A method for separating silver and copper in silver electrolytic waste liquid

A technology for electrolytic waste liquid and silver-copper, applied in chemical instruments and methods, copper sulfate, silver compounds, etc., can solve the problems of frequent liquid production, low reactivity of silver oxide powder, and high silver content, so as to reduce the frequency of liquid production and The amount of liquid production, the reduction of yellow smoke, and the excellent recovery effect

Active Publication Date: 2022-05-31

JINLONG COPPER +2

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] For example, Liu Facun, Ma Yutian, Zhang Yan, et al. Study on the process of extracting 1# silver from silver electrolysis waste liquid by using swirl electrolysis technology [J]. Precious Metals, 2013 (s1). It is recorded in an article that using swirl electrolysis technology can Effectively recover silver with higher purity from silver electrolysis waste liquid, and the recovery efficiency of silver is better, but the efficiency of this technical scheme is low, and swirling flow electrolysis is difficult to apply to industrial production; another example is the new process of comprehensive recycling of silver electrolysis waste liquid [J]. World Nonferrous Metals, 2013 (11). This scheme uses sodium hydroxide to precipitate metal ions in electrolytic waste liquid to obtain silver oxide, and returns to neutralize electrolytic waste liquid to hydrolyze and precipitate impurity ions

This scheme can theoretically remove lead, antimony, bismuth, copper and other elements, but the hydrolysis acidity of copper and silver is close, and the reactivity of silver oxide powder is low, so the high silver content in the precipitate requires further silver recovery

[0005] Another example is Chinese patent "silver electrolytic waste liquid treatment method" (authorization publication number is CN102010036B), Chinese patent "a kind of method for reclaiming silver from silver-containing aqueous solution" (application publication number is CN108374095A) and other patent documents, most of which are The recovery of silver is achieved through special electrolysis and electrodeposition, but in fact the recovery efficiency is low, and it does not solve the problem of frequent liquid production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

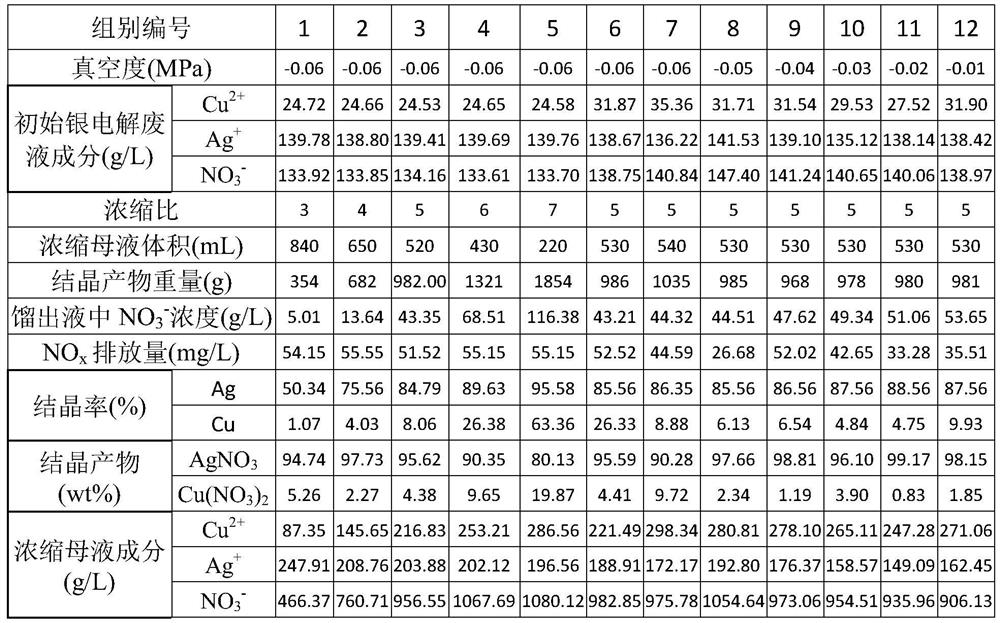

[0030]

[0035]

[0036]

[0037] As can be clearly seen from Table 2, after adding the copper powder, substantially all silver ions can be removed, and only copper ions are left. But when copper

[0041]

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

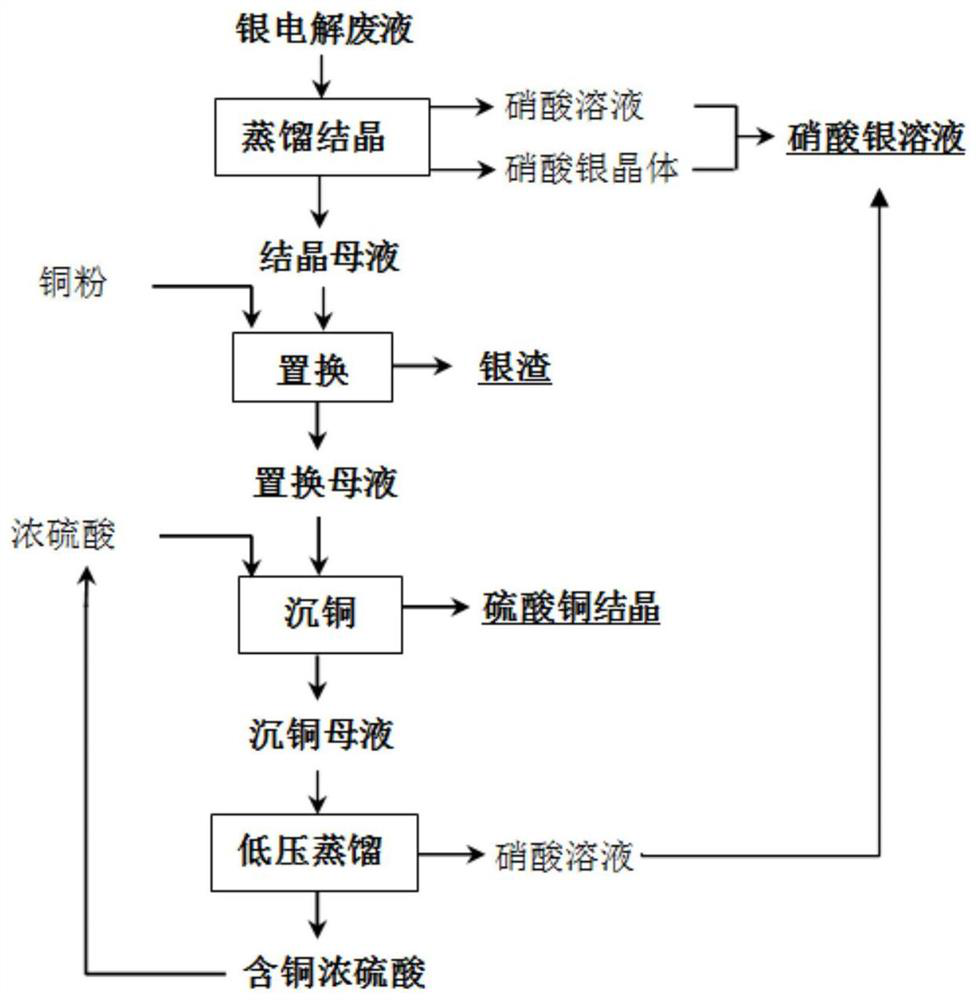

The invention belongs to the field of metal smelting, and specifically relates to a method for separating silver and copper in silver electrolysis waste liquid. First, the silver electrolysis waste liquid is concentrated and crystallized, filtered, and then copper powder is added to the obtained filtrate for replacement, and the filtrate obtained after filtering again is It is the waste liquid after silver recovery. Using the above scheme, first concentrate the silver electrolysis waste liquid, because the solubility of silver nitrate is relatively small, and because of the high ion content in the waste liquid, silver nitrate crystallizes out after concentration, and silver nitrate crystals are obtained by filtration; then use silver and copper According to the difference in the activity of the two metals, copper powder is used to replace the silver slag, thereby realizing the recovery of silver, that is, the separation of silver and copper. The scheme of the present invention is simple and efficient, and the silver recovery rate can be as high as over 99%.

Description

A kind of method for separating silver and copper in silver electrolysis waste liquid technical field The invention belongs to the metal smelting field, be specifically related to a kind of method of silver-copper separation in silver electrolysis waste liquid. Background technique [0002] The anode crude silver obtained by pyro-smelting is generally purified by electrolytic refining. Mass fraction of silver in anode silver Generally above 97%, the type and content of impurity elements vary with different smelting raw materials and processes. in electrolysis During the refining process, the impurity elements such as copper, lead, bismuth, and antimony in the anode silver are dissolved in the anode and enter the electrolyte. The position is negative than that of silver, so it is easy to be enriched in the electrolyte. When the concentration of impurity ions is high, not only the current efficiency of cathode silver deposition is Significant decline, and the quality o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G5/00C01G3/10

CPCC01G5/00C01G3/10Y02P10/20

Inventor 文燕郑国渠黄辉荣李春侠曹华珍王海荣甘秀江张惠斌崔平汪永红

Owner JINLONG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com