attached to an airframe of an aircraft; a generator connected to an engine shaft of the engine; a first electric motor driven using electric power including electric power generated by the generator; a rotor attached to the airframe of the aircraft and driven using a driving force output by the first electric motor; and a control device configured to control an operating state of the engine. The control device includes a flow rate controller which reduces the flow rate of fuel supplied to the engine so that the engine does not misfire when a decrease in output of the engine is promoted using a driving force output by a second electric motor included in the generator, and a drive controller which controls the magnitude of the driving force output by the second electric motor so that the temperature of the engine does not exceed an allowable temperature.

Owner:HONDA MOTOR CO LTD

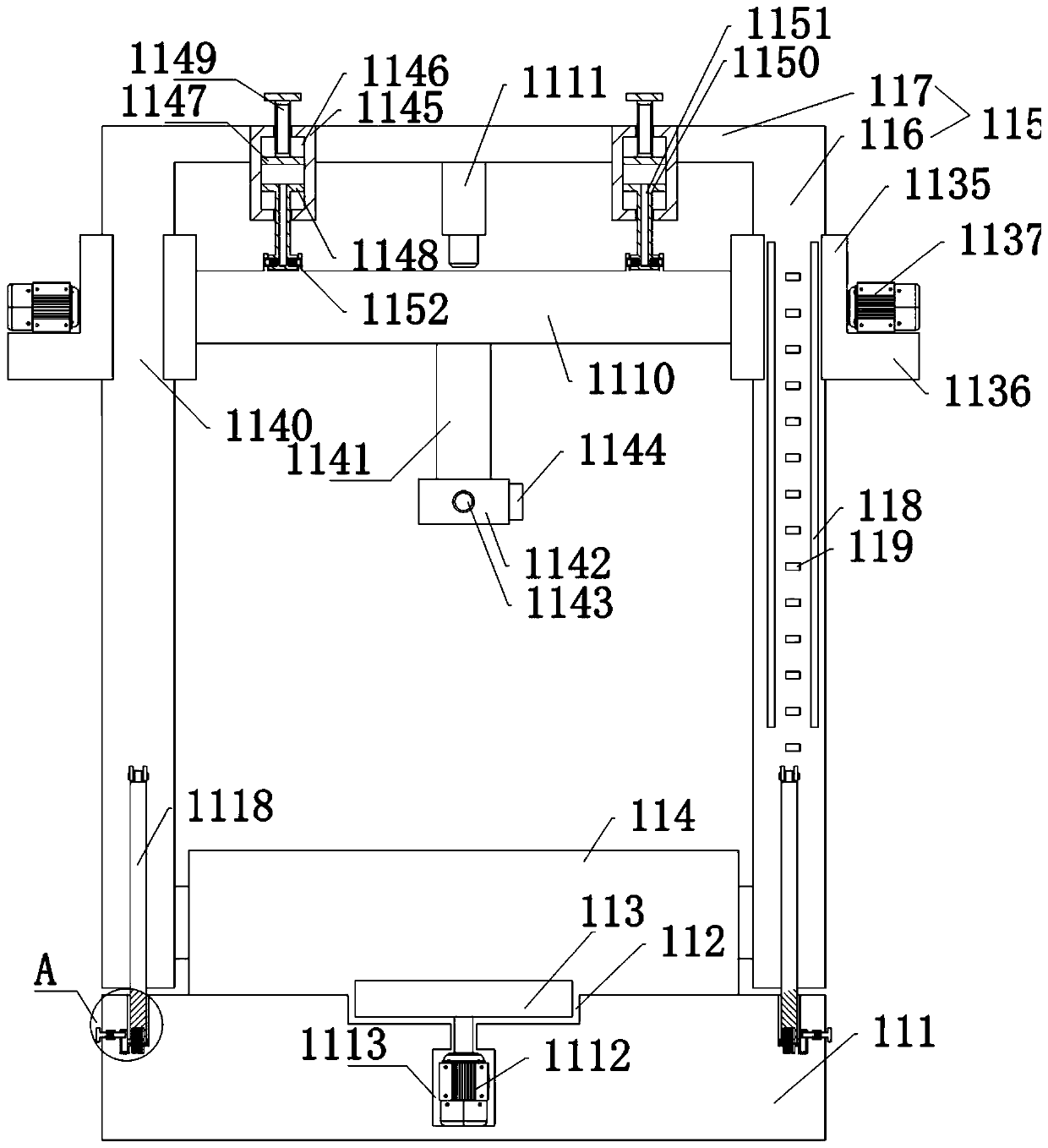

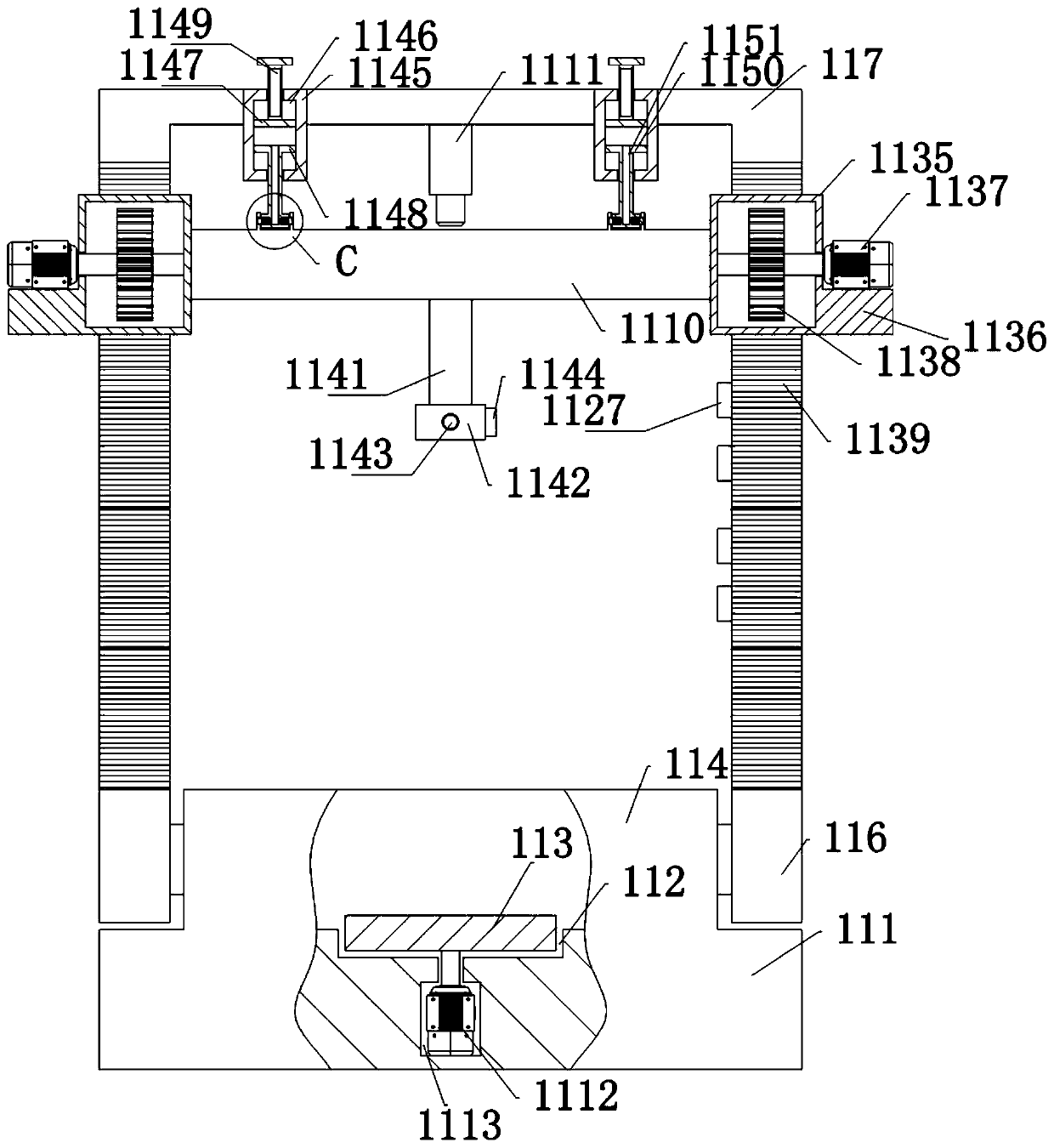

Adjustable school uniform ironing process for school uniform made of natural plant dyed fabric

ActiveCN112011942AAdjust ironing parametersReduce friction and collisionTextile treatment by spraying/projectingTextile shapingMechanical engineeringIndustrial engineering

The invention provides an adjustable school uniform ironing process for a school uniform made of natural plant dyed fabric. A conveying belt is installed in a support, and an ironing die is installedon the support; the ironing die comprises two first rails, a telescopic ironing device is slidably mounted between the two first rails, and a school uniform body ironing device is arranged on the telescopic ironing device; and each second rail is provided with a sleeve ironing device in a sliding mode, and the sleeve ironing devices are driven by a second power devices. The ironing die corresponding to the standard school uniform is used for ironing, no dead angle exists in the ironing process, and when standard school uniform of different sizes is ironed, only the corresponding ironing die needs to be replaced; and the school uniform body and the sleeves are ironed separately, so that ironing parameters can be adjusted conveniently according to the characteristics of the ironed parts, andthe uniform is more stretched and attractive.

Owner:WEIFANG SUNTECH GARMENT CO LTD

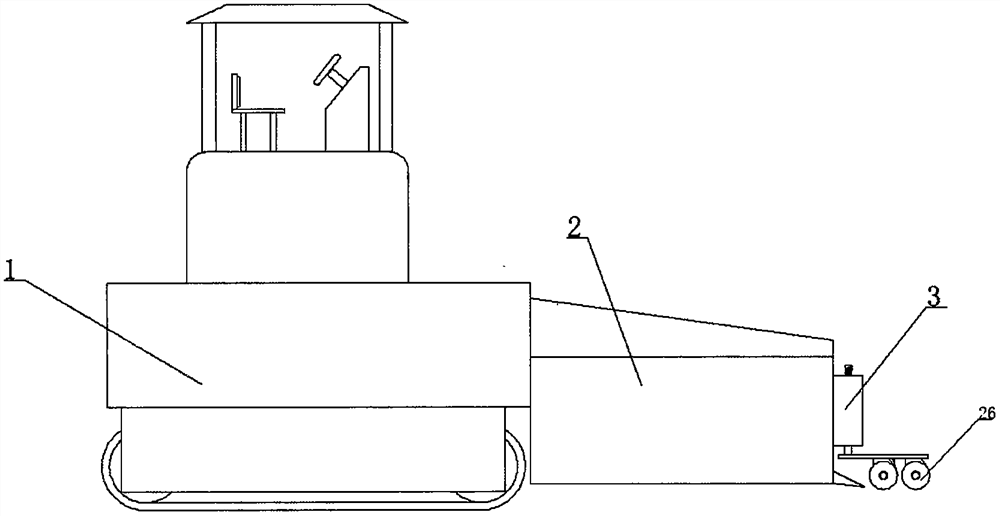

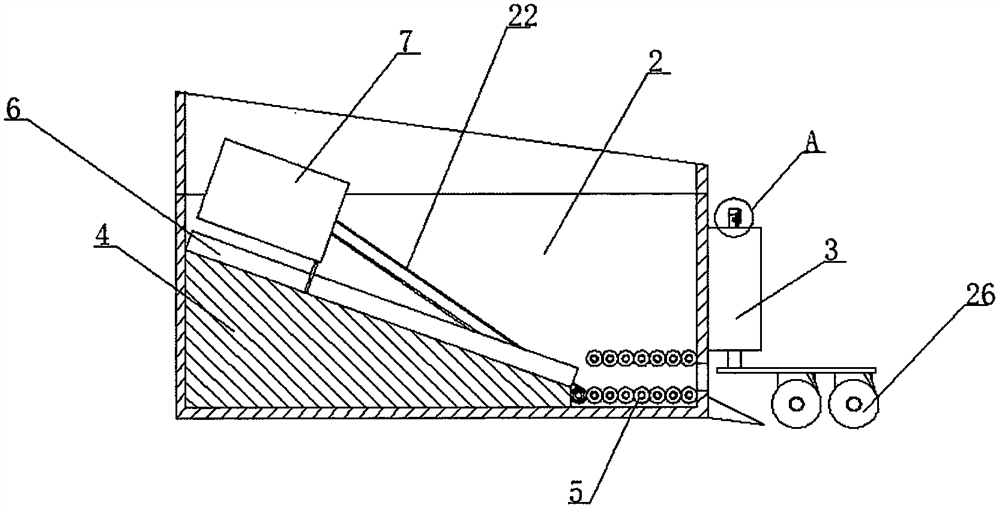

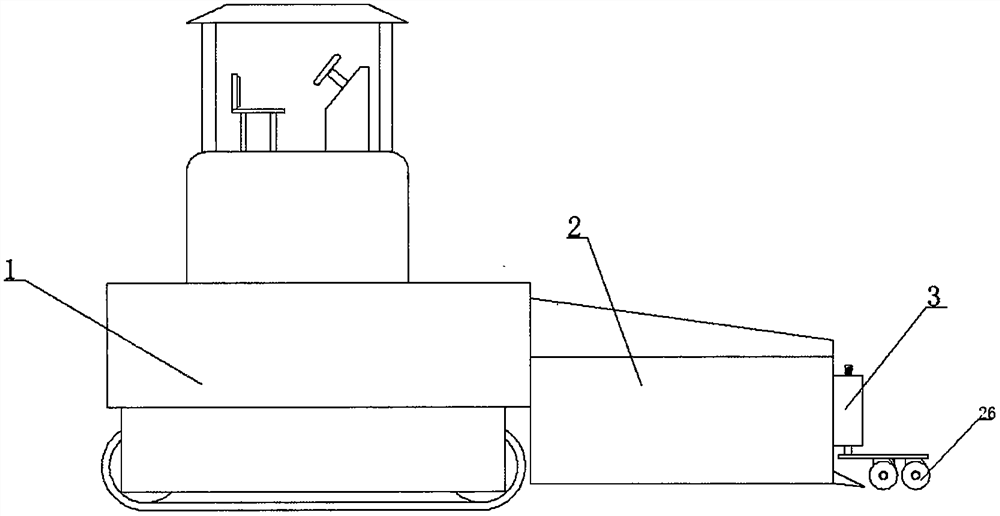

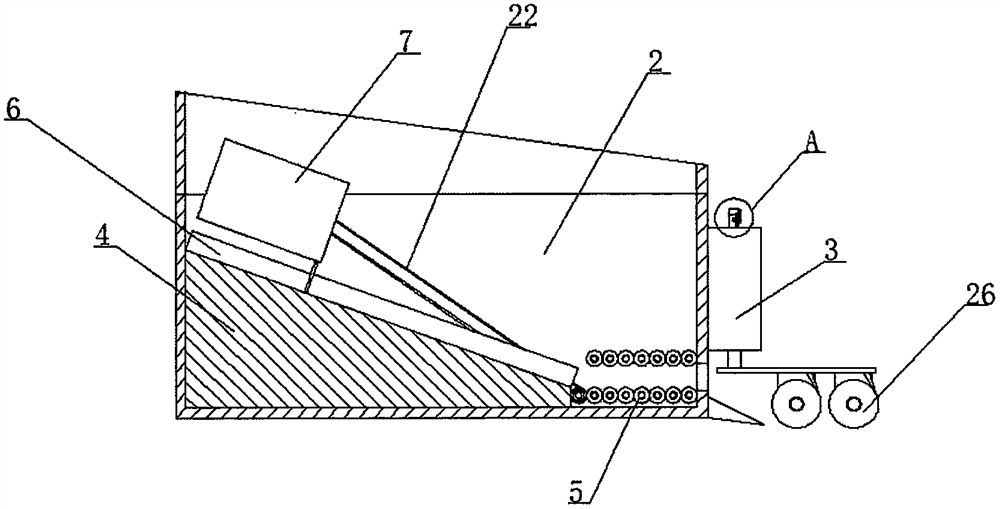

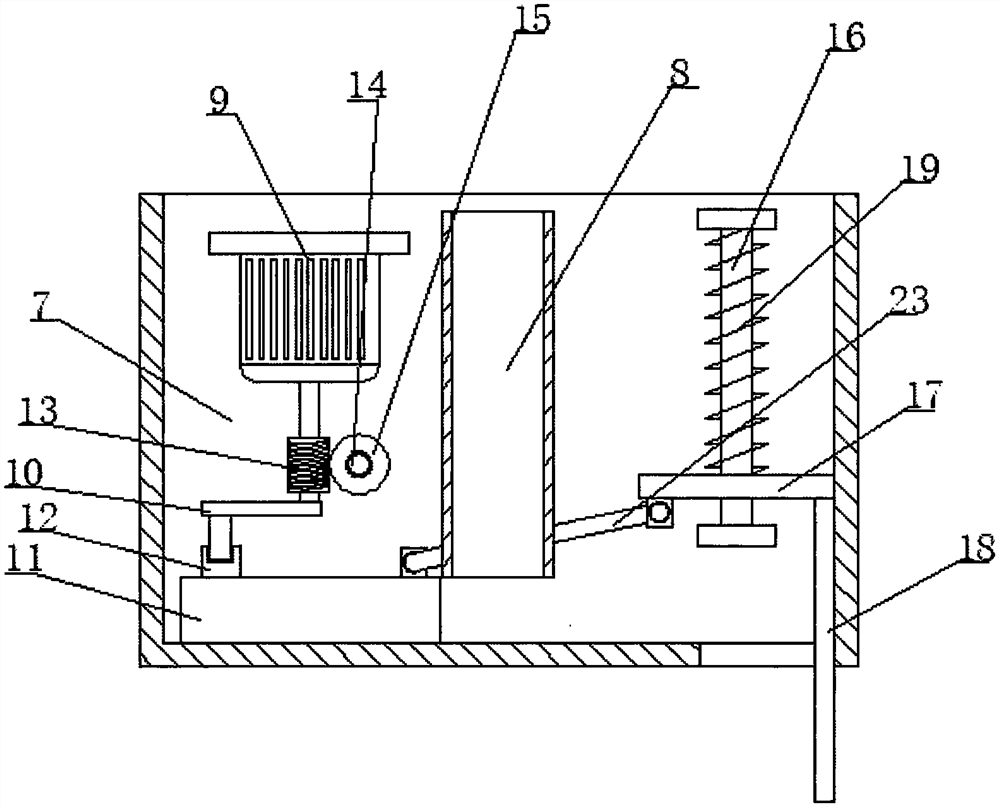

Paver for municipal engineering construction and construction method thereof

ActiveCN113073520AAvoid damageIncrease elasticityRoads maintainenceStructural engineeringAutonomation

The invention belongs to the field of municipal machinery, particularly relates to a paver for municipal engineering construction and a construction method of the paver, and provides the following scheme aiming at the problems that an existing adopted automatic paver is high in cost on one hand, complex in operation on the other hand and partially needs to be operated manually. The scheme is that the paver comprises a machine body, a mounting box is fixedly mounted on one side of the machine body, an inclined panel is fixedly mounted on the inner wall of the bottom of the mounting box, a plurality of conveying rollers are rotatably connected into the mounting box at equal intervals, a discharging hole is formed in the inner wall of the bottom of one side of the mounting box, and the conveying rollers are all located on one side of the inclined panel. Enclosures are fixedly installed on both sides of the inclined panel. According to the paver, automatic floor tile laying can be achieved, and the floor tiles can be compacted after being laid, so that manual laying can be effectively replaced, the manual use cost is greatly reduced, the working efficiency can be effectively improved, and therefore the paver has good practicability.

Owner:JINAN MUNICIPAL ENG CONSTR GRP CO LTD

School uniform made from natural plant dyed fabric and intelligent production line of school uniform

ActiveCN109730375AImprove dyeing effectHas natural antibacterial effectUniformsTextile treatment by spraying/projectingProduction lineEngineering

The invention provides a school uniform made from a natural plant dyed fabric and an intelligent production line of the school uniform. The production method comprises the following steps: adopting cloth made from gardenia fruit natural plant dyes, sequentially performing figure measure and sampling on the students, determining models of the school uniform, cutting the natural plant dyed fabric, sewing and forming the natural plant dyed fabric, pressing after molding, cocking, packing and warehousing. The intelligent production line of the school uniform made from the natural plant dyed fabricsequentially comprises intelligent student sampling and figure measuring equipment, digital school uniform model equipment, a cloth cutting unit, a sewing machine and adjustable school uniform pressing equipment according to the production process. The cloth made from gardenia fruit natural plant dyes is excellent in dyeing effect, has a natural antibacterial effect and is favorable for ecological environmental protection and student health; and the figure measure data of the students on the production line is accurate, the clothing sample is accurate in model, convenient and rapid, and the school uniform can be smooth and beautiful specified at split pressing of the style of the school uniform.

Owner:潍坊尚德服饰有限公司

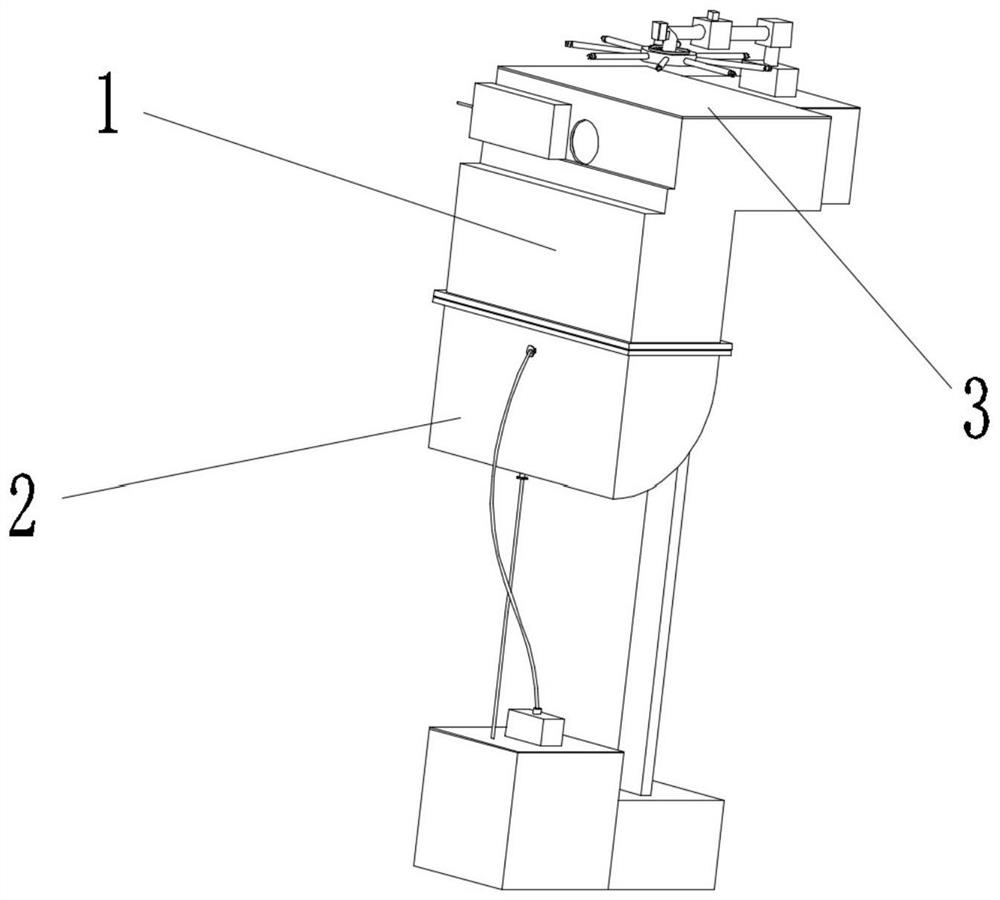

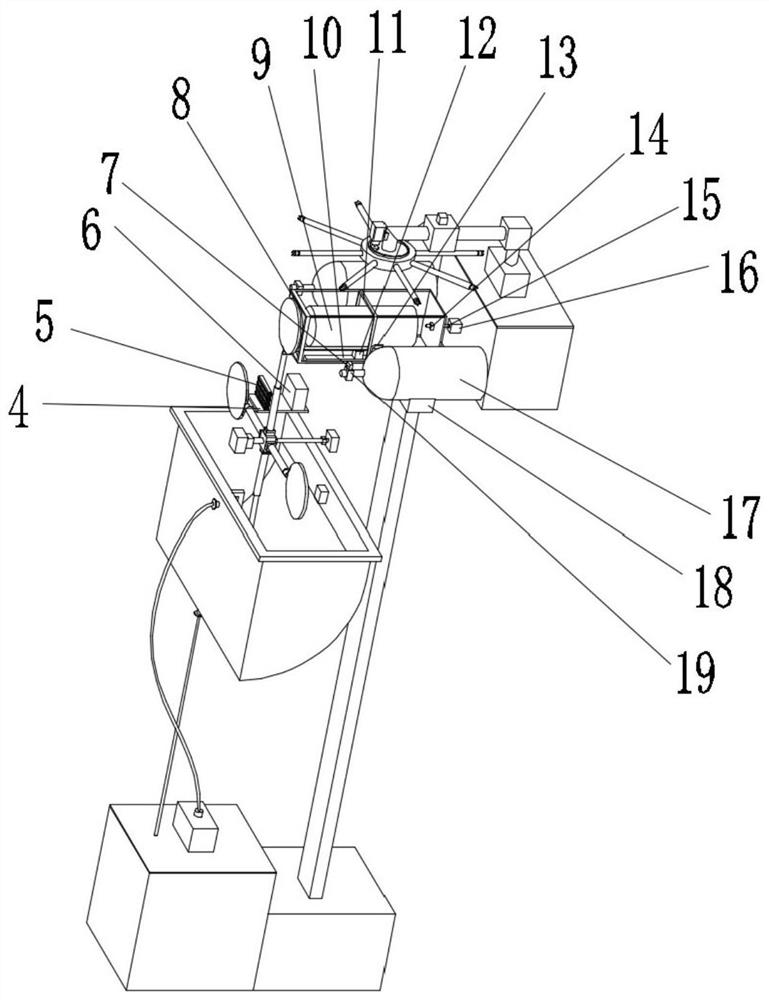

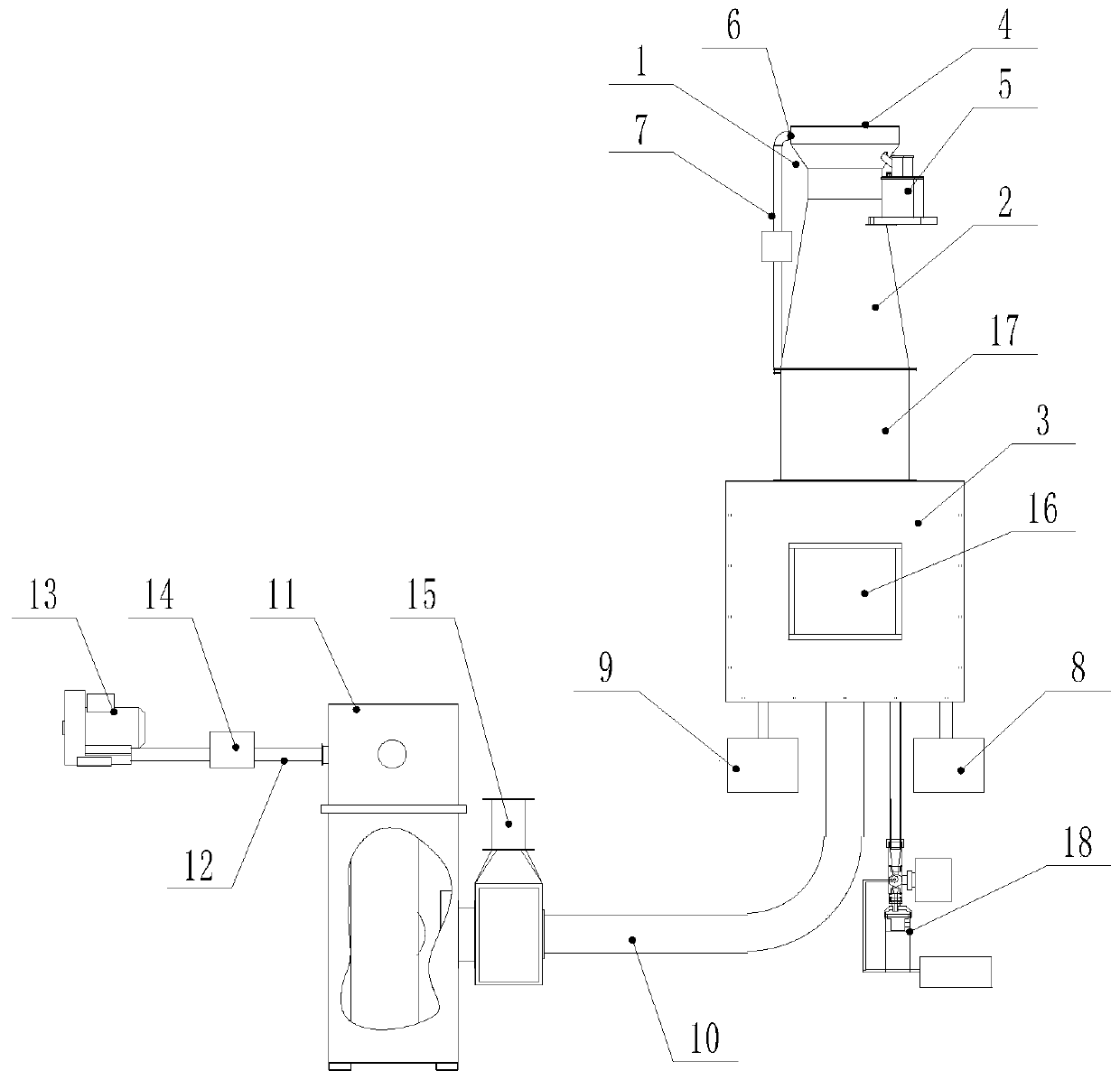

Calibration system and calibration method for aerodynamic particle size spectrometer

PendingCN110441202AImprove Calibration AccuracyImprove accuracyDispersed particle filtrationParticle size analysisAirflowEngineering

Owner:张家港谱析传感科技有限公司

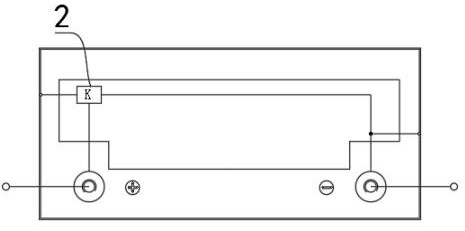

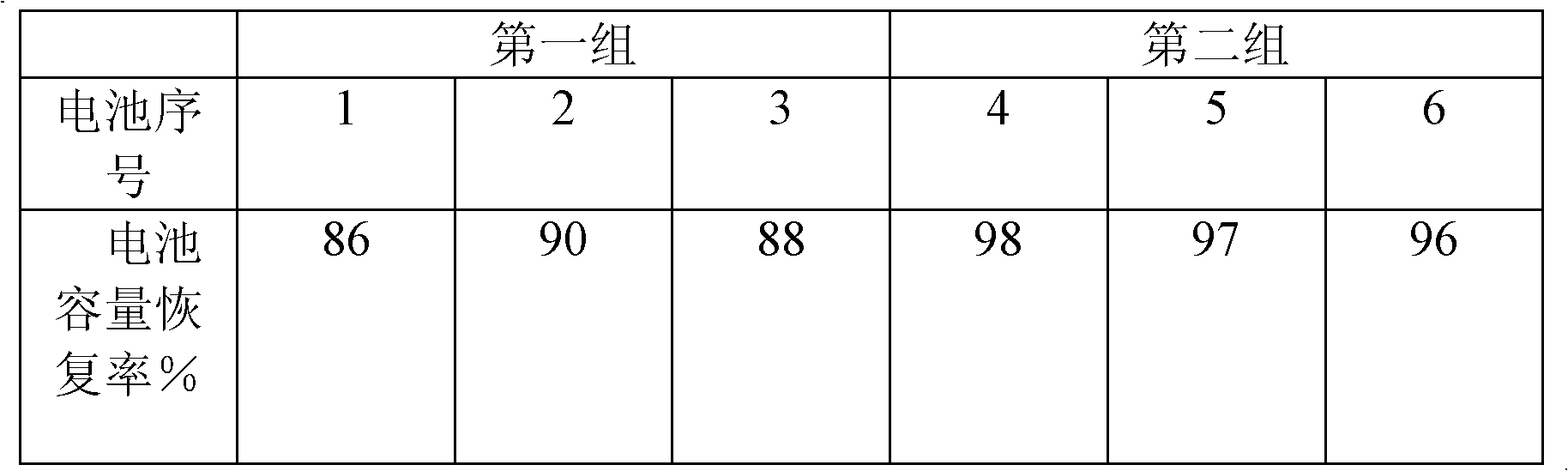

Storage battery low-temperature charging and discharging method based on temperature compensation

ActiveCN111682274AAvoid life-shortening conditionsMeet the needs of low temperature and sufficient chargingLead-acid accumulatorsSecondary cells charging/dischargingFloating chargeElectrical battery

The invention discloses a storage battery low-temperature charging and discharging method based on temperature compensation. The method comprises the following steps that 1) when the environment temperature is lower than -10 DEG C during charging and discharging of a battery, a temperature compensation device is started to raise the temperature; (2) in a low-current 0.05-0.1 CA pre-charging judgment stage, charging reaches 0.3-0.4 H, if the voltage of a single battery cell does not reach 2V, the charger gives an alarm to display abnormality, and charging is ended; 3) segmented charging, concretely, in the first stage, the constant current is 0.21-0.24 CA until the voltage of a battery cell is 2.4 V, or the charging time reaches 1-4H; in the second stage, the constant current is 0.1-0.2 CAuntil the single-cell voltage of the battery is 2.45 V or the charging time reaches 3-8H; in the third stage, the current is limited to be 0.01-0.05 CA, the constant voltage of a single cell of the battery is 2.48 V, the current is lower than 0.01, or charging reaches 1-2H; in the fourth stage, the constant current is 0.07-0.08 CA until the voltage of a single cell of the battery is 2.5 V and thecharging time reaches 0.5 H; and in the fifth stage, the voltage of the cell of the battery is limited to 2.29-2.3 V, and the current is limited to 0.005-0.02 CA for long-time floating charge. According to the storage battery low-temperature charging and discharging method based on temperature compensation, the problem that the service life is shortened due to insufficient charging of the storagebattery at a low temperature can be avoided.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

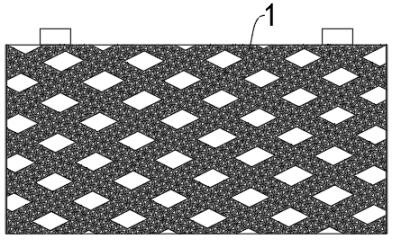

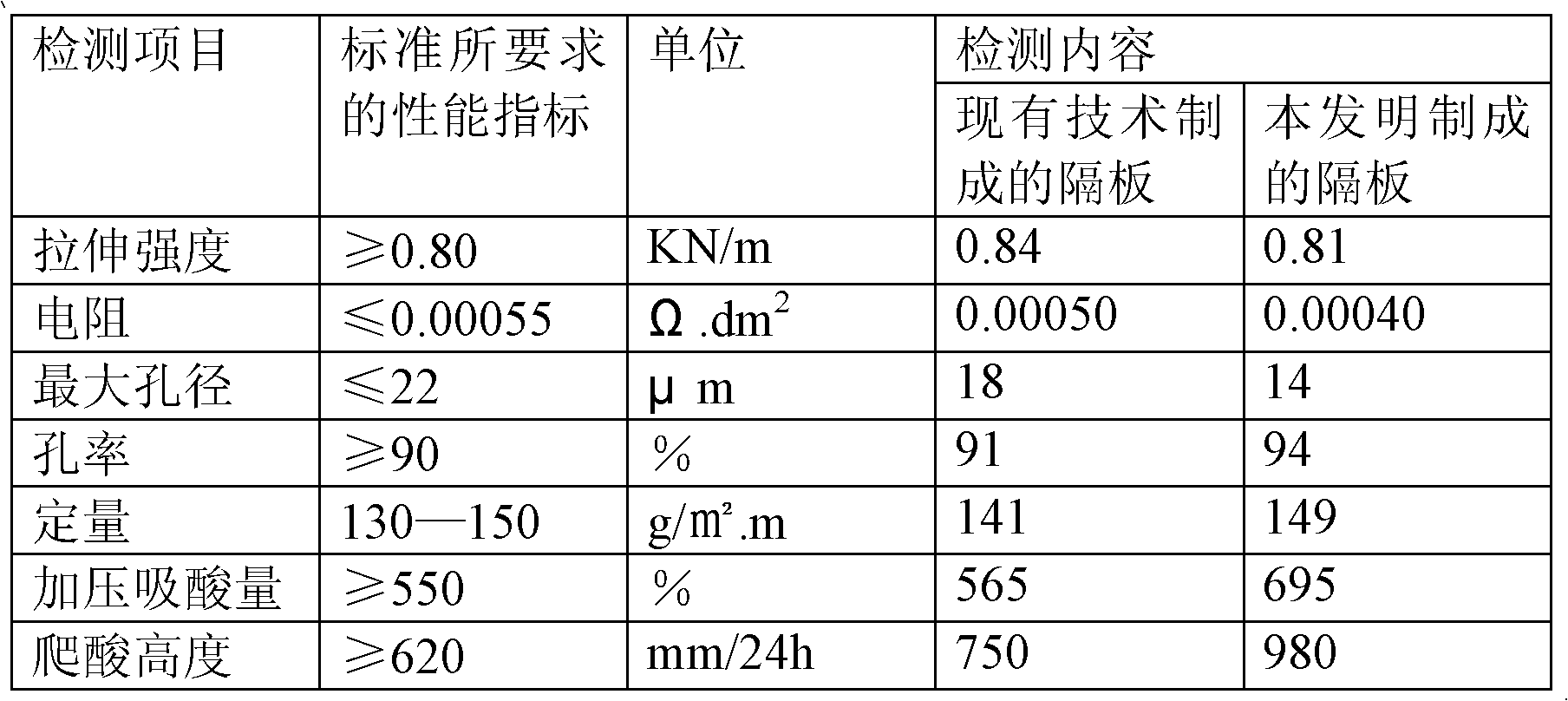

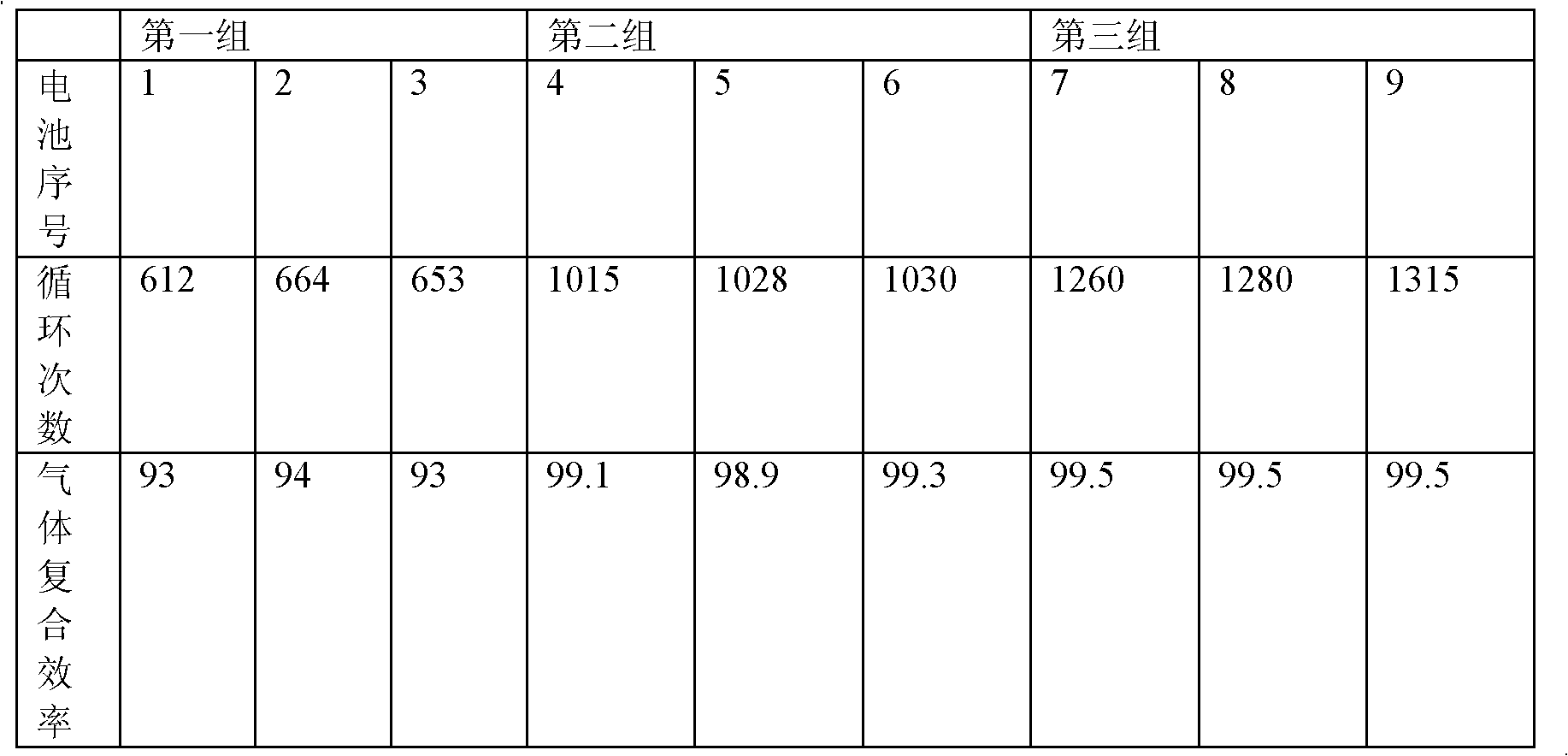

Colloid storage battery separator and preparation method thereof

The invention relates to a colloid storage battery separator and a preparation method thereof. The colloid storage battery separator comprises the following raw materials in part by weight: 100 parts of ultrafine glass fibers, 4 to 20 parts of silicon dioxide powder and 2 to 8 parts of modified kieselguhr. The modified kieselguhr is prepared by drying kieselguhr, adding a sulfuric acid solution into the dried kieselguhr, then adding a polyfluortetraethylene emulsion and drying the mixture. For a battery formed by the separator, the circulating life of the battery can be prolonged, the air outlet of the battery is reduced, acid liquor can be uniformly distributed in the battery and meanwhile, the micro short circuit of the battery, which is caused by a lead dendritic crystal penetration separator, can be effectively prevented.

Owner:SHANDONG LIAOCHENG UNIVERSAL GLASS CO LTD

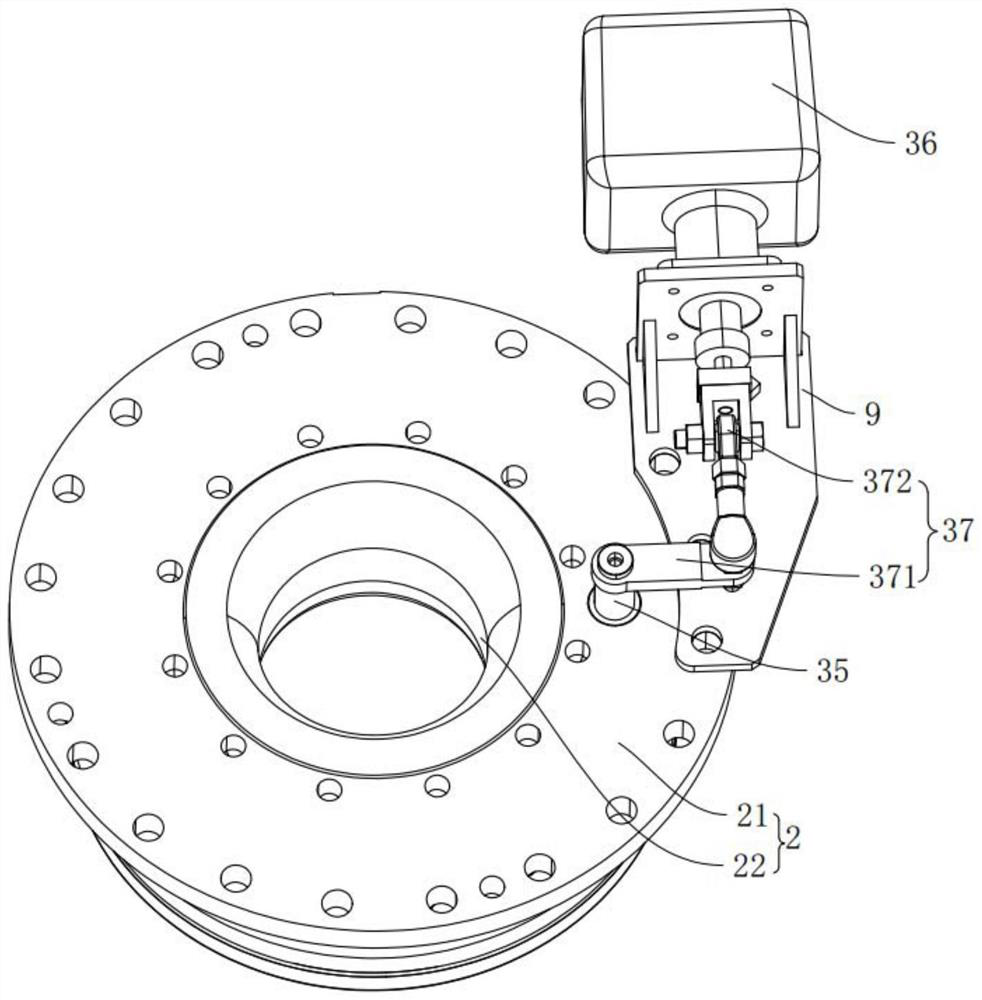

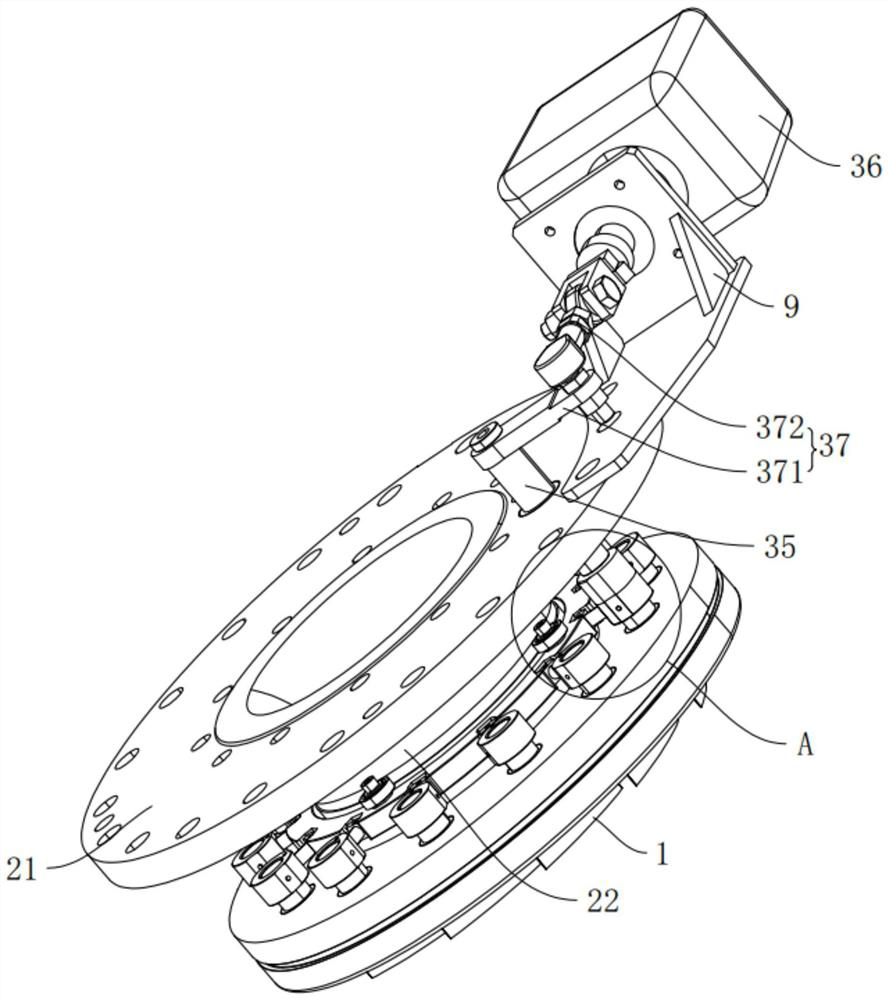

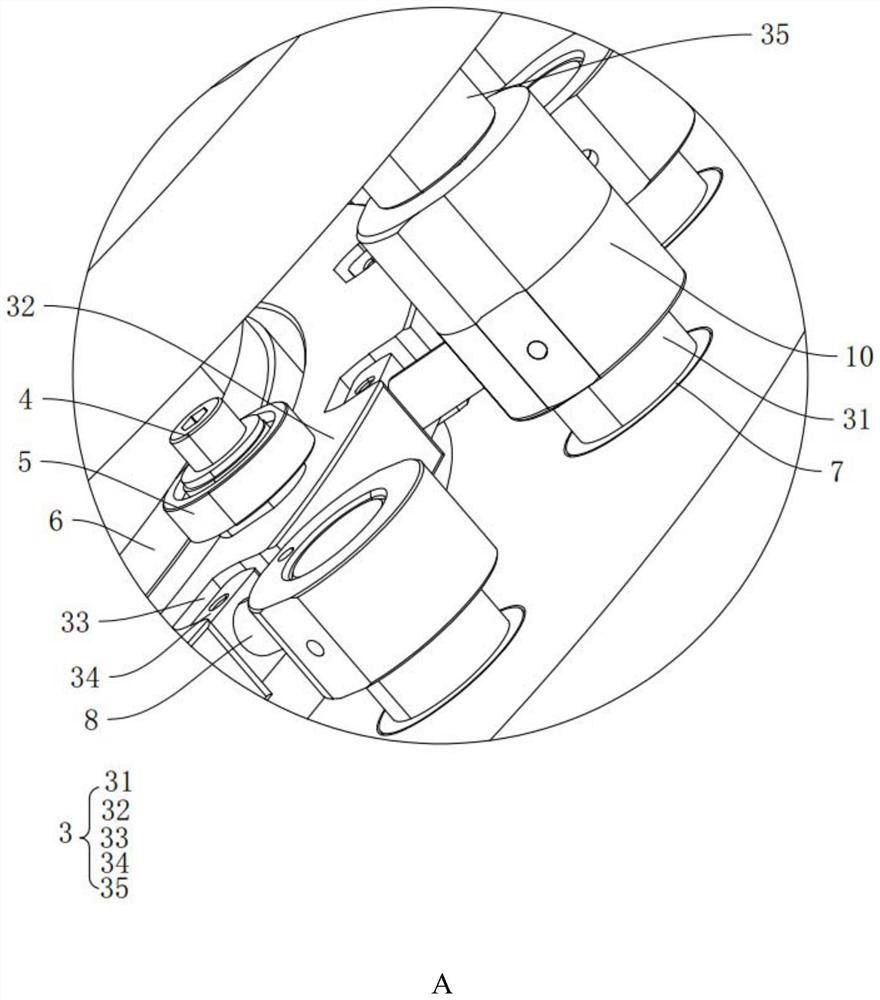

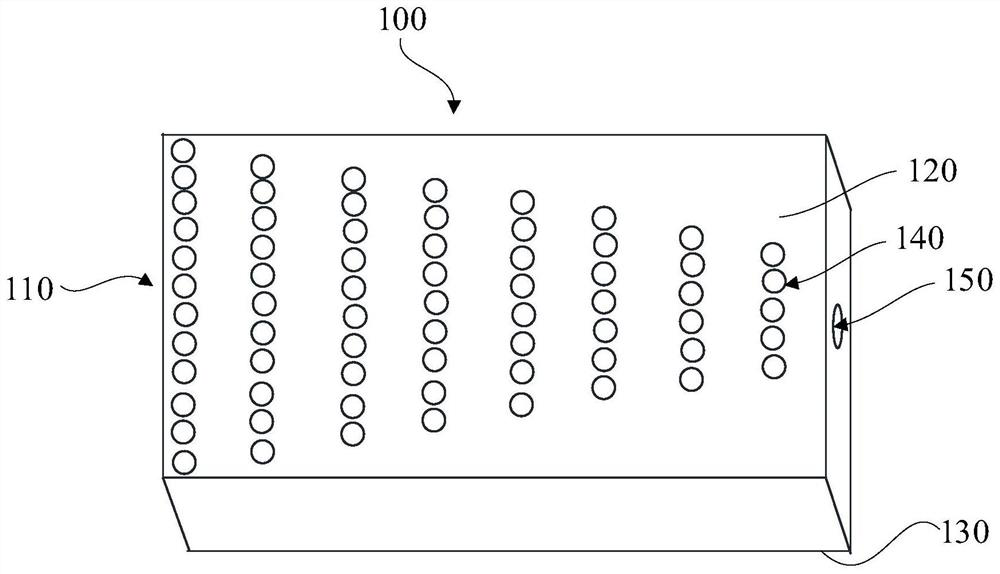

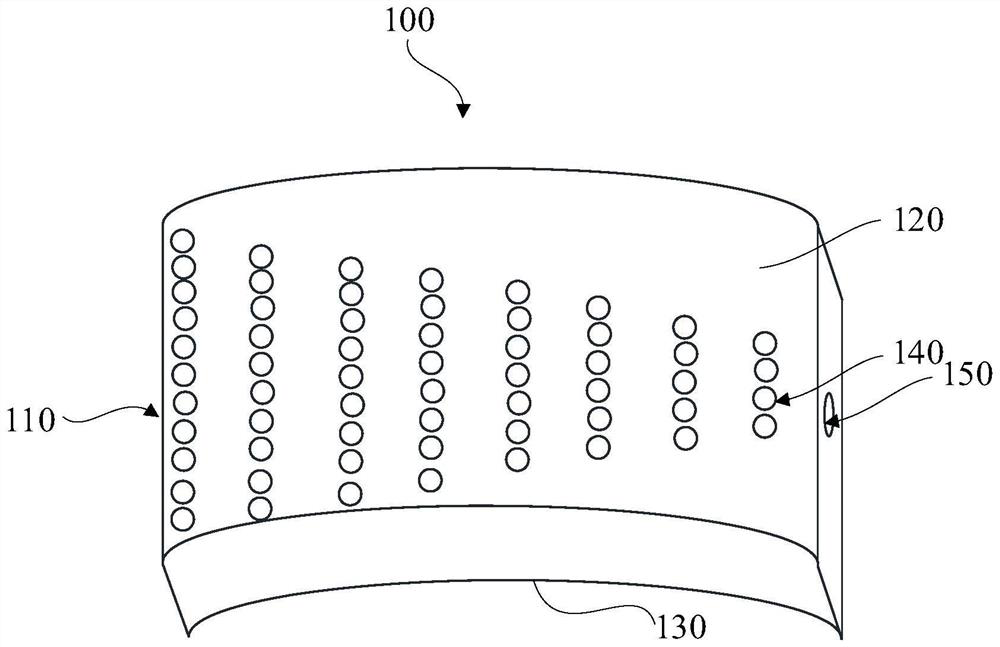

Variable diffuser structure of centrifugal machine and centrifugal machine

PendingCN113883096AAdjust the flow areaLow inhalationPump componentsPump controlEngineeringMechanical engineering

The invention relates to a variable diffuser structure of a centrifugal machine and the centrifugal machine. The variable diffuser structure of the centrifugal machine comprises a flow guide body, a plurality of diffuser blades and a connecting rod driver. The diffuser blades are annularly arranged on one side of the flow guide body and rotationally connected with the flow guide body. The connecting rod driver is used for simultaneously driving the multiple diffuser blades to rotate in the same direction. The variable diffuser structure of the centrifugal machine has the effects that the surge area of the centrifugal compressor is widened, the centrifugal compressor can operate under the working condition of 40%-100%, the surge area is enlarged, the adaptability of the centrifugal compressor is wider, the application requirements of customers under partial loads are met, and the requirement of stable operation of the centrifugal compressor is met.

Owner:钛灵特压缩机无锡有限公司

Gas outlet method of converter in anhydrous hydrofluoric acid production line

ActiveCN109289444AReduce gas output per unit timeReduce corrosionGas treatmentDispersed particle separationProduction lineHydrogen fluoride

The invention discloses a gas outlet method of a converter in an anhydrous hydrofluoric acid production line. The method comprises the following steps: (1) an air inlet buffer is assembled; (2) pipelines are connected, concretely a reducing multi-way connecting pipe is connected to the air inlet buffer, and connecting pipes are connected with the reducing multi-way connecting pipe; (3) water pipesare connected at the places where the connecting pipes are connected with a washing tower, each water pipe is provided with an electromagnetic valve, and a corresponding central control electric boxis arranged; (5) air outlet is carried out: concretely the air inlet buffer is turned on after a preparation reaction starts for 5-10 minutes, and hydrogen fluoride gas flows dispersedly into the connecting pipes and then is sent into the washing tower through the connecting pipes; (6) pipeline washing is carried out. On one hand, the air inlet buffer is arranged to reduce the air outlet volume ofthe hydrogen fluoride gas in unit time, so that the gas conveying volume in unit time in the connecting pipes is low, and then the corrosion effect of the hydrogen fluoride gas on pipe walls is reduced; and on the other hand, a plurality of connecting pipes are adopted for shunting and conveying the hydrogen fluoride gas, and the conveying volume of each connecting pipe is reduced, so that the corrosion effect is further buffered, and production safety is improved.

Owner:浙江森田新材料有限公司

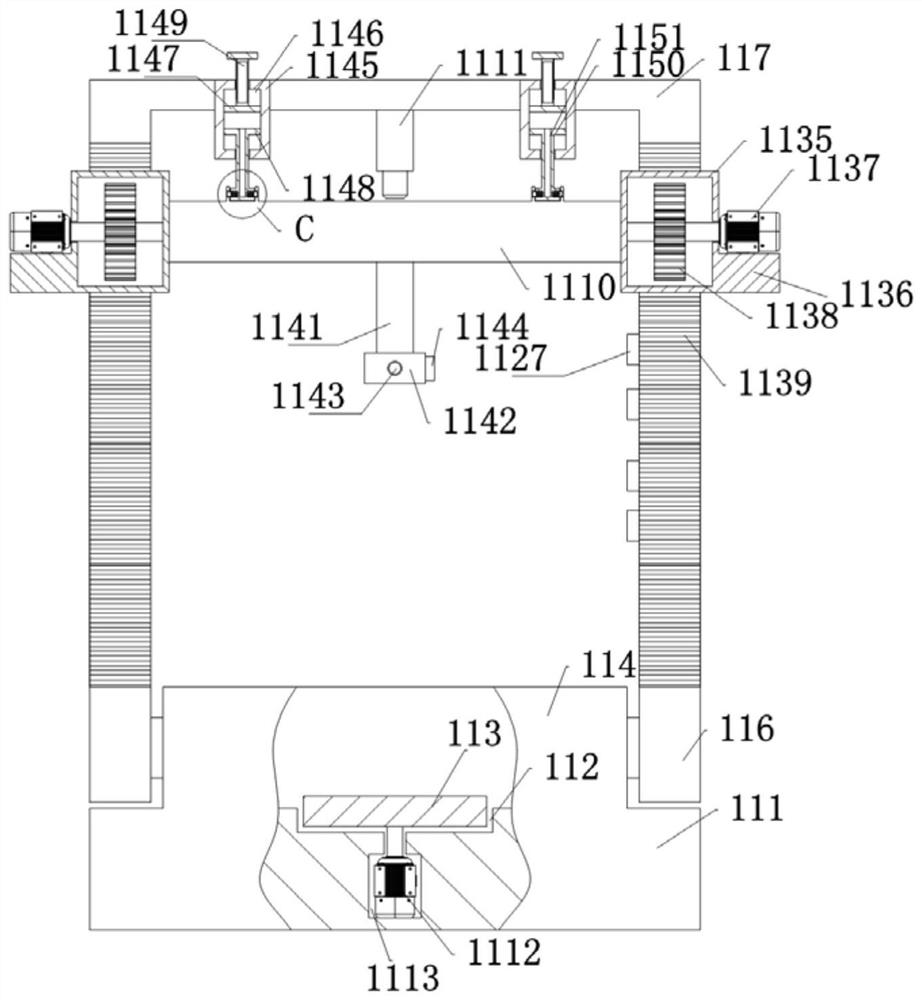

A paver for municipal engineering construction and its construction method

ActiveCN113073520BAvoid damageIncrease elasticityRoads maintainenceArchitectural engineeringMechanical engineering

The invention belongs to the field of municipal machinery, in particular to a paver for municipal engineering construction and a construction method thereof. Aiming at the existing automatic paver which has been adopted, on the one hand, the cost is high, on the other hand, the operation is complicated, and part of it requires For the problem of manual operation, the following scheme is proposed. The paver includes a machine body. An installation box is fixedly installed on one side of the body, and a sloping plate is fixedly installed on the bottom inner wall of the installation box. A plurality of conveying rollers are rotatably connected, and a discharge hole is opened on the inner wall of the bottom of one side of the installation box, and the plurality of conveying rollers are all located on one side of the inclined plate, and both sides of the inclined plate are fixedly installed with coaming plates , the present invention can realize automatic laying of floor tiles, and can carry out compaction after laying floor tiles, can effectively replace manual laying with this, greatly reduces labor use cost, and can effectively improve work efficiency, therefore has good practicability.

Owner:JINAN MUNICIPAL ENG CONSTR GRP CO LTD

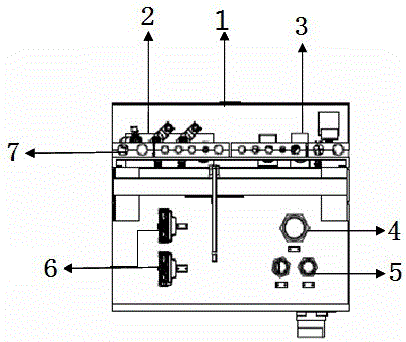

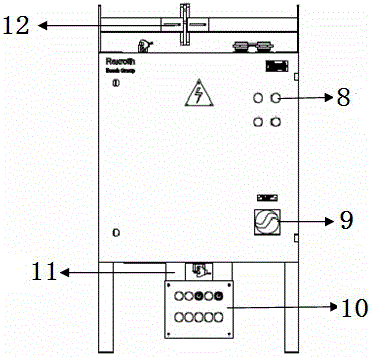

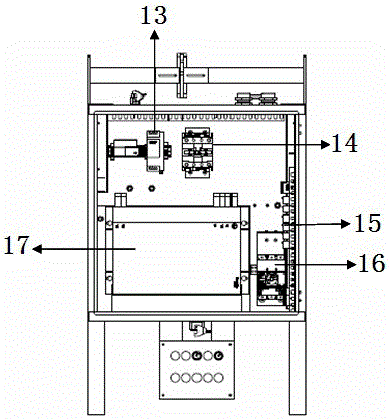

Integrated intermediate-frequency welding control cabinet

InactiveCN106238857ACompact structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesWater channelPower switching

The invention relates to an integrated intermediate-frequency welding control cabinet. An enclosure frame of an integrated intermediate-frequency welding control system is provided with a cooling system water channel unit, a pressure control system air channel unit, a main power incoming line, welding gun incoming lines, welding gun I / O ports, pipe clamps, indicator lights, a main power switch, an operation box, a control panel support and a suspended boom. A 24V power source, an alternating current contactor, an intermediate relay, a main power switch and a controller are arranged inside the integrated intermediate-frequency welding control system. According to the integrated intermediate-frequency welding control cabinet, the size of the welding control system is reduced, the structure is simple, on-site installation is easy, fault points are reduced, the cost is lowered, and maintenance is simple.

Owner:合肥国声电子通信有限责任公司

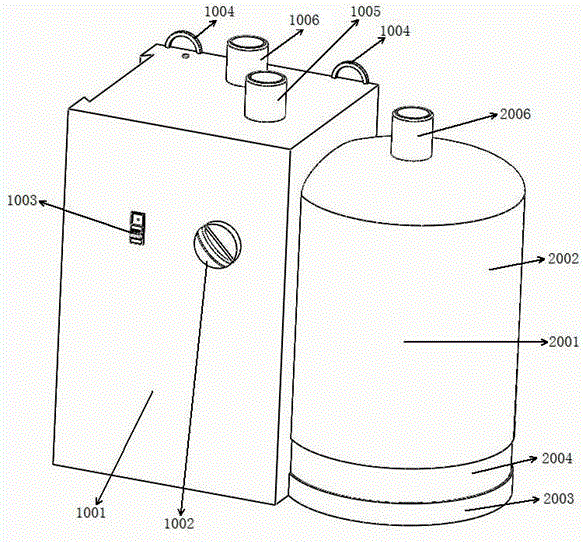

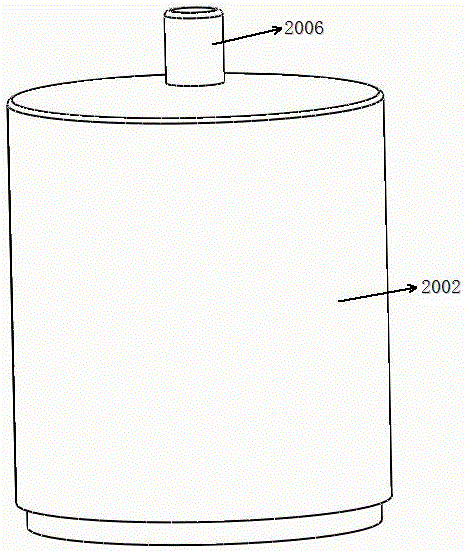

A multifunctional aeroallergen removal system

ActiveCN104721979BEasy loadingReduce volumeBreathing filtersBreathing masksAir pumpComplementary filter

The invention discloses a multifunctional aeroallergen removing system which is mainly composed of an air source assembly, a composite filter, an airbag assembly and a filter mask. The air source assembly is composed of a small direct-current rechargeable battery, a minitype direct-current electrical pump packaged in a mainframe box, a negative-ion generator and a negative ion electrode on an air pump exhaust passage. The composite filter is a main filter, and comprises a composite filter upper cover, an airflow turn-back support, a composite filter lower cover and a filter material. The airbag assembly comprises an airbag, an airbag air inlet shunting guide pipe and an airbag air outlet shunting guide pipe, the airbag air inlet shunting guide pipe and the airbag air outlet shunting guide pipe are arranged at the two ends of the airbag, and thin branch guide pipes are arranged on the two guide pipes respectively. The filter mask is composed of a sealing soft edge, a filter mask support and a filter component, and the filter component is an auxiliary filter of the system. The respiratory tract of a user can be isolated from dirty environment air, and therefore the treatment aim is achieved. The system can be used for personal protection in places with obvious air pollution. Good social benefits and economic benefits are achieved.

Owner:廖景峰

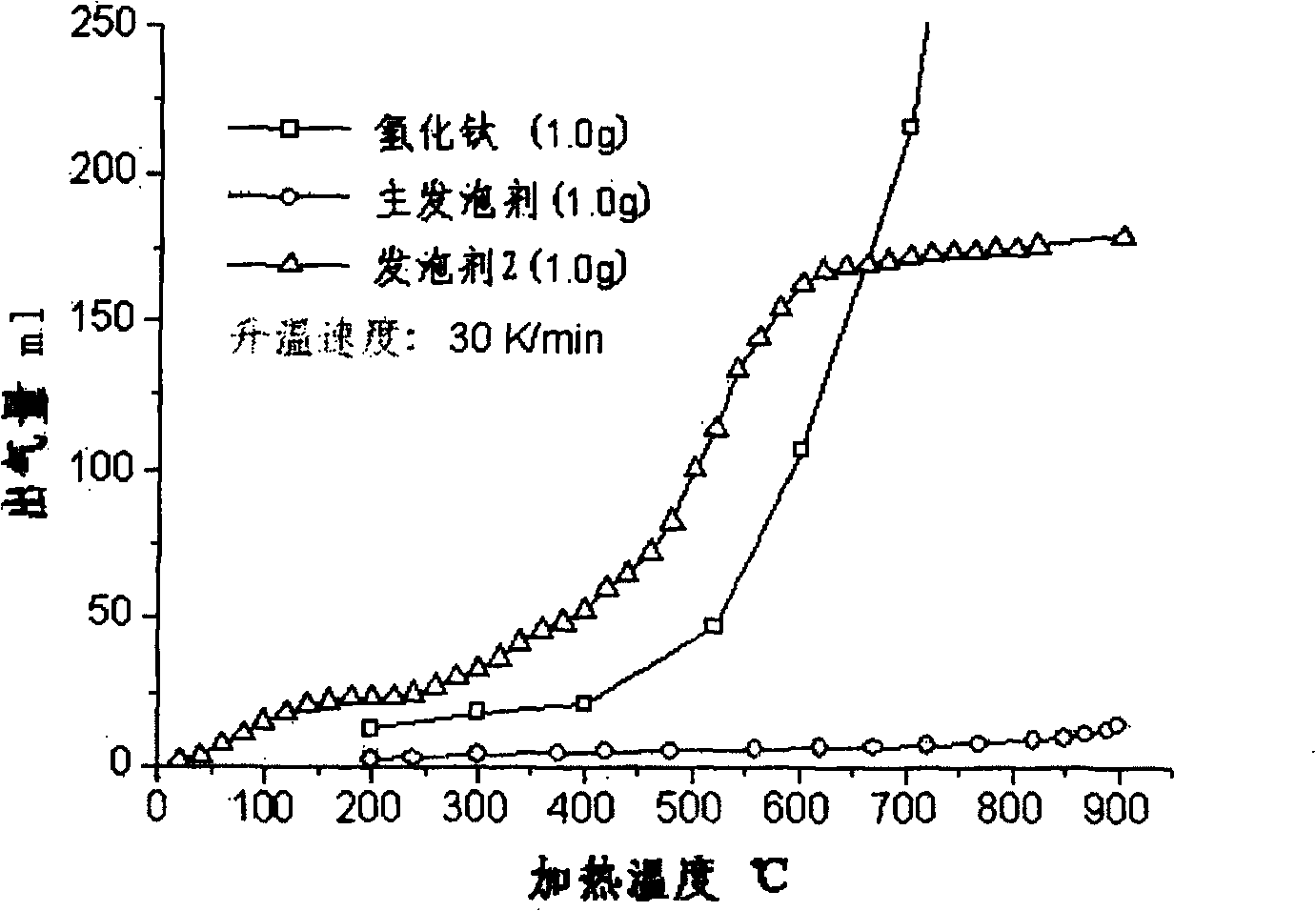

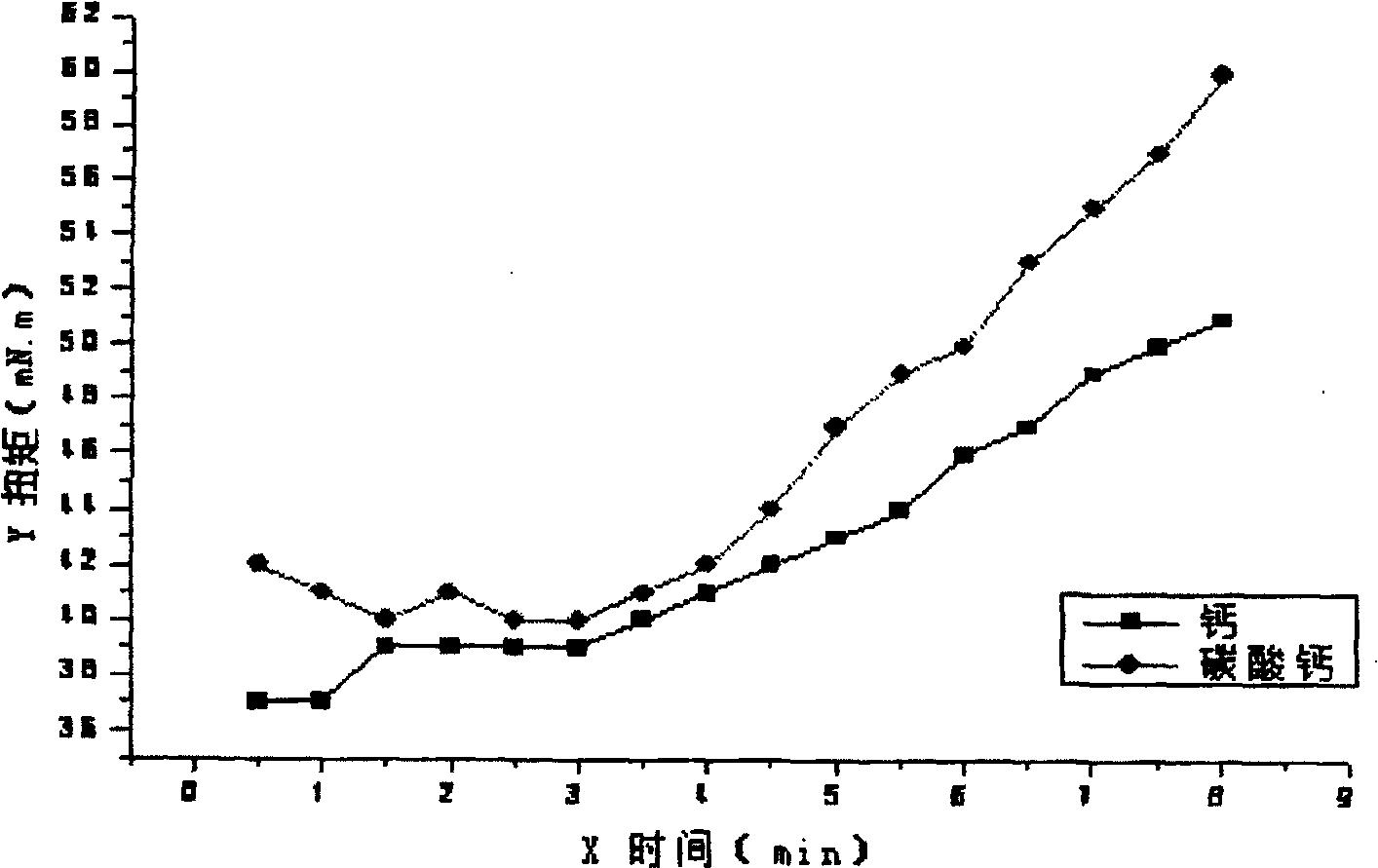

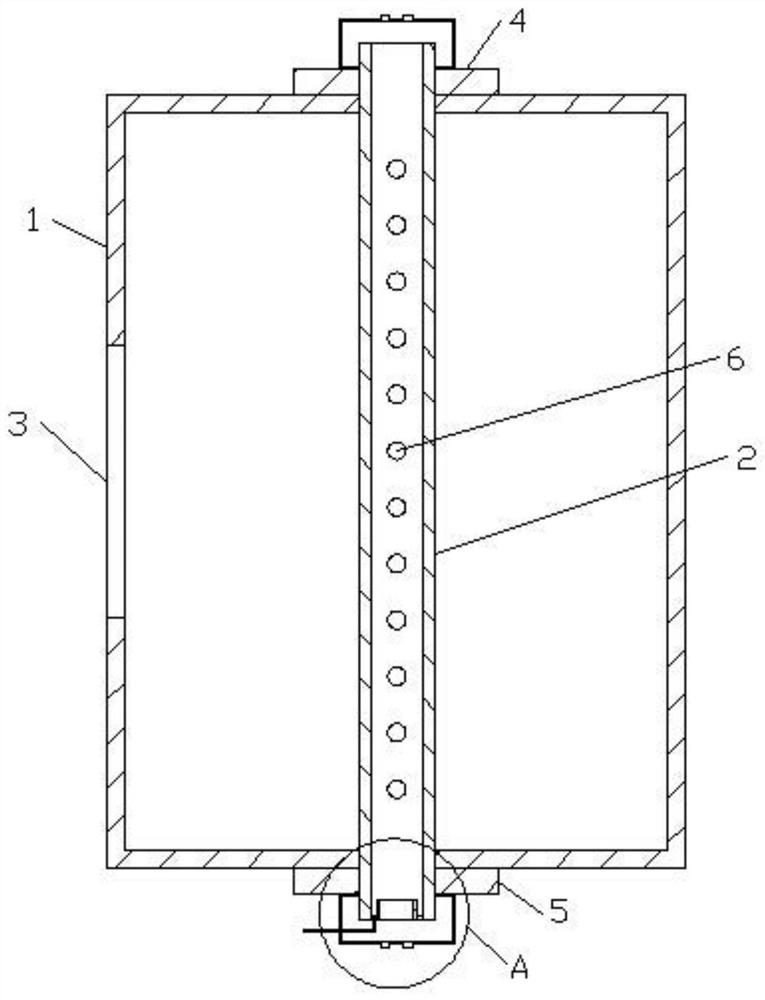

Foamed aluminium and aluminum alloy tackifying foaming preparation method

Owner:SOUTHEAST UNIV

Air knife device

ActiveCN111112374BEasy to pass throughLess quantityExtrusion cleaning devicesStructural engineeringAir knife

The invention discloses an air knife device, which comprises an air box and a pipe. The air box is provided with an air inlet. The upper and lower ends of the pipe extend out of the air box from the wire outlet and the wire inlet respectively. A stopper is fixed on the outer wall of the pipe and located at the upper end of the air box. A tightening block is provided on the outer wall of the pipe and located at the lower end of the air box. Air holes are provided, and the air holes are arranged in three rows, and the included angle between two adjacent rows of air holes is 120°, and vertical grooves are arranged on the inner wall of the pipe and opposite the air holes. The air knife unit facilitates threading and reduces the amount of lubricating oil falling into the air box.

Owner:安庆金田尼龙材料科技有限公司

Welding protection device and welding method

ActiveCN114714028AReduce gas outputImprove utilization efficiencyFinal product manufactureWelding/cutting auxillary devicesShielding gasStructural engineering

According to the welding protection device and the welding method, a connecting assembly is connected with a blowing part to adjust the position, relative to the back face of a welding seam, of the blowing part, and the blowing part is driven by the connecting assembly, so that openings, distributed in the first direction, of the blowing part can synchronously move in the moving direction of a welding head; and in the reverse extending direction of the moving direction of the welding head, the air blowing amount of the air blowing piece to all positions of the back face of the welding seam is gradually increased in the moving direction of the welding head. Due to the fact that the temperature of the welding seam is gradually reduced in the reverse extension direction of the moving direction of the welding head, the oxidation reaction activity of the welding seam is gradually reduced along with the reduction of the temperature of the welding seam, and in order to improve the utilization efficiency of the protective gas and save the protective gas, the gas output of the protective gas of the blowing part is gradually reduced in the direction opposite to the first direction. The problems that when the size of the back face of a to-be-welded part is large, the utilization rate of protective gas is low, and a large amount of protective gas needs to be consumed are solved.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD +1

Packaging method of low-temperature vacuum infrared detector

PendingCN113964233AReduce gas outputIncrease roughnessLaser beam welding apparatusSemiconductor devicesFiberSilicon dioxide

The invention relates to a packaging method of a low-temperature vacuum infrared detector, and belongs to the technical field of semiconductors. The method comprises the following steps: polishing the inner surface of a vacuum tube metal shell except a germanium window and a base loading surface; preparing a heat insulation film layer composed of a polyimide layer and an alumina fiber cloth layer on the inner surface and the loading surface; plating a passivation film made of a silicon dioxide or aluminum oxide material on the surface of the heat insulation film layer to form a passivation film layer; and installing an infrared detector chip and a refrigerator on the loading surface, and after electrodes and pins are bonded, carrying out vacuum exhaust and laser fusion welding in a cavity of a vacuum welding workbench so that vacuum sealing packaging is achieved. According to the packaging method, the vacuum sealing of the infrared detector can be realized while the temperature impact on the infrared detector chip caused by a high temperature in the packaging and welding process is avoided; and according to the packaging method, the air output of the inner wall of the vacuum tube after packaging can be effectively reduced, leakage holes in the packaging position of the vacuum tube are effectively reduced, and therefore the vacuum holding time of the low-temperature vacuum infrared detector is prolonged.

Owner:云南昆物新跃光电科技有限公司

Automobile brake system

InactiveCN108382375AIncrease pressureIncrease frictionBraking element arrangementsVehicle frameFriction force

The invention relates to an automobile brake system. The automobile brake system comprises an automobile body, wherein the automobile body comprises an automobile frame, a chassis is arranged at the bottom of the automobile body, travelling wheels are arranged at the lower end of the automobile body, a ventilating pipeline is arranged on the upper side of the automobile body, an air inlet is formed in the front end of the ventilating pipeline, middle air outlets are formed in the middle part of the ventilating pipeline, a tail air outlet is formed in the rear part of the ventilating pipeline,and hydraulic lifting mechanisms are arranged on the chassis of the automobile body; an automobile tail aerodynamic brake device is arranged at the upper end of the tail of an automobile; aerodynamichydraulic mechanisms at the tail part in the ventilating pipeline and the automobile tail aerodynamic brake device are in transmission connection with a foot brake pedal in the automobile body througha linking mechanism; and the aerodynamic hydraulic mechanisms at the middle part of the ventilating pipeline, the hydraulic lifting mechanisms and the automobile tail aerodynamic brake device are intransmission connection with a hand brake through the linking mechanism. According to the automobile brake system disclosed by the invention, an auxiliary brake mechanism is additionally arranged, andthe contact area of the auxiliary brake mechanism and the ground can be enlarged, so that friction force is increased, and further the effect of emergency brake can be achieved.

Owner:荆门宁杰机电技术服务有限公司

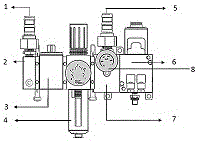

Universal conversion integrated gas circuit module

InactiveCN106270916AReduce gas outputEasy maintenanceWelding/cutting auxillary devicesAuxillary welding devicesInlet pressureEngineering

The invention relates to a universal conversion integrated gas circuit module which comprises a gas inlet pagoda joint (1), a gas inlet sealing connector (2), a three-way valve (3), a filtering pressure regulating valve (4), a welding gun pagoda joint (5), an electromagnetic valve (6) and a gas distribution block (7). The gas inlet pagoda joint (1) is mounted at the top end of the gas inlet sealing connector (2), and the welding gun pagoda joint (5) is mounted on the gas distribution block (7). When the temperature collected by a temperature sensor is T1, it shows that a welding gun works effectively; when the temperature collected by the temperature sensor is T2 and continues for a period of time to t1, a control unit regulates the gas inlet pressure to the electromagnetic valve (6) through the filtering pressure regulating valve (4), the output gas pressure is controlled through the electromagnetic valve (6) to enable the pressure of the gas output from the head of the welding gun of an electrode holder to be decreased; and when the temperature collected by the temperature sensor is T2 and continues for a period of time to t2, the control unit directly shuts off the electromagnetic valve (6).

Owner:合肥国声电子通信有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com