Silver powder preparing technology for controlling grain size through control over adding amount of sodium hydroxide

A sodium hydroxide and preparation process technology, applied in the field of electronic paste, can solve the problems of limited adaptability, inability to meet various needs, and inconvenient adjustment of silver powder particle size, and achieve a narrow particle size range, which is conducive to environmental protection , high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

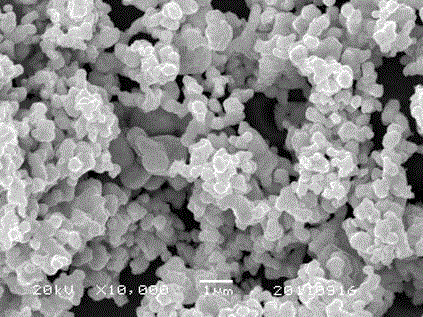

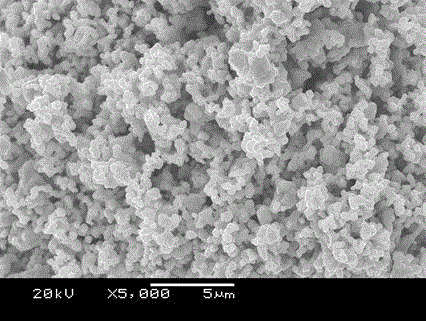

Image

Examples

Embodiment 1

[0038] A kind of silver powder preparation process of controlling particle size by controlling sodium hydroxide addition in the present embodiment comprises the following steps:

[0039] Step S100: taking silver nitrate crystals to prepare silver nitrate solution, sodium hydroxide crystals to prepare sodium hydroxide solution, and glucose crystals to prepare glucose solution; including the following specific steps:

[0040] Step S110: Add 80,000 g of silver nitrate crystals to 83 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0041] Step S120: Add 37300-42504 g of sodium hydroxide crystals into 240 L of deionized water, and stir continuously until all of them are dissolved to obtain a sodium hydroxide solution;

[0042] Step S130: Add 6664g of glucose crystals into 14.4L of hot deionized water, and stir continuously until all are dissolved to obtain a glucose solution;

[0043] Step S200: under stirring, the sil...

Embodiment 2

[0049] This embodiment is further optimized on the basis of Example 1. A silver powder preparation process that controls the particle size by controlling the amount of sodium hydroxide added includes the following steps:

[0050] Step S100: taking silver nitrate crystals to prepare silver nitrate solution, sodium hydroxide crystals to prepare sodium hydroxide solution, and glucose crystals to prepare glucose solution; including the following specific steps:

[0051] Step S110: Add 80,000 g of silver nitrate crystals to 83 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0052] Step S120: Add 42504 g of sodium hydroxide crystals into 240 L of deionized water, and stir continuously until all of them are dissolved to obtain a sodium hydroxide solution;

[0053]Step S130: Add 6664g of glucose crystals into 14.4L of hot deionized water, and stir continuously until all are dissolved to obtain a glucose solution;

[0054...

Embodiment 3

[0059] This embodiment is further optimized on the basis of Example 1. A silver powder preparation process that controls the particle size by controlling the amount of sodium hydroxide added includes the following steps:

[0060] Step S100: taking silver nitrate crystals to prepare silver nitrate solution, sodium hydroxide crystals to prepare sodium hydroxide solution, and glucose crystals to prepare glucose solution; including the following specific steps:

[0061] Step S110: Add 80,000 g of silver nitrate crystals to 83 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0062] Step S120: Add 40572 g of sodium hydroxide crystals to 240 L of deionized water, and stir continuously until all of them are dissolved to obtain a sodium hydroxide solution;

[0063] Step S130: Add 6664g of glucose crystals into 14.4L of hot deionized water, and stir continuously until all are dissolved to obtain a glucose solution;

[0064]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com