Patents

Literature

99results about How to "Batch stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

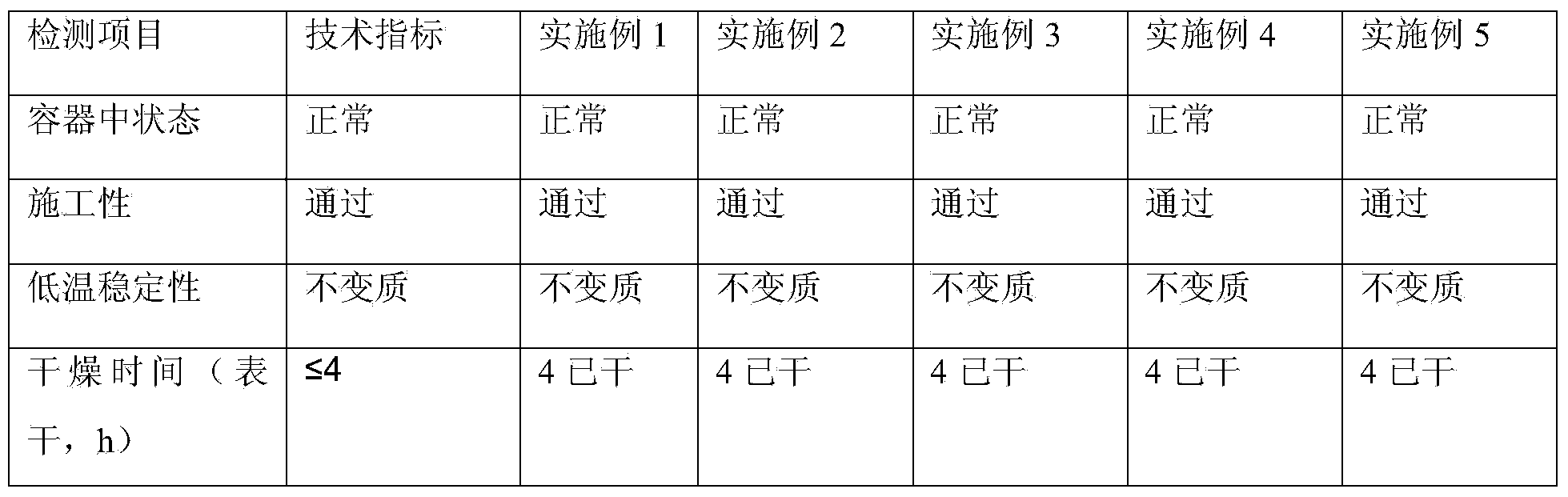

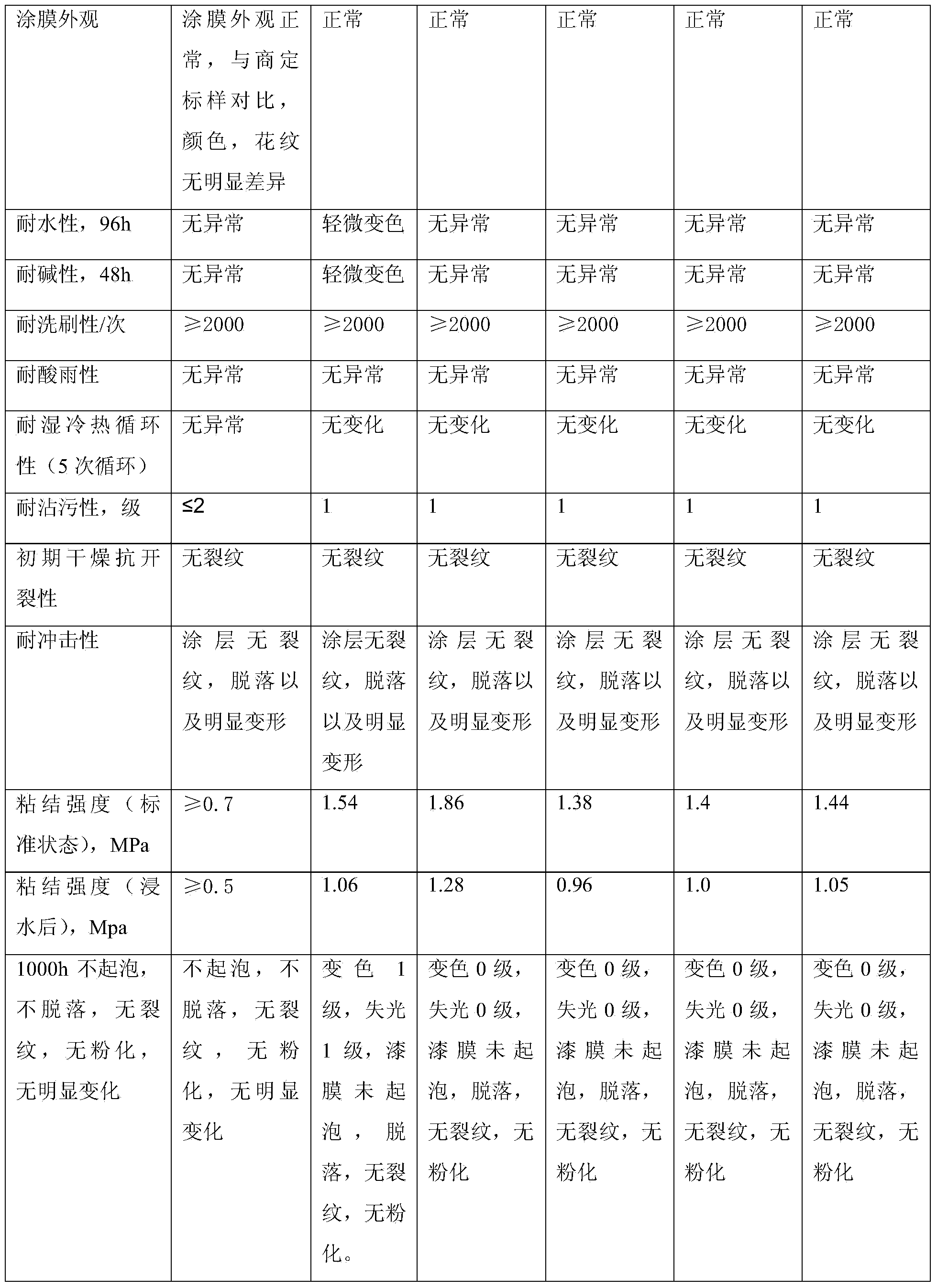

Water-based colorful real stone-type stone-like coating and production process thereof

ActiveCN104293056ANot easy to sinkAddressing Fragile ConsequencesMulticolor effect coatingsWater basedEmulsion

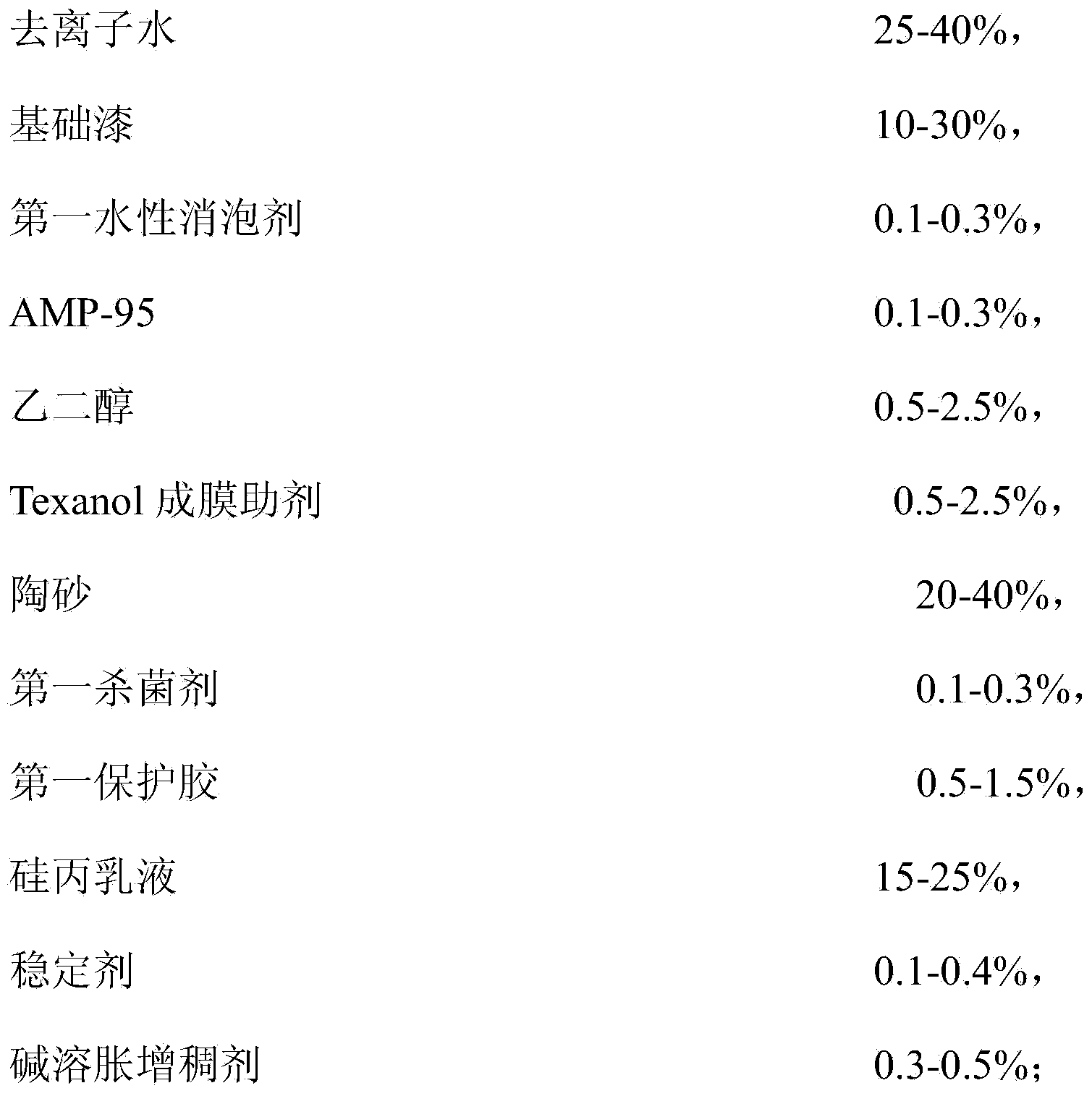

The invention discloses a water-based colorful real stone-type stone-like coating and a production process thereof. A few of colorful real stone-type stone-like coatings at present are good in crack resistance, high in fidelity and good in weather fastness, but are complicated in production process, and high in demands on production personnel; particles are easily broken; and the storage stability is poor. The water-based colorful real stone-type stone-like coating disclosed by the invention comprises the following raw materials in percentage by mass: 25%-40% of deionized water, 10%-30% of a base paint, 0.1%-0.3% of a first water-based defoaming agent, 0.1%-0.3% of AMP-95, 0.5%-2.5% of ethylene glycol, 0.5%-2.5% of a Texanol coalescing agent, 20%-40% of ceramsite sand, 0.1%-0.3% of a first sterilizing agent, 0.5%-1.5% of first protective glue, 15%-25% of a silicone acrylic emulsion, 0.1%-0.4% of a stabilizer and 0.3%-0.5% of an alkali swelling thickening agent. The coating disclosed by the invention is good in storage stability; and particles are not easily broken.

Owner:杭州潮头建材有限公司

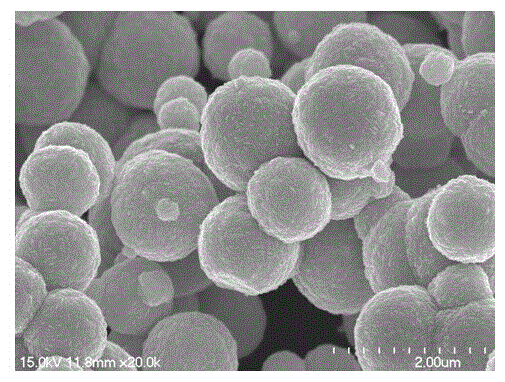

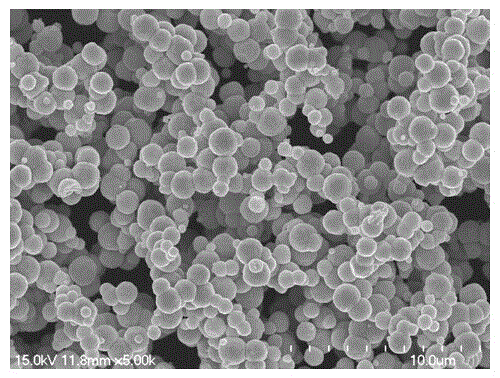

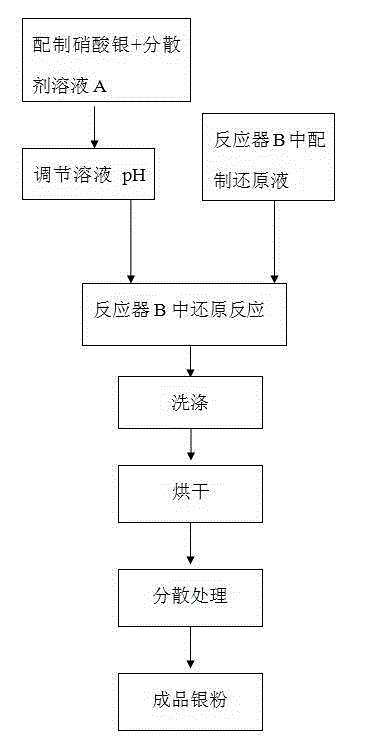

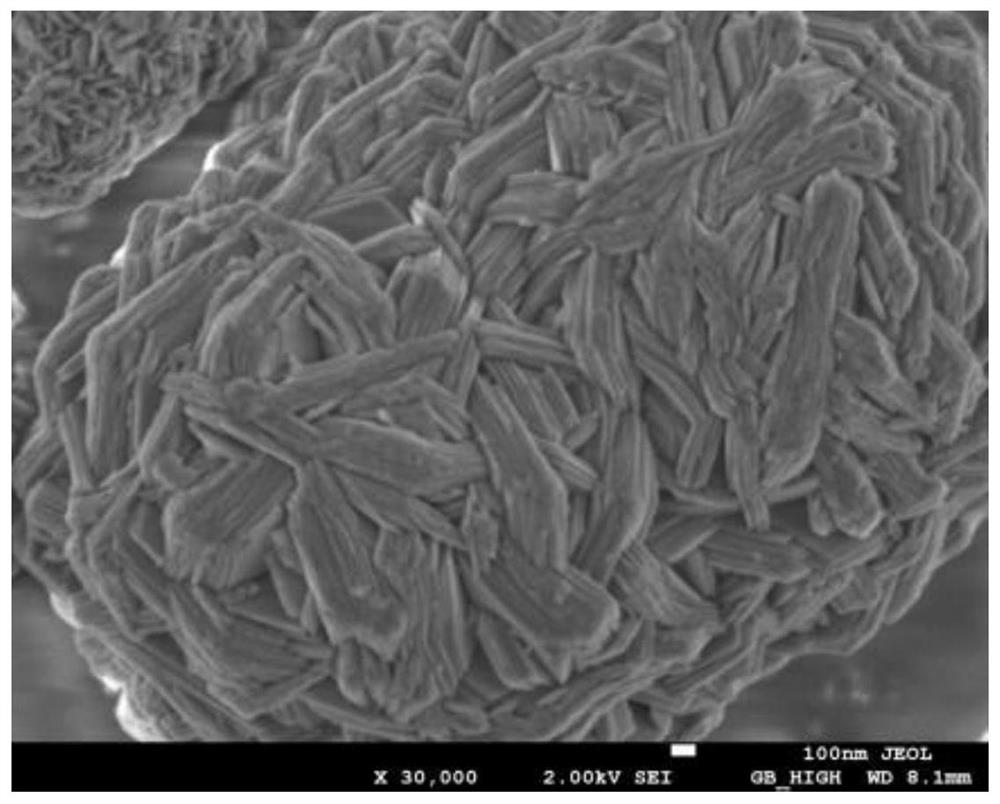

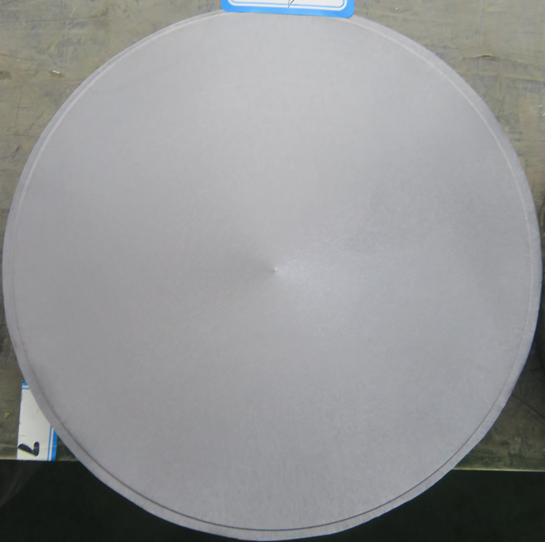

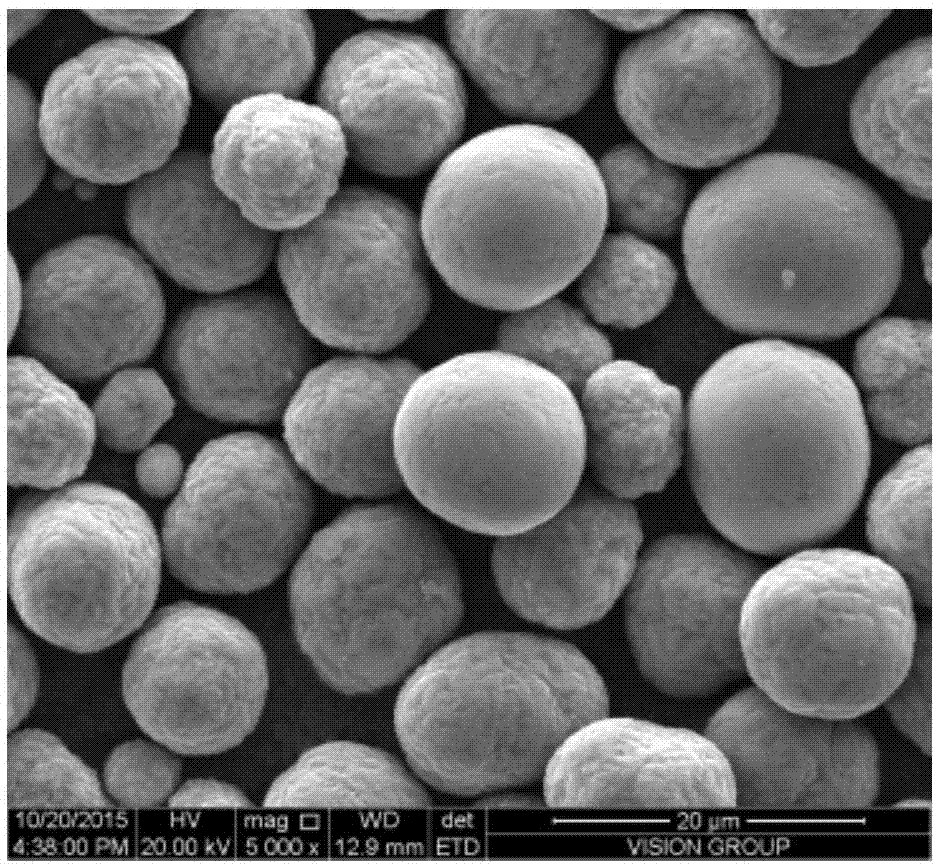

Method for preparing spherical silver powder

The invention provides a method for preparing spherical silver powder. The method comprises the following steps of (1) weighing silver nitrate, and adding deionized water to prepare a silver nitrate solution with the silver ion concentration of 50-100g / L; (2) adding an organic dispersing agent into the silver nitrate solution, and uniformly mixing, wherein the weight of the organic dispersing agent is equal to 1%-5% of the weight of the silver nitrate; adding (NH4)2SO4 (ammonium sulfate) solution with the concentration of 150-250g / L, and adjusting the pH (potential of hydrogen) value to 4-6.5, so as to obtain a first water solution; (3) weighing ascorbic acid, and preparing into a reducing solution with the ascorbic acid concentration of 70-90g / L; (4) adding the reducing solution into the first water solution, and mixing, wherein the ratio of usage amounts of the first water solution and the reducing solution is 0.8:1; controlling the reaction temperature at 15-35 DEG C, using a high-efficiency stirrer to stir, and reacting for 15-20min, so as to obtain reaction sediments; (5) using the deionized water to wash the sediments, filtering and drying the sediments to obtain the dry silver powder, and then loading the dry silver powder into a high-speed rotary vibration powder sifting machine to disperse, so as to obtain the silver powder with high tap density.

Owner:中国船舶重工集团公司第七一二研究所

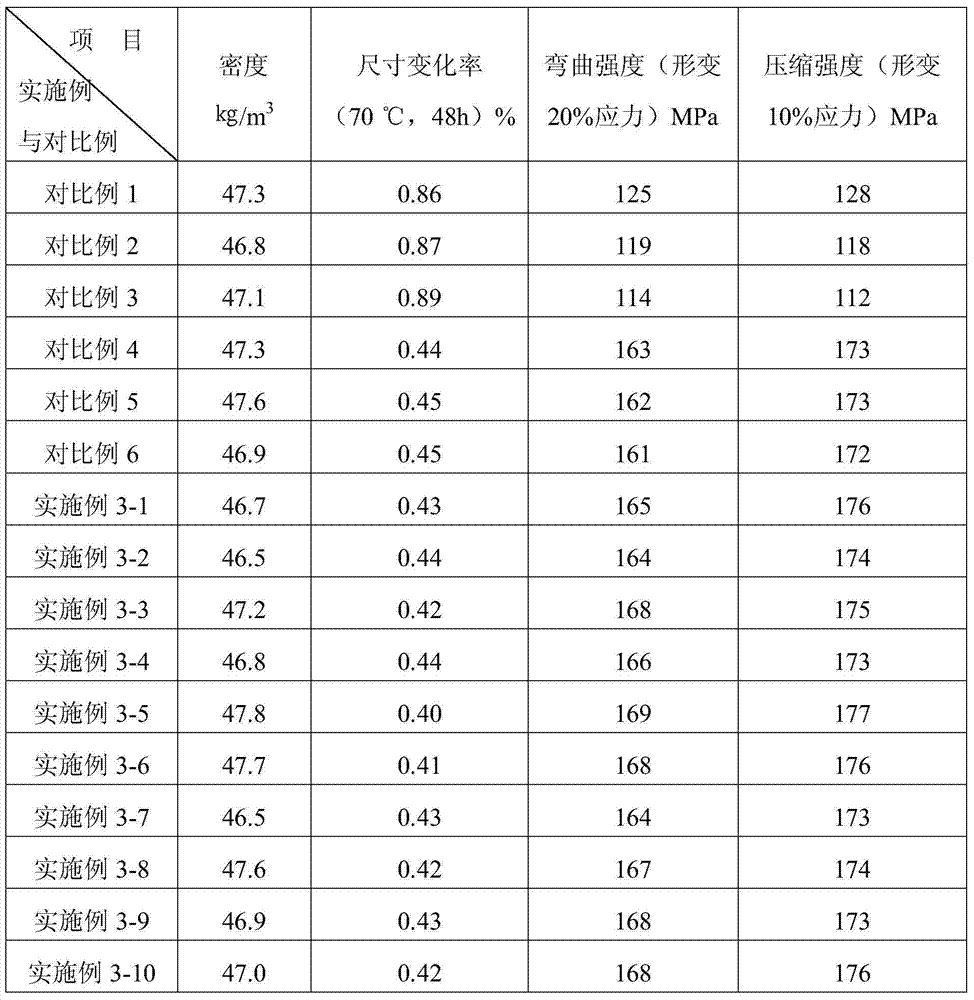

High-functionality degree polyester polyol and preparation method thereof

ActiveCN104262596AReduce usageLow viscosityOrganic-compounds/hydrides/coordination-complexes catalystsPlastic recyclingPolyesterPolyurethane adhesive

The invention discloses high-functionality degree polyester polyol and a preparation method thereof. The high-functionality degree polyester polyol comprises the following components in parts by mass: 900-1200 parts of polyester alcoholysis liquid, 900 parts of phthalic anhydride, 400-600 parts of aliphatic dibasic acid, 800-1000 parts of dihydric alcohol, 550-900 parts of polyhydric alcohols, 0.3-0.5 part of esterification catalyst. The preparation method comprises the following steps: carrying out an esterification reaction, removing the moisture, performing condensation polymerization, thereby obtaining the product. According to the high-functionality degree polyester polyol, the average functionality degree is 2.4-2.5, the viscosity is less than or equal to 10000mPa.S at the temperature of 25 DEG C, the hydroxyl value is 300-350mgKOH / g, the acid value is less than or equal to 1mgKOH / g, and the polyester polyol is non-crystallizable after being stored for three months under the condition of 2 DEG C. The polyester polyol disclosed by the invention can be widely applied to the fields of rigid polyurethane foam plates, polyurethane elastomers and polyurethane adhesives.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

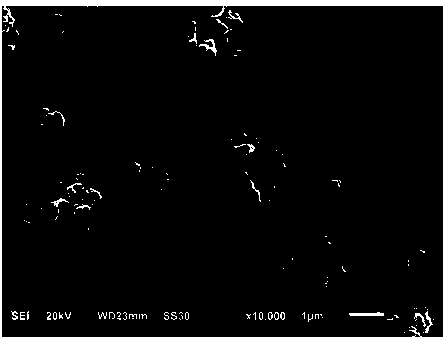

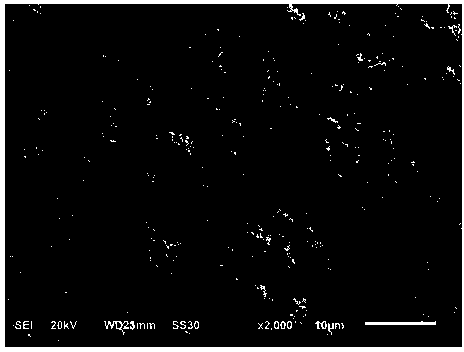

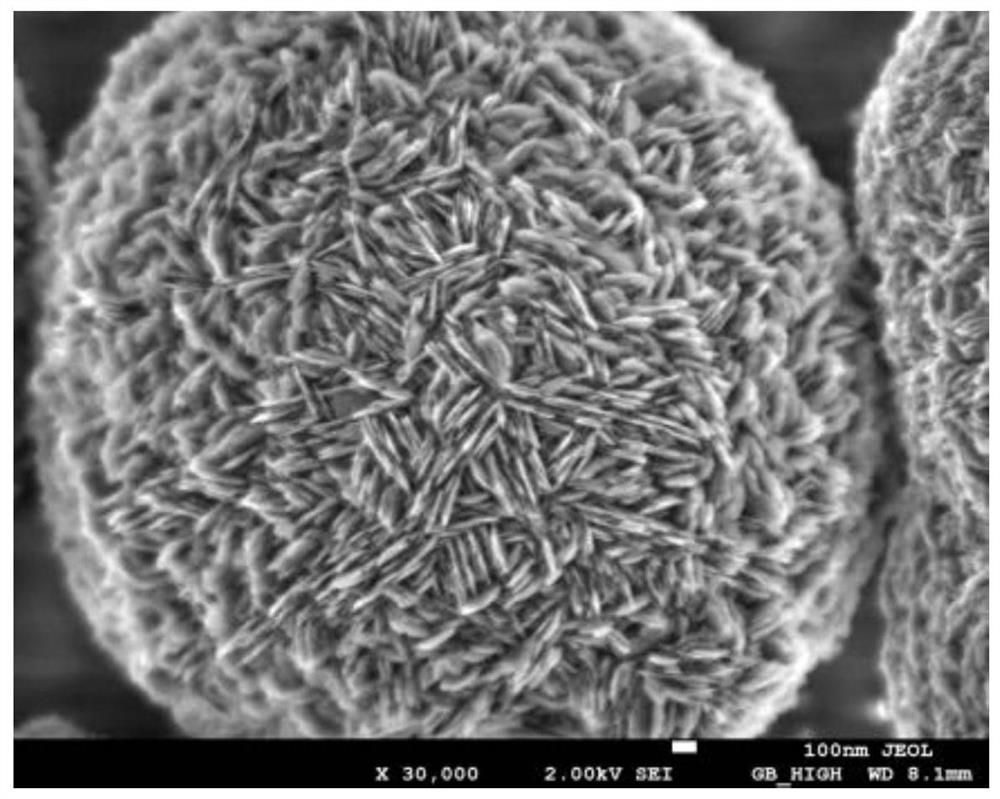

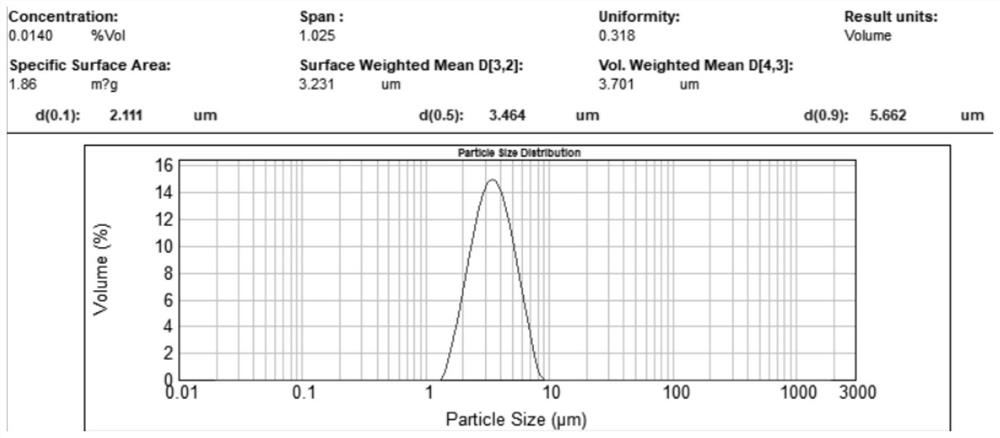

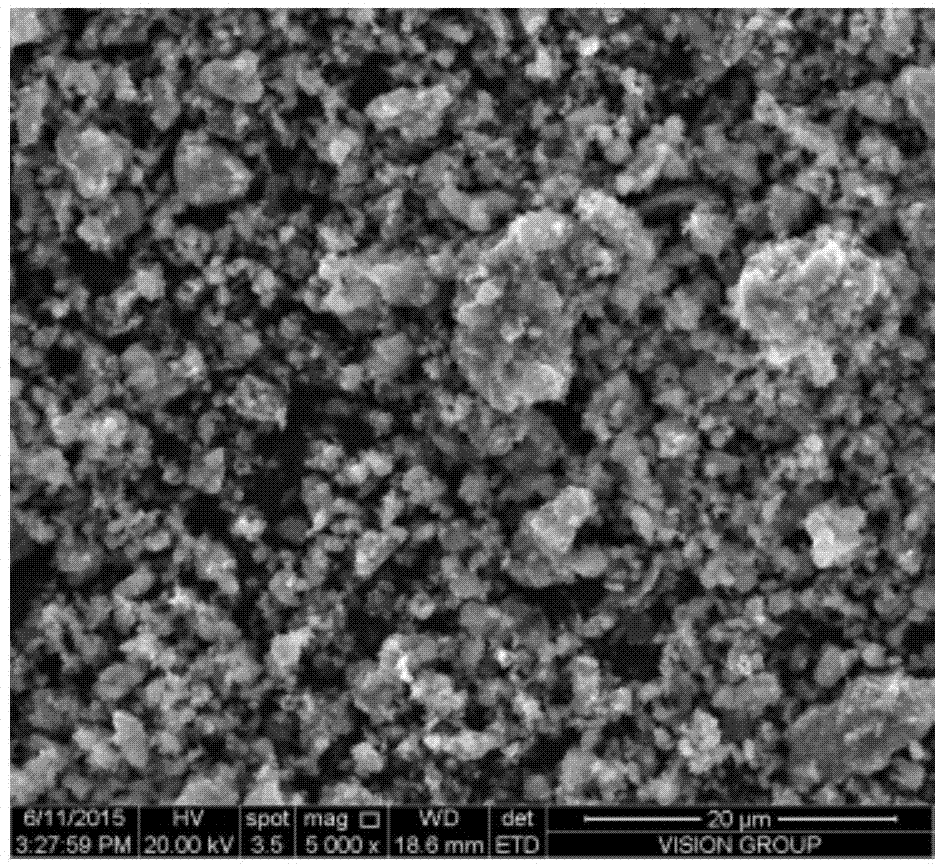

Method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with method

The invention relates to a method for preparing high-specific-surface-area cotton-shaped super-fine silver powder and silver powder prepared with the method. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder comprises the following steps of A, preparing a first water solution; B, preparing a second water solution; C, conducting reduction treatment; D, conducting washing; E, conducting drying and sieving, and obtaining the dried finished high-specific-surface-area cotton-shaped super-fine silver powder. According to the silver powder prepared with the method, the specific surface area is over 6.5 m<2> / g, and the burning lose content is smaller than 1.5 after heat treatment is conducted for one hour at the temperature of 538 DEG C. The method for preparing the high-specific-surface-area cotton-shaped super-fine silver powder and the silver powder prepared with the method have the advantages that the method is controlled effectively, the prepared silver powder is high in quality and stable, the production efficiency is high, pollution is avoided, the requirement for environment protection is met, after the silver power is prepared into silver paste, the viscosity and the rheological property of electrocondution slurry are maintained, the conductivity of a silver film obtained by burning the electrocondution slurry is not changed, and the proportion of the silver powder in the electrocondution slurry can be reduced. The silver powder prepared with the method has the outstanding advantages that the particle size distribution range is narrow, the dispersibility is high, the purity is high, and the specific surface area is high and is an ideal material for silver paste for electrodes of electronic components.

Owner:中船黄冈贵金属有限公司

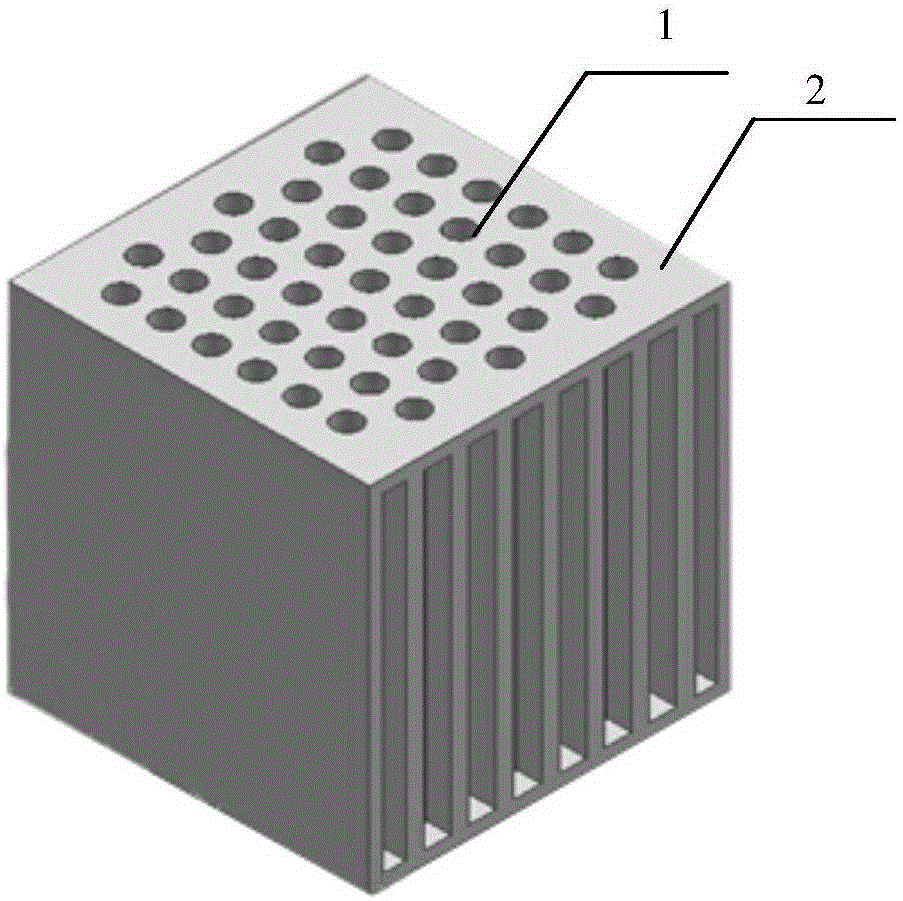

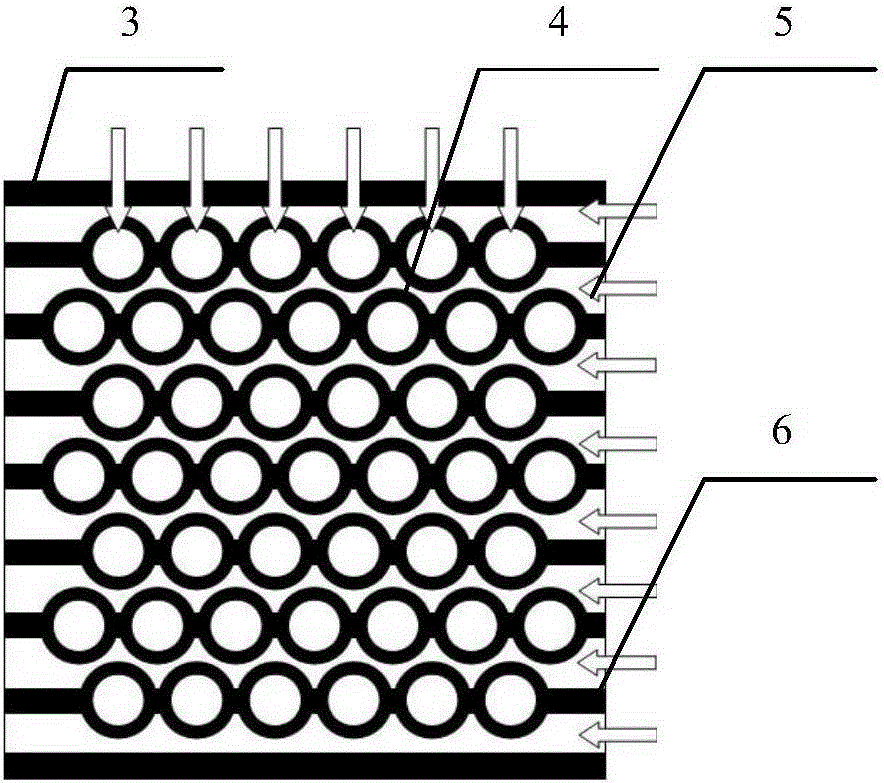

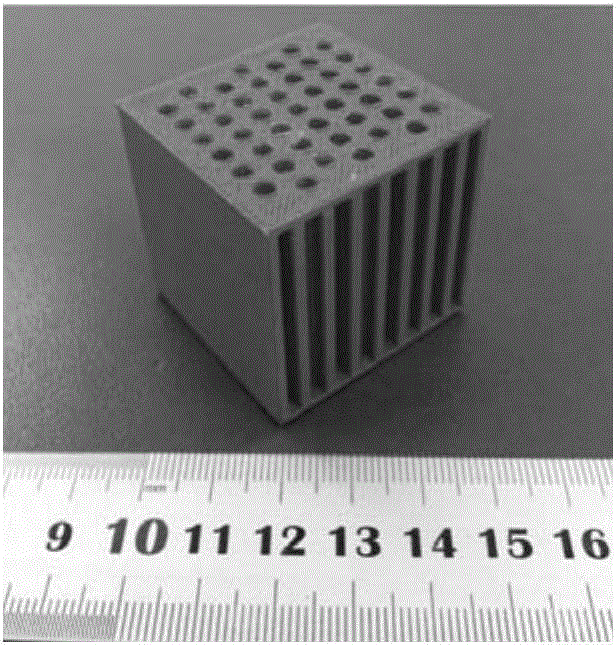

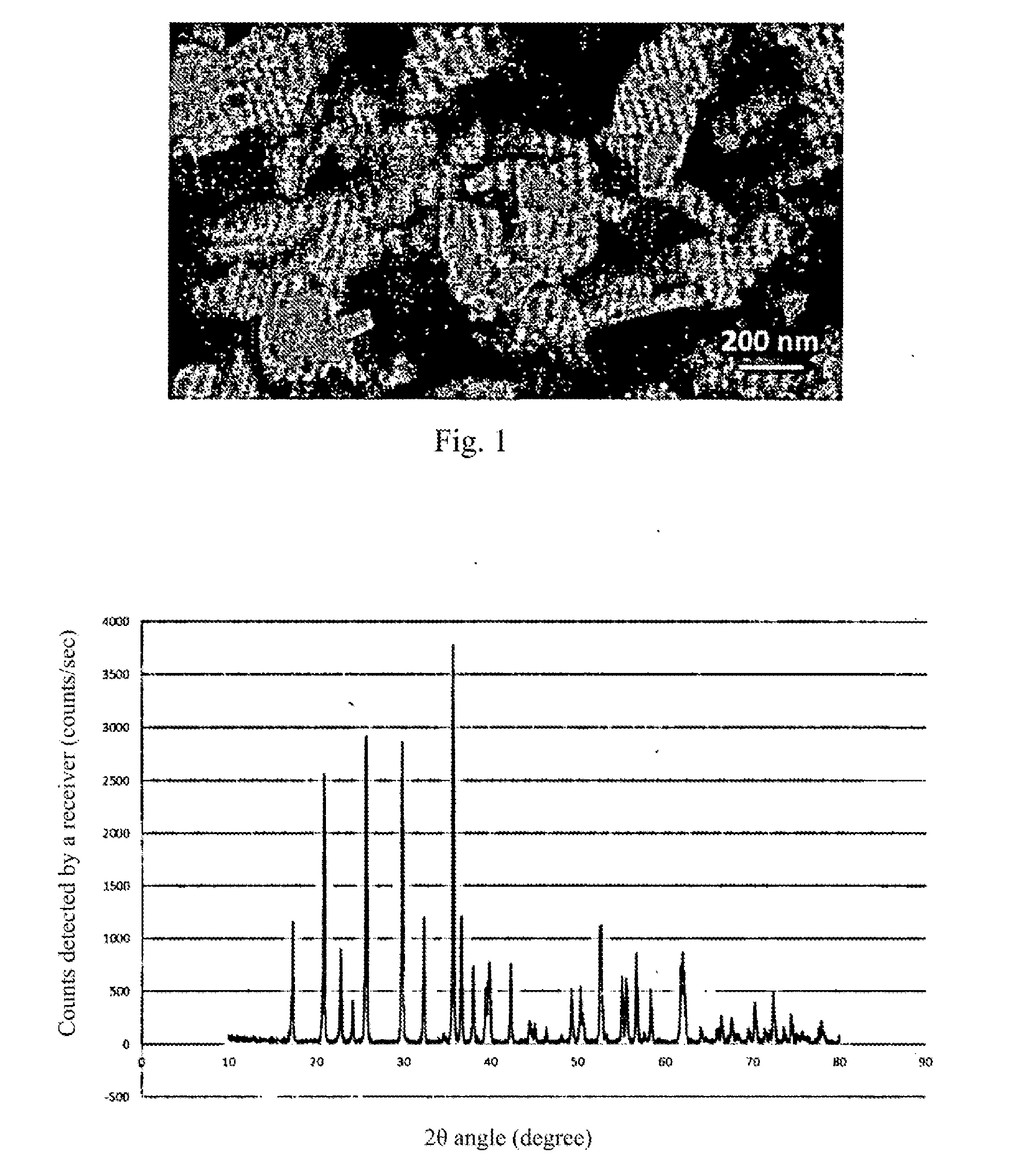

Method for three-dimensionally printing honeycomb-type solid oxide fuel cell with three-dimensional channel

ActiveCN105355947AFast mass transferShort processCell electrodesSolid electrolyte fuel cellsMaterials scienceRaw material

The invention relates to a method for three-dimensionally printing a honeycomb-type solid oxide fuel cell with a three-dimensional channel, and belongs to the technical field of solid oxide fuel cells. According to the method, positive pole ceramic powder or negative pole ceramic powder serves as a raw material, a structure is designed through three-dimensional mapping software, outputting is carried out through a ceramic three-dimensional printer, and a green body of a honeycomb-type positive pole support body or a negative pole support body with a three-dimensional channel structure is printed and prepared with a one-step method; after the green body is sintered, the positive pole support body or the negative pole support body is obtained; an electrolyte layer and a negative pole layer are sequentially deposited on the positive pole support body to form a positive-pole honeycomb-type solid oxide fuel cell with an emulsion impregnation method; an electrolyte layer and a positive pole layer are sequentially deposited on the negative pole support body to form a negative-pole honeycomb-type solid oxide fuel cell with an emulsion impregnation method. According to the method, preparing is efficient, cost is saved, the mass transfer rate is greatly increased, the automation degree is high, and the batch is stable.

Owner:SHANDONG UNIV OF TECH

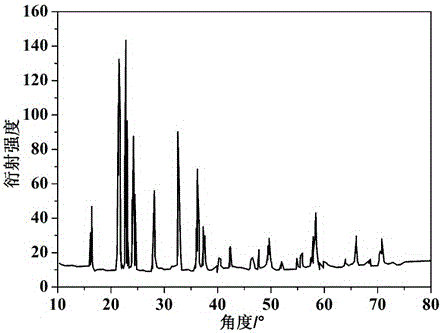

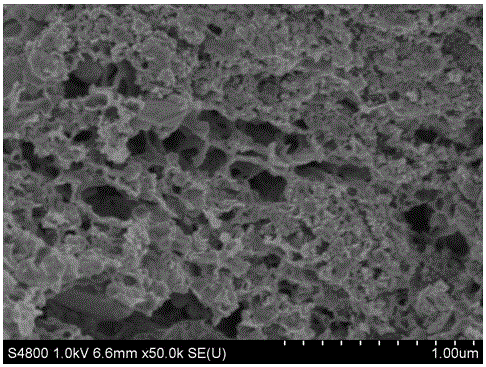

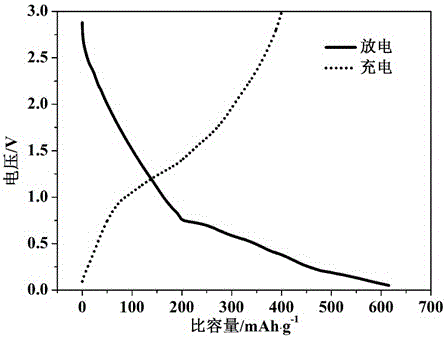

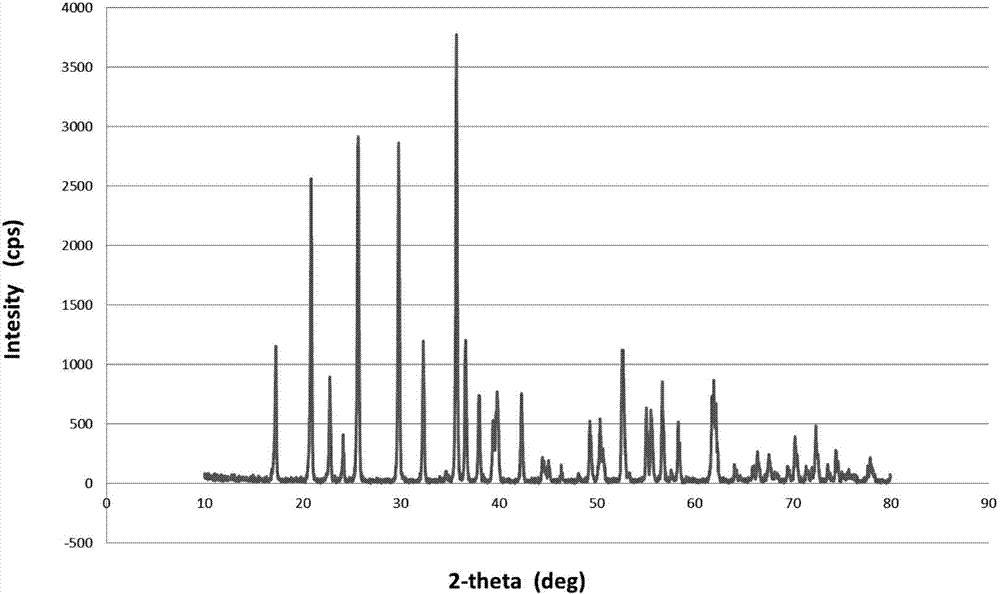

Preparation method for carbon-coated lithium vanadate used as negative electrode material of lithium ion battery

InactiveCN105720254ASmall grain sizeRich sourcesCell electrodesSecondary cellsPower batteryPhysical chemistry

The invention relates to a preparation method for a carbon-coated lithium vanadate used as a negative electrode material of a lithium ion battery. EDTA and ammonium hydroxide are added to deionized water and stirred to form a clarified transparent EDTA diamine water solution; a vanadium source and a lithium source are added and stirred to form a yellow green transparent solution; the transparent solution is evaporated and dried to obtain a blue lithium vanadate precursor; and after the precursor is grinded and smashed, the precursor is pre-calcined under a reducing atmosphere or an inert atmosphere, and then the processed precursor is re-smashed and re-sintered to obtain the carbon-coated lithium vanadate. The carbon-coated lithium vanadate prepared by the invention has the characteristics of uniform particles, stable batches, stable electrochemical performance and the like; and meanwhile, the material has a relatively good discharging platform and a relatively bright application prospect in the power battery industry.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for synthesizing ferric phosphate material

The invention relates to a method for synthesizing a ferric phosphate material, belonging to the technical field of lithium ion cathode materials. The method for synthesizing the ferric phosphate material comprises the following steps of: (1) manufacturing a hollow spherical template: stirring oil with carbon hydrogen bonds and a water-soluble surfactant free of metal ions for 0.1-10 h in a water solution to form an emulsion, wherein the weight ratio of the oil to the surfactant is 1:(1-9), and the total weight of the oil and the surfactant accounts for 0.1-5% of the solution; (2) precipitating ferric phosphate: adjusting the pH value of an acid solution containing phosphates and ferric salts by using the emulsion to form ferric phosphate precipitate, wherein the precipitate is adhered to an emulsion microsphere to form a structure of which the exterior is ferric phosphate and the kernel is the emulsion microsphere; and (3) processing the ferric phosphate microsphere: filtering and drying the ferric phosphate microsphere, calcining the ferric phosphate microsphere at high temperature to form a hollow / shell structure microsphere ferric phosphate material. The method provided by the invention has the advantages of simple process, operation convenience, stable ferric phosphate microsphere, large rate discharge capacity and low temperature capacity and the like.

Owner:天津恒普科技发展有限公司

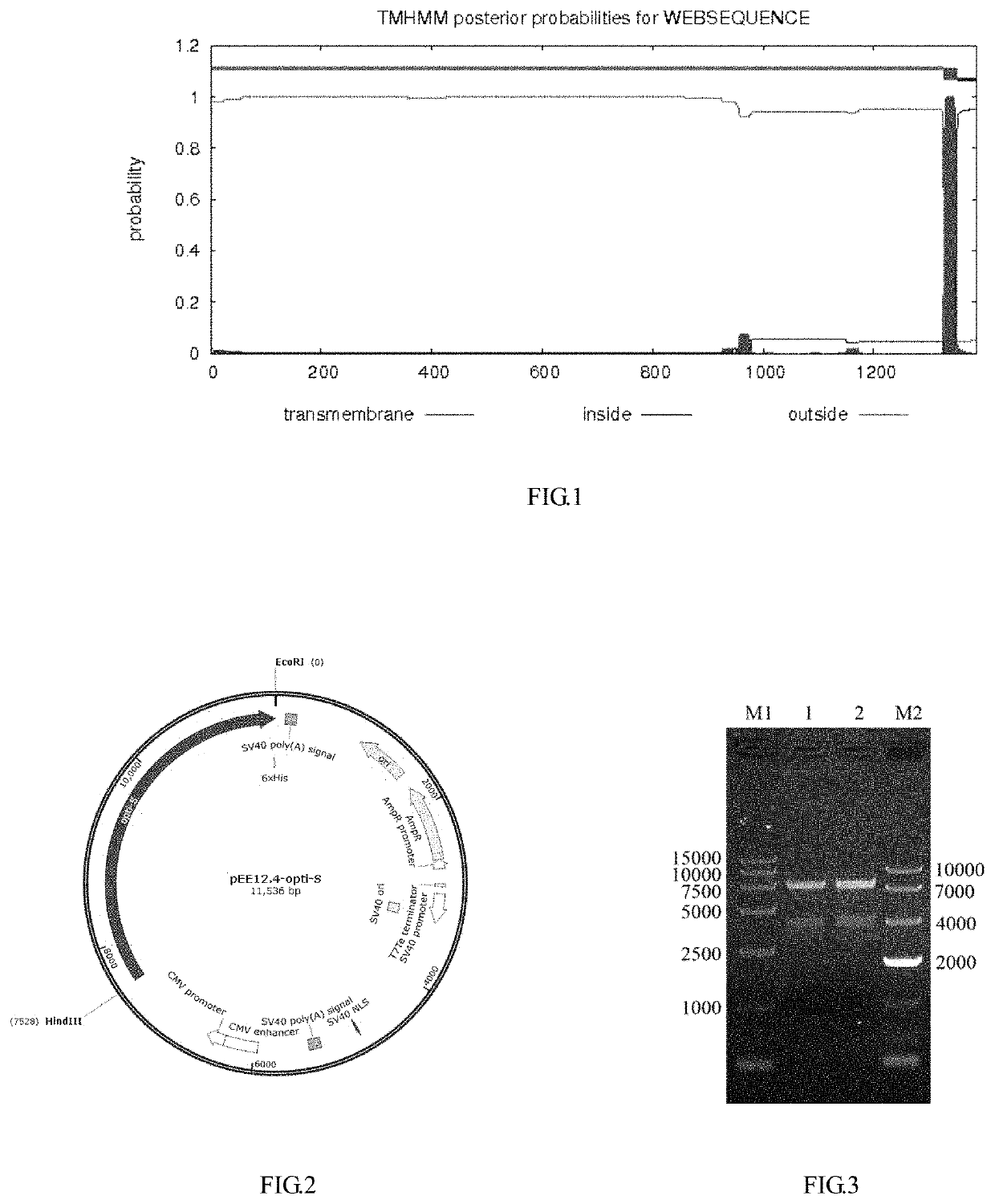

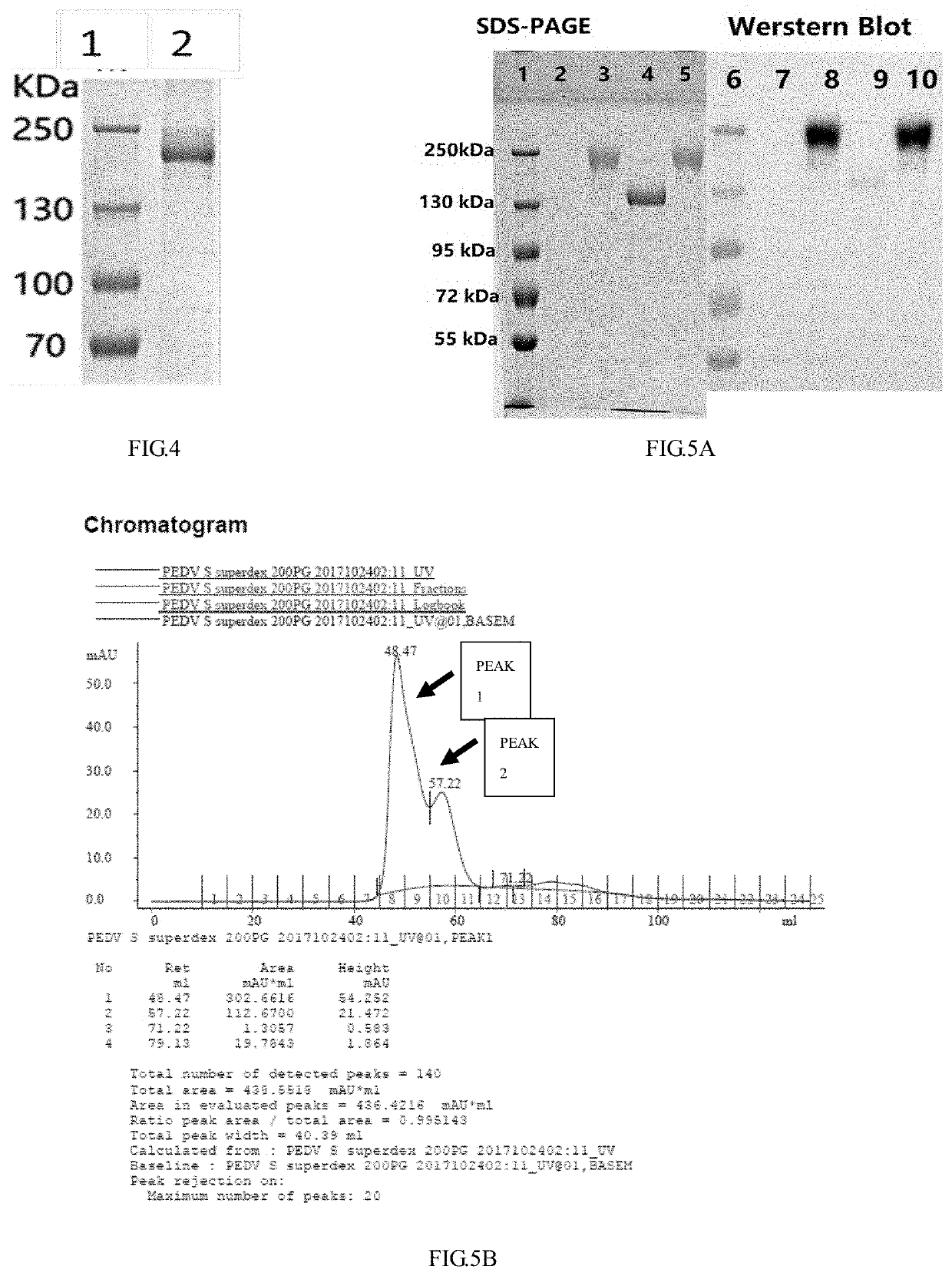

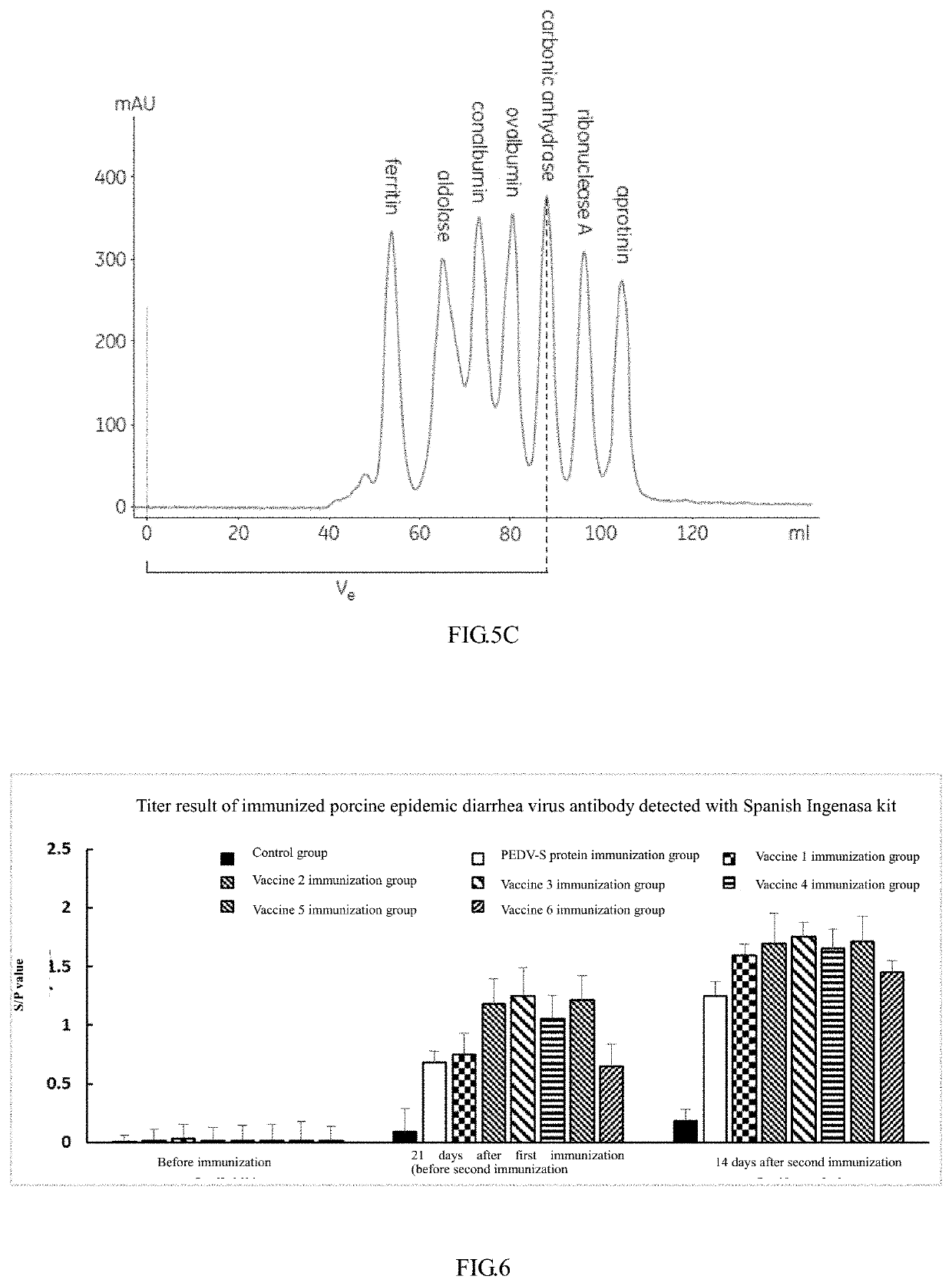

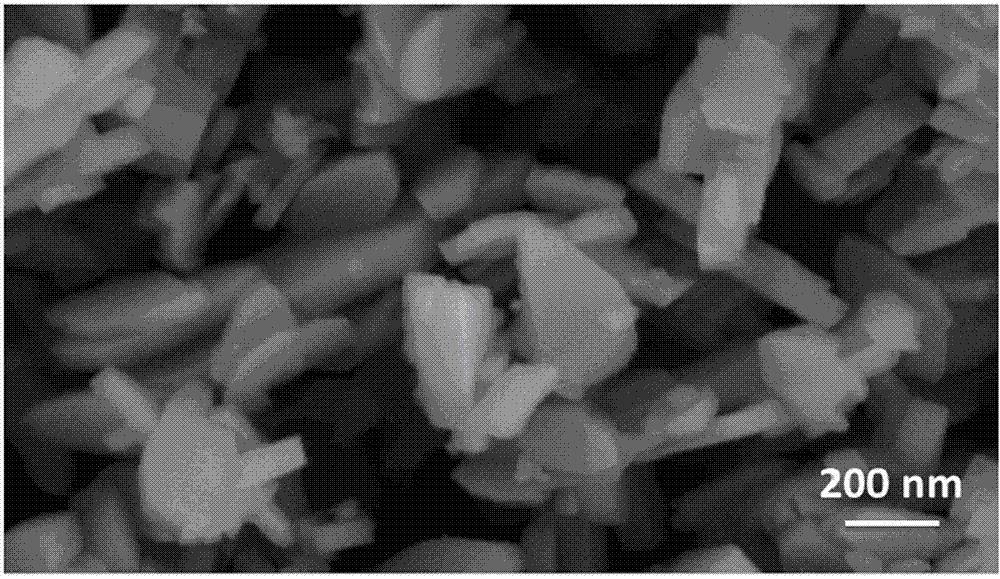

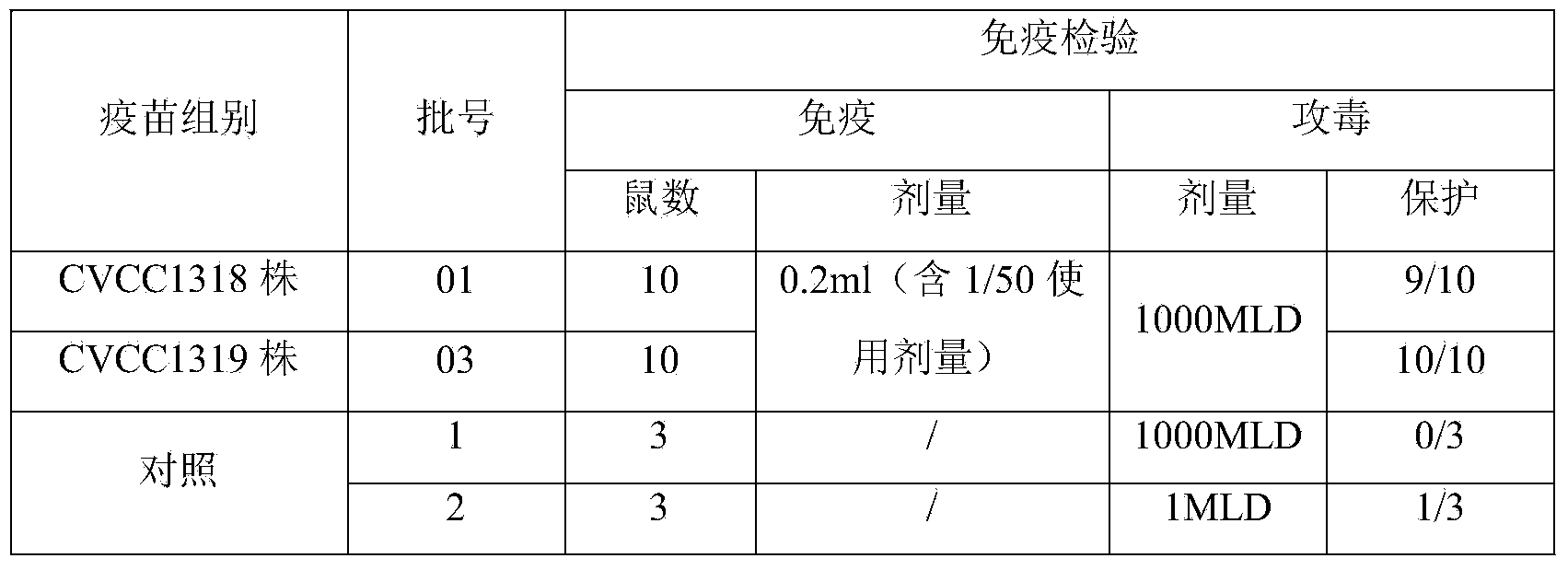

Porcine epidemic diarrhea virus s protein and subunit vaccine thereof as well as method for preparing subunit vaccine and application thereof

ActiveUS20200188508A1Improve securityImproving immunogenicitySsRNA viruses positive-senseViral antigen ingredientsEpidemic diarrheaAdjuvant

The disclosure discloses a porcine epidemic diarrhea virus S protein and a subunit vaccine thereof as well as a method for preparing the subunit vaccine and application thereof. The vaccine contains 30˜220 μg of a recombinant porcine epidemic diarrhea virus S protein and a pharmaceutically acceptable ISA 201 VG adjuvant. A method for preparing the subunit vaccine comprises the following steps: (1) cloning the recombinant porcine epidemic diarrhea virus S protein; (2) expressing and purifying the recombinant porcine epidemic diarrhea virus S protein; (3) preparing the recombinant porcine epidemic diarrhea virus S protein prepared in (2) into a water phase; (4) emulsifying the water phase and the ISA 201 VG adjuvant in a volume ratio of 46:54 to obtain a vaccine. The vaccine is high in safety, good in immunogenicity, stable in batches, low in production cost and strong in immunogenicity. On the other hand, CHO cell strains suspending and stably and efficiently expressing the PEDV-S protein are successfully constructed and screened for the first time. The CHO cell strain can express the PEDV-S protein in high yield, the yield can reach 1 g / L, and the expressed PEDV-S protein is easy to purify.

Owner:NOVO BIOTECH CORP

Method for synthesizing nano lithium iron phosphate without water of crystallization through atmospheric water phase

ActiveCN103400983AMild reaction conditionsReduce energy consumptionCell electrodesSecondary cellsLithium iron phosphateFerrous salts

The invention discloses a method for synthesizing nano lithium iron phosphate without water of crystallization through an atmospheric water phase, belonging to a method for preparing lithium-ion positive materials. The preparation process comprises the following steps of: preparing lithium phosphate, preparing a lithium phosphate water-phase suspension, preparing a ferrous salt solution, preparing the nano lithium iron phosphate without water of crystallization and recovering and recycling lithium in a lithium iron phosphate mother solution. The method has the beneficial effects of mild reaction condition, less time bucket, low energy consumption, stable batch and uniform and controllable force; as the lithium in the mother solution is recovered and recycled, the cost can be reduced; the method is beneficial to industrial production.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Three-dimensional printing method for honeycomb type electric catalyzing membrane reactor with three-dimensional channel

ActiveCN105500493AFast mass transferMass transfer automationCellsAdditive manufacturing apparatusMembrane reactorElectrolyte

The invention relates to a three-dimensional printing method for a honeycomb type electric catalyzing membrane reactor with a three-dimensional channel, and belongs to the technical field of solid oxide electrolytic tanks. The method is characterized in that the three-dimensional printing forming technology of a ceramic material is utilized, an electrolytic ceramic powder is used as a raw material, a three-dimensional drawing software is adopted, and a ceramic three-dimensional printer can perform output, so as to print and form a green body of the honeycomb type electric catalyzing membrane reactor with the three-dimensional channel by one step; the green body is subjected to sintering treatment to obtain an electrolyte supporting body; a cathode and an anode or the anode and the cathode are correspondingly deposited on the upper inner side and the upper outer side of the electrolyte supporting body by the emulsion impregnation method, thus forming the honeycomb type electric catalyzing membrane reactor with the three-dimensional channel. The method is efficient in preparation, can save the cost and greatly improve the mass transfer rate, and is high in automation degree, and stable in batch.

Owner:SHANDONG UNIV OF TECH

High-nickel single-crystal small-particle ternary precursor and continuous preparation method thereof

ActiveCN113373517AHigh solid contentIncrease collisionPolycrystalline material growthFrom normal temperature solutionsPhysical chemistrySingle crystal

The invention discloses a high-nickel single-crystal small-particle ternary precursor and a continuous preparation method thereof. The method comprises the following steps of: preparing a soluble ternary mixed salt solution, and adding H2O2 and an additive to obtain a mixed solution; adding a part of the mixed solution and a precipitant solution into a first reaction kettle for nucleation reaction, and continuously overflowing a reaction product to a second reaction kettle; when the addition amount of the ternary precursor crystal nucleus slurry accounts for 40-60% of the volume of the second reaction kettle, starting stirring in the second reaction kettle; adding the other part of the mixed solution and the precipitant solution into the second reaction kettle for growth reaction, starting overflow, continuously overflowing a reaction product to a concentration machine for concentration, and returning the product to the second reaction kettle; and carrying out aging, filter-pressing, washing and drying to obtain the high-nickel single-crystal small-particle ternary precursor. The technical problems that an existing intermittent method for preparing the high-nickel single-crystal small-particle ternary precursor is low in yield, low in production efficiency, high in cost and poor in batch stability, and nickel and lithium cations are mixed in the subsequent calcination process are solved.

Owner:南通金通储能动力新材料有限公司

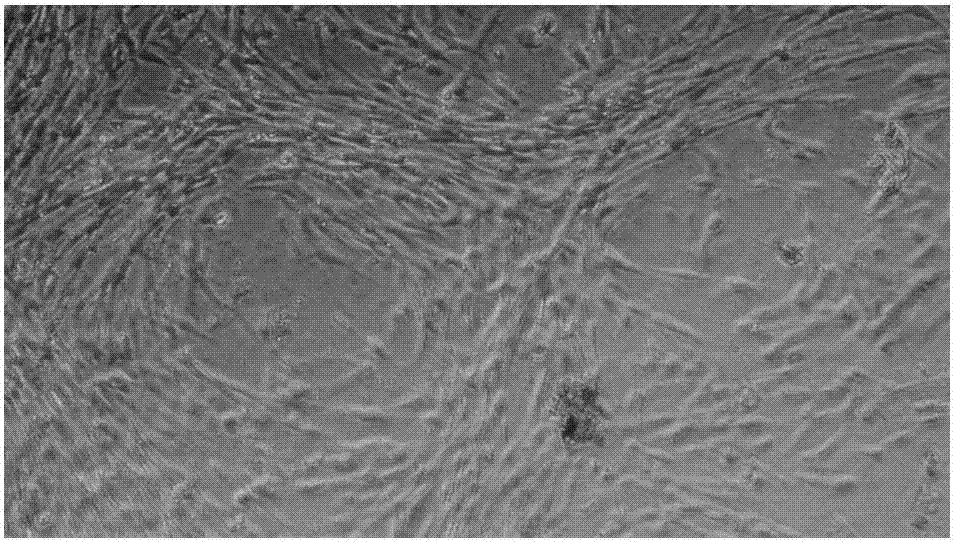

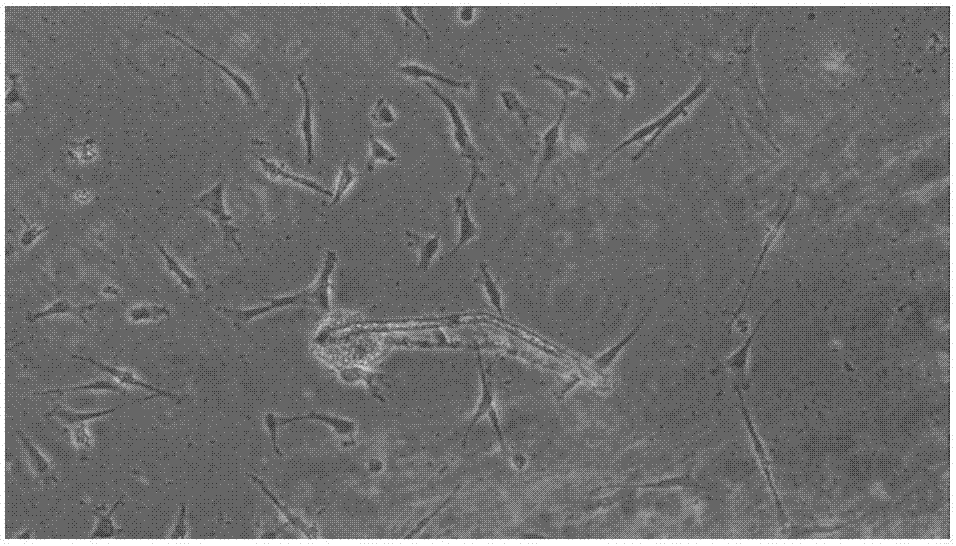

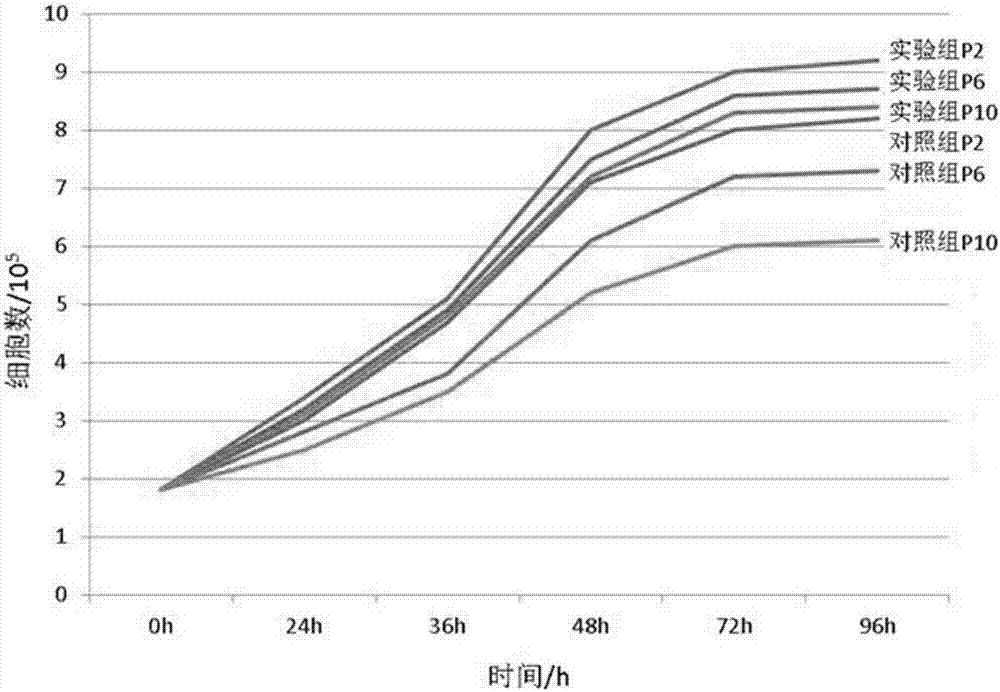

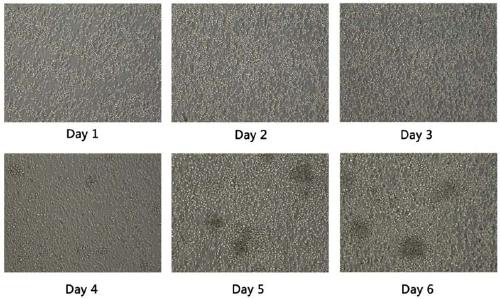

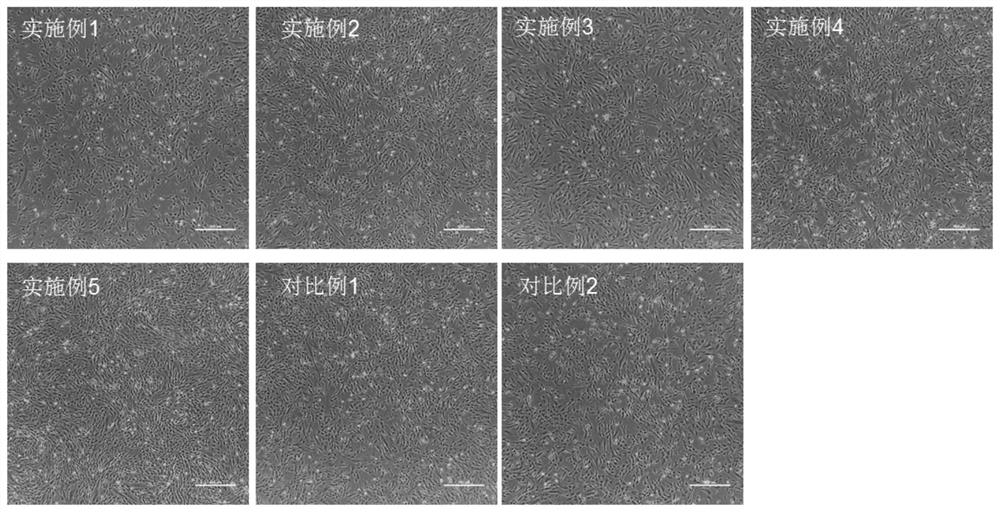

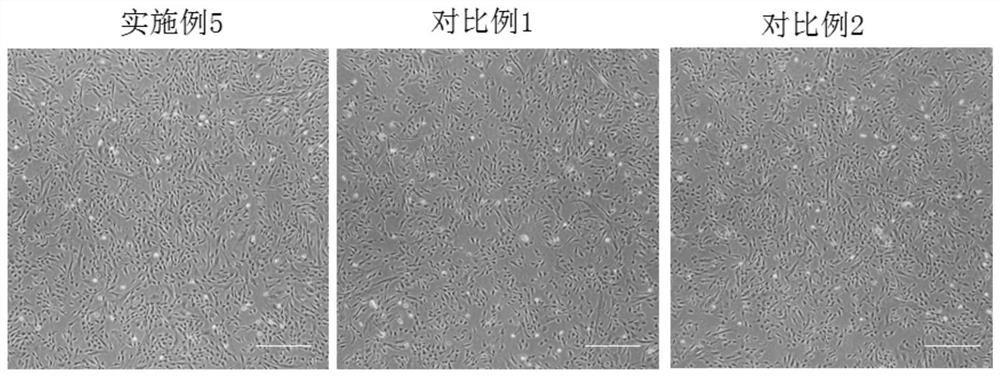

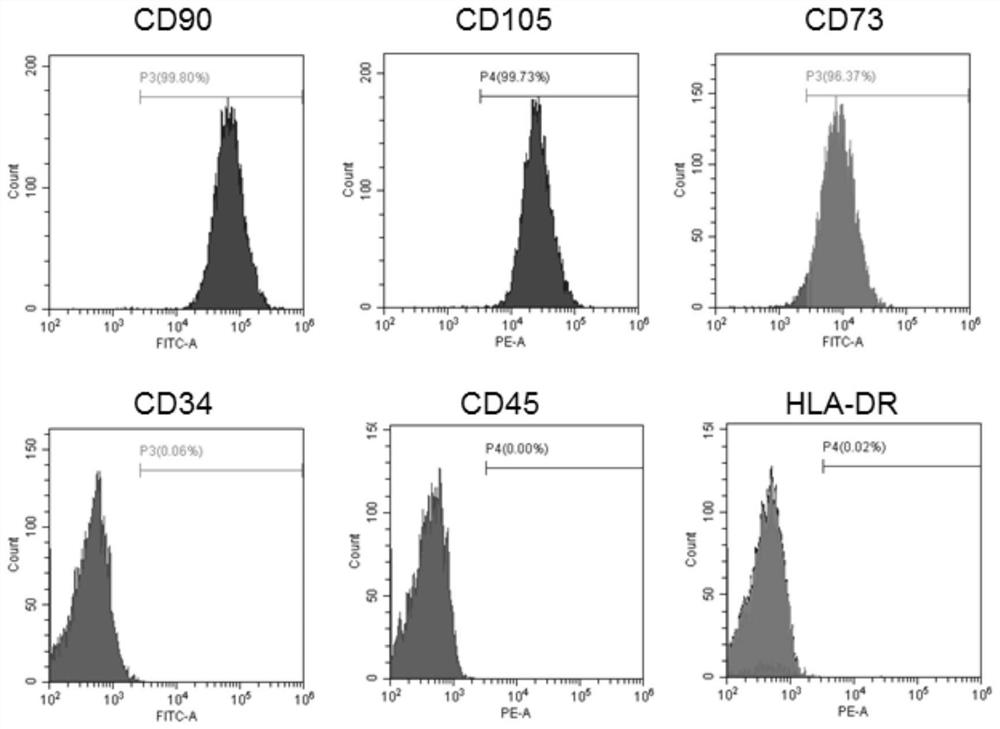

Human umbilical cord mesenchymal stem cell culture method

InactiveCN107189982AReduce the risk of contaminationEasy to useCell dissociation methodsSkeletal/connective tissue cellsWharton's jellyUmbilical cord tissue

The invention discloses a human umbilical cord mesenchymal stem cell culture method, which comprises: (1) obtaining an umbilical cord tissue; (2) separating Wharton's Jelly; (3) cutting the Wharton's Jelly into tissue blocks, inoculating the tissue blocks into a T75 culture bottle, adding an appropriate amount of a primary culture medium, placing into a CO2 incubator, carrying out standing culture for 3 days, supplementing 5 ml of the primary culture medium at the 4th day, changing the culture medium every 2-3 days from the 4th day, removing the tissue block when cells start to migrate from the majority of the tissue blocks, changing the culture medium, and carrying out passage amplification when the cell density achieves 80% and above; and (4) after the treatment, re-suspending with a passage culture medium. According to the present invention, the animal-derived additive is not used during the culture process, such that the safety is provided; and the operation is simple and convenient, and the culture time is short.

Owner:北京焕生汇生物技术研究院有限公司

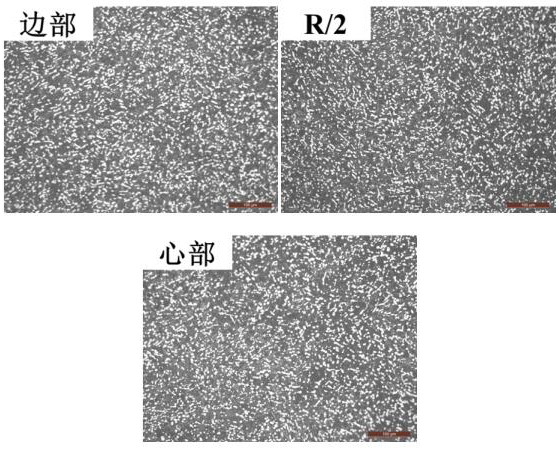

Forging processing method for TC32 titanium alloy large specific bar

ActiveCN112676503APrecise regulationSolve the problem of poor toughness matchingMetal-working apparatusMetallurgyTitanium alloy

The invention relates to the technical field of titanium alloy forging, in particular to a forging processing method for a TC32 titanium alloy large specific bar. The method comprises the steps: performing recrystallized homogenized forging after cogging forging; then performing forging at a beta transition temperature; and finally, forging a product. Tissues are regulated and controlled precisely to obtain needed mechanical properties. The consistence of flaw detection level of the bar is improved. The obtained tissues and performance are uniform, and the yield is improved.

Owner:湖南湘投金天钛业科技股份有限公司

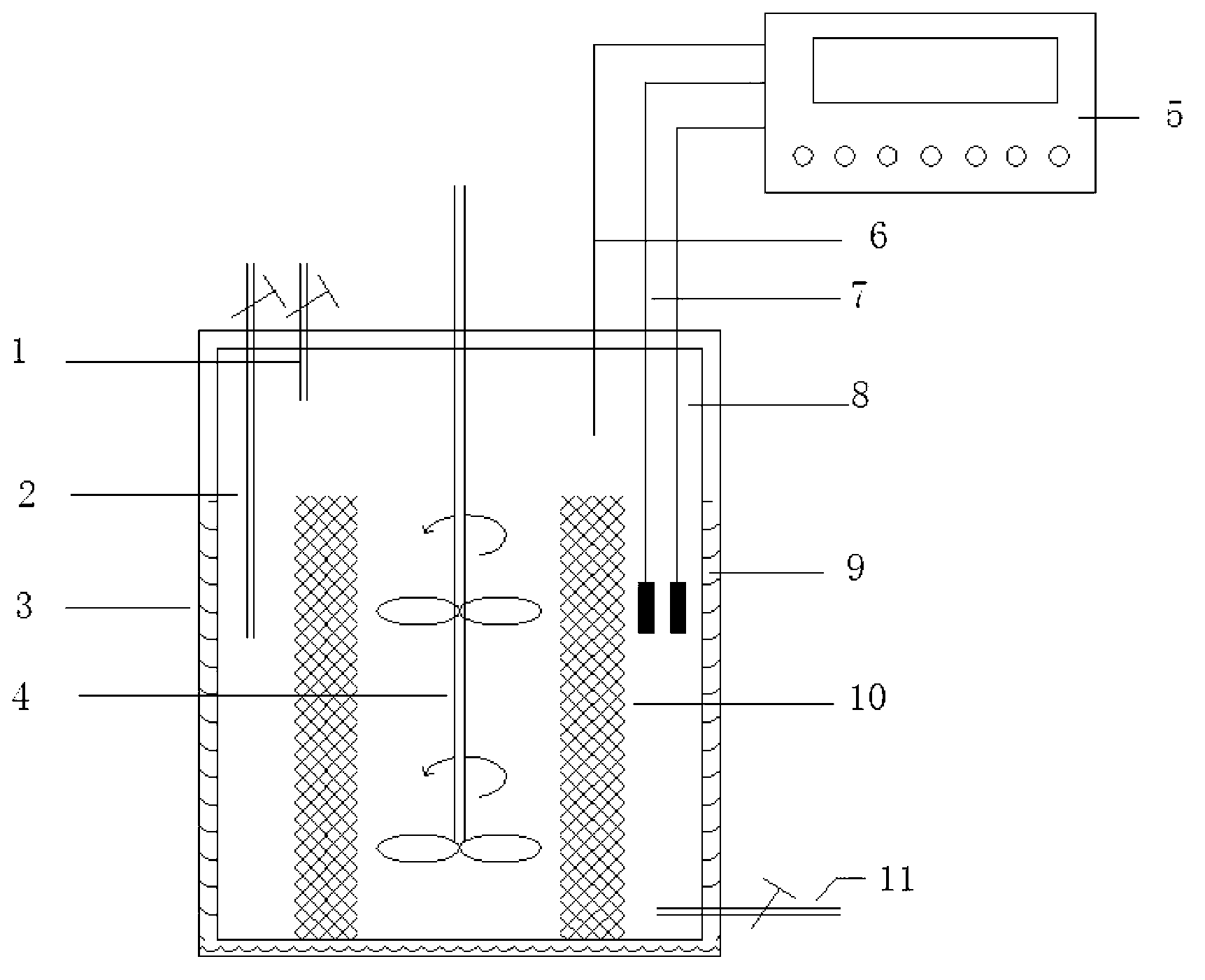

Fermentation method for lactobacillus with high cell density

ActiveCN103255083AGuaranteed bacterial countReach homeostasisBacteriaMicroorganism based processesHigh cellFiber

The invention relates to the technical field of biological products, and discloses a fermentation method for lactobacillus with high cell density. The fermentation method comprises the steps of constructing a fibrous bed reactor, preparing a culture medium, inoculating, culturing by fermenting, detecting microbial content, collecting fermentation liquor and the like. According to the fermentation method, fiber materials are successfully arranged inside the reactor as carriers of immobilized lactobacillus cells, and the number of the lactobacillus cells can be substantially enhanced in fermentation of lactobacillus with the fibrous bed and under specific fermentation conditions. The biological reactor can be separately used or be taken as a seed fermentation tank to be combined with a common reactor for carrying out sequence fermentation in batches or continuous fermentation, and has the characteristics of being high in production efficiency and stable in batch production, shortening a fermentation period, ensuring high cell density and the like; fiber materials used by the method are cheap; the device is simple and convenient to operate, the production cost is low, and the fermentation method can be well applied to industrialized production of cells of lactobacillus such as lactobacillus acidophilus, lactobacillus bulgaricus and bifidobacterium.

Owner:BIOFORTE BIOTECHSHENZHEN CO LTD

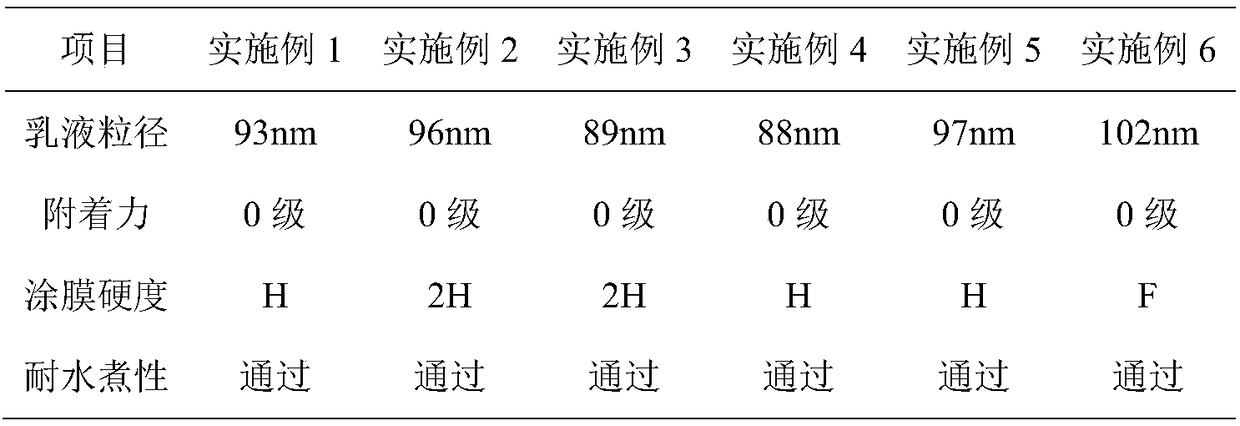

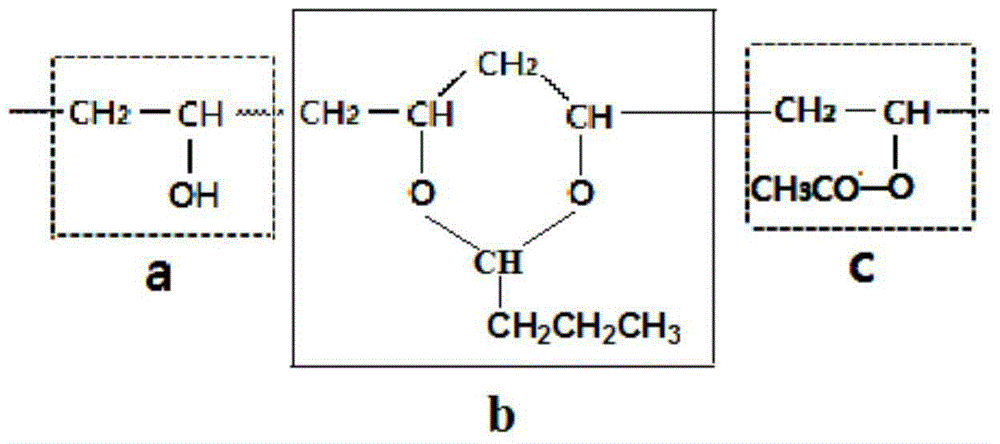

Waterborne photo-curing resin and application thereof

The invention provides waterborne photo-curing resin and application thereof, and belongs to the technical field of a coating material and an adhesive. A technical scheme is characterized by polymerizing monomers containing C-C double bonds through free radicals, thus obtaining an acrylate prepolymer; linking the C-C double bonds to a polymer structure, and then carrying out neutralization and water dispersion, thus obtaining a product. According to the waterborne photo-curing resin and the application thereof, provided by the invention, the waterborne photo-curing resin can be conveniently and quickly prepared by emulsifyinng a traditional photo-curing monomer or prepolymer in a prepared acrylate water dispersion; a main component of the waterborne photo-curing resin is an acrylate polymer, and a curing coating layer has good weather resistance and good boiling stability; in the waterborne photo-curing resin prepared by adopting the technical scheme, the solid content can be up to 50percent, and the viscosity is low; through formula design, the waterborne photo-curing resin can be widely applied to the fields of waterborne coating materials and adhesives.

Owner:北京乾瑞科技有限公司

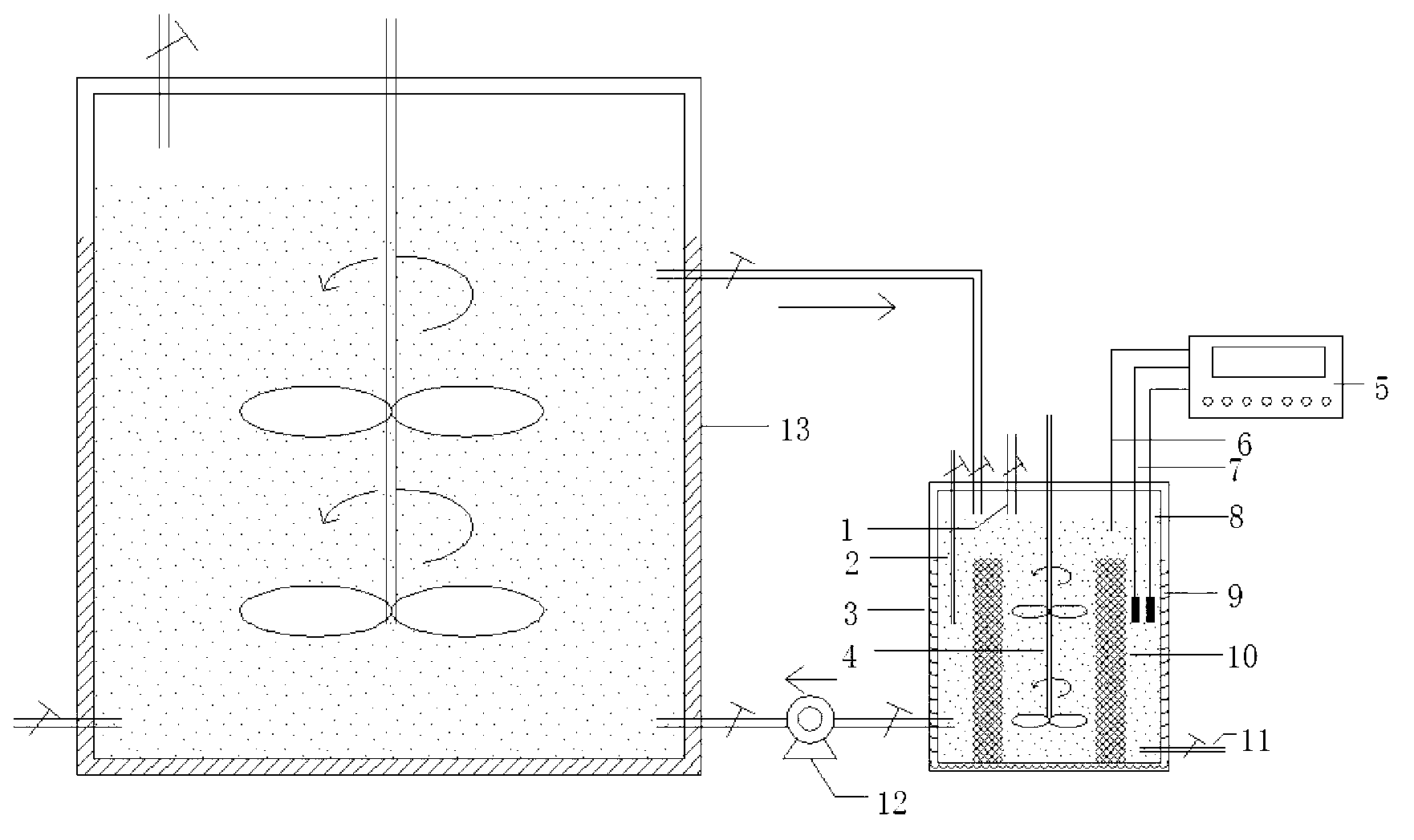

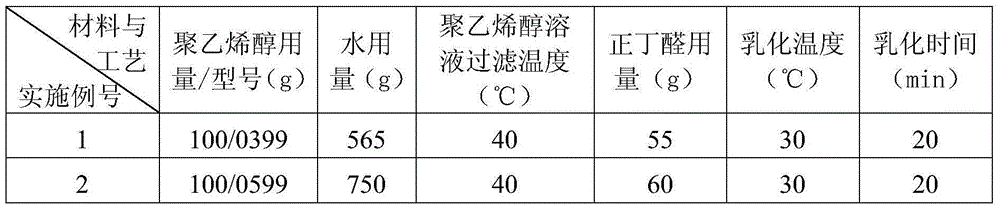

Continuous preparation method for catalytically synthesizing polyvinyl butyral resin through organic acid

The invention discloses a continuous preparation method for catalytically synthesizing polyvinyl butyral resin through organic acid. The continuous preparation method is characterized in that by mass, 500 parts of polyvinyl alcohol-n-butyl aldehyde aqueous emulsion is prepared and continuously and simultaneously put into a high-shear mixer with 100 parts of 2.5% organic acid aqueous emulsion, and the polyvinyl alcohol-n-butyl aldehyde aqueous emulsion and the 2.5% organic acid aqueous emulsion are mixed and react for 10 min-20 min at shearing rate of 50S-1-150S-1 with the shear force 50 Pa-150 Pa at 30 DEG C-40 DEG C, then are sent to an aging kettle and sequentially processed through first-stage reaction at 39-41 DEG C for 3-4 h and second-stage reaction at 59-61 DEG C for 2-3 h to complete the polymerization process; mother liquid is removed through a centrifugal machine, solid substances are processed through water washing, alkali washing, water washing and drying, and then the powder polyvinyl butyral resin is prepared. The continuous preparation method is continuous in preparation, high in efficiency, low in energy consumption and stable in product quality; the prepared polyvinyl butyral resin is suitable for the fields of photovoltaicpackaging materials, architectural safety glass, safety glass for cars and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Preparation method for hydroxyethyl starch

ActiveCN102617743AReduce molecular weightReduce the degree of polymerizationUltrafiltrationActivated carbon

The invention belongs to the technical field of medicines, and particularly relates to a preparation method for 130 / 0.4 hydroxyethyl starch. The method mainly comprises the following steps of gelatinizing and hydrolyzing, performing hydroxyethyl etherification, performing rough filtration, decolorizing and clarifying, performing refined filtration, performing ultrafiltration and drying. According to the method, insoluble chitosan is used for decolorization and clarification, and the conventional process in which activated carbon is used for decolorization is improved, so production efficiency and the quality of hydroxyethyl starch are improved. The method overcomes the defects that decolorization efficiency is low, the adsorption amount is limited, filtration time of feed liquid is long, and toxin in the feed liquid exceeds the limit and the like because the active carbon is used for decolorization in the conventional process, adsorption speed of insoluble chitosan is 6 times that of the active carbon, and the adsorption amount of insoluble chitosan is 5.5 times more than that of the active carbon; the insoluble chitosan can be repeatedly used, secondary pollution is avoided, high mechanical intensity is achieved, and filtration is not influenced; and the raw materials of the produced hydroxyethyl starch are stable in batch, and the quality of the produced hydroxyethyl starch is reliable and meets the national standard.

Owner:李育强

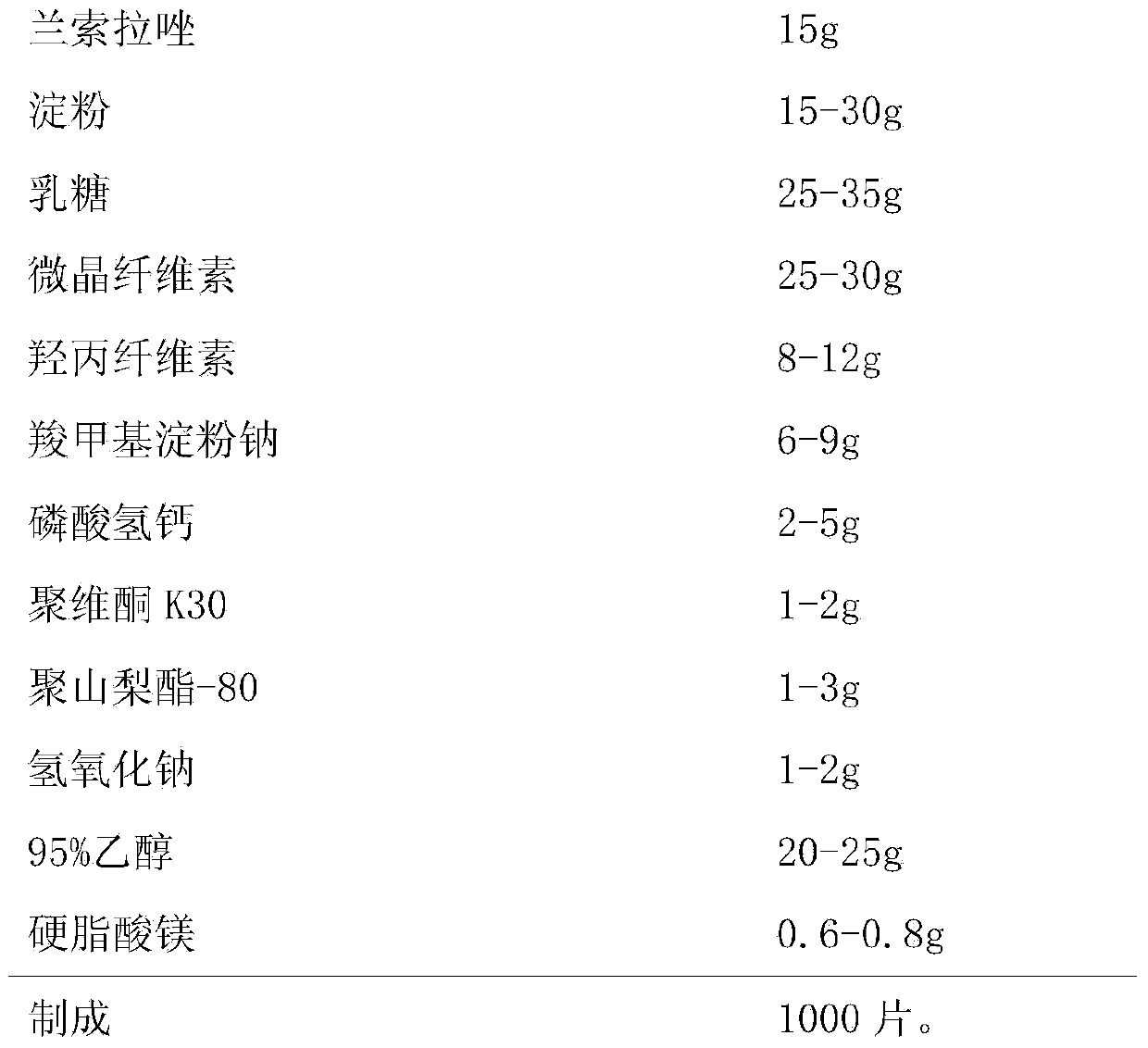

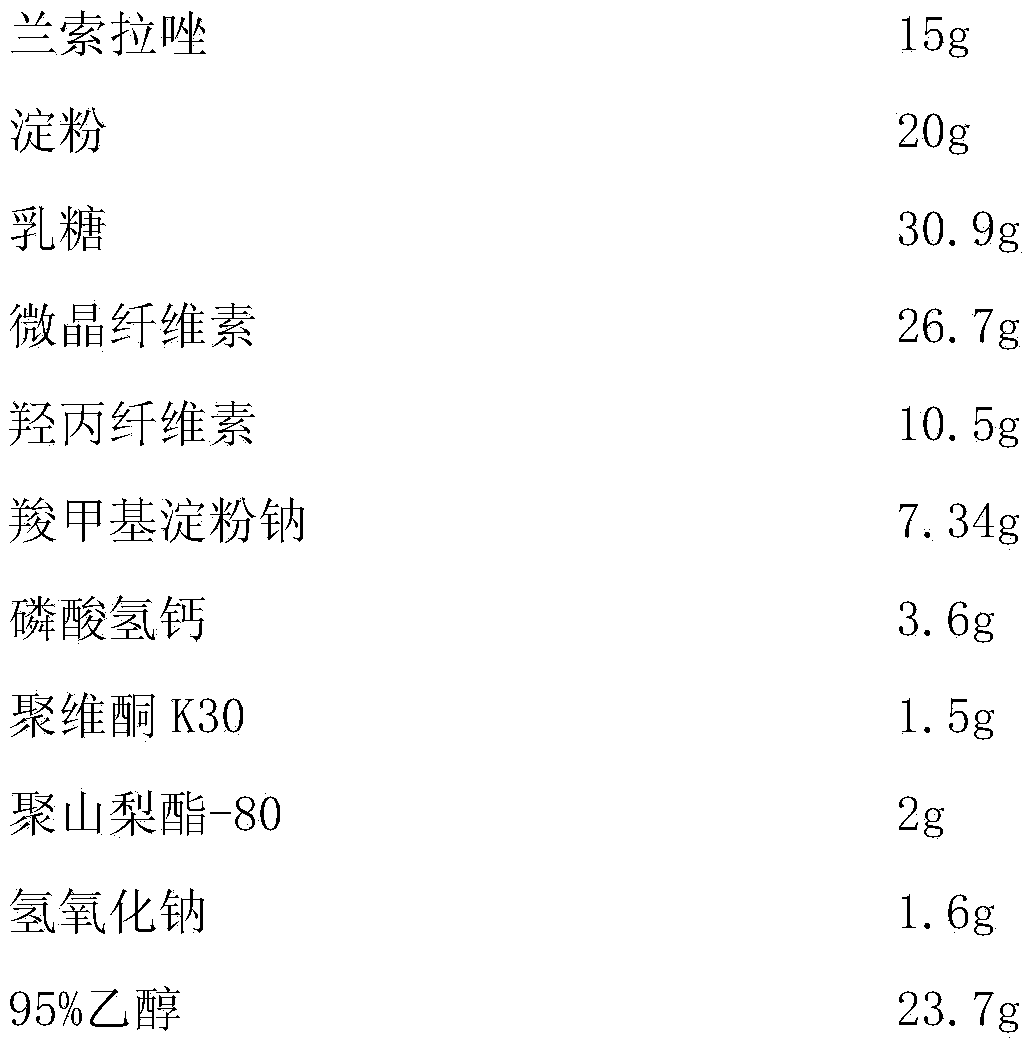

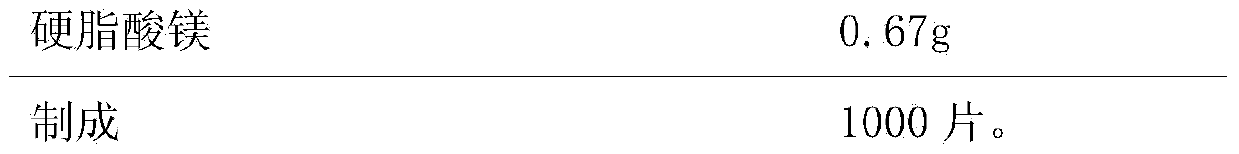

Lansoprazole enteric-coated tablet and preparation method thereof

ActiveCN104188935AImprove solubilityIncreased release rateOrganic active ingredientsDigestive systemSolubilitySodium hydroxide

The invention discloses a lansoprazole enteric-coated tablet and a preparation method thereof. The preparation method comprises the following steps: preparing lansoprazole and pharmaceutic adjuvants comprising starch, lactose, microcrystalline cellulose, hydroxypropyl cellulose, sodium carboxymethyl starch, calcium hydrogen phosphate, povidone K30, sodium hydroxide, magnesium stearate and the like into a tablet core; coating the tablet core with an isolated layer, and finally coating the tablet core with an enteric-coated layer so as to obtain the lansoprazole enteric-coated tablet. According to the method, the solubility and releasing rate of the lansoprazole are effectively improved, so that the oral bioavailability of the lansoprazole is improved. The formula process for preparing the lansoprazole enteric-coated tablet is simple, convenient and stable, and is suitable for mass industrial production.

Owner:JINAN LIMIN PHARMA

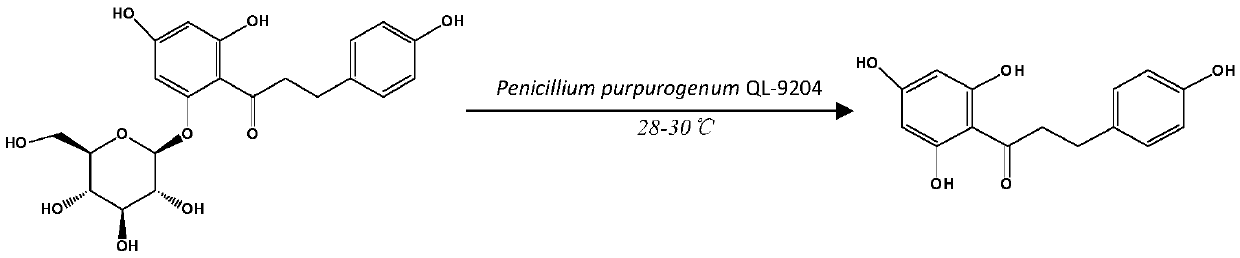

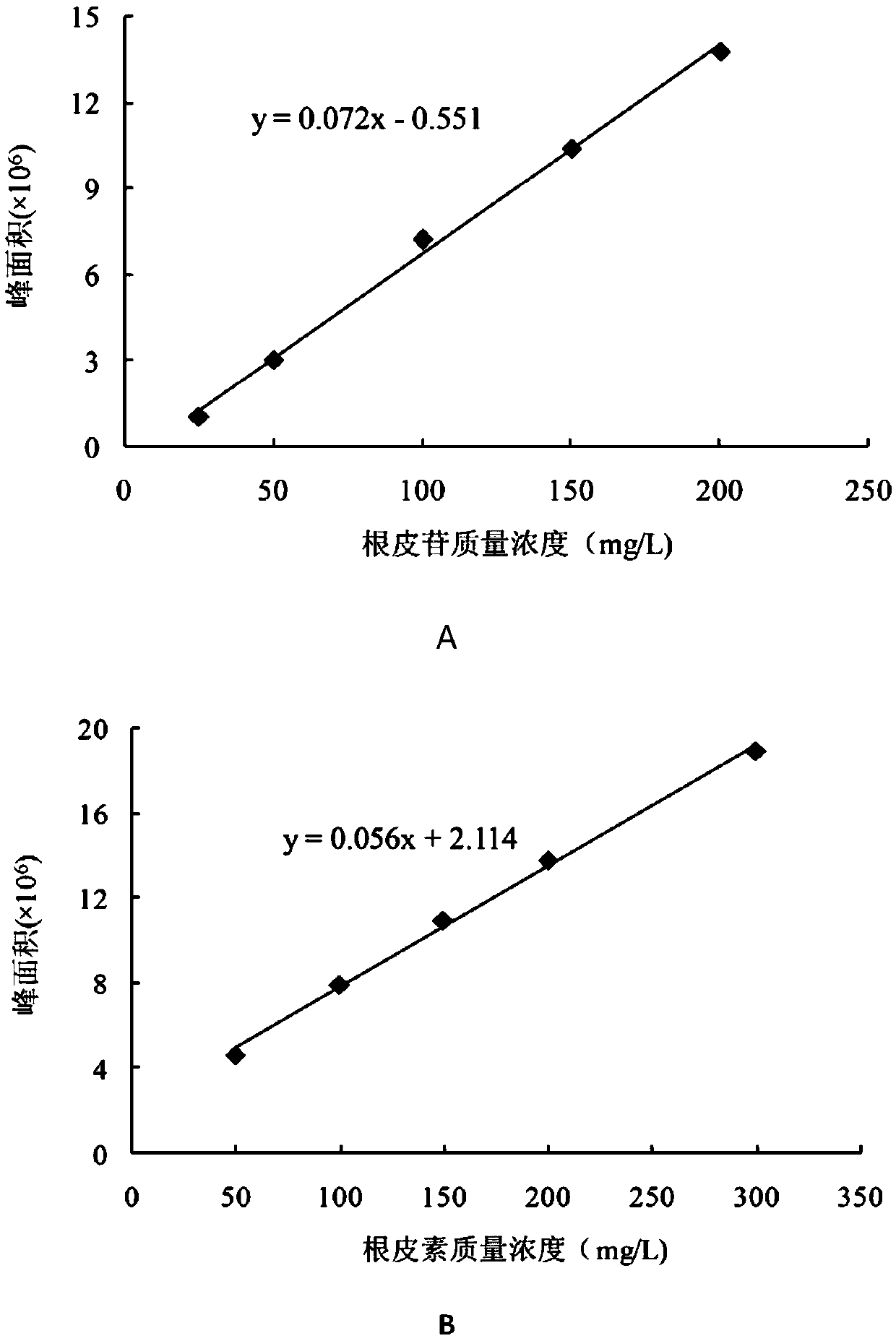

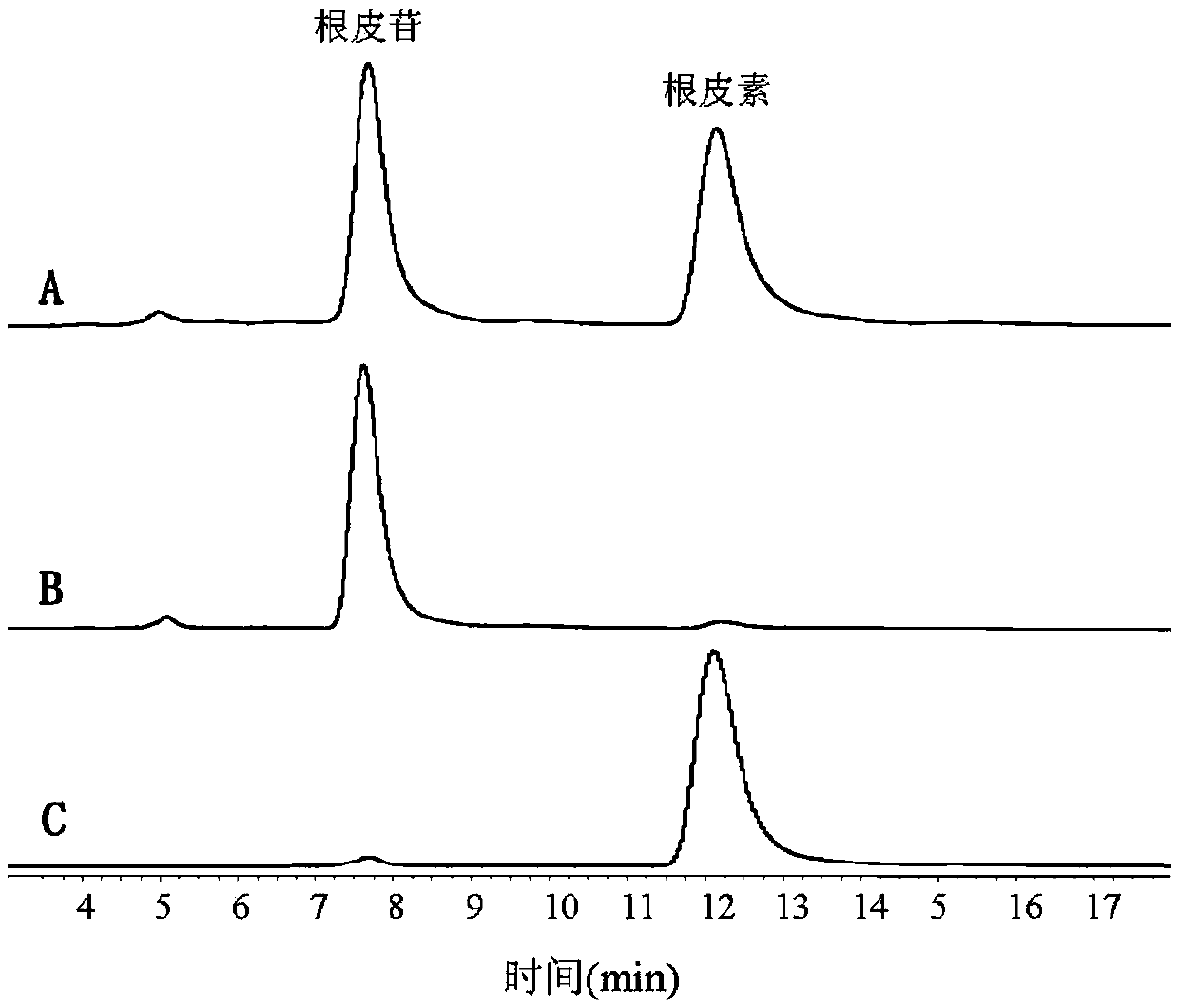

Penicillium purpurescens QL-9204 and application for preparing phloretin during phlorizin conversion

ActiveCN105543108AGrow fastImprove anti-bacterial abilityFungiMicroorganism based processesPenicillium cainiiFermentation

The invention discloses penicillium purpurescens QL-9204 and application for preparing phloretin during phlorizin conversion. The penicillium purpurescens QL-9204 is a strain free of toxicity and harm and safe to use. The penicillium purpurescens QL-9204 grows rapidly, and is high in hybrid bacteria resistance, easy to culture and stable in batch; a fermentation medium is simple in components and low in market price, thereby being low in production cost; a substrate plorizin is directly put into a crude enzyme for conversion, the enzyme separation and purification steps are omitted, the technology is simple, and the penicillium purpurescens QL-9204 is easy to apply industrially; the phloretin conversion yield is high and can reach 92.5% to the maximum, and the penicillium purpurescens QL-9204 has the advantages that few by-products are produced, and the product is easy to extract.

Owner:ZHEJIANG UNIV OF TECH

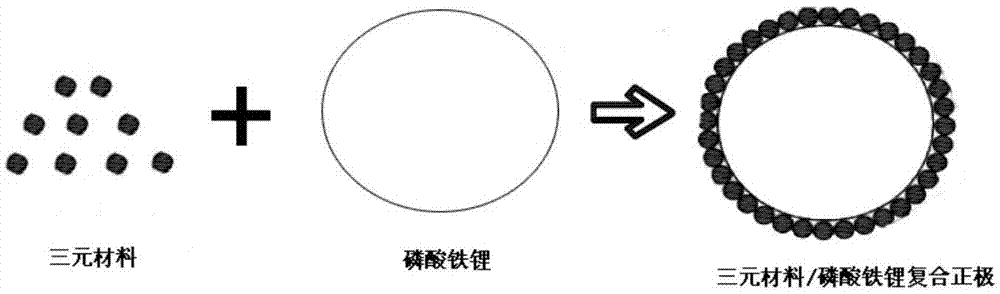

Preparation method and application of ternary positive electrode material for battery

InactiveCN106992297AShort cycleReduce consumptionFinal product manufactureCell electrodesLithium iron phosphateMixed materials

The invention provides a preparation method and application of a ternary positive electrode material for a battery, belonging to the field of ternary batteries. The preparation method comprises the following steps: providing a ternary material and lithium iron phosphate; and mixing the ternary material with lithium iron phosphate so as to form a mixed material and carrying out ball milling on the mixed material to allow the particle sizes of the mixed material to be in normal distribution so as to obtain the ternary positive electrode material for the battery, wherein the ternary material has a median diameter D50 of 8 to 10 [mu]m, the lithium iron phosphate has a median diameter D50 of 1 to 2 [mu]m, and the mixed material has a median diameter D50 of 9 to 13 [mu]m.

Owner:SHENZHEN CENT POWER TECH

Production process of ruthenium trichloride

ActiveCN106335932ANo pollutionShorten the production cycleRuthenium/rhodium/palladium/osmium/iridium/platinum halidesAlcoholSolvent

The invention relates to a production process of ruthenium trichloride. According to the process, RuO4 gas is produced according to a traditional method; diluted hydrochloric acid is adopted for absorbing the RuO4 gas till the concentration of Ru in the solution ranges from 59 g / L to 61 g / L, meanwhile, the pH value is adjusted to range from 1.9 to 2.1, and a ruthenium-containing solution is obtained; a dispersing solvent is added into the ruthenium-containing solution, the adding volume of the dispersing solution is 9.8-10.2% of the volume of the ruthenium-containing solution, and the dispersed ruthenium-containing solution is obtained; the dispersing solvent is a mixture of hydrogen peroxide, ethyl alcohol and acetone according to the volume ratio of 1:(7.9-8.1):(0.95-1.05), the obtained dispersed ruthenium-containing solution is spray-dried through a spray dryer, and ruthenium trichloride powder is obtained. A traditional production process of ruthenium trichloride is improved, continuous, large-scale and equipment production is achieved, and the purposes of being short in production period, low in cost and free of polluting the environment are achieved.

Owner:昆明铂磊科技有限公司

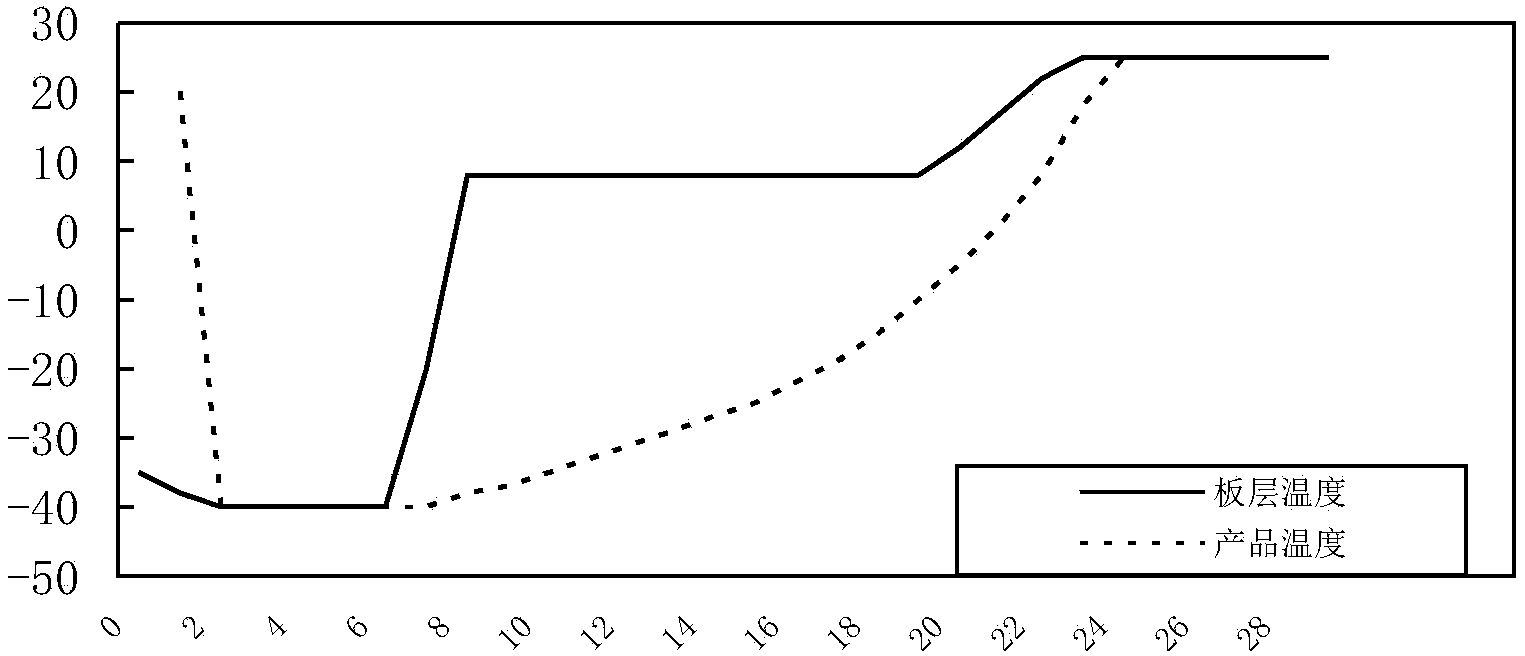

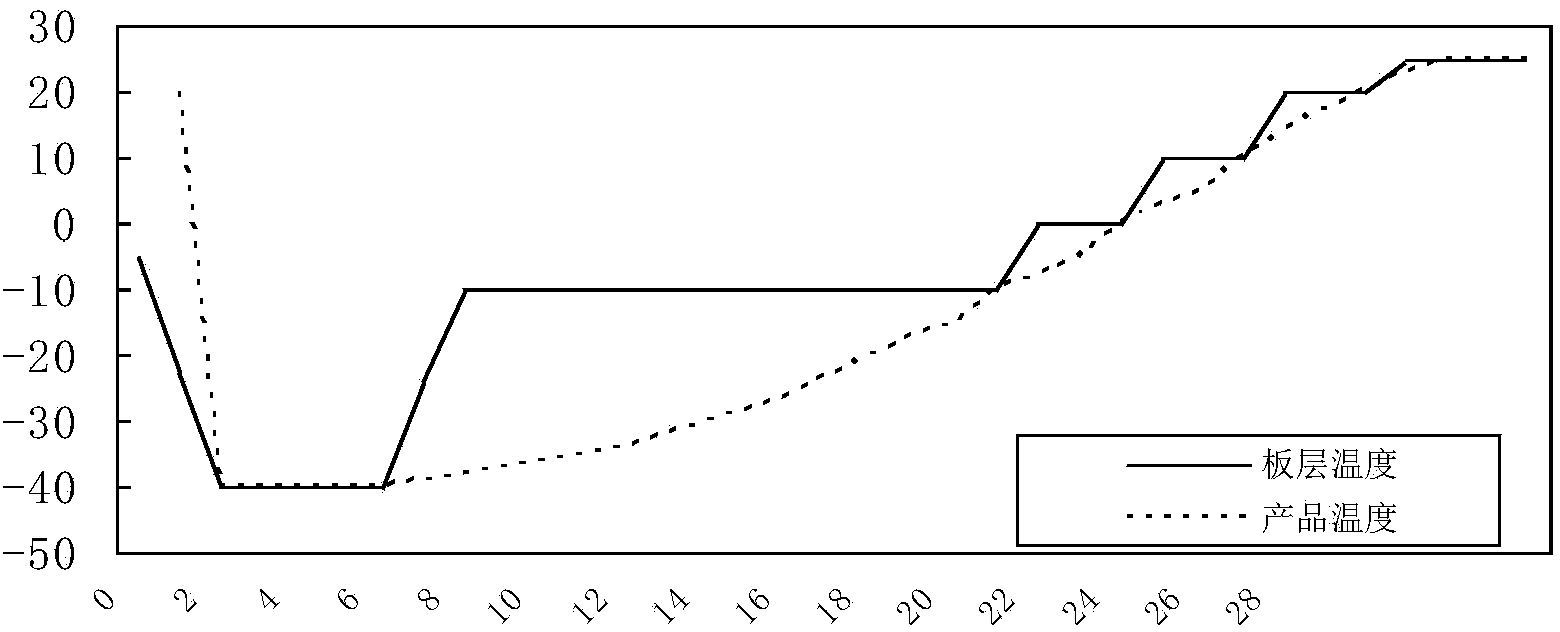

Method for producing swine erysipelas live vaccine

ActiveCN104306963ASource controllableHigh activityAntibacterial agentsBacterial antigen ingredientsFreeze dryCulture bacteria

The invention relates to application of a synthetic medium and a freeze-drying protective agent in the production of a swine erysipelas live vaccine. The synthetic medium provided by the invention is designed according to growth characteristics and growth requirements of bacillus erysipelatos-suis, is controllable in raw material sources of the formula, is not influenced by materials such as beef, beef liver, pig stomach and so on, is stable in batch, simple in manufacturing, convenient to use, suitable for carrying out high cell density culture of bacteria and high in amount of culture bacteria; in the freeze-drying process, through the adoption of the freeze-drying protective agent developed for the characteristics of the bacillus erysipelatos-suis and a matched freeze-drying curve, the activity of the bacteria is effectively protected in the freeze-drying process, so that the survive rate of the freeze-dried bacteria is increased and the vaccine is preserved for a long time at 2-8 DEG C and can be preserved for 24 months.

Owner:北京中海生物科技有限公司 +1

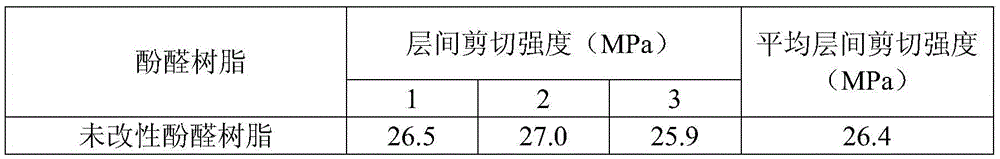

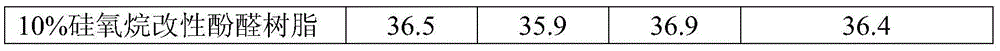

Siloxane-modified phenolic resin for hot melt preimpregnation technology and preparation method of siloxane-modified phenolic resin for hot melt preimpregnation technology

The invention discloses a siloxane-modified phenolic resin for a hot melt preimpregnation technology and a preparation method of the siloxane-modified phenolic resin for the hot melt preimpregnation technology. The siloxane-modified phenolic resin for the hot melt preimpregnation technology is prepared from, by mass, 50-100 parts of phenolic resin, 1-10 parts of toughening agent and 1-20 parts of siloxane. The siloxane-modified phenolic resin for the hot melt preimpregnation technology has the advantages that release moisture is little when the resin is cured, micropore forming can be reduced, flexibility, impact resistance and interlaminar shear strength of phenolic resin cured materials are improved effectively, and the siloxane-modified phenolic resin is higher than traditional RF (phenolic resin) in heat resistance.

Owner:XI AN JIAOTONG UNIV

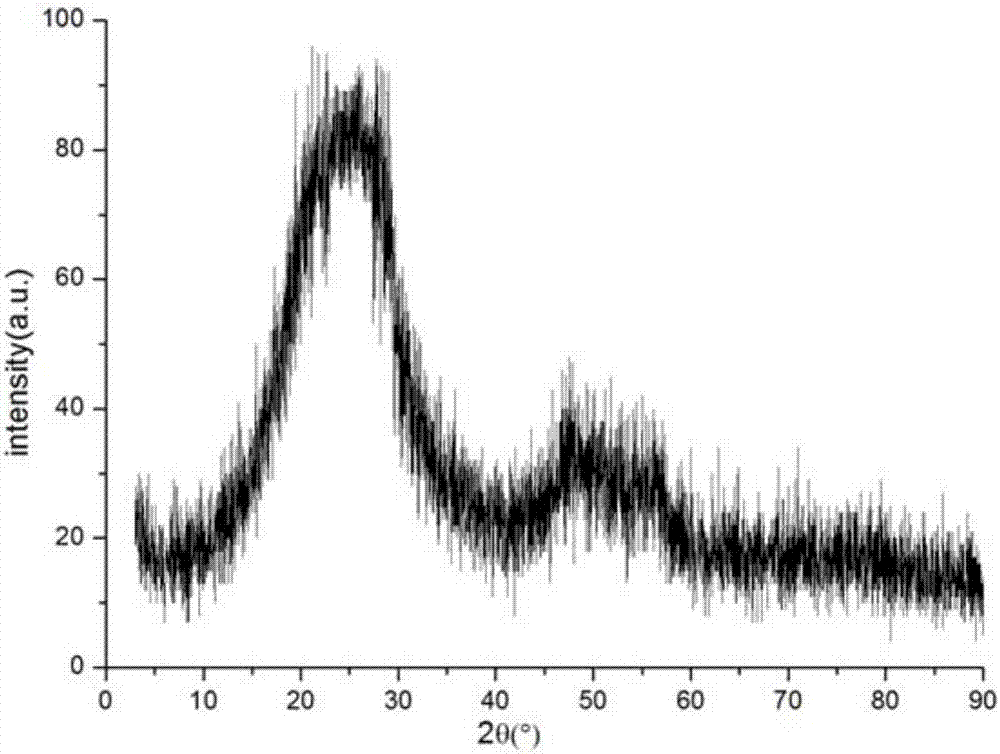

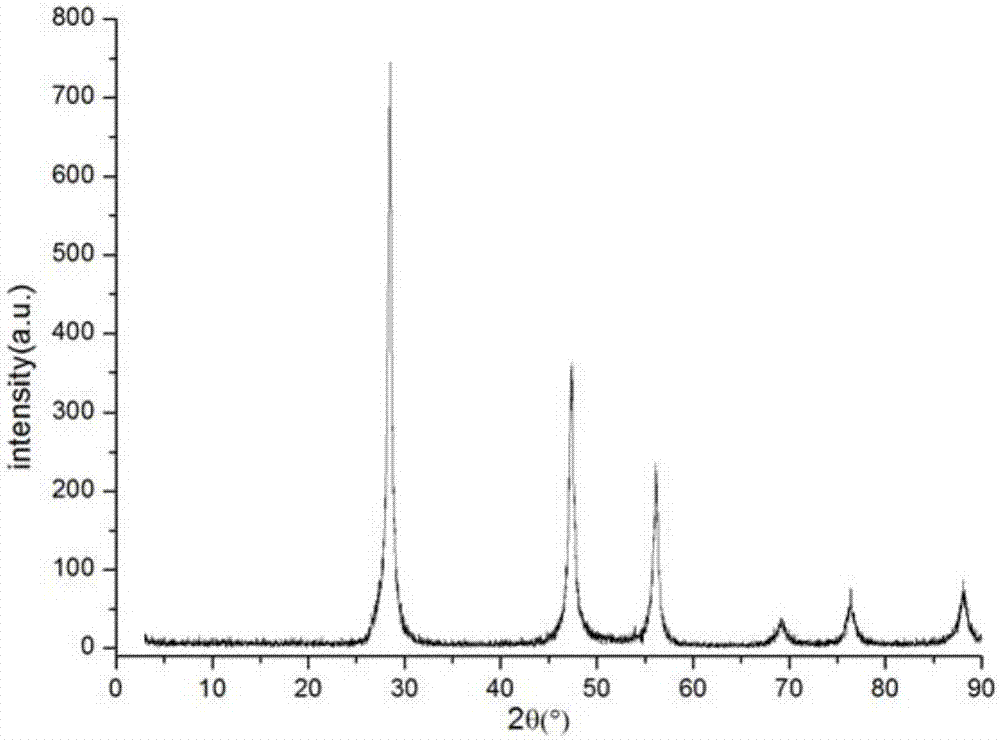

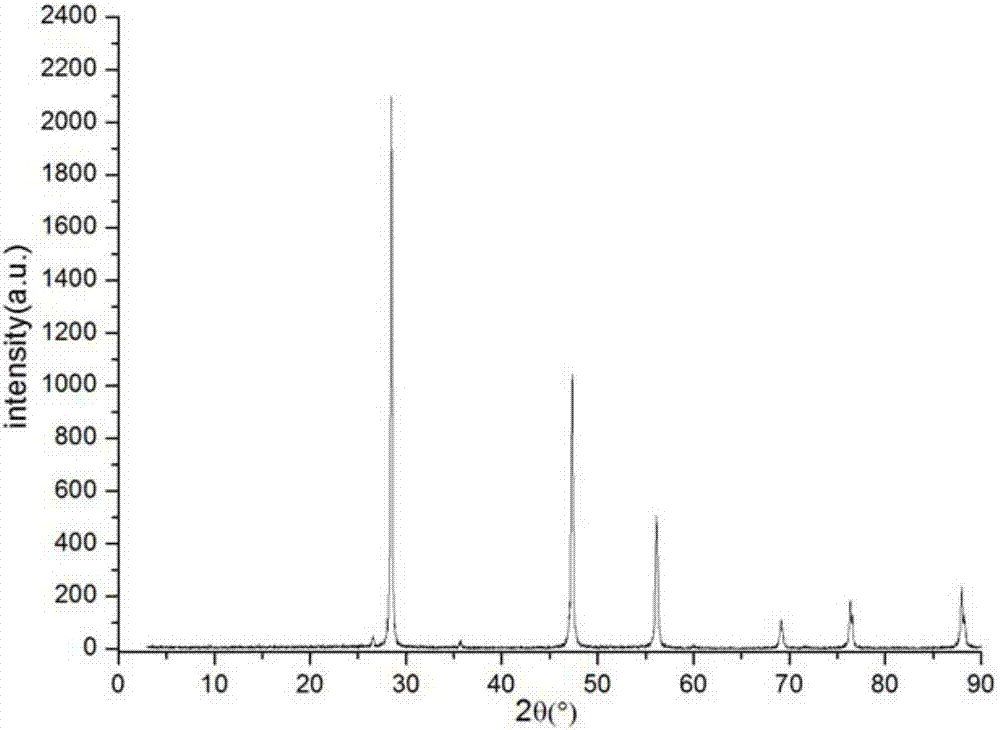

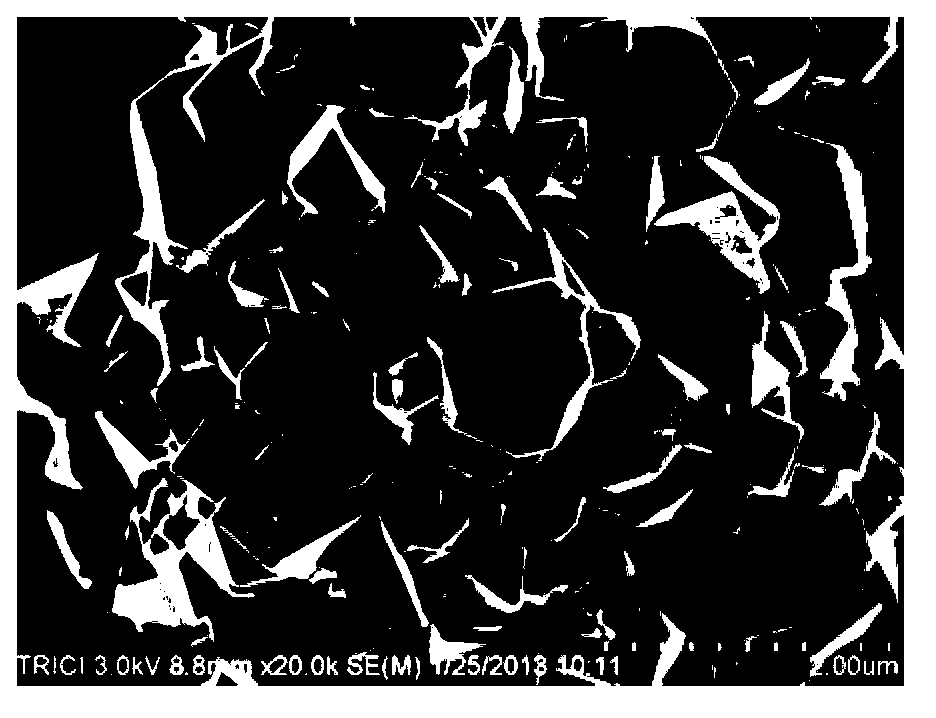

Preparation method of amorphous silicon powder body, amorphous silicon powder body and lithium ion battery

The invention belongs to the technical filed of amorphous silicon preparation and relates to a preparation method of an amorphous silicon powder body, the amorphous silicon powder body and a lithium ion battery. The preparation method of the amorphous silicon powder body comprises the following steps: taking metallurgical grade silicon as a raw material and preparing a master ingot by adopting a smelting manner; performing melt-spinning on the master ingot in a manner of rapid solidification of a single roll to prepare an amorphous silicon strip; performing embitterment treatment on the amorphous silicon strip to obtain an embrittlement strip; and performing crushing treatment on the embrittlement strip to obtain the amorphous silicon powder body. The preparation method of the amorphous silicon powder body, provided by the invention, is simple and efficient in process, environmentally-friendly, lower in cost and easy for industrial production realization. The amorphous silicon powder body can buffer the stress produced by change in silicon volume, reduce the volume expansion effect of an electrode and further improve the cyclic stability of an electrode material.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

Preparation method for lithium ion battery positive electrode material with 4.5 V voltage platform

ActiveCN103236532AUniform component distributionStable crystal structureCell electrodesNickel saltElectrical battery

The invention relates to a preparation method for a lithium ion battery positive electrode material with a 4.5 V voltage platform. The preparation method comprises the following steps: preparing a soluble lithium salt compound, a soluble nickel salt compound and a soluble manganese salt compound according to a metal ion molar ratio of Li to Ni to Mn of 1:0.5:1.5, dissolving, and uniformly stirring, wherein the total concentration of the metal ions in the solution is 0.2-5 mol / L; adding a complexing agent after dissolving, placing the solution into a sealed container, heating the solution to a temperature of 150-200 DEG C, and adding a lithium hydroxide or sodium hydroxide solution with a concentration of 0.5-5 mol / L under a stirring state until the pH value achieves 10-13; and carrying out constant temperature stirring for 10-24 h, cooling, and sequentially carrying out filtering, washing and drying on the product to obtain the LiNi0.5Mn1.5O4 material. The prepared LiNi0.5Mn1.5O4 material has characteristics of uniform component distribution and stable crystal structure, wherein 0.2 C (1 C is 147 mA / g) discharge capacity at a room temperature can be 132 mAh / g, the voltage platform is stabilized to more than 4.7 V, and uniformity different between batches is less.

Owner:HEBEI UNIV OF TECH

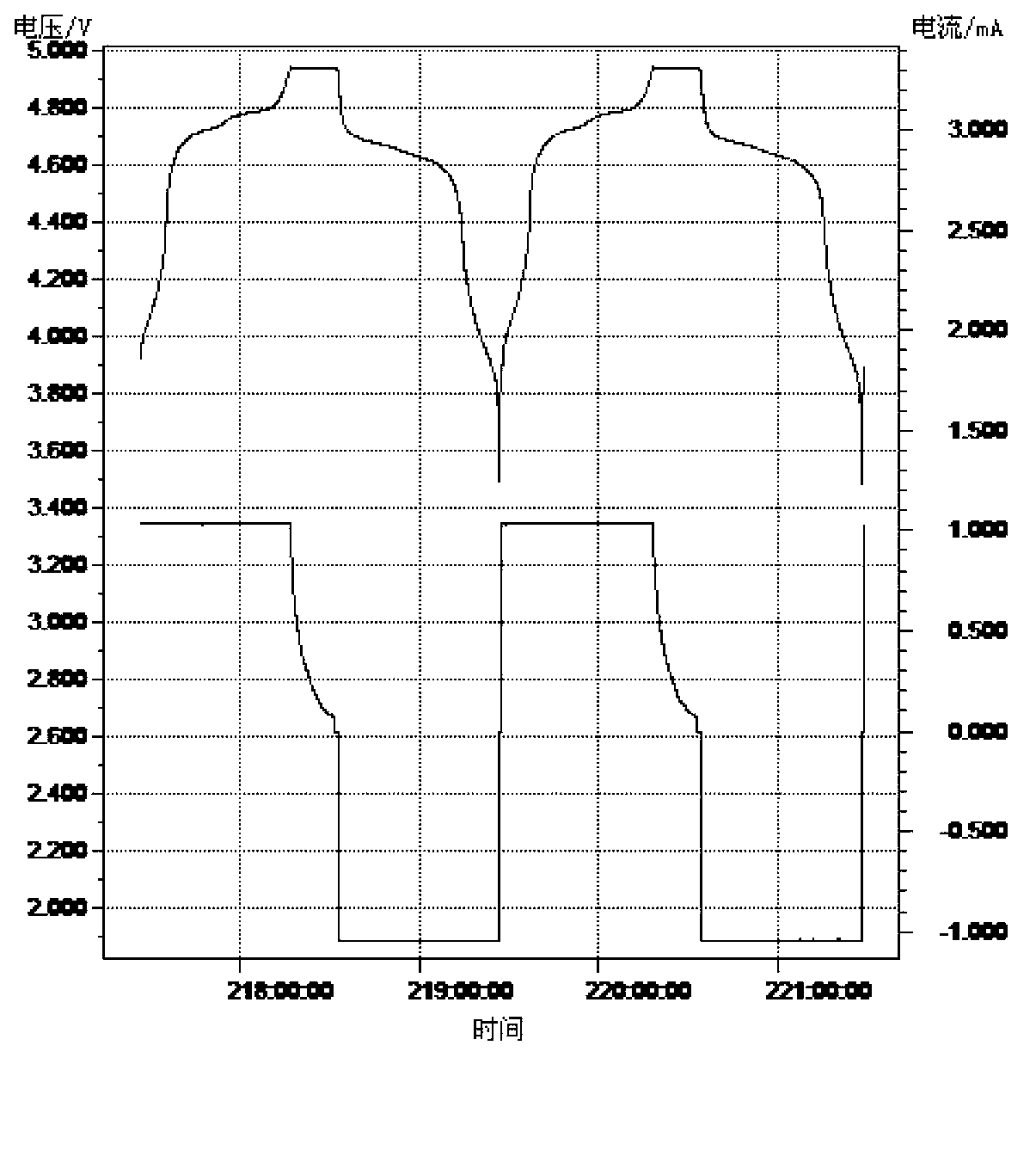

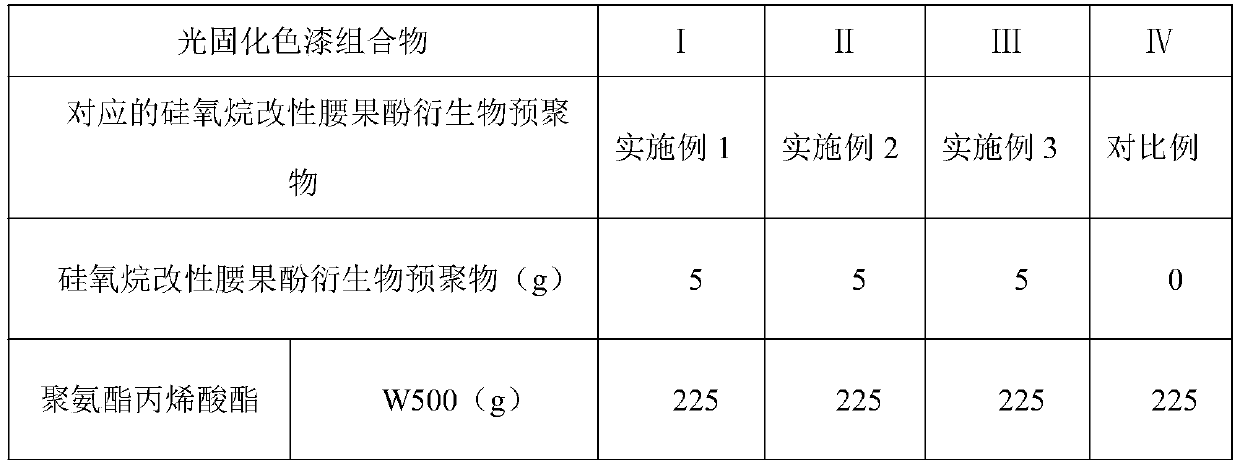

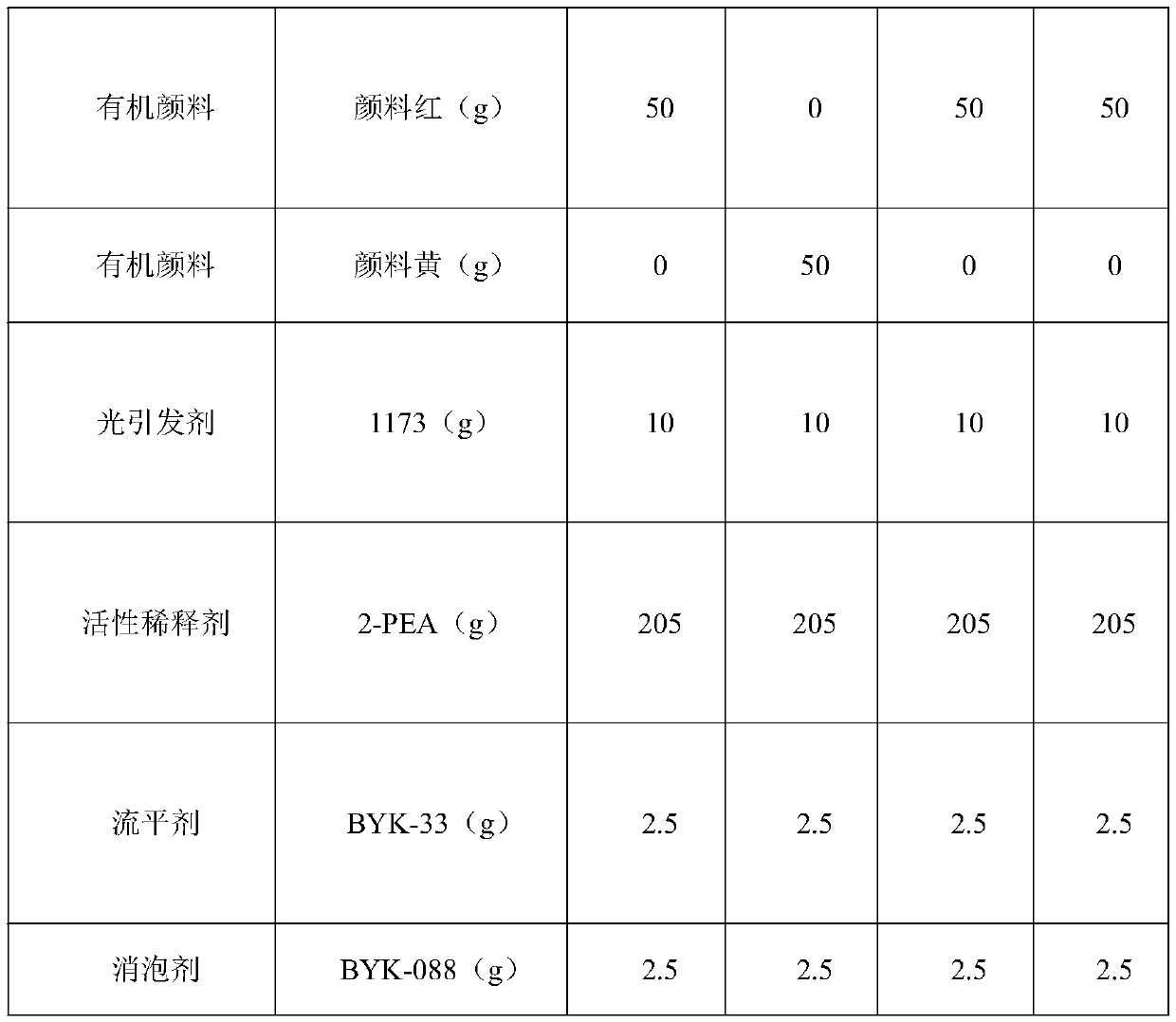

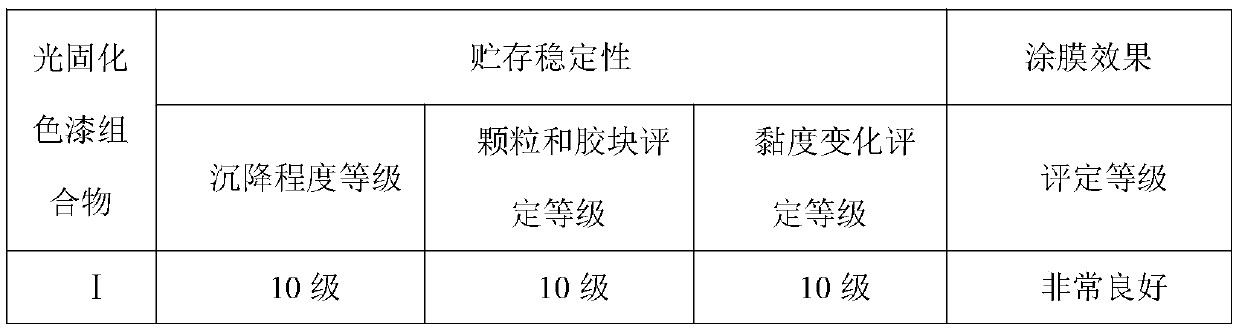

Siloxane modified cardanol derivative prepolymer as well as preparation method and application thereof

ActiveCN111393597AGood storage stabilityImprove wettabilityPolyurea/polyurethane coatingsPtru catalystSilanes

The invention belongs to the technical field of high-molecular polymerization, and discloses a siloxane modified cardanol derivative prepolymer as well as a preparation method and application thereof.The siloxane modified cardanol derivative prepolymer is prepared by putting cashew nut shell oleyl alcohol, isocyanate propyl silane and a catalyst into a reaction kettle in a nitrogen protective atmosphere, reacting at 80-90 DEG C, sampling, monitoring an NCO characteristic peak by adopting a Fourier infrared spectrometer until the NCO characteristic peak completely disappears, cooling, filtering and discharging. The molar ratio of OH of the cashew nut shell oleyl alcohol to NCO of the isocyanate propyl silane is 1: (0.5-1). The cashew nut shell oleyl alcohol can interact with pigment through large pi conjugation or hydrogen bonds, the wettability of the pigment can be improved, and the cashew nut shell oleyl alcohol is used for dispersing the pigment. Meanwhile, the cardanol derivativeprepolymer is grafted to the surface of the pigment, so that the storage stability of the pigment is greatly improved.

Owner:广州五行材料科技有限公司

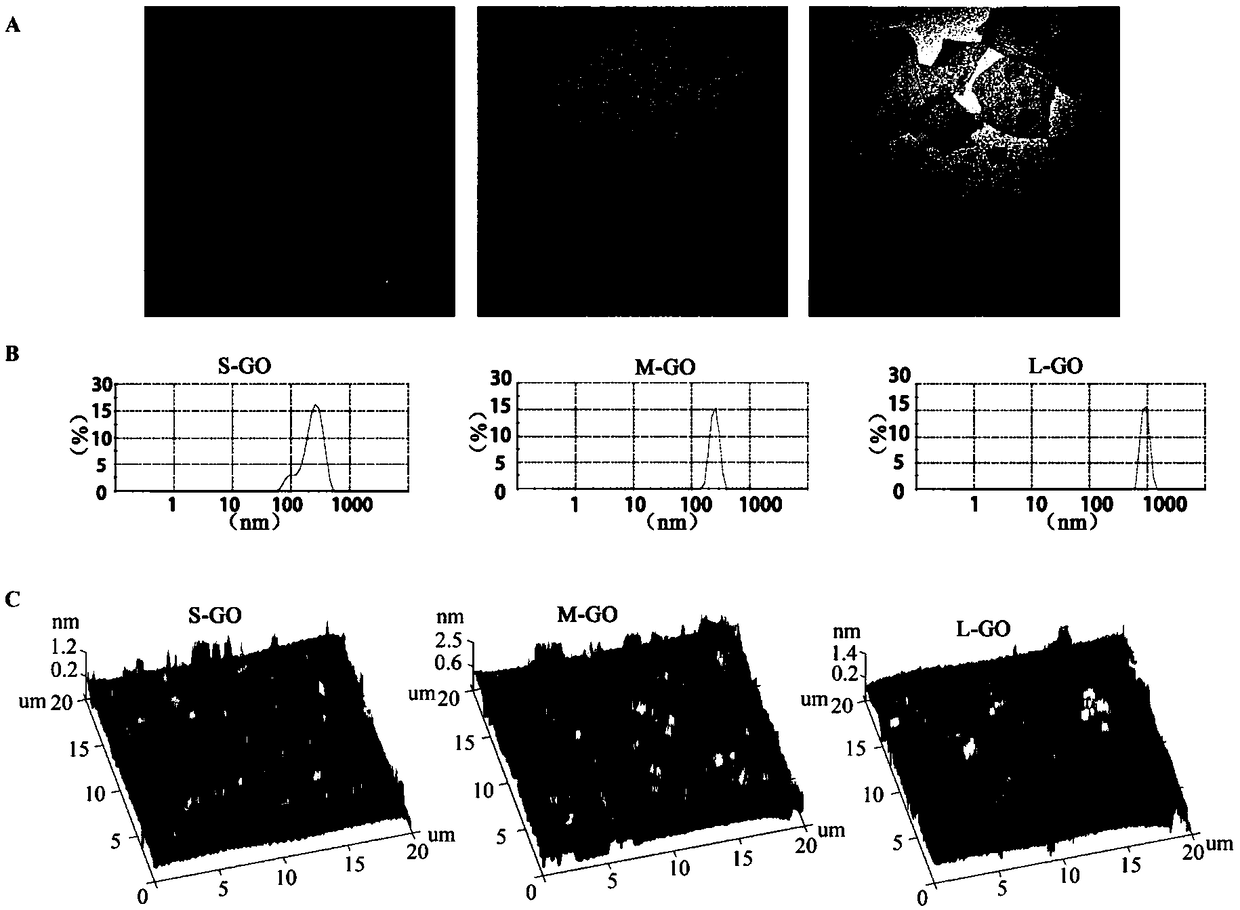

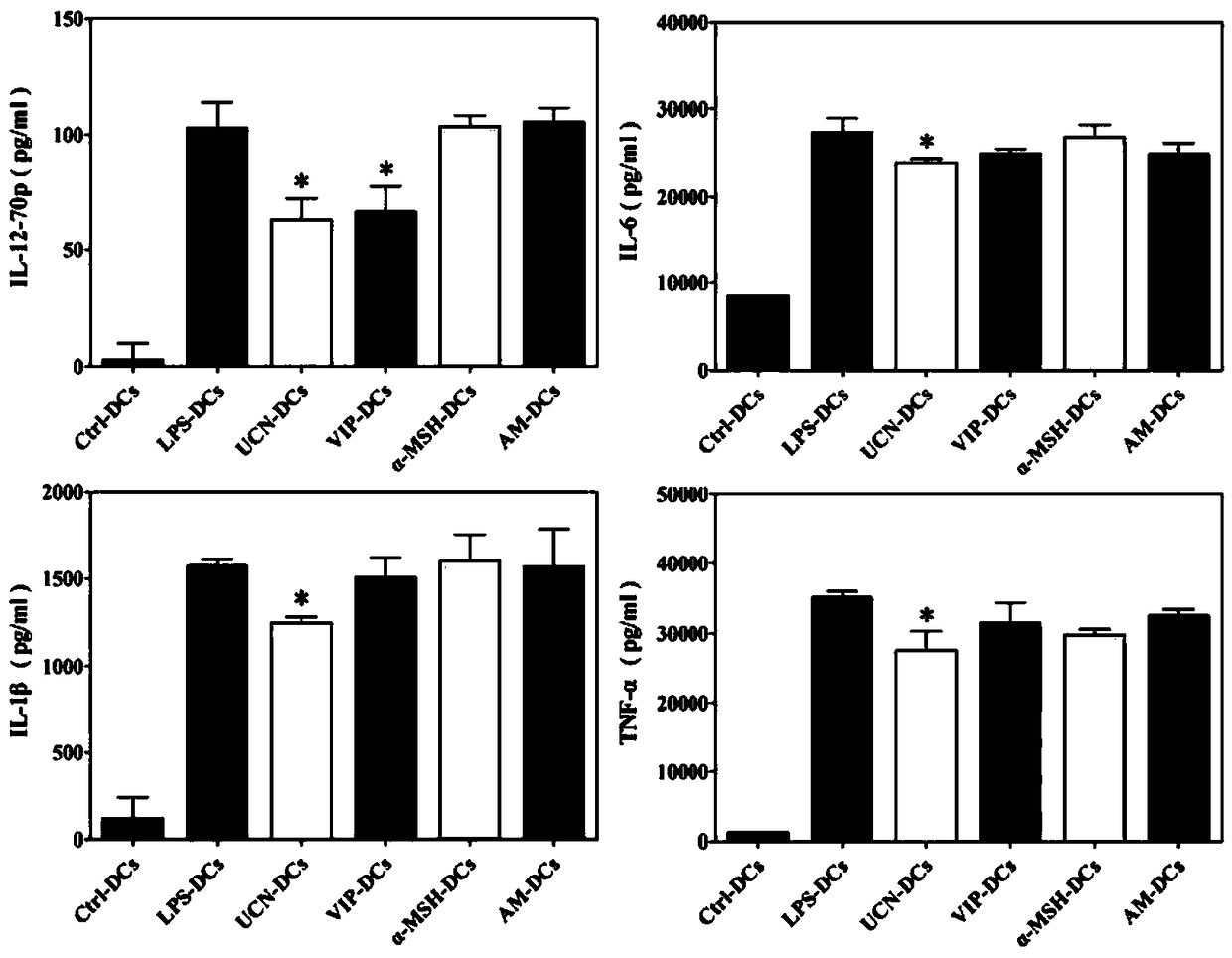

Dendritic cell inducer and preparation method and application thereof

ActiveCN109468275ABatch stableLow pricePeptide/protein ingredientsInorganic active ingredientsDiseaseDendritic cell

The invention discloses a dendritic cell inducer and a preparation method and application thereof. The dendritic cell inducer is a compound of nervous peptide and graphene oxide, and dendritic cells can be induced into tolerant dendritic cells. Compared with other immunomodulators such as rapamycin and cocktail of cytokines, the compound is suitable for inducing the tolerant dendritic cells, has the advantages of simplicity in preparation, high stability and low price, and can be used for treating autoimmune diseases such as acute-graft-versus-host diseases, rheumatic arthritis and antoimmunediabetes.

Owner:ACADEMY OF MILITARY MEDICAL SCI

Method for synthesizing nano-lithium iron phosphate without water of crystallization in aqueous phase at normal pressure

ActiveUS20160145103A1Short timeLow energy consumptionPhosphatesCell electrodesWater of crystallizationElectrode material

A method for synthesizing nano-lithium iron phosphate without water of crystallization in aqueous phase at normal pressure, which is part of a preparation method for a lithium ion positive electrode material. The preparation process comprises the following steps: preparing lithium phosphate, preparing an aqueous phase suspension of lithium phosphate, preparing a ferrous salt solution, preparing nano-lithium iron phosphate without water of crystallization, and recovering and recycling lithium in a mother solution of lithium iron phosphate. The present invention has the beneficial effects of mild reaction conditions, a short time, low energy consumption, reduced costs due to the recovery and recycling of lithium in the mother solution, stable batches, uniform and controllable strength, and being conducive to industrial production.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Serum-free, protein-free and DMSO-free cell freezing medium and application thereof

ActiveCN113424820AClear ingredientsBatch stableDead animal preservationNaCl - Sodium chlorideSucrose

The invention discloses a serum-free, protein-free and DMSO-free cell freezing medium and application thereof. The invention firstly discloses the serum-free, protein-free and DMSO-free cell freezing medium. The serum-free, protein-free and DMSO-free cell freezing medium comprises the following components: a glucose injection, a compound amino acid injection, glycerol, monopotassium phosphate, disodium hydrogen phosphate, sodium chloride, sucrose, hydroxyethyl starch, adenosine triphosphate-disodium magnesium chloride and water. The invention further discloses application of the cell freezing medium in cryopreservation of cells. The cell freezing medium is clear in component and stable in batch, and meets the requirement of industrial transformation. Besides, the cell freezing medium is free of serum, protein and DMSO, the activity and dryness of the cells can be stably maintained for a long time when the cells are cryopreserved, the recovered cells can be directly used for clinical application, and the safety requirement and the effectiveness requirement of the clinical application are met.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

Method for synthesizing graphene-doped nanometer manganese-rich lithium iron phosphate under conditions of normal pressure and water phase

ActiveCN103956464AMild reaction conditionsLow costCell electrodesSecondary cellsLithium iron phosphateGranularity

The invention discloses a method for synthesizing graphene-doped nanometer manganese-rich lithium iron phosphate under conditions of normal pressure and water phase. The method comprises the following steps: preparing lithium phosphate, preparing a graphene or graphene oxide water suspension, preparing a lithium phosphate and graphene or graphene oxide mixed suspension, preparing a divalent manganese salt and ferrite mixed solution, preparing graphene-doped or graphene oxide-doped nano manganese-rich lithium iron phosphate, and recycling lithium from a mother solution. Compared with the prior art, the method has the advantages that the method for synthesizing graphene-doped nanometer manganese-rich lithium iron phosphate under conditions of normal pressure and water phase is mild in reaction conditions and low in equipment cost; the prepared product is high in electrical property and capacity, good in rate capability, stable in batch and uniform and controllable in granularity; the lithium in the mother solution can be recycled, so that the production cost is lowered, and the requirement of industrialized production is met.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com