Patents

Literature

494results about How to "Reduce the presence of hazardous substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

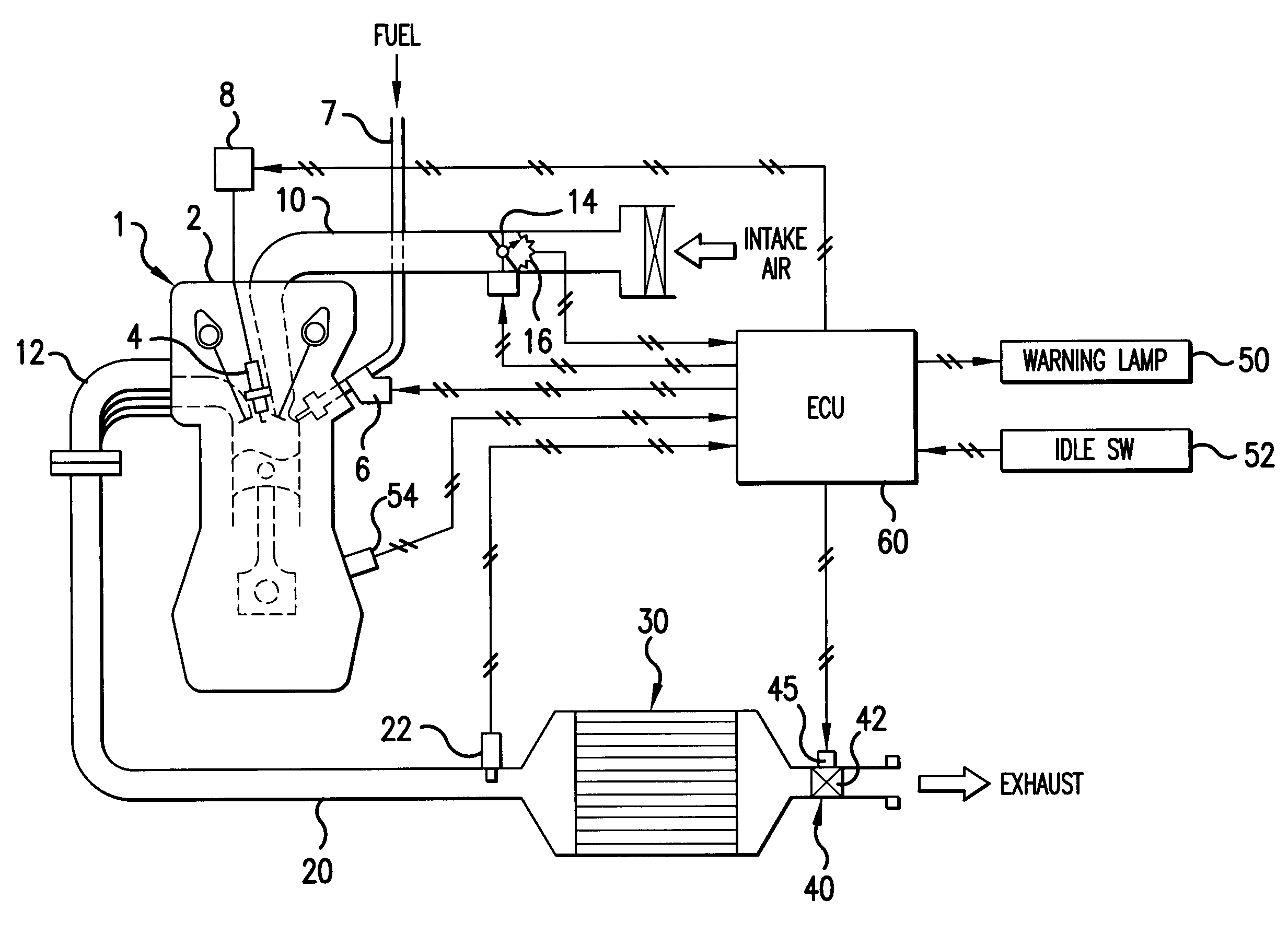

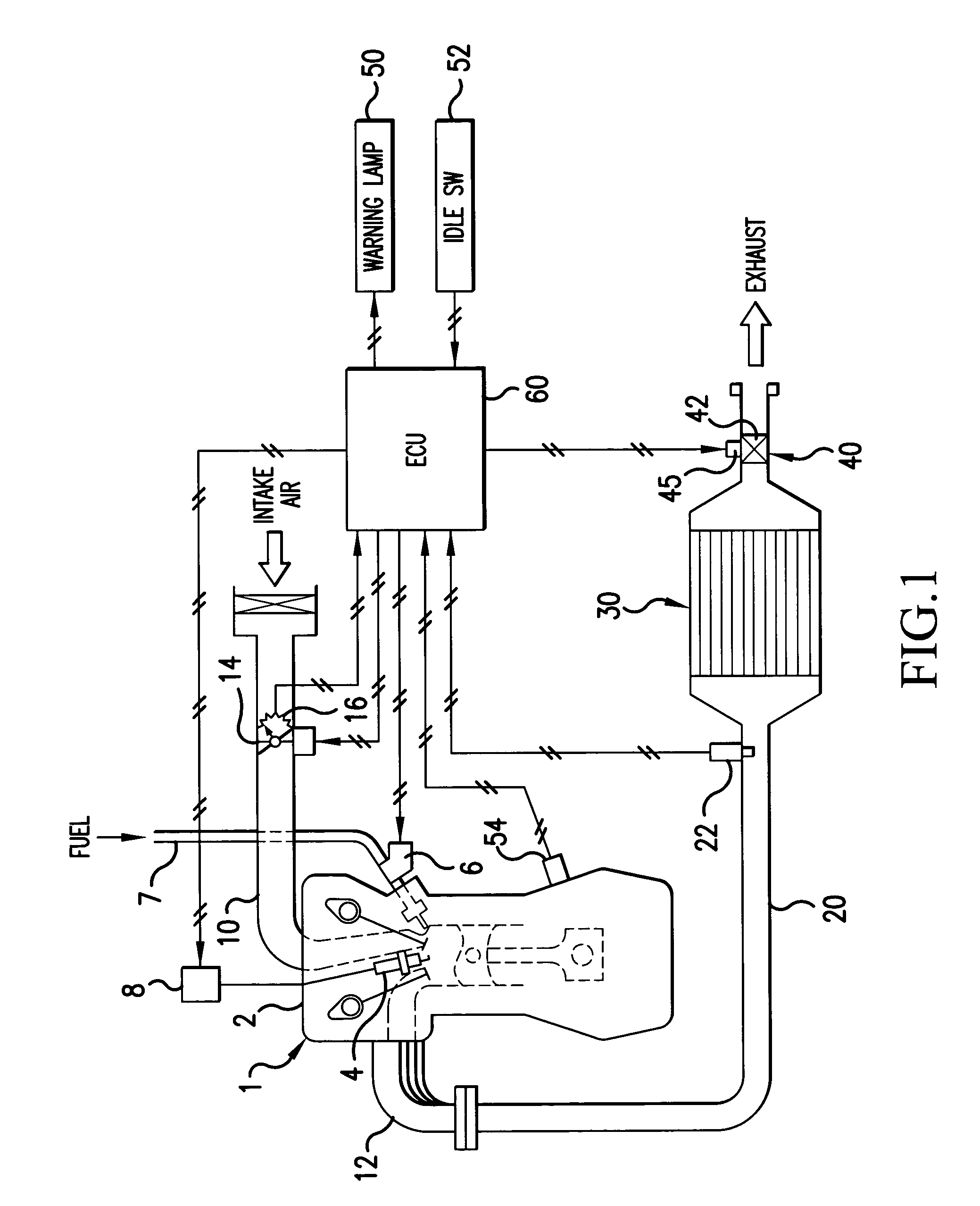

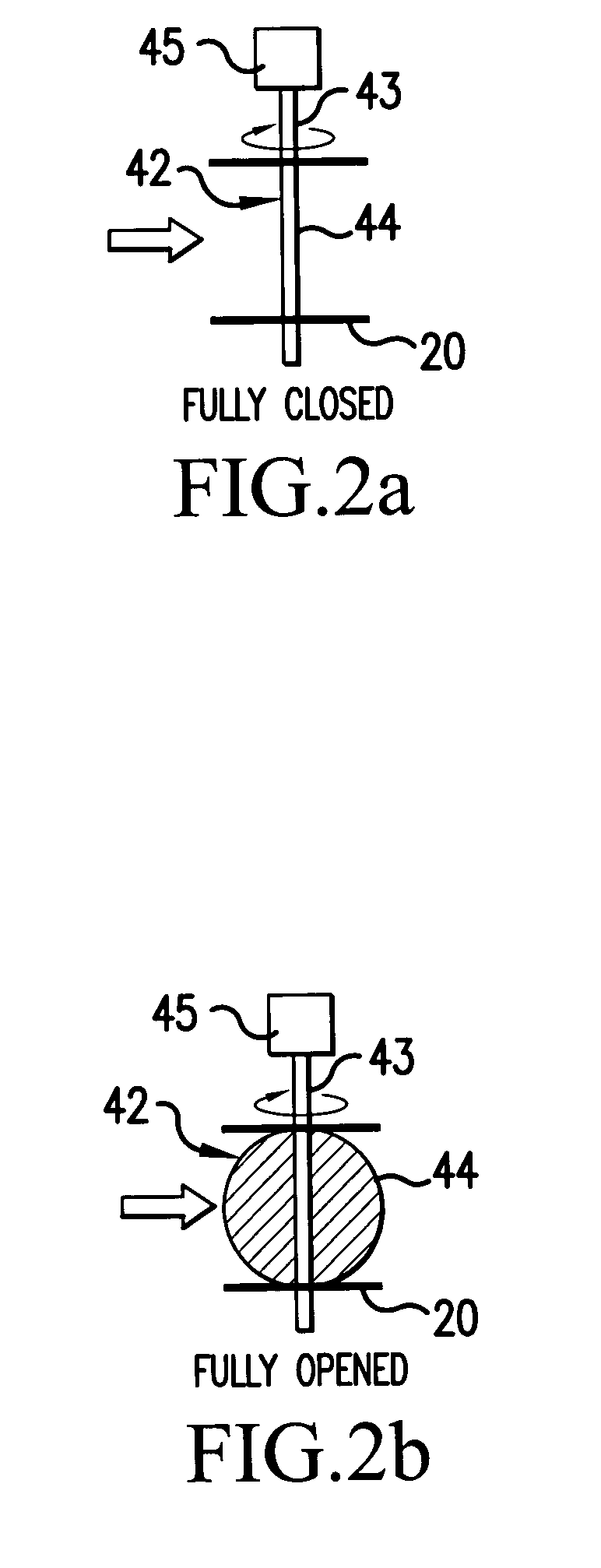

Exhaust emission control apparatus for internal combustion engine

InactiveUS6968677B2Reliable detectionReduce the presence of hazardous substancesAnalogue computers for vehiclesElectrical controlAir volumeExternal combustion engine

There is provided an exhaust emission control apparatus for an internal combustion engine, which includes a failure diagnostic device that fixes three parameters selected from the group consisting of the engine speed detected by an engine speed detecting device, the fuel quantity controlled by a fuel quantity control device, the ignition timing controlled by an ignition timing control device, and the intake air volume controlled by an intake air control device at respective predetermined values, and finds values of the remaining one parameter, and compares the values of the remaining one parameter with each other to determine whether an exhaust flow control apparatus has failed or not.

Owner:MITSUBISHI MOTORS CORP

Mixed electronic cigarette tobacco liquid

ActiveCN102813278AThe smoke is rich and satisfyingTaste mellowTobacco treatmentTobacco devicesKetoneFlavor

The invention provides a mixed electronic cigarette tobacco liquid. The mixed electronic cigarette tobacco liquid comprises the following components in parts by weight: 3-30% of Zimbabwe tobacco extract liquid, 2-25% of American burley tobacco extract liquid, 2-15% of Maryland tobacco extract liquid, 1-10% of Turkish oriental tobacco extract liquid, 1-10% of Greek oriental tobacco extract liquid, 1-10% of Yunnan Baoshan oriental tobacco extract liquid, 1-10% of Xinjiang oriental tobacco extract liquid, 1-8% of tobacco ketone 1035, 1-5% of tobacco alcohol 1036, 0.5-5% of tobacco essence, 0.1-2.5% of natural nicotine, 5-25% of edible glycerol, 1-10% of distilled water, 1-15% of edible alcohol and the balance of propylene glycol. The mixed electronic cigarette tobacco liquid provided by the invention provides a traditional tobacco substitute with mixed taste which is beneficial to the health and satisfying the need of smokers; the mixed electronic cigarette tobacco liquid is characterized by an international mixed style, the smoke is intense and enough, the smoke flavor is pure and mild; the mixed electronic cigarette tobacco liquid is natural and harmonious with the style characteristic and taste of the mixed tobacco; harmful substances are few; and the health of the smokers is benefited.

Owner:SHENZHEN HANGSEN STAR TECH

Method for increasing retention rate of calcium carbonate in paper-process reconstituted tobacco sheets

The invention relates to a method for increasing the retention rate of calcium carbonate in paper-process reconstituted tobacco sheets. The purpose of the invention is to solve the problems that: since the prior art directly adds calcium carbonate, the bonding force between the calcium carbonate and tobacco fibers is weak, as a result, loss is severe, the material utilization rate is low, the amount of waste water to be treated is large, and the treatment cost is high. The technical point is that: needed chemical constituents are extracted from tobacco material, residue is ground into pulp after extraction, and the concentration of the pulp is regulated between 3 percent and 25 percent; the solution of soluble carbonate accounting for 4 percent to 40 percent of the weight of dry fibers in the pulp is added into the pulp, and is fully stirred and uniformly mixed, and impregnation is then carried out for 20 to 150 minutes, so that the fibers of the pulp can be impregnated with the soluble carbonate; the solution of soluble calcium salt, the molar mass of which is approximately equal to the molar mass of the soluble carbonate, is added into the impregnated pulp, and is fully stirred and uniformly mixed, static reaction is then carried out for 30 to 180 minutes, and the reaction temperature is controlled at 5 DEG C to 50 DEG C; and after the static reaction, the pulp is made into reconstituted tobacco sheets by papermaking equipment.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

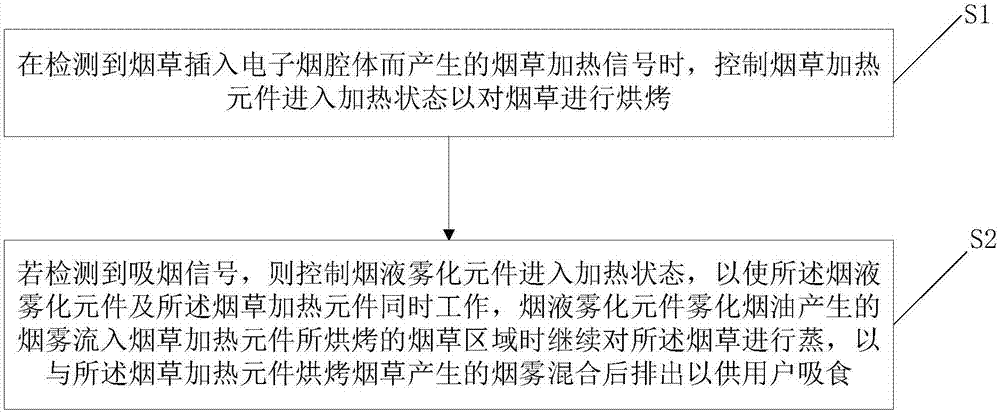

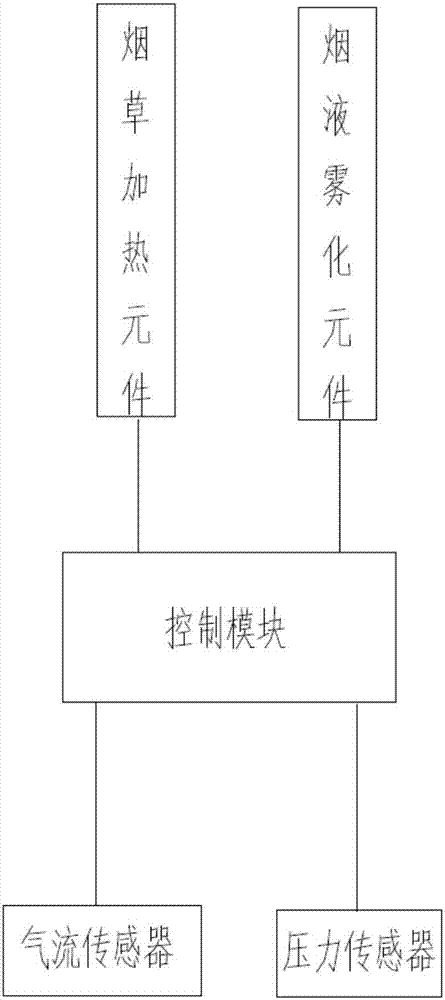

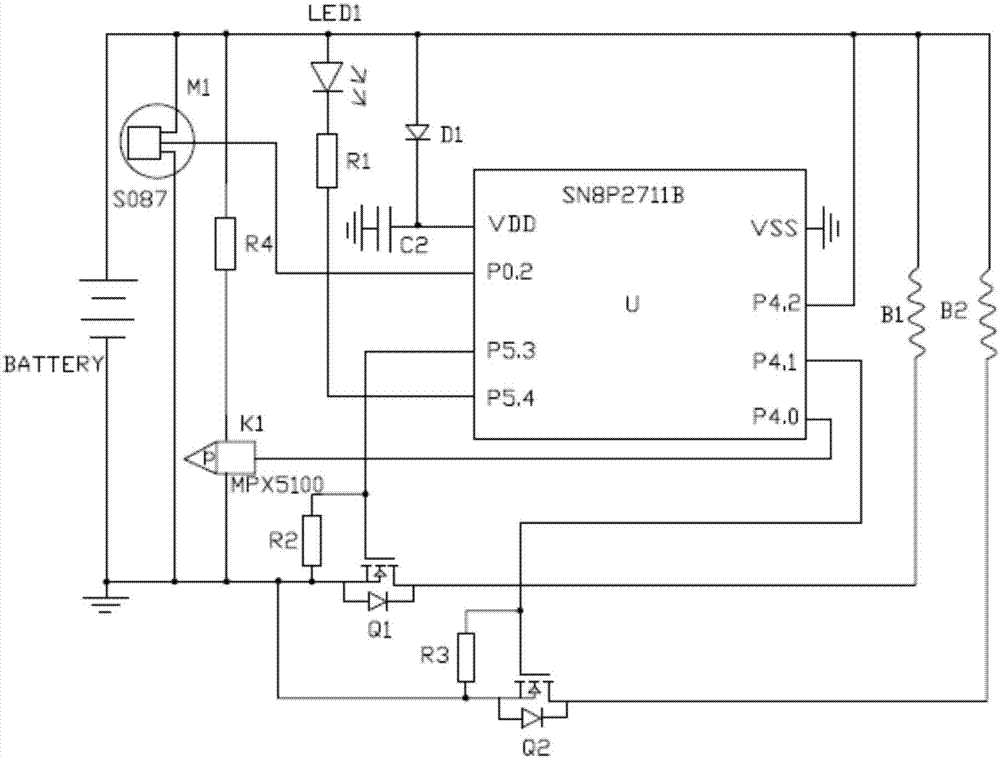

Method for controlling electronic cigarette and electronic cigarette

InactiveCN107278125AEasy to useReduce the presence of hazardous substancesTobacco devicesHazardous substanceEngineering

The present invention discloses a method for controlling an electronic cigarette, comprising the following steps: S1, controlling the tobacco heating element to enter a heating state for baking the tobacco when detecting a tobacco heating signal generated when the tobacco is inserted into the cavity of the electronic cigarette; S2, controlling a tobacco liquid atomizing element to enter a heating state so that the tobacco liquid atomizing element and the tobacco heating element work at the same time if the smoking signal is detected, wherein the smoke generated by atomized tobacco oil of the tobacco liquid atomizing element flows to the tobacco area baked by the tobacco heating element to steam further, so as to be mixed with the smoke generated by baking the tobacco by the tobacco heating element and discharged for a user to smoke. Accordingly, the invention also discloses an electronic cigarette. The method allows smoking of the aromatic smell of tobacco and can reduce the harmful substances to a large extent.

Owner:HUIZHOU KIMREE TECH

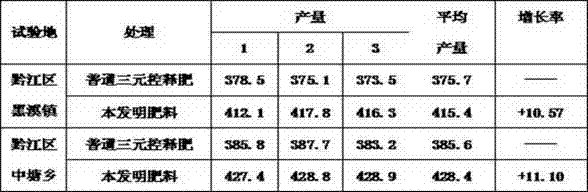

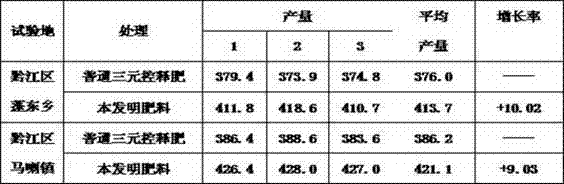

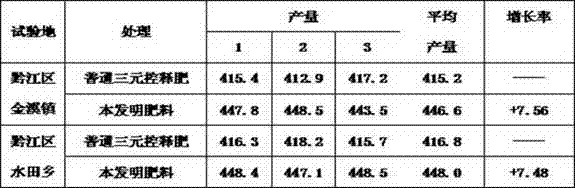

Complex control type long-acting controlled-release organic and inorganic biological fertilizer

InactiveCN103044146AControl releaseReach the dosageBio-organic fraction processingOrganic fertiliser preparationSodium BentonitePhosphate

The invention provides a complex control type long-acting controlled-release organic and inorganic biological fertilizer and belongs to the technical field of fertilizers. A raw material formula comprises 24-28 parts of urea, 6-8 parts of monoammonium phosphate, 6-8 parts of potassium sulfate, 55-65 parts of chicken manure fermented fertilizer, 7-9 parts of wood charcoal powder, 1.8-2.2 parts of calcium superphosphate, 0.8-1.2 parts of bentonite and 1 part of solid inoculant. The complex control type long-acting controlled-release organic and inorganic biological fertilizer has the beneficial effects that firstly, a nitrogen phosphorus and potassium fertilizer and the wood charcoal powder are mixed and granulated; the wood charcoal powder has the adsorption function so that fertilizer nutrients can be slowly released; the outer surfaces of initial grains are covered by a mixture of the calcium superphosphate and the bentonite to control the releasing of the nutrients; the chicken manure fermented fertilizer is used for covering the grains and then the solid inoculant is sprayed; the inoculant can control the releasing of nitrogen, phosphorus and potassium; and then the outer surface of the inoculant is covered by the mixture of one layer of the calcium superphosphate and the bentonite, so that the complex control type long-acting controlled-release organic and inorganic biological fertilizer is formed through a plurality of times of slow release and controlled release.

Owner:重庆润绿生物有机肥有限公司

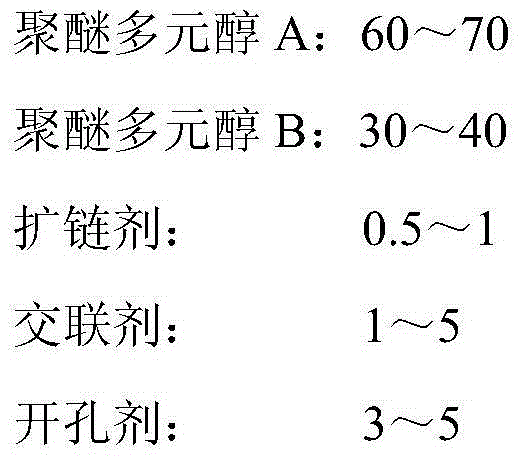

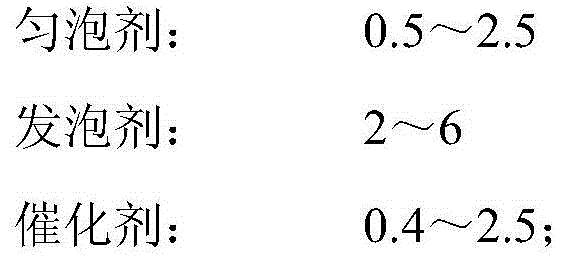

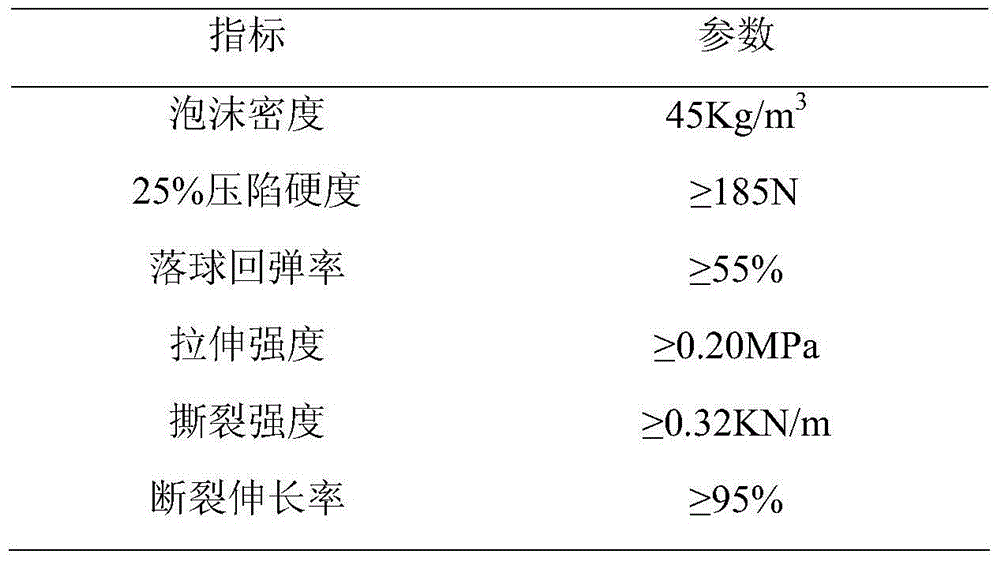

High-bearing low-density low-odor high-rebounding foam material and preparing method thereof

The invention belongs to the technical field of polyurethane, and particularly relates to a high-bearing low-density low-odor high-rebounding foam material and a preparing method of the foam material. The foam material is prepared from an ingredient A and an ingredient B according to a mass ratio of A:B=1:(0.4-0.6), wherein through being metered in parts by mass, the ingredient A consists 60 to 70 parts of polyether glycol A, 30 to 40 parts of polyether glycol B, 0.5 to 1 part of chain expanding agents, 1 to 5 parts of crosslinking agents, 3 to 5 parts of hole forming agents, 0.5 to 2.5 parts of uniform foaming agents, 2 to 6 parts of foaming agents and 0.4 to 2.5 parts of catalysts; the ingredient B is an isocyanate mixture. The independently developed high-functionality-degree and high-molecular-weight special polyether glycol is used as major raw materials for preparing the high-rebounding foam, so that the goals of reducing the foam density and improving the foam carrying capability are achieved; the use of the polymer polyol is avoided, so that the VOC (volatile organic compound) harmful substances and the odor are reduced; the requirements of the environment-friendly high-performance and high-rebounding foam are met. The preparing method is simple, and the operation is easy.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Complex microbial preparation capable of resisting replant obstacle resistance and preparation method thereof

InactiveCN101974428AImprove disease resistancePrevent fungalFungiAgriculture tools and machinesBacillus megateriumStreptomyces

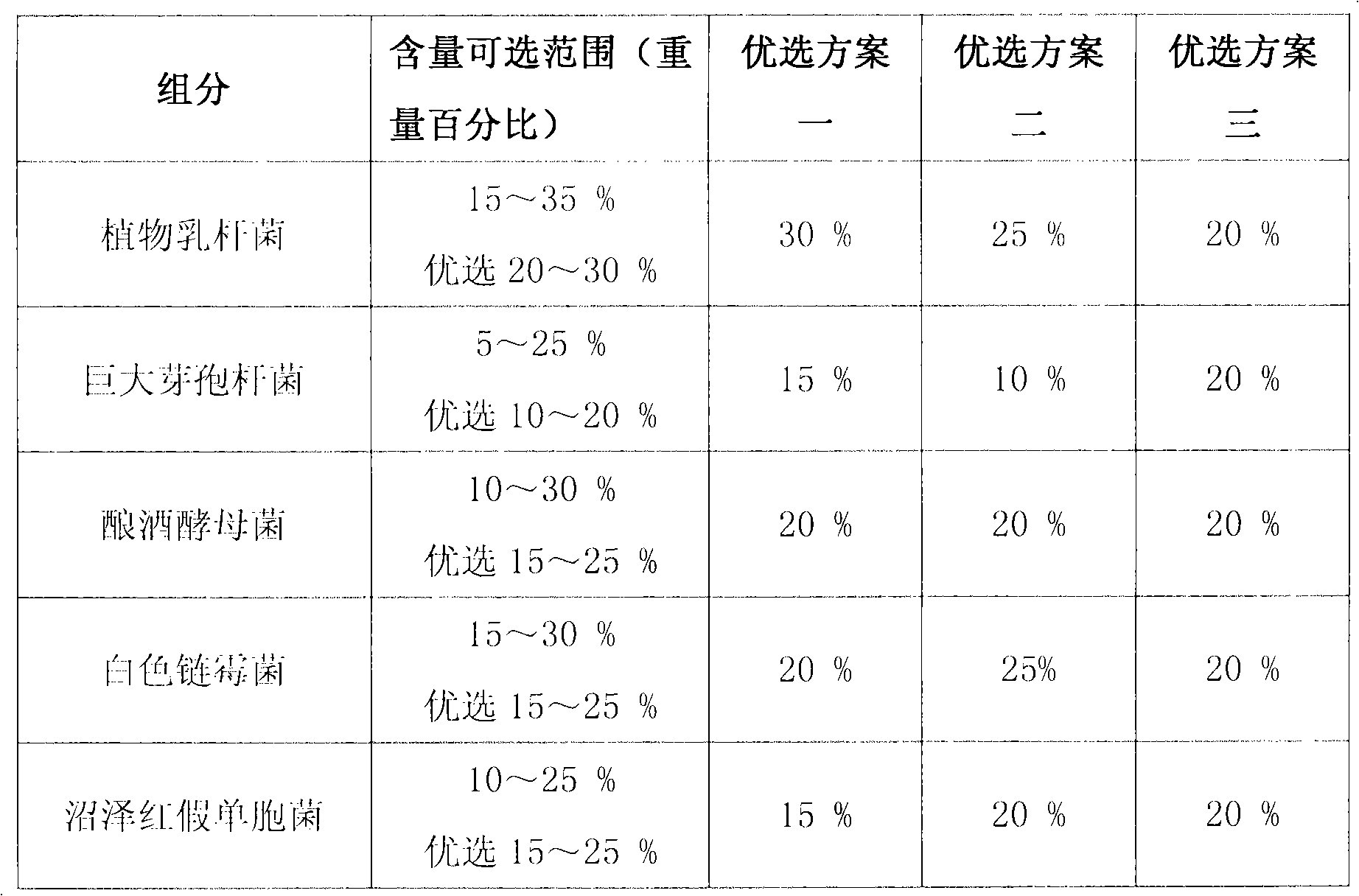

The invention discloses a complex microbial preparation for resisting replant obstacle. The complex microbial preparation comprises lactobacillus plantarum, bacillus megaterium, saccharomyces cerevisiae, streptomyces albus and rhodopseudomonas palustris, and is prepared by co-culturing the bacterial components by anaerobic and aerobic combined fermentation technology, wherein the complex microbial preparation comprises the following bacterial components in percentage by weight: 15 to 35 percent of lactobacillus plantarum, 5 to 25 percent of bacillus megaterium, 10 to 30 percent of saccharomyces cerevisiae, 15 to 30 percent of streptomyces albus and 10 to 25 percent of rhodopseudomonas palustris.

Owner:北京意科乐生态科技有限公司

Electronic cigarette atomized liquid

The invention provides electronic cigarette atomized liquid which comprises, in weight percent, 0.1-5.0% of tobacco leaf extracting flavor, 1.0-10.0% of effective portion extracting solution of non-tobacco plants, 0.2-3.0% of synthetic edible flavor, 0.1-3.6% of natural nicotine and the balance mixed glycerin and propylene glycol. The electronic cigarette atomized liquid is a traditional tobacco substitute meeting requirements of smokers, facilitating health and with mixed taste and is strong and satisfying in smoke, velvety in smoking flavor, natural and harmonious, harmful substances are smaller than allowable values of relevant international standards, and the health of the smokers is facilitated.

Owner:SHENZHEN HANGSEN STAR TECH

Solid waste biological treatment technology based on earthworm breeding

InactiveCN106106372AIncrease contentLow costFood processingClimate change adaptationSludgeHazardous substance

The invention discloses solid waste biological treatment technology based on earthworm breeding. The invention discloses a method for treatment of sludge and solid waste and the like through earthworm breeding in combination with harmless biological treatment so that contents of nitrogen, phosphorus, potassium, amino acid, crude proteins and other nutrients can be improved after bio-fermentation technology and earthworm coelomic digestive treatment. Therefore, a large number of harmful substances and heavy metal content (lower than an NY 525-2012 agricultural industry standard), earthworm cats are raw material for organic fertilizers with high quality. Raw material is low in cost. Process is simple and easy to master. The purpose of eco-environment protection is fulfilled. The technology belongs to circular economy which is an industry greatly supported by China. The technology is suitable for scale production and promotion.

Owner:刘建忠

Electronic cigarette control method and electronic cigarette

InactiveCN107105793AReduce the presence of hazardous substancesTobacco devicesHazardous substanceEngineering

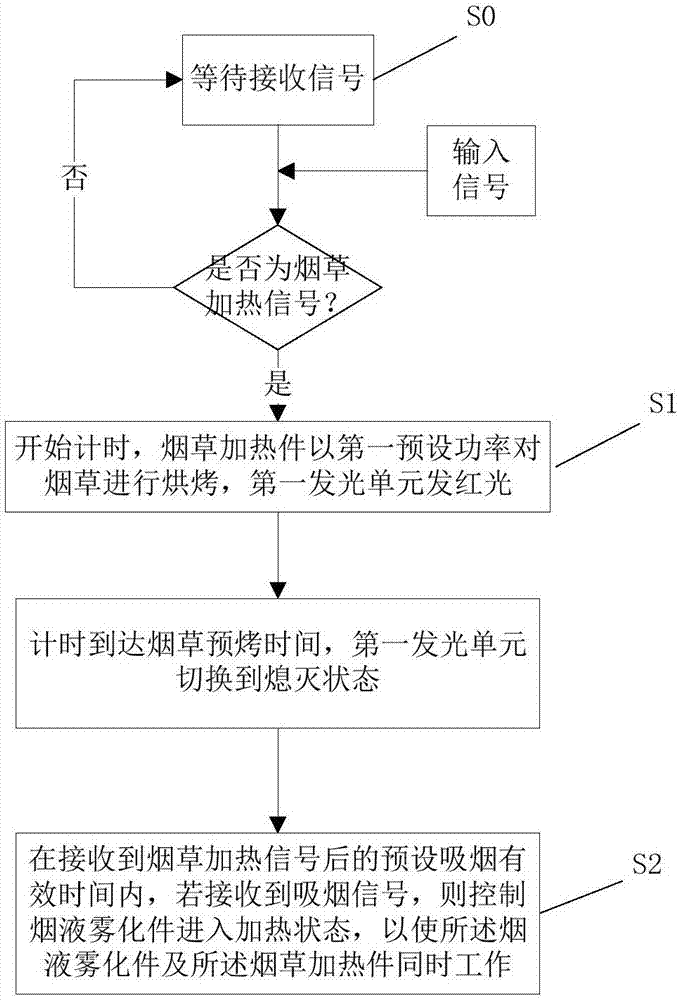

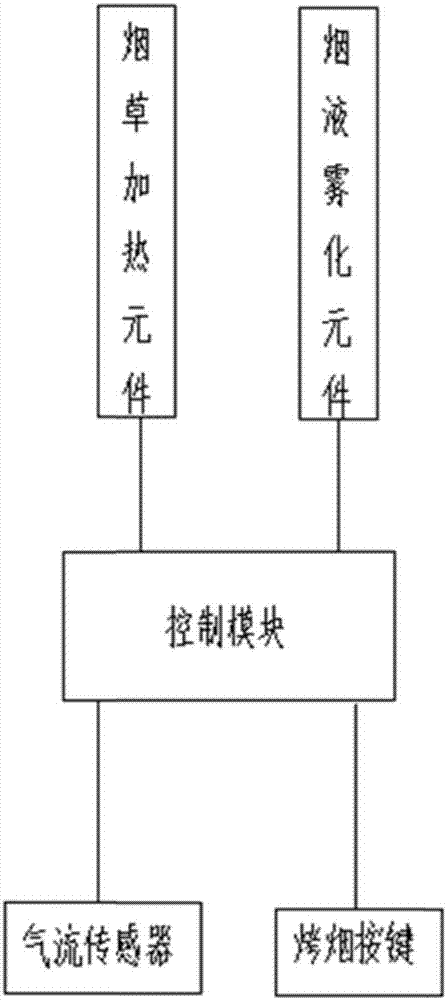

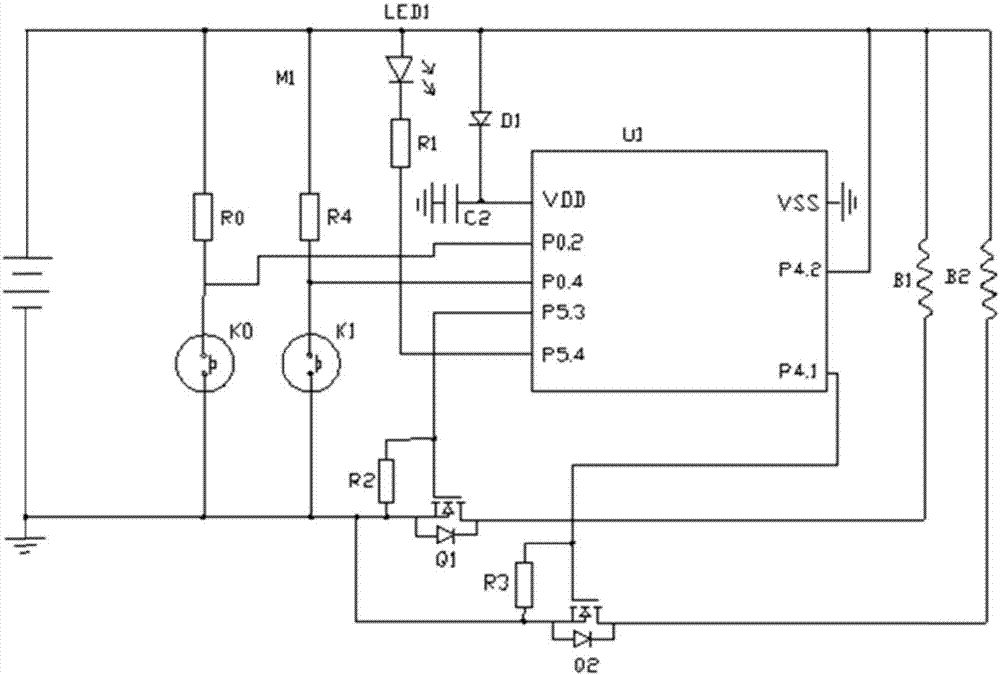

The present invention discloses an electronic cigarette control method and an electronic cigarette. The method comprises the steps of S1 if a tobacco heating signal is received, controlling a tobacco heating member to enter a heating state, baking the tobacco with a first preset power; S2 within the preset smoking effective time after the tobacco heating signal is received, if a smoking signal is received, controlling a tobacco juice atomization member to enter the heating state to enable the tobacco juice atomization member and the tobacco heating member to work simultaneously, wherein when the smog generated by using the tobacco juice atomization member to the tobacco juice flows in a tobacco area baked by a heating element, the tobacco is evaporated continuously, the smog and the smog generated by using the tobacco heating member to brake the tobacco are mixed and then are discharged for the users to smoke, wherein the tobacco heating signal is a signal generated by pressing a tobacco baking button, and the smoking signal is a signal generated by pressing a smoking button.Based on the present invention, the effects of enjoying the fragrance of the tobacco and reducing the hazardous substance to a larger extent can be realized at smoking.

Owner:HUIZHOU KIMREE TECH

Flue-cured tobacco type electronic cigarette solution

The invention provides flue-cured tobacco type electronic cigarette solution which comprises the following quality proportioning components: 5-50% Yunnan flue-cured tobacco extracting solution, 1-10% tobacco ketone 1035, 1-10% tobacco ketone 1036, 0.5-5% tobacco flavour, 0.1-2.5% natural nicotine, 5-25% medical glycerol, 1-10% distilled water, 1-15% edible alcohol and balance propylene glycol. According to the flue-cured tobacco type electronic cigarette solution, a traditional tobacco succedaneum which accords with Chinese smoker needs is beneficial to health, and the traditional tobacco succedaneum has natural full-bodied Yunnan flue-cured tobacco odour, and is elegant and fine in absorption, abundant and satisfied in odour, moderate in strength, purified in agreeable aftertaste, small in hazardous substance and beneficial to health of bodies of smokers. The traditional tobacco succedaneum is sweat and engenders liquid.

Owner:SHENZHEN HANGSEN STAR TECH +1

Tobacco fiber paper filter stick and preparation method thereof

InactiveCN103829374AConsistent colorRealize visualizationCigarette manufactureTobacco smoke filtersTarPapermaking

The invention relates to the field of tobacco filter sticks, and discloses a tobacco fiber paper filter stick and a preparation method of the tobacco fiber paper filter stick. The paper filter stick is composed of a filter element and forming paper, wherein the filter element is obtained by coiling paper fiber, the paper fiber is tobacco fiber pulp and long fiber pulp which are obtained by grinding tobacco raw materials and long fiber raw materials into liquid, then the tobacco fiber pulp and the long fiber pulp are subjected to pulp matching, sheet making, squeezing and drying to be manufactured into a fiber paper base, and the tobacco fiber paper filter stick can be obtained through smearing, drying and rolling. On the basis of wet process papermaking, tobacco fiber and long fiber are mixed according to a proper proportion in the pulp matching stage of papermaking, and the obtained paper filter stick not only has higher tar and nicotine removing capacity than a cellulose acetate filter stick, but also can successfully eliminate wooden offensive odor of the long fiber. Raw materials of the filter stick come from natural plants, and therefore the filter stick only has the scent of tobacco and does not have the scent of paper or chemical fiber, the color of the filter stick is consistent to that of cut tobacco of cigarettes, and the filter stick has the texture of natural material of tobacco and guides a new direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

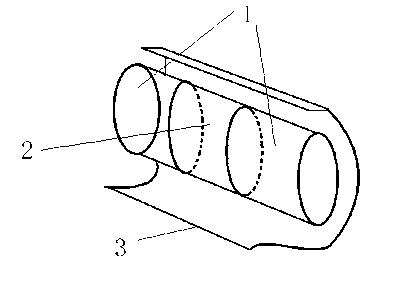

Ternary tobacco fiber paper filter stick of composite moistening plants and preparation method thereof

ActiveCN103054189AImprove adsorption capacityPromote absorptionCigarette manufactureTobacco smoke filtersFiberCellulose acetate

The invention relates to the technical field of tobacco filter sticks and discloses a ternary tobacco fiber paper filter stick of composite moistening plants. The ternary tobacco fiber paper filter stick is composed of a filter element and a molding paper wrapped on the filter element, the filter element comprises two sections of tobacco fiber paper filter elements and a moistening plant filter element arranged between the two sections of tobacco fiber paper filter elements, the tobacco fiber paper filter element is reeled by paper fibers, and the moistening plant filter element is pressed by throat moistening plant particle. The ternary tobacco fiber paper filter stick is based on wet-method papermaking and enables tobacco fiber slurry and long fiber slurry to be mixed according to appropriate proportion in a papermaking slurry mixing stage, and the prepared paper filter stick has stronger tar and nicotine removal capability than cellulose acetate fibers, does not bring in miscellaneous gas, wet whistles and returns sweet. Raw material resources are natural plants, the ternary tobacco fiber paper filter stick has no paper or chemical fiber taste, the color of the ternary tobacco fiber paper filter stick is same with that of cigarette scraps, the ternary tobacco fiber paper filter stick has strong natural material texture of tobaccos, and guides a new research direction for the technical field of cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND

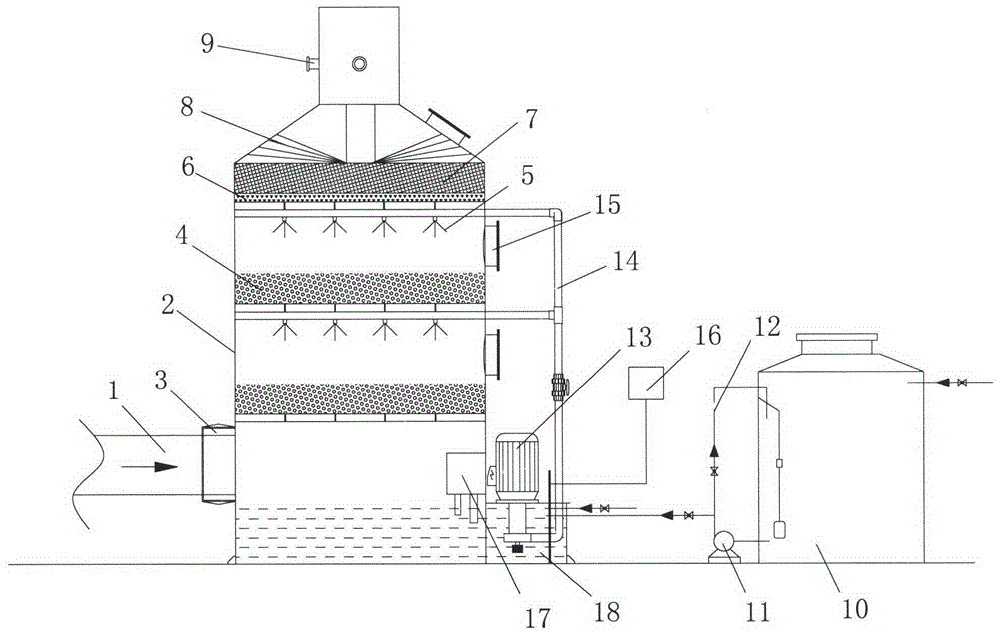

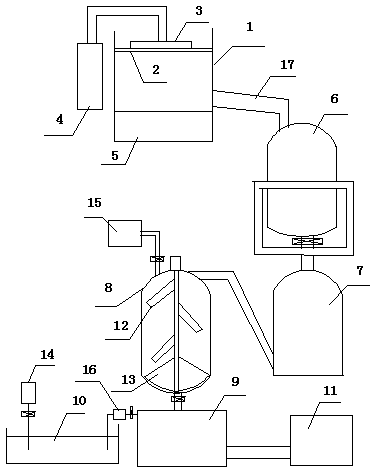

Waste gas treatment device and method for lubricating oil production line

ActiveCN103949133AEmission reductionReduce the presence of hazardous substancesCombination devicesLow noiseGlass fiber

The invention relates to a waste gas treatment device and method for a lubricating oil production line. The waste gas treatment device comprises a cylinder body, a glass fiber filter, spray heads, filler layers, an active carbon adsorption layer, a circulating water pump, a liquid storage tank and a dosing tank, wherein the glass fiber filter is arranged at an air inlet in the lower end of the cylinder body, the filler layers are fixed in the middle in the cylinder body, the spray heads are correspondingly arranged above the filler layers, the active carbon adsorption layer is correspondingly arranged above the spray heads, the circulating water pump is arranged on the liquid storage tank and is connected with the spray heads, and the dosing tank is communicated with the interior of the liquid storage tank through a dosing pump. According to the waste gas treatment device and the waste gas treatment method, by carrying out several procedures of water absorption, water removal and active carbon adsorption, harmful substances in the waste gas generated in a production process of lubricating oil can be greatly reduced and are far lower than national discharge standards; the device has the advantages of low resistance, low energy consumption, low noise, high processing efficiency, high corrosion resistance, high strength, convenience in dismounting and maintaining, lightness, durability and the like.

Owner:江苏司能润滑科技有限公司

Treatment technique suitable for high salt and high concentrated organic wastewater

InactiveCN101381190AEfficient processThe process is simple and easy to operateFatty/oily/floating substances removal devicesMultistage water/sewage treatmentChemistryPetroleum

The invention provides a treatment process applicable to high-salinity high-concentration organic wastewater. Aiming at three types of high-salinity high-concentration organic wastewater (wherein contained salts are NH4Cl, MgCl2 and MgSO4), the invention adopts physical adsorption, oil-phase and aqueous-phase separation, coagulation and air-flotation, oxidation, concentration and crystallization, oxidation, biological treatment and a series of processes for treatment. The treatment process removes COD and NH3-N in the wastewater, ensures that the pH value of the wastewater can meet the secondary discharge standard of the petrochemical industry class in Integrated Wastewater Discharge Standard (GB8978-1996), and can recover useful salt materials, namely NH4Cl, MgCl2.6H2O and MgSO4.7H2O (content accounts for 10 to 20 percent of raw water) from the three types of wastewater. The treatment process obtains remarkable economic benefit at the same time of treating sewage, and can also be used for reducing the cost for sewage treatment. The treatment process has the advantages of low cost, high efficiency, easy operation and no secondary pollution, and is applicable to the treatment of the high-salinity high-concentration organic wastewater.

Owner:YUNNAN UNIV

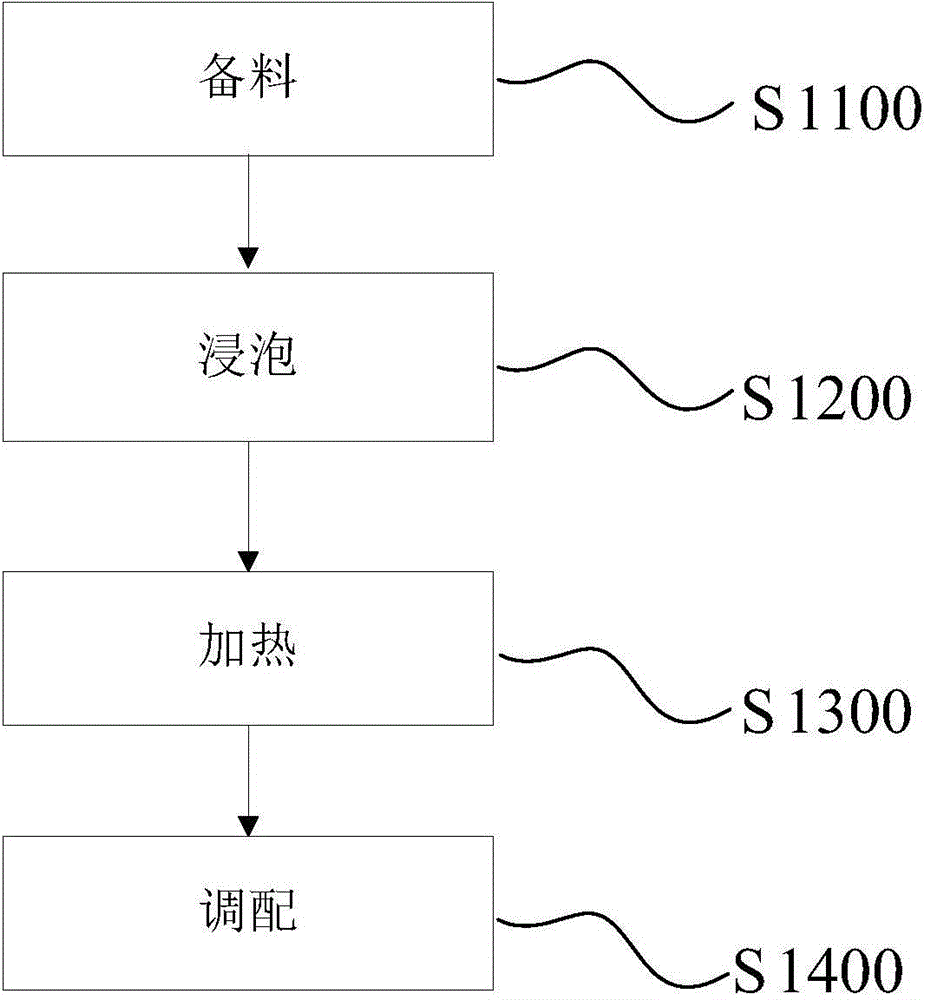

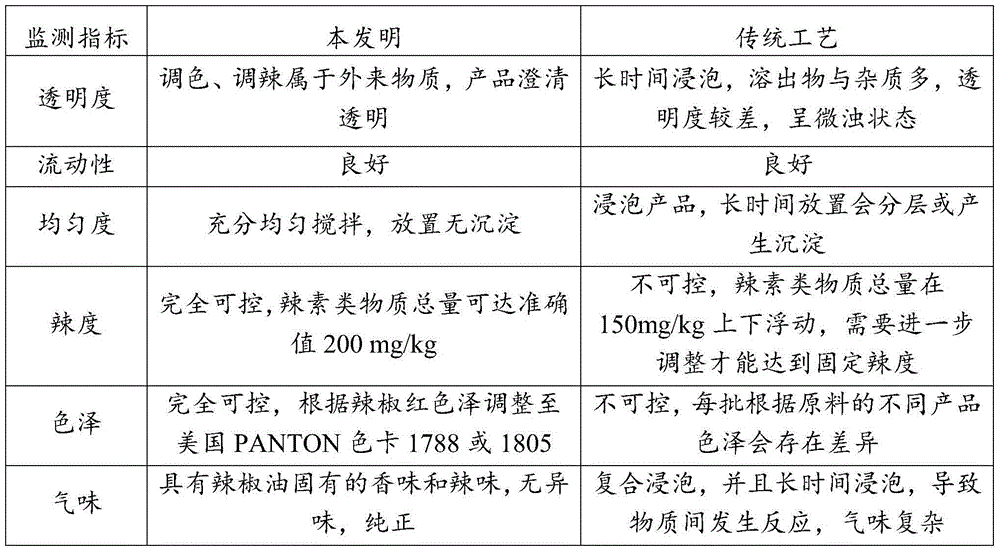

Chili oil and preparation method thereof

ActiveCN104366421AAvoid continuous high temperature fryingDeliciousFood preparationFood ingredient as mouthfeel improving agentVegetable oilHazardous substance

The invention discloses chili oil made of main ingredients and auxiliary ingredients. The main ingredients include, by weight, 1-5 parts of capsanthin, 0.1-0.5 part of chilli extract, 50-100 parts of dried chilli and 500-1600 parts of vegetable oil. The auxiliary ingredients include, by weight, 10-50 parts of spices and 100-200 parts of seasoning. The invention further discloses a preparation method of the chili oil. The capsanthin and the chilli extract are natural mixtures extracted from soaked dry vegetable chillies, continuous high-temperature deep fry in preparation of chili oil is avoided by adding the natural color and pungency reinforcing ingredients, and accordingly hazardous substances generated in deep fry are reduced, and the chili oil is more nutritious and healthier and tastes delicious. The chili oil not only can replace edible oil for cooking dishes but also can be directly used for direct dressing of cold dishes, braised dishes and the like.

Owner:YUNNAN RAINBOW BIO TECH

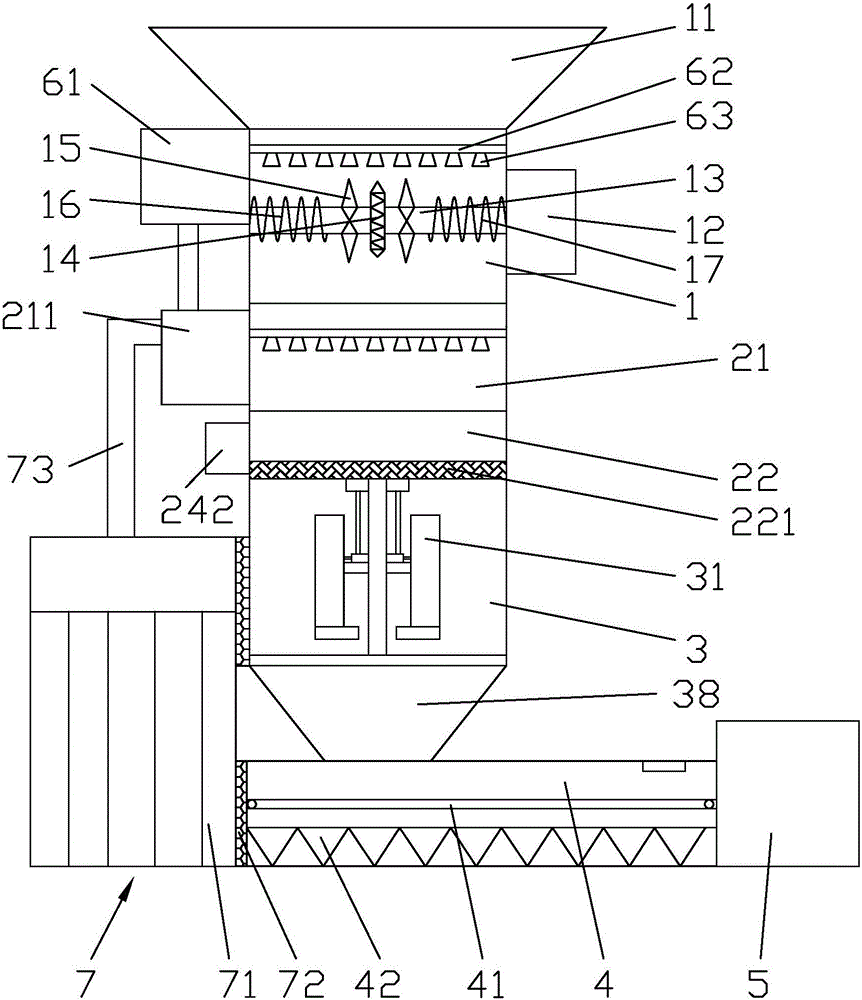

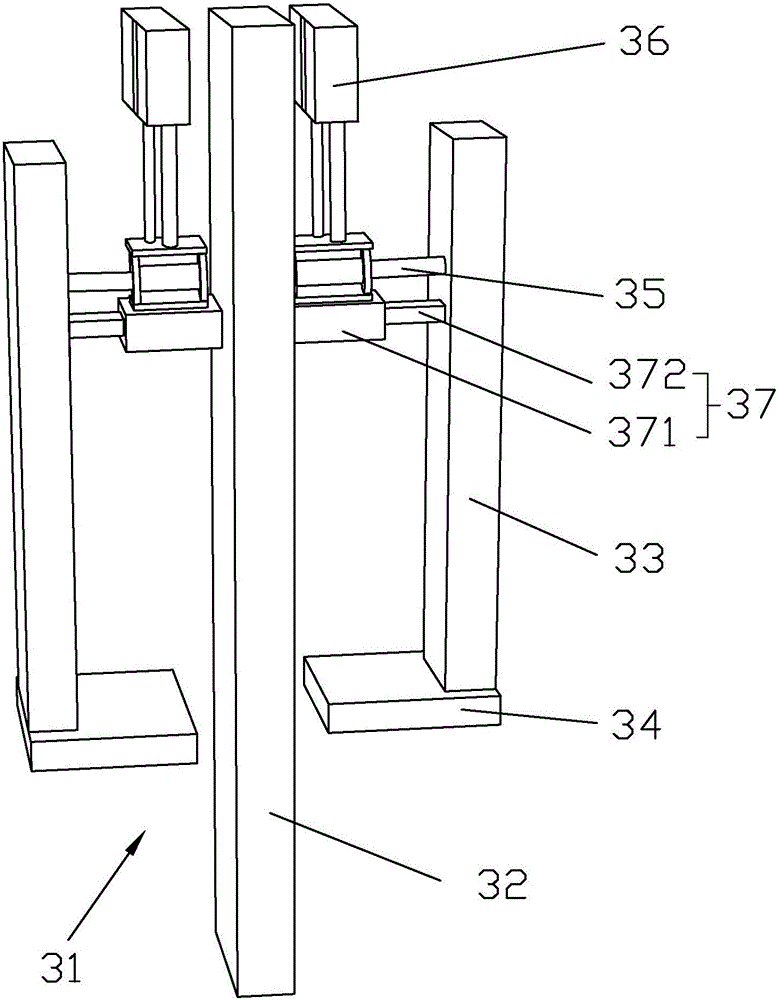

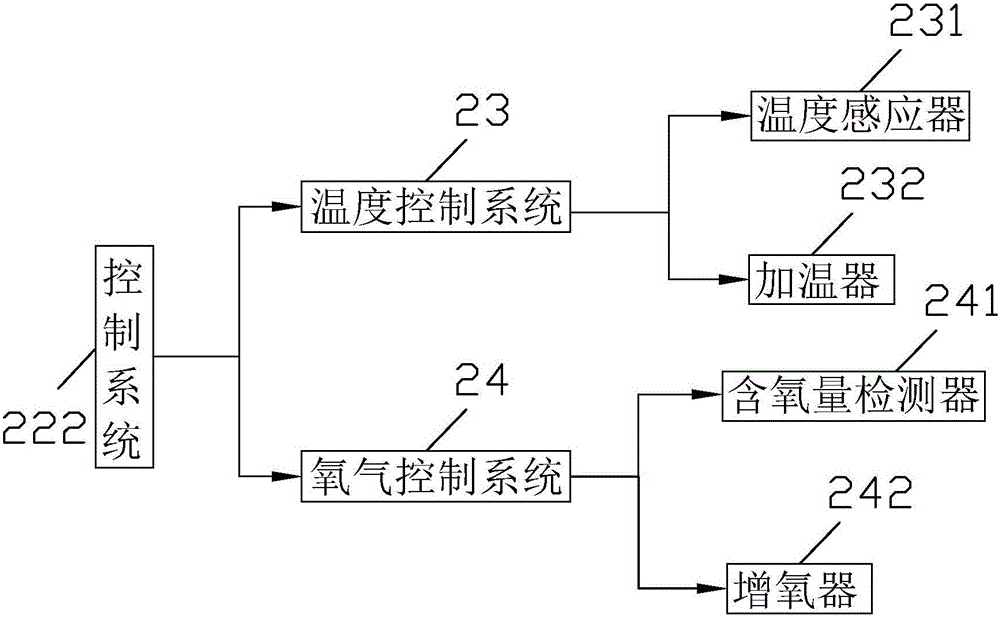

Sludge treating machine applied to ecological river and treating method of sludge treating machine

ActiveCN106082570ASmall particlesEasy to handleSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemical treatmentSludge

The invention mainly discloses a sludge treating machine applied to an ecological river and a treating method of the sludge treating machine. The treating machine comprises a pulverizing bin, a treating bin, a water drainage bin, a drying bin and a storage bin, wherein a feeding hopper is arranged above the pulverizing bin; a pulverizing mechanism is arranged in the pulverizing bin; the treating bin comprises a chemical treating bin and a microbial treating bin; a filter pressing device is arranged in the water drainage bin; the water drainage bin is connected with the drying bin through a material guiding plate; a conveying mechanism and a heating mechanism are arranged in the drying bin; and a discharging opening of the conveying mechanism is connected with the storage bin. The treating method comprises the following steps: sludge digging, pulverizing treatment, chemical treatment, microbial treatment, water drainage treatment, drying treatment and storage. The method is simple and effective, convenient to operate, environmentally friendly, and high in treatment efficiency, the quality of the sludge is improved effectively, toxic and harmful substances in the sludge are reduced, meanwhile, water in the sludge is reduced, storage and conveyance of the sludge are facilitated, and purposes of changing harmful substances into beneficial substances, recycling materials and protecting the environment achieved.

Owner:浙江景昌建设有限公司

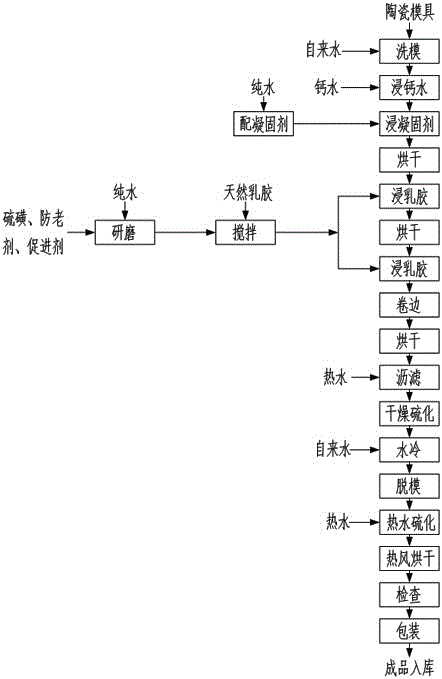

Production method of latex gloves

The invention discloses a production method of latex gloves. The production method comprises the following ten steps of mold washing, calcium water soaking, drying, latex soaking, edge curling, drying, leaching, drying vulcanization, water cooling and mold releasing. The production method has the beneficial effects that the surfaces of the latex gloves produced through the method are good, the physical performance is good, and few harmful substances are generated in the latex gloves.

Owner:南京润京乳胶制品有限公司

Cigarette filter rod with zeolite fragrance beads and cigarette zeolite fragrance bead preparation method

The invention discloses a cigarette filter rod with zeolite fragrance beads and a cigarette zeolite fragrance bead preparation method. The cigarette filter rod comprises the zeolite fragrance beads, the zeolite fragrance beads take zeolite as a carrier, adsorb essence suitable for cigarette and are provided with open adsorption holes, and the adsorption holes adsorb the essence. According to the cigarette filter rod, the zeolite fragrance beads serve as solid fragrance beads and are used in cigarette filter rod, zeolite has open adsorption holes and high adsorption capacity, fragrant substances can be stably released when cigarettes are smoked after densely covered adsorption holes of the zeolite adsorb the essence, and stable fragrance can be acquired when the cigarettes are smoked.

Owner:SHANGHAI JUHUA TECH

Production and using method of organic bio-fertilizer

InactiveCN101538177AImprove qualityIncrease profitFertiliser formsFertilizer mixturesHazardous substanceAnimal protein

The invention relates to a production method of organic bio-fertilizer. The method comprises the following steps: organic substances such as bean dregs, tobacco waste, scum, turf, animal protein, hoof meal, bone ash, pork skin, shell powder, and the like are prepared into powdery substances and evenly mixed, and then are fermented and decayed by using fermenting micro-organisms, after the content of the flora reaches 3 billion per gram, the inorganic elements such as N, P, K, and the like are added, the powdery substances are prepared into granular substances and dried, the dried granules together with bacteria strain, chitin and abamectin are mixed with water to form a package, and a product is formed after dehydration. The invention has the advantages that the method improves the quality of crops, reduces harmful substances and the content of heavy metal, improves the utilization ratio of the fertilizer, reduces the environmental pollution, improves the soil and cultivates the land capability.

Owner:段贺民

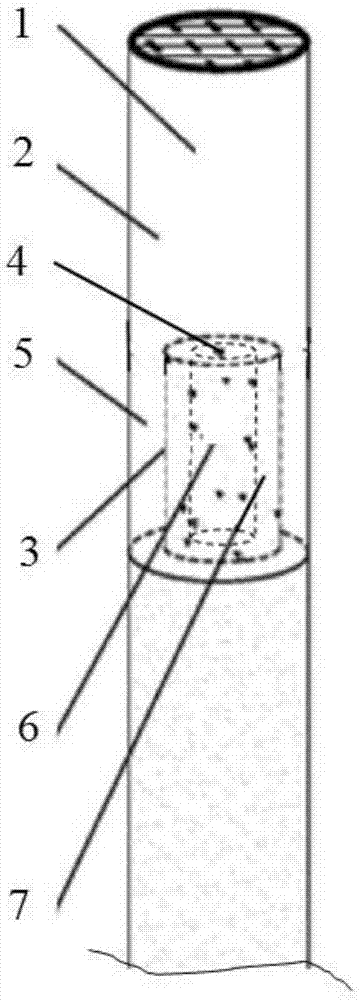

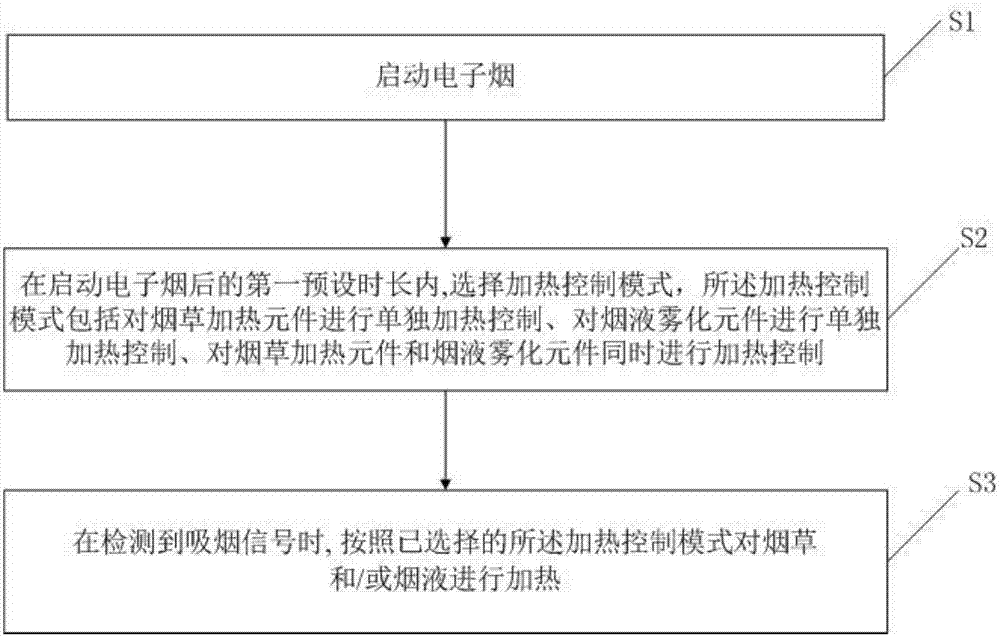

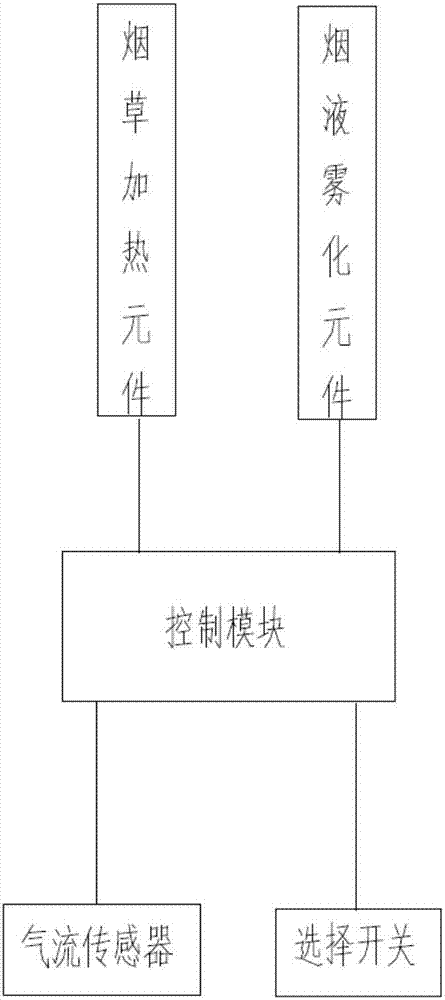

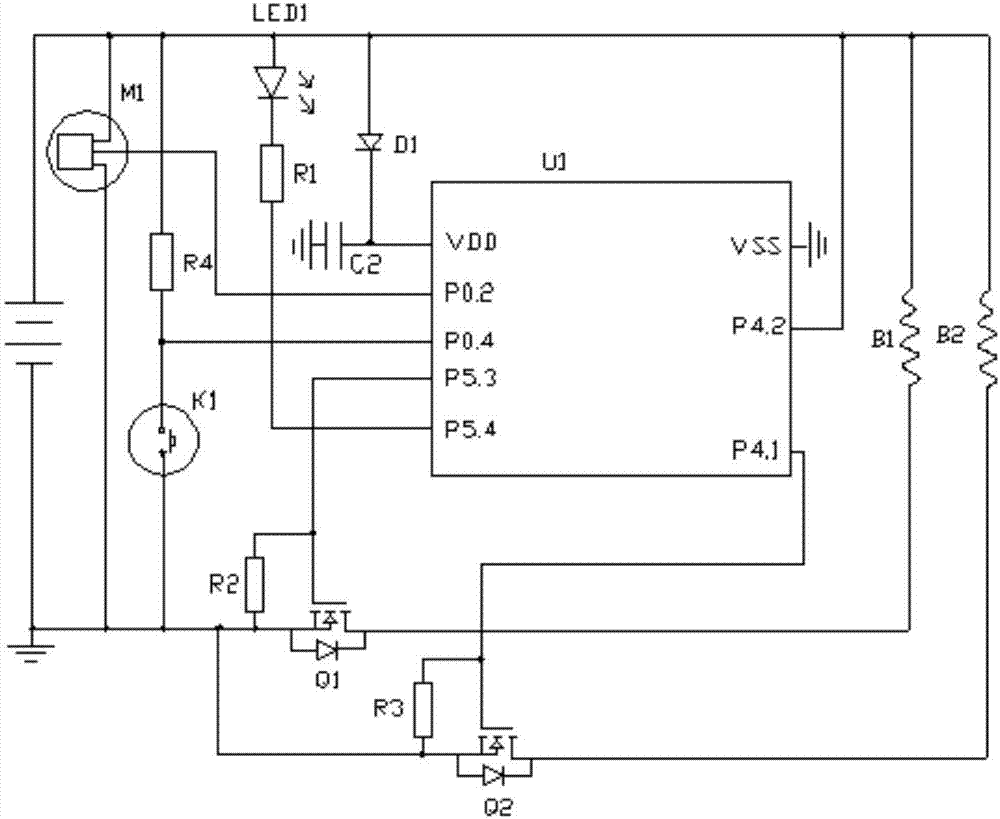

Method for controlling electronic cigarette and electronic cigarette

InactiveCN107278126AAchieve heatingMeet various smoking needsTobacco devicesHazardous substanceElectronic cigarette

The present invention discloses a method for controlling an electronic cigarette, comprising the following steps: S1, activating the electronic cigarette; S2: selecting a heating control mode for a first preset duration after starting the electronic cigarette, wherein the heating control mode includes: separately controlling heating of a heating element, and separately controlling heating of a smoke liquid atomizing element, and simultaneous control of heating of the heating element and the smoke liquid atomizing element; and S3, heating tobacco and / or tobacco oil according to the selected heating control mode when the smoking signal is detected. The method can meet diversified smoking needs of users, and can extract the aromatic smell of tobacco and can reduce the harmful substances to a large extent.

Owner:HUIZHOU KIMREE TECH

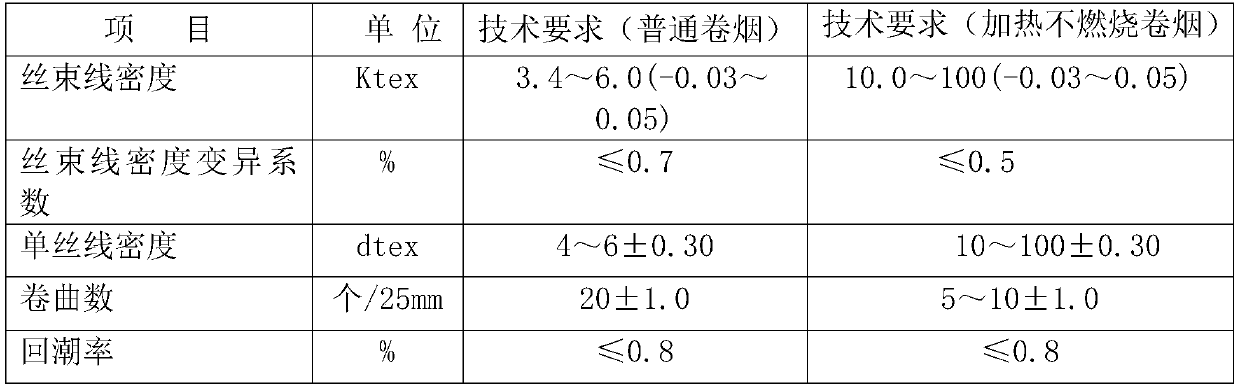

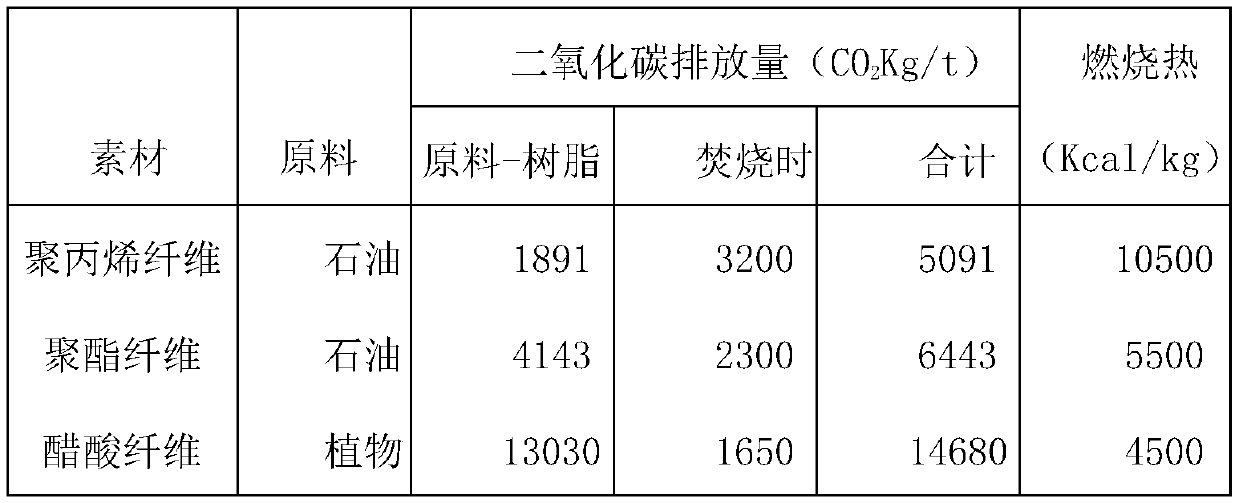

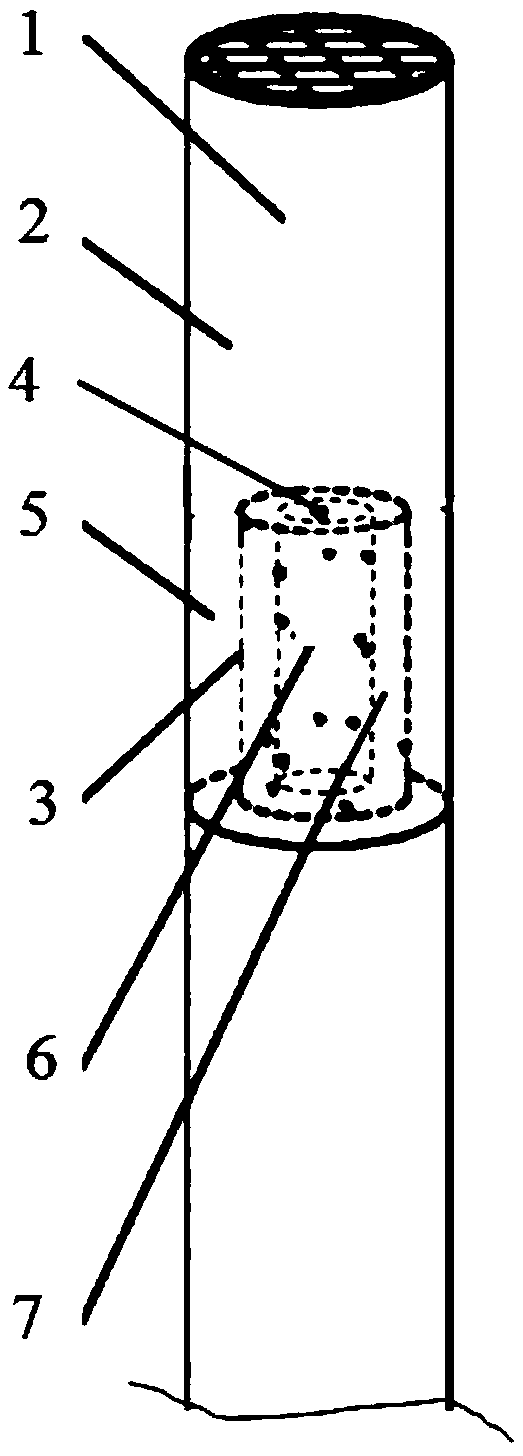

Cigarette tow with phase change heat absorption function and preparation method of cigarette tow

InactiveCN109763189AUnique smelling styleReduce the temperatureFlame-proof filament manufactureCigarette manufactureAbsorption capacityHazardous substance

The invention discloses a cigarette tow with a phase change heat absorption function. The tow is obtained as follows: microcapsules containing a phase change agent are added to a food fiber-grade polylactic acid material in a melt spinning process, and drying, melting, spinning, cooling, oiling, drafting, crimping and drying setting processes are performed. During smoking of a cigarette with a filter tip processed from fiber prepared with the preparation method, polylactic aid hollow fiber has high adsorption / absorption capacity for polar and non-polar smoke component gases; meanwhile, the temperature of smoke passing through the filter tip is increased, the polylactic acid material and the phase change material in the microcapsules absorb heat during phase state conversion, the smoke temperature is decreased, a harm reduction effect is realized, the prepared cigarette with the polylactic acid filter tip has unique smell absorption style, and harmful substances in smoke can be effectively filtered out.

Owner:云南中成道和新材料科技有限公司

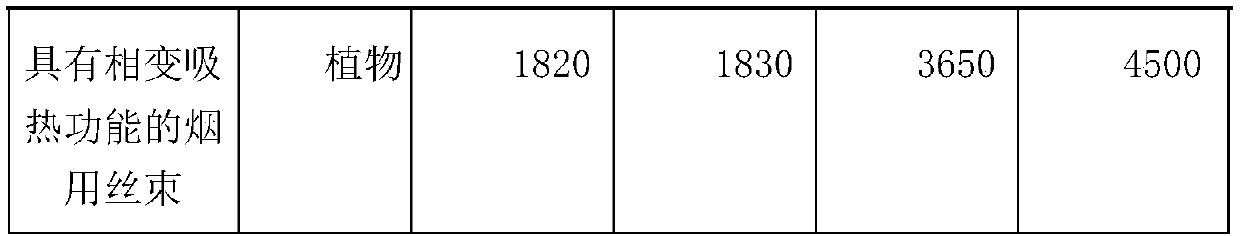

Method and device for animal feces innocent treatment

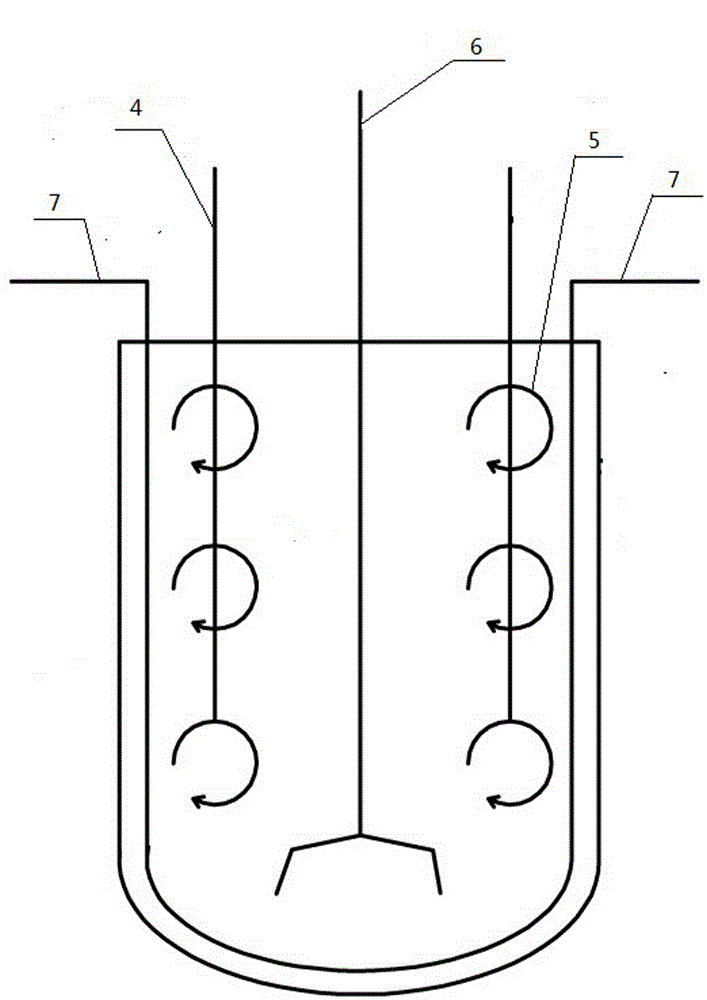

InactiveCN104529113ARealize harmless treatmentRealize pollution controlBio-organic fraction processingTreatment using aerobic processesFecesBiofuel

The invention discloses a method and device for animal feces innocent treatment. Through pre-treatment, methane tank-based treatment, biological filter filtration and constructed wetland-based purification, biogas slurry produced from manure water in a methane tank by biogas production flows through a constructed wetland mixed with microbes and is used for animal manure water purification treatment so that animal culturing farm manure water pollutant discharge is improved and environmental pollution is reduced. The biogas subjected to anaerobic treatment is used as a biofuel, sediment at the bottom of the methane tank can be processed to form fertilizer, and the biogas slurry is subjected to constructed wetland filtration, plant root absorption and microbe digestion so that requirements of the livestock and poultry industry pollutant discharge standard (GB18596-2001) are satisfied. Through effective combination of the methane tank and the constructed wetland prepared from a high-performance biofilter, the device and the method have the advantages of simple construction, low operation cost, good effects, no secondary pollution and environment improvement and really realizes animal culturing farm manure water effective-treatment and no pollution of positions surrounding a field.

Owner:YICHANG GUANGDA CERAMIC PROD

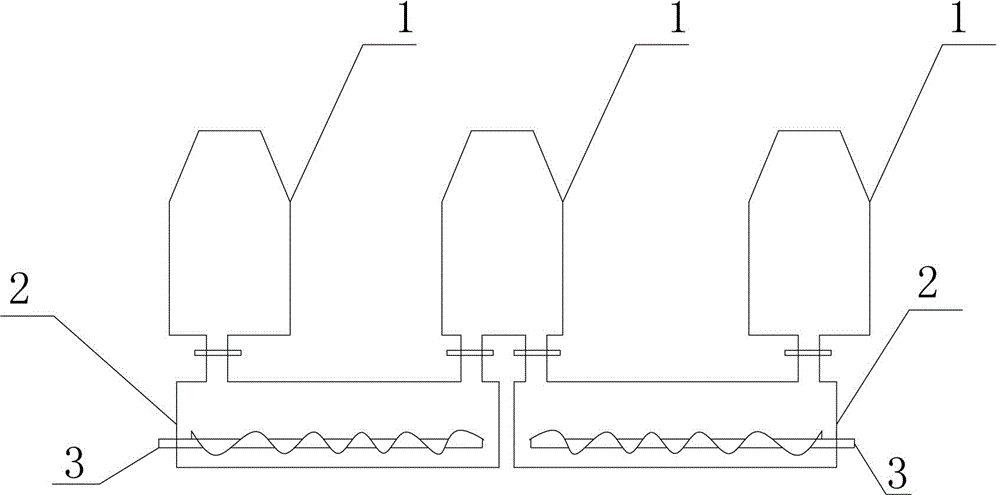

Method for preparing non-fried instant freshwater fish

The invention provides a method for preparing a non-fried instant freshwater fish, comprising the concrete steps of preparing a raw material fish, carrying out pretreatment (scale, head, tail and innards removing), washing clearly, cutting and shaping, soaking in ice water, soaking in water containing salt and vinegar, curing at a low temperature, draining, performing roast smoking, stoving, baking, spouting oil, filling, carrying out vacuum seal and microwave sterilization, boxing up to obtain the finished product. The fish prepared by adopting the method for preparing the non-fried instant freshwater fish has the advantages of no fishy smell, good taste, no poisonous or harmful substance of fried foods, little oil content and capability of guaranteeing the product quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cigarette filter rod containing aromatic silica gel beads and preparation method of aromatic silica gel beads for cigarettes

InactiveCN107836749AStrong adsorption performanceImprove stabilityTobacco smoke filtersCigarette filterSilica gel

Owner:SHANGHAI JUHUA TECH

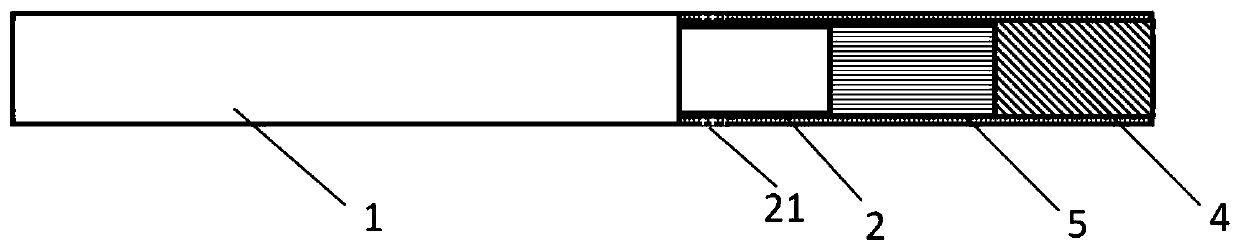

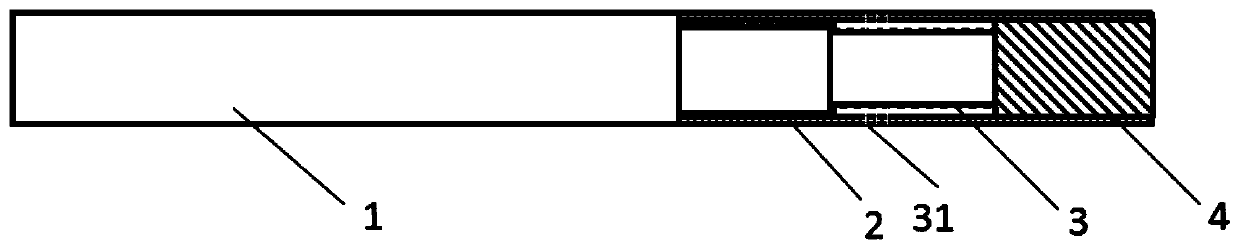

Dual-purpose smoking product

PendingCN110403235AGuaranteed smoke productionRaise the ratioTobacco treatmentCigar manufactureFlavorMass ratio

The invention discloses a dual-purpose smoking product which is suitable for being smoked after being ignited and smoked in a heat-not-burn mode at the same time. The dual-purpose smoking product comprises a cigarette core section (1), a supporting section (2) and a filtering section (4) which are sequentially connected; the supporting section (2) and the filtering section (4) are wrapped by forming paper to form a filter tip rod; the cigarette core section (1) and the filter tip rod form the smoking product through tipping paper; a cigarette core base material of the cigarette core section (1) comprises reconstituted tobacco and cut tobacco, and the mass ratio of the reconstituted tobacco to the cut tobacco is 1:1 to 7:3; the reconstituted tobacco comprises a first aroma-increasing substance with a boiling point greater than or equal to 200 DEG C and a second aroma-increasing substance with the boiling point being less than 200 DEG C. According to the structure of the smoking product,cooling and smoke filtering can be both achieved, the comfortable and fast smoking feeling is provided, flavors and fragrances with different boiling points are added to meet the smoking taste requirements of different conditions, the cigarette core section (1) can meet the requirements of consumers on nicotine, and the smoking amount can be ensured in the heat-not-burn state.

Owner:CHINA TOBACCO YUNNAN IND

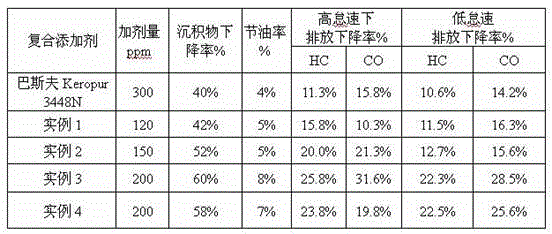

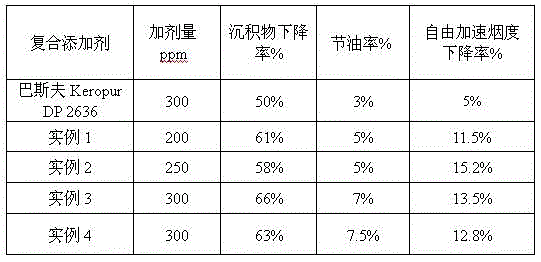

Composite high-cleanness fuel oil additive and preparation method thereof

ActiveCN105647600AImprove detergencyReduce wearLiquid carbonaceous fuelsFuel additivesCombustion chamberHazardous substance

The invention relates to the field of oil product additives, in particular to a composite high-cleanness fuel oil additive and aims at providing a composite high-cleanness fuel oil additive for improving the dynamic properties, cleanness and corrosion and abrasion resistance of fuel oil and a preparation method thereof. The composite high-cleanness fuel oil additive is prepared from, by mass, a detergent main agent 10-60%, an anti-abrasion agent 0-10%, a corrosion inhibitor 0-10%, an antioxidant 0-5%, carrier oil 15-40% and the balance a thinner, wherein the detergent main agent is one or more of polyisobutylene phenol mannich base, PEA polyether amine and polyisobutylene amide. The fuel oil adopting the composite additive has good cleanness, the colloid, carbon deposition and coking at automobile jet nozzles, throttle valves, combustion chambers and other parts can be obviously reduced, the abrasion of components of a fuel system can be reduced, the oxidative deterioration of the fuel oil and the additive can be inhibited, and the harmful substances in engine tail gas emissions can be reduced.

Owner:SHAANXI YANCHANG PETROLEUM ENERGY TECH CO LTD

Tobacco slice and cigarette

ActiveCN103211288AReduce the presence of hazardous substancesReduce tarTobacco preparationHazardous substanceTar

The invention provides a tobacco slice and a cigarette. The tobacco slice comprises a slice substrate, wherein the slice substrate is prepared by adopting a mixture comprising agricultural waste materials and tobacco waste materials as raw materials. The cigarette comprises cut tobacco, wherein 2 to 100 mass percent of cut tobacco slices are mixed in the cut tobacco, in addition, the tobacco slice comprises the slice substrate, and the slice substrate is prepared by adopting a mixture comprising agricultural waste materials and tobacco waste materials as raw materials. The tobacco slice prepared by adopting the mixture of the agricultural waste materials and the tobacco waste materials as the raw materials is added into the cigarette, harmful substances in the main flow smoke gas of the cigarette can be obviously reduced, the tar is reduced, and the smoke gas state is improved, so the main flow smoke gas is fluffy and soft, the mouth feeling comfort is improved, the oral cavity residue is reduced, the defect of smoke gas concentration reduction caused by too high content when only non-tobacco slices are adopted can be overcome, meanwhile, the goal of resource reutilization is also reached, and the problem of tobacco slice raw material shortage is solved.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Aluminum slag recovery equipment and process

ActiveCN108220611ARecycle thoroughlyRealize harmless treatmentSolid waste disposalProcess efficiency improvementSlagHazardous substance

The invention belongs to the technical field of aluminum slag recovery, and particularly relates to an aluminum slag recovery equipment and process. The aluminum slag recovery equipment can realize two-step recovery of aluminum slag by extrusion treatment and heating centrifugal separation treatment, so that the aluminum slag can be recovered more thoroughly, and the harmless treatment of slag ashcan be realized to prevent the slag ash from harming the environment. According to the aluminum slag recovery process, aluminum in the aluminum slag is completely recovered by two times of the recovery process, and the recovery rate is as high as 93%, so that huge economic benefits are produced, and aluminum resources are greatly saved; no salt fluxing agent is applied, so that the pollution to the environment is reduced; and the slag ash is finally subjected to harmless treatment, harmful substances in the slag ash can be greatly reduced, and the pollution to the environment of the slag ashis reduced.

Owner:山东创新精密科技有限公司

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com