Integrated intermediate-frequency welding control cabinet

An integrated, control cabinet technology, applied in gas flame welding equipment, welding equipment, welding equipment and other directions, can solve the problems of rough overall structure, many hidden trouble points, difficult transportation, etc., to achieve compact overall structure, save gas consumption, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

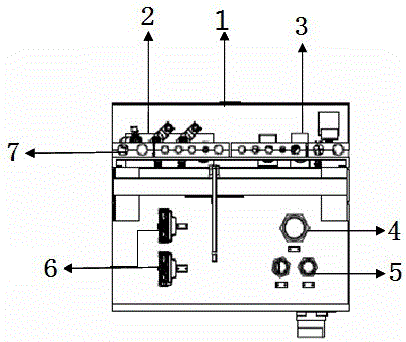

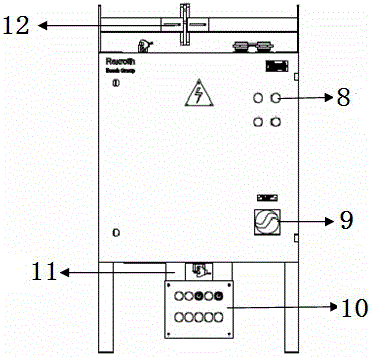

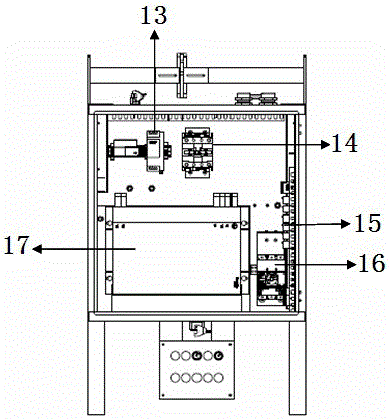

[0022] The patent of the present invention is described further below by accompanying drawing:

[0023] Such as figure 1 , figure 2 and image 3 As shown, the integrated intermediate frequency welding control cabinet, the frame 1 of the integrated intermediate frequency welding control cabinet is equipped with a cooling system water circuit unit 2, a pressure control cabinet gas circuit unit 3, a main power supply line 4, a welding torch incoming line 5, and a welding torch I / O interface 6, pipe clamp 7, indicator light 8, main power switch 9, operation box 10, control panel bracket 11 and suspension boom 12; the interior of the integrated intermediate frequency welding control cabinet is equipped with 24V power supply 13, AC contactor 14. Intermediate relay 15, main power switch 16 and controller 17. The positions of various interfaces and the models used can be adjusted according to actual conditions.

[0024] The air circuit unit 3 of the pressure control cabinet inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com