Patents

Literature

129results about How to "Increase the value of reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge dryer with increased retention time

InactiveCN102123957AReduce processing costs and timeIncrease the value of reuseSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEngineeringSludge

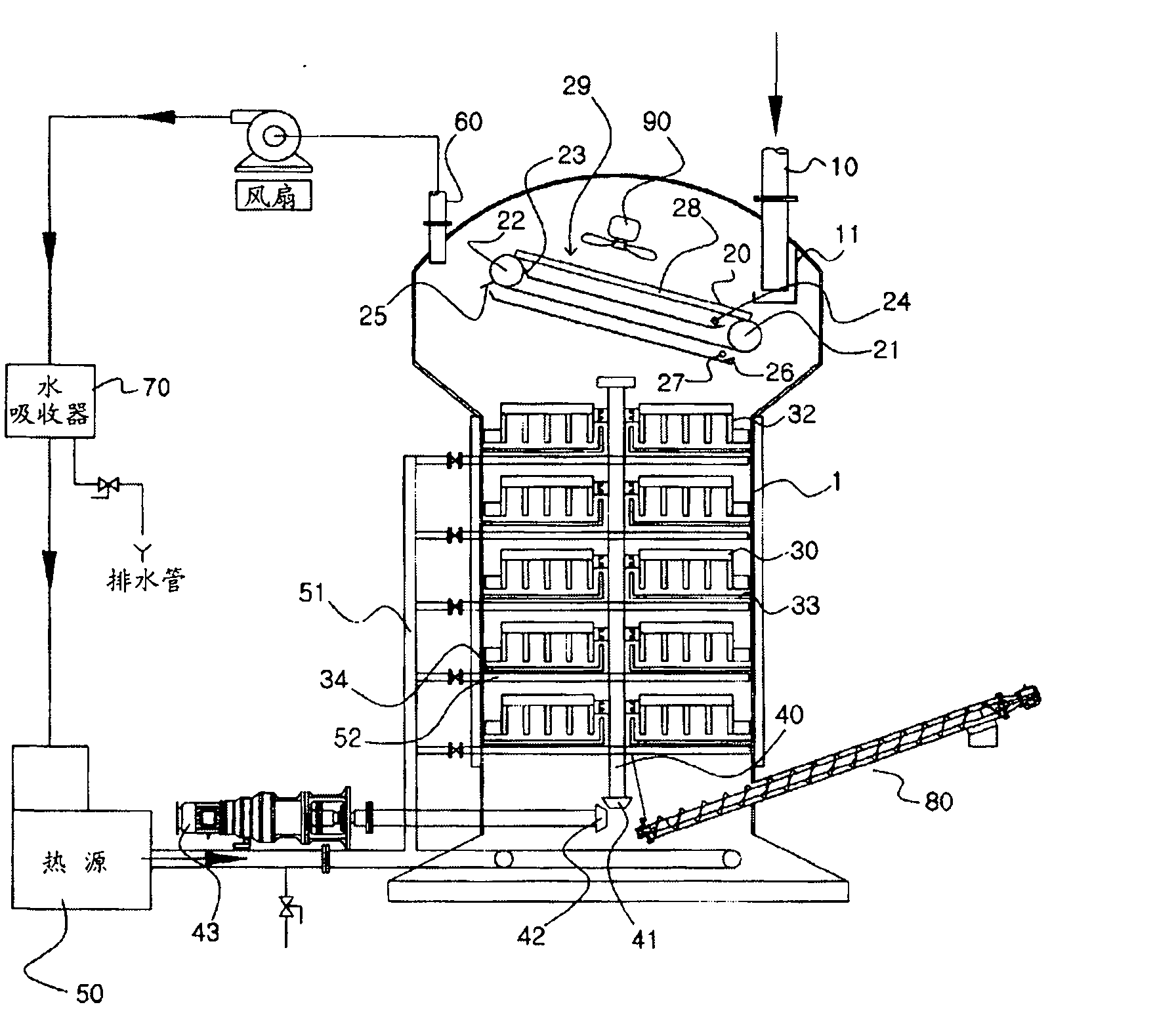

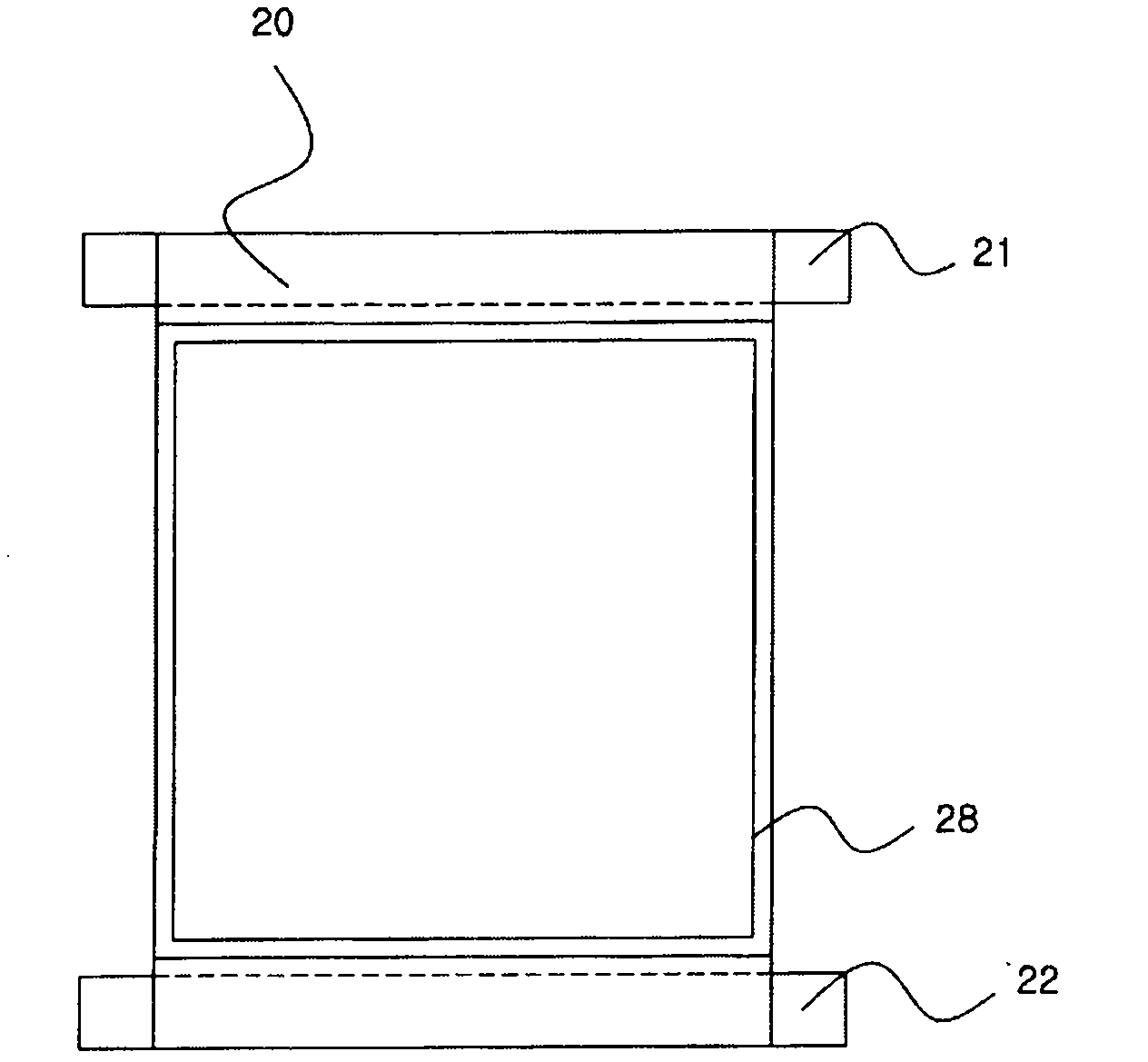

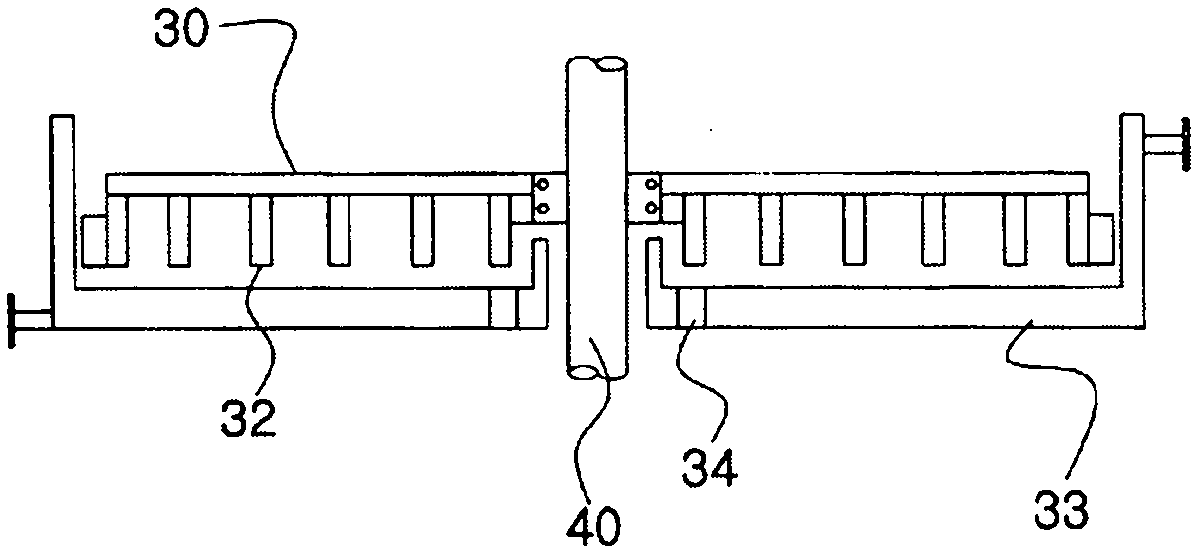

The present invention relates to a sludge dryer with increased retention time, comprising a main body having a space formed therein for the insertion and drying of sludge; an input formed in the upper part of the main body to introduce the sludge into the main body from the outside; a plurality of drying plates that are installed vertically in a multistage manner to dry the sludge by receiving the sludge introduced by the input and retaining the sludge; a shaft installed in the vertical direction at the center of the main body and rotated by the power transmitted from a central motor; one or more moving scrapers installed in the radial direction on the respective drying plates, and having a plurality of movers that are connected to the shaft and obliquely coupled at a predetermined interval so that the sludge supplied to the drying plates is gradually moved to the central part or the outer peripheral part of the drying plates while rotating; drop grooves that are respectively formed in an alternating fashion in the central part and the outer peripheral part in the upper and lower drying plates that are installed in a multistage manner such that sludge moved to the central part or the outer peripheral part of the drying plates can be dropped to a lower stage by the movers; and a supply pipe connected to a heat source via a hot air pipe and installed at the lower side of each drying plate so as to supply heat to the respective drying plates.

Owner:SEWON INDUSTIRIES

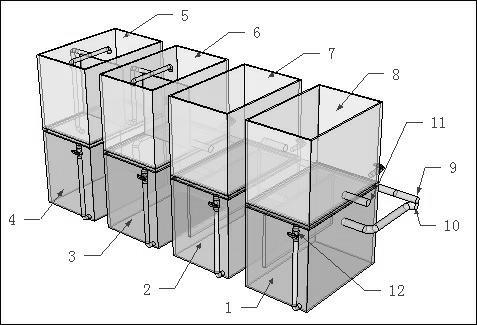

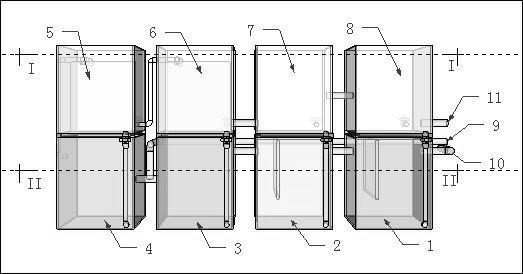

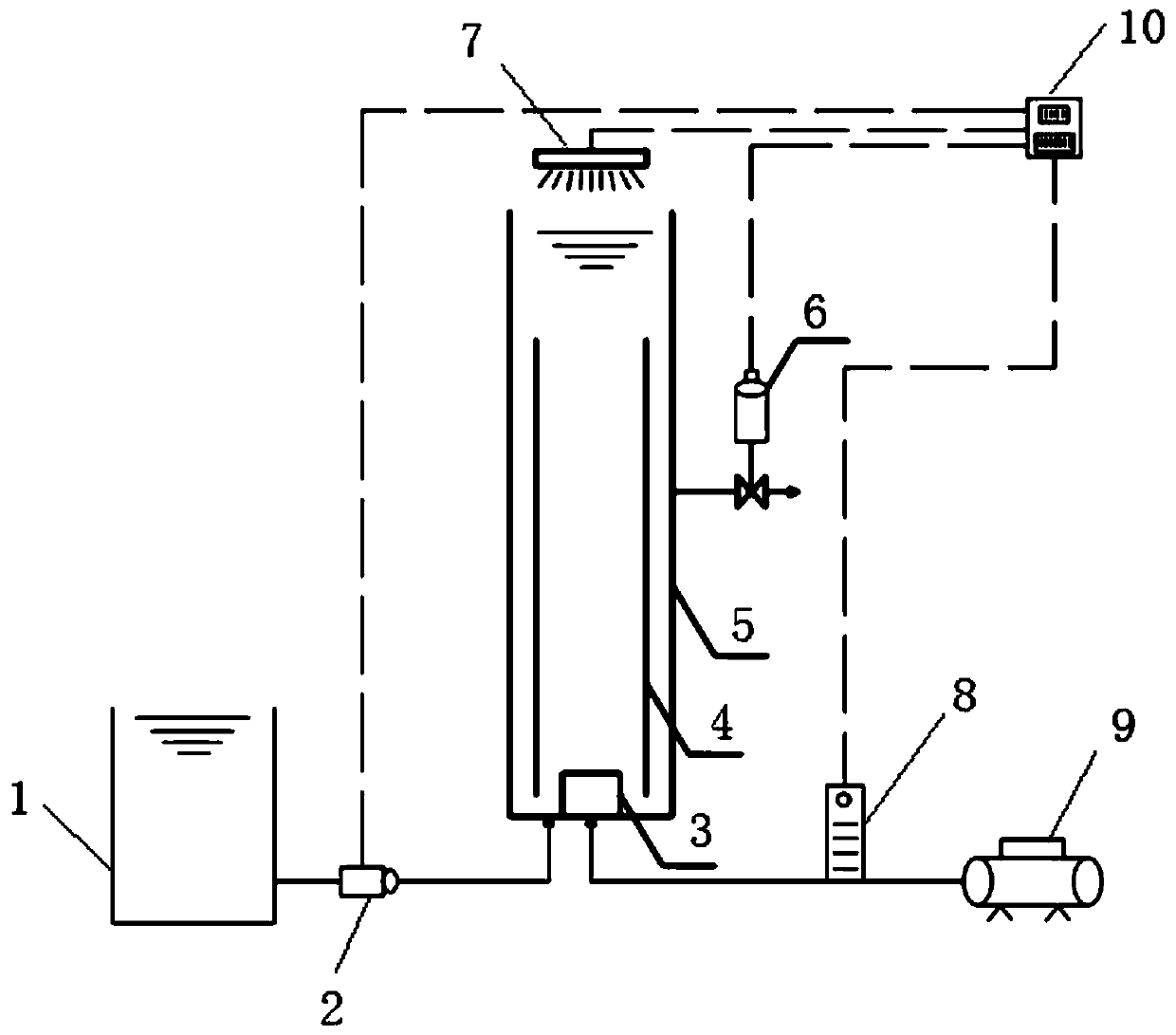

Modularized sewage ecological treatment system

InactiveCN102219340AIncrease the value of reuseRealize eco-environmental protectionBio-organic fraction processingClimate change adaptationConstructed wetlandWater quality

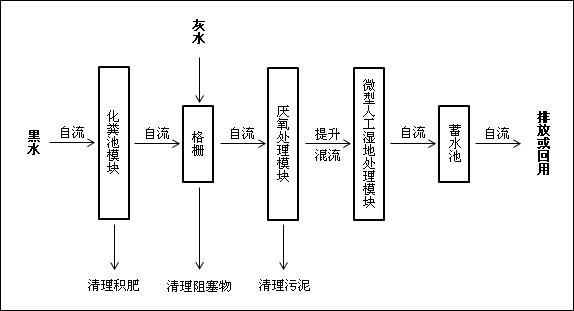

The invention relates to a modularized sewage ecological purification system comprising four main parts: a septic-tank module, an anaerobic treatment module, a mini-type artificial wetland treatment module and a water impoundment settling module. Sewage flows through the septic-tank module, the anaerobic treatment module, then the mini-type artificial wetland treatment module and the water impoundment settling module to realize the process flows of the classification collection, anaerobic pretreatment, deep ecological purification on the sewage, and the system is designed aiming at the dispersing type domestic sewage treatment. The modularized sewage ecological purification system consists of standard unit modules which can be installed rapidly in parallel or in series according to the treatment amount, the number of different unit modules can be added or decreased according to the state of entering water quality and the requirement on yielding water quality, thus achieving optimal treatment effect. Due to the modularized design, the ecological purification system has the advantages of rapid installation, flexible arrangement, low cost, high efficiency, and easy integration with ecological scenery.

Owner:谢伟健 +1

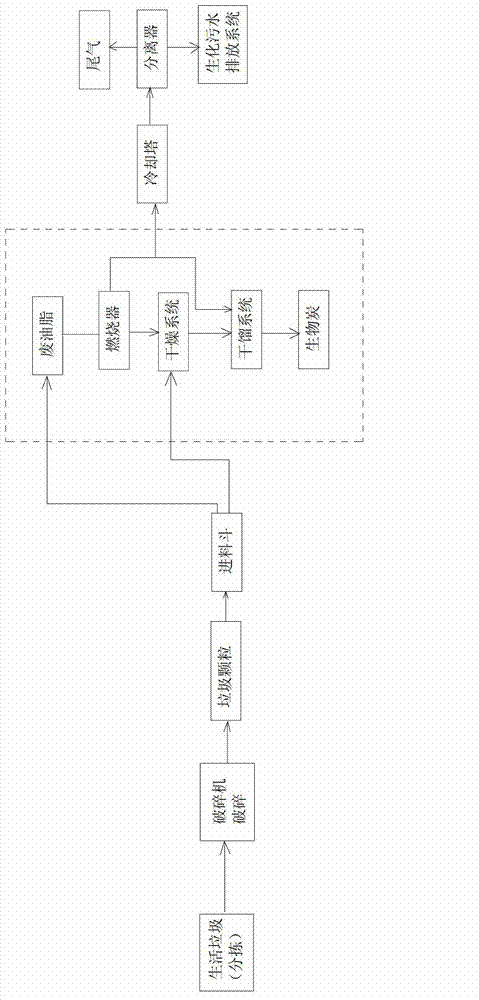

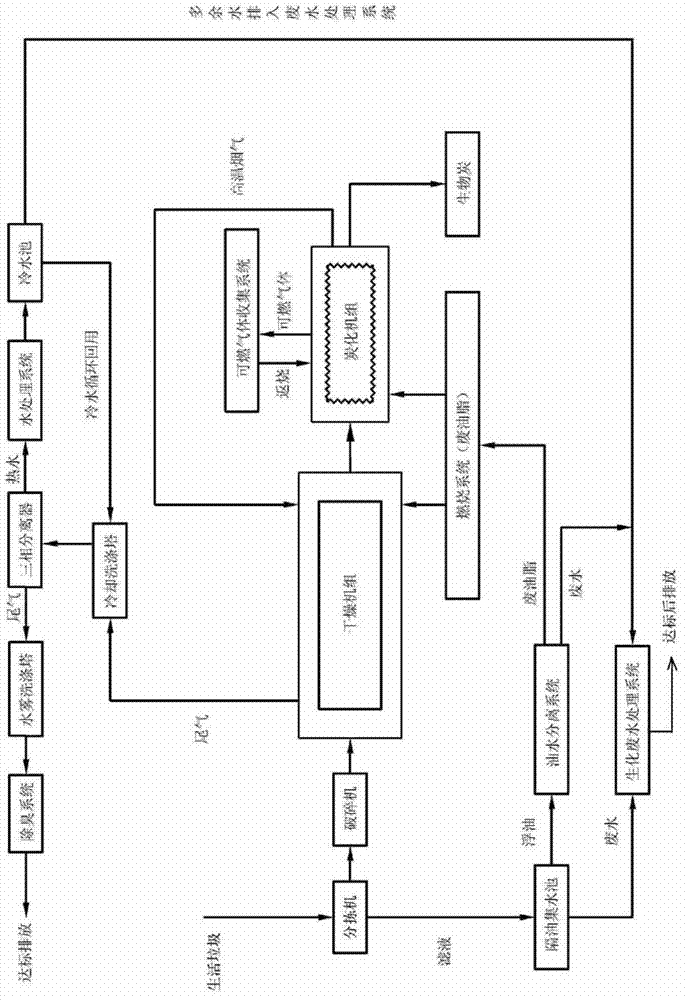

Environment-friendly comprehensive treatment method for household garbage and waste oil and fat

ActiveCN103111455AIncrease valueEliminate environmental pollutionSolid waste disposalDirect heating destructive distillationHot blastScrew conveyor

The invention discloses an environment-friendly comprehensive treatment method for household garbage and waste oil and fat. The method comprises the following steps of: (1) sorting the household garbage, breaking the household garbage into garbage particles through a breaking machine, and conveying the garbage particles to a feeding hopper through a spiral transmitting machine; (2) carrying out the procedures of pre-heating, drying and dry distillation on the garbage particles to obtain charcoal through a sealed spiral conveying machine; (3) separating part of waste oil and fat into two parts through an oil and water separating system, and burning one part of waste oil and fat as fuel through a hot blast stove so as to perform drying and dry distillation on the garbage and convert the garbage into charcoal; and (4) treating the other part of wastewater through a biochemical wastewater treatment system, and discharging the processed wastewater reaching the standard. The comprehensive treatment method disclosed by the invention is a hazard-free, reducing and recycling technology for the household garbage, is free from pollution in processing, low in cost, good in practicability and high in operability, and has remarkable social and economic benefits.

Owner:陈丰

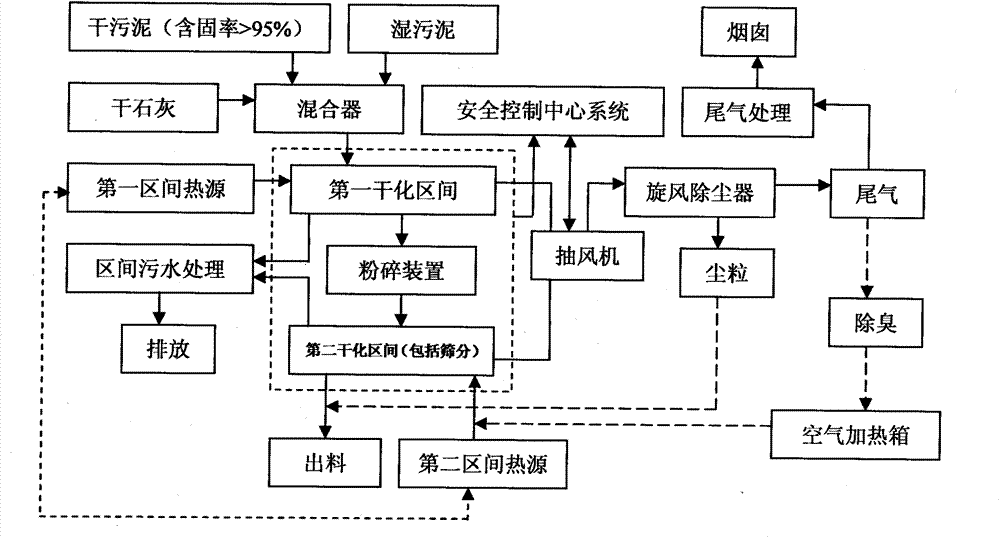

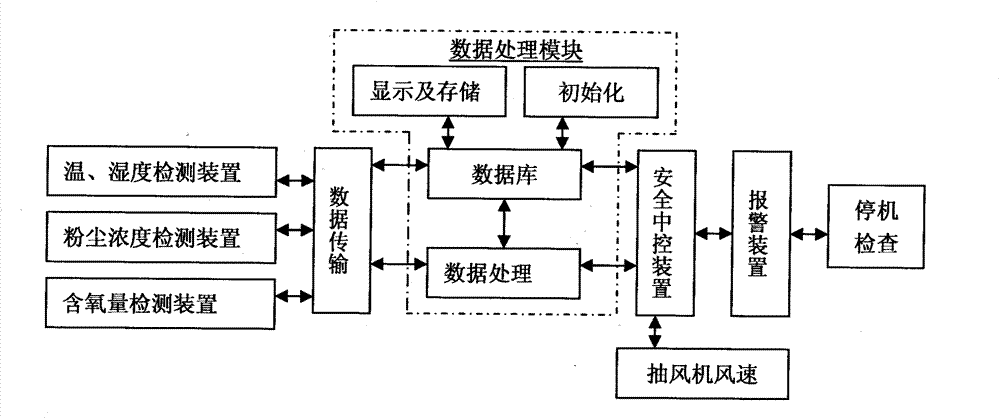

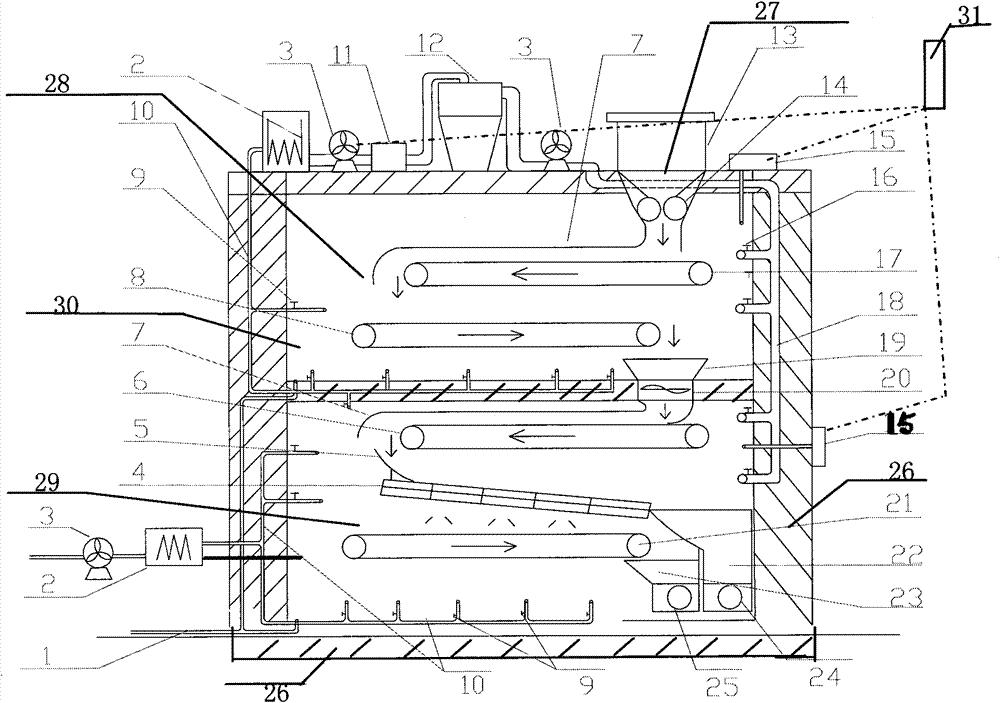

Vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions

InactiveCN103803769ASolve the costSolve cohesionSludge treatment by de-watering/drying/thickeningRefluxThermal insulation

The invention discloses a vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions. The method comprises the following steps: dividing a sludge drying process into a dried material back-mixing stage, a first drying stage, a crushing treatment stage, a second drying stage and a final screening and discharging stage, wherein the sludge drying operation is performed under monitoring of a safety monitoring system. The equipment comprises a heating box provided with multiple energy interfaces, a rolling plodder, a drying box (a crusher, a metallic screen and a conveyer belt are arranged in the drying box, and the interior of the drying box is partitioned into two intervals by a thermal insulation material and the crusher position in the middle), an exhaust fan, a dust remover, a deodorization device, a water vapor reflux pipe and is also equipped with a safety control center system. According to the sludge drying equipment, the drying method can be effectively performed. The problems of cost, adhesion and safety during sludge drying are appropriately solved, the drying efficiency is high, the discharging uniformity is high, and the sludge resource recycling value is high.

Owner:CHONGQING JIAOTONG UNIVERSITY

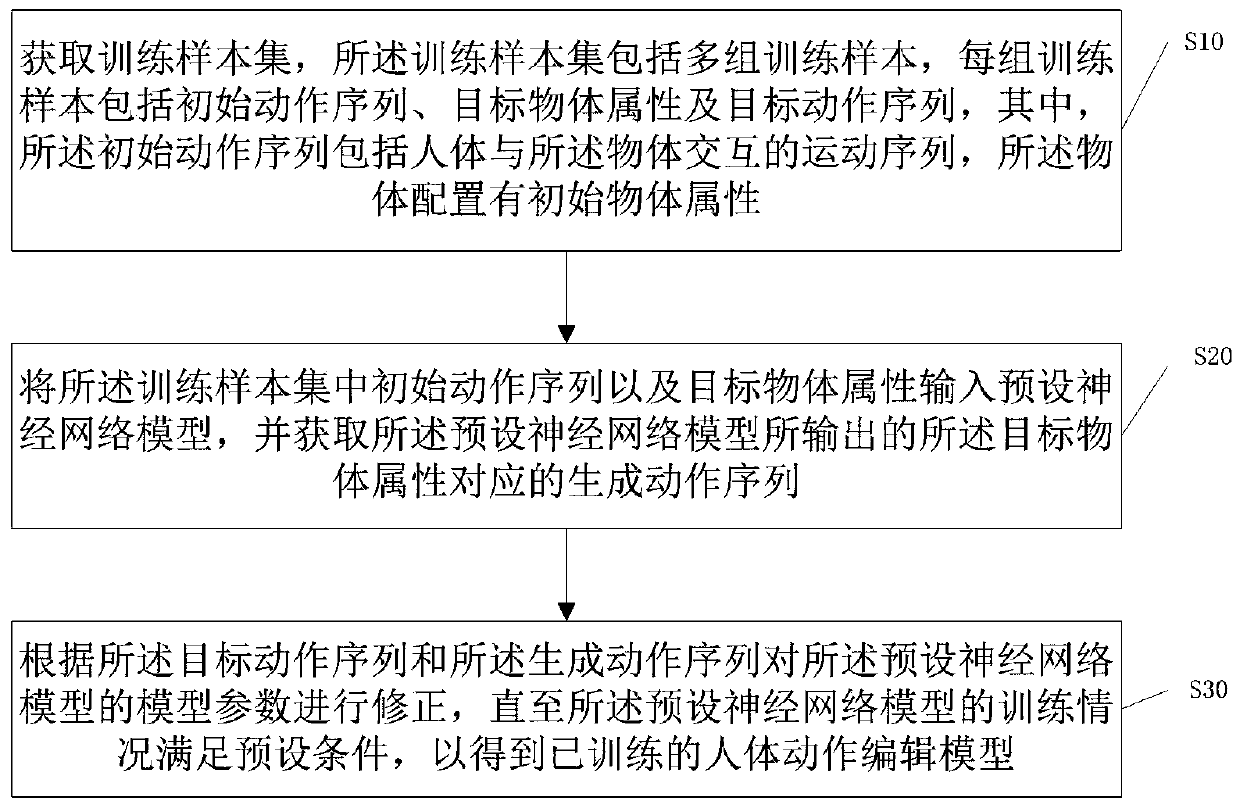

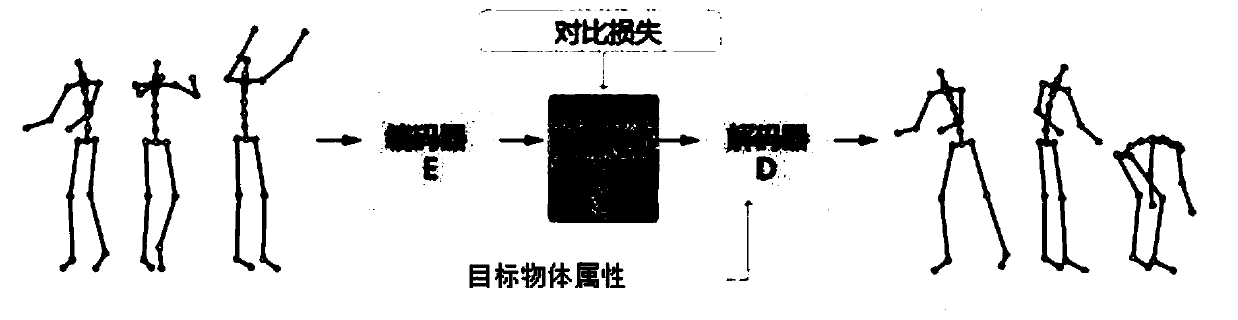

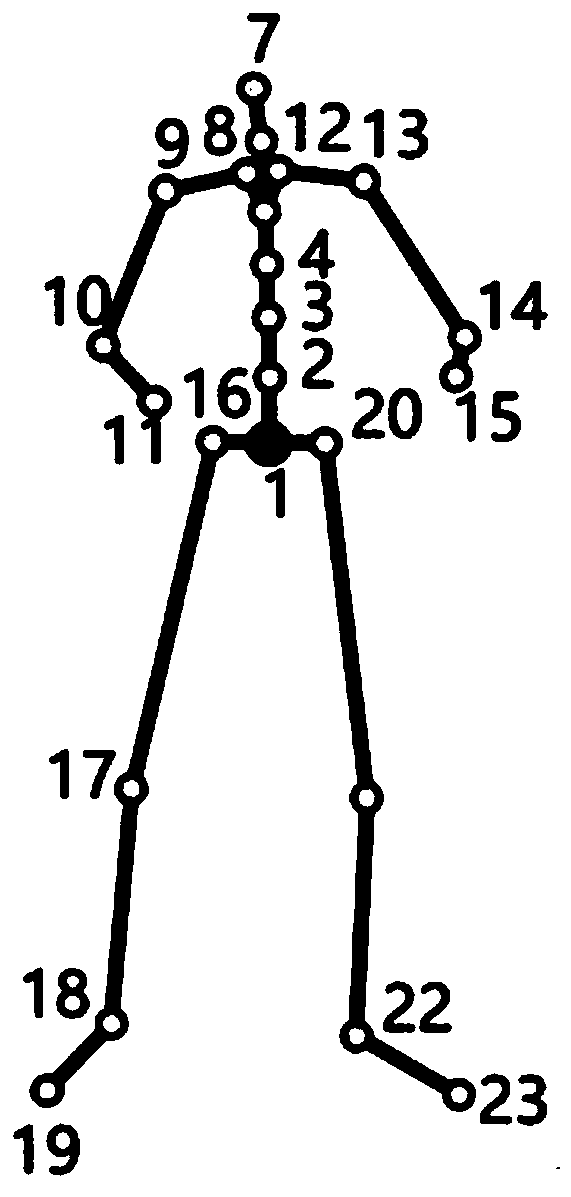

Generation method of human body action editing model, storage medium and electronic device

PendingCN110533752AReduce the amount of human interventionIncrease reuse valueAnimationNeural learning methodsNetwork modelObject Attribute

The invention discloses a generation method of a human body action editing model, a storage medium and an electronic device. The method comprises the following steps: taking an initial action sequence, target object attributes and a target action sequence as training samples; inputting the initial action sequence and the target object attribute into a preset neural network model, and obtaining a generated action sequence output by the preset neural network model; and training the preset neural network model according to the target action sequence and the generated action sequence to obtain a trained human body action editing model. Through using an interaction action sequence of a person and an object as a training sample, the human body action style migration is realized only by utilizingthe object attributes, so that the human intervention amount in the data preprocessing process is reduced, the human-object interaction movement matched with the attributes can be correspondingly generated by applying different attributes of the same object, and the reuse value of the action capture data is improved.

Owner:SHENZHEN UNIV

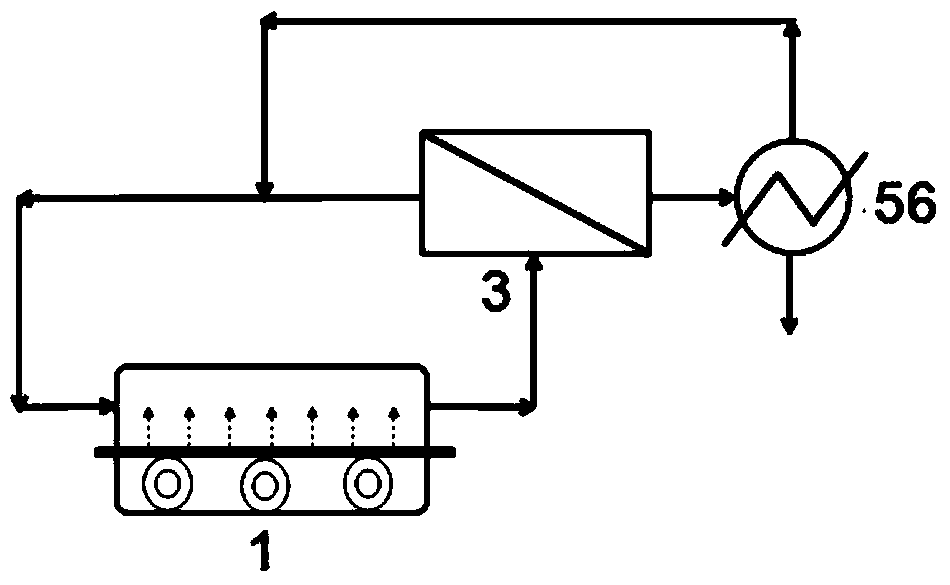

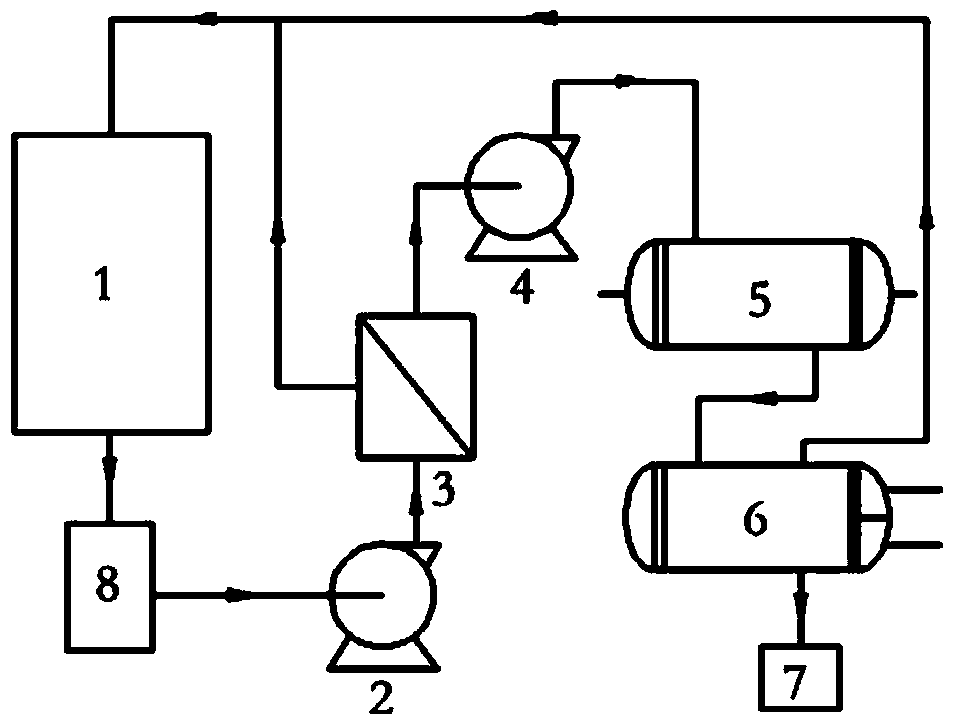

Membrane-method recovery process for realizing zero emission of volatile organic compound

ActiveCN103706224AAchieve emissionsRealize full recyclingDispersed particle separationMembrane methodOrganic solvent

The invention discloses a membrane-method recovery process for realizing the zero emission of a volatile organic compound. Waste gas which is generated by an organic compound generation system and contains the volatile organic compound directly enters a membrane separation system or is cooled and then enters the membrane separation system. A membrane can be separated by using the difference between the pressures of the upstream and downstream sides of the membrane as impelling force. Gas with high content of the volatile organic compound is obtained on the permeation side of the membrane through enrichment. Gas with low content of the volatile organic compound is obtained on the non-permeation side of the membrane. The gas with the high content of the volatile organic compound on the permeation side of the membrane enters a condensation system to directly obtain part of the organic compound. Meanwhile, uncondensed gas returns to the organic compound generation system, and the gas with the low content of the volatile organic compound on the non-permeation side of the membrane returns to the organic compound generation system. The two flows of returned gas pass through the organic compound generation system, are mixed with a part of the volatile organic compound, and re-enter the membrane separation system for next circulation. According to the process, any emitted gas is eliminated, and the zero emission is realized. The process plays an important role in recovery of an organic solvent.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

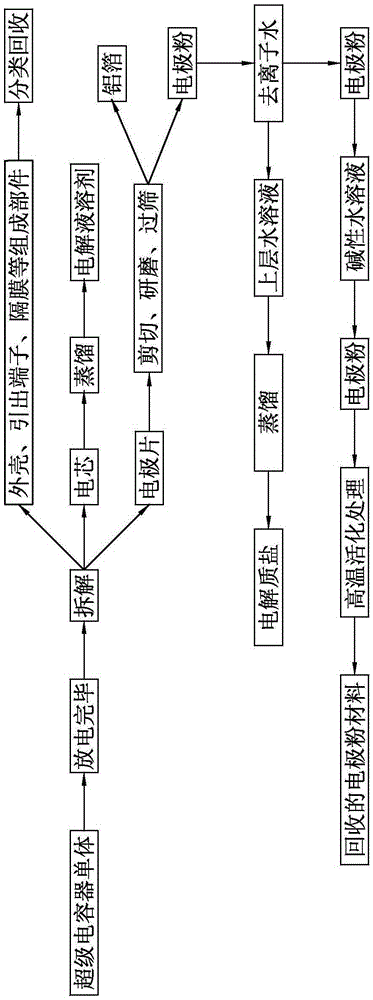

Resource recycling method for super capacitor

InactiveCN105234147AImpact reuseRealize recycling of resourcesSolid waste disposalRecovery methodHazardous substance

The invention relates to a resource recycling method for a super capacitor and belongs to the technical field of energy materials. The recycling method includes the steps that a super capacitor single body completing discharging is demounted to obtain a cell and an electrode plate; the cell is distilled to obtain an electrolyte solvent; the electrode plate is sheared, ground and screened, then electrode powder and aluminum foil are obtained through separation. The electrode powder is washed through deionized water, an upper-layer water solution and the washed electrode powder are separated, an alkaline water solution is added to the washed electrode power for washing again, and finally, the electrode powder is activated at a high temperature and a recycled electrode powder material is obtained. According to the recycling method, the innocent treatment of the waste super capacitor single body is ensured, meanwhile, the main materials composing the single body are recycled effectively on the basis that harmful substances such as an organic solvent are not introduced, environment friendliness of the whole-life cycle of the super capacitor is achieved, and the reuse value of main materials such as electrodes and electrolytes is improved.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

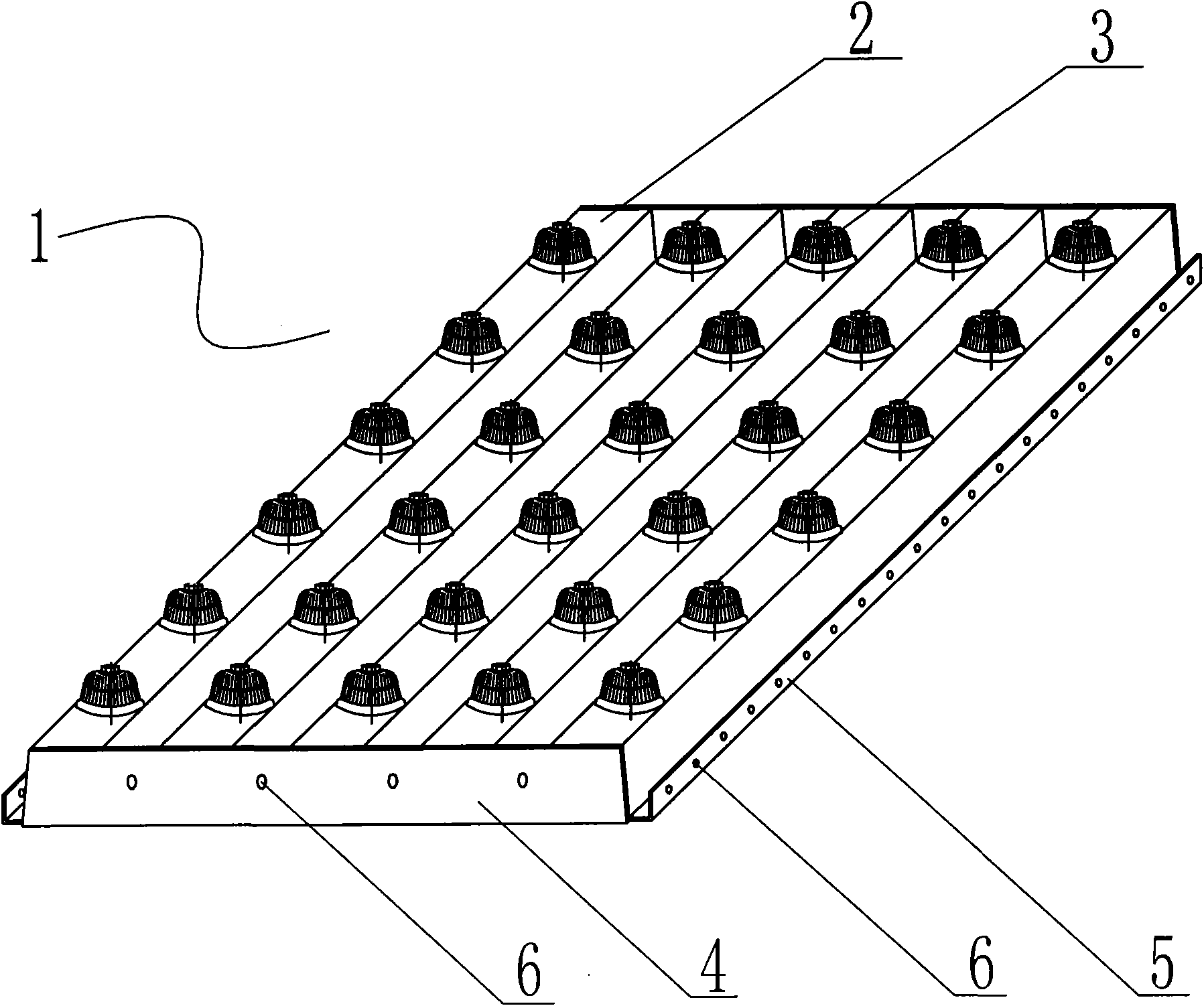

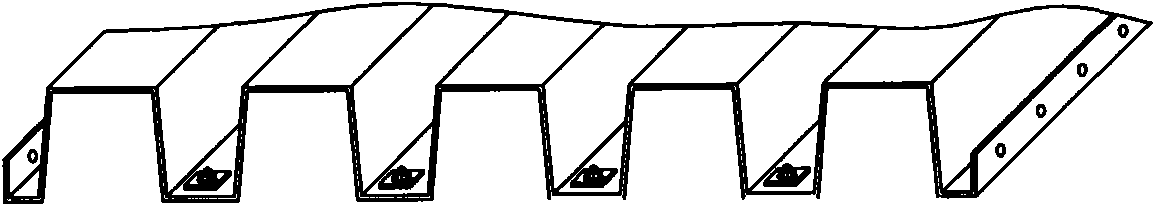

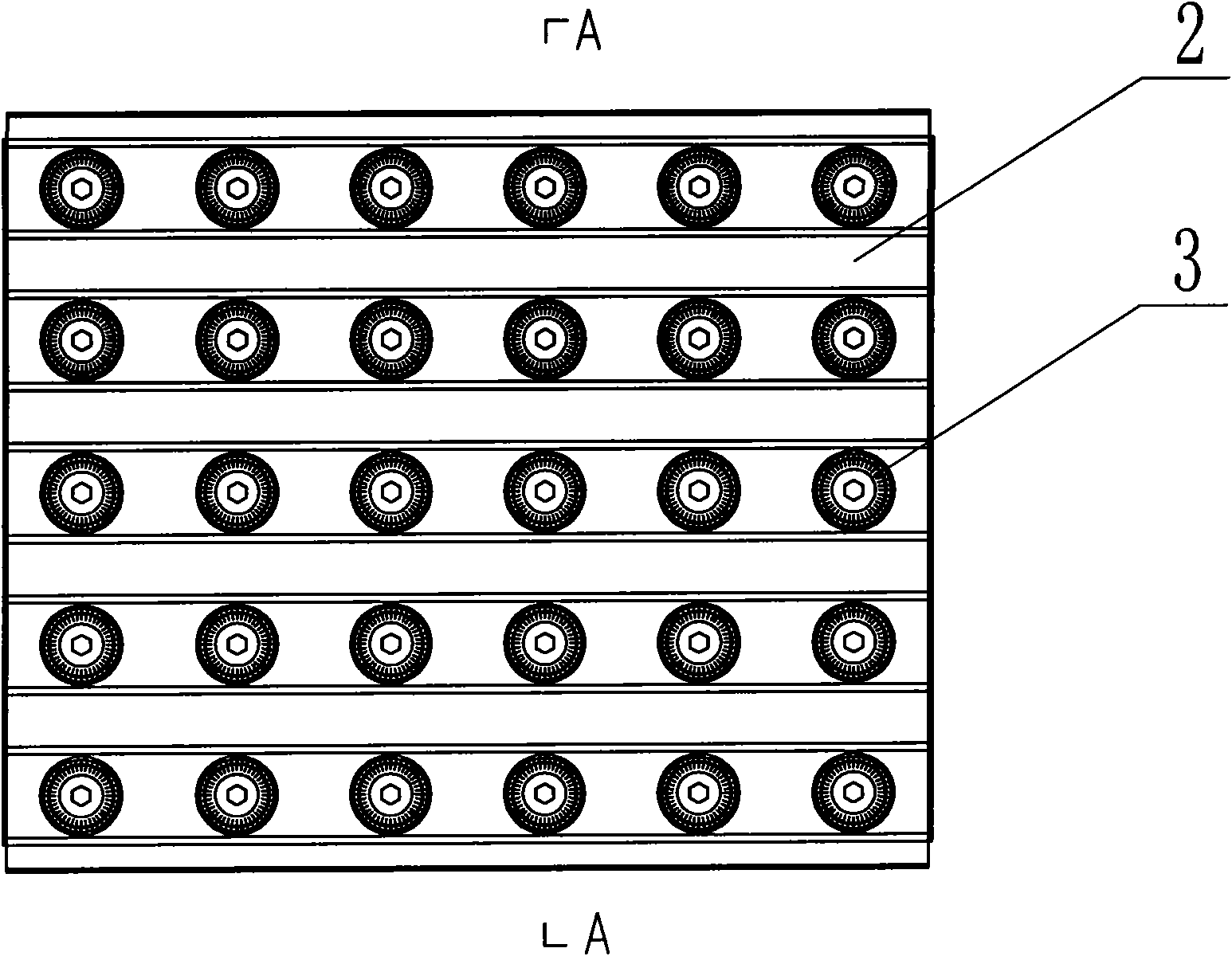

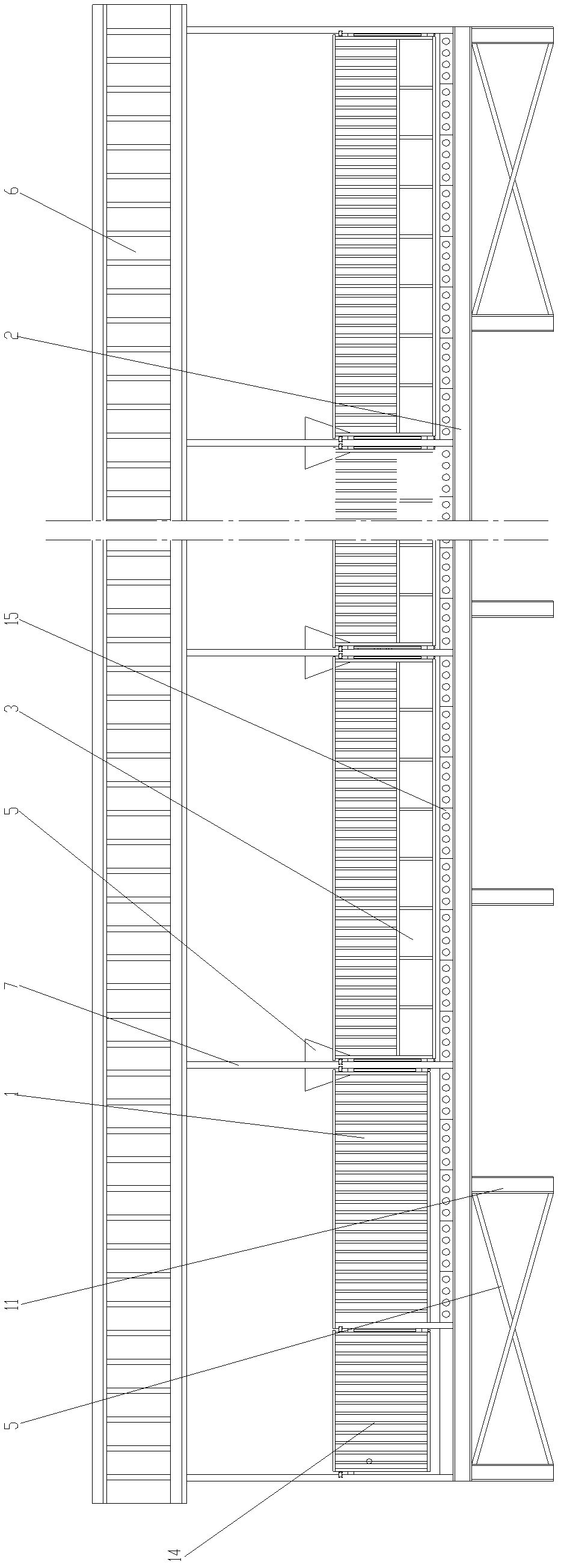

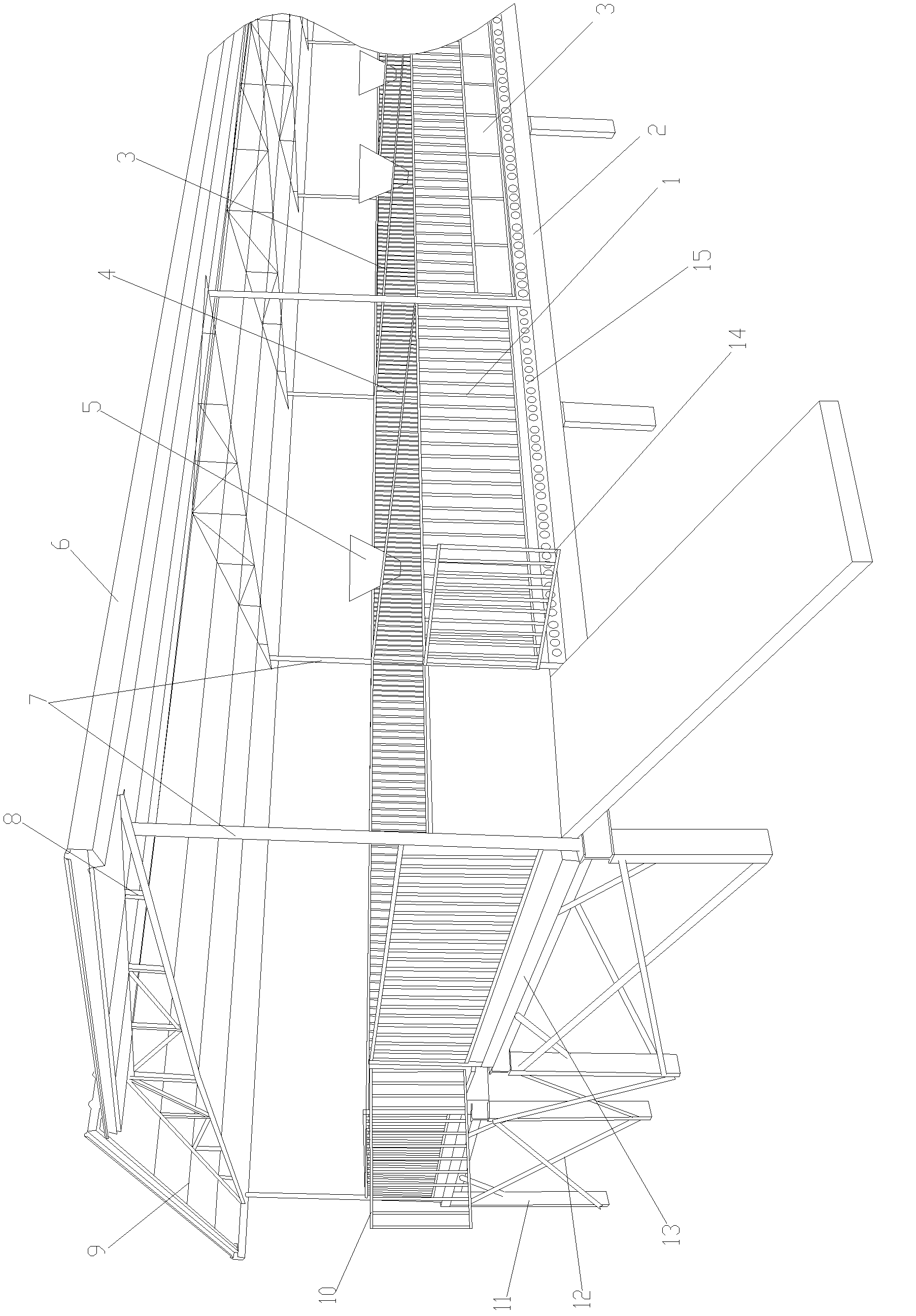

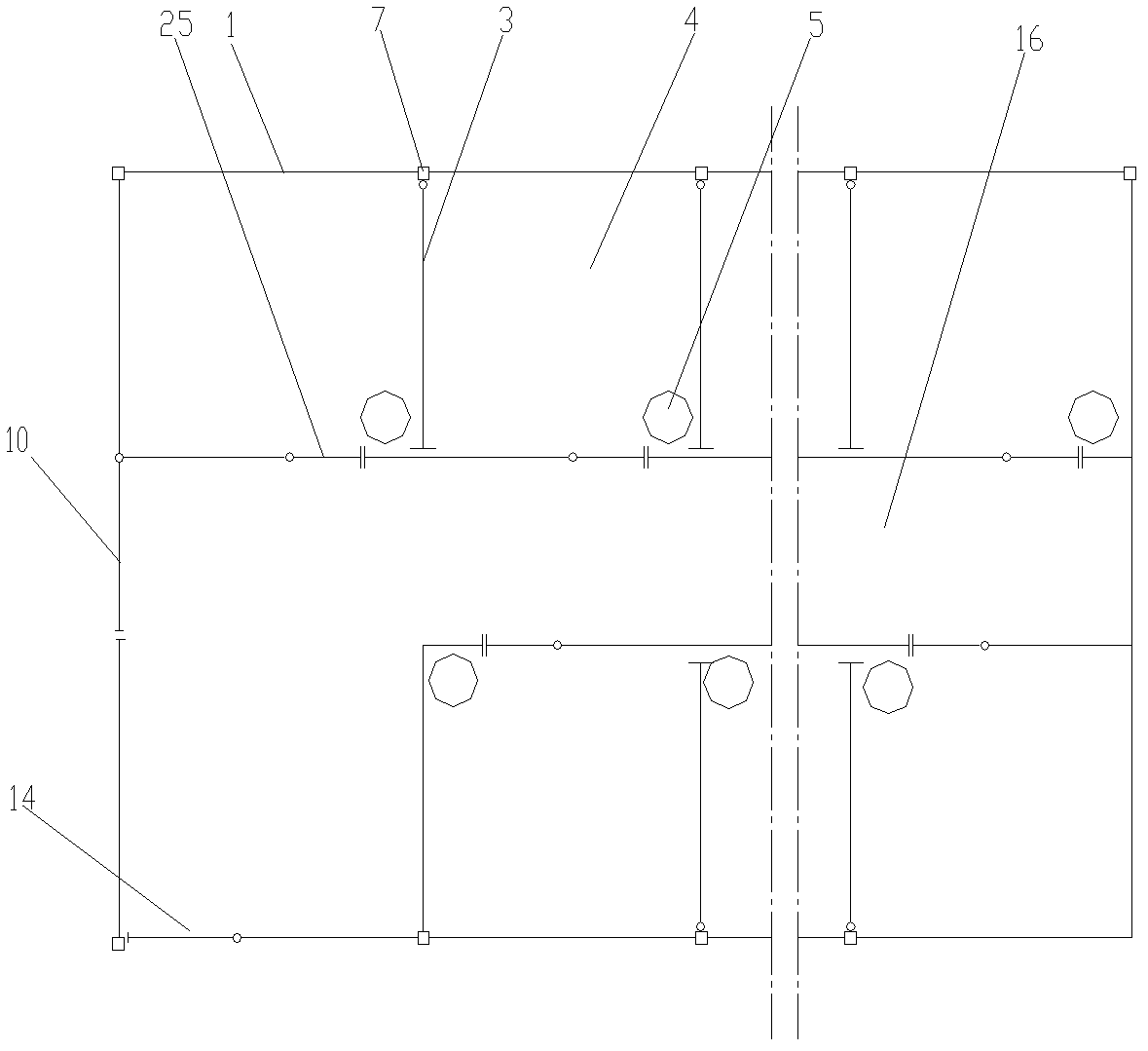

Stainless steel filter head plate

ActiveCN101817568AExtended service lifeThe service life is equivalentWater/sewage treatment by sorptionLow loadAtmospheric pressure

The invention discloses a stainless steel filter head plate with a novel structure, comprising a stainless steel filter plate and a filter head. The stainless steel filter head plate is characterized in that the stainless steel filter plate is a corrugated plate; the filter head is arranged on a wave crest; two sides of the stainless steel filter plate, which are perpendicular to a corrugated direction, are provided with closing plates, and the other two sides of the same are provided with connecting plates; the closing plates and the connecting plates are all provided with connecting screw holes; and the shape of the cross section of the corrugated plate is a continuous trapezoid preferably. The stainless steel corrugated plate has very high rigidity and can meet the requirement for moving upper and lower loads in a filter pool and balance the tiny difference of air pressure and water pressure during the back wash of the bottom of the filter plate inside the filter pool because back wash air and water which are positioned at the bottom of the filter plate are communicated on wave crest and wave trough positions due to the corrugated structure of a filter plate surface; and in addition, the stainless steel filter head plate also has the advantages of safety, hygiene, long service life, portability, simple structure, convenient installation, simultaneous installation and use, high residual value, and the like.

Owner:ZHEJIANG LIANCHI WATER EQUIP

Detachable type combined pigsty

The invention discloses a detachable type combined pigsty. The pigsty is a ventilated fence type combined structure, and comprises a pigsty roof and a pigsty main body, wherein the pigsty main body is used for supporting the pigsty roof through a top beam of a truss structure, and comprises detachably connected fences, bottom beams of the pigsty and a pigsty floor, and the pigsty floor is supported by the bottom beams of the pigsty. According to the invention, as a detachable and ventilated fence type combined pigsty is adopted, an optimum ventilation effect is achieved, so that the accumulation of dirty gases is avoided, and infectious pig diseases caused by the problem on circulation are avoided; therefore, the detachable type combined pigsty is favorable for the prevention and treatment of diseases, breeding cost is reduced, and pig breeding benefit is increased; as a detachable structure is adopted, the detachable type combined pigsty is movable; the whole pigsty is convenient to disassemble and transport in case of relocation, so that recycling value of materials is improved, small destruction to the original land for the pigsty, particularly no damage on farmland, is realized, and therefore the problem on the large-area destruction to the farmland of the conventional pigsty in the prior art is solved, use cost and construction cost are saved, and a better environmental protection property is realized.

Owner:重庆海林生猪发展有限公司

Low-temperature cultivation algal-bacterial symbiotic granular sludge method

ActiveCN110697884ARaise the initial concentrationIncrease biomassSustainable biological treatmentBiological water/sewage treatmentActivated sludgeAlgae

The invention discloses a low-temperature cultivation algal-bacterial symbiotic granular sludge method. The method comprises the steps that activated sludge subjected to acclimation or mature aerobicgranular sludge is inoculated to a gas stripping type batch reactor, algae fluid is fed into the reactor, stuffy aeration is carried out for 3 days to 7 days after the algae fluid is fed, the reactorreceives light and aeration during the process of stuffy aeration without drainage, and nutrients are fed into the reactor every four hours to eight hours, and after stuffy aeration is finished, the reactor runs according to the process including low-speed water inlet, aeration, sedimentation and drainage with the cycle ranging from 4 hours to 8 hours; and the process mentioned above is carried out on the condition that the indoor temperature ranges from 9 DEG C to 15 DEG C, and when the inoculated sludge is the aerobic granular sludge, the reactor runs for 3 days to 10 days according to the cycle to generate green or brown algal-bacterial symbiotic granules. The algal-bacterial symbiotic granules cultivated with the low-temperature cultivation algal-bacterial symbiotic granular sludge method has the advantages of being capable of resisting the low-temperature environment, high in treatment efficiency, good in sedimentation performance and the like, and the method is an efficient, economic and environment-friendly sewage treatment strategy, and thereby having the good application prospect and great significance.

Owner:SHANDONG UNIV

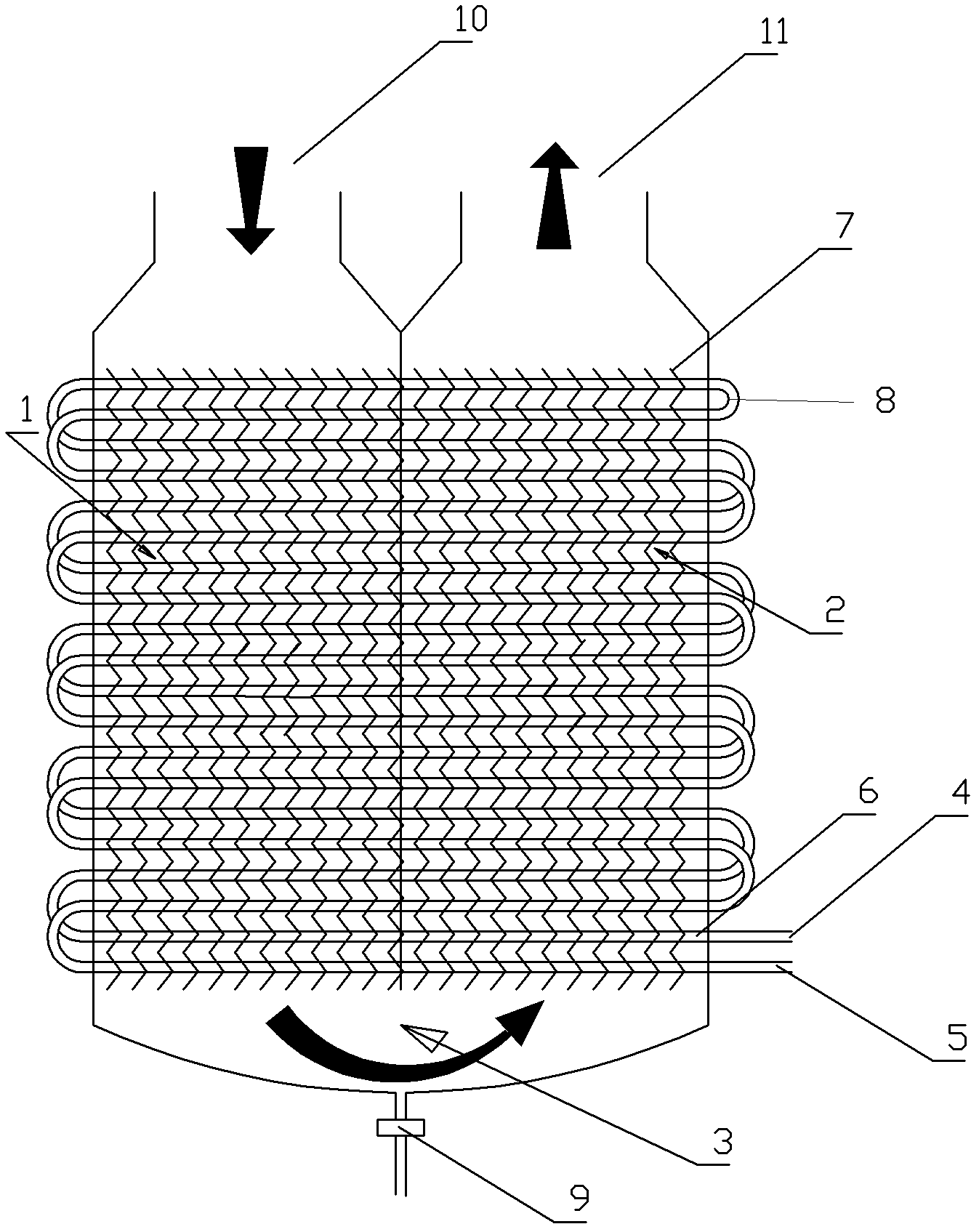

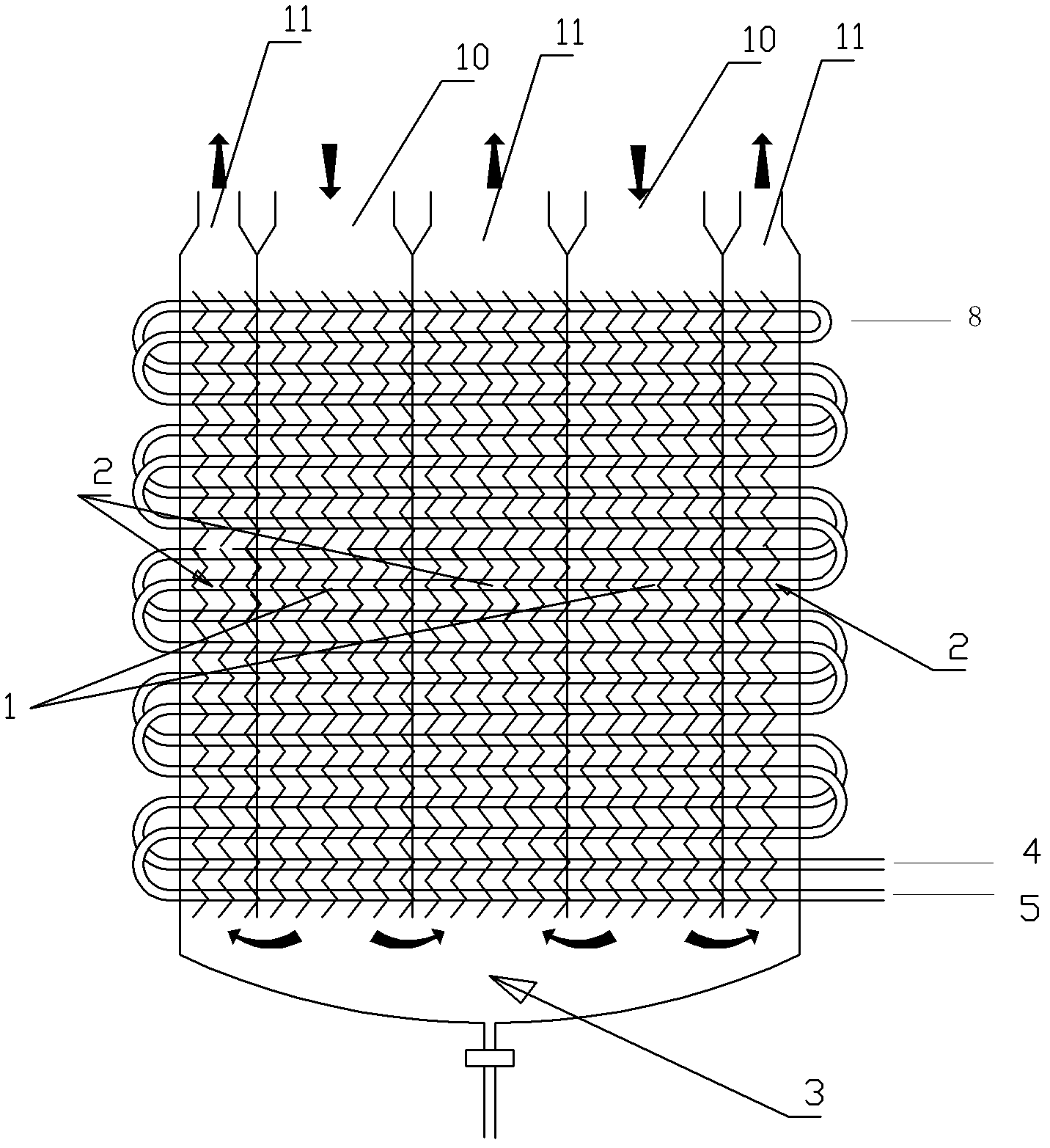

Device for condensation liquefaction recovery of organic exhaust gas

ActiveCN102716597AReduce recycling costsSimple structureVapor condensationProcess engineeringEngineering

The invention discloses a device for condensation liquefaction recovery of organic exhaust gas. The device is characterized in that the device comprises an inlet gas heat exchange chamber, an outlet gas heat exchange chamber and a liquid inlet pipe; cooling fins are respectively arranged in the inlet gas heat exchange chamber and the outlet gas heat exchange chamber; the liquid inlet pipe circuitously extends upward from bottom to top and then goes back to the initial position along a route close to an original route; all horizontally-arranged horizontal pipe sections of the liquid inlet pipe respectively pass through the cooling fins; the top of the inlet gas heat exchange chamber is provided with an inlet; the top of the outlet gas heat exchange chamber is provided with an outlet; the bottom of the inlet gas heat exchange chamber is communicated with the bottom of the outlet gas heat exchange chamber by a sealing connection chamber; and the sealing connection chamber is provided with an outlet. The device for condensation liquefaction recovery of organic exhaust gas is environmentally friendly, has high efficiency, saves energy, reduces a cost of exhaust gas recovery, has a simple structure, and has functions of recovering organic exhaust gas and dehumidifying air.

Owner:GUANGDONG PHNIX ECO ENERGY SOLUTION

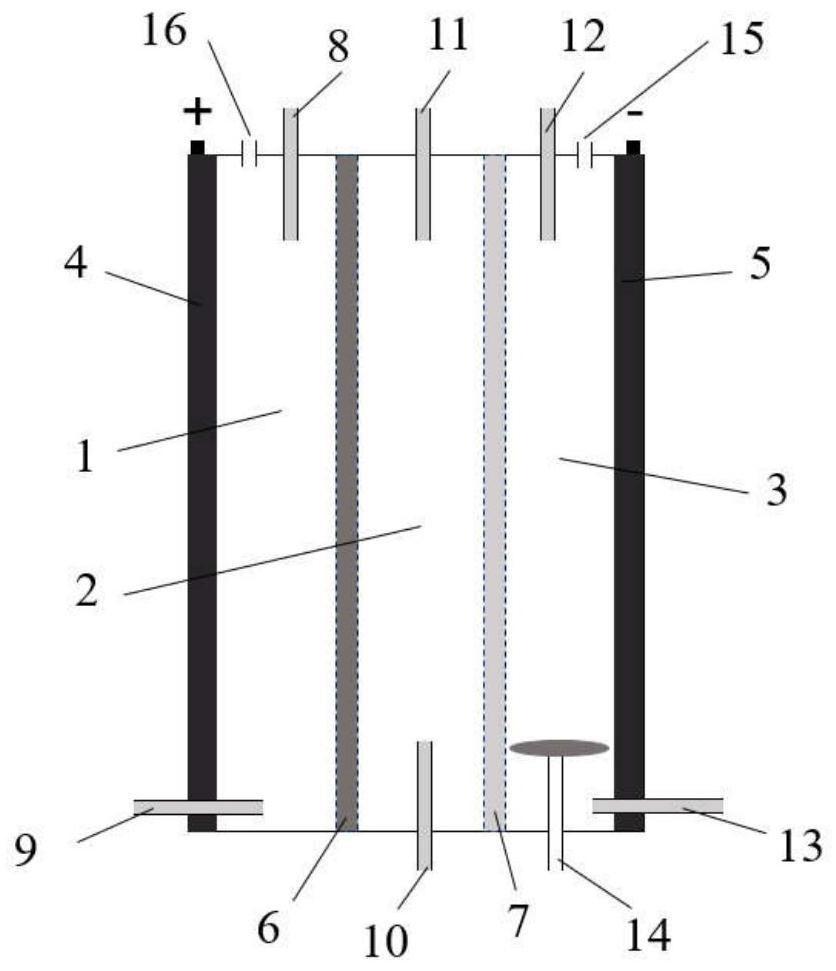

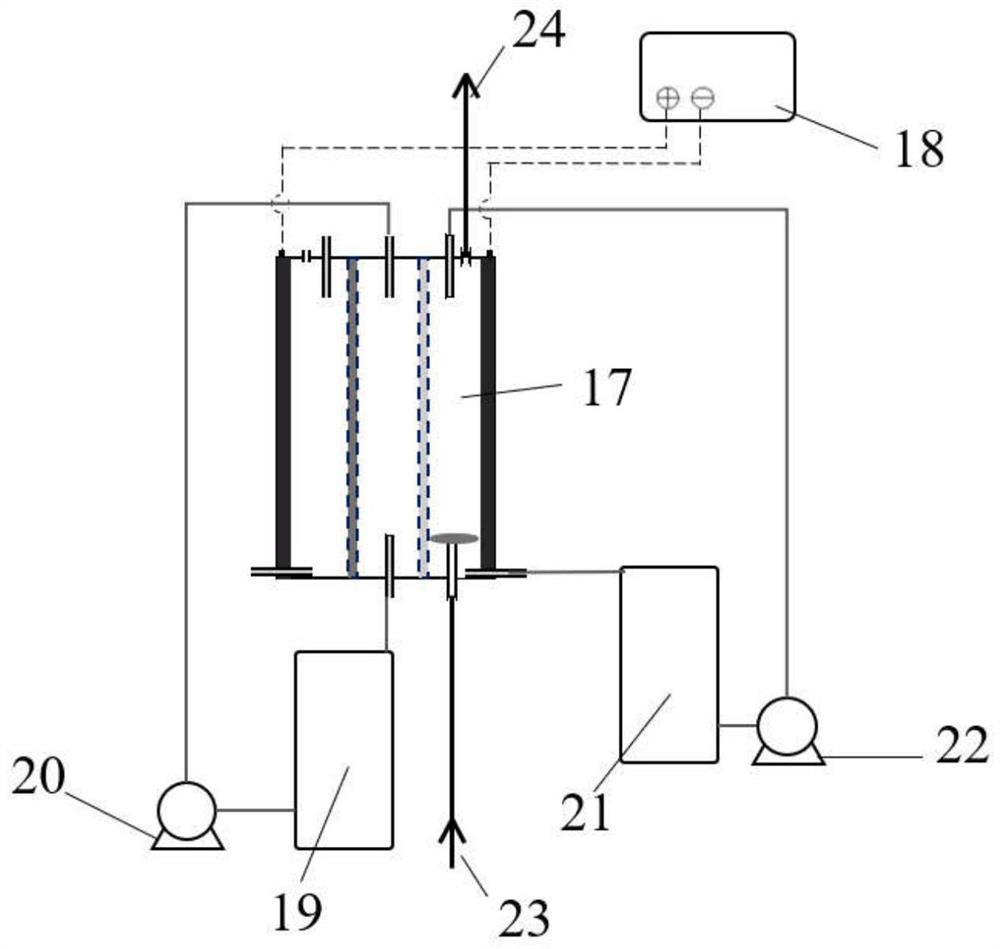

Method and device for capturing carbon dioxide and simultaneously producing sulfuric acid by sodium bisulfate

The invention belongs to the field of flue gas purification, and discloses a method and a device for capturing carbon dioxide and simultaneously producing sulfuric acid by using sodium bisulfate. According to the method, a desulfurization byproduct (NaHSO4) is converted into H2SO4 by using a three-grid electrodialysis device, and CO2 in flue gas is captured in a cathode chamber. Under the action of electric field driving and an ion exchange membrane, HSO4<-> enters an anode chamber to generate H2SO4 and is concentrated, and Na<+> enters the cathode chamber to generate NaOH; and CO2 containinggas to be treated is introduced from the cathode chamber and is absorbed and captured by NaOH. The technology is simple, green and economical, carbon dioxide in the flue gas is captured in the comprehensive utilization process of the sodium bisulfate solution, good environmental benefits are achieved, updating and upgrading of the flue gas treatment technology in China are promoted, and the treatment pressure of desulfurized gypsum is relieved.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Method for burning organic silicon waste gas and recycling diluted hydrochloric acid

InactiveCN101922717AReduce contentImprove dust removal effectChlorine/hydrogen-chlorideEnergy inputSilica particleVapor–liquid separator

The invention discloses a method for burning organic silicon waste gas and recycling diluted hydrochloric acid. The recyclable diluted hydrochloric acid is obtained by the steps of burning at high temperature in an incinerator, recycling in a waste heat boiler, dedusting by a high-efficient deduster, cooling in a quench tower and absorbing in a falling film absorber, wherein the high-efficient deduster is a PCHD type high-efficient deduster manufactured by Tianci Dedusting Device Plant, Fujian. In the invention, a high-efficient deduster drying method is utilized for adsorption and dedusting and can be used for removing a great part of most silica granules and other impurities in gas; and then the quench tower is used for cooling smoke. The invention has good dedusting effect compared with the prior art adopting the steps of firstly cooling smoke by the quench tower, and then spraying and dedusting by utilizing a circular diluted hydrochloric acid wet method of a Venturi and a gas-liquid separator. The content of nanosilica granules in the recycled diluted hydrochloric acid granules is reduced to be lower than 10ppm, the reuse value of the recycled diluted hydrochloric acid is enhanced, and the application field of the high-efficient deduster is widened.

Owner:SEDIN NINGBO ENG

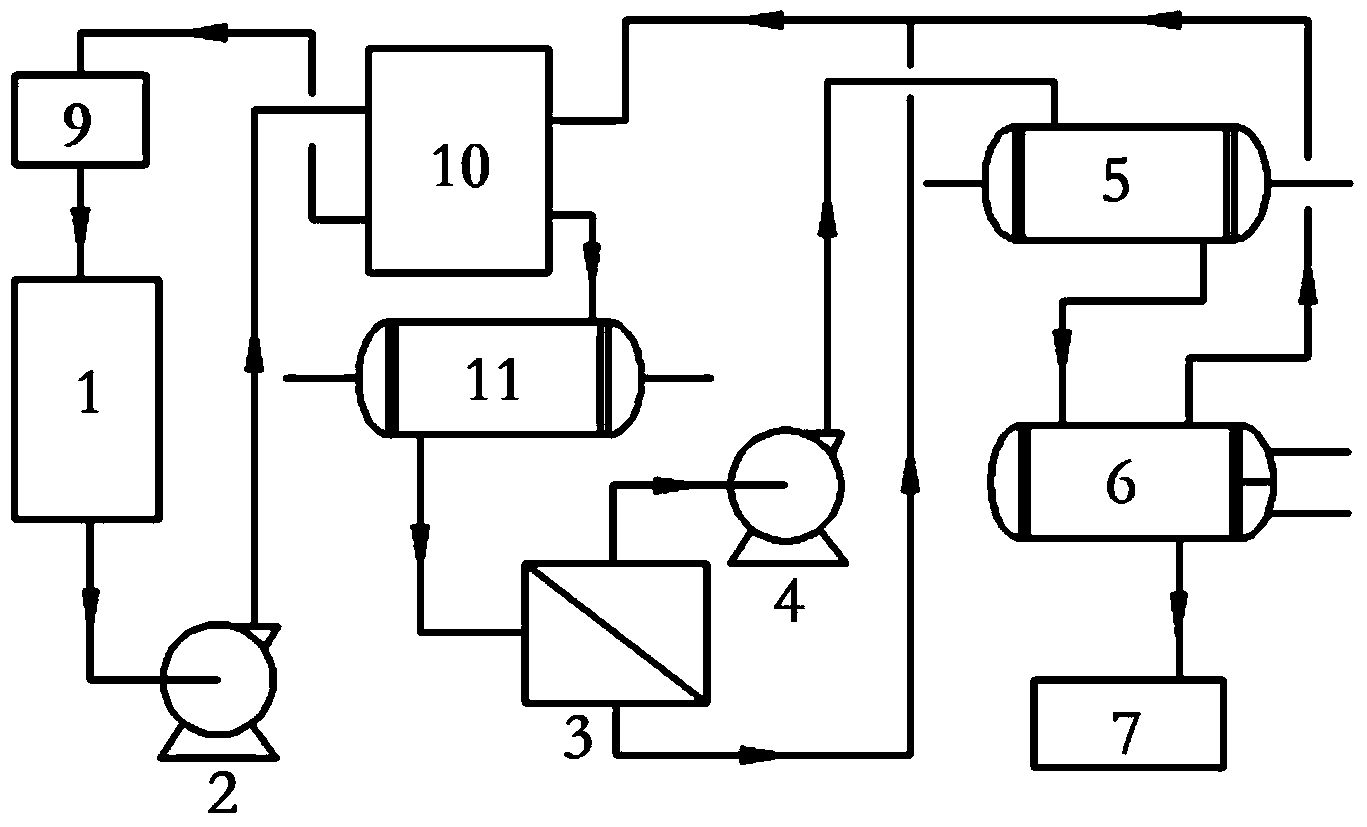

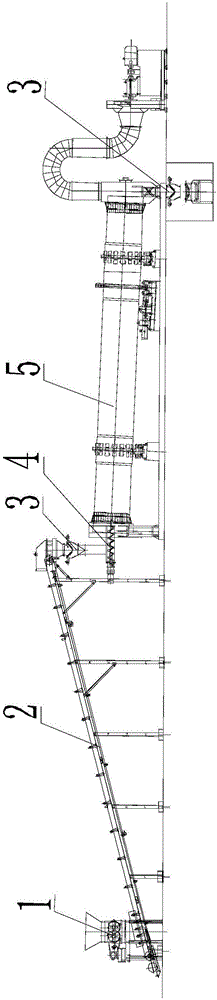

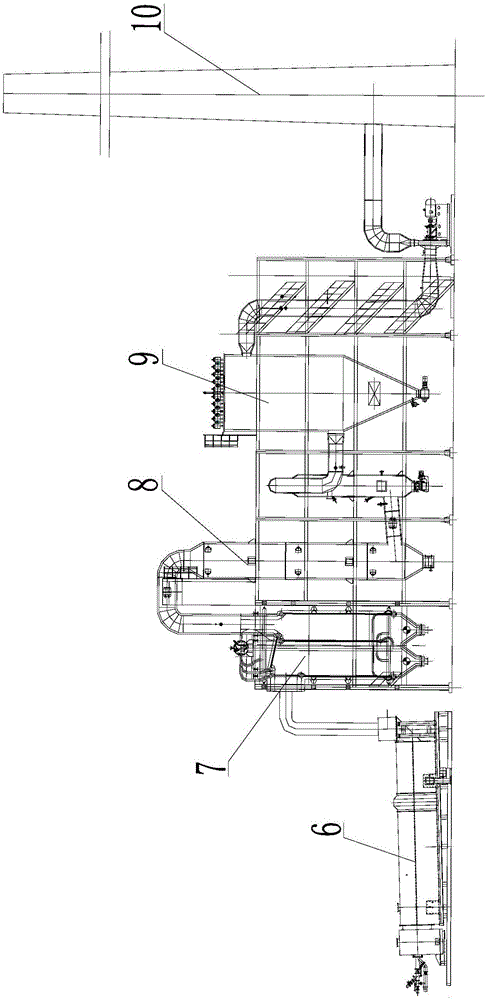

Harmless treatment system for oil field sludge

InactiveCN106196107AStable combustion temperatureGuaranteed combustion qualitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCatalytic pyrolysisSludge

The invention discloses a harmless treatment system for oil field sludge, and relates to a harmless treatment device for mixed sludge, which contains complex chemical compositions and is high in content of pollutants, in oil field exploitation. The harmless treatment system comprises a feeding device, a rotating drying machine, a catalytic pyrolysis furnace, a waste heat boiler, a quench tower, an absorption tower and a chimney. The feeding device is located at the inlet end of the rotating drying machine. The outlet end of the rotating drying machine is connected with the inlet end of the catalytic pyrolysis furnace. The outlet end of the catalytic pyrolysis furnace is connected with the inlet end of the waste heat boiler. The number of the outlet ends of the waste heat boiler is two, wherein one outlet is a flue gas outlet connected with the inlet end of the absorption tower to collect dust in flue gas particles, and the other outlet is a hot water outlet connected to a domestic water or production water pipeline through a pipeline. The outlet end of the absorption tower is connected with the chimney. The harmless treatment system has the characteristics of novel structure, mature technology, high waste heat utilization rate, relatively thorough harmless treatment, environmental protection and energy conservation.

Owner:朝阳重型机器制造有限公司

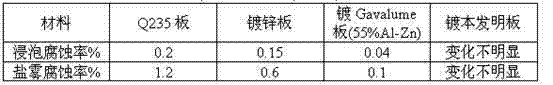

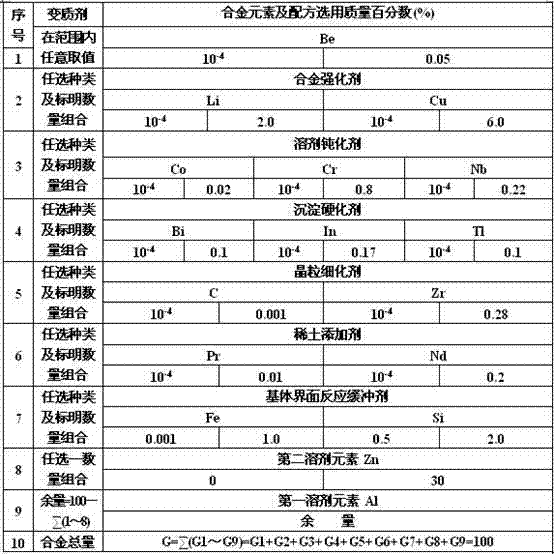

Immersion plating aluminum alloy coating materials with low cost and high property

The invention discloses immersion plating aluminum alloy coating materials with low cost and high property. By element weight percentage, components of the alloy comprise 5-15 parts of zinc, 10-4-10-3 parts of polarization metamorphic agent, 0.1-1.0 part of lithium, 0.1-0.2 part of carbonic oxide, 0.25-0.5 part of precipitation hardening agent, 0.2-0.3 part of grain refiner, 0.01-0.1 part of lanthanum, 0.3-0.8 part of substrate interface reaction buffer, aluminium and inevitable microimpurity. The immersion plating aluminum alloy coating materials are low in cost and high in property.

Owner:贵州铝厂有限责任公司

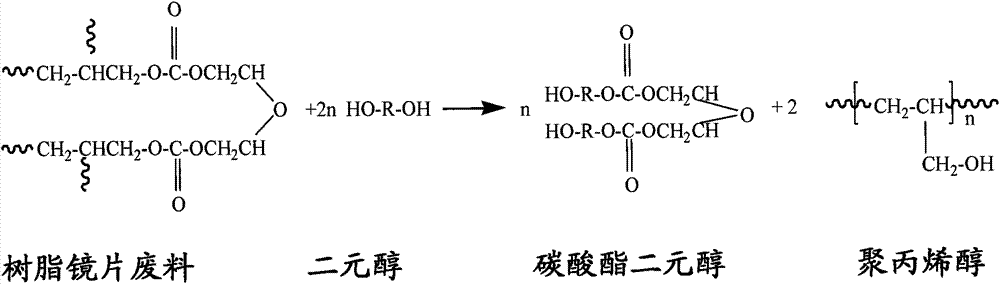

Recycling method of thermosetting resin lens waste

ActiveCN103483620AIncrease the value of reuseImprove use valuePlastic recyclingAlcoholReaction temperature

The invention discloses a recycling method of thermosetting resin lens waste. The method includes: (1) preparing thermosetting resin lens waste powder; (2) in terms of mass, adding 100 parts of the thermosetting resin lens waste powder, 100-400 parts of an alcoholysis agent, and 0.4-6 parts of a catalyst into a reactor; (3) controlling the alcoholysis reaction temperature at 120DEG C-260DEG C; and (4) letting the reaction last for 1-3h, then stopping heating, and performing cooling to obtain an alcoholysis product. According to the method provided in the invention, the resin lens waste undergoes thorough alcoholysis, the reaction time is short, and the solution transparency is good. The catalyst dosage is small, no influence can be generated on the product application, and the recycling value of the alcoholysis product is enhanced.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

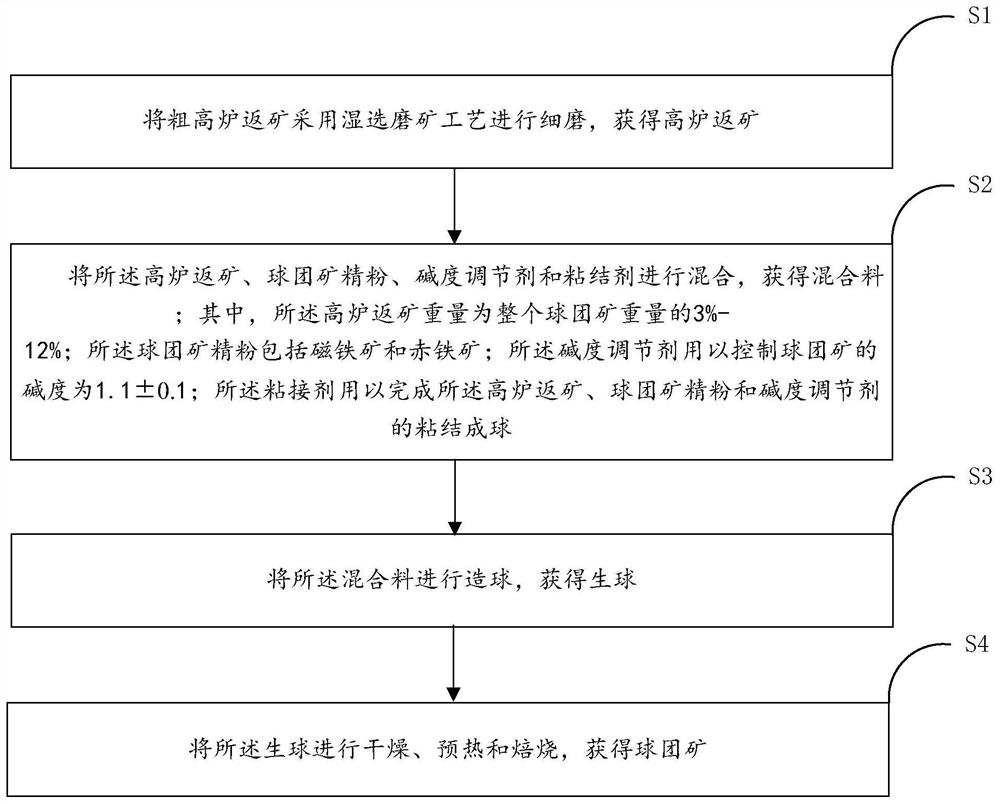

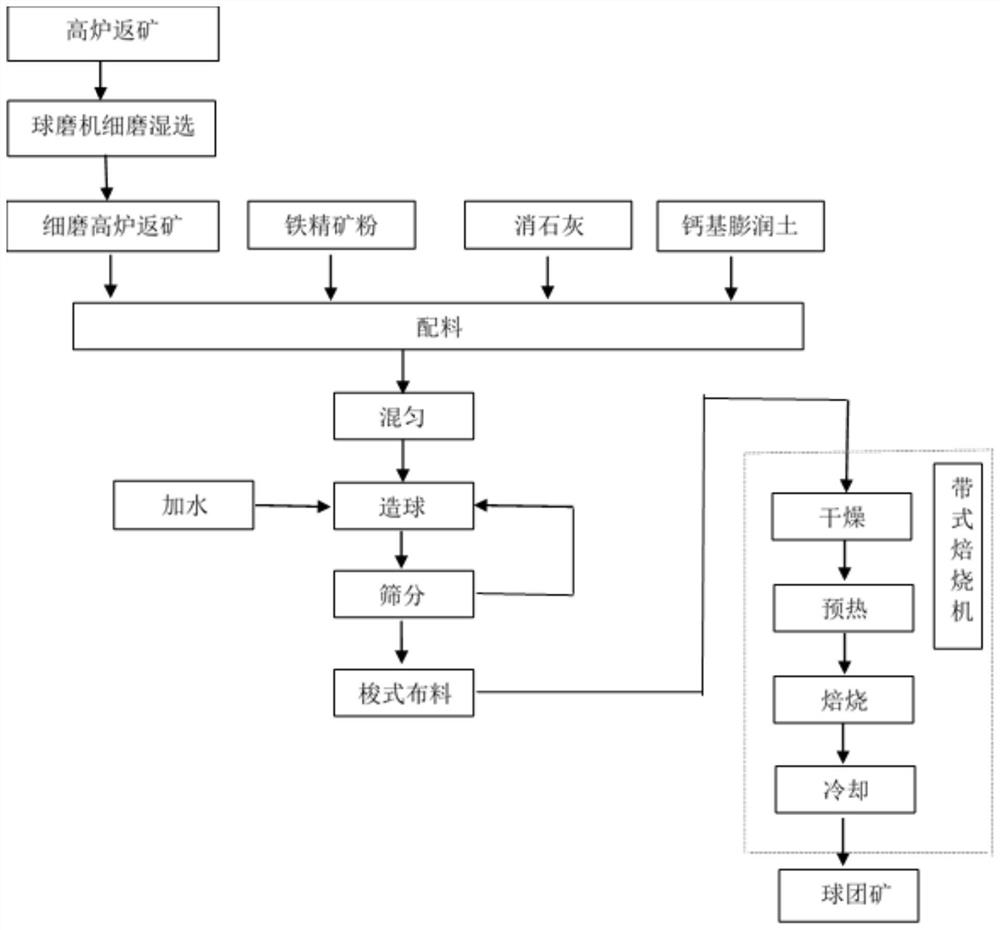

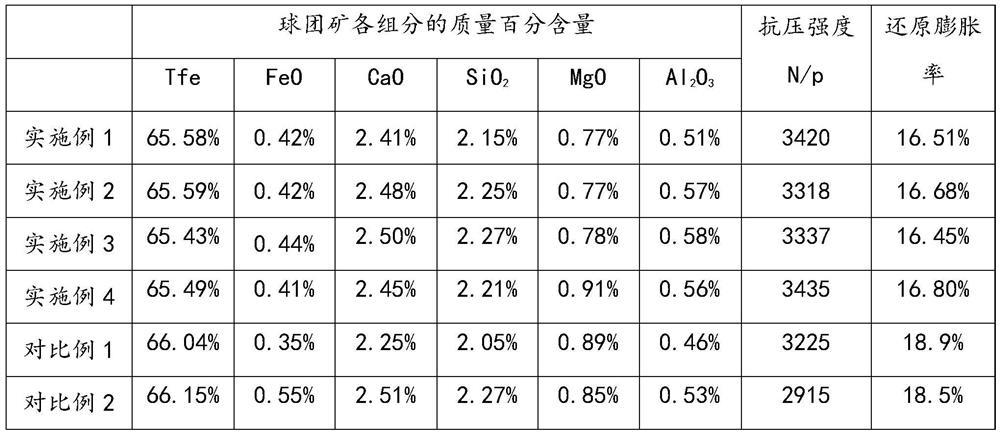

Pellet and preparation method thereof

ActiveCN113186391AImprove product qualityLow costBlast furnace detailsProcess efficiency improvementSocial benefitsMagnetite

The invention particularly relates to a pellet and a preparation method thereof, and belongs to the technical field of blast furnace burden. The pellet comprises the following components of blast furnace return mine, pellet fine powder, an alkalinity regulator and a binder, wherein the weight of the blast furnace return mine is 3-12% of the weight of the whole pellet; the pellet fine powder comprises magnetite and hematite; and the alkalinity regulator is used for controlling the alkalinity of the pellet to be 1.1 + / -0.1. The pellet and the method provide a new utilization approach for the blast furnace return mine, improve the reuse value of the blast furnace return mine, not only can realize efficient resource utilization of valuable elements such as Fe, Ca, Mg and Ti in the blast furnace return mine, but also can produce pellet with excellent quality, environment friendliness and lower cost, meanwhile, after the blast furnace return mine is added, the reduction expansion rate of the pellet is effectively reduced, the blast furnace return mine is added to replace part of high-price pellet concentrate powder, pellet which is good in quality, environmentally friendly and low in cost is produced, and larger environmental benefits, social benefits and economic benefits are obtained.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Humic fertilizer and preparation method thereof

InactiveCN105541422AImprove production efficiencyShort preparation timeOrganic fertilisersEnzymatic hydrolysisThree stage

The invention discloses a humic fertilizer and a preparation method thereof, relates to the field of organic fertilizers, in particular to the field of humic fertilizers, and also relates to the preparation field of humic fertilizers at the same time. According to the preparation method disclosed by the invention, by virtue of a three-stage screw extruder, plant wastes together with coal gangues are subjected to crushing, mild enzymatic hydrolysis, and microbial fermentation to realize fast, efficient and continuous preparation of the humic fertilizer, the used equipment is simple, and the used raw materials are clean and environment-friendly, so that the humic fertilizer has a good economic prospect.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Packaging method for vacuum package which can be repeatedly manufactured and used

InactiveCN101565106AIncrease the value of reuseReduce the amount requiredPackage recyclingAgriculture tools and machinesCheck valveVacuum pump

The invention relates to a packaging method for a vacuum package which can be repeatedly manufactured and used, which is characterized in that a sealing packaged article outlet is arranged on a packaging body with a sealing packaged article inlet, a self-sealing unidirectional exhausting nozzle or a check valve is arranged on the outlet or the packaging body, when the packaged article is packaged in the packaging body through the inlet, the inlet is sealed; gas in the packaging body is pumped by connecting a portable vacuum pump with the unidirectional exhausting nozzle or the check valve, thereby manufacturing vacuum package. The present invention can repeatedly manufacture or use the vacuum package, can randomly adjust pressure according to requirement of packaging body, greatly develops application range of the vacuum package, is simple, convenient and flexible, fully increases recycling value of package, reduces pollution, saves more than half of package amount, improves the package quality more than double, and can be reclaimed for other use.

Owner:刘同益

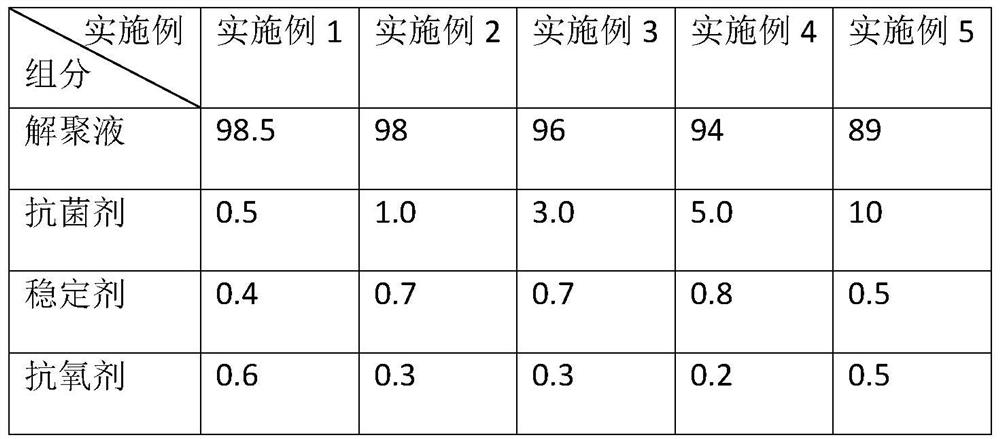

Method for preparing antibacterial regenerated polyester by waste polyester alcoholysis method

Owner:ZHEJIANG SCI-TECH UNIV

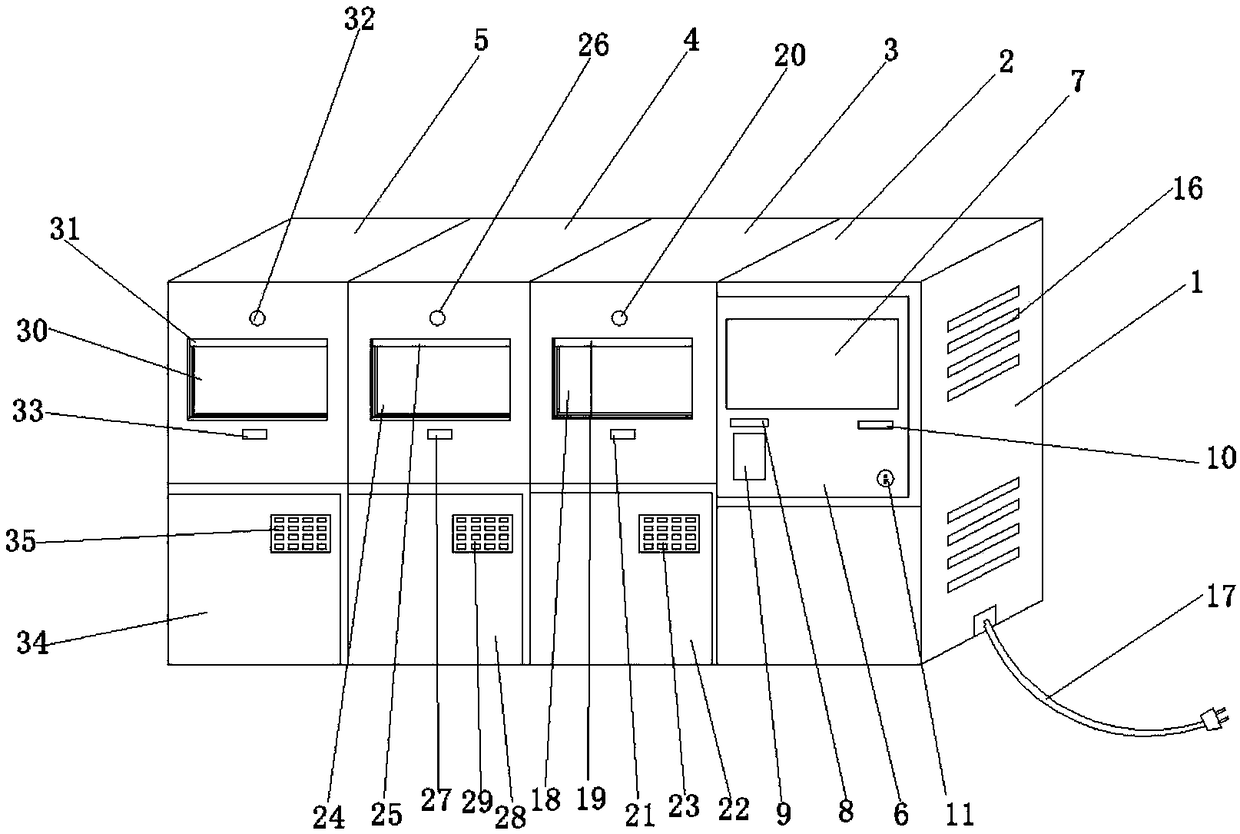

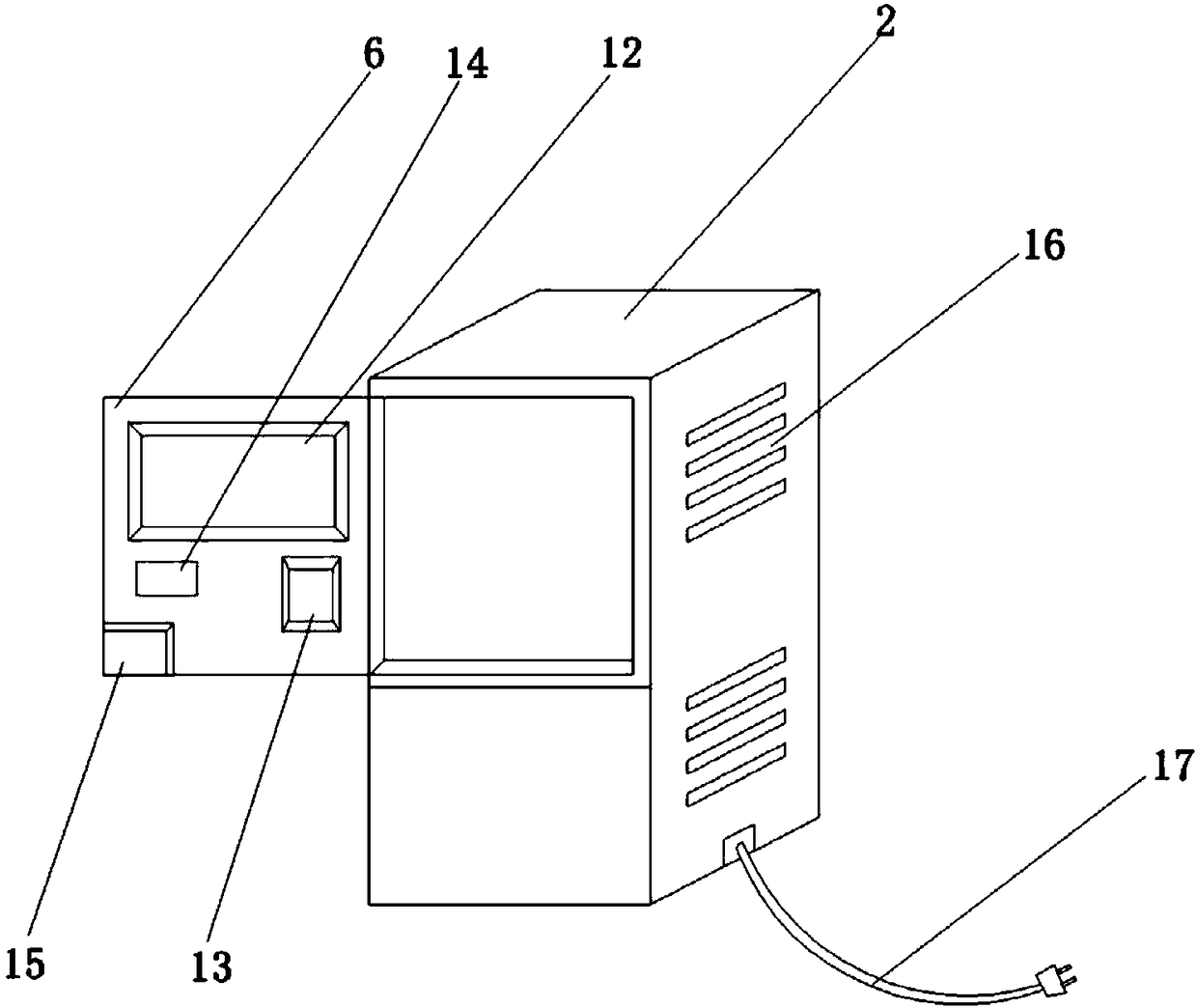

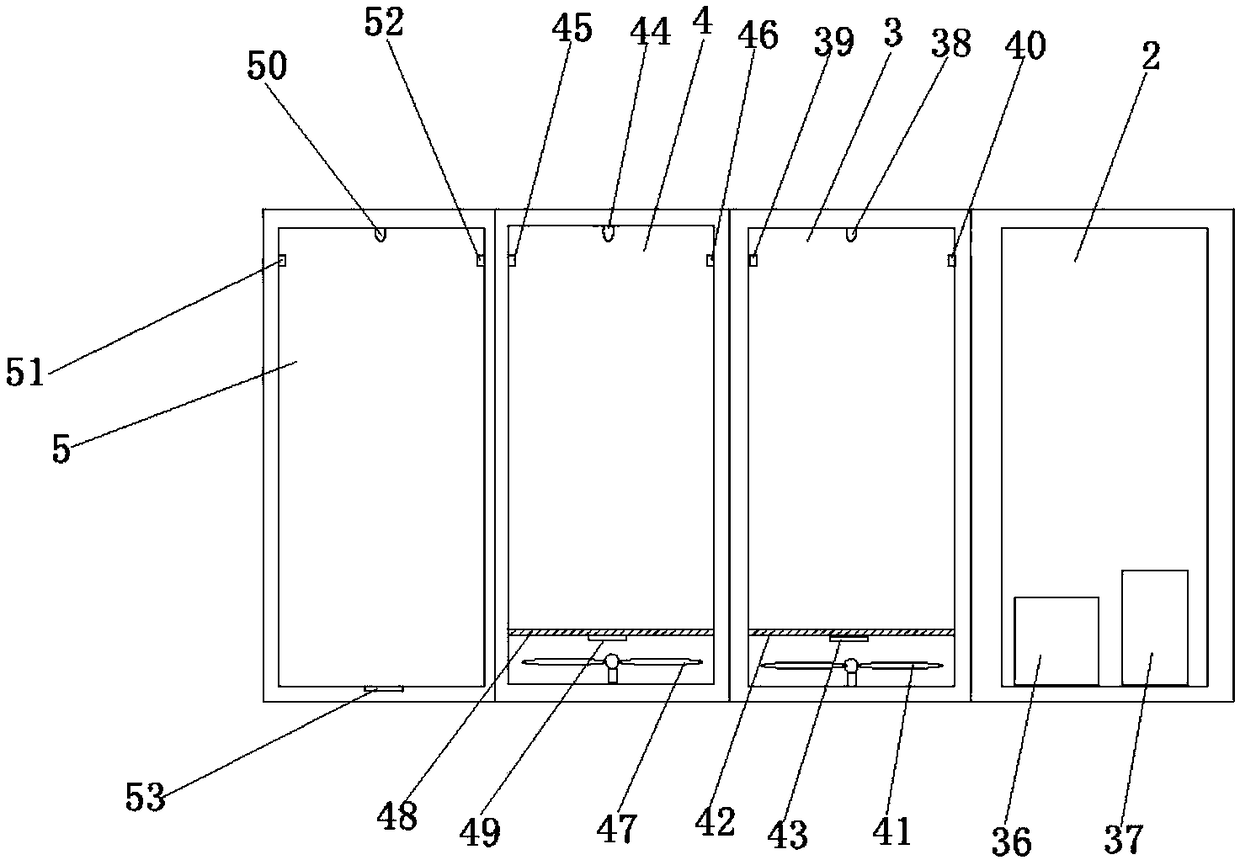

Renewable resource classification and recovery box

InactiveCN108328155ARaise recycling awarenessIncrease the value of reusePaper recyclingWaste collection and transferComputer moduleCard reader

The invention provides a renewable resource classification and recovery box. The renewable resource classification and recovery box comprises a box main body; the box main body is divided into a mainbox body, a first sub-box body, a second sub-box body and a third sub-box body; an access door is arranged on the upper portion of the front side of the main box body; a touch screen is arranged on the upper portion of the front side of the access door; a bank card slot is formed in the left side of the lower portion of the touch screen; a radio frequency card reader is arranged on the lower portion of the bank card slot; a bill outlet is formed in the right side of the lower portion of the touch screen; a plug is arranged on the lower portion of the bill outlet; and an input and output moduleis arranged on the upper portion of the reverse side of the access door and corresponds to the touch screen. According to the renewable resource classification and recovery box, different types of waste such as metal, plastic and paper can be weighed, fees can be returned, so that people can classify the waste and then put the waste into the recovery box, and therefore the enthusiasm of people can be improved, the recovery treatment awareness of the waste can be enhanced, and the recycle value of the waste can also be enhanced.

Owner:湖州高锐工贸有限公司

Flue-gas biological desulphurization and organic wastewater combined treatment method

InactiveCN102476862ASmall footprintSimple and fast operationDispersed particle separationTreatment with aerobic and anaerobic processesSulfate radicalsEmission standard

The invention relates to a flue-gas biological desulphurization and organic wastewater combined treatment method. Biochemical pollutant in organic wastewater is used as a special nutrition source for high-efficiency alkaline-producing bacteria, sufficient alkalinity is generated, sulfur dioxide in flue gas is absorbed and neutralized, the absorbed SO2 is oxidized to form sulfate radical by the aid of a catalytic effect of microbial enzyme, and the flue gas is purified and meets the emission standard. Simultaneously, synchronous treatment of the wastewater is realized by the aid of biological desulphurization to a certain degree. Waste heat of the flue gas is absorbed by the wastewater, the temperature of water of a wastewater drainage desulphurization unit can reach 30 DEG C at least, the problem of difficulty in biochemical treatment due to over low temperature of wastewater in winter is solved, the waste heat of the flue gas and the biochemical pollutant in the waste water can be utilized to the greatest extent, and elemental sulfur can be obtained from the sulfate radical by the aid of a reducing bacterial and biochemical oxidization effect in follow-up wastewater biochemical treatment.

Owner:庞金钊

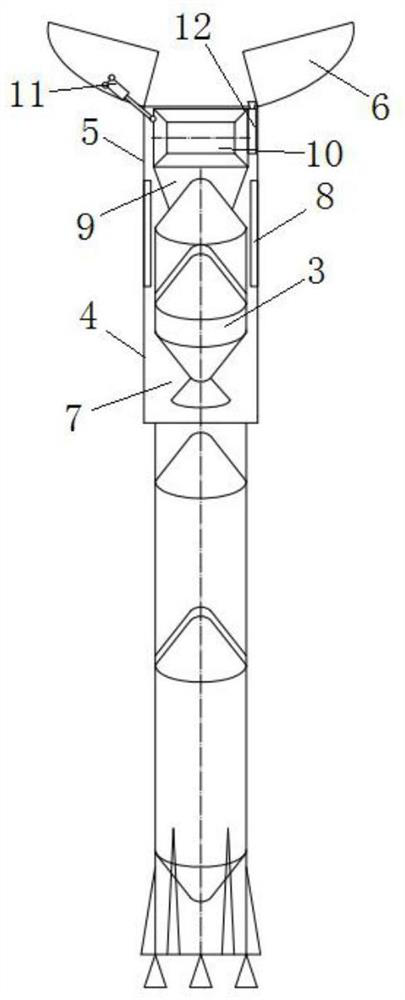

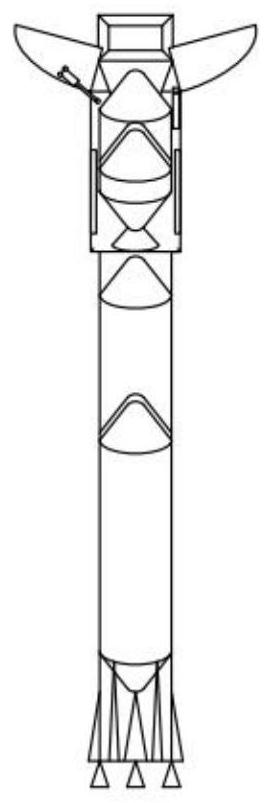

End cover and first-stage integral recovery low-cost second-stage low-orbit carrier rocket

PendingCN113148230AHigh reuse valueImproved flight environmentCosmonautic vehiclesCosmonautic partsSatelliteStructural engineering

The invention discloses an end cover and first-stage integral recovery low-cost second-stage low-orbit carrier rocket which comprises a first-stage rocket body, a rocket sleeve cover and a second-stage rocket body, wherein the rocket sleeve cover comprises a barrel cover, an end cover shell section and an end cover, the barrel cover is arranged at the front end of the first-stage rocket body, and the barrel cover is used for containing the second-stage rocket body; the bottom of the barrel cover is provided with an adaptive support used for installing a second-stage rocket body, the inner wall of the barrel cover is provided with a sliding rail combination, the sliding rail combination is connected with the second-stage rocket body in a sliding fit mode, the front end of the second-stage rocket body is provided with a satellite adaptive support, and a satellite load is installed on the satellite adaptive support; the end cover is composed of a plurality of petals hinged to an end cover shell section, the multi-petal end cover is in a hemisphere shape after being folded, and opening and closing of the end cover are controlled through an end cover actuator; and a reverse thrust rocket is further arranged at the front end of the inner wall of the end cover shell section. According to the end cover and the first-stage overall recovery low-cost second-stage low-orbit carrier rocket, 100% overall recovery can be achieved, repeated use can be achieved after detection and evaluation, and the reuse value is higher.

Owner:精易兴航(北京)科技创新有限公司

Method for preparing self-adhesive antibacterial sheath-core fiber by regenerating waste polyester

PendingCN112760748AKeep green and environmental protectionReduce white pollutionMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention discloses a method for preparing a self-adhesive antibacterial skin-core fiber by regenerating waste polyester. The method is characterized in that antibacterial low-melting-point regenerated polyester is used as a skin layer, regenerated polyester is used as a core layer, and a coaxial self-adhesive antibacterial skin-core structure composite fiber is prepared through melt composite spinning. On one hand, prepared fibers completely adopts the recycled polyester as a raw material, the green and environment-friendly characteristics of the recycled polyester are well maintained, the current white pollution problem of the waste polyester is effectively relieved, meanwhile, energy conservation and emission reduction are achieved, petroleum consumption is reduced, and extremely high environment-friendly benefits are achieved; and on the other hand, nano-silver or cuprous oxide is used as an antibacterial agent to endow the regenerated polyester with a broad-spectrum antibacterial effect, so that the self-adhesion performance and high-value applicability of the regenerated polyester are remarkably improved, the reutilization value of the waste polyester is favorably improved, the regenerated polyester industry is promoted to develop towards high-end application, and then industry development and industry transformation and upgrading are promoted.

Owner:ZHEJIANG SCI-TECH UNIV

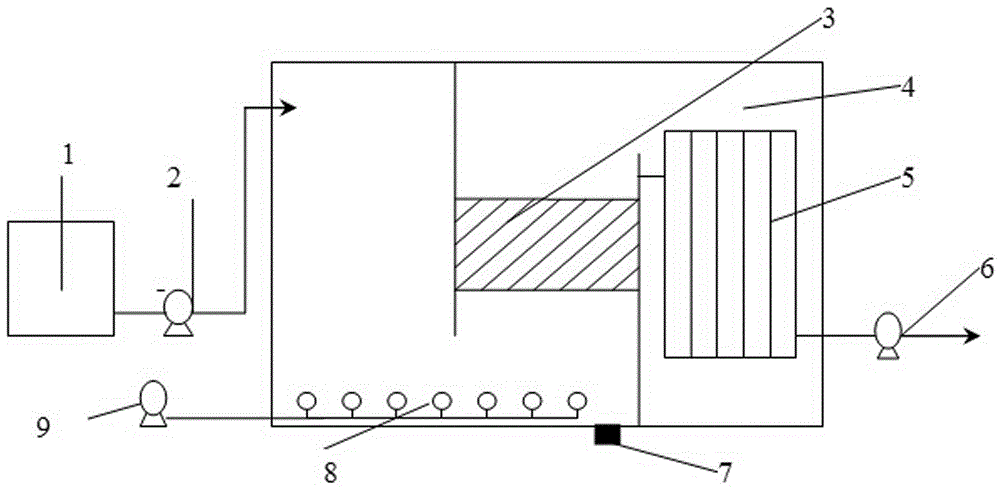

Integrated membrane bioreactor for recycling schoolyard wastewater

InactiveCN106219742ASave resourcesReduce pollutionBiological treatment apparatusSustainable biological treatmentEconomic benefitsEngineering

The invention discloses an integrated membrane bioreactor for recycling schoolyard wastewater. The integrated membrane bioreactor comprises a water inlet tank, a water inlet pump, an inclined plate, a membrane bioreactor, a membrane component, a sucking pump, a sludge discharge hole and an aerator, wherein the water inlet tank is connected with the water inlet of the membrane bioreactor via the water inlet pump; the sludge discharge hole is formed in the bottom of the membrane bioreactor; the inclined plate, the membrane component and the aerator are arranged inside the membrane bioreactor; the aerator is arranged at the bottom of the membrane bioreactor; the inclined plate is positioned on the water inlet side of the membrane bioreactor; the membrane component is positioned on the water outlet side of the membrane bioreactor and is connected with the sucking pump. As the integrated membrane bioreactor is organically combined with schoolyard wastewater, not only is schoolyard wastewater effectively treated, but also treated water can be recycled for toile flushing, greening and the like, and environmental benefits and economic benefits of urban pollution treatment, energy conservation and emission reduction and pollutant recycling and reuse are increased to a very large extent.

Owner:曹雯雯

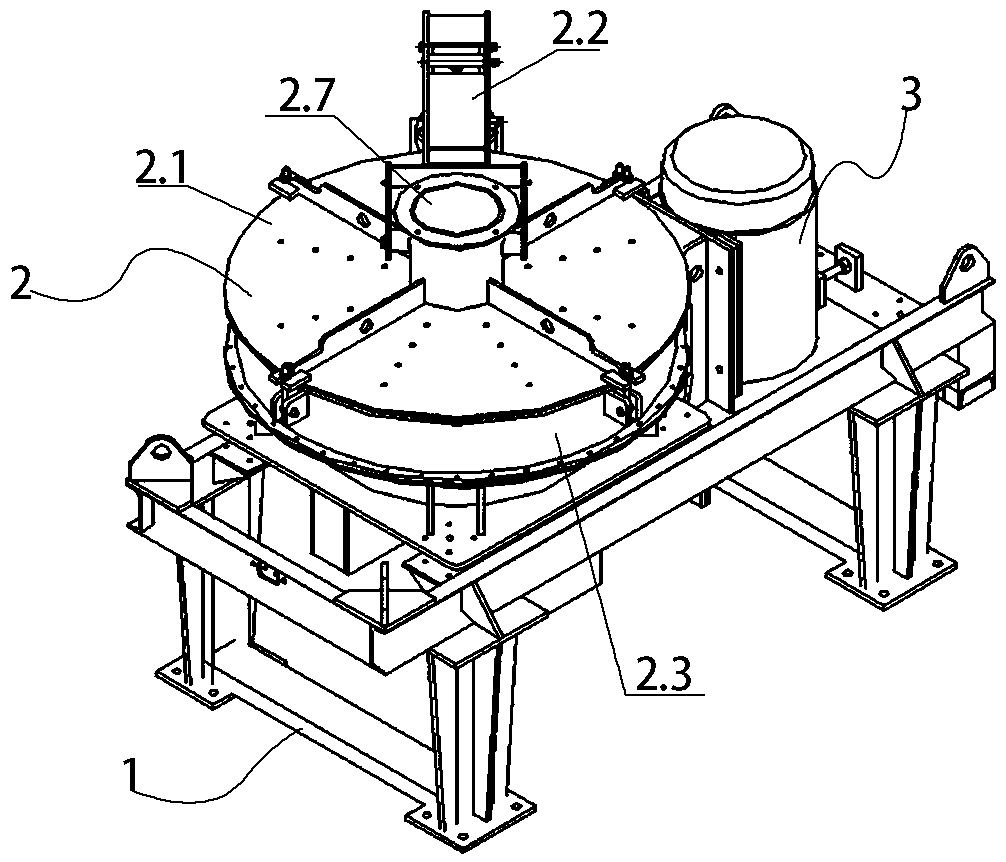

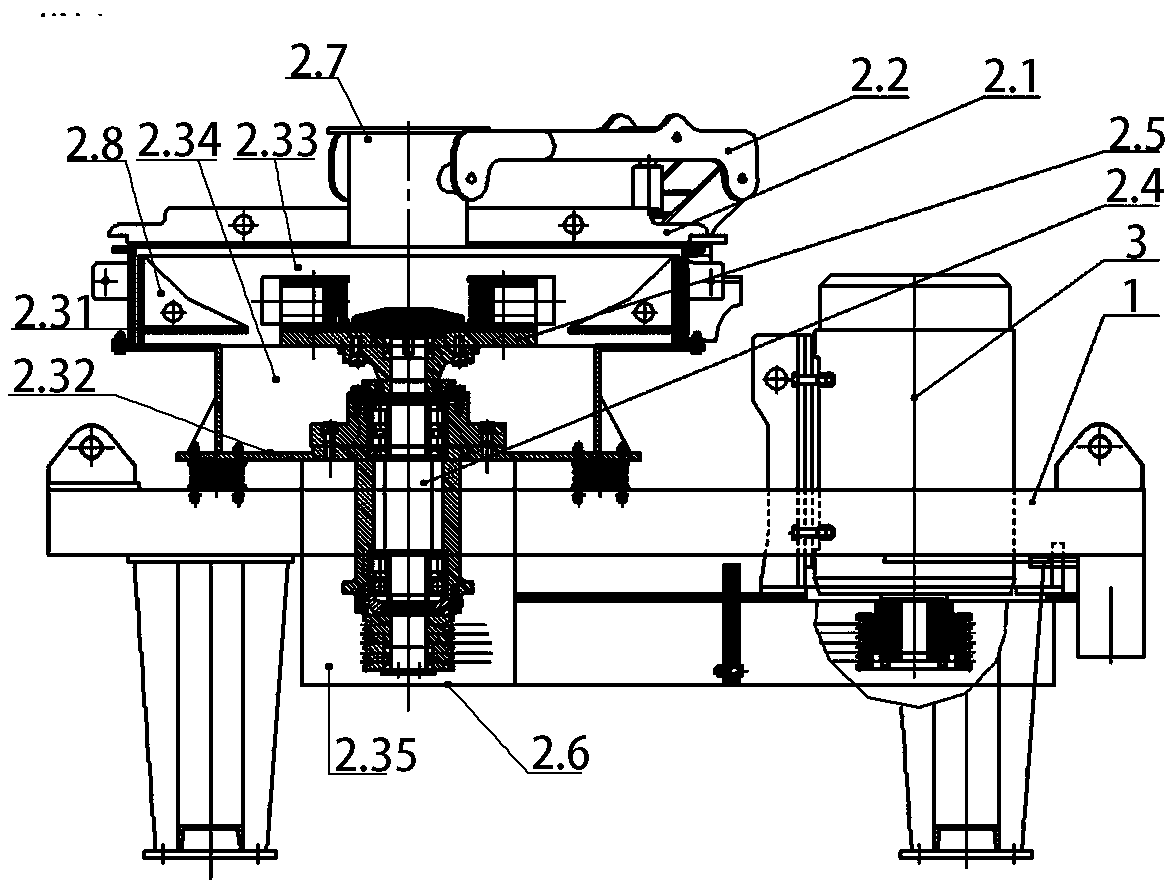

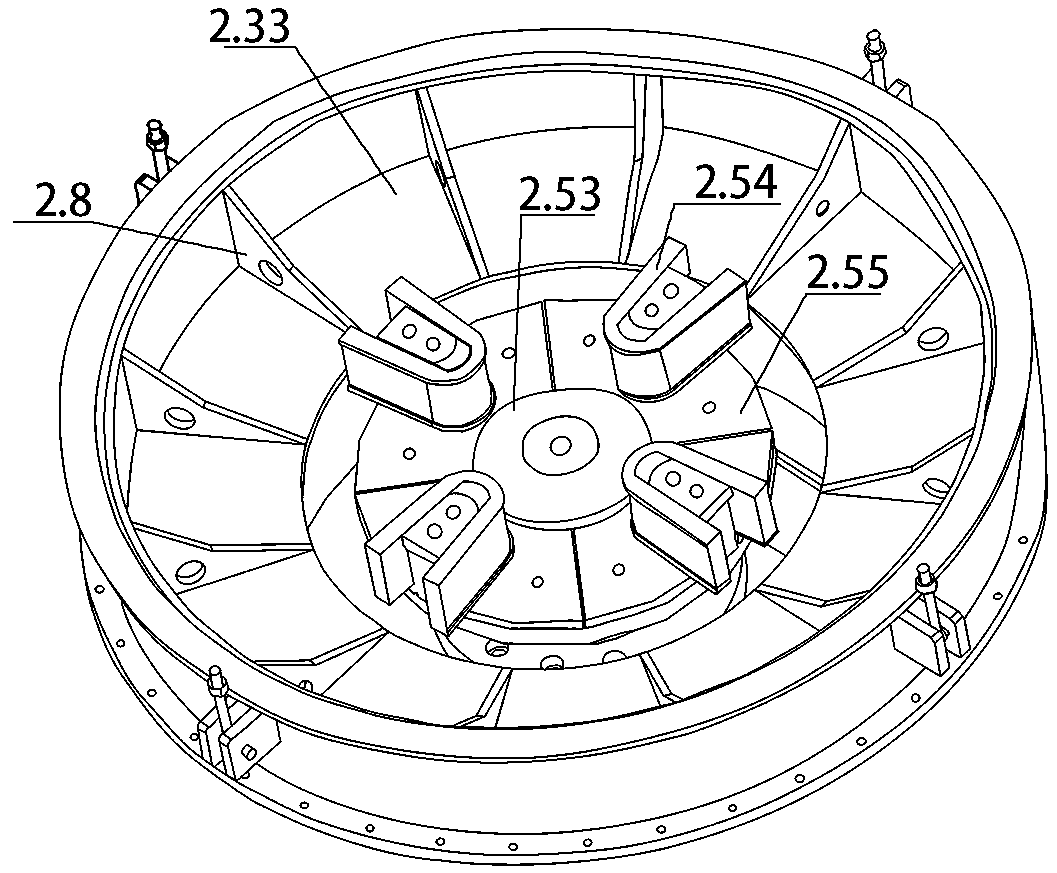

Centrifugal recycled aggregate stripping shaper

PendingCN110523497AAchieve strippingAchieving processing powerGrain treatmentsElectric machineryEngineering

The invention discloses a centrifugal recycled aggregate stripping shaper. A machine body comprises a stripping bin, a driving main shaft and a stripping rotor; the driving main shaft is arranged in the center of the stripping bin and powered by a motor; the stripping rotor is arranged on the driving main shaft and comprises a rotating shaft, a turntable, a material distribution conical head and arunner head; a steel lining is laid on the turntable; the material distribution conical head is located in the center of the turntable, and the runner heads are evenly distributed around the materialdistribution conical head. Materials enter the shaper and are rapidly accelerated by the material distribution conical head, then the materials are thrown to the periphery by the horseshoe-shaped runner heads and impact on a wing plate of a shaping bin and form a continuous material curtain with the materials thrown out by the runner heads after being rebounded; the materials are crushed in a crushing cavity under the multiple impact action of the steel lining and other materials, and complete separation is achieved. The centrifugal recycled aggregate stripping shaper is reasonable in structure, high in stripping and shaping efficiency, high in natural aggregate reduction degree, free of damage to the performance, capable of effectively reducing the cost and improving the recycled aggregate quality and recycling value and suitable for large-batch concrete solid waste treatment.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

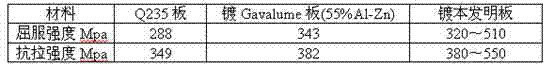

Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and preparation method thereof

InactiveCN102650026AOrganizational structure optimizationAchieving resistance to acid, alkali and salt corrosionHot-dipping/immersion processesAlloy coatingUltimate tensile strength

The invention discloses a Be and multi-combination degenerative low-zinc hot-dipped aluminum alloy coating material and a preparation method thereof. The alloy comprises the following components in weight percentage: not greater than 30 percent of Zn, 10<-4>-0.05 percent of Be, 10<-4>-6.0 percent of alloy enhancer, 10<-4>-1.0 percent of solvent passivator, 10<-4>-0.5 percent of sediment hardening agent, 10<-4>-1.0 percent of grain refiner, 10<-4>-1.0 percent of rare earth addition, 0.001-2.0 percent of matrix interface reaction buffering agent and the balance Al and unavoidable trace impurities. The aluminum alloy coating material produced according to the technical scheme provided by the invention can be used for forming light and thin high-quality coatings on the surfaces of steel and iron alloy, wherein the light and thin high-quality coatings are attractive and are high in corrosion resistance, abrasion resistance, strength and ductility and good in matrix metallurgical bonding. The aluminum alloy coating material can be used for anti-corrosion coatings on the surfaces of steel and iron alloy products. Production equipment for the aluminum alloy coating material does not need to be specially made; the source of the raw material is rich; the starting cost is low; and the industrial waste can be conveniently and cyclically utilized.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

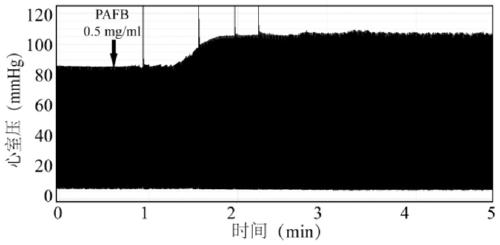

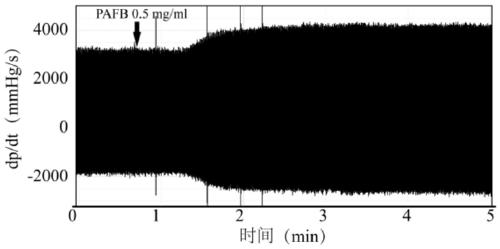

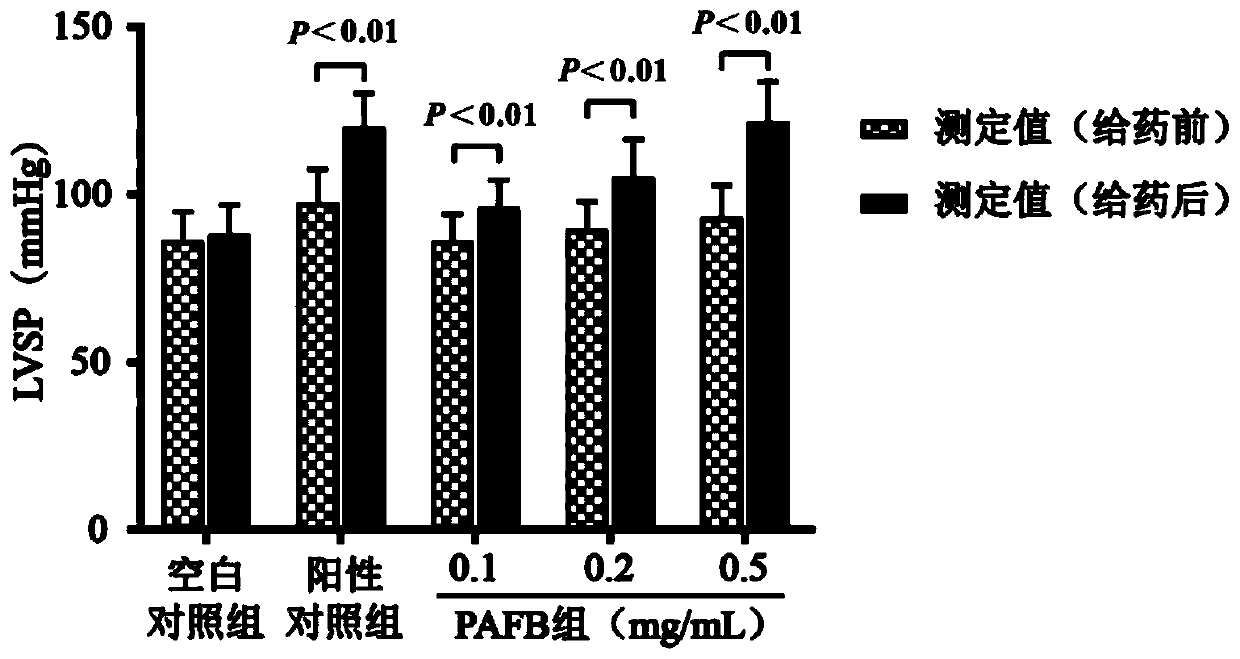

Metabolite extract of intestinal flora in American cockroach excrement as well as preparation method and application of extract

ActiveCN111249311AIncrease the value of reuseHigh medicinal valueAnthropod material medical ingredientsCardiovascular disorderBiotechnologyMetabolite

The invention belongs to the technical field of traditional Chinese medicine, and particularly relates to metabolite extract of intestinal flora in American cockroach excrement as well as a preparation method and an application of the extract. The extract adopts the American cockroach excrement as a raw material, is prepared by steps of ultrasonic extraction, filtration, macroporous resin separation and the like, has a positive inotropic action, can enhance normal myocardial contractility without obvious heart rate increase or heart damage, and can be used for preparing drugs for treating cardiac failure.

Owner:YUNNAN TENGCHONG PHARMA FACTORY

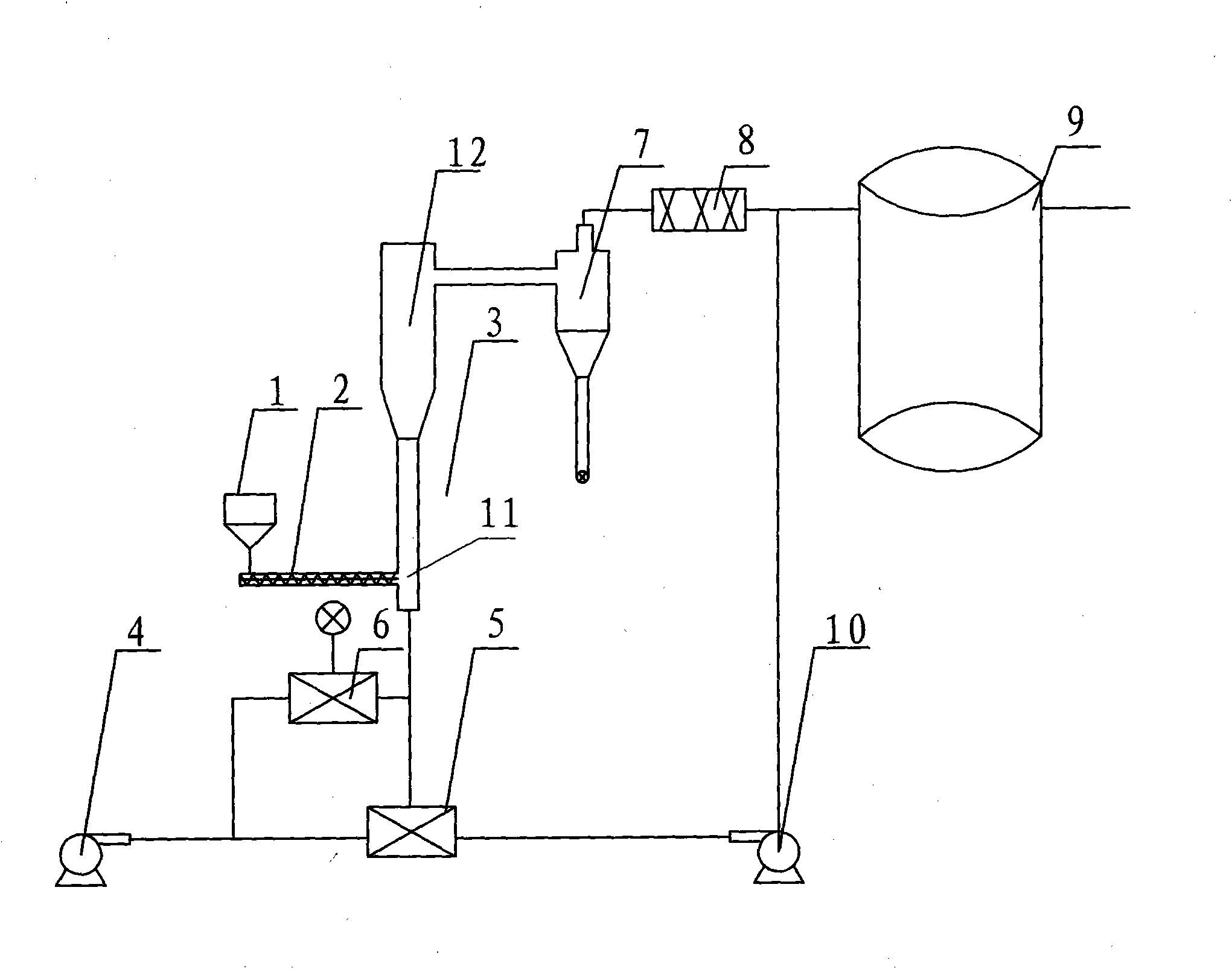

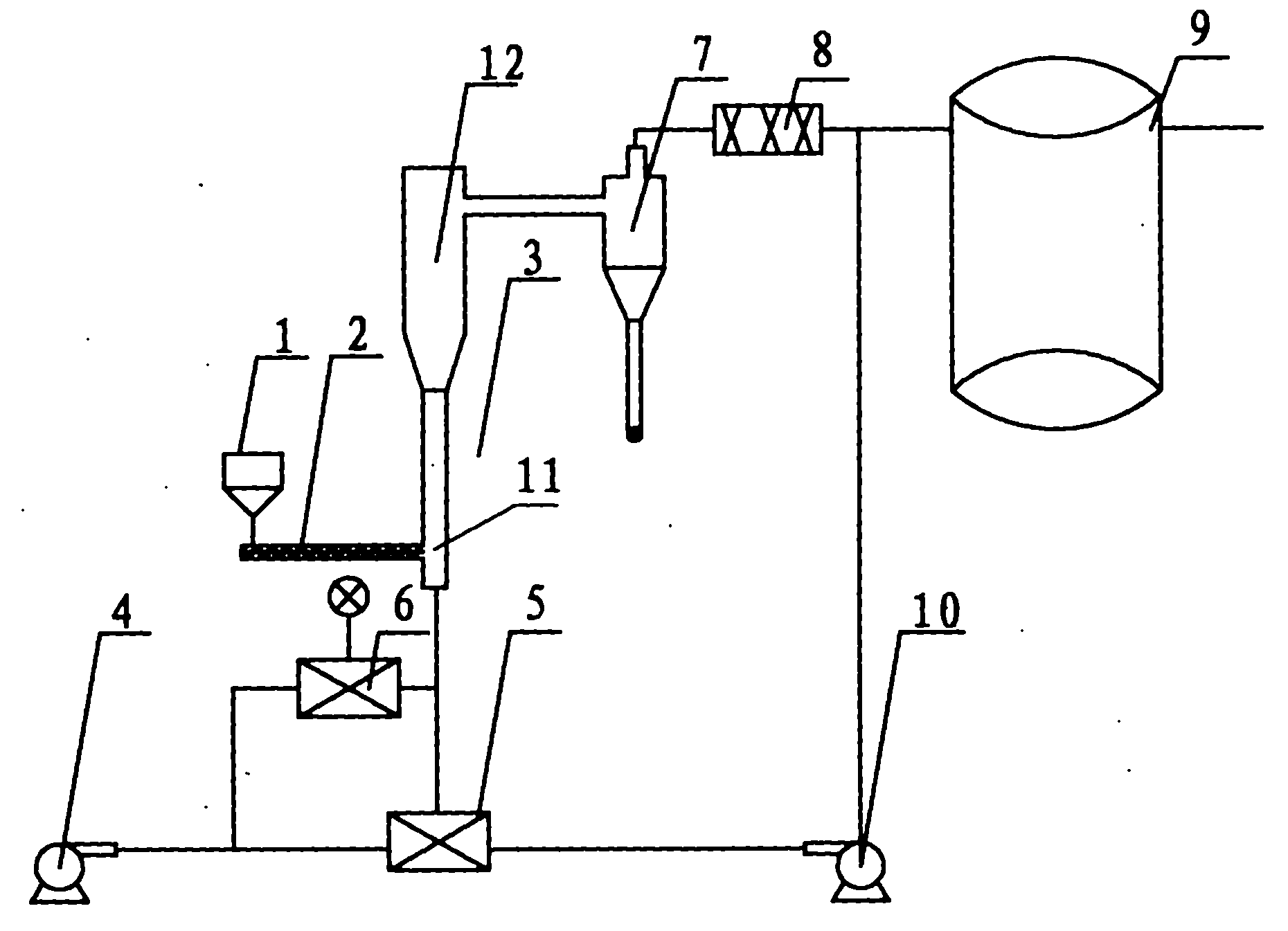

Solid fuel pneumatic conveying heating method and system capable of controlling content of ash combustible

InactiveCN102134496AGood combustion reaction speedIncrease the value of reuseDirect heating destructive distillationEnergy inputTO-18Combustor

The invention discloses a solid fuel pneumatic conveying heating method and system capable of controlling the content of ash combustible, wherein the method is characterized in that: at room temperature, solid fuel particles with grain size of 0 to 8mm are conveyed into a conveying section of a jetting bed combustor via a worm feeder; air and gas mixed fuel is combusted in a smoke generator when the jetting bed combustor is ignited in order to generate the smoke with the pressure from 3000 to 8000pa and the temperature from 400 to 1000 DEG C, the smoke is fed to the conveying section of the jetting bed combustor, after the combustion of the jetting bed combustor becomes stable, a smoke mixer is closed, the air at room temperature and the smoke are fed to the smoke mixer via a blower so that the oxygen content of the mixed gas is 10% to 18%; and the mixed gas carrying the solid fuel enters a combustion section of the jetting bed combustor at the speed of 9 to 15m / s, the ash combustible which is subjected to cyclic jetting combustion enters a cyclone separator to obtain solid coke and semicoke, a part of the smoke discharged by the cyclone separator enters a waste heat boiler through a dust remover for the purpose of reutilization, and another part of the smoke is fed to the smoke mixer by a circulating fan to serve as recycling smoke for controlling the oxygen content.

Owner:DAQING OILFIELD CO LTD +1

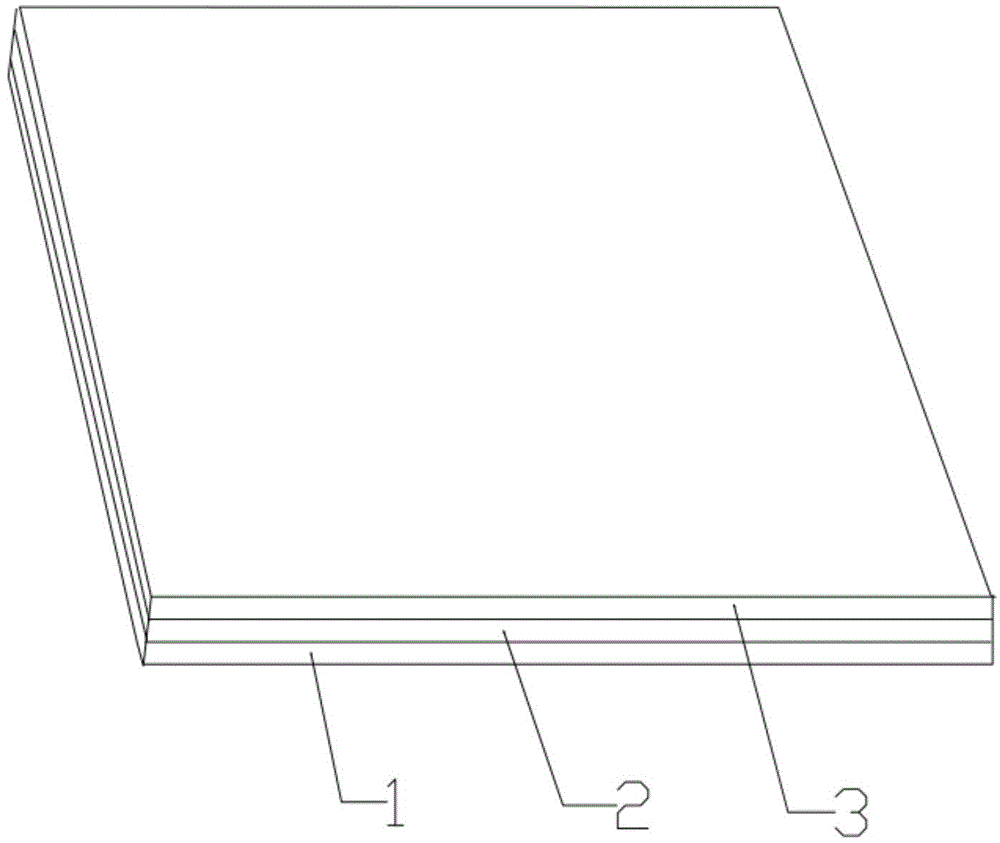

Plastic film with layering control function and preparation method thereof

ActiveCN104890333ASpeed upInaccessibleSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention relates to a plastic film with a layering control function and a preparation method thereof. The plastic film comprises a bonding layer, an easy-to-tear layer and a stripping layer, wherein the bonding layer is prepared from ethylene-acrylic acid copolymer or ethylene-methacrylic acid copolymer; the easy-to-tear layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, ethylene-methacrylic acid ionic polymer, poly-1-butene, silicon dioxide, beta-propionic acid octade, triphenyl phosphite, N,N'-ethylenebisoctadecanamide, 2,6-Di-tert-butyl-4-methylphenol, oleamide, triphenyl phosphate and oleyl palmitamide according to a certain weight ratio; the stripping layer is prepared from a blend formed by mixing ethylene-vinyl acetate copolymer, low-density polyethylene and a linear low-density polyethylene resin material according to a certain weight ratio. The plastic film with the layering control function ensures that an external sheath layer of an optical cable or an electric cable can be disengaged from the bonding layer and also ensures that a metal-plastic composite belt is free of moisture invasion.

Owner:烟台万泰通信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com