Silver-loaded TiO2-modified bamboo charcoal material and preparation method thereof

A bamboo charcoal, silver-loaded technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of high cost, no sterilization and humidity control effects, complex process, etc., and achieves adsorption. Poor ability, good adsorption and humidity control effect, good photocatalytic sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Bamboo charcoal pretreatment: choose 400-mesh bamboo charcoal, first boil the bamboo charcoal with deionized water for 30 minutes, then wash and filter with deionized water, repeat this 3 times, and dry it in a constant temperature drying oven at 105°C before use.

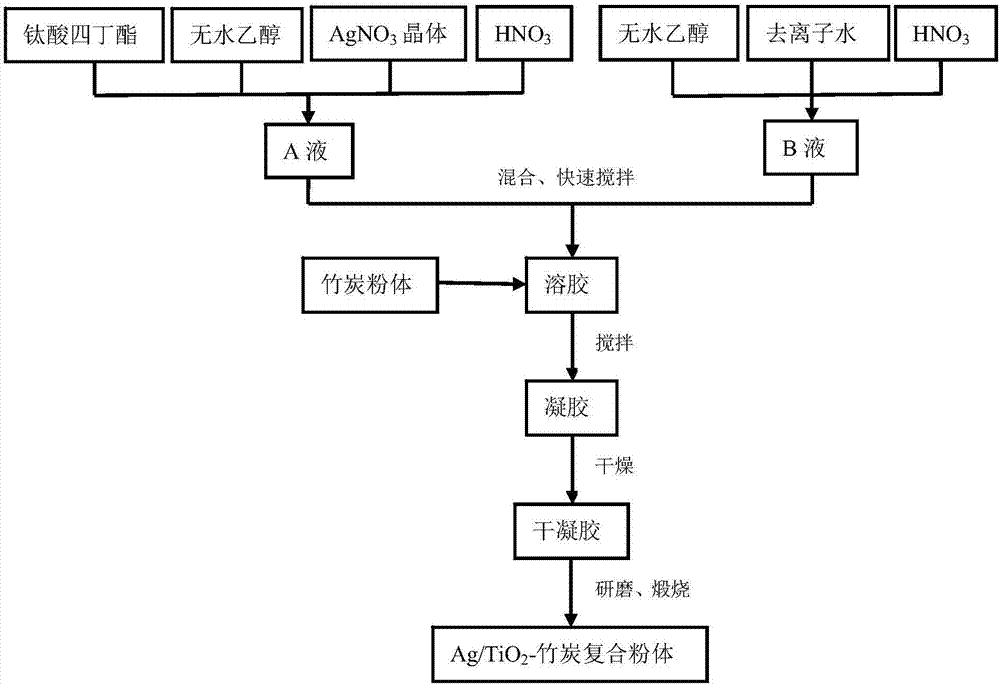

[0029]Take 8ml of tetrabutyl titanate liquid, add 12ml of absolute ethanol and mix evenly, then add 0.12g of silver nitrate crystals, adjust the pH of the mixed solution to 5.0 with nitric acid, stir well to obtain mixed solution A; take another 8ml of absolute ethanol solution , add 18ml of deionized water, adjust the pH of the solution to 2.0 with nitric acid, and stir evenly to obtain the mixed solution B; under vigorous stirring, quickly add the mixed solution B to the mixed solution A, and continue stirring for several hours until a transparent and clear sol, and then add 25g of pretreated bamboo charcoal powder, and then fully stir until the gel is formed; the above gel is placed in the air to dry and a...

Embodiment 2

[0033] Bamboo charcoal pretreatment: select 500-mesh bamboo charcoal, first boil the bamboo charcoal with deionized water for 30 minutes, then wash and filter with deionized water, repeat this 3 times, and dry it in a constant temperature drying oven at 105°C for later use.

[0034] Take 8ml of tetrabutyl titanate liquid, add 12ml of absolute ethanol and mix evenly, then add 0.1g of silver nitrate crystals, adjust the pH of the mixed solution to 4.5 with nitric acid, stir well to obtain mixed solution A; take another 8ml of absolute ethanol solution , add 18ml of deionized water, adjust the pH of the solution to 2.0 with nitric acid, and stir evenly to obtain the mixed solution B; under vigorous stirring, quickly add the mixed solution B to the mixed solution A, and continue stirring for several hours until a transparent and clear sol, then add 40g of pretreated bamboo charcoal powder, and then fully stir until a gel is formed; the above gel is placed in the air to dry and age ...

Embodiment 3

[0038] Bamboo charcoal pretreatment: select 400-mesh bamboo charcoal, first boil the bamboo charcoal with deionized water for 30 minutes, then wash and filter with deionized water, repeat this 3 times, and dry it in a constant temperature drying oven at 105°C before use.

[0039] Take 0.02mol of tetrabutyl titanate liquid, add 0.12mol of absolute ethanol and mix evenly, then add 0.051g of silver nitrate crystals, adjust the pH of the mixed solution to 5.0 with nitric acid, and stir to obtain mixed solution A; Water ethanol solution, add 0.6mol deionized water, adjust the pH of the solution to 2.5 with nitric acid, stir evenly to obtain mixed solution B; under vigorous stirring, quickly add mixed solution B to mixed solution A, and continue stirring for a certain period of time until Form a transparent and clear sol, then add 17.016g of pretreated bamboo charcoal powder, and then fully stir until a gel is formed; place the above gel in the air to dry and age for 1 day, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com