Method for producing filmÊöcoated controlled release fertilizer of degradable film prepared by reclaiming thermoplastic resin

A technology of plastic resin and controlled-release fertilizer, applied in fertilizer forms, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of high production cost and sales price of coated fertilizers, difficult field crops to popularize and apply, and high cost of controlled-release fertilizers. Significant yield and synergistic effects, excellent quality and results, low cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

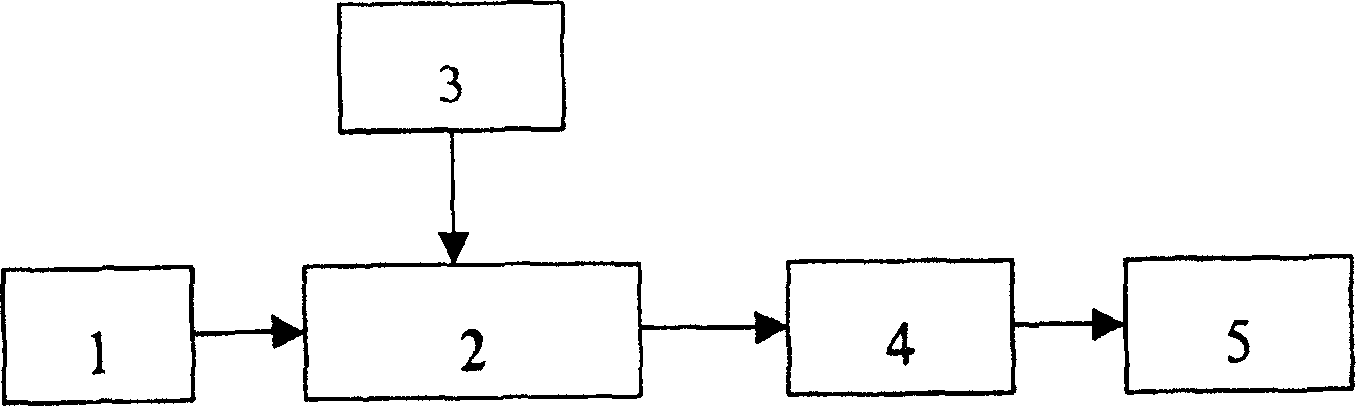

Image

Examples

Embodiment 1

[0010] Put 100kg of granular compound fertilizer with a diameter of 2-5mm into the fluidized bed, heat to 60-80°C, mix 3.0kg of recycled polyethylene plastic film and 3.0kg of recycled polystyrene foam in 50kg of dichloromethane and Add 0.5kg of diatomaceous earth, corn flour and rubber powder to the mixed solvent of tetrachlorethylene each accounting for 1 / 2, heat to 90-100°C, use a two-fluid nozzle to atomize the air at an air pressure of 4kpa at a rate of 2kg per minute Progress spraying, spray all 100kg of solution onto the fertilizer granules. The obtained controlled release compound fertilizer, the polymer film accounts for about 6% of the total weight of the fertilizer, and the controlled release time of the nutrient is about 6 months when the fertilizer is placed in water or soil at 25°C.

Embodiment 2

[0012] Put 200kg of urea with a diameter of 2-4mm into the fluidized fluidized bed, heat it to 50-70°C, mix 4kg of recycled polyethylene plastic film and 6kg of recycled polystyrene foam into 100kg of tetrachlorethylene and dichloromethane Add 1.0kg of light calcium carbonate powder, wheat flour and rubber powder to 1 / 2 of the mixed solvent, heat to 80-90°C, spray on the large area with a two-fluid nozzle at an atomization pressure of 4kpa at a speed of 2kg per minute On granular urea, the obtained controlled-release fertilizer film accounts for about 5% of the total weight of all controlled-release fertilizers. This fertilizer is in 25 ℃ water or soil, and the nutrient release time is about 3 months.

Embodiment 3

[0014] Put 100kg of granular potassium sulfate with a diameter of 2-5mm into the fluidized fluidized bed, heat it to 70-80°C, mix 3kg of recycled polyethylene and 2kg of recycled polystyrene in 40kg of tetrafluoroethylene and methylene chloride at a ratio of 2 : 0.5 kg of 400 mesh talcum powder, sweet potato powder and rubber powder were added in the mixed solvent of 1. Heating to 100°C, using a dual-fluid nozzle to spray on the fertilizer particles at an atomization pressure of 4kpa at a rate of 2kg per minute, the resulting controlled-release potassium fertilizer, the film accounts for about 5% of the total weight of the fertilizer, in water or soil at 25°C In , the nutrient controlled release time is about 4 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com