Preparation method and application of ternary positive electrode material for battery

A composite positive electrode material and ternary battery technology, which is applied in the direction of battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problem of inability to ensure the uniform mixing of ternary materials and lithium iron phosphate, affecting the electrochemical performance and safety performance of batteries, etc. problems, to achieve the effect of good safety performance, short cycle time and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

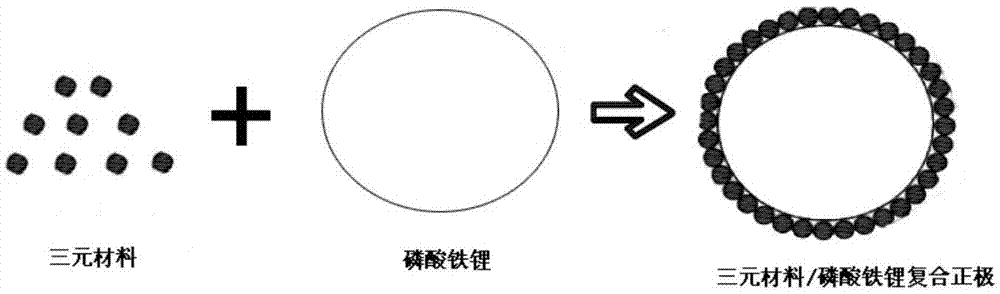

[0033] An embodiment of the present invention provides a method for preparing a composite positive electrode material for a ternary battery, comprising the following steps:

[0034] S01. Provide ternary materials and lithium iron phosphate;

[0035] S02. The ternary material and lithium iron phosphate are mixed to form a mixed material, and the mixed material is ball milled so that the particle size of the mixed material conforms to a normal distribution, and a composite positive electrode material for a ternary battery is obtained, wherein, The median diameter D50 of the ternary material is 8-10um, the median diameter D50 of the lithium iron phosphate is 1-2um, and the median diameter D50 of the mixed material is 9-13um.

[0036] Specifically, in the above step S01, the ternary material is a conventional ternary material in the field of ternary batteries. As a preferred embodiment, the ternary material is LiNi 1-x-y co x mn y o 2 , where 0

Embodiment 1

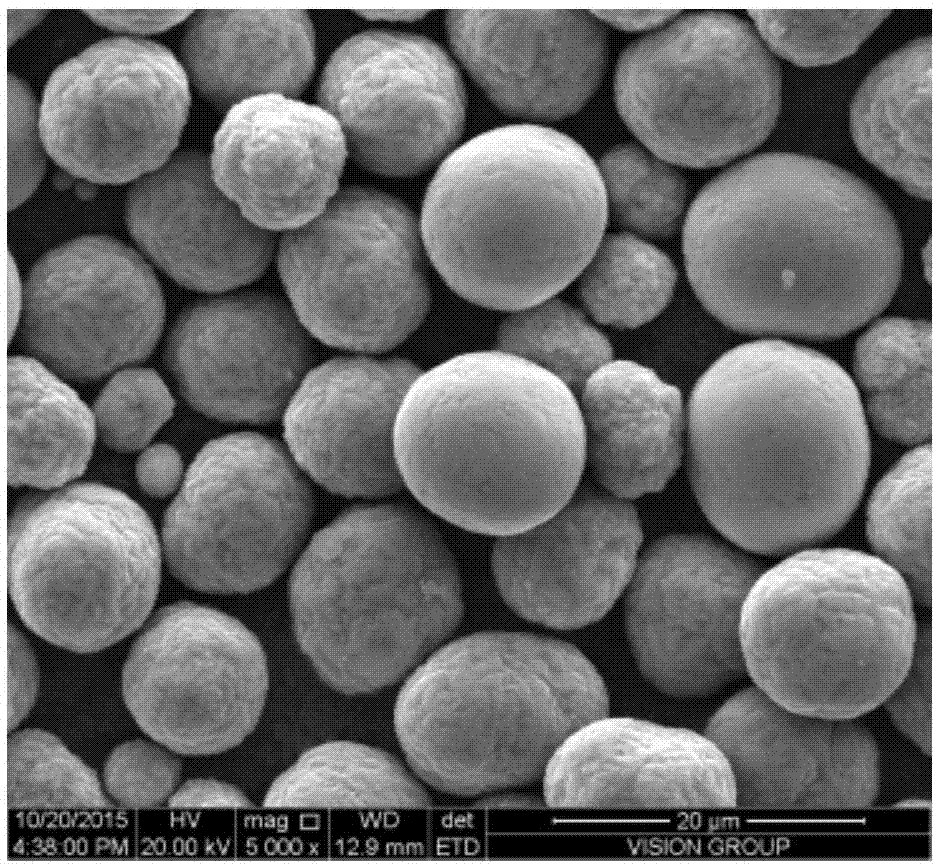

[0059] Will LiNi 0.5 co 0.2 mn 0.3 o 2 with LiFePO 4 Mix according to the mass ratio of 8:2, and ball mill until the particle size is normally distributed (D50=10.5um). The SEM image of the ternary battery composite positive electrode material after ball milling is as follows Figure 4 As shown, the particle size-cumulative particle percentage curve and the particle size distribution curve are as Figure 5 As shown, wherein, the particle size-cumulative particle percentage curve represents the weight percentage of particles less than or equal to a certain particle size in the total particles, and the particle size distribution curve represents the weight percentage of the particles with the corresponding particle size in the total particles . The above mixture is used as the positive electrode material, and the ternary soft pack battery PL556888 with an energy density of 181Wh / Kg is prepared according to the conventional soft pack lithium ion battery assembly process and ...

Embodiment 2

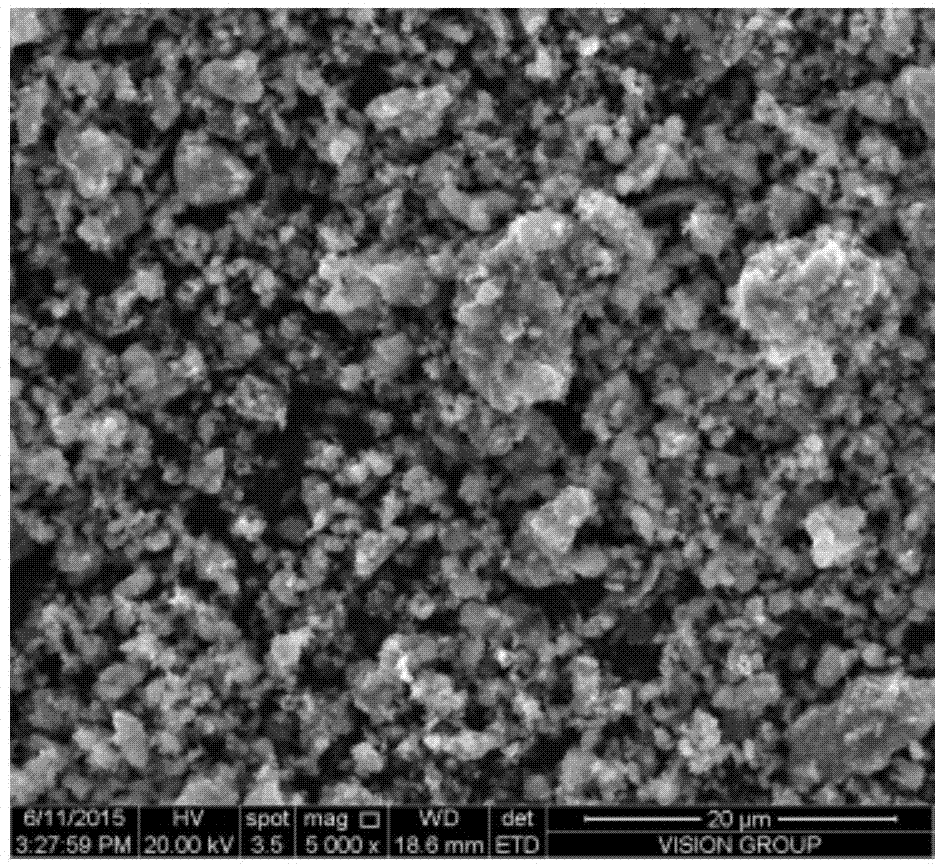

[0061] Will LiNi 0.5 co 0.2 mn 0.3 o 2 with LiFePO 4 Mix according to the mass ratio of 7:3, and ball mill until the particle size is normally distributed (D50=11.38um). Figure 6 As shown, wherein, the particle size-cumulative particle percentage curve represents the weight percentage of particles less than or equal to a certain particle size in the total particles, and the particle size distribution curve represents the weight percentage of the particles with the corresponding particle size in the total particles . The above mixture is used as the positive electrode material, and the ternary material soft-pack battery PL556888 with an energy density of 158Wh / kg is prepared according to the conventional soft-pack lithium-ion battery assembly process and chemical conversion process. The gram capacity of the positive electrode material is 143mAh / g, as shown in Figure 8 ;Cycle 200 times without attenuation, such as Figure 9 . Acupuncture and overcharge tests were carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com