Patents

Literature

323 results about "Crystallization Purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation of a product from a saturated solution by cooling the liquid or adding precipitants which lower the solubility of the desired product so that it forms crystals.

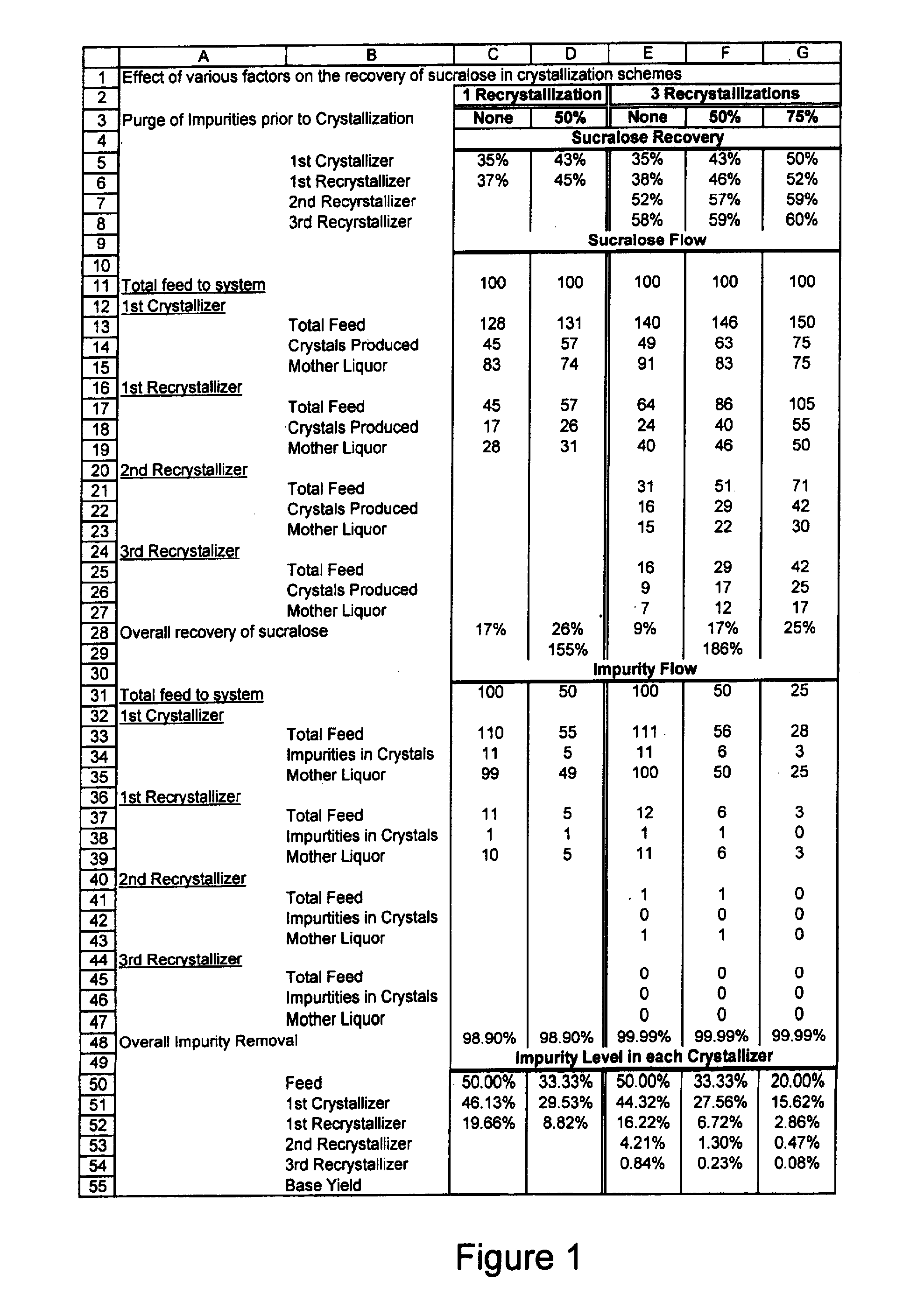

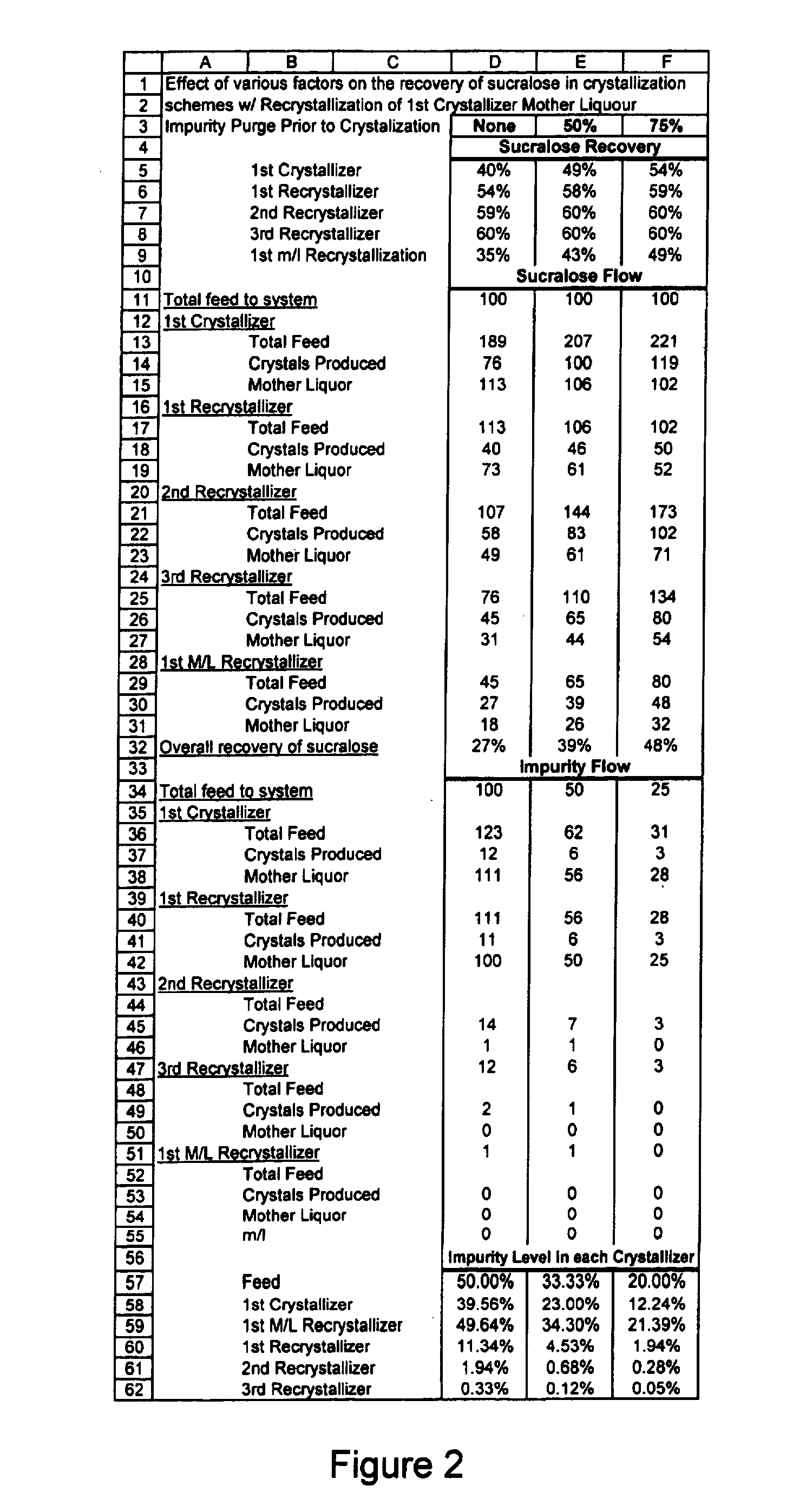

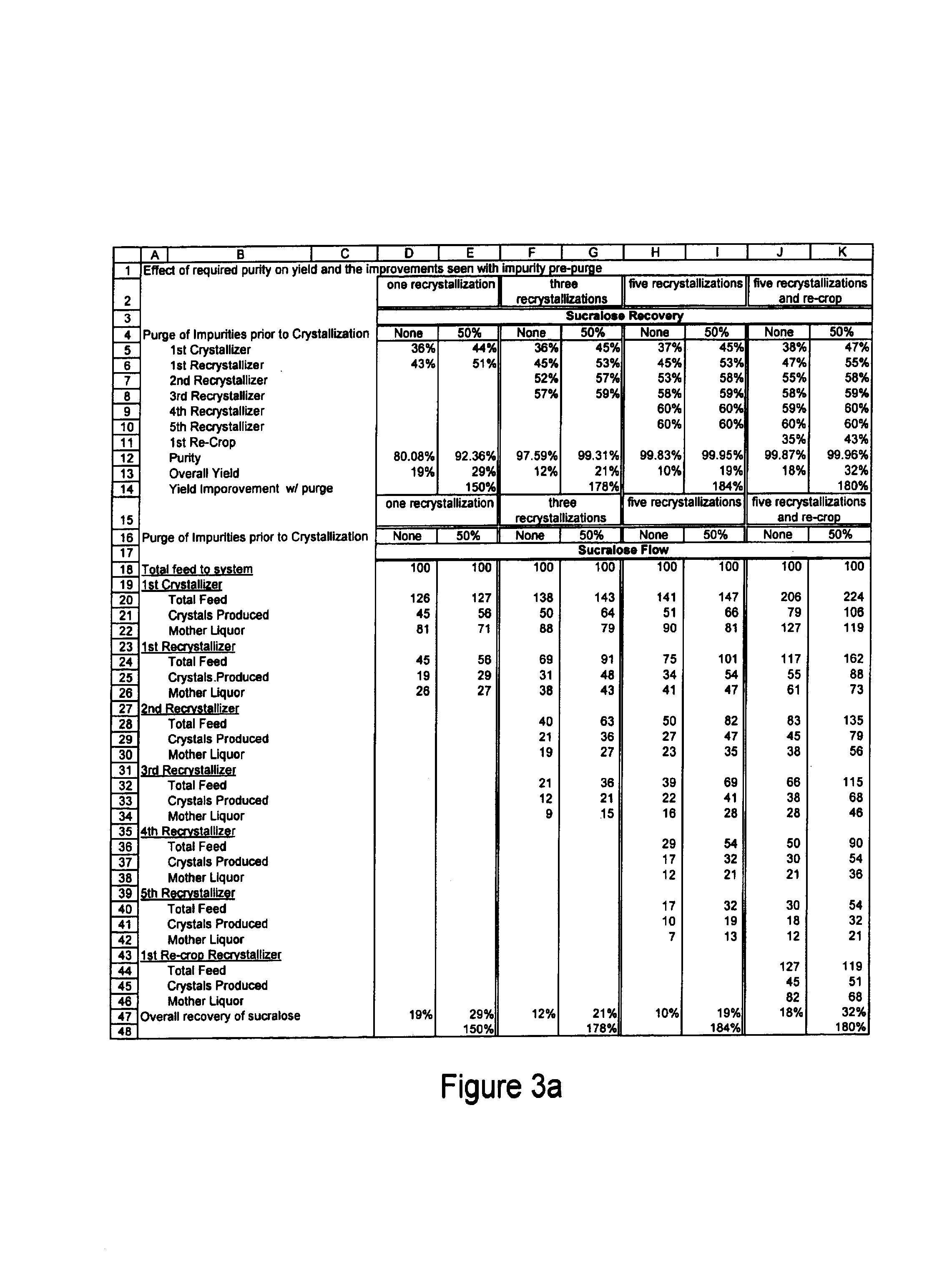

Process for improving sucralose purity and yield

InactiveUS6998480B2Improve efficiencyHigh purityEsterified saccharide compoundsSugar derivativesSucraloseCrystallization Purification

This invention relates to processes for purifying sucralose by the use of an initial non-crystallization purification procedure followed by three or more sequential crystallization steps and recycle of the mother liquor remaining from each crystallization step to the feed of another crystallization or purification step. This invention also relates to sucralose compositions as well as compositions comprising the sucralose compositions of the present invention. These compositions may be highly pure and have a superior taste profile.

Owner:TATE & LYLE TECH LTD

Melt crystallization purification of lactides

Melt crystallization purification of lactide; and separation and purification of lactides existing in more than one isomeric form.

Owner:NATUREWORKS LLC

Preparation method of difluorosulfimide salt

The invention discloses a preparation method of difluorosulfimide salt. The preparation method comprises the following steps: (1) adding dichlorosulfimide and a nitrogen-containing hydrogen fluoride complex which are used as reaction raw materials into an organic solvent for reaction at 0-100 DEG C, and after reaction, distilling to remove the organic solvent to obtain a difluorosulfimide and nitrogen-containing ion compound; (2) adding the ion compound obtained in the step (1) into a water solution of metal alkali or salt, neutralizing until the solution is neutral, distilling, drying, re-crystallizing by using the organic solvent, and purifying to obtain difluorosulfimide salt. According to the preparation method, the nitrogen-containing hydrogen fluoride complex is adopted as a fluorating agent, so that the whole reaction is carried out in a homogeneous system, the fluorating reaction is relatively safe, the efficiency is relatively high, and the product yield is more than 98%; a process route is simple, the yield is high, and the production cost is relatively low.

Owner:ZHANGJIAGANG HICOMER CHEM CO LTD

Method for extracting xylose from viscoce chemical fiber squeezed alkali liquor

InactiveCN104099431ASave resourcesReduce pollutionArtificial filament recoveryTextile/flexible product manufactureFiberHydrolysate

The invention relates to a method for extracting xylose from viscoce chemical fiber squeezed alkali liquor. According to the technical scheme, the method comprises the following steps: pre-filtering to obtain pre-concentrated liquor; filtering the pre-concentrated liquor through a nanofiltration membrane to obtain concentrated liquor; adding hydrochloric acid to the concentrated liquor to obtain hydrolysate; adding hydrolysate to NaOH until being neutral; decolorizing; regulating the concentration of NaCl; cooling at constant speed until reaching room temperature; enabling glucose in hydrolysate to cocrystallize with NaCl to remove glucose; treating filtrate through ion exchange columns to obtain purified liquor; crystallizing and purifying the purified liquor for the second time to obtain coarse xylose; refining the coarse xylose to obtain final xylose. With the adoption of the method, the resource is saved, the economic benefit is brought to enterprises, and the environment is protected.

Owner:沈阳新华环保技术有限公司

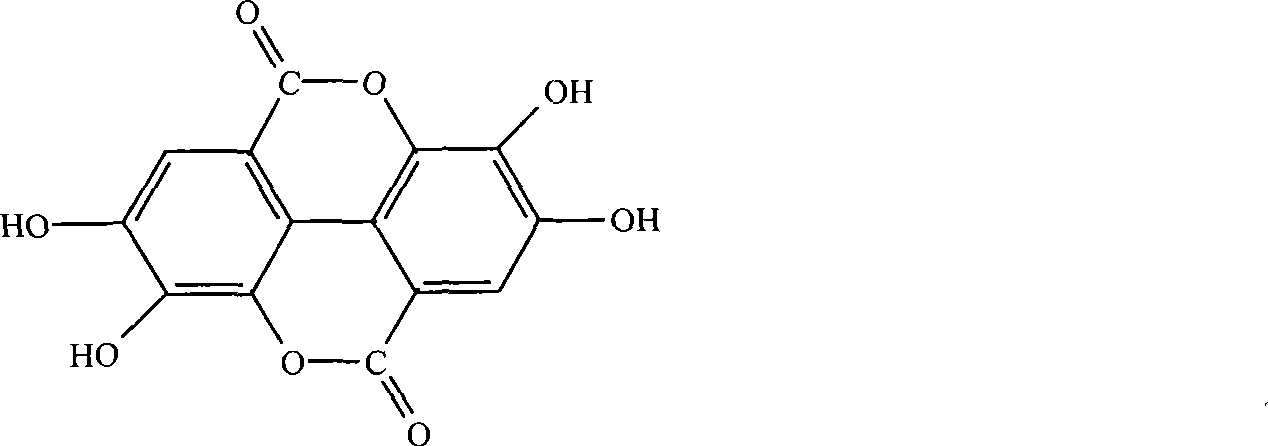

Method for preparing ellagic acid from pomegranate bark by enzyme process

The invention relates to a method of using pomegranate rind as raw material to prepare ellagic acid by enzymatic method, belonging to the food, medical and chemical fields. The method uses the pomegranate rinds which are numerously discarded by people in China as raw materials to extract ellagitannin. The characteristics of high catalysis efficiency, strong selectivity, moderate processing conditions, and the like of enzyme are used to obtain tannase containing degraded ellagitannin through fermentation. The enzymatic reaction between the tannase and the ellagitannin happens to generate the ellagic acid. After the solvent crystallization purification, the medical ellagic acid with dear price and high purity is obtained. The method can lower the cost of the raw material, reuse wastes, improve the yield and the purity of the ellagic acid and can be applied to the large scale production.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing manganese sulfate by high-temperature crystallization process

InactiveCN101224908AReduce manufacturing costImprove product qualityManganese sulfatesManganese sulphateManganese(II) carbonate

The invention provides a method for producing high-purity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressure-filtered to obtain a manganese sulfate solution with the content of 160-200g / L, which is pumped to a manganese sulfate solution for carrying out crystallization and purification; the crystallization and purification includes crystallization, solid-liquid separation, dissolution, pressure filtration and other technologies; the pressure-filtered manganese sulfate solution can be crystallized and purified repeatedly as required. The invention can adopt a large amount of low-grade manganese ore with the manganese content of 10-20 percent as the raw material to produce the high-purity manganese sulfate solution and further deep process various high-purity manganese products, such as: electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade mangano-manganic oxide and manganese monoxide, chemical manganese dioxide, industrial grade manganese sulfate monohydrate, chemical grade manganese sulfate monohydrate, medicine grade manganese sulfate monohydrate, food grade manganese sulfate monohydrate, analytically pure manganese sulfate monohydrate and so on.

Owner:广西双德锰业有限公司

Method of purifying moxidectin through crystallization

Methods for the purification of the macrolide moxidectin result in higher purity levels than can often otherwise be obtained. The crystalline moxidectin is then used in a wide variety of pharmaceutical and veterinary applications, including the prevention, treatment and control of parasites in plants, animals and humans.

Owner:ZOETIS W LLC

Bulleyaconitine A preparation method

InactiveCN106008344AReduce manufacturing costImprove production efficiencyOrganic chemistrySilica gelNatural medicine

The invention relates to the natural medicine preparation field, and in particular, relates to a bulleyaconitine A preparation method; the preparation method comprises four steps: extraction, extraction separation, column chromatography separation purification, and crystallization purification. According to the bulleyaconitine A preparation method provided by the invention, alumina column chromatography is used for replacing silica gel column chromatography, so that the production cost is saved; a petroleum ether-diethylamine binary system is used as an eluent and is easy to recycle and reuse, so as to reduce environmental pollution.

Owner:YUNNAN UNIV OF TRADITIONAL CHINESE MEDICINE

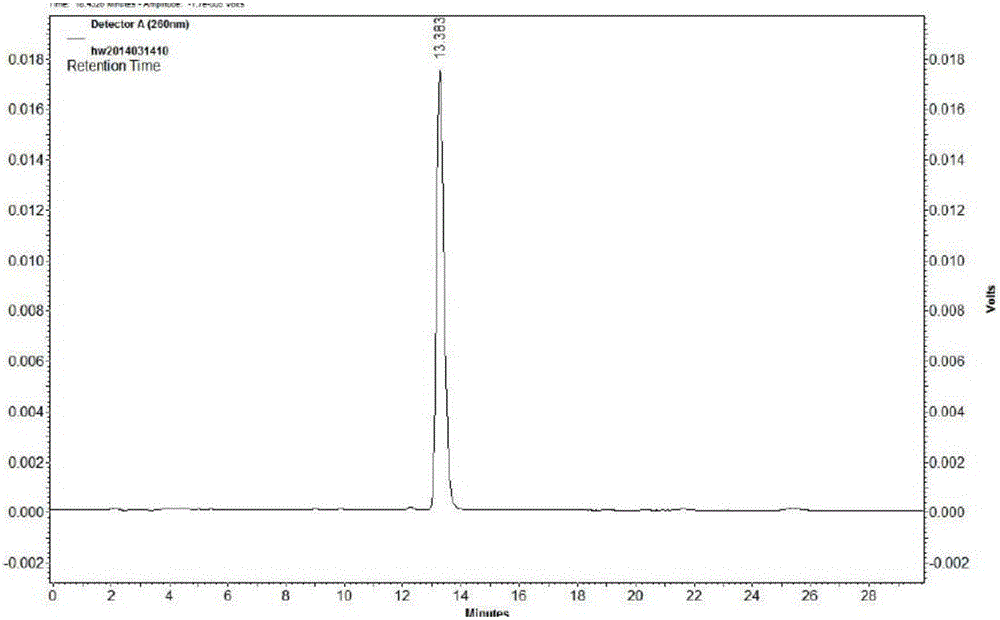

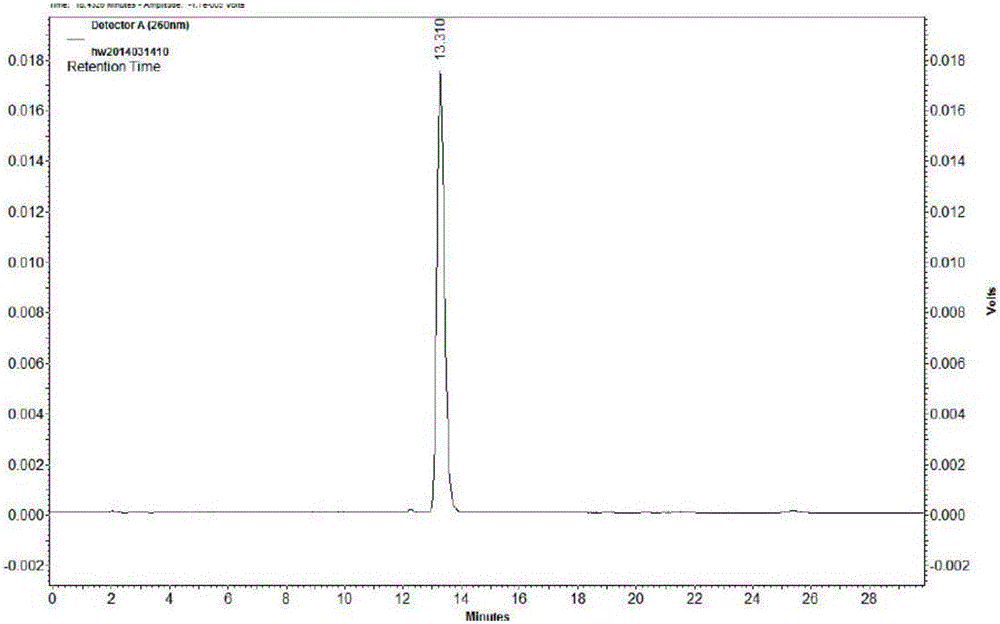

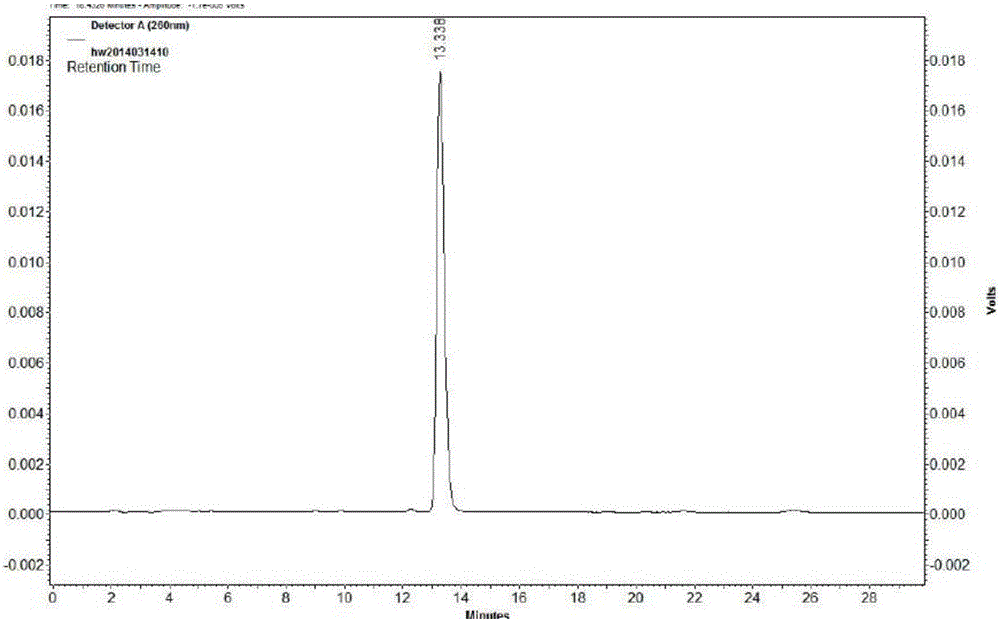

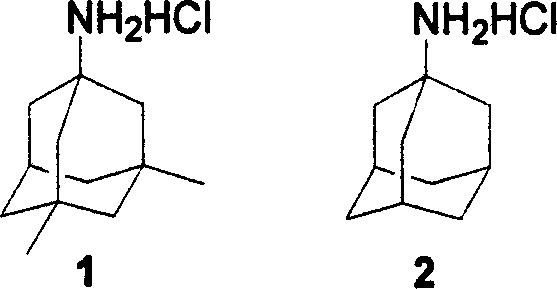

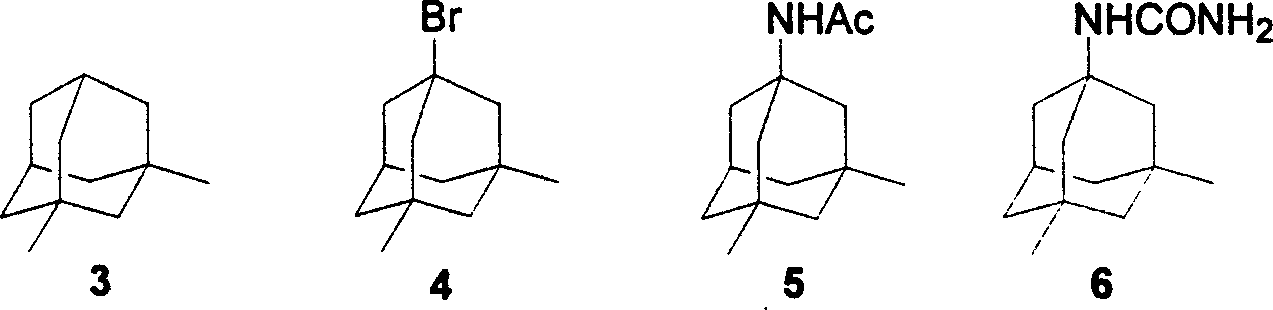

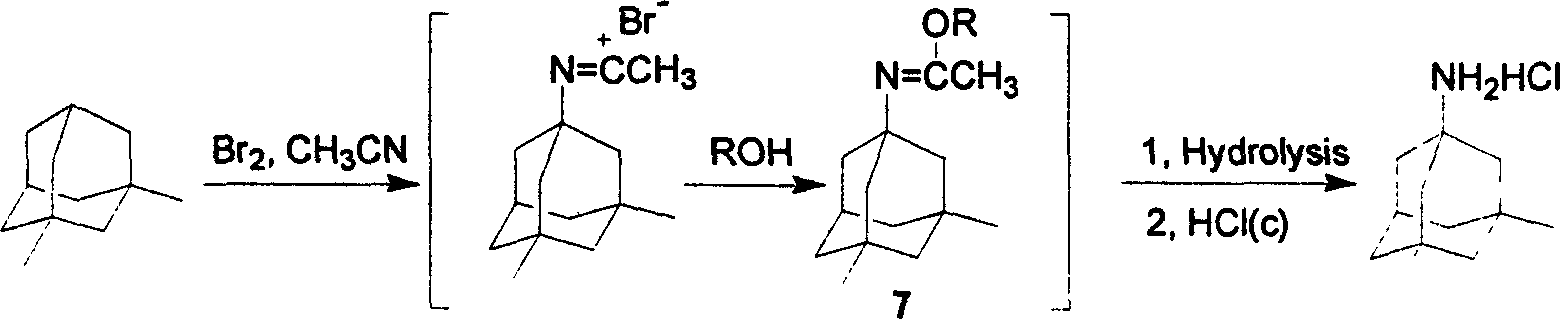

Method of synthesizing amantadine hydrochloride

InactiveCN1556094ASmall side effectsMild reaction conditionsOrganic compound preparationAmino compound preparationAlcoholBoiling point

A process for synthesizing adamantanamine hydrochloride from 1,3-dimethyl adamantane include browo reaction while Ritter reaction, adding the resultant mixture in the mixture of polar proton solvent and alcohol solvent, stirring while alcoholyzing, regulating pH, alkaline hydrolyzing to generate adamantanamine, extracting in arylhydrocarbon solvent, water washing, drying, filtering, vacuum concentrating of filtrate, reacting on concentrated hydrochloric acid to obtain coarse product, and recrystallizing in the mixed solvent of alcohol and arylhydrocarbon.

Owner:NANJING UNIV

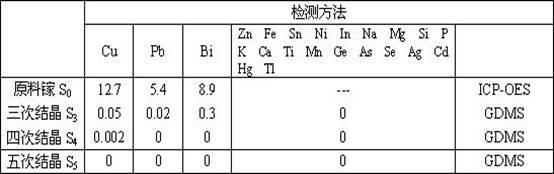

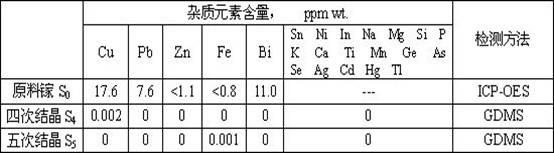

Large-scale production method for preparing high purity gallium

ActiveCN102618734AEnsure consistencyImprove the purification effectProcess efficiency improvementLiquid metalProcess conditions

The invention discloses a large-scale production method for preparing high purity gallium, which adopts a partial crystallization purification technique to implement the operation, and comprises the following steps of: placing a seed crystal of metal gallium into the bottom part of a crystallization vessel; filling liquid metal gallium into the crystallization vessel; cooling the bottom part of the crystallization vessel, and setting the technical conditions of the fractional crystallization that a temperature gradient is 1.1 to 1.4 DEG C / cm and the temperature is kept uniform in the horizontal direction; and maintaining an average crystallization speed of 3.3 to 4.2g / min and a crystallization interception ratio of 75 to 90 percent. Compared with the prior art, the method has good purification effect, high conversion efficiency, low consumption of electric power and no application of chemical agent and can realize the mass production.

Owner:朝阳金美镓业有限公司

Method for extracting flavone from folium ginkgo

The invention discloses a method for extracting flavone from folium ginkgo and relates to the technical field of an extraction technology. The method provided by the invention comprises the following steps: dry folium ginkgo is crushed, a folium ginkgo powder is immersed in warm water of 40-60 DEG C for extraction, solid-to-liquid ratio during extraction is 1:10 (V / W), extraction time is 3 hours, extraction is carried out for three times, filtration is carried out after extraction, and filtrates are merged; and dissolution is carried out by the use of 5 times volume of water of 40-50 DEG C after an extract liquid is concentrated and dried, extraction is carried out for three times by the use of an anhydrous ethyl acetate solvent, multiple crystallization treatments are carried out continuously by the use of anhydrous ethyl acetate, solid-to-liquid ratio during the crystallization process is 1:5, and a crude crystallized product undergoes one time of supercritical CO2 extraction and drying process so as to obtain ginkgo flavone with purity of over 98%. The technology of the invention is simple. Extraction separation and crystallization purification are directly carried out without complex, time-consuming and energy-consumption technologies such as column chromatography and the like. By supercritical CO2 extraction, purity of ginkgo flavone exceeds 98%.

Owner:GUANGXI LAIJI BIOENG

Synthesis method of neotame

The invention relates to a synthesis method of neotame. The method comprises the following steps: (1) adding aspartame and 3,3-dimethyl-butyl aldehyde to an organic solvent in a vacuum state, reacting at the reaction temperature of 20-50 DEG C for 5-24 hours, carrying out concentration and separation at 0-50 DEG C after reaction is ended, concentrating to obtain white paste, adding deionized water to devitrify, thus obtaining a neotame intermediate imine in a centrifuging manner; (2) adding imine and an organic solvent to a hydrogenation reactor, introducing hydrogen until the pressure is 0.1-0.5MPa, adding a catalyst, reacting at the temperature of 35-40 DEG C for 5-30 hours, filtering and removing the catalyst, concentrating the filtrate and removing an organic solvent, and recrystallizing and purifying by water, methanol or ethanol, so as to obtain the neotame. According to the synthesis method, the defects in the prior art are overcome, high-purity imine is generated, the activity of the catalyst is reduced, the selectivity of the catalyst on the imine is increased, the service life of the catalyst is prolonged, the reaction impurity is reduced, and the product purity is improved.

Owner:SHANDONG BENYUE BIOTECH

Method for purifying epsilon-caprolactam and method for preparing epsilon-caprolactam

ActiveCN102452982AFully removedNo foulingLactams preparationLactams separation/purificationBeckmann rearrangementMolecular sieve

The invention provides a method for purifying a crude epsilon-caprolactam product, which comprises the following steps of: dissolving the crude epsilon-caprolactam product in halogenated hydrocarbon to obtain a halogenated hydrocarbon solution of epsilon-caprolactam; and performing evaporative crystallization on the solution at the temperature of between -10 and 50 DEG C under reduced pressure to separate an epsilon-caprolactam crystal. The invention also provides a method for preparing the epsilon-caprolactam, which comprises the following steps of: performing Beckmann rearrangement reaction on gas-phase cyclohexanone-oxime in the presence of a molecular sieve catalyst with a melt flow index (MFI) structure, and distilling a reaction product to obtain the crude epsilon-caprolactam product; and performing crystallization purification by the method for purifying the crude epsilon-caprolactam product, and performing hydrogenation reaction on the epsilon-caprolactam crystal obtained after purification in the presence of a hydrogenation catalyst. By the method for purifying the crude epsilon-caprolactam product, the epsilon-caprolactam which meets the industrial product requirement can be obtained, and the phenomenon of scale formation in the crystallization process is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

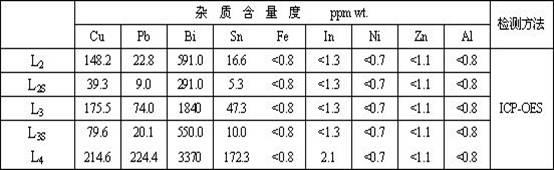

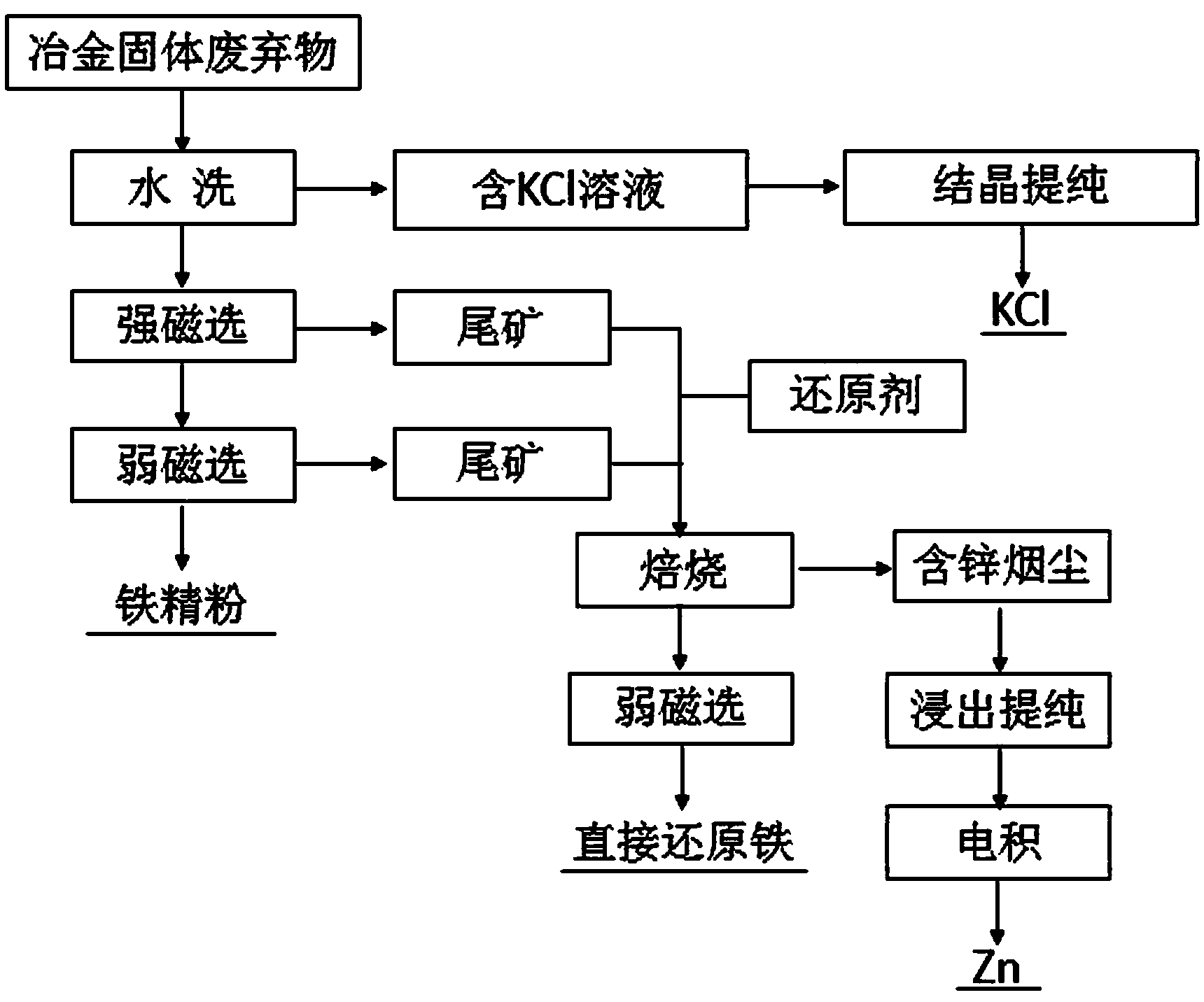

Comprehensive recovery method of ferrous metallurgical solid wastes

The invention relates to a comprehensive recovery method of ferrous metallurgical solid wastes. The method adopts the technical scheme that the following steps are included: firstly, the ferrous metallurgical solid wastes are washed with water to immerse KCI in the leaching solution; KCI is extracted through crystallization and purification; high-intensity magnetic separation and low-intensity magnetic separation are performed on the washing residue to obtain powered iron; the mixture of mineral tailings of magnetic separation and a reducing agent are roasted, so that zinc in the solid wastes is reduced and volatilized, and the reduced and volatilized zinc enters into fume; metallic zinc is obtained through leaching, refinement, electro-deposition of the fume containing zinc; the direct reduced iron is obtained through the low-intensity magnetic separation of the roasting residue. With the adoption of the comprehensive recovery method of the ferrous metallurgical solid wastes, elements such as Fe, C and the like in the solid wastes can be effectively recycled and reutilized, and non-ferrous metals like K and Zn in the solid wastes can be extracted, so that the comprehensive utilization of the metallurgical solid wastes is facilitated.

Owner:XINGTAI POLYTECHNIC COLLEGE

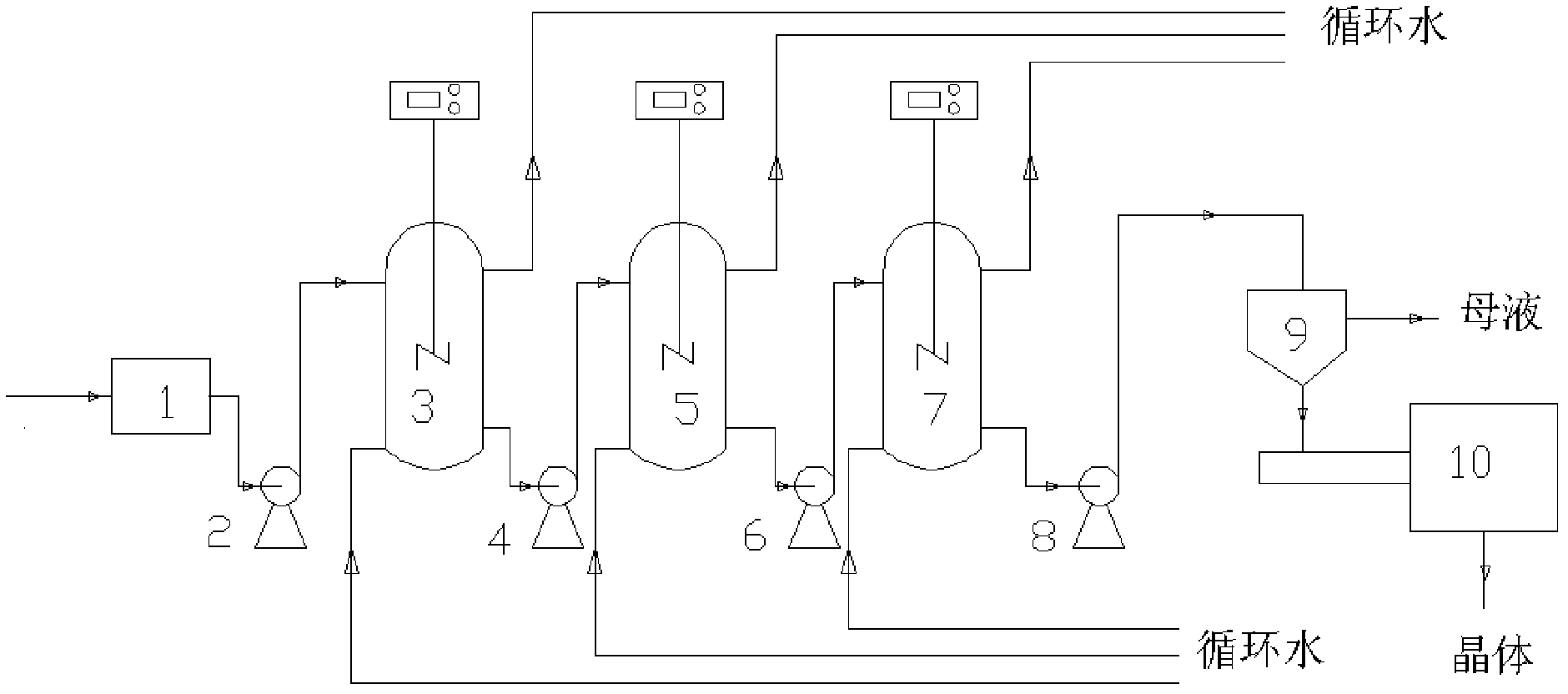

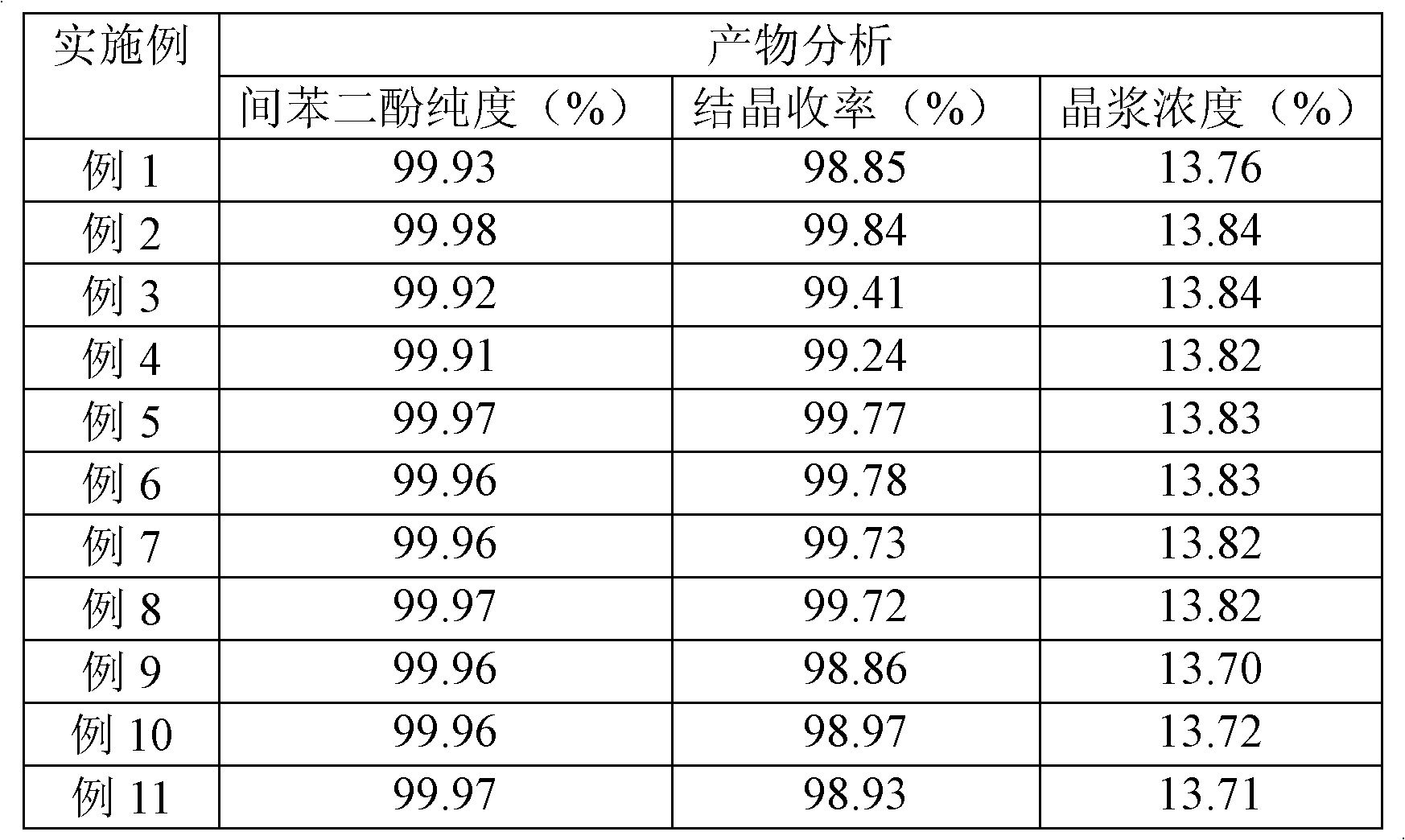

Method for purifying resorcinol by means of continuous crystallization

InactiveCN102643169AEffective growth rate controlGuaranteed stabilityOrganic chemistryOrganic compound preparationMagmaToluene

A method for purifying resorcinol by means of continuous crystallization belongs to the technical field of separation and purification of resorcinol, and includes: dissolving the resorcinol into methylbenzene in weight ratio of (6.0-6.1):1, and enabling solution to enter a primary crystallizer to crystallize with the temperature and stirring speed of the primary crystallizer constant; enabling magma to enter a secondary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop; enabling magma to enter a tertiary crystallizer, and crystallizing at a certain crystallizing temperature, at a certain stirring speed and by means of equal stop, wherein the temperature of the primary crystallizer, the temperature of the secondary crystallizer and the temperature of the tertiary crystallizer are sequentially decreased; and subjecting the magma to solid-liquid separation, and then scrubbing and drying obtained crystals by the methylbenzene. The method realizes continuous operation of crystallization and purification, operating cost is reduced, production capacity is improved, and stability of operating parameters is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH

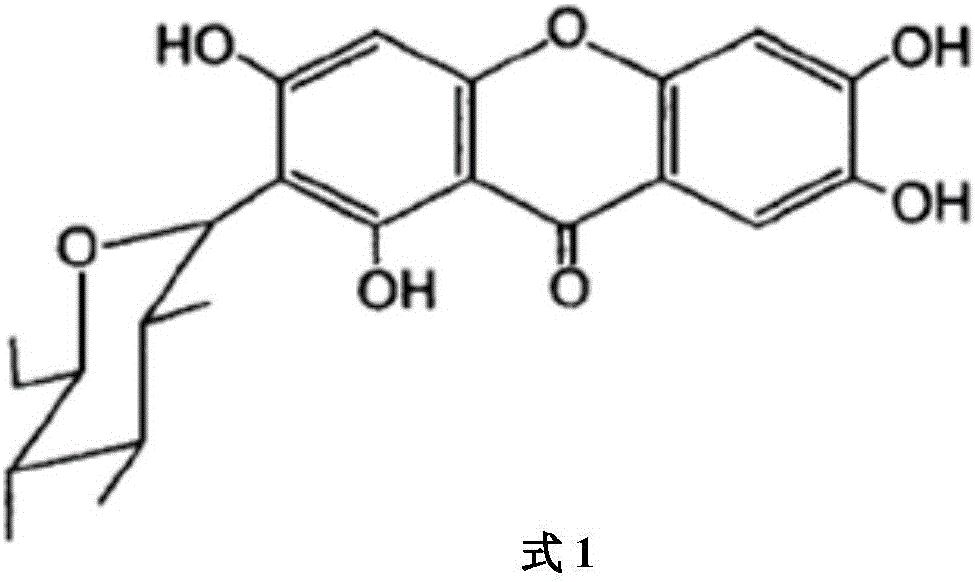

Method for extracting and separating mangiferin from mango leaves

The invention belongs to the field of plant extraction, and specifically relates to a method for extracting and separating mangiferin from mango leaves. The technical problem to be solved by the invention is to provide a brand-new method for extracting and separating the mangiferin from the mango leaves. The method is simple and easy to operate, and the mangiferin with relatively high purity can be obtained. The extraction method disclosed by the invention comprises the following steps: A, raw material preparation; B, ester extraction and impurity removal; C, methyl alcohol extraction; D, concentration washing, so that a mangiferin crude product with the purity of 60% to 70% can be obtained; the extraction method further comprises the step E of crystallization purification, so that a mangiferin pure product with the purity of 90% to 98% can be obtained. According to the extraction method disclosed by the invention, the relatively high mangiferin can be obtained just by using several simple extraction and separation means, so that the operation is simple and convenient, and the cost is greatly reduced. According to the extraction method disclosed by the invention, the mangiferin crude product with the purity of 60% to 70% and the mangiferin pure product with the purity of 90% to 98% can be obtained respectively, the yield of the mangiferin crude product is greater than or equal to 83%, and the yield of the pure product is greater than or equal to 65%.

Owner:PANZHIHUA UNIV +1

Crystallizing and purifying Method for preparing puerarin in high purification

InactiveCN1563029AConstant temperature controlHigh puritySugar derivativesSugar derivatives preparationFreeze-dryingPuerarin

This invention relates crystallization purification method for producing super pure microestrol by using miroestrol extractum as raw material, being dissolved insolvent. said supersaturated solution is placed constant or varying magnetic field with magnetic flux of 0.1-10 tesla, after each crystallization, the purity is higher than 95%; and after 2-5 crystallization, the purity of the product is over 99.7%. This invention crystallization method is sipmle, no need of refrigeration drying or spray-drying method which are energy-consumption process. This invention method has advantages of: commercialization prodn., and super high purity product of standard product of miroestrol.

Owner:HEFEI UNIV OF TECH

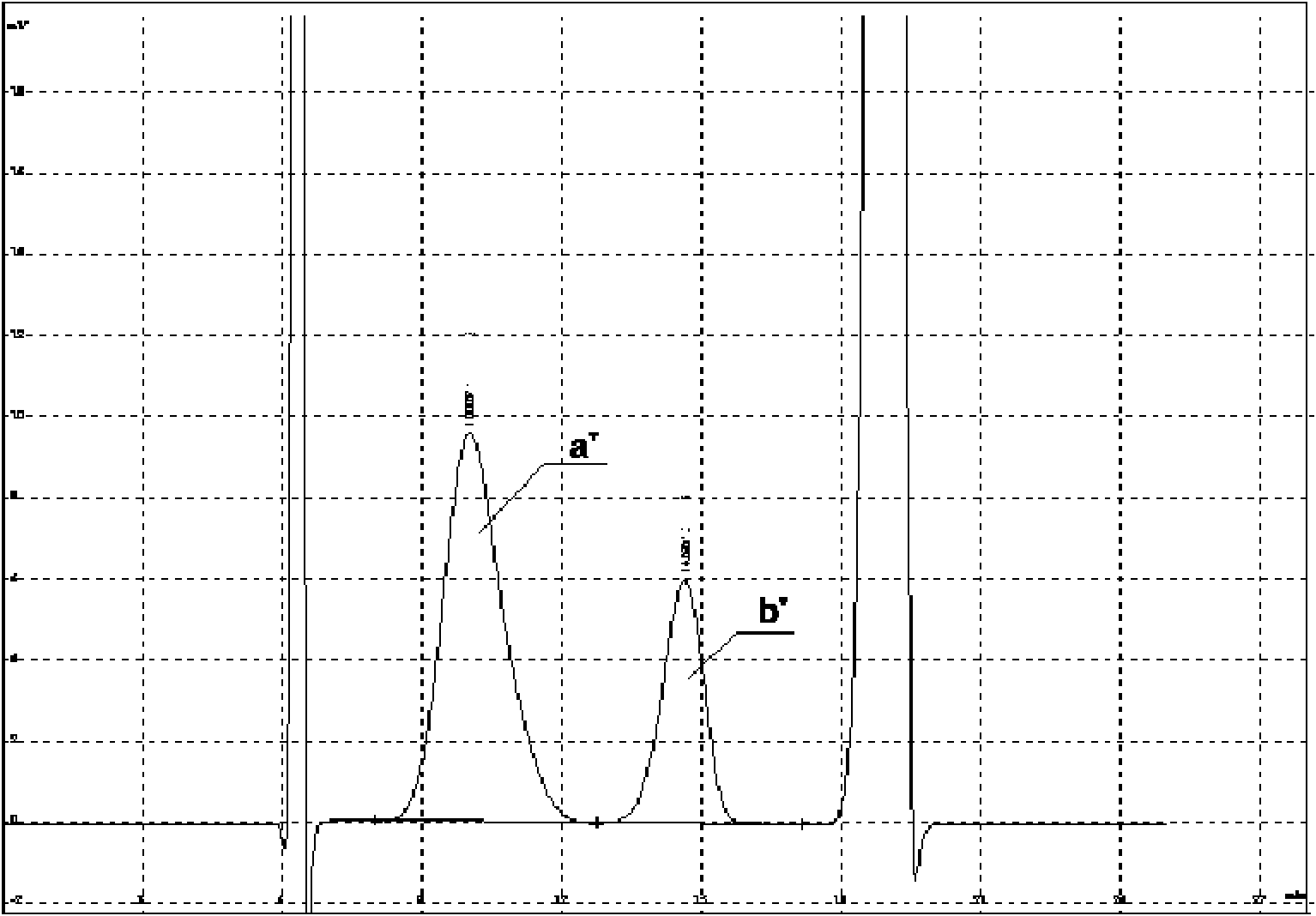

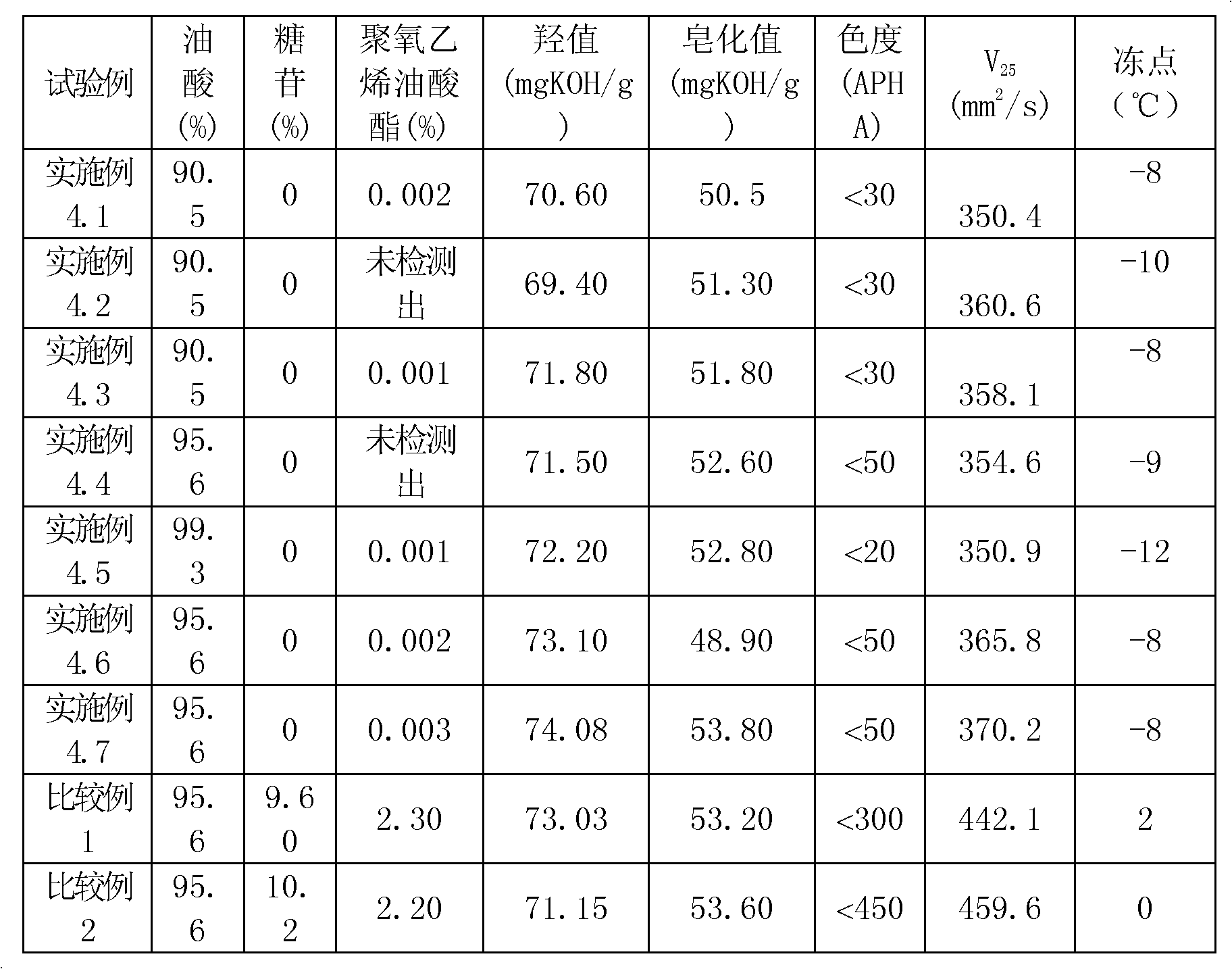

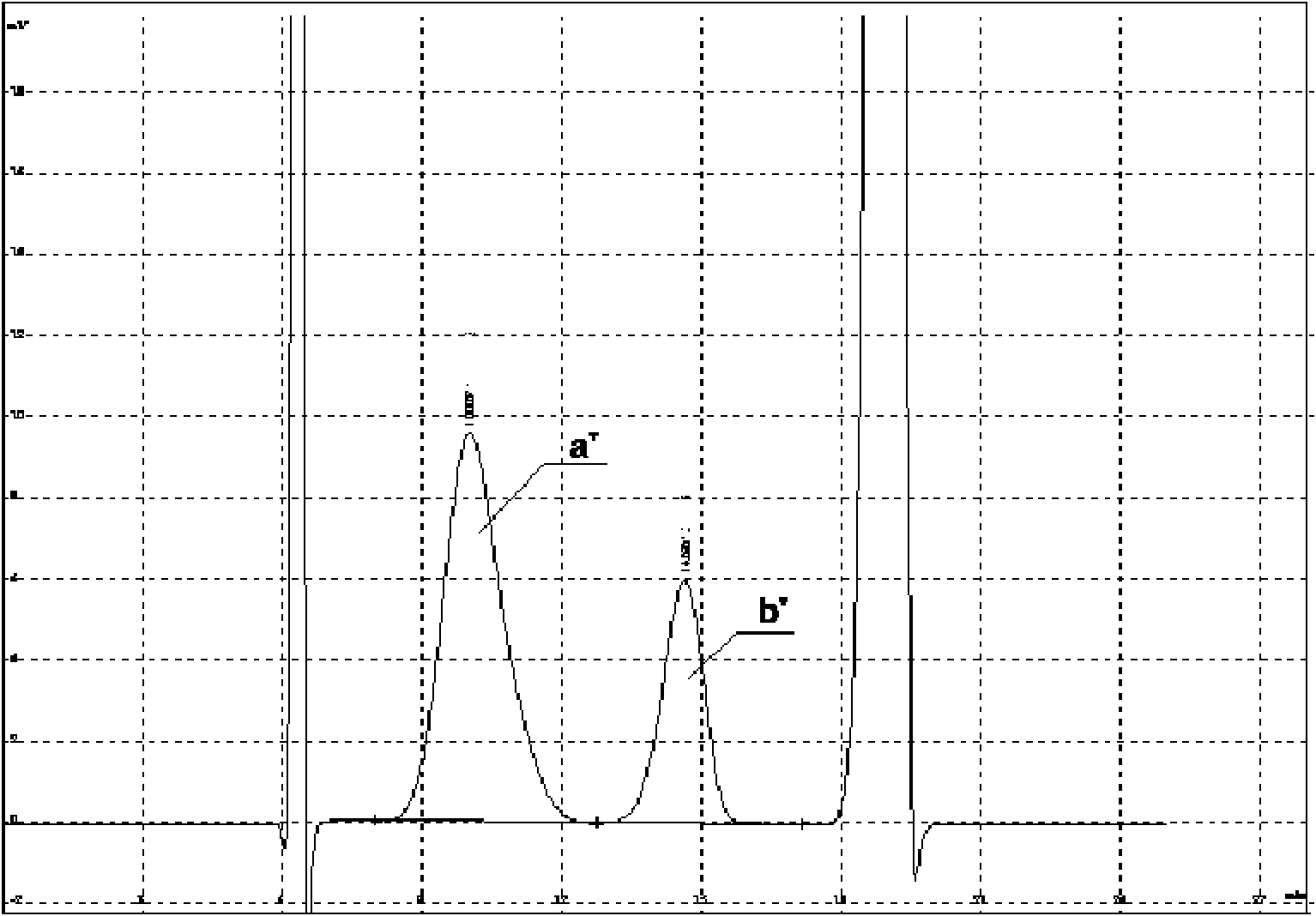

Method for synthesizing polysorbate-80 for injection

ActiveCN101983977AHigh purityEfficient removalPharmaceutical non-active ingredientsDistillationEthylene oxide

The invention provides a method for synthesizing polysorbate-80 for injection, comprising the following steps: (1) taking sorbierite as a raw material, partially dehydrating the sorbierite under the conditions of an acid catalyst and a vacuum state, and carrying out crystallization and purification for three times on the dehydrated sorbierite to obtain primary high-purity dehydrated sorbierite II; (2) further dehydrating the high-purity primary dehydrated sorbierite II and then carrying out reduced pressure distillation and purification to obtain secondary high-purity dehydrated sorbierite III; (3) mixing the high-purity primary dehydrated sorbierite II with the high-purity secondary dehydrated sorbierite III in proportion to obtain high-purity dehydrated sorbierite IV; carrying out addition polymerization on the high-purity dehydrated sorbierite IV under the condition of a basic catalyst and ethylene oxide to obtain dehydrated sorbierite polyoxyethylene ether V; and (4) reacting the dehydrated sorbierite polyoxyethylene ether V with high-purity oleic acid under the action of an esterification catalyst and then refining the reactant of the dehydrated sorbierite polyoxyethylene ether V and the high-purity oleic acid to obtain the polysorbate-80 for injection. The liquid chromatogram (LC) of the polysorbate-80 for injection has two principal product peaks without other impurity peaks; and compared with the conventional craft products, the polysorbate-80 for injection is higher in purity, more stable in the technology, is controllable, meets the injection requirements in quality and has more reliable safety in clinical application.

Owner:南京威尔药业科技有限公司

Method for recycling manganese sulfate by using electrolytic metal manganese waste slag

InactiveCN101767827AReduce manufacturing costImprove product qualityManganese sulfatesElectrolysisSlag

The invention discloses a method for recycling manganese sulfate by using electrolytic metal manganese waste slag, which comprises the following steps of: carrying out heating reaction, deironing, heavy metal removal, neutralizing and filter-pressing on waste slag for producing the electrolytic metal manganese to obtain 160-200g / L manganese sulfate solution, pumping the manganese sulfate solution for crystallization and purification. The crystallization purification comprises process of crystallization, solid-liquid separation, dissolution, filter-pressing and the like, and the filter-pressed manganese sulfate solution also can be repeatedly crystallized and purified for many times according to requirements. Various manganese products taking the manganese sulfate as raw material are produced by using the method of recycling manganese sulfate by using the waste slag for producing the electrolytic metal manganese, the method not only reduces the production cost, but also improves product quality with low production energy consumption and no environment pollution, and three-waste emission can achieve the national environmental protection emission standard.

Owner:杜祖德

Method for recycling ammonium sulphate from waste mineral slag of electrolytic manganese metal

InactiveCN101767802AReduce manufacturing costImprove product qualityAmmonium sulfatesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for recycling ammonium sulphate from waste mineral slag of electrolytic manganese metal. The method comprises the following steps of: carrying out heating reaction, iron removal, heavy metal removal, neutralization and filter pressing on the waste mineral slag slurry in the production of the electrolytic manganese metal to obtain 160 g / L to 200 g / L manganese sulphate solution, pumping the manganese sulphate solution accounting for 80% of the total volume of a crystallizing boiler, and carrying out the crystallization and purification on the manganese sulphate solution, wherein the crystallization and purification comprises the processes of crystallization, solid-liquid separation, dissolution, filter pressing and the like, recycling the excess heat by an auxiliary crystallization tower, reducing the temperature of the drained waste water from 210 DEG C to 80-85 DEG C, and then feeding the waste water to a waste water treatment tank; under a certain force of stirring, adding lime cream slurry and carrying out the replacement reaction on ammonium sulphate in the waste water and lime cream slurry to generate calcium sulphate and exhaust ammonia gas, and introducing ammonia gas to an ammonia spray tower to prepare ammonia. The invention adopts the method for recycling ammonium sulphate from waste mineral slag of electrolytic manganese metal, not only reduces the cost of production, but also improves the quality of product and has low energy consumption and no pollution to environment; and the three wastes discharge meets the national discharge standard of environmental protection.

Owner:杜祖德

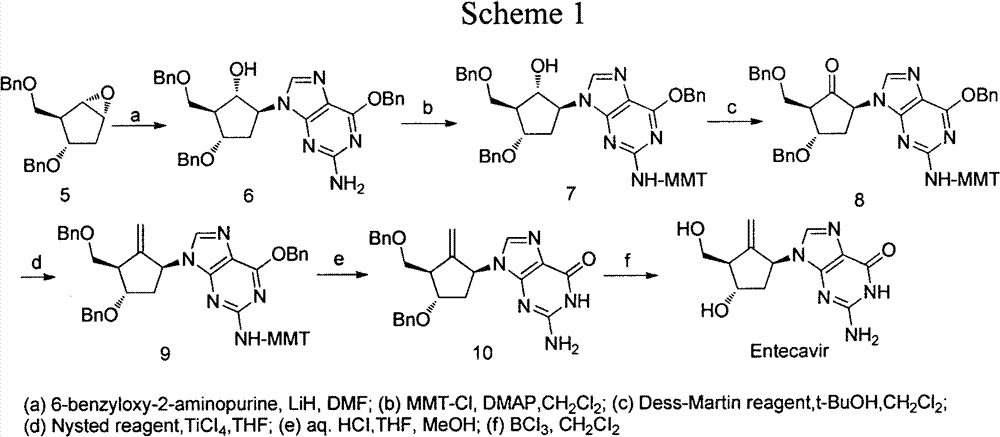

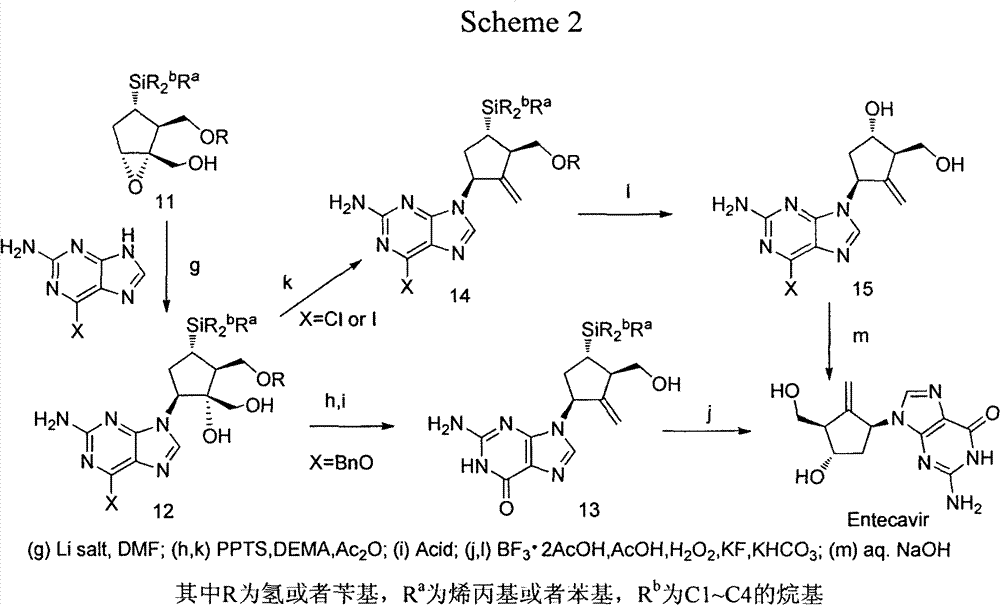

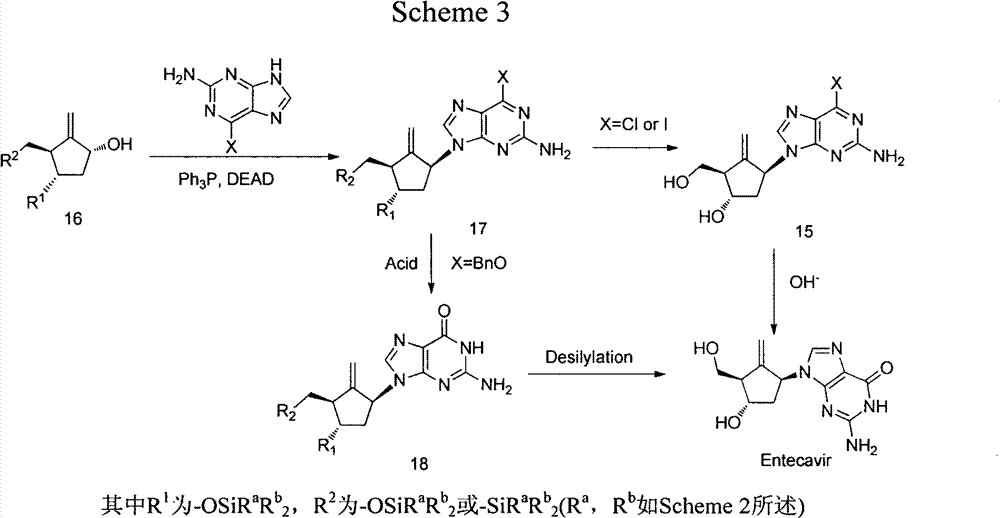

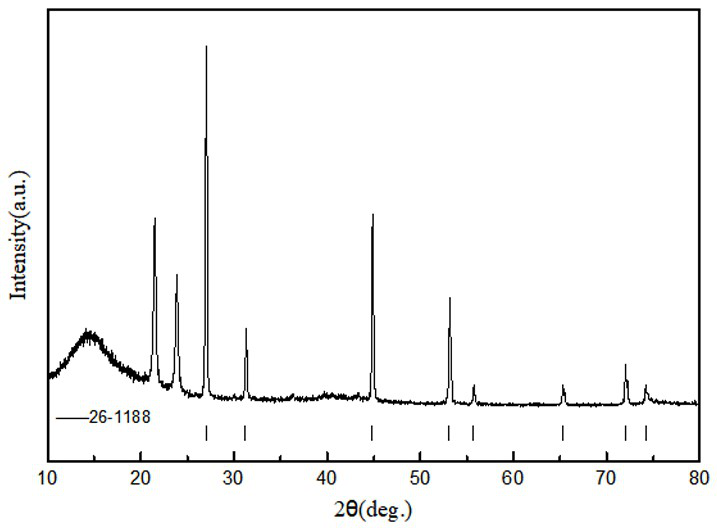

Synthesis method for medicine entecavir for treating hepatitis B

The invention belongs to the field of medicine synthesis, and provides a method for synthesising entecavir by taking (1R,2S,3S,5R)-3-(1-phenyl cyclo-silicon)-6-oxa-bicyclo[3.1.0] hexane-1,2-dimethyl carbinol as a raw material. The synthesis method comprises the following steps of: combining the raw material with purine compounds at first, then building a chiral five-membered exocyclic double bond via deoxidization reaction, and finally removing a protecting group to obtain entecavir. Via the cyclosilane structure of the raw material, the rigidity of molecules is enhanced, so that the product obtained via the method is easier to crystallize and purify; and the tar generated during the reaction is less, and the yield is high. Therefore, the synthesis method is good in industrialization prospect.

Owner:NANJING UNIV OF TECH

Method for extracting geniposide from gardenia yellow pigment waste liquor

ActiveCN103087129AIncrease profitAchieve zero emissionsSugar derivativesSugar derivatives preparationIsobutanolReverse osmosis

The invention discloses a method for extracting geniposide from gardenia yellow pigment waste liquor, which mainly comprises the following steps: concentrating gardenia yellow pigment waste liquor used as a raw material through a reverse osmosis membrane, extracting with isobutanol, decolorizing with active carbon, concentrating, performing crystallization purification twice, and finally drying. The invention can solve the waste problem that the gardenia effective component can not be economically and effectively recovered from the gardenia yellow pigment producing waste liquor in an environment-friendly way.

Owner:广西山云生化科技股份有限公司

Method of preparing and purifying lithium sulfide

The invention relates to a method for preparing and purifying lithium sulfide, which comprises the following steps: proportionally dissolving lithium sulfate and a soluble carbon source in deionized water, and carrying out spray drying granulation to obtain powder; calcining the powder obtained by granulation under the protection of an inert atmosphere; and in a dehumidifying and drying environment, washing the powder obtained by calcining with absolute ethyl alcohol, filtering out insoluble lithium sulfate and carbon powder, crystallizing and purifying the filtrate, and drying the solid to obtain lithium sulfide. The yield of lithium sulfide obtained by calcining after drying granulation is high (higher than 93%), wherein high-purity lithium sulfide is obtained after purification with absolute ethyl alcohol. The method has the advantages of simple preparation and purification processes, low equipment requirements, cyclic utilization of the purification solvent, environmental friendliness and easiness in industrial implementation.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for producing xylose by use of xylose mother liquid

ActiveCN102964393AHigh purityIncrease crystallization rateSugar derivativesSugar derivatives preparationFiltrationPolysaccharide

The invention provides a method for producing xylose by use of xylose mother liquid, which comprises the following steps of: adding a certain amount of ion exchange liquid into the xylose mother liquid in xylose production to adjust the concentration of the dry matter of xylose liquid to 10-30%; enabling the mixed xylose liquid to pass through a filter membrane for intercepting 0.1-0.5kD molecular weight to intercept polysaccharide in the mixed xylose liquid and keep small-molecular monosaccharide in the filtrate; processing with a cation exchange column and an anion exchange column so as to control the content of cations and anions in the filtrate below 10ppm; and concentrating and crystallizing to obtain a finished product of xylose. By adding ion exchange liquid into the xylose mother liquid which is hard to crystallize, the purity of xylose in the xylose liquid is improved; the pigment and polysaccharide in the mixed xylose liquid are removed by membrane separation of a filter membrane, and the xylose liquid after the membrane filtration is concentrated; and since the polysaccharide component in the xylose liquid is removed, the xylose mother liquid hard to crystallize is crystallized and purified, the total crystallization rate of xylose is improved by about more than 10%, and the xylose production cost is greatly reduced.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Crystallization purification method of thiourea

ActiveCN102976990AGood moisturizing effectPrevent problems such as darkening of colorOrganic chemistryThioureaPhysical chemistry

The invention belongs to the technical field of fine chemical industry and relates to crystallization purification technology of chemicals, in particular to the crystallization purification technology for of thiourea. According to the crystallization purification method of the thiourea, surfactant is mainly adopted to solubilize impurity of the thiourea solvent system in a selected mode, the crystallization ability of the impurity is reduced, the impurity is left in fluid phase, and the purity degree of the thiourea is increased. The crystallization purification method of the thiourea is simple in operation, easy to control, low in energy consumption and free of special equipment input, obtained products are even in crystallization and good in whiteness, content of crystallization is higher than 99%, and the crystallization purification method of the thiourea suitable for crystallizing the thiourea product in industrial production, satisfying demands of medicine, fine chemical and other industries, and improving purity degree of down-stream products.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Production method of high-purity 2-chloro-5-trifluoromethylpyridine

The invention provides a production method of high-purity 2-chloro-5-trifluoromethylpyridine. The production method comprises the following steps: under the action of a silicon dioxide-aluminum oxide-chromic oxide catalyst, gasifying the raw materials acrolein and propyl aldehyde, and reacting with an ammonia gas to generate 3-methylpyridine; gasifying the 3-methylpyridine and carbon tetrachloridetogether, reacting in a chlorine atmosphere to obtain 2-chloro-5-trichloromethylpyridine, and performing fluoro-substitution to obtain a crude product of 2-chloro-5-trifluoromethylpyridine; heating to melt the crude product of 2-chloro-5-trifluoromethylpyridine; refrigerating and circulating in a low-temperature thermostat; cooling and crystallizing and separating to obtain recrystal; sweating the recrystal; repeating the processes of circulating, melting, recrystallizing and sweating to obtain high-purity 2-chloro-5-trifluoromethylpyridine. According to the production method provided by theinvention, 3-methylpyridine is adopted as a raw material, and the 2-chloro-5-trifluoromethylpyridine is molten, recrystallized and purified so that the product has high purity and stable yield.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

Method for preparing neohesperidin in physiological fallen fruits of grapefruits by alcohol/salt double-water-phase system

ActiveCN109293721AReduce extraction timeMild extraction conditionsSugar derivativesSugar derivatives preparationInorganic saltsAlcohol

The invention belongs to the technical field of extraction of plant ingredients, and discloses a method for preparing neohesperidin in physiological fallen fruits of grapefruits by an alcohol / salt double-water-phase system. The method comprises the following steps: collecting dry grapefruit physiological fallen fruits; crushing the dry grapefruit physiological fallen fruits; pulverizing the dry grapefruit physiological fallen fruits; preparing and constructing a double-water-phase system; carrying out hot dip extraction; carrying out separation and phase splitting by a liquid-liquid-solid three-phase disc separating machine; concentrating; carrying out water sedimentation crystallization and filtering; carrying out ultra-filtration film assisted hot water recrystallization purification; carrying out cooling crystallization; and carrying out drying and packing. Advanced processes such as dip extraction through isopropanol / NaH2PO4 inorganic salt double-water-phase system, ultra-filtration film assisted hot water recrystallization purification and the like are adopted, and the whole process has the advantages of short production period, mild extracting conditions, simplicity and convenience in operation, high selectivity to target products, good product quality, small amount of waste water, easiness in treatment and the like, the yield of the prepared neohesperidin reaches 5.7%, and the HPLC content is greater than or equal to 95%.

Owner:张家界普兰植物开发有限公司

Method and device for preparing high-purity boric acid

The invention discloses a method and device for preparing high-purity boric acid. The method comprises the steps of (1) ion exchange pretreatment, (2) evaporation re-crystallization purification and (3) suction filtration drying. According to the differences of the solubility of boric acid in an aqueous solution at different temperatures and a theory that the solubility of boric acid changes faster along with temperature changes than that of impurities, boric acid is purified. The method can adopt industrial boric acid as a raw material, and is easily-available in raw material, low in cost, simple in process step and convenient to operate.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

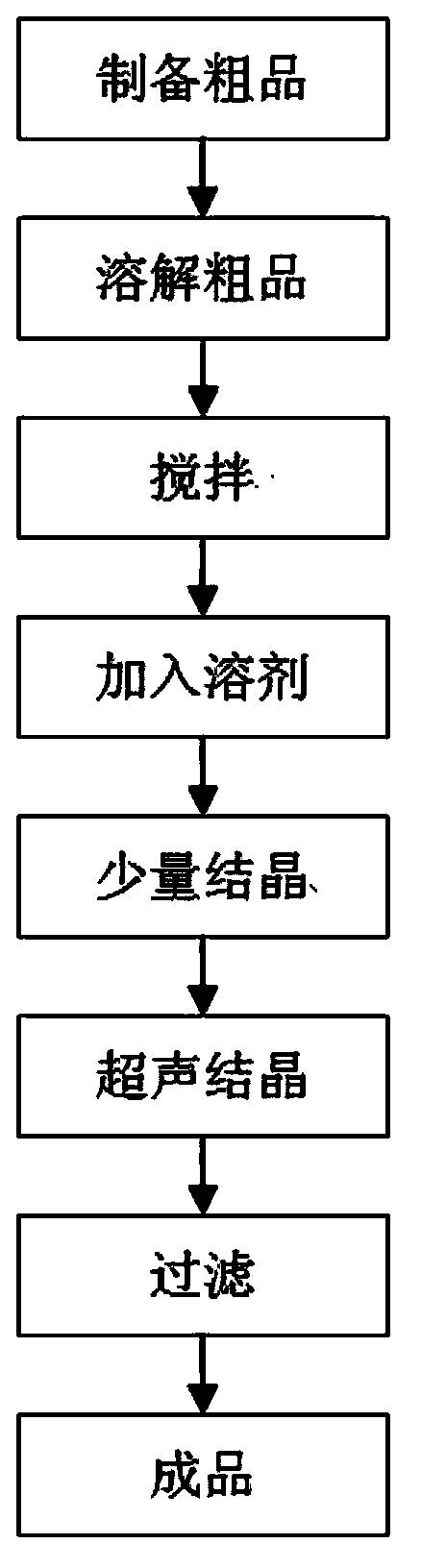

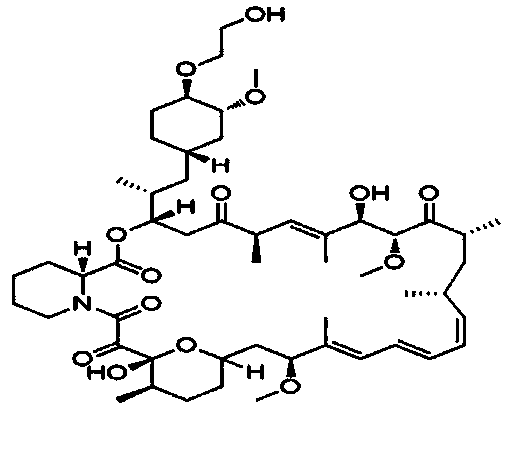

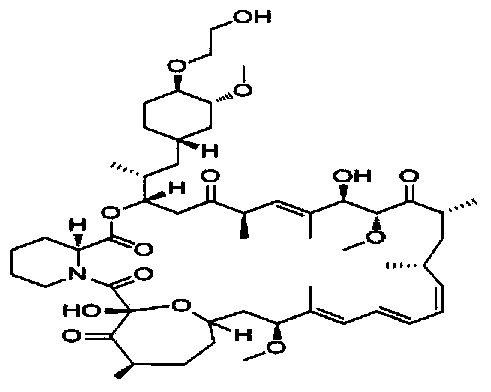

Everolimus crystallization purification method

The invention aims at overcoming everolimus crystallization difficulties caused by unstable structures such as olefinic bond and ester bond in the everolimus structure, and provides an everolimus crystallization purification method. According to the invention, a synthesized everolimus raw material is treated through normal-phase column chromatography, such that an everolimus crude product is obtained; the everolimus crude product is dissolved by using a water-containing organic solvent under low temperature, and sufficient stirring is carried out; an alkane organic is added to the everolimus solution, and stirring is continued; when a small amount of crystals appear, crystallization is changed into ultrasonic crystallization; and filtering is carried out, such that the everolimus finished product is obtained. With the method provided by the invention, everolimus crystal conversion to isomer is blocked, and the conversion from isomer to everolimus crystal is realized. Also, significant effect is provided on removing or reducing other impurities. The method also has the advantages of good crystallization effect, high yield, low cost, and low requirement on equipment.

Owner:CHENGDU YATU BIOLOGICAL TECH

Method for extracting biphenyl and indole from recycling washing oil of coal oil

ActiveCN101245044AHigh purityIncrease the value of reuseDistillation purification/separationExtraction purification/separationCoal tarSolvent extraction

The invention provides a method for extracting biphenyl and indole from the recycled wash oil of coal tar at the same time, which comprises the steps: (1) obtaining rich indole biphenyl fractions from the decompression and the rectification of the recycled wash oil; (2) carrying out multistage extraction and separation to the rich indole biphenyl fractions by using a double solvent extracting agent which comprises a polar solvent and a non-polar solvent, the weight ratio of the indole biphenyl fractions to the polar solvent to the non-polar solvent is 1:0.25 to 1:0.5 to 1.5 and the extraction temperature is 10 to 50 DEG C; (3) indole products are obtained by the rectified purification and the crystallized purification of the extraction solution; (4) biphenyl products are obtained by the rectified purification and the crystallized purification of the extraction solution. The method is simple and can extract and obtain highly pure biphenyl and indole from the recycled wash oil of the coal tar, which promotes the recycling value of the recycled wash oil of the coal tar, and the recycling use of the solvents reduces production cost, thus the method is suitable for industrial production.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com