Method for preparing antibacterial regenerated polyester by waste polyester alcoholysis method

A technology of recycled polyester and polyester alcohol, which is applied in the field of chemical fiber materials, can solve the problems of single performance of recycled polyester, achieve mild antibacterial effect, reduce white pollution, and reduce oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The recovered waste polyester (polyester pulp block, polyester bottle flakes) is dewatered and deoxidized to obtain the waste polyester raw material, which is put into the depolymerization reactor with ethylene glycol in a mass ratio of 1:2. The depolymerization reaction was carried out for 2 hours at 200° C. using zinc acetate catalyzed to prepare a depolymerization product containing ethylene terephthalate. The prepared depolymerization liquid is passed through a 100-mesh filter device, and impurities and insoluble matter in the depolymerization liquid are preliminarily filtered out. A high-purity depolymerization solution is obtained.

[0025] The cuprous oxide antibacterial agent with a particle size range of 200-500 nm is prepared by reducing copper sulfate with ascorbic acid.

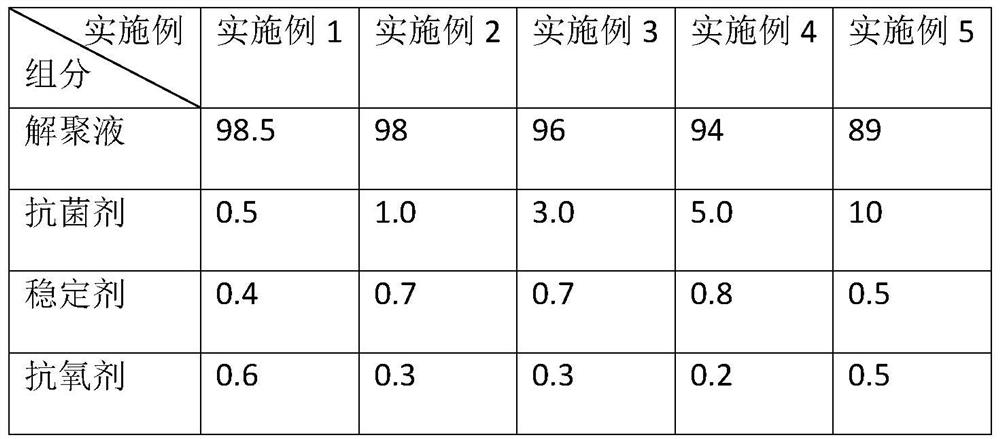

[0026] Take the depolymerization solution and antibacterial agent according to Table 1, stir continuously for 1 hour, and then drop into the precondensation kettle together with antioxidan...

Embodiment 2

[0030] The recovered waste polyester (polyester fiber and polyester waste silk) is dewatered and deoxidized to obtain the waste polyester raw material, which is put into the depolymerization reactor with ethylene glycol in a mass ratio of 1:4, and then The depolymerization reaction was carried out for 6 hours at 180° C. under the catalysis of zinc acetate, and the depolymerization product containing ethylene terephthalate was prepared. The prepared depolymerization liquid is passed through a 100-mesh filter device, and impurities and insoluble matter in the depolymerization liquid are preliminarily filtered out. A high-purity depolymerization solution is obtained.

[0031] The nano-silver antibacterial agent with a particle diameter ranging from 10 to 150 nm is prepared by reacting silver salt (silver nitrate) with ammonia water (the concentration of the ammonia water is marked as 5 mol / L).

[0032] Take depolymerization solution and antibacterial agent according to table 1, ...

Embodiment 3

[0036] The recovered waste polyester (polyester pulp block) is dewatered and deoxidized to obtain the waste polyester raw material, which is put into the depolymerization reactor at a mass ratio of 1:3 with ethylene glycol, and used at 195°C Zinc acetate catalyzes the depolymerization reaction for 4 hours to prepare a depolymerized product containing ethylene terephthalate. The prepared depolymerization liquid is passed through a 100-mesh filter device, and impurities and insoluble matter in the depolymerization liquid are preliminarily filtered out. A high-purity depolymerization solution is obtained.

[0037] The cuprous oxide antibacterial agent with a particle size range of 200-500 nm is prepared by reducing copper sulfate with ascorbic acid.

[0038] Take the depolymerization solution and antibacterial agent according to Table 1, stir continuously for 1 hour, and then drop into the precondensation kettle together with antioxidant (1010 antioxidant, BASF) and stabilizer (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com