Vertical inter-partition sludge drying method and equipment with crushing and safety monitoring functions

A technology for sludge drying and safety monitoring, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of high reuse value of sludge resources, reducing the generation of odorous gas, and solving high cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

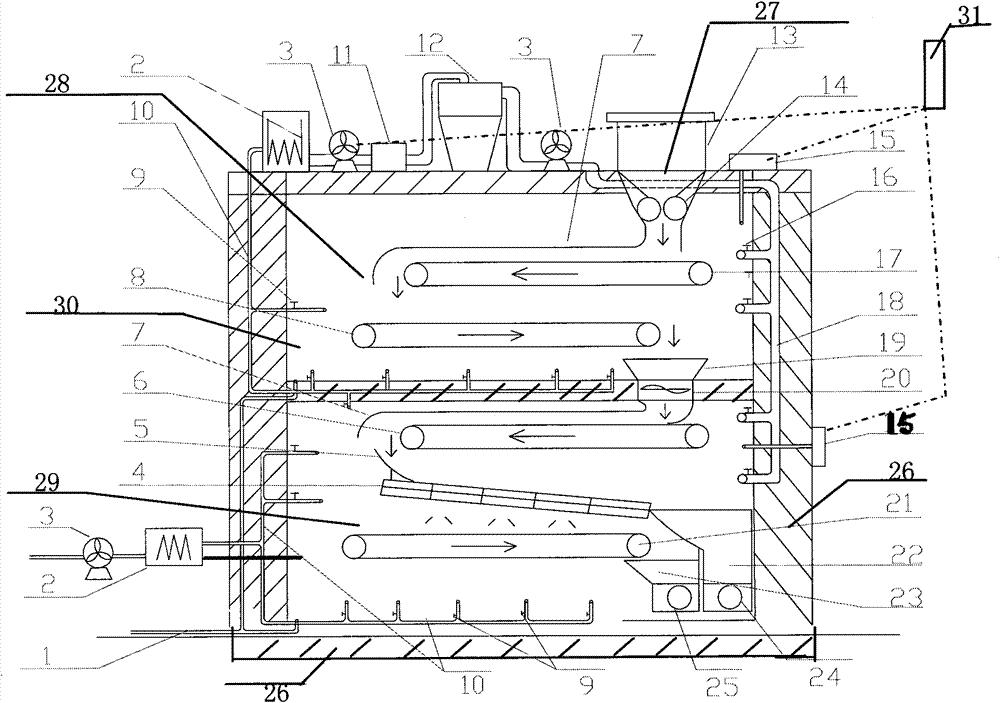

[0021] The invention provides a sludge drying method and equipment with vertical divisions and functions of crushing and safety monitoring. The present invention will be further described in detail below through specific embodiments.

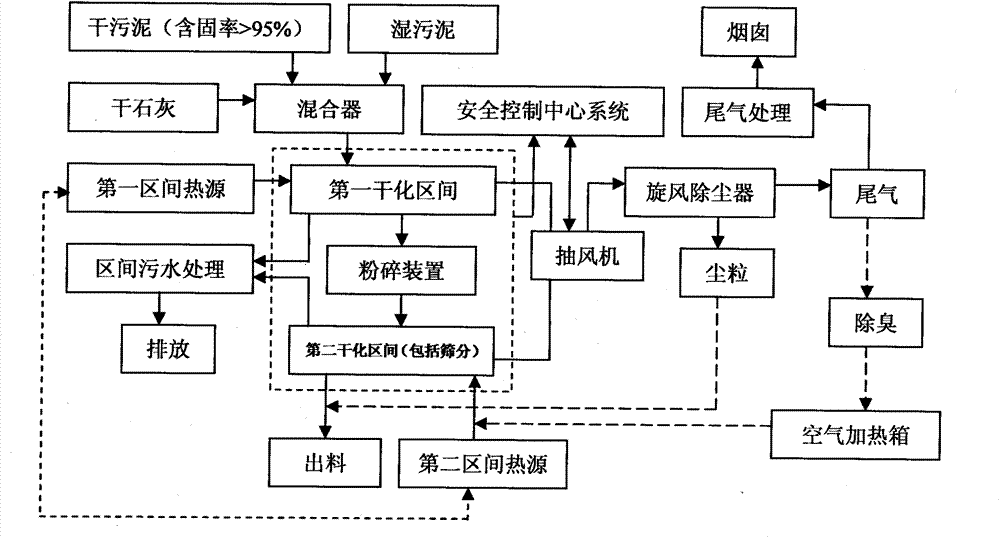

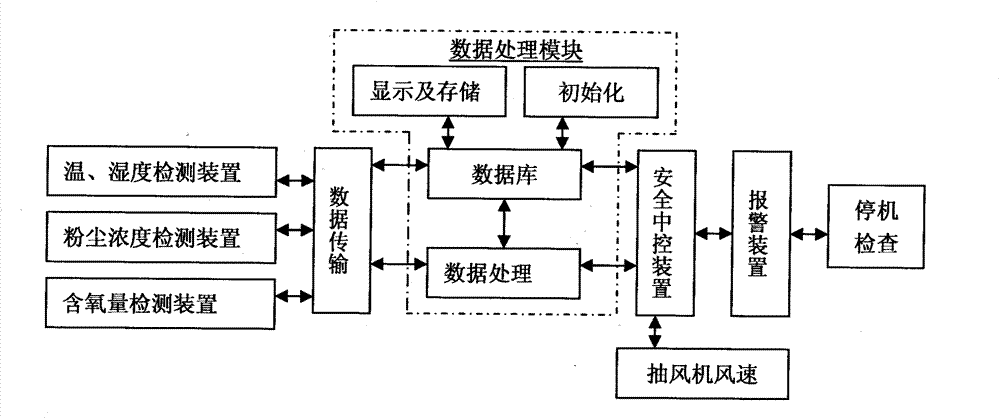

[0022] combined with figure 1 , 2, 3 to illustrate the method provided by the invention. The method provided by the invention includes a dry material back-mixing stage, a first drying stage, a crushing treatment stage, a second drying stage and a final screening and granulation stage.

[0023] In the dry material back-mixing stage, after the moisture content of the sludge is reduced to about 80% by mechanical dehydration, the wet sludge with a moisture content of about 80% is mixed with dry sludge with a solid content greater than 95% and dry lime in a certain proportion. The dry sludge acts as a "pearl nucleus" in the sludge mixture, which can reduce the bonding between the sludge and the equipment and improve the drying efficiency of the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com