Chili oil and preparation method thereof

A technology of chili oil and chili red, which is applied in the directions of food preparation, food ingredients as taste modifiers, and functions of food ingredients, etc., can solve problems such as unfavorable human health and production of harmful substances, and achieve the effect of reducing harmful substances and delicious taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

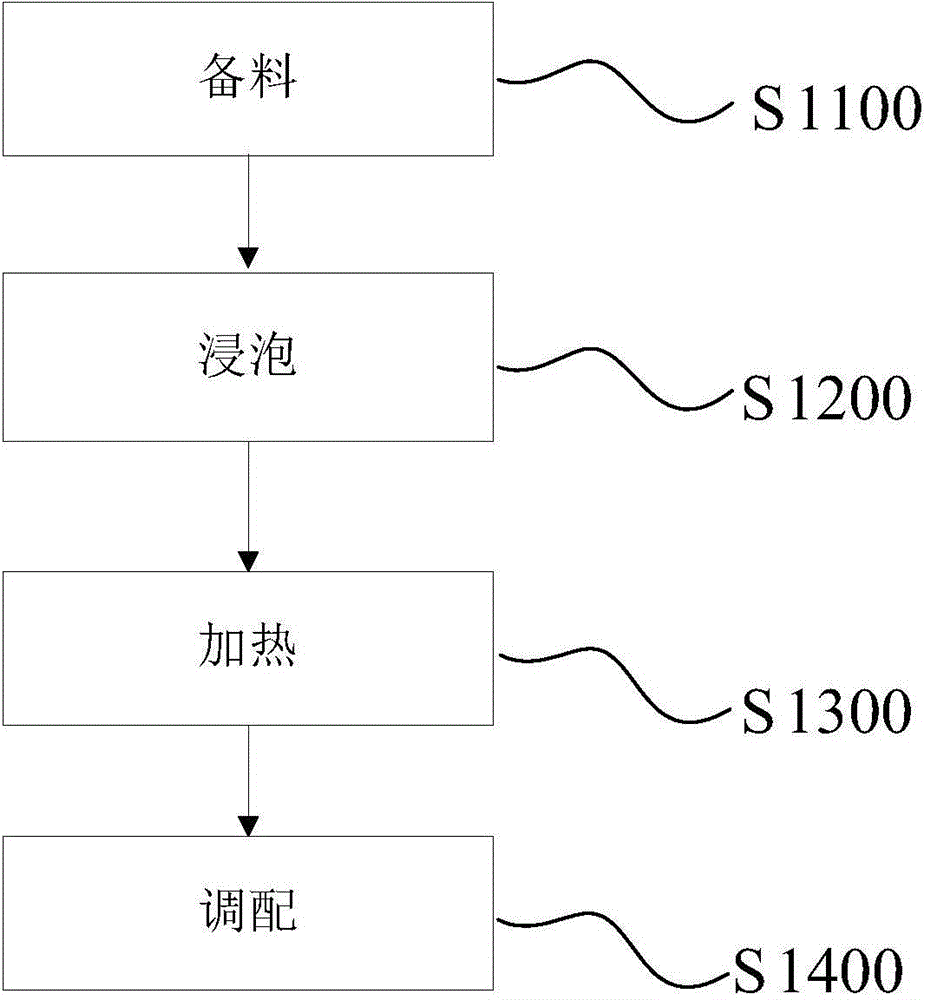

[0026] On the other hand, the present invention also provides the preparation method of above-mentioned chili oil. figure 1 A schematic flow diagram showing the preparation method of chili oil according to the present invention. Such as figure 1 Shown, this preparation method comprises the steps:

[0027] Material preparation step S1100: prepare main ingredients and auxiliary materials, wherein the main ingredients include 1-5 parts by weight of capsicum red, 0.1-0.5 parts by weight of capsicum essence, 50-100 parts by weight of dried chili, 500-1600 parts by weight of vegetable oil, and the auxiliary materials include 10 parts by weight of spices -50 parts by weight, 100-200 parts by weight of seasoning;

[0028] Soaking step S1200: Soak the dried peppers, spices and seasonings in vegetable oil for 2-4 hours, and filter to obtain crude oil;

[0029] Blending step S1400: adding capsicum red and capsicum essence into the crude oil, and stirring evenly.

[0030] Wherein, in ...

Embodiment 1

[0036] The raw material that present embodiment prepares capsicum oil is:

[0037] Main ingredients: 1600g vegetable oil, 1g capsicum red, 0.1g capsicum essence, 50g dried chili, 100g fresh chicken fir; accessories: a. 8g cinnamon, 16g star anise; b. Seasoning: 80g salt, 30g sugar, 20g fresh onion, 20g peeled garlic, 20g fresh ginger, 30g dried pepper.

[0038] Wash the fresh chicken fir as the main ingredient, wash the green onions, garlic and ginger as the auxiliary ingredients, and then dry them. Cut off the chicken fir (1-2cm section), grind the dried chili into powder; grind other auxiliary materials except salt and sugar into powder.

[0039] Add dried chili powder, chicken fir segment, and all other auxiliary materials into the vegetable oil at 60° C. for 3 hours in the order of main ingredients first and auxiliary materials. During the soaking process, stir every 15 minutes until the aroma comes out.

[0040] Filter the vegetable oil to remove residue with a 50-mesh...

Embodiment 2

[0042] The raw materials and method for preparing chili oil in this example are the same as those in Example 1, except that the amount of vegetable oil is 500g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com