Method and device for purifying silver nitrate through layered overall crystallization

A technology of silver nitrate and crystallization, applied in the field of saturated crystallization purification of silver nitrate solution, can solve the problems of limited application scope, difficult to use melt crystallization, difficult to apply, etc., and achieve the effects of improving product purity, high crystallization efficiency, and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation of the raw material of silver nitrate solution, the raw material is obtained by reacting national standard 2# silver ingot with analytical pure 63% nitric acid, and 87% wt silver nitrate solution is obtained after vacuum evaporation, and the temperature is 98°C.

[0041] The purity testing of silver nitrate raw materials and products uses the testing method in "GB / T 670-2007 Chemical Reagent Silver Nitrate", and the testing results are shown in Table 1.

Embodiment 1

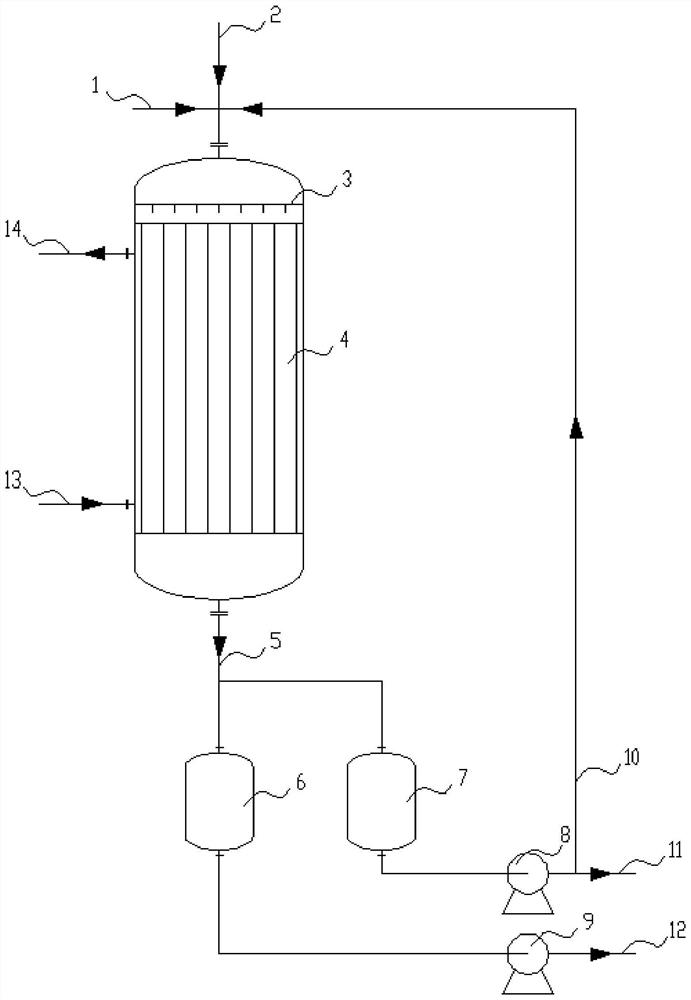

[0043] use as figure 1 The device shown, first, liquid phase feeding: 830kg of silver nitrate raw material solution was added to a 1.2m3 falling film crystallizer (heat exchange crystallizer 4) through feed line 1; Distributor 3 distributes film inside the crystallizer tube; material enters 1m3 mother liquor storage tank 7 through discharge line 5; material circulation pump 8 circulates material through circulation line 10;

[0044] Then, cooling and crystallization: start the cooling cycle in the 4-shell side of the heat exchange crystallizer, the ethylene glycol solution is cooled at a cooling rate of 0.5°C / min, cooled from 95°C to 0°C, and the ethylene glycol solution is kept at a constant temperature of 0°C for 1 hour. The temperature is controlled by a programmed thermostat. The material circulation pump 8 was stopped, and after standing for 1 hour, the mother liquor adsorbed on the crystal surface in the tube pass of the heat exchange crystallizer 4 was drained and ent...

Embodiment 2

[0051] The high-purity silver nitrate prepared in Example 1 utilizes the method and device to re-crystallize again, and the results of the purity of the product obtained are shown in Table 1. The comparison between Example 2 and Example 1 found that the purity of silver nitrate was further improved. YS / T476-2005 "Silver Nitrate for Photographic Use" standard test, which can reach the second grade of silver nitrate for photographic use with higher purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com