Stainless steel filter head plate

A stainless steel and filter plate technology, applied in the field of water treatment, can solve the problems of difficult handling, loading and unloading, increasing repeated investment, and cumbersome production process, so as to improve production efficiency and standardization, shorten installation and maintenance periods, and simplify The effect of the installer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

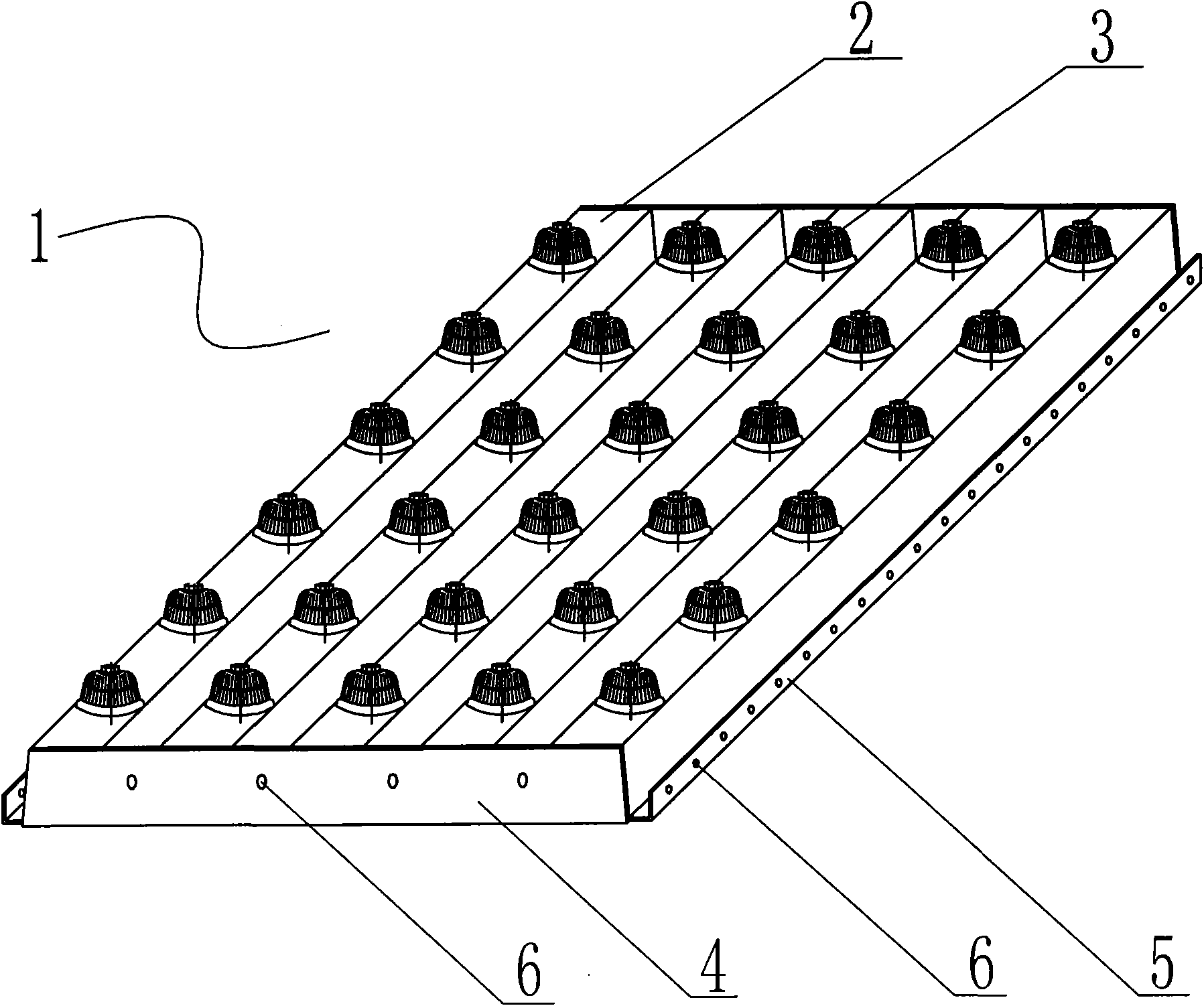

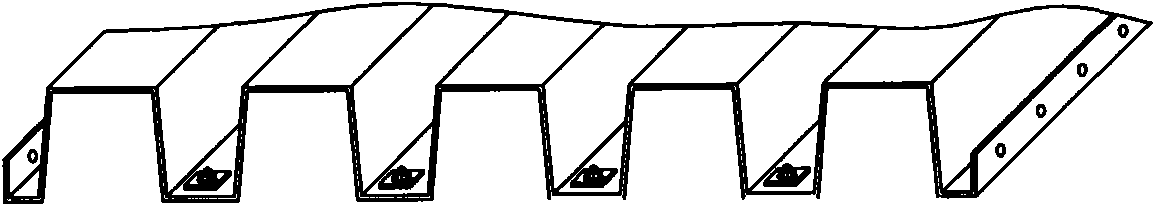

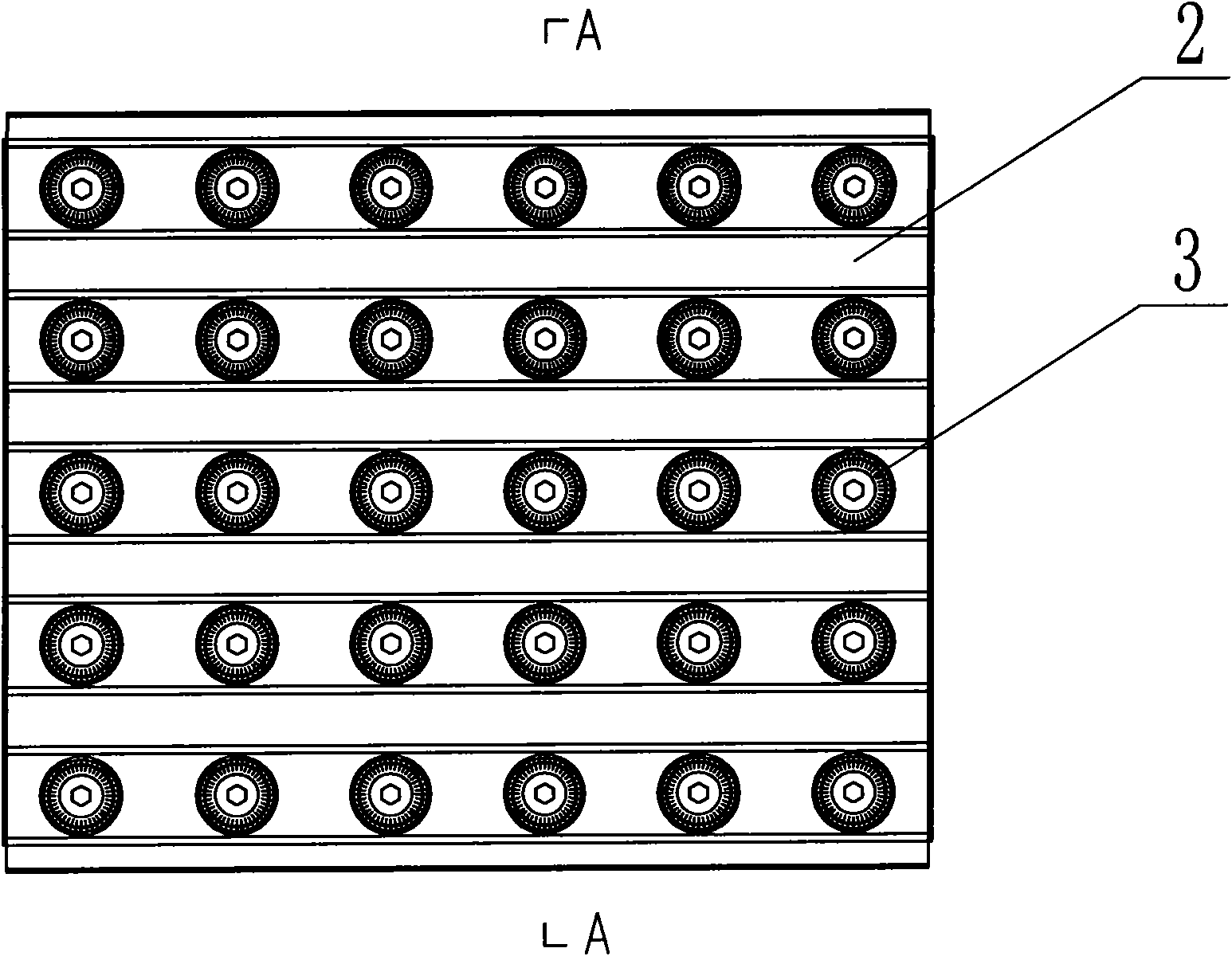

[0032] Such as Figure 1-4 The stainless steel filter head plate 1 shown is composed of a stainless steel filter plate 2 and a filter head 3, the stainless steel filter plate 2 is a corrugated plate, and its cross-sectional shape is a continuous trapezoid.

[0033] The wave crest of the corrugated plate is provided with a round hole for installing the filter head. The filter head fixing piece passes through the round hole, and is connected on both sides of the plate surface through threads, rubber soft gaskets and other structures. After the connection, the fixing piece is fixed firmly with the stainless steel plate. The filter head 3 is connected with the filter head holder mounted on the filter plate by threads.

[0034] Both sides of the stainless steel filter plate 2 perpendicular to the wave direction are provided with sealing plates 4, and the other two sides are provided with connecting plates 5, and both the sealing plates and the connecting plates are provided with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com