Method for preparing spherical silver powder

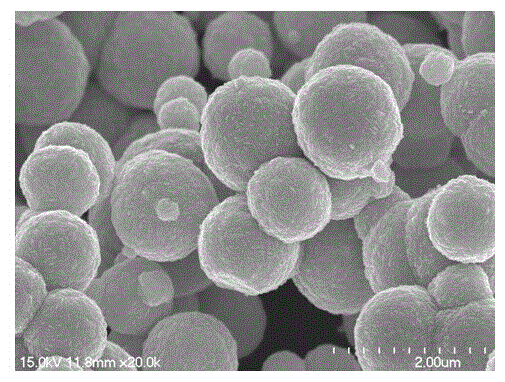

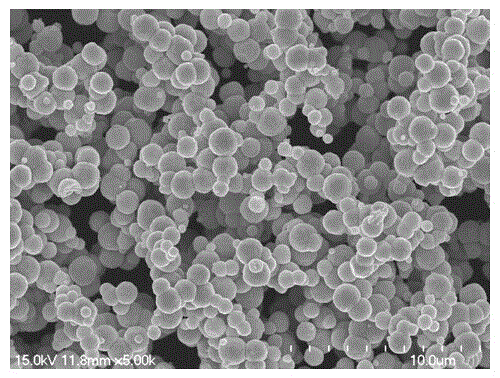

A technology of silver powder and silver nitrate, which is applied in the field of silver powder, can solve the problems of low concentration of silver nitrate, uncontrolled reaction process, difficulty of silver paste on solar front grid, etc., and achieve narrow particle size distribution, low environmental pollution and good sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

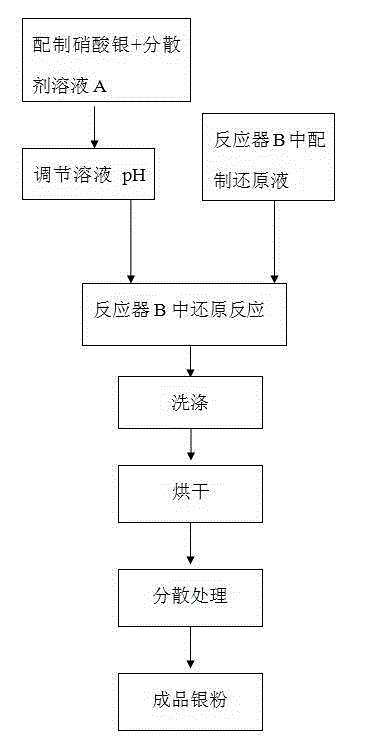

[0023] Preparation of silver nitrate solution: Add 15Kg of silver nitrate crystals into container A with a volume of 200L, add deionized water until the liquid level reaches the 160L mark, stir to dissolve the silver nitrate crystals, add 255g of polyvinyl alcohol dissolved in 2L of deionized water solution, and then (NH 4 ) 2 SO 4 solution (50g / L) to adjust the pH of the silver nitrate solution to 5.5, keep the solution temperature stable at 30±2°C, and keep stirring; prepare ascorbic acid solution: add 13.5Kg ascorbic acid to container B with a volume of 500L, and add deionized water to the liquid level When the ascorbic acid reaches the 160L mark, stir and dissolve the ascorbic acid, the temperature of the solution is stable at 30±2°C, keep stirring; add the solution in container A to container B, stir vigorously with a high-shear emulsifier until the reaction is fully complete, then lower it to sink. Wash the precipitate obtained by the reaction with deionized water, dr...

Embodiment 2

[0025] Preparation of silver nitrate solution: Add 15Kg of silver nitrate crystals into container A with a volume of 200L, add deionized water until the liquid level reaches the 160L mark, stir to dissolve the silver nitrate crystals, add 300g of polyvinylpyrrolidone dissolved in 2L of deionized water solution, and then (NH 4 ) 2 SO 4 solution (50g / L) to adjust the pH of the silver nitrate solution to 6, keep the solution temperature stable at 25±2°C, and keep stirring; prepare ascorbic acid solution: add 13.5Kg ascorbic acid to container B with a volume of 500L, and add deionized water to the liquid level When the ascorbic acid reaches the 160L mark, stir and dissolve the ascorbic acid, the temperature of the solution is stable at 25±2°C, keep stirring; add the solution in container A to container B, stir vigorously with a high-shear emulsifier until the reaction is fully complete, then lower it to sink. Wash the precipitate obtained by the reaction with deionized water, d...

Embodiment 3

[0027] Preparation of silver nitrate solution: Add 15Kg of silver nitrate crystals into container A with a volume of 200L, add deionized water until the liquid level reaches the 160L mark, stir and dissolve the silver nitrate crystals, add 150g of polyvinyl alcohol and 2L of deionized water to dissolve 120g gelatin solution, then use (NH 4 ) 2 SO 4 solution (50g / L) to adjust the pH of the silver nitrate solution to 5.8, keep the solution temperature stable at 35±2°C, and keep stirring; prepare ascorbic acid solution: add 13.5Kg ascorbic acid to container B with a volume of 500L, and add deionized water to the liquid level When the ascorbic acid reaches the 160L mark, stir and dissolve the ascorbic acid, the temperature of the solution is stable at 35±2°C, keep stirring; add the solution in container A to container B, stir vigorously with a high-shear emulsifier until the reaction is fully completed, then lower it to sink. Wash the precipitate obtained by the reaction with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com