Easily degradable vegetable oil-coated controlled-release fertilizer and technology for preparing same

A technology of coated controlled-release fertilizers and vegetable oils, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of slow degradation of membrane shells and high prices, and achieve the effects of protecting the environment, reducing fertilization costs, and avoiding agricultural non-point source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

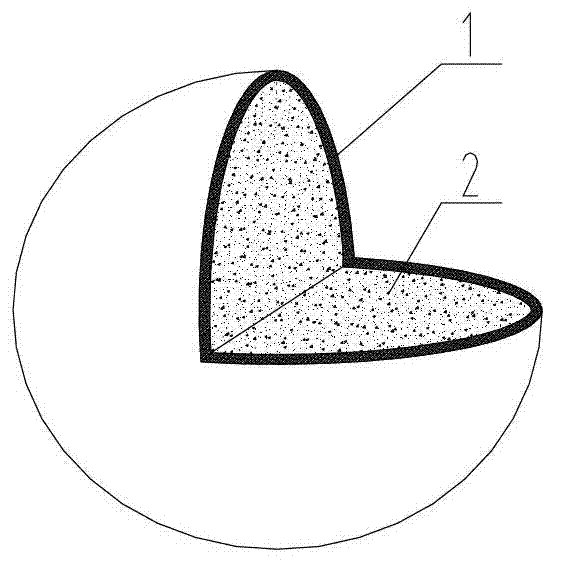

[0042] Embodiment 1, vegetable oil coated urea

[0043] (1) Sieve and weigh 1000kg of granular urea, transport it to the granulator, and preheat it to 50-60°C.

[0044] (2) Component A: 10kg vegetable oil, 1kg glycerin, 4.5kg xylene, 0.5kg plant fiber, stir and react for 50min at 55-65℃ in the reactor;

[0045] Component B: Add 2kg of phthalic anhydride to 10kg of vegetable oil, and react in a reactor at 180°C for 1.2h.

[0046] Take component A and component B and mix evenly, which is the vegetable oil coating agent; set aside;

[0047] (3) Add the vegetable oil coating agent in step (2) to the granular urea in the granulator in step (1), the dosage of the vegetable oil coating agent is 1.4wt% of the weight of the core fertilizer, and keep the fertilizer temperature at 50~60°C , using the mutual friction of fertilizer particles, the vegetable oil spreads evenly on the surface of the moving fertilizer particles, and finally solidifies to form a smooth and dense film layer, c...

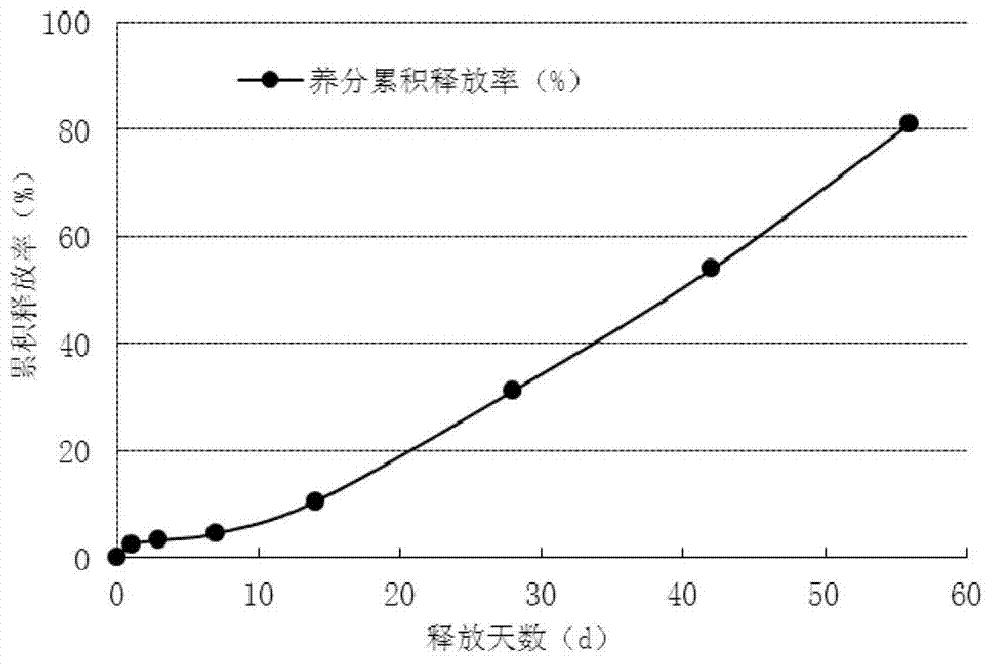

Embodiment 2

[0049] Embodiment 2, vegetable oil coated urea

[0050] (1) Sieve and weigh 1000kg of granular urea, transport it to the granulator, and preheat it to 50-60°C.

[0051] (2) Component A: 6.2kg of vegetable oil, 0.70kg of pentaerythritol, 2.79g of xylene, and 0.31kg of plant fiber were stirred and reacted in a reactor at 55-65°C for 1.2h;

[0052] Component B: add 1kg phthalic anhydride to 5kg vegetable oil, and react in the reactor at 110°C for 1.5h;

[0053] Mix component A and component B evenly, it is vegetable oil coating agent, set aside;

[0054] (3) Add the vegetable oil coating agent in step (2) to the granular urea in the granulator in step (1), the dosage of the vegetable oil coating agent is 1.6wt% of the weight of the core fertilizer, and keep the fertilizer temperature at 50~60°C , using the mutual friction of fertilizer particles, the vegetable oil spreads evenly on the surface of the moving fertilizer particles, and finally solidifies to form a smooth and dense...

Embodiment 3

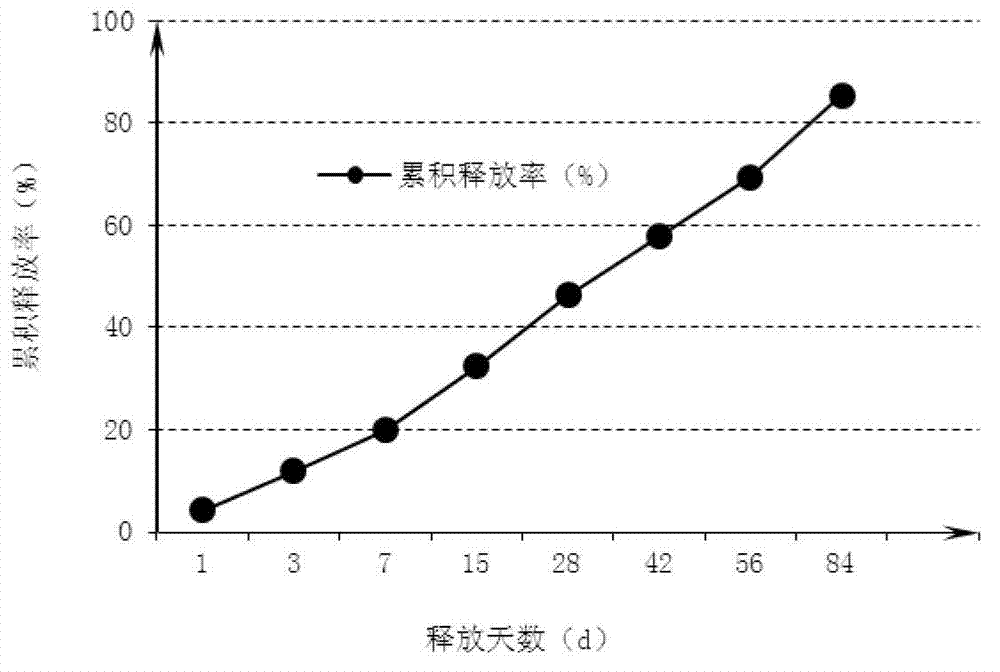

[0056] Embodiment 3, vegetable oil coated controlled-release compound fertilizer

[0057] (1) Sieve and weigh 500kg of Shima 45% (15-15-15) granular fertilizer, transport it to the granulator, and preheat it to 50-60°C.

[0058] (2) Component A: Take 6kg of vegetable oil, 1.5kg of trimethylolpropane, 1.5g of xylene, and 0.3kg of plant fiber, and stir in a reactor at 55-65°C for 2 hours;

[0059] Component B: add 0.5kg isophthalic acid to 2.7kg vegetable oil, and react in a reactor at 130°C for 1.6h.

[0060] Mix component A and component B evenly, it is vegetable oil coating agent, set aside;

[0061] (3) Add the vegetable oil coating agent in step (2) to the granular urea in the granulator in step (1), the dosage of the vegetable oil coating agent is 2.5wt% of the weight of the core fertilizer, and keep the fertilizer temperature at 50~60°C , using the mutual friction of fertilizer particles, the vegetable oil spreads evenly on the surface of the moving fertilizer particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com