Sludge treating machine applied to ecological river and treating method of sludge treating machine

A sludge treatment and ecological river channel technology, applied in biological sludge treatment, sludge treatment, sludge treatment and other directions, can solve the problems of deterioration of properties, poor land, loss of use value, etc., to improve the quality and effect of treatment, reduce sludge The effect of reducing the water content and reducing the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

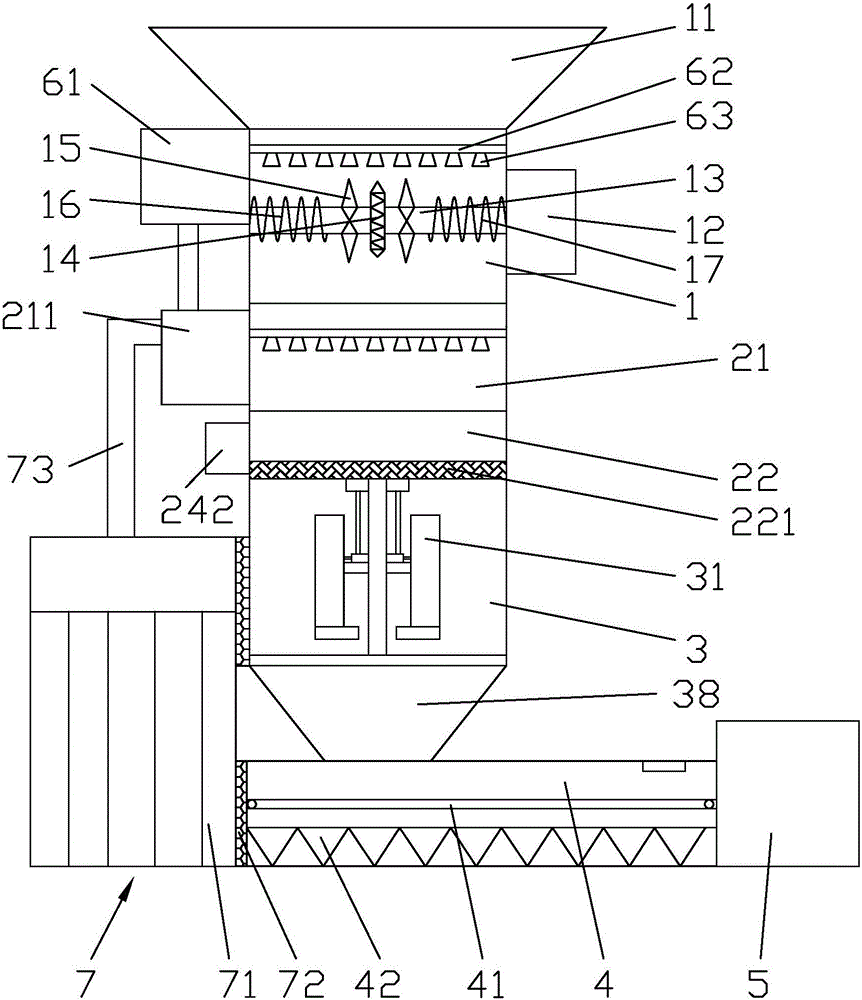

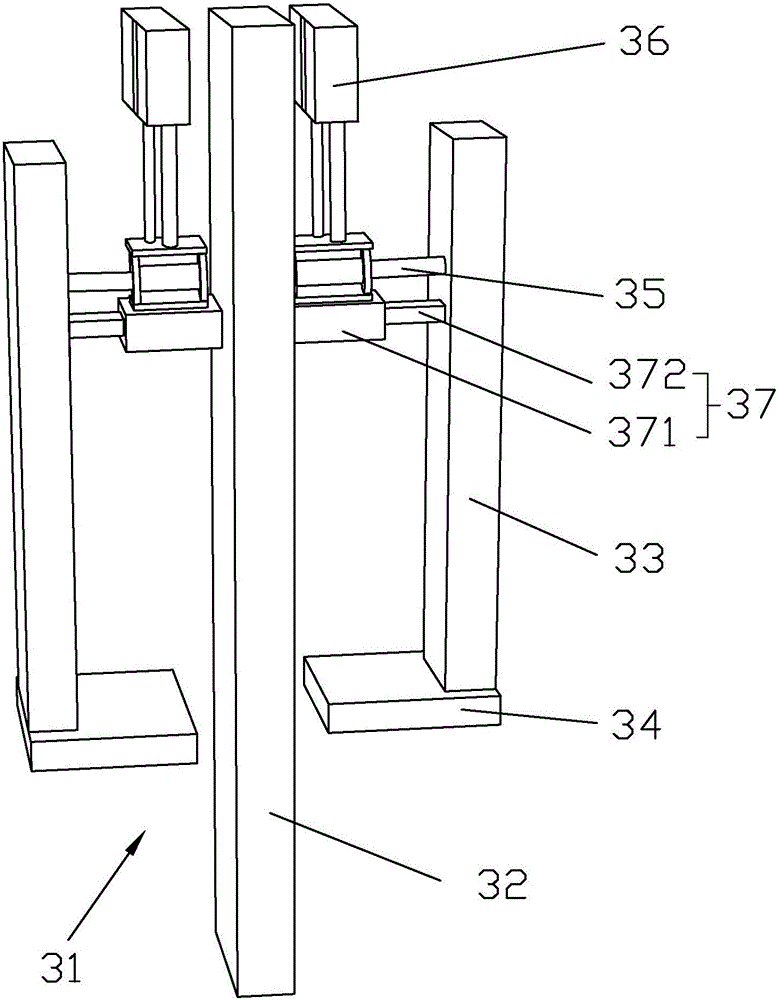

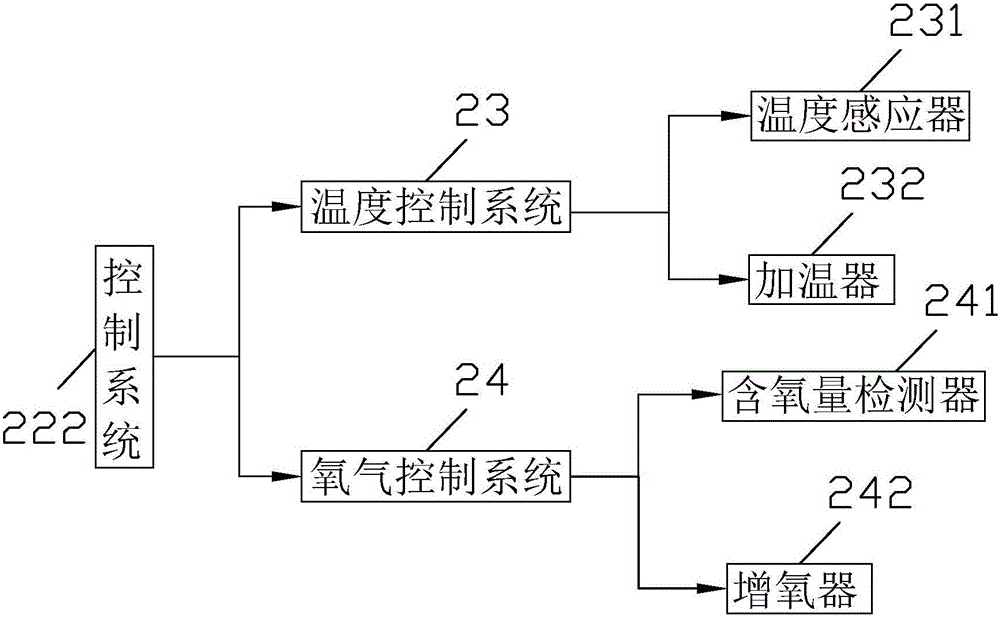

[0044] Such as Figure 1-4 As shown, it is a sludge treatment machine applied to ecological rivers of the present invention, including a crushing bin 1, a processing bin, a drainage bin 3, a drying bin 4 and a storage bin 5, and a feeding hopper 11 is arranged above the crushing bin 1, The crushing chamber 1 is equipped with a crushing mechanism, and the crushing chamber 1 first receives the original sludge poured from the feed hopper 11, and crushes the large pieces of original sludge and impurities mixed in the sludge through the crushing mechanism to make the particles finer. , which is convenient for later processing. The crushing mechanism comprises a driver 12, a rotating rod 13, a crushing disc 14 and a crushing knife 15, the rotating rod 13 is connected with the driver 12, the crushing disc 14 is sleeved at the middle position of the rotating rod 13, and the crushing knife 15 is located at the left and right sides of the crushing disc 14 respectively. On the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com