Method for preparing silver nanoparticles with water-soluble starch

A technology of water-soluble starch and silver nanoparticles, which is applied in the direction of nanotechnology, can solve the problems of high price, high equipment requirements, and high silver nano-impurity content, and achieve the effect of convenient operation, simple equipment, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Wash the glass container with aqua regia, and then rinse it with deionized water;

[0025] (2) Take 25ml (0.46mol / L) water-soluble starch aqueous solution into a flask, heat to boiling, and boil for 5 minutes;

[0026] (3) Add 5ml (0.006mol / L) silver nitrate solution into the flask, test the pH value to 6.88, react under boiling conditions for 15 minutes, 20 minutes, 25 minutes, 30 minutes, 35 minutes and then take samples.

[0027] (4) The samples obtained after the above different reaction times were centrifuged at 8000 rpm for 10 minutes, and the obtained precipitate was dried at 40-50°C for 10 minutes to obtain silver nanoparticles.

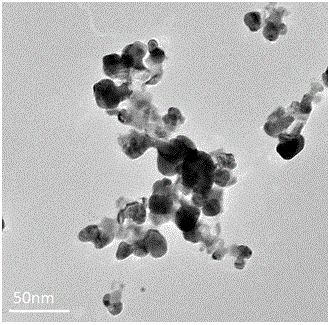

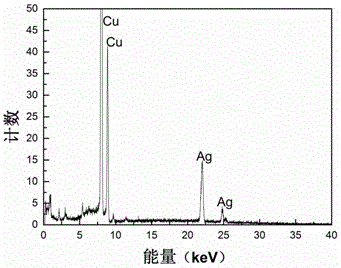

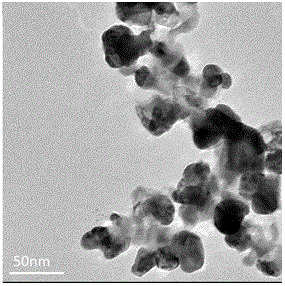

[0028] figure 1 The ultraviolet-visible absorption spectrum (UV-Vis) chart was measured after centrifuging the samples obtained from the above reaction for 15 minutes, 20 minutes, 25 minutes, 30 minutes, and 35 minutes with a UV-2600 ultraviolet spectrophotometer from Shimadzu Corporation of Japan. The absorption peaks produced b...

Embodiment 2

[0032] (1) Wash the glass container with aqua regia, and then rinse it with deionized water;

[0033] (2) Take 25ml (0.58mol / L) water-soluble starch aqueous solution into the flask, heat to boiling, and boil for 15 minutes;

[0034] (3) Add 5ml (0.0075mol / L) silver nitrate solution into the flask, test the pH value to 6.71, react under boiling conditions for 15 minutes, 20 minutes, 25 minutes, 30 minutes, 35 minutes and then take samples.

[0035] (4) The samples obtained after the above different reaction times were centrifuged at 8000 rpm for 10 minutes, and the obtained precipitate was dried at 40-50°C for 10 minutes to obtain silver nanoparticles.

Embodiment 3

[0037] (1) Wash the glass container with aqua regia, and then rinse it with deionized water;

[0038] (2) Take 25ml (0.70mol / L) water-soluble starch aqueous solution into a flask, heat to boiling, and boil for 25 minutes;

[0039] (3) Add 5ml (0.009mol / L) silver nitrate solution into the flask, test the pH value to 6.56, react under boiling conditions for 15 minutes, 20 minutes, 25 minutes, 30 minutes, 35 minutes and then take samples.

[0040] (4) The samples obtained after the above different reaction times were centrifuged at 8000 rpm for 10 minutes, and the obtained precipitate was dried at 40-50°C for 10 minutes to obtain silver nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com