A paver for municipal engineering construction and its construction method

A paver and engineering technology, applied in construction, road, road repair, etc., can solve the problems of heavy workload of floor tiles, many uncertain factors of manual laying, and a large amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

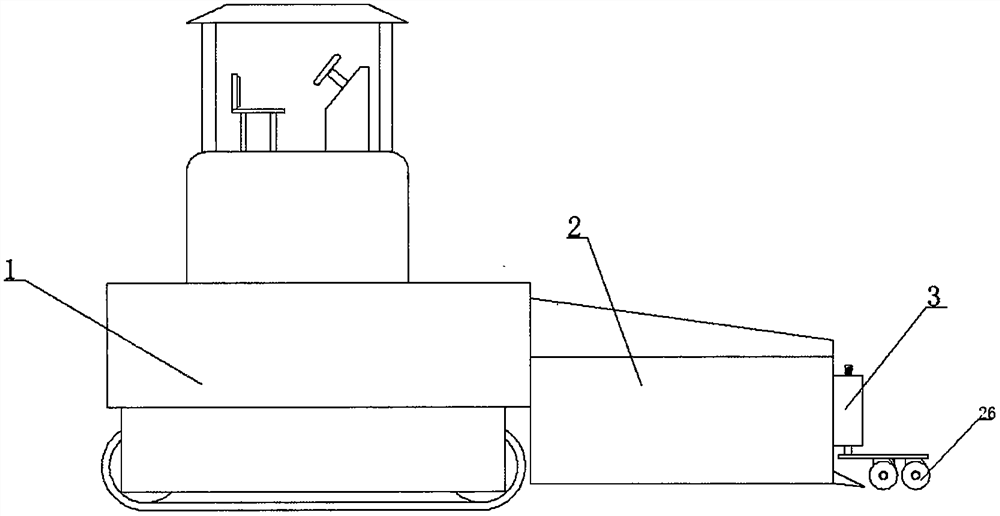

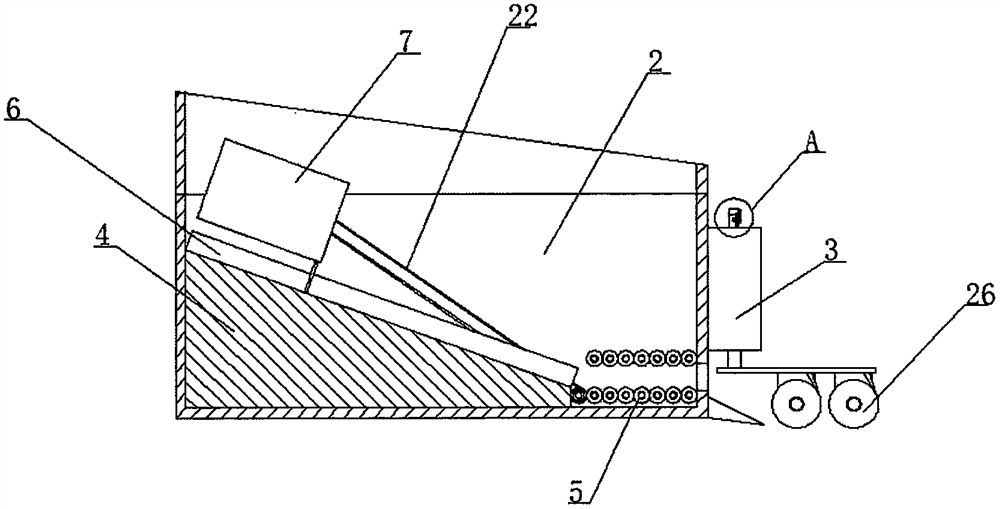

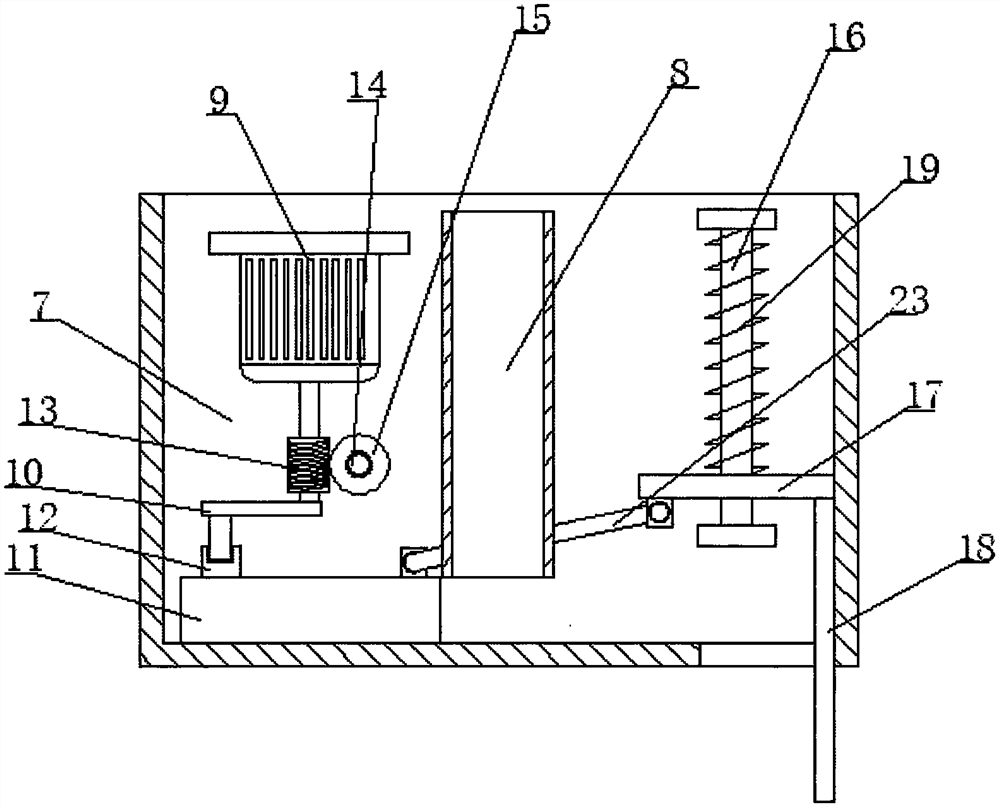

[0037] refer to Figure 1-7 , a paver for municipal engineering construction is proposed in this embodiment, body 1, an installation box 2 is fixedly installed on one side of the body 1, and an inclined panel 4 is fixedly installed on the bottom inner wall of the installation box 2. The characteristics of the panel 4 make it easy to slide the floor tiles onto the conveying rollers 5. There are a plurality of conveying rollers 5 rotated at equal intervals in the installation box 2, and a discharge hole is opened on the bottom inner wall of one side of the installation box 2, and multiple conveying rollers The rollers 5 are all located on one side of the inclined plate 4, and both sides of the inclined plate 4 are fixedly installed with a coaming plate 6. The coaming plate 6 can be used to limit the position of the floor tiles, so as to avoid the position deviation of the floor tiles. Multiple conveying rollers 5 are connected by mutual transmission, and the mounting box 2 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com