Environment-friendly comprehensive treatment method for household garbage and waste oil and fat

A comprehensive treatment and domestic waste technology, applied in the petroleum industry, solid waste removal, special form of dry distillation, etc., can solve the problems of lagging development of recycling and treatment capacity and level, weak domestic waste treatment technology, and affecting the living quality of residents, etc. Achieve the effect of low cost, high recovery rate and increased value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

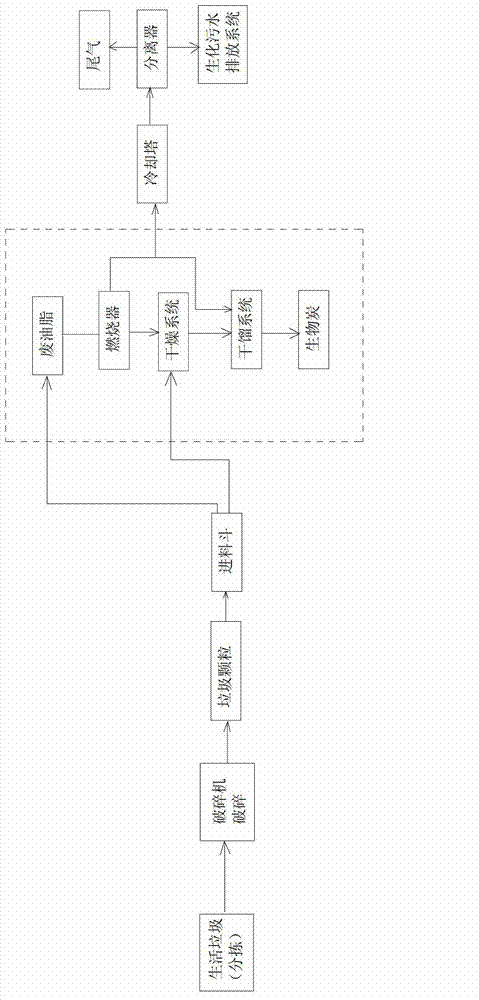

[0026] combined reference figure 2 As shown, the domestic garbage and waste oil environmental protection comprehensive treatment method of the present invention comprises steps:

[0027] Step S1: After sorting the domestic waste, it is broken into waste particles with a particle size of 1-2 cm by a tooth crusher, and transported to the feeding hopper by a screw conveyor;

[0028] Step S2: On the one hand, the garbage particles are transported to the desiccant group through a sealed screw conveyor, and the crusher is connected to the drying unit through a pipeline; under normal pressure, the pre-pyrolysis temperature is 100-400°C, and the pyrolysis time is 1 ~3 hours, the flammable gas produced by the reaction is directly injected into the hot blast stove for combustion;

[0029] The tail gas produced after drying is discharged into the cooling scrubber, which is connected to the three-phase separator, in which, the hot water coming out is connected to the water treatment sys...

Embodiment 2

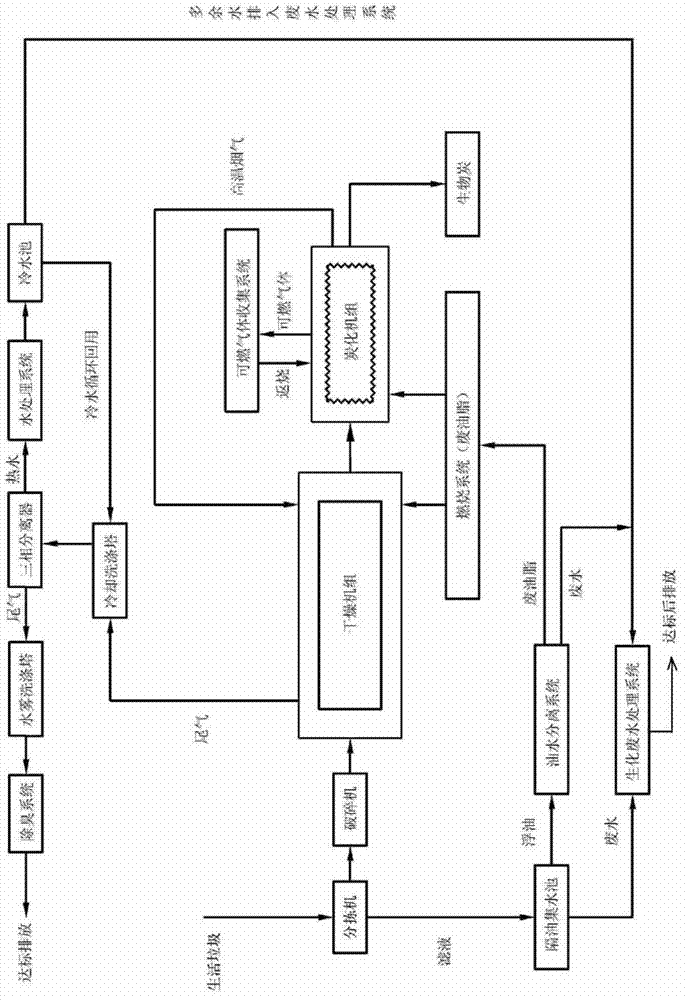

[0036] The environmental protection comprehensive treatment method of domestic garbage and waste oil of the present invention further comprises the steps of:

[0037] Step S1: After sorting the domestic waste, it is broken into waste particles with a particle size of 1-2 cm by a tooth crusher, and transported to the feeding hopper by a screw conveyor;

[0038] Step S2: On the one hand, the garbage particles are transported to the desiccant group through the sealed screw conveyor, and sent to the pre-pyrolysis device (drying unit) through the sealed screw conveyor for preliminary drying; the pre-pyrolysis device is an external heat Type piston propulsion machine, scraper machine or screw conveyor, under normal pressure, the pre-pyrolysis temperature is 200-300 ℃, the pyrolysis time is 1.5 hours, and the oil, gas and carbon residue produced by the reaction are discharged separately;

[0039] Step S3: On the other hand, the liquid garbage is divided into two parts by the oil-wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com