Adjustable school uniform ironing process for school uniform made of natural plant dyed fabric

一种天然植物、可调式的技术,应用在织物表面修剪、喷雾/喷射纺织材料处理、纺织品和造纸等方向,能够解决测量数据误差大、易污染造作环境、耗费大时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0039] School uniforms made of natural plant dyed fabrics are made of gardenia fruit natural plant dyes. Students take samples in turn to determine the school uniform version, cut natural plant dyed fabrics, and sew and shape natural plant dyed fabrics. Afterwards ironing, garment inspection, packaging and warehousing.

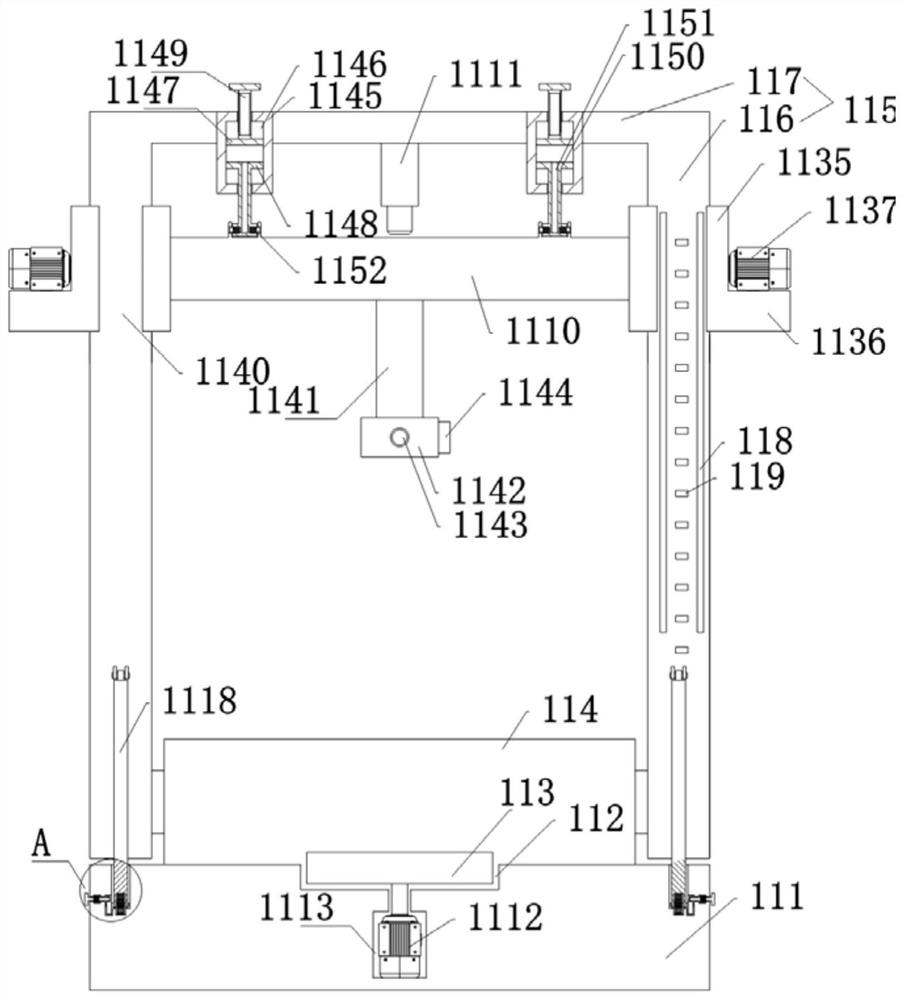

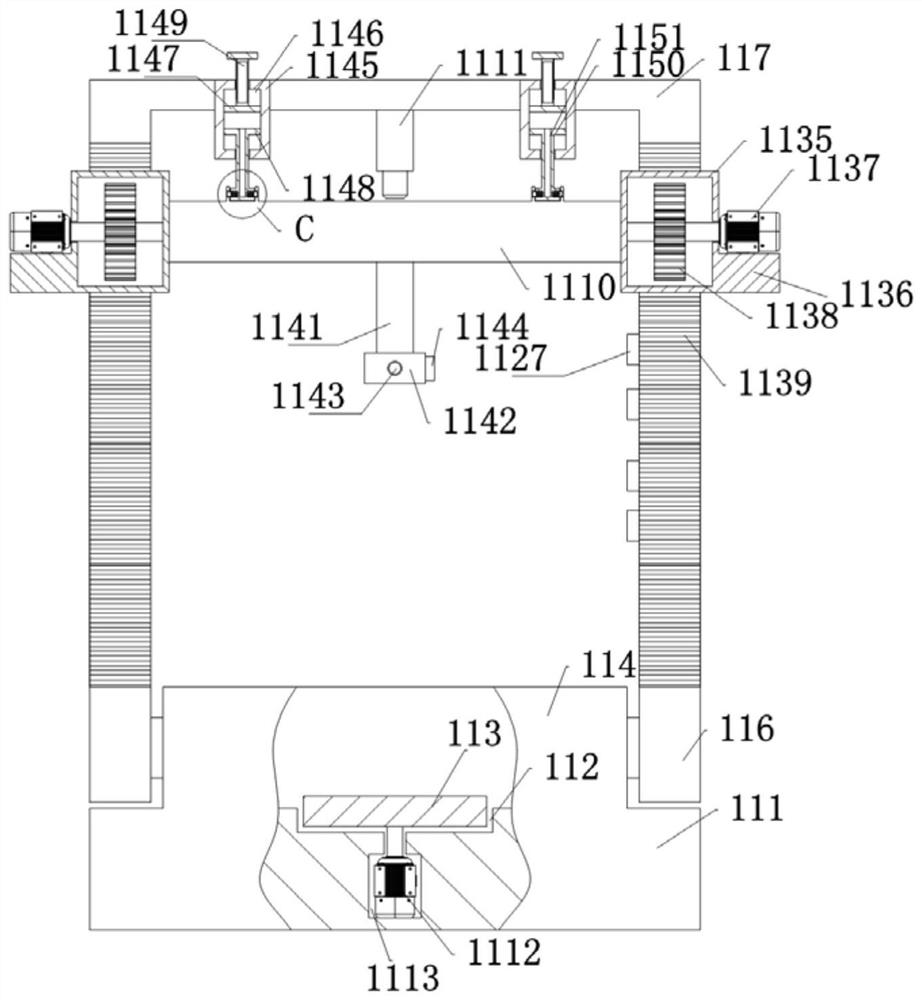

[0040] Such as figure 1 As shown, the intelligent school uniform production line made of natural plant dyed fabrics includes intelligent chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com