Patents

Literature

36 results about "SILVER NITRATE CRYSTALS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial supermolecule aquogel and preparation method and application thereof

InactiveCN101564400AEasy to prepareEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingSILVER NITRATE CRYSTALS

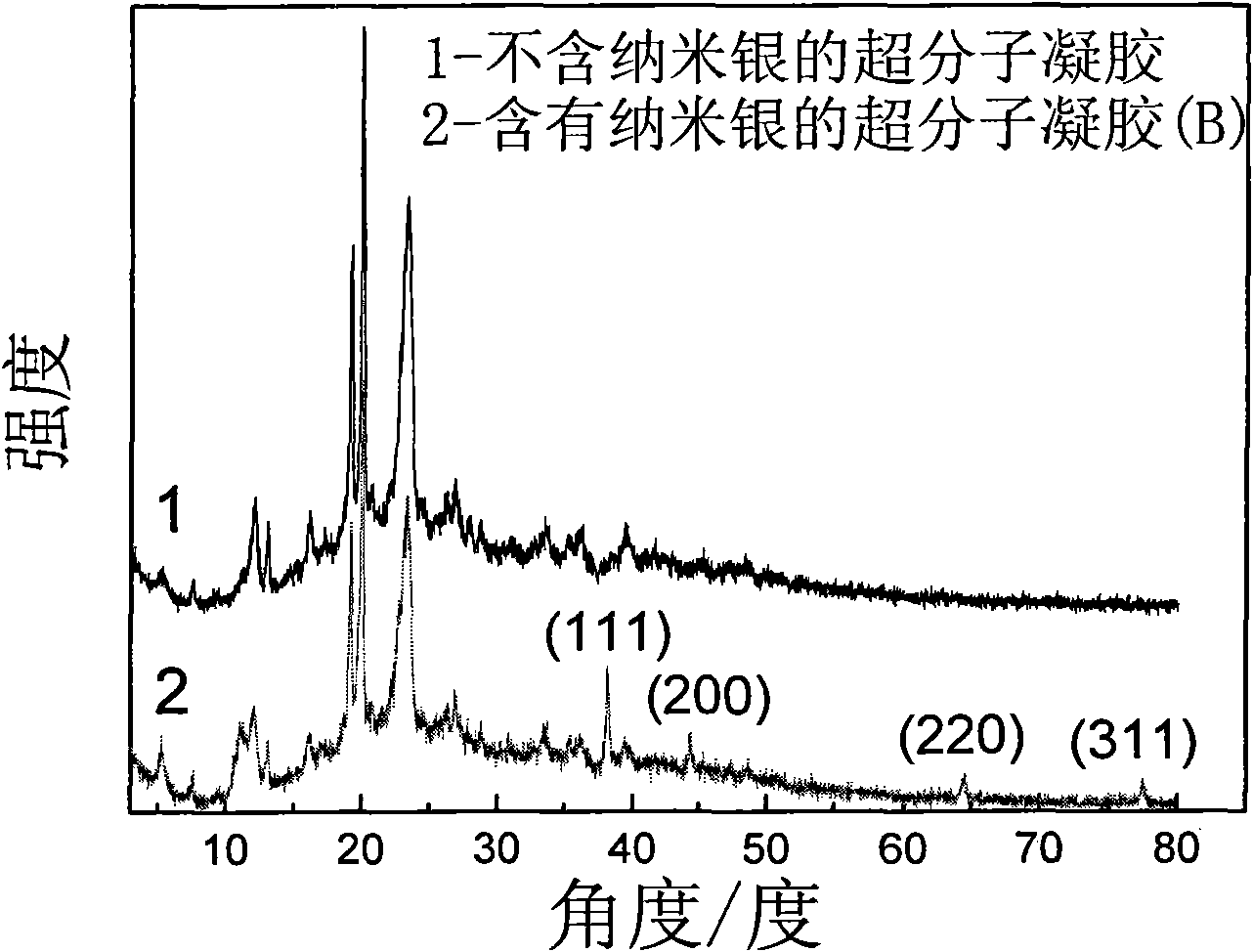

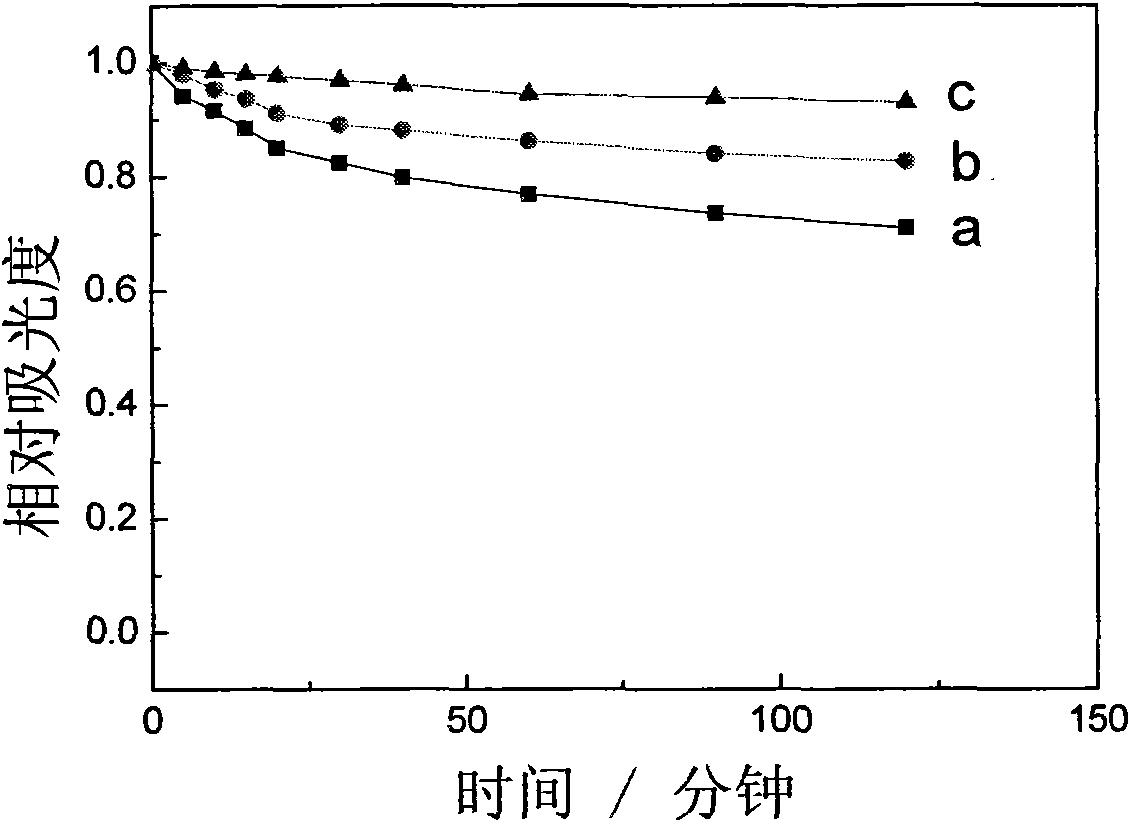

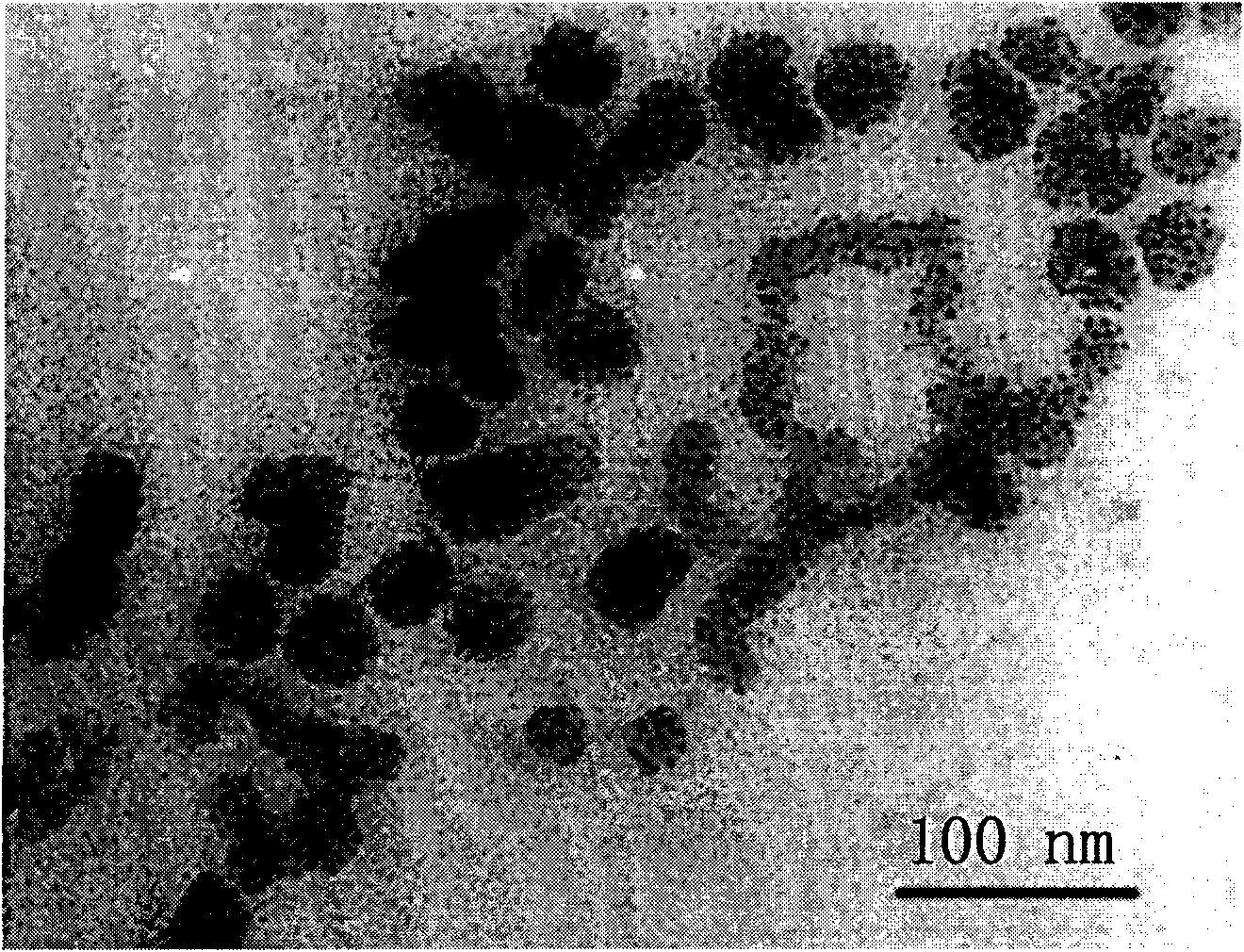

The invention discloses a method for in-situ preparing antibacterial supermolecule aquogel. The method comprises the following operation steps: silver nitrate crystal and polyethyleneglycol-polypropylene glycol-polyethyleneglycol triblock copolymer solution are mixed and stirred to obtain mixed solution; the steps of stirring the mixed solution for 15 minutes and ultrasonically dispersing the mixed solution for 5 minutes are alternatively carried out for 2-4 hours to obtain nano silver sol; and the nano silver sol and Alpha-cyclodextrin solution are mixed, stirred and stands at the room temperature to obtain hydrogel. The hydrogel can be used for preparing injectable drug carriers. The invention has the advantages of simple operation, adjustable gel strength and the gelation time, room temperature forming, no involvement of chemical cross linking reaction and the usage of organic solvent, favorable biocompatibility and antibacterial property of obtained gel, and the like and is prospective to be widely applied in the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

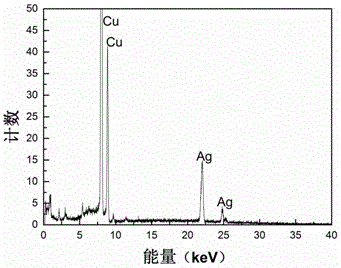

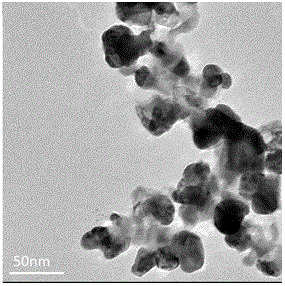

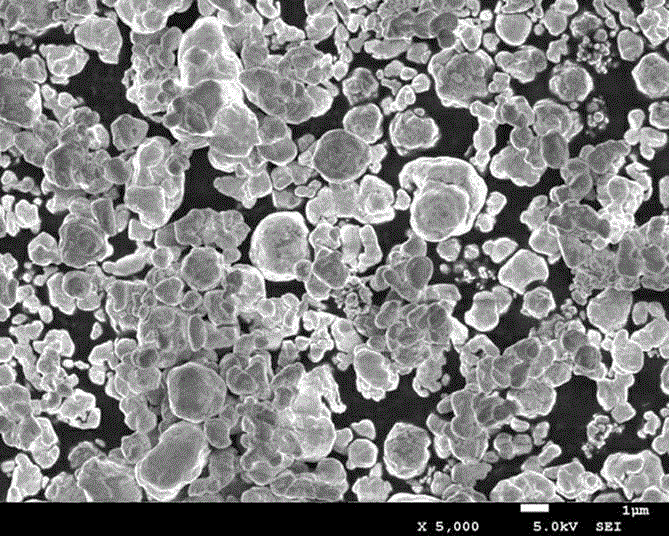

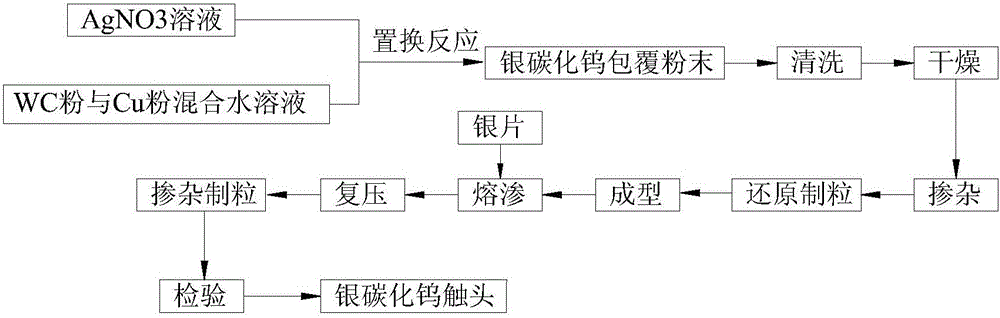

Method for preparing silver-tungsten carbide contact material from silver-coated tungsten carbide powder and silver-tungsten carbide contact material

ActiveCN103824710AHigh densityHigh hardnessContactsElectrical resistance and conductanceHigh density

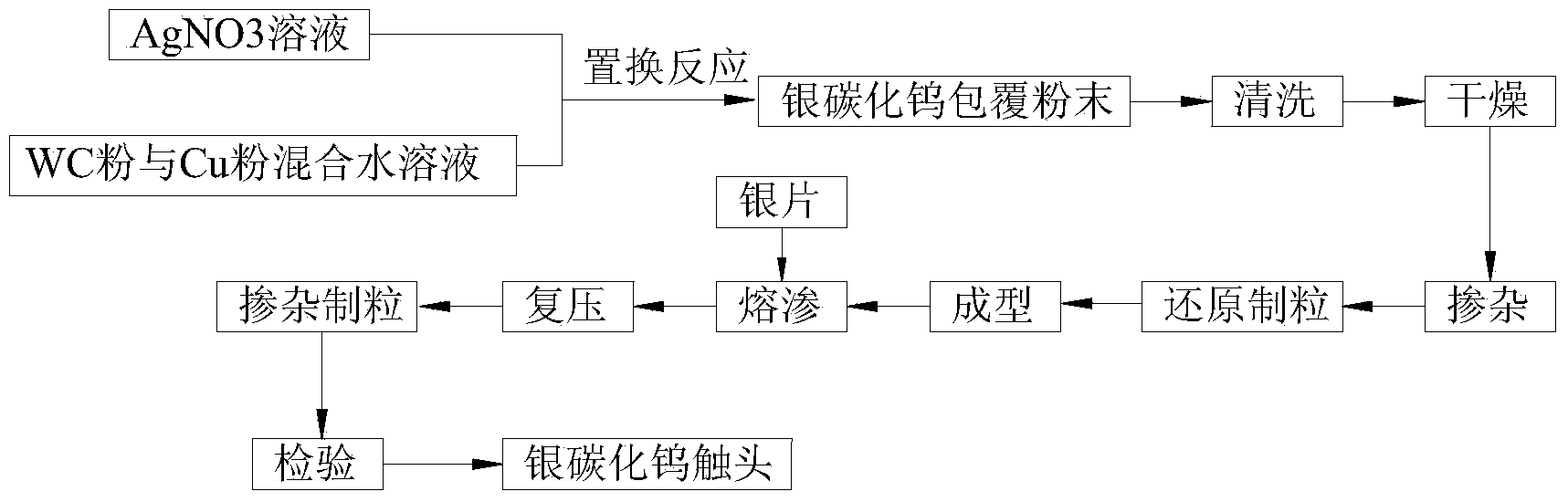

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

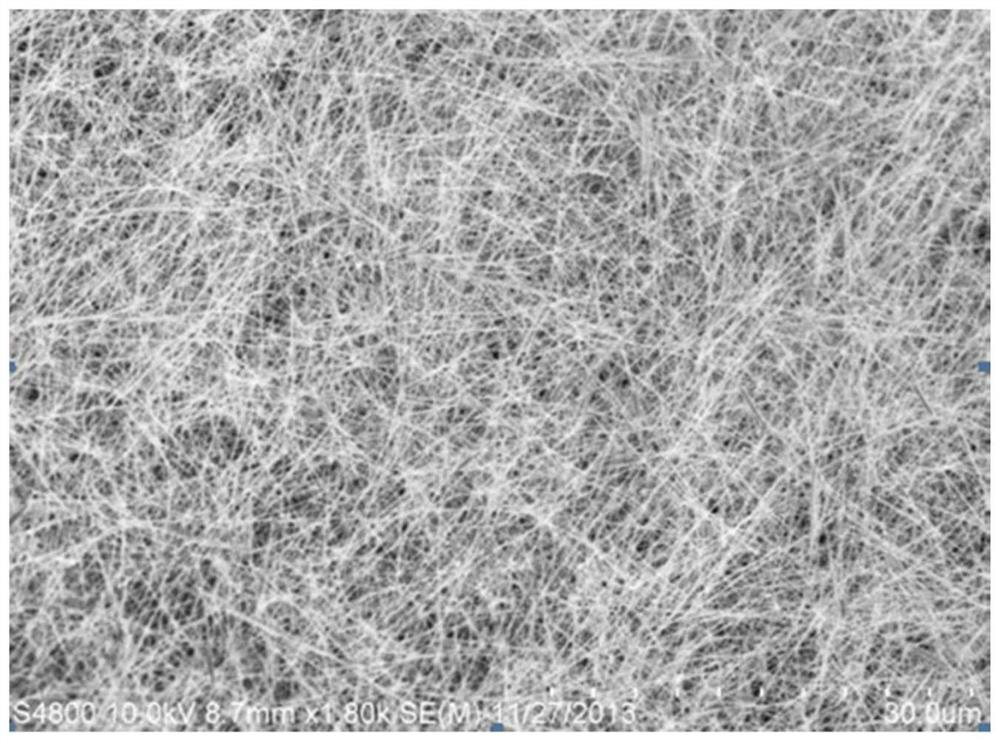

Preparation method of antibacterial nanofibers

InactiveCN104313720AStable manufacturingEasy to operateArtificial filament washing/dryingFilament/thread formingFiberCellulose acetate

The invention discloses a preparation method of antibacterial nanofibers, which comprises the following steps of: by mass, using 6 to 9 parts of acetone, 1 to 3 parts of dimethylacetamide and 0.5 to 2 parts of water as the raw materials, mixing the raw materials to prepare a solvent and adding cellulose acetate particles and silver nitrate crystals into the solvent to prepare cellulose acetate electrostatic spinning solution; carrying out electrostatic spinning on the cellulose acetate electrostatic spinning solution; carrying out drying treatment on the obtained electrostatic spinning fibers at a temperature of 60 DEG C and under the vacuum condition; and irradiating the dried electrostatic spinning fibers for 4 to 8 hours by ultraviolet light and reducing silver ions into silver nanoparticles so as to obtain the nanorfibers with an antibacterial function. The preparation method enables the electrostatic spinning solution to stably prepare the nano cellulose with the antibacterial function mainly by determining the optimal content of water and silver nitrate in the electrostatic spinning solution, is simple to operate and is low in cost.

Owner:吴江中天喷织有限公司

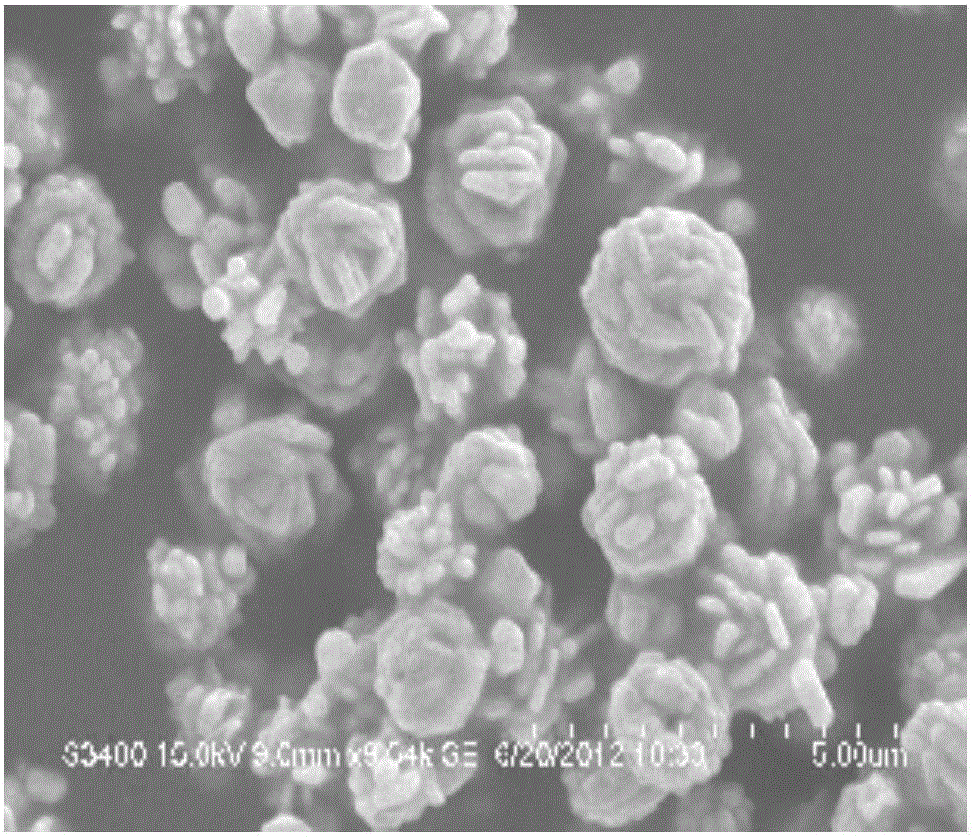

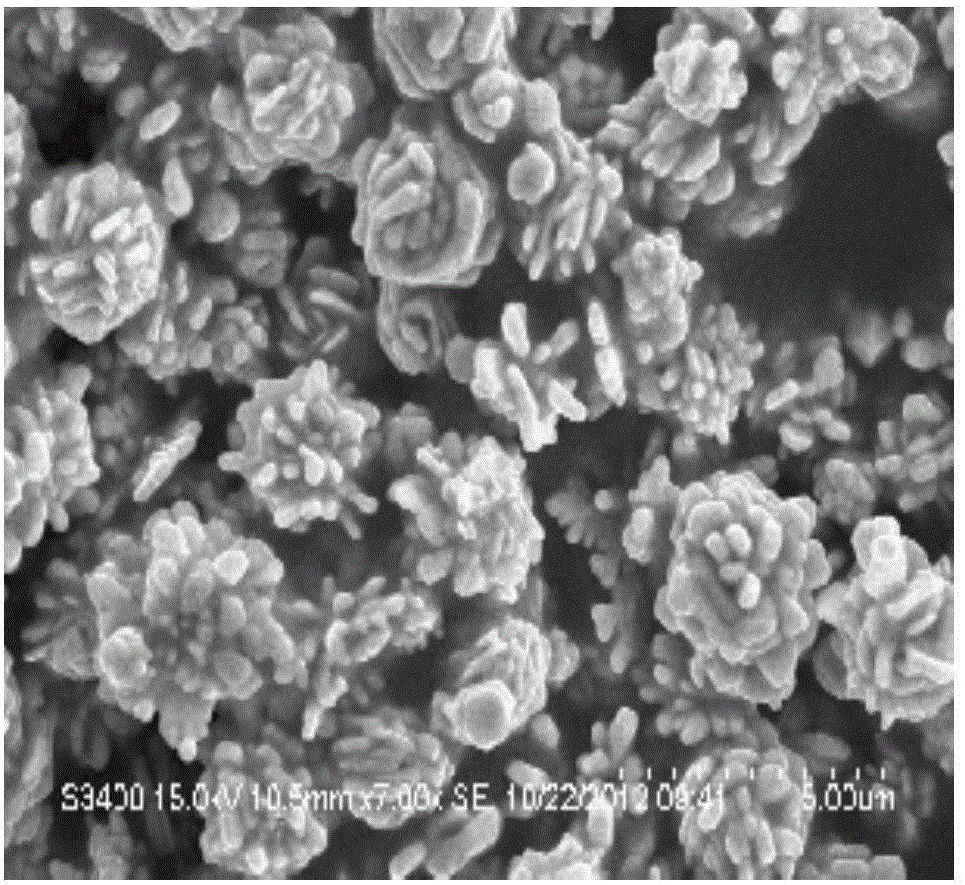

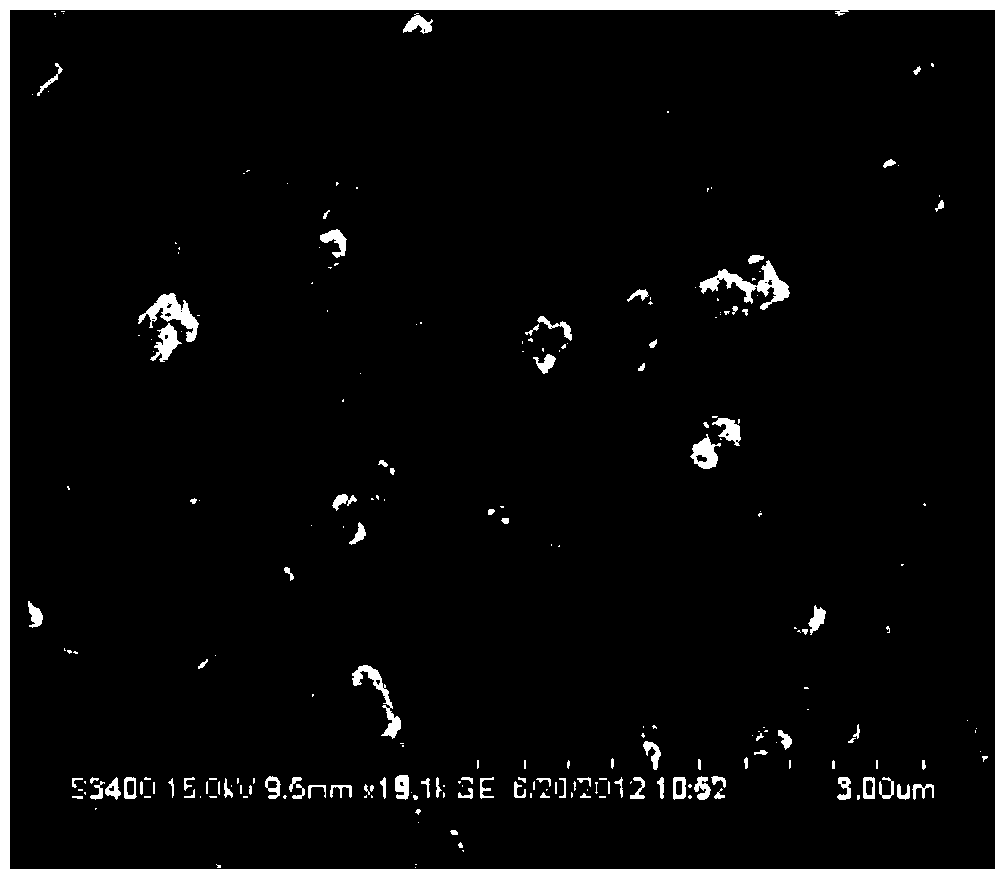

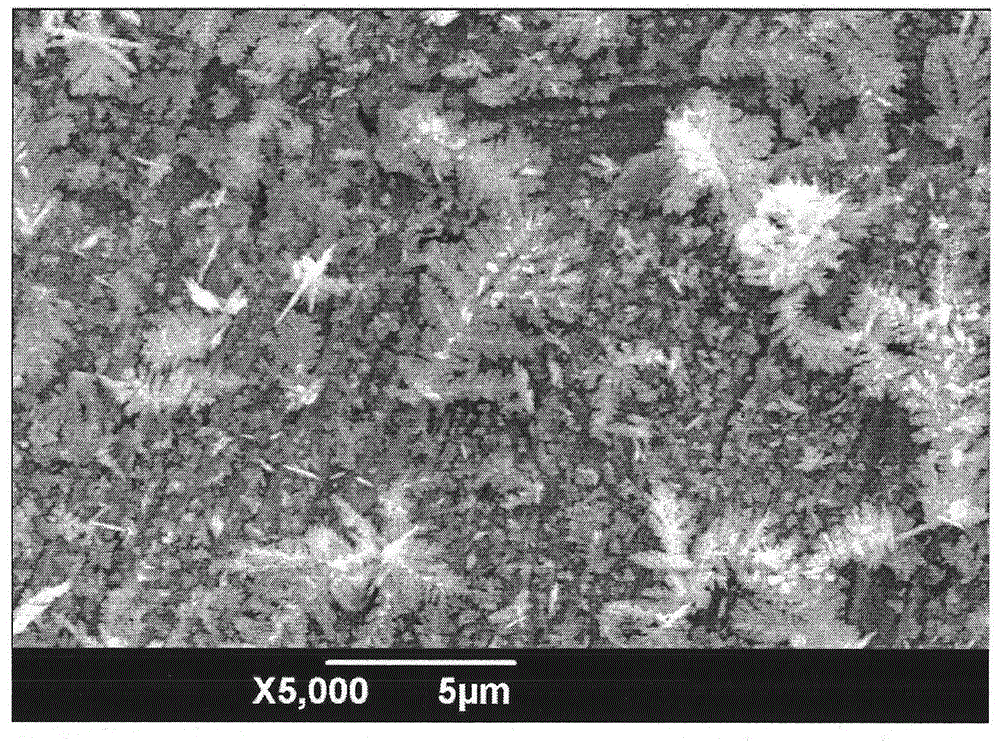

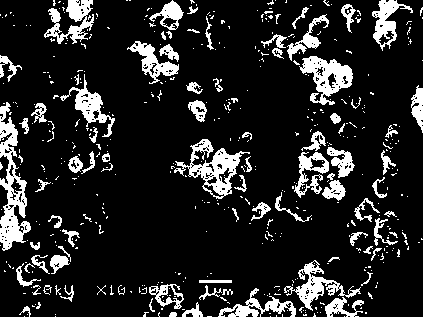

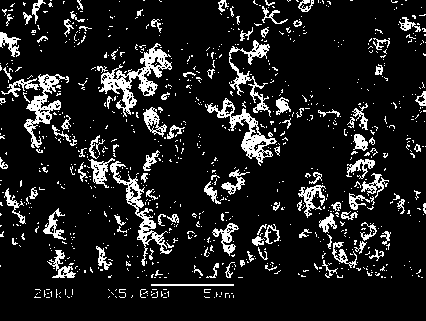

Synthetic method for flower type silver micron particles

The invention discloses a method for synthesizing flower-shaped silver micro-particles. The method comprises the following steps of respectively measuring ascorbic acid solid powder and silver nitrate crystal, and respectively dissolving the ascorbic acid solid powder and the silver nitrate crystal into deionized water for standby use; placing the prepared ascorbic acid solution into the silver nitrate solution, and ensuring the mol ratio of the ascorbic acid and the silver nitrate to be (0.8-1.2):1; immediately adding a cleaned stainless steel sheet into the mixed solution; magnetically stirring the reaction materials for 180min to 360min after the stainless steel sheet is added, and ending the reaction; taking out and centrifugally separating the stainless steel sheet in the material after the reaction is ended, and precipitating and washing the stainless steel sheet to obtain the flower-shaped silver micro-particles. By adopting the method, the shape of a product is controllable, simplicity in operation can be realized, the condition is moderate, and the repeatability is good.

Owner:JIANGSU UNIV OF TECH

Preparation method of cellulose acetate electrostatic spinning solution

InactiveCN104404635AStable manufacturingEasy to operateSpinning solutions preparationArtifical filament manufactureWater bathsCellulose acetate

The invention discloses a preparation method of a cellulose acetate electrostatic spinning solution. The preparation method comprises the following steps of taking 6-9 parts of acetone by mass, 1-3 parts of dimethylacetamide by mass and 0.5-2 parts of water by mass as raw materials to prepare solvent after mixing; adding cellulose acetate particles and silver nitrate crystals into the solvent, slowly heating to 60-80 DEG C at the heating speed of increasing by 2-5 DEG C at every minute and stirring for 60-120 minutes to fully dissolve the cellulose acetate particles so as to obtain a composite cellulose acetate solution containing 1 wt%-3wt% of silver nitrate; after the composite cellulose acetate solution is cooled, adding ammonium bicarbonate which is 1 wt%-3wt% of the mass of the composite cellulose acetate solution, placing in water bath at 40 DEG C, and mechanically stirring to carry out expansion treatment so as to obtain the cellulose acetate electrostatic spinning solution. According to the preparation method, nano-cellulose with an anti-bacterial function is stably prepared by the electrostatic spinning solution through determining the optimum contents of water and silver nitrate in the electrostatic spinning solution, and the preparation method has the advantages of simplicity in operation and low cost.

Owner:苏州丽达纺织有限公司

Method for preparing silver nanoparticles with sugarcane extract

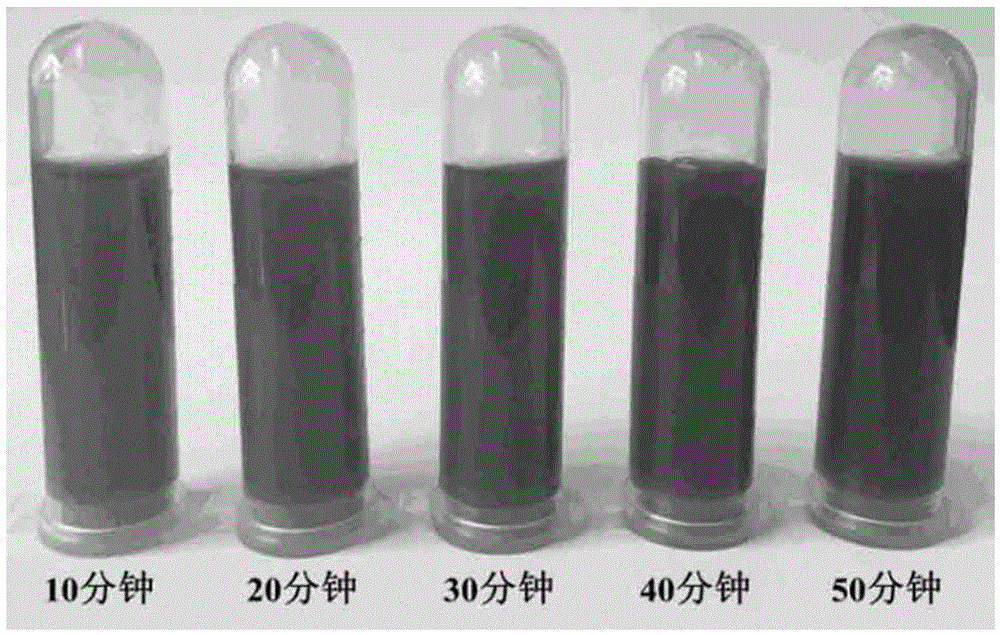

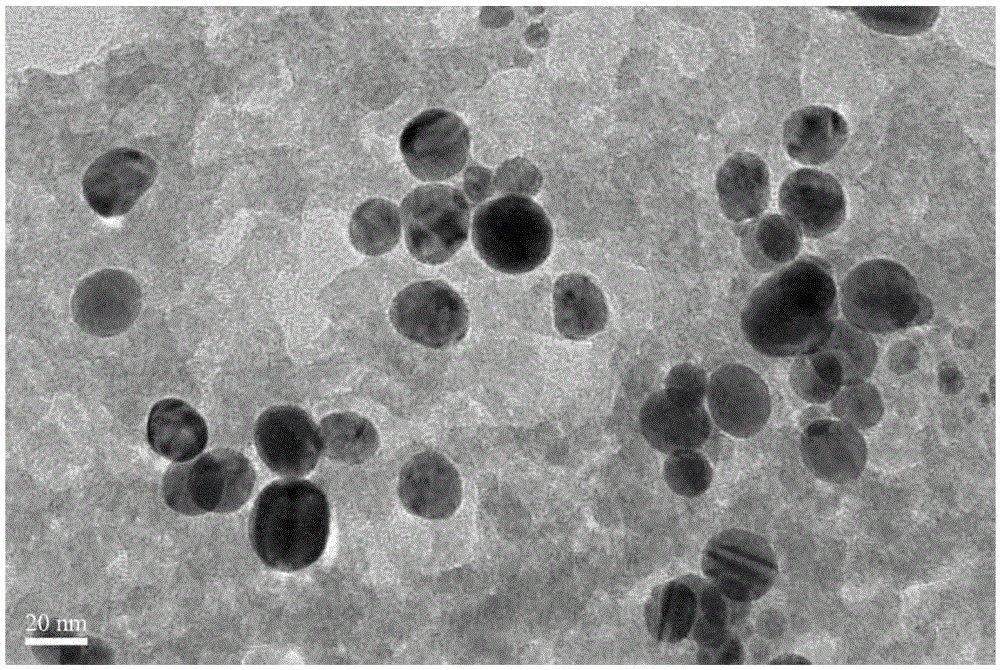

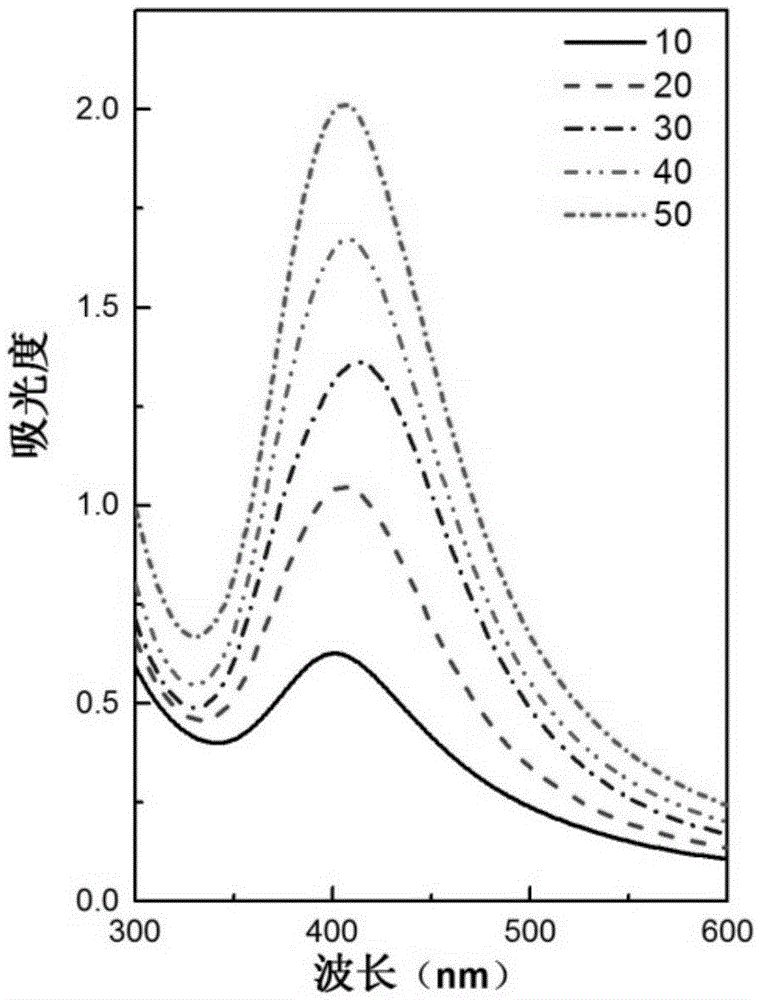

ActiveCN105478795AGood dispersionSignificant surface plasmon resonance signalTransportation and packagingMetal-working apparatusSILVER NITRATE CRYSTALSSugarcane extract

The invention discloses a method of preparing silver nanoparticles with a sugarcane extract. The method comprises the following steps: preparing the sugarcane extract; dissolving silver nitrate crystals into deionized water to prepare a silver nitrate solution with the concentration to be 0.005-0.02 mol / L; and adding an alkaline solution in the sugarcane extract, keeping a pH value of a reaction system to range from 8.5-10.5, then heating to boiling, adding the silver nitrate solution with the concentration to be 0.005-0.02 mol / L in the boiling state, reacting for 10-50 minutes, carrying out centrifugal separation on an obtained reaction solution after reaction is finished, and drying obtained precipitates to obtain the silver nanoparticles. The preparation method is simple, is easy to operate and cannot cause pollution to environment. The prepared silver nanoparticles are uniform, are good in dispersibility, do not have toxic chemical reagent residues on the surfaces, express obvious optical signals and can be widely applied to the field of biological medicines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Production method of photography-level silver nitrate

InactiveCN102040241AHigh purityImprove identitySilver salt compositionsSilve compoundsIngotSILVER NITRATE CRYSTALS

The invention discloses a production method of photography-level silver nitrate, comprising the following steps: (1) taking pure nitric acid and deionized water for standby; (2) adding a silver ingot the purity of which is more than 99.9% into a kettle, adding the pure nitric acid, heating to 60-65 DEG C, vacuumizing the kettle, and keeping excess silver, thus obtaining reactive fluid; (3) adding the reactive fluid into a diluting tank, diluting the reactive fluid with pure water until the specific gravity of solution is 1.4-1.5g / cm<3>, and standing for 24 hours; (4) adding decontamination agent (magnesium carbonate), and carrying out solid-liquid separation; (5) after separation, causing liquid phase to enter a condensed crystallization kettle, evenly stirring at the revolving speed of 25-30r / min to prepare silver nitrate crystal; and (6) filtering and drying the silver nitrate crystal, and drying the crystal, thus obtaining the photography-level silver nitrate. The silver nitrate produced by method provided by the invention has the advantages of high purity, good identity and good stability.

Owner:中科铜都粉体新材料股份有限公司

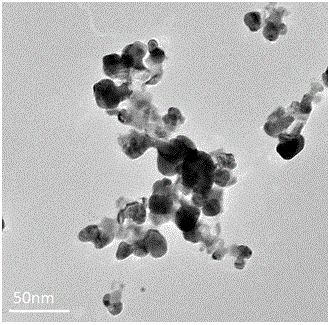

Method for preparing silver nanoparticles with water-soluble starch

The invention provides a method for preparing silver nanoparticles with water-soluble starch. The method comprises the following steps that the water-soluble starch is dissolved in deionized water to prepare a water-soluble starch aqueous solution of which the concentration is 0.4-1.1 mol / L; silver nitrate crystals are dissolved in deionized water to prepare a silver nitrate solution of which the concentration is 0.006-0.014 mol / L; and the water-soluble starch aqueous solution is heated until boiled, the silver nitrate solution is added in the boiled water-soluble starch aqueous solution, the pH value of a reaction system is kept to 6.0-7.0, after being conducted for 15-35 min under the boiling condition, reaction is completed to obtain a reaction solution, the reaction solution is centrifugally separated to obtain a precipitate, and the precipitate is dried to obtain the silver nanoparticles. In the method, the adopted devices are simple and convenient to operate. The water-soluble starch is conveniently obtained, low in cost, and nontoxic. The prepared silver nanoparticles can be applied to the field of biological medicine.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for synthesizing flower-shaped silver micro-particles

The invention discloses a method for synthesizing flower-shaped silver micro-particles. The method comprises the following steps of respectively measuring ascorbic acid solid powder and silver nitrate crystal, and respectively dissolving the ascorbic acid solid powder and the silver nitrate crystal into deionized water for standby use; placing the prepared ascorbic acid solution into the silver nitrate solution, and ensuring the mol ratio of the ascorbic acid and the silver nitrate to be (0.8-1.2):1; immediately adding a cleaned stainless steel sheet into the mixed solution; magnetically stirring the reaction materials for 180min to 360min after the stainless steel sheet is added, and ending the reaction; taking out and centrifugally separating the stainless steel sheet in the material after the reaction is ended, and precipitating and washing the stainless steel sheet to obtain the flower-shaped silver micro-particles. By adopting the method, the shape of a product is controllable, simplicity in operation can be realized, the condition is moderate, and the repeatability is good.

Owner:江苏全泽环保科技有限公司

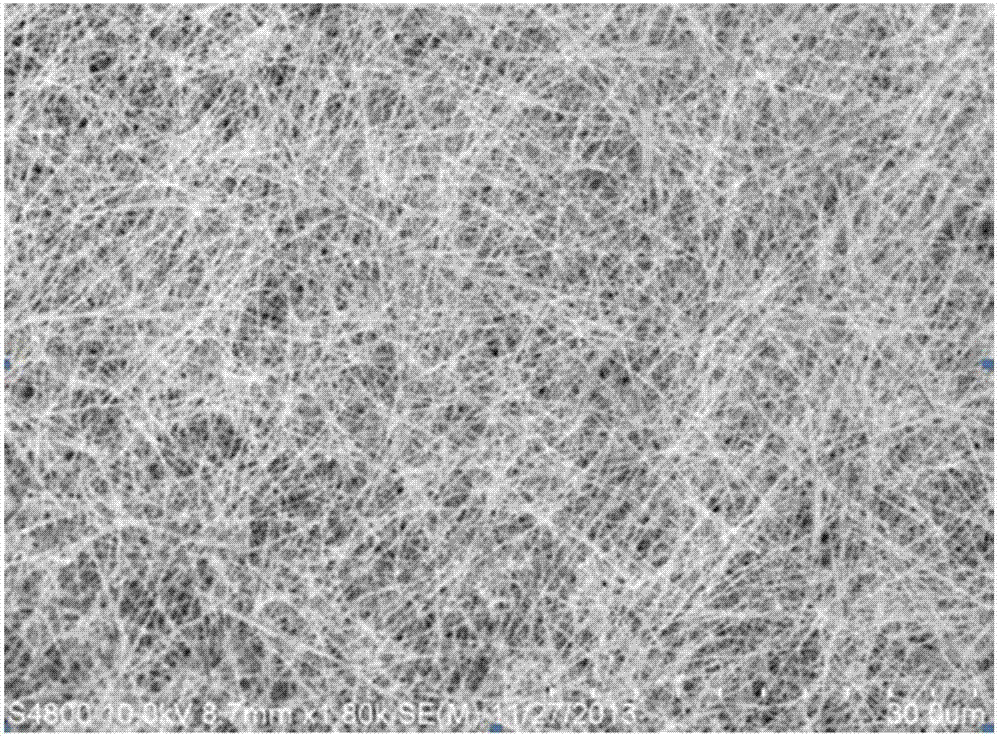

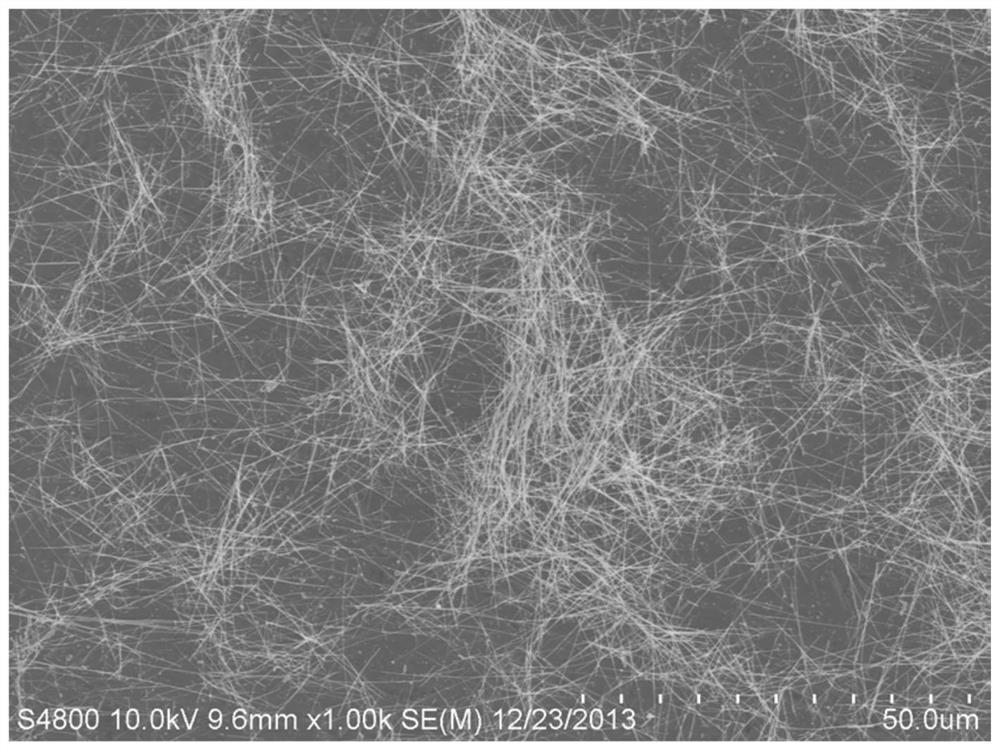

Method for preparing and separating silver nanowires under normal pressure in large scale

ActiveCN107486561AGood dispersionAvoid Pretreatment DeteriorationMaterial nanotechnologyTransportation and packagingAlcoholPolyol

The invention discloses a method for preparing and separating silver nanowires under normal pressure in a large scale. Firstly, a crystal type control agent is prepared into a solution, then the solution of the crystal type control agent, polyvinylpyrrolidone and polyhydric alcohol are taken and added into a reaction kettle to be stirred and subjected to temperature rise, and a first mixture is obtained, wherein with silver nitrate crystals as reference, the mass ratio of the crystal type control agent, the polyvinylpyrrolidone and the polyhydric alcohol in the reaction kettle is (5*10<-4>-2*10<-3>): (0.7-1.4): (50-100); the silver nitrate crystals are dispersed to obtain a silver nitrate / polyatomic alcohol solution which is added into the first mixture in three times, and after heat preserving, cooling is performed till normal temperature is achieved so that a second mixture can be obtained; and absolute ethyl alcohol with the volume being 3-6 times of the volume of the second mixture then is added in, after stirring, the second mixture and the absolute ethyl alcohol are transferred into a settling tank, by setting the height of the settling tank, standing separation is performed in a manner that both ends are broken off, and a material of the settling tank is not soluble with the silver nanowires. The preparation method is simple, and the obtained silver nanowires are good in dispersing performance and wide in application range.

Owner:NANJING UNIV OF POSTS & TELECOMM

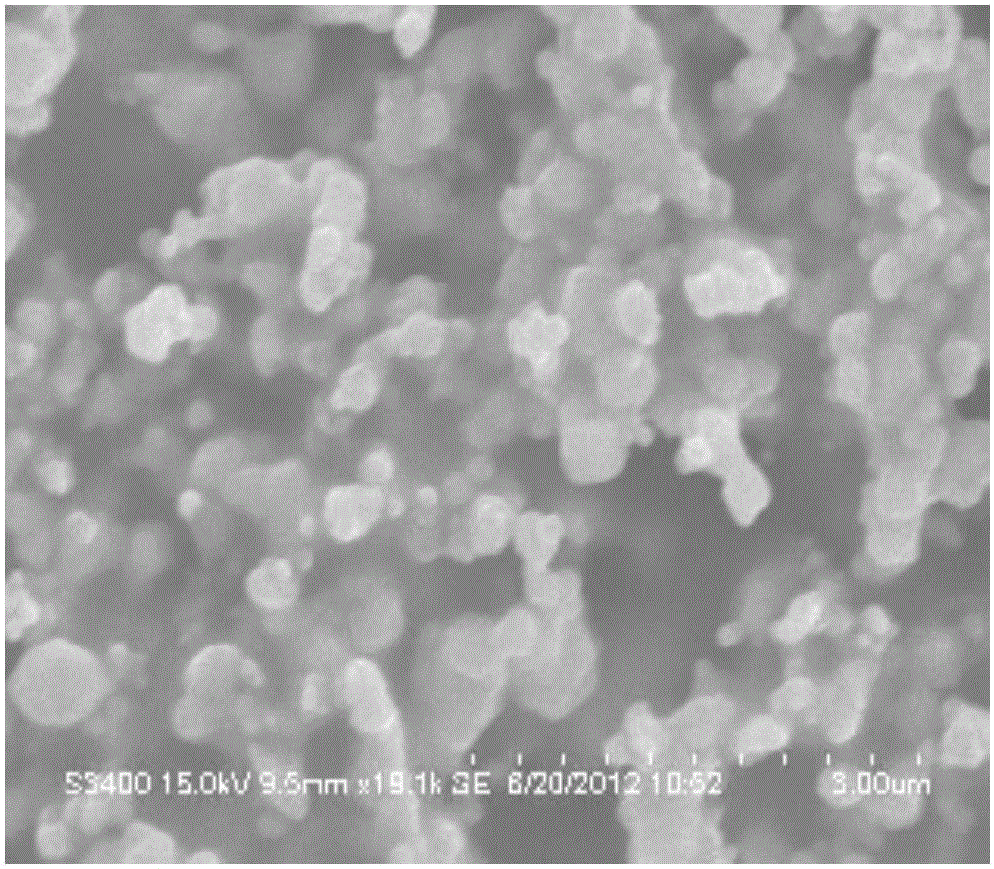

Method for preparing high-purity superfine silver powder

The invention discloses a method for preparing high-purity superfine silver powder. The method comprises the following steps: a, purifying silver nitrate crystals; b, purifying sodium chloride crystals; c, preparing a silver chloride precipitate; d, putting the silver chloride precipitate obtained in the step c into a fourth container, further adding a water-ethanol solution of NH2OH*HCl into the fourth container, continuously stirring till the silver chloride precipitate is completely dissolved, wherein the reaction temperature is 20-25 DEG C, the stirring speed is 350-450r / minute, and suspended black solids are generated on the liquid surface; e, performing filtration and drying under a vacuum condition, and obtaining the high-purity superfine silver powder. The method has the beneficial effects that the silver powder can be prepared from reaction under a homogeneous condition, is small in granularity and uniform in granule, needs no addition of a dispersing agent, is easy to wash and high in silver powder purity; during the ionic reaction in the solution, the contact area is large and the reaction speed is high; the reaction is under normal pressure, the production process is simple and the cost is low; no pollutant is discharged.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE +1

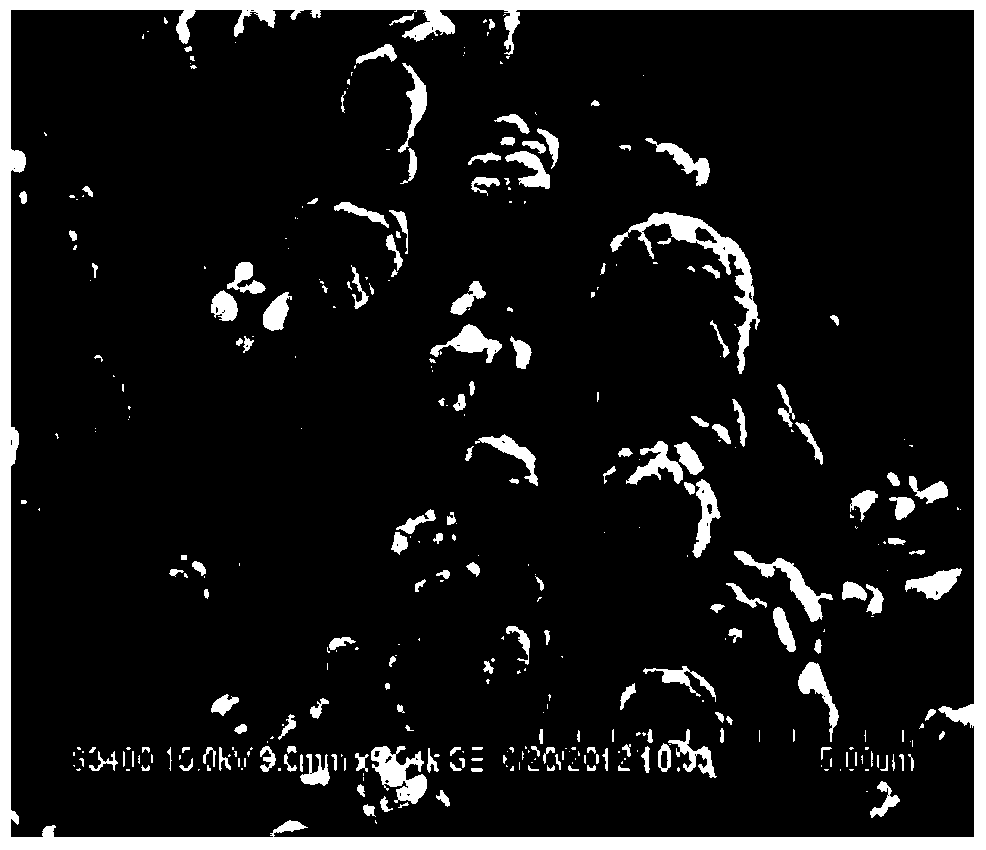

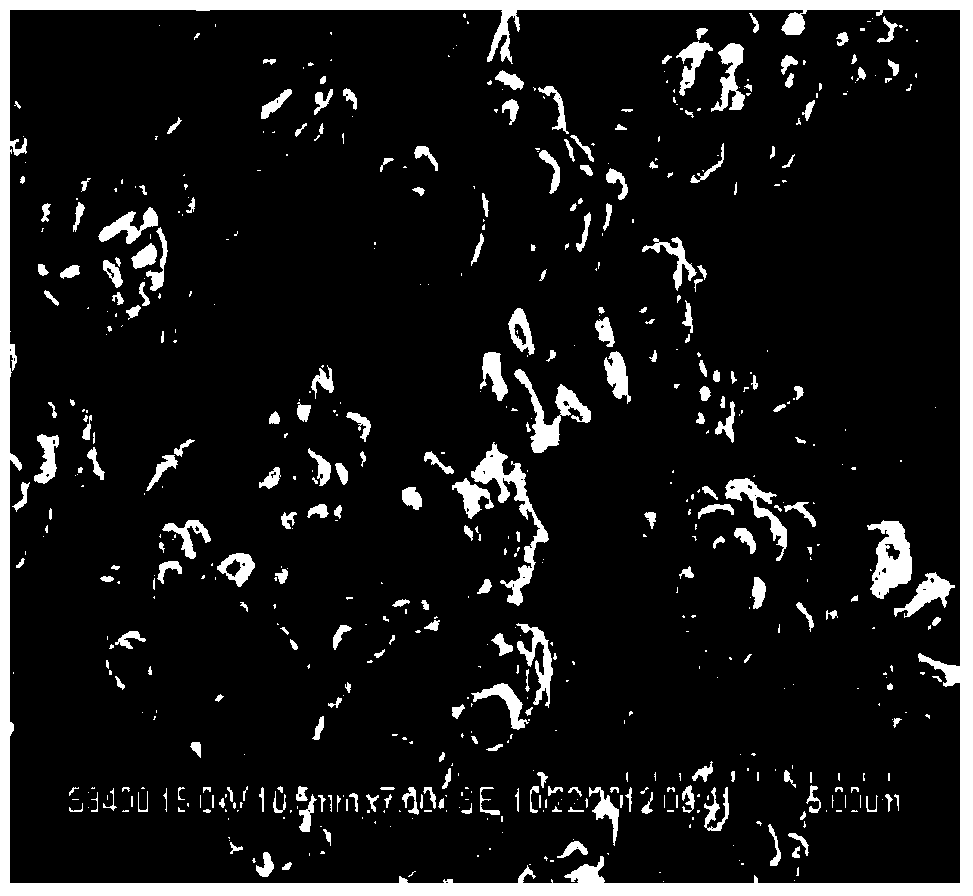

Replacement reaction method for preparation of silver dendritic super-hydrophobic surface

InactiveCN105671523ASimple methodEasy to operateLiquid/solution decomposition chemical coatingAlcoholDistilled water

The invention discloses a replacement reaction method for preparation of a silver dendritic super-hydrophobic surface. The method comprises the steps that 1, silver nitrate crystals are dissolved in distilled water and stirred to be even so as to obtain a solution A; 2, tetradecanoic acid is dissolved in absolute ethyl alcohol to obtain a solution B; 3, an oxide layer on the surface of a copper matrix is removed and then washed out sequentially through distilled water and absolute ethyl alcohol, and the copper matrix is dried for standby application; 4, the copper matrix is immersed in the solution A to be subjected to replacement reaction; and 5, the copper matrix obtained in the step 4 is washed out sequentially through distilled water and absolute ethyl alcohol, then the solution B is evenly smeared on the surface of the washed copper matrix, the surface of the copper matrix is aired and slightly wiped with a sponge, and then the silver dendritic super-hydrophobic surface is obtained. By the adoption of the method, the contact angle of the prepared super-hydrophobic surface on the copper matrix can reach more than 156 degrees, and the super-hydrophobic property keeps stable after the super-hydrophobic surface is put under the normal condition for one year.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of silver powder for low-temperature conductive adhesive

The invention discloses a preparation method of silver powder for a low-temperature conductive adhesive. At first, silver nitrate crystals are dissolved in deionized water, and the metallic silver concentration of solutions is adjusted to 50g / L-300g / L; then alkali solutions are added and stirred evenly, the pH of the solutions is adjusted to be equal to 8-14, the temperature of the solutions is adjusted to 30-70 DEG C, excessive reductant solutions are slowly dripped, and stirring continues after dripping is finished to obtain superfine silver slurry; and the superfine silver slurry is stilled, the lower layer silver powder is washed, additives are added and fully dispersed for 10 minutes, drying is conducted until the constant weight is reached, and the silver powder for the low-temperature conductive adhesive is obtained. The process amplification is high, the process controllability is high, and the process is environment-friendly. The obtained superfine silver powder has stable indicators, appropriate particle size distribution and good disperstiveness. The preparation method is suitable for low-temperature curing conductive paste.

Owner:西安宏星电子浆料科技股份有限公司

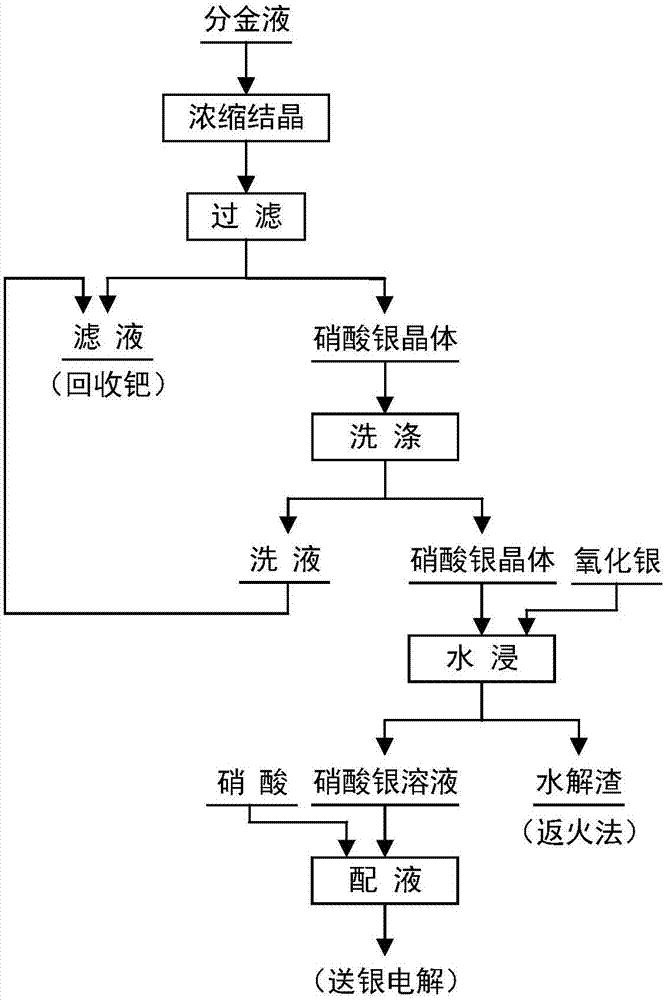

Preparation method of silver electrolyte

InactiveCN107326396AImprove direct yieldReduce repeated recyclingPhotography auxillary processesElectrolysis componentsSmelting processEconomic benefits

The invention discloses a preparation method of a silver electrolyte. The preparation method comprises the following steps that (1) parting liquid is concentrated, then cooled and crystallized, then solid-liquid separation is conducted, and filtrate and silver nitrate crystals are obtained; (2) the silver nitrate crystals are pumped and filtered under the negative pressure and then washed till the silver nitrate crystals are colourless; (3) deionized water is added into the colorless silver nitrate crystals, the silver nitrate crystals is heated through steam and stirred to be completely dissolved, after the final pH value of a solution is adjusted to 5.0-6.5, solid-liquid separation is conducted, and hydrolysis residue and silver nitrate solution are obtained; and (4) after the concentration of Ag+ and the acidity of nitric acid in the silver nitrate solution are adjusted, the silver nitrate solution returns to an electrolytic bath to be electrolyzed. According to the preparation method of the silver electrolyte, the technological process is simple, operation is easy and convenient, the cost is low, the environment-friendly benefits are high, the direct recovery rate of silver in the electrolyzing process can be effectively increased and can reach 92%-93.5%, the repeated recovery times of metal in the smelting process are decreased, the production cost is saved, and the economic benefits of enterprises are improved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

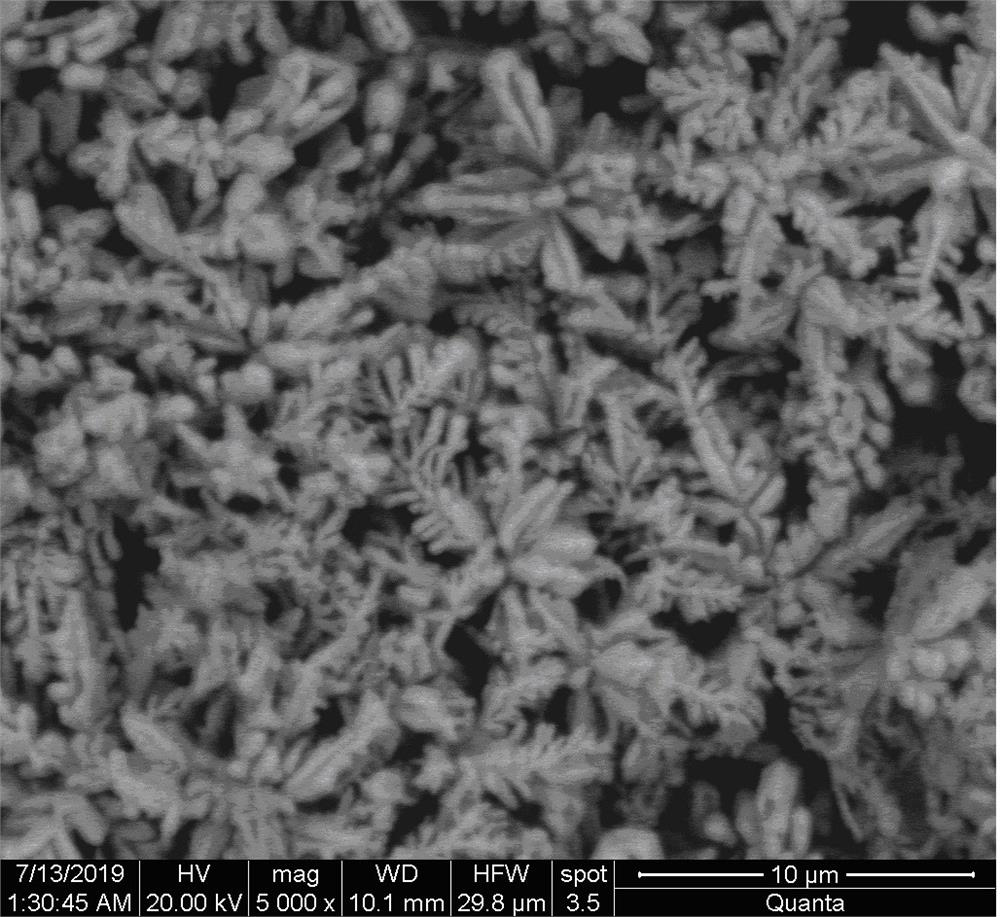

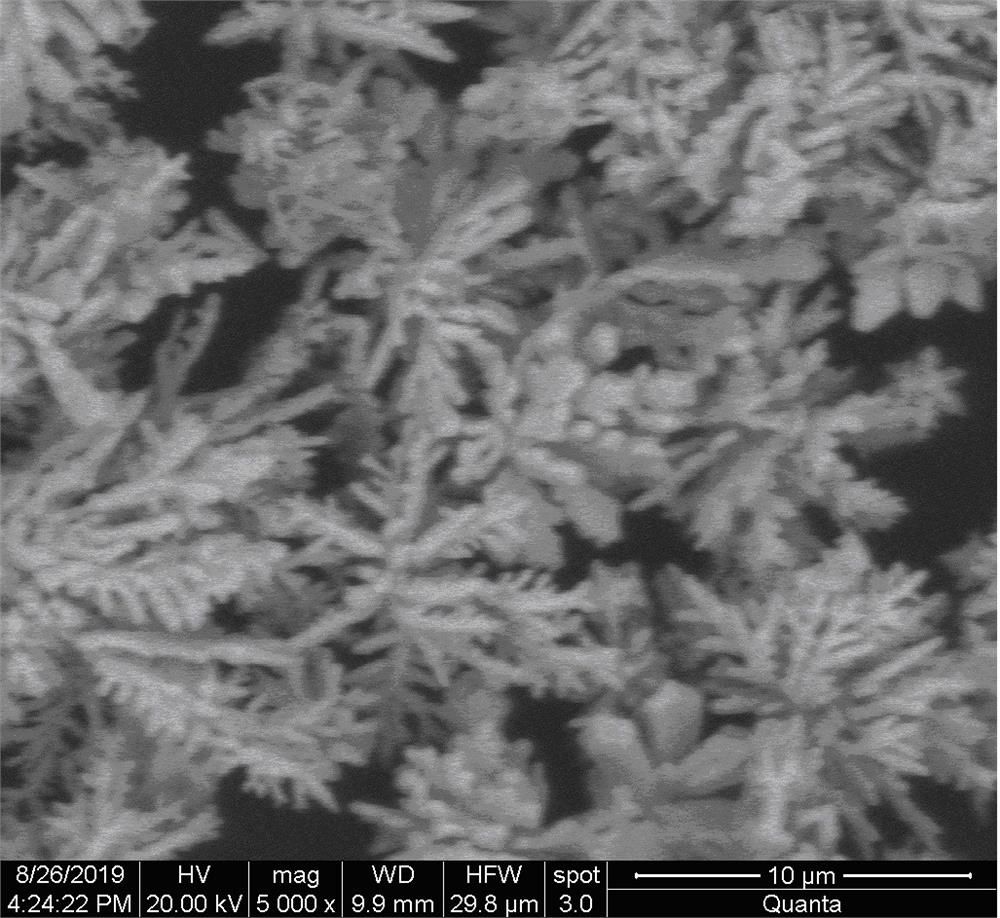

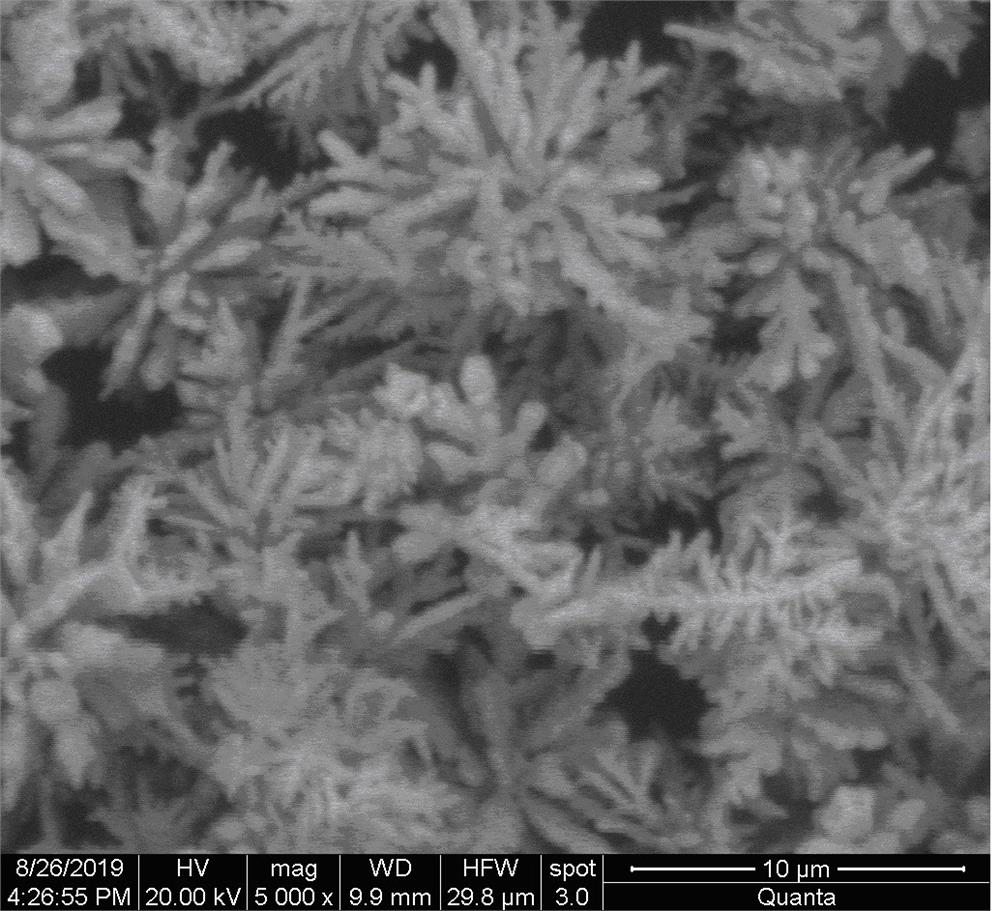

Preparing method of dendritic silver powder

ActiveCN110935888ANo pollution in the processReduce processing costsSILVER NITRATE CRYSTALSMacromolecule

The invention discloses a preparing method of dendritic silver powder. The method includes the steps of dissolving silver nitrate crystals in deionized water to prepare a silver nitrate solution, dissolving ascorbic acid or glucose in deionized water to prepare a reducing agent solution, dropwise adding the silver nitrate solution to the reducing agent solution for chemical reduction reaction, stopping stirring when the silver nitrate solution is all dropwise added, performing solid-liquid separating on silver powder through suction filtration, and then performing drying to obtain the dendritic silver powder. No polymeric dispersants are added to the silver powder prepared through the method, washing and collecting are simple, waste liquid disposal cost is low, and the silver powder is friendly to the environment and suitable for industrial batch production; and by adjusting the content of a nucleation control agent to control the morphology of the silver powder, the prepared silver powder is dendritic silver powder with the trunk average length of 5-15 [mu]m and the single-branch average length of 0.5-3 [mu]m.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Preparation technique for silver powder for preparing printing paste

The invention discloses a preparation technique for silver powder for preparing printing paste. The preparation technique comprises the following steps that S100, silver nitrate crystals are used for preparing a silver nitrate solution; S200, sodium carbonate crystals are used for preparing a sodium carbonate solution; S300, the silver nitrate solution and the sodium carbonate solution are fully mixed, so that a solution A is obtained; S400, a formaldehyde solution is added into the solution A till a complete reaction is completed, so that a solution B is obtained; and S500, a nitric acid solution is added into the solution B, the pH value is regulated, stirring continues to be conducted, and the silver powder is obtained. The silver powder prepared through the preparation technique is narrow in particle size distribution range and good in morphology consistency and can be suitable for printing paste of different application systems, and the preparation technique is simple.

Owner:成都市天甫金属粉体有限责任公司

Method and product thereof for preparing silver tungsten carbide contact material from silver-coated tungsten carbide powder

ActiveCN103824710BHigh densityHigh hardnessContactsElectrical resistance and conductanceSILVER NITRATE CRYSTALS

The invention discloses a method for preparing a silver-tungsten carbide contact material from silver-coated tungsten carbide powder and the silver-tungsten carbide contact material. According to the technical scheme, a silver-tungsten carbide electrical contact is prepared from raw materials, i.e., a silver nitrate crystal and tungsten carbide powder, by a chemical coating powder preparation process and a liquid-phase infiltration process; the prepared silver-tungsten carbide electrical contact comprises the following components in percentage by weight: 38%-42% of tungsten carbide, 0-0.2% of additives and the balance being silver, wherein the additives are one or more selected from nickel, copper and zirconium. The silver-tungsten carbide contact material prepared by the method has the advantages of high density, high hardness, low and stable contact resistance, uniform metallographic structure, favorable high-temperature oxidation resistance, electric arc erosion resistance, wear resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

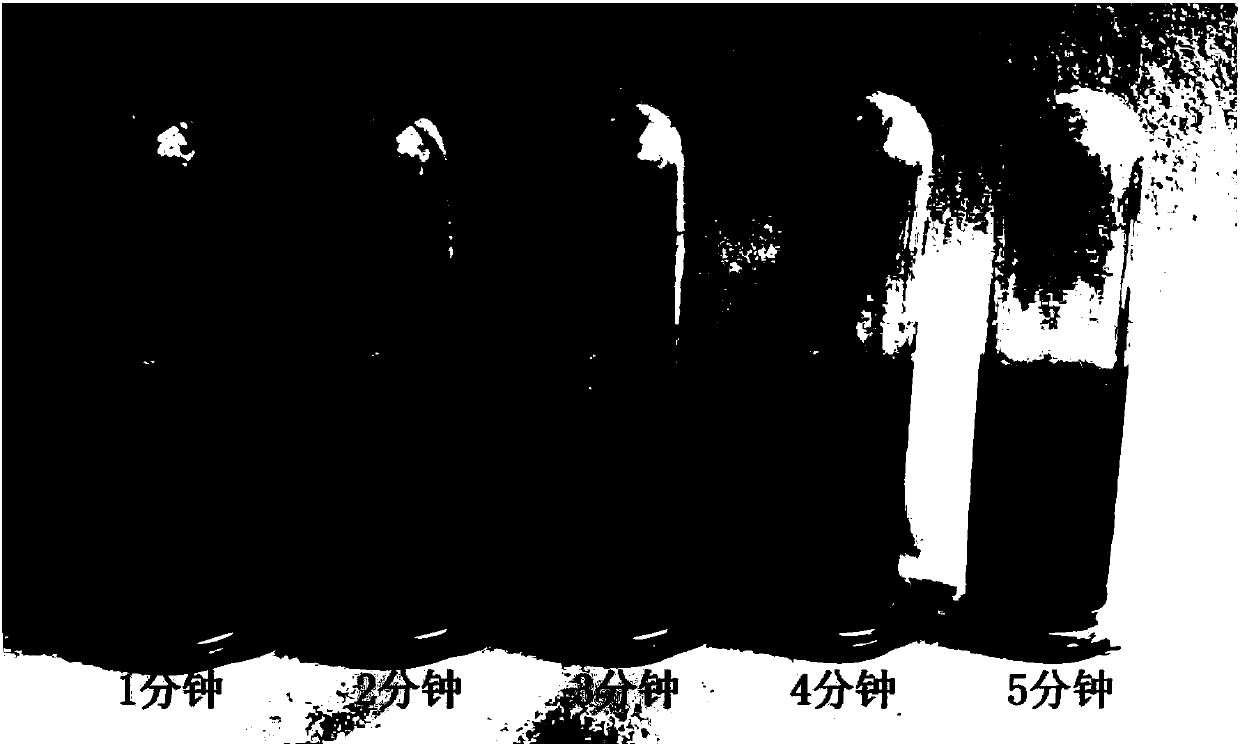

Method for preparing silver nanoparticles through caulis sargentodoxae extracting solution

InactiveCN107685152ALow priceNo toxicityMaterial nanotechnologyTransportation and packagingSILVER NITRATE CRYSTALSReaction system

The invention provides a method for preparing silver nanoparticles through a caulis sargentodoxae extracting solution. The method comprises the steps of adding caulis sargentodoxae into deionized water, heating the deionized water containing the caulis sargentodoxae to be boiled and conducting centrifugal separation to obtain a supernatant, namely, the caulis sargentodoxae extracting solution; dissolving silver nitrate crystals into the deionized water to form a silver nitrate solution; heating the caulis sargentodoxae extracting solution to be boiled, adding the silver nitrate solution into the boiling caulis sargentodoxae extracting solution, keeping the pH of a reaction system within 5.3-6.3, conducting a reaction for 1-5 min in a boiling state, conducting centrifugal separation on an obtained reaction solution after completion of the reaction, and drying obtained precipitates to obtain silver nanoparticles. According to the preparation method, adopted equipment is simple, and operation is convenient. The caulis sargentodoxae extracting solution is convenient and easy to get and low in price and has no toxicity. The surfaces of the prepared silver nanoparticles cannot generate toxic chemical reagent residues and generate obvious optical signals. Thus, the synthetized silver nanoparticles can be applied to the biological medicine field.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A kind of preparation method of cellulose acetate electrospinning solution

InactiveCN104404635BStable manufacturingEasy to operateSpinning solutions preparationArtifical filament manufactureWater bathsAcetic acid

The invention discloses a preparation method of a cellulose acetate electrostatic spinning solution. The preparation method comprises the following steps of taking 6-9 parts of acetone by mass, 1-3 parts of dimethylacetamide by mass and 0.5-2 parts of water by mass as raw materials to prepare solvent after mixing; adding cellulose acetate particles and silver nitrate crystals into the solvent, slowly heating to 60-80 DEG C at the heating speed of increasing by 2-5 DEG C at every minute and stirring for 60-120 minutes to fully dissolve the cellulose acetate particles so as to obtain a composite cellulose acetate solution containing 1 wt%-3wt% of silver nitrate; after the composite cellulose acetate solution is cooled, adding ammonium bicarbonate which is 1 wt%-3wt% of the mass of the composite cellulose acetate solution, placing in water bath at 40 DEG C, and mechanically stirring to carry out expansion treatment so as to obtain the cellulose acetate electrostatic spinning solution. According to the preparation method, nano-cellulose with an anti-bacterial function is stably prepared by the electrostatic spinning solution through determining the optimum contents of water and silver nitrate in the electrostatic spinning solution, and the preparation method has the advantages of simplicity in operation and low cost.

Owner:苏州丽达纺织有限公司

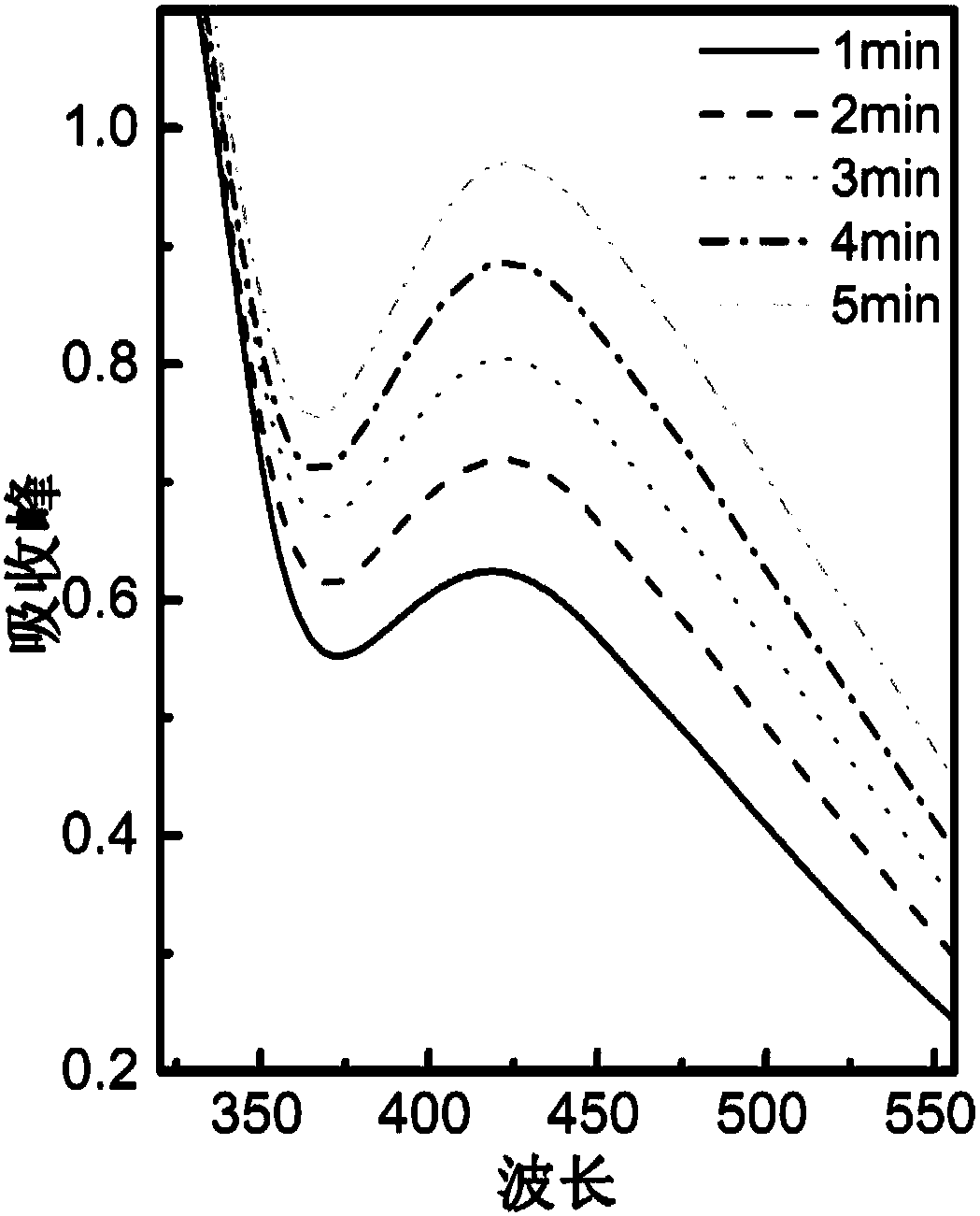

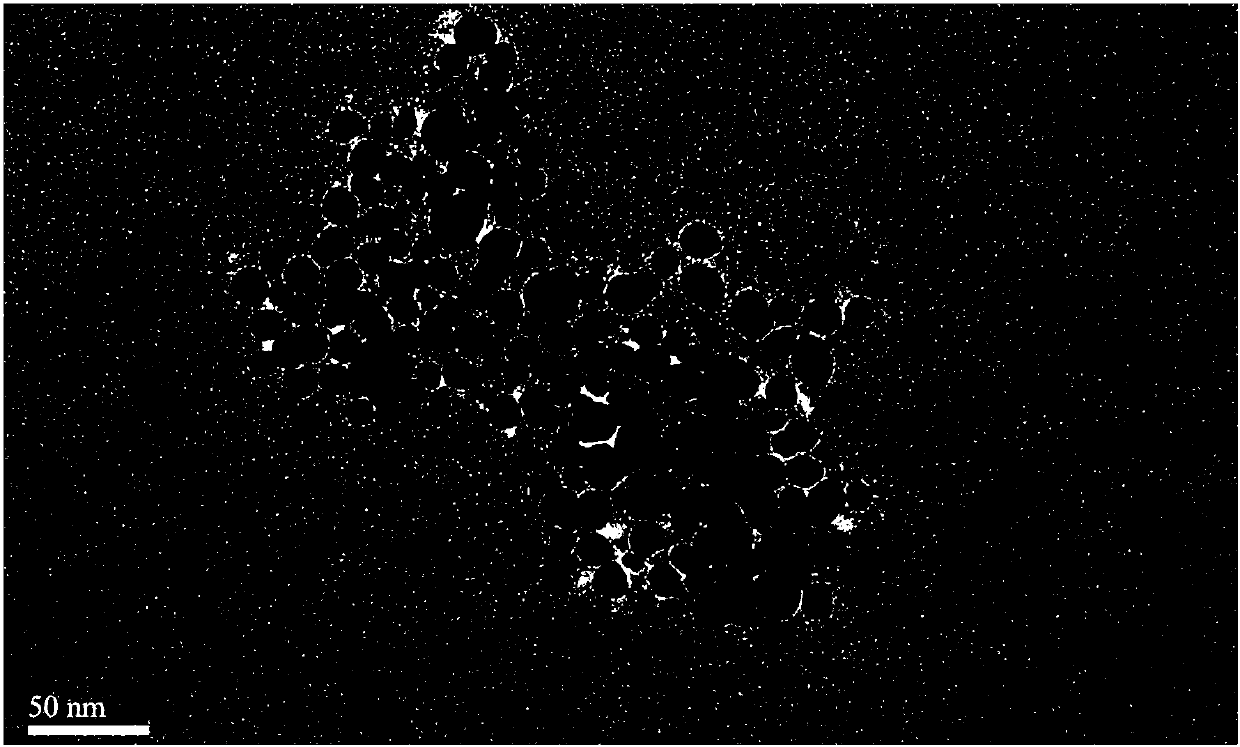

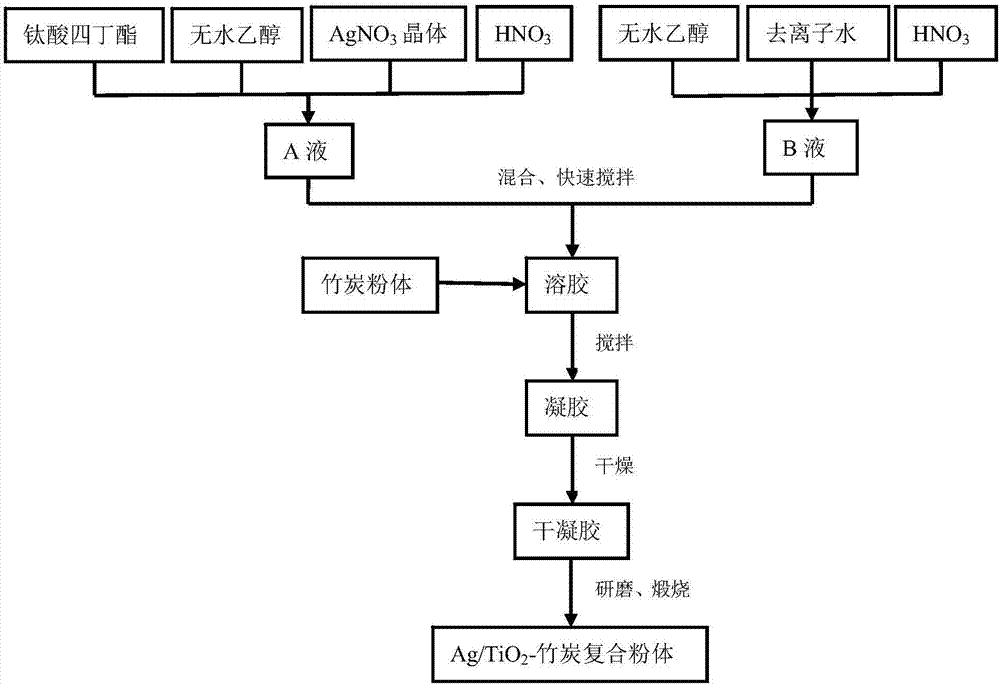

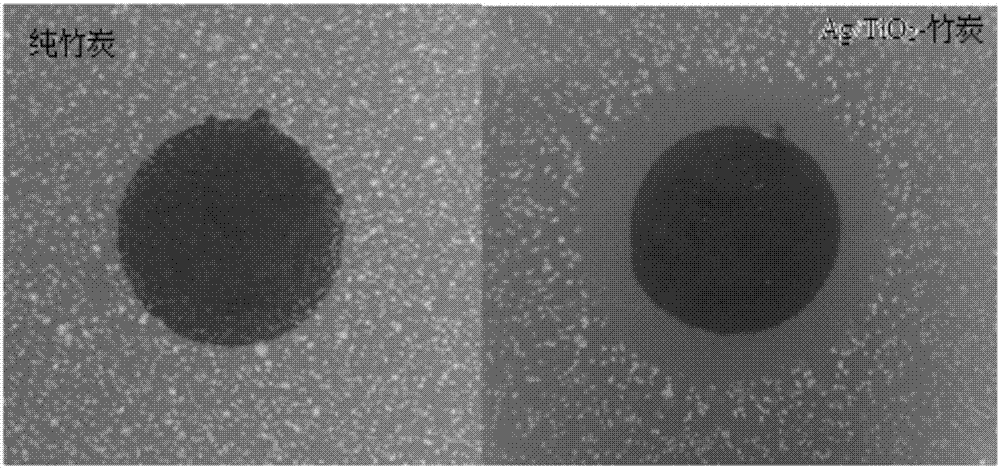

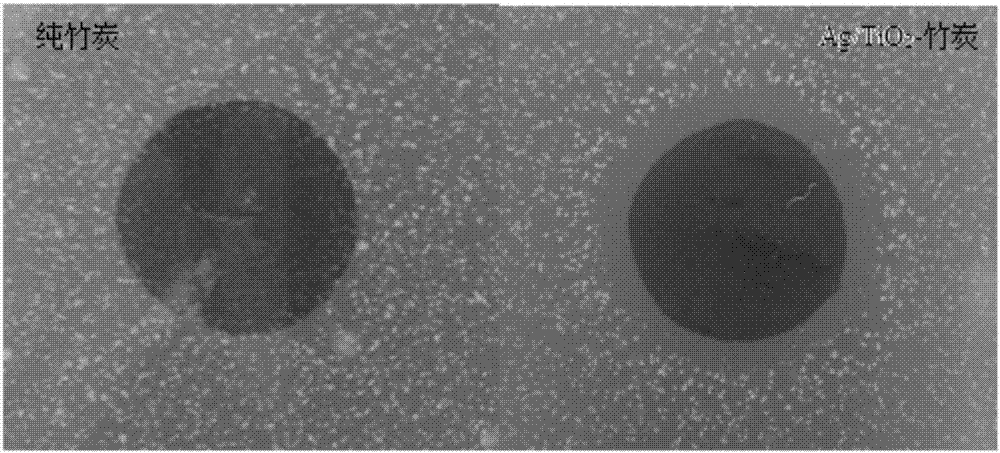

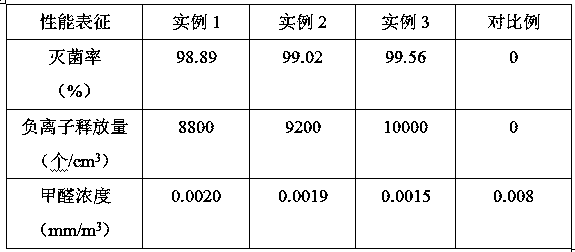

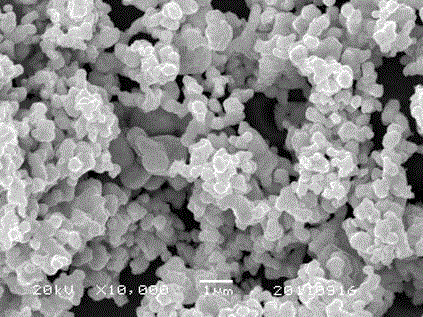

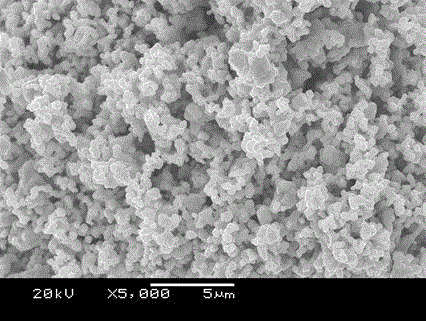

Silver-loaded TiO2-modified bamboo charcoal material and preparation method thereof

InactiveCN106925216ASimple processShort preparation cycleBiocideOther chemical processesAlcoholSILVER NITRATE CRYSTALS

The invention relates to a silver-loaded TiO2-modified bamboo charcoal material and a preparation method thereof. The silver-loaded TiO2-modified bamboo charcoal material is prepared through the following steps of (1) weighing tetrabutyl titanate, mixing tetrabutyl titanate with one part of absolute ethyl alcohol, adding silver nitrate crystal and adjusting the pH to 4-5 to obtain a mixed solution A; (2) weighing the remaining absolute ethyl alcohol and mixing the remaining absolute ethyl alcohol with deionized water and adjusting the pH to 1-2.5 to obtain a mixed solution B; (3) adding the mixed solution to the mixed solution A under intense stirring, and stirring until transparent clarified sol is formed, adding bamboo charcoal powder and carrying out stirring reaction to form gel; and (4) ageing, drying, burning and cooling the gel obtained in the step (3) to obtain the silver-loaded TiO2-modified bamboo charcoal material. compared with the prior art, the composite material has a porous adsorption function of bamboo charcoal and a visible light catalytic sterilization function of silver-loaded nano TiO2, and the bamboo charcoal and the silver-loaded nano TiO2 can work together for complementary advantages, so that the composite material has excellent adsorption, humidification and photocatalytic sterilization effects.

Owner:TONGJI UNIV

Preparation method of multifunctional ecological ceramic floor tile

InactiveCN109928722ALarge specific surface areaMany surface active sitesCeramic materials productionCeramicwarePlastic materialsCell membrane

The invention relates to a preparation method of a multifunctional ecological ceramic floor tile, and belongs to the technical field of decoration materials. The multifunctional ecological ceramic floor tile capable of releasing negative ions can be prepared from nitrate crystals and tourmaline powder as raw materials by adopting nano-silver / tourmaline composite powder prepared by a room-temperature solid-phase method to serve as a sterilizing agent, carbon powder and starch as a pore-forming agent, the released negative oxygen ions have relatively high activity and a strong redox effect, andcan destroy bacterial cell films or the activity of cellular protoplasmic reactive enzyme so as to achieve the purpose of antibacterial sterilization, nano-silver can be combined with a phosphide anda sulfide on the bacterial cell films, so that the permeability of the cell films is destroyed; the nano-silver entering the cell films can react with the sulfide or the phosphide in proteins and DNAin cells, and the function of intracellular enzyme and the replication and transcription of the DNA are blocked; high-alumina mud as a plastic material is added to improve the sintering strength; andblack talc is added to improve the foaming property of a sample.

Owner:常州市雪宜物资有限公司

Silver powder preparing technology for controlling grain size through control over adding amount of sodium hydroxide

ActiveCN105458285AImprove protectionNarrow particle size rangeHazardous substanceReaction temperature

The invention discloses a silver powder preparing technology for controlling the grain size through control over the adding amount of sodium hydroxide. The technology comprises the following steps that S100, silver nitrate crystals are taken to prepare a silver nitrate solution, sodium hydroxide crystals are taken to prepare a sodium hydroxide solution, and glucose crystals are taken to prepare a glucose solution; S200, in the stirring state, the silver nitrate solution is slowly added in the sodium hydroxide solution, and a solution A is obtained; S300, under the condition that the reaction temperature is 20-30 DEG C, the glucose solution is slowly added into the solution A and constantly stirred till the reaction is thorough, and a solution B is obtained; and S400, the solution B continues to be stirred for a period of time, then solid and liquid separation is carried out, a solid body is taken, washed and dried, and silver powder is obtained. The prepared silver powder is small in grain size distribution range and can be suitable for printing sizing agents of different application systems, toxic and harmful substances do not exist in waste liquid, the grain size of the silver powder can be controlled, and the preparing technology is simple.

Owner:晶澜光电科技(江苏)有限公司

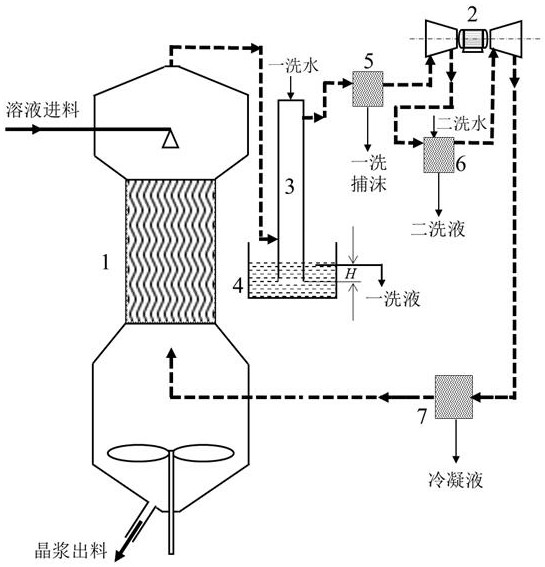

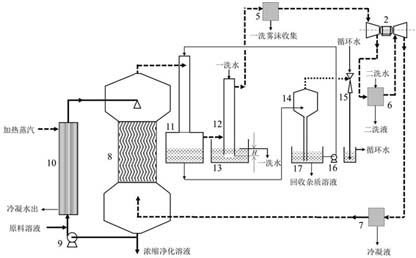

Method and device for removing volatile impurities in aqueous solution and preparing crystal product through air circulation gas stripping concentration

ActiveCN114247172AReduce input power consumptionDistillation regulation/controlSolution crystallizationAir cyclePhosphoric acid

The invention relates to a method and a device for removing volatile impurities in an aqueous solution and preparing a crystal product through air circulation gas stripping concentration, which are characterized in that a group of vertical corrugated plate arrays, gas-liquid distribution structures respectively connected with the upper part and the lower part of the vertical corrugated plate arrays and the like form gas-liquid countercurrent flow heat and mass transfer on the surfaces of falling films on the two sides of corrugated plates; the purification effect that the water solution with the water content not lower than 40% and the volatile impurity not higher than 3.0% is concentrated till the water content is lower than 35% and the volatile impurity content is lower than 0.1% is achieved, and crystal mush with the ratio of the crystal particle amount to the total solute mass larger than 40% is prepared from the water solution with the water content not lower than 15%. And a constant mass flow air closed circulation system is formed by the pressure stabilizing tower and the constant pressure water seal tank. The method has the advantages that energy is saved, closed circulation is achieved, and emission is avoided, for example, the energy consumption for preparing 400 kg of silver nitrate crystals from the 82.34% silver nitrate aqueous solution does not exceed 5 kWh, and the energy consumption for air circulation for removing 1000 kg of fluorine from the wet-process phosphoric acid solution containing 2.0% of fluorine does not exceed 100 kWh.

Owner:SICHUAN UNIV

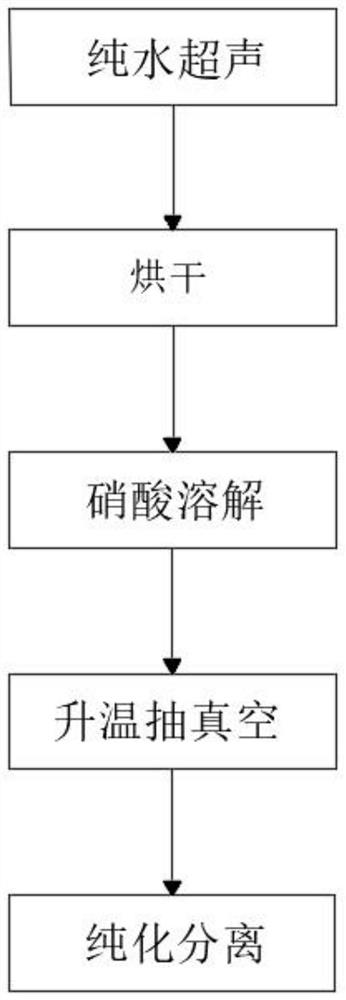

Method for recycling silver nanowire waste

PendingCN112939057AIncreased rigor is the processing effectSilve compoundsOrganic solventPhysical chemistry

The invention discloses a method for recycling silver nanowire waste, which comprises the following five construction procedures: pure water ultrasonic treatment of silver nanowires, drying, nitric acid dissolution, heating and vacuumizing, and purification and separation. The method comprises five steps. Silver-containing waste materials left after purification are recycled, an organic solvent is collected and washed, residual silver solids are dissolved through nitric acid and recrystallized, other impurities are not introduced in synthesis, and even chlorine and bromide ion-containing solids required by previous reaction are complexed, washed and dissolved in water by ammonia water, so that higher silver nitrate crystals can be obtained, namely, silver nanowire raw materials. By means of the repeated utilization, the rigorous treatment process, namely the treatment effect, is increased in the aspects of drying, heat preservation, vacuumizing and the like.

Owner:重庆烯宇新材料科技有限公司

A kind of preparation method of dendritic silver powder

The invention discloses a preparation method of dendritic silver powder. Silver nitrate crystals are dissolved in deionized water to prepare a silver nitrate solution, ascorbic acid or glucose are dissolved in deionized water to prepare a reducing agent solution, and the silver nitrate solution is added dropwise to the reducing agent. The chemical reduction reaction is carried out in the solution, after the dropwise addition of the silver nitrate solution is completed, the stirring is stopped, the solid-liquid separation of the silver powder is carried out by means of suction filtration, and then the dendritic silver powder is obtained by drying; the silver powder prepared by the method of the present invention does not add any polymer dispersion It is easy to wash and collect, the waste liquid treatment cost is low, it is environmentally friendly, and it is suitable for industrial mass production; by adjusting the content of the nucleation control agent to control the morphology of the silver powder, the prepared silver powder is dendritic silver powder, and the average length of the trunk is 5~ 15 microns, the average length of a single branch is 0.5 to 3 microns.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

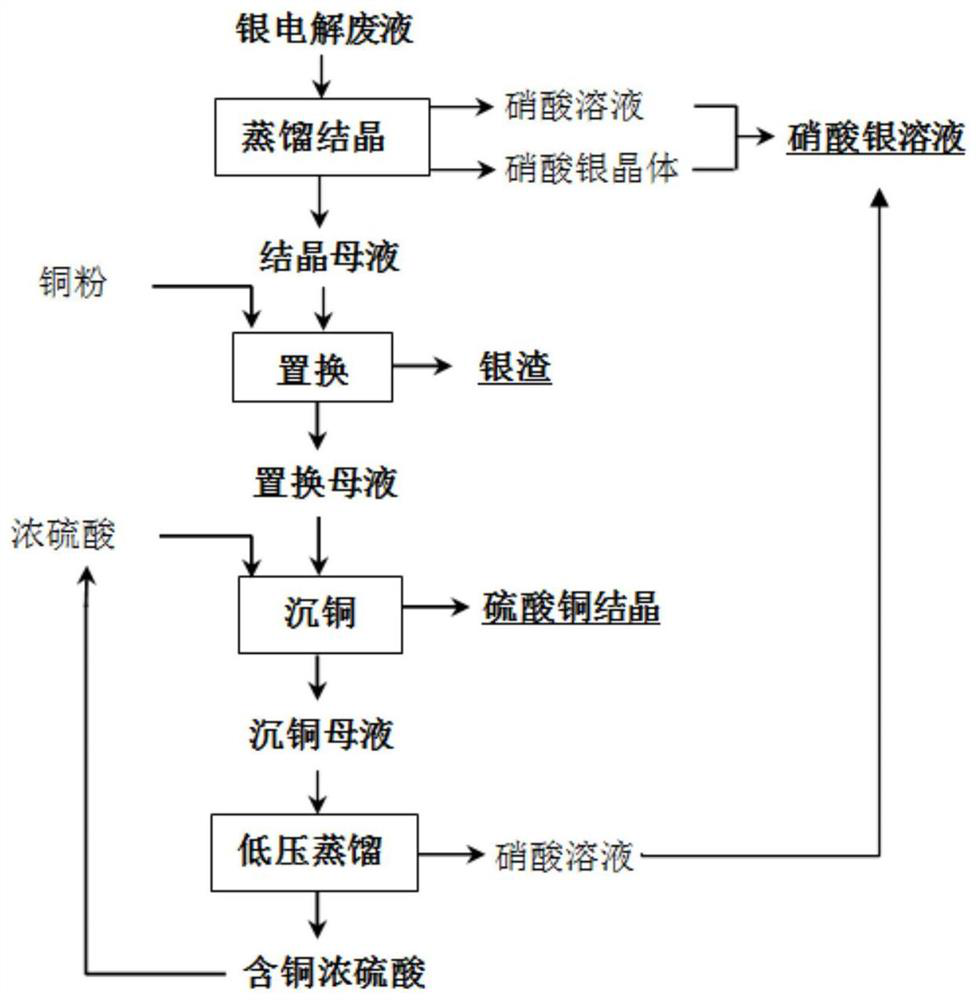

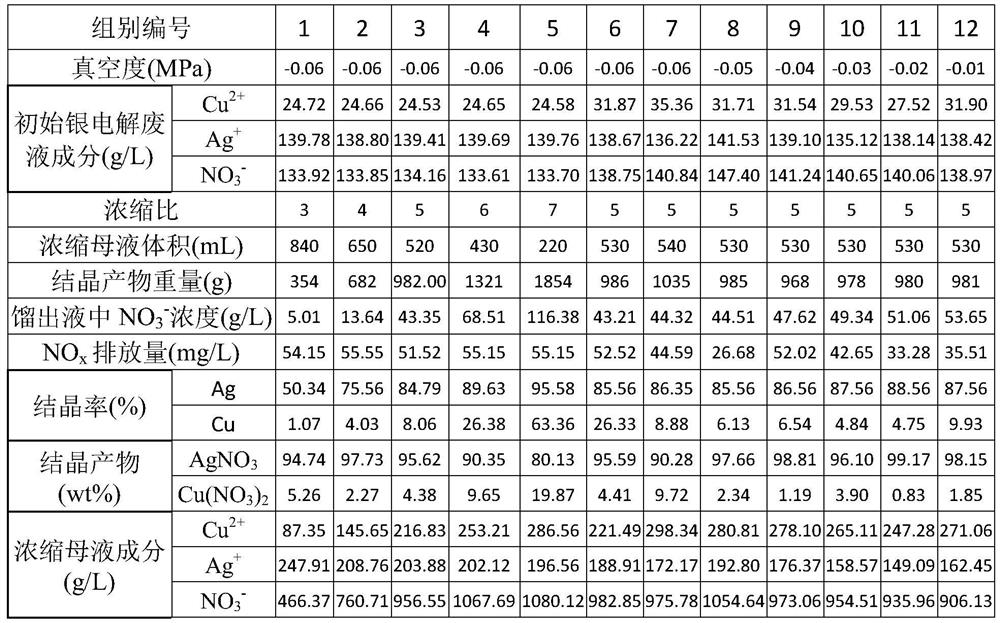

A method for separating silver and copper in silver electrolytic waste liquid

ActiveCN111099652BEfficient recyclingEffectivenessProcess efficiency improvementCopper sulfatesSlagPhysical chemistry

The invention belongs to the field of metal smelting, and specifically relates to a method for separating silver and copper in silver electrolysis waste liquid. First, the silver electrolysis waste liquid is concentrated and crystallized, filtered, and then copper powder is added to the obtained filtrate for replacement, and the filtrate obtained after filtering again is It is the waste liquid after silver recovery. Using the above scheme, first concentrate the silver electrolysis waste liquid, because the solubility of silver nitrate is relatively small, and because of the high ion content in the waste liquid, silver nitrate crystallizes out after concentration, and silver nitrate crystals are obtained by filtration; then use silver and copper According to the difference in the activity of the two metals, copper powder is used to replace the silver slag, thereby realizing the recovery of silver, that is, the separation of silver and copper. The scheme of the present invention is simple and efficient, and the silver recovery rate can be as high as over 99%.

Owner:JINLONG COPPER +2

Method and device for purifying silver nitrate through layered overall crystallization

PendingCN114797157AHigh purityIncrease heat transfer areaSolution crystallizationCrystallization by component evaporationFluid phasePhysical chemistry

The invention discloses a method and device for purifying silver nitrate through layered overall crystallization, the method comprises the steps of liquid phase feeding, cooling crystallization, draining, heating and residual liquid discharging, cleaning and material dissolving and discharging, the characteristic that silver nitrate is extremely high in solubility under the temperature rising condition is utilized, the silver nitrate is creatively and overall crystallized on a heat exchange surface, and the heat exchange efficiency is improved. And mother liquor contained in the crystals and among the crystals is discharged under a heating condition, so that the purity is improved. The device comprises a heat exchange crystallizer, a high-purity silver nitrate storage tank, a mother liquor storage tank, a material circulating pump, a product pump and a connecting pipeline. By changing the system structure of the device, the device is applied to the purification process of the silver nitrate solution, and the high-purity silver nitrate solution is prepared by dissolving silver nitrate crystals with pure water. The device is large in heat transfer area and high in crystallization efficiency, and the purity of the prepared high-purity silver nitrate can reach the photographic level.

Owner:浙江海钛新材料科技股份有限公司

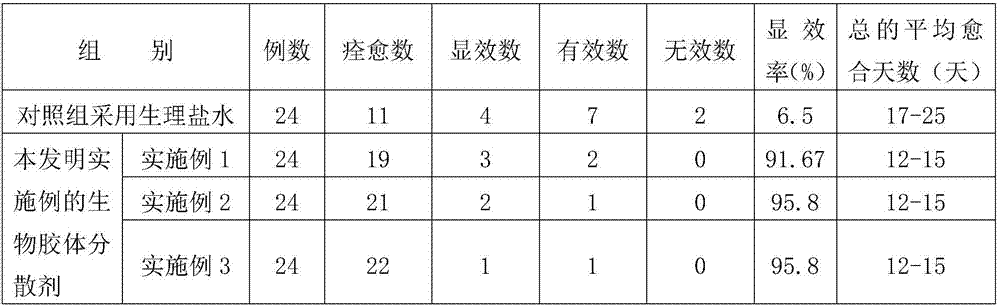

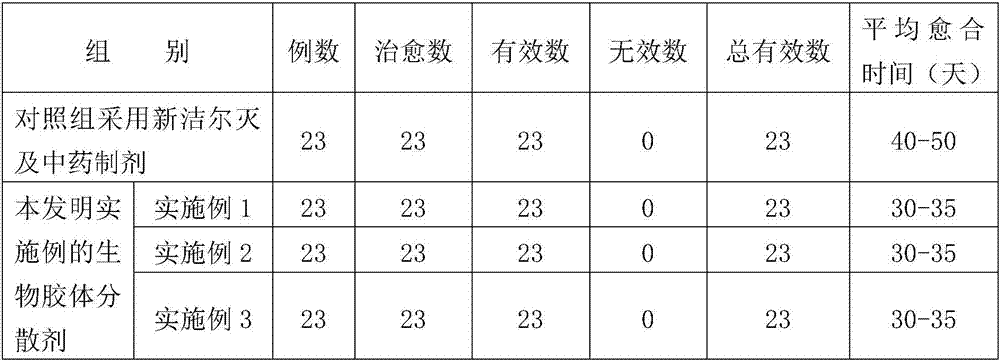

Biocolloid dispersant and preparation method thereof

InactiveCN107496452ASpeed up healingSafeHydroxy compound active ingredientsAntipyreticMentholGlycerol

The invention relates to a biocolloid dispersant and a preparation method thereof. The preparation method comprises the following steps: adding silver nitrate crystals into pure water, and uniformly stirring, so that silver nitrate crystal solution is obtained; adding glycerol into the pure water, and uniformly stirring, so that dilute glycerol solution is obtained; adding menthol into the pure water, and uniformly stirring, so that menthol solution is obtained; uniformly stirring the glycerol solution with the menthol solution, so that mixed liquor is obtained; uniformly stirring the silver nitrate crystal solution with the mixed liquor, so that silver nitrate crystal solution mixed liquor is obtained; adding ternary acid into the silver nitrate crystal solution mixed liquor, and carrying out acidifying treatment, so that the silver nitrate crystal solution mixed solution is obtained; adding tartaric acid solution into the silver nitrate crystal solution mixed solution, and uniformly stirring, so that standby solution is obtained; adding sodium alginate into the pure water, heating, dissolving and stirring, then adding a penetrating agent, and stirring, so that a stabilizer is obtained; and adding the standby solution into a stirring container filled with the pure water, stirring, adding the stabilizer, continuously stirring, and sequentially standing, filtering and filling, so that the biocolloid dispersant finished product is obtained.

Owner:苏州汇涵医用科技发展有限公司

A large-scale atmospheric pressure preparation and separation method of silver nanowires

ActiveCN107486561BGood dispersionAvoid Pretreatment DeteriorationMaterial nanotechnologyTransportation and packagingPolyolPyrrolidinones

Owner:NANJING UNIV OF POSTS & TELECOMM

A kind of silver powder preparation technology that controls particle size by controlling sodium hydroxide addition amount

ActiveCN105458285BImprove protectionNarrow particle size rangeHazardous substanceReaction temperature

The invention discloses a silver powder preparing technology for controlling the grain size through control over the adding amount of sodium hydroxide. The technology comprises the following steps that S100, silver nitrate crystals are taken to prepare a silver nitrate solution, sodium hydroxide crystals are taken to prepare a sodium hydroxide solution, and glucose crystals are taken to prepare a glucose solution; S200, in the stirring state, the silver nitrate solution is slowly added in the sodium hydroxide solution, and a solution A is obtained; S300, under the condition that the reaction temperature is 20-30 DEG C, the glucose solution is slowly added into the solution A and constantly stirred till the reaction is thorough, and a solution B is obtained; and S400, the solution B continues to be stirred for a period of time, then solid and liquid separation is carried out, a solid body is taken, washed and dried, and silver powder is obtained. The prepared silver powder is small in grain size distribution range and can be suitable for printing sizing agents of different application systems, toxic and harmful substances do not exist in waste liquid, the grain size of the silver powder can be controlled, and the preparing technology is simple.

Owner:晶澜光电科技(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com