Dual-purpose smoking product

A smoking product and a dual-purpose technology, which is applied in the fields of tobacco, application, and tobacco treatment, and can solve problems such as insufficient radial support force of the pipe wall, poor taste and sensory experience, and limited contact area between smoke and the pipe wall of the support section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

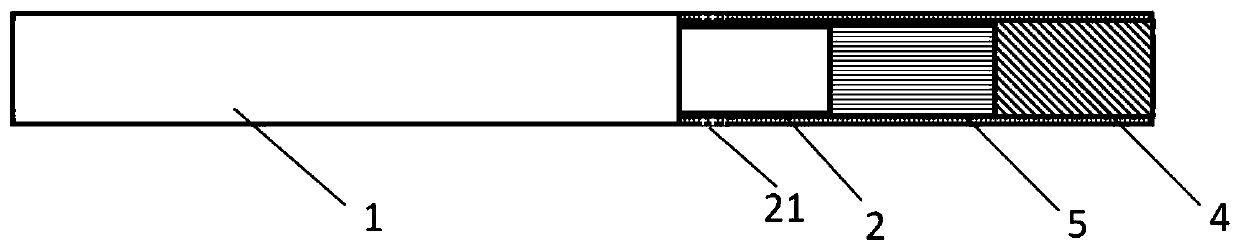

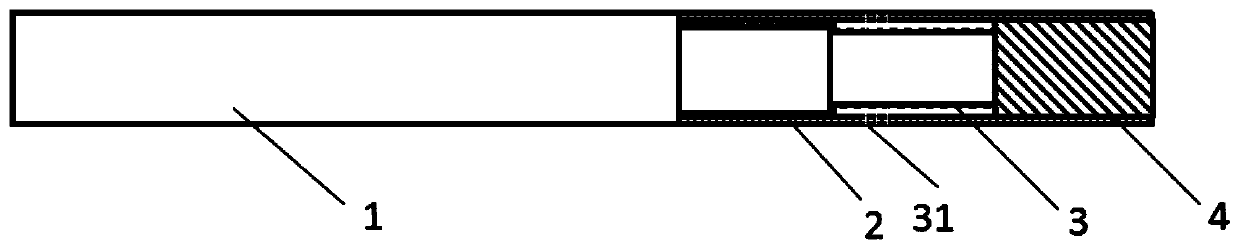

[0042] Such as figure 2 As shown, the present invention provides a dual-purpose smoking article. The dual-purpose smoking article refers to that the smoking article is suitable for both ignited smoking and heating non-combustion smoking, and includes a cigarette core section 1 and a supporting section connected in sequence 2. The empty pipe section 3 and the filter section 4, the support section 2, the empty pipe section 3 and the filter section 4, the empty pipe section 3 is wrapped by forming paper to form a mouthpiece, the tobacco core section 1 and the The mouth stick forms a smoking article through the tipping paper;

[0043] Wherein, the empty pipe section 3 is made of acetate fiber tow, and the wall thickness of the empty pipe section 3 is 1.0 mm.

[0044] The empty pipe section 3 is provided with a ventilation hole 31 that penetrates the empty pipe section 3 in a radial direction;

[0045] The core base material of the core section 1 includes reconstituted tobacco leaves a...

Embodiment 2

[0055] Smoking product comparative sample 1 and smoking product sample 1 were respectively smoked with the matching heat-not-burn cigarette smoking appliance under the same conditions. During the smoking process, the temperature of the smoking product core section 1 was about 200°C. Sensory evaluation of smoking products by multiple sensory reviewers, mainly investigating six indicators of smoke volume, aroma, strength, coordination, irritation, and taste; the scores of the six quality inspection indicators are: smoke volume 0-10 points, aroma 0-30 points, strength 0-10 points, coordination 0-10 points, irritation 0-15 points, taste 0-25 points, the total score of 6 evaluation indicators is 100 points, In addition, the higher the score of the five evaluation indexes of smoke volume, aroma, fragrance, strength, coordination, and taste, the stronger the feeling of the evaluation index during the puffing process, and the higher the irritation evaluation index score represents the f...

Embodiment 3

[0063] The smoking product sample 1 and the commercially available traditional cigarette are ignited and smoked under the same conditions. During the smoking process, the temperature of the smoking product core section 1 is about 700-900°C. Sensory evaluations of smoking products were conducted by a number of sensory reviewers, mainly investigating six indicators of gloss, aroma, coordination, odor, irritation, and aftertaste; the score values of the six quality inspection indicators are: gloss 0 ~5 points, aroma volume 0~32 points, coordination 0~5 points, miscellaneous odors 0~12 points, irritation 0~20 points, aftertaste 0~25 points, the total score of 6 evaluation indicators is 100 points, And the higher the score of the 4 evaluation indexes of gloss, aroma, coordination, and aftertaste, the stronger the feeling of the evaluation index during the puffing process. The higher the scores of the two evaluation indexes of odor and irritation, the higher the evaluation index dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com