Production method of latex gloves

A technology of latex gloves and a production method, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of poor physical properties of latex gloves and easy occurrence of rubber particles, and achieves good surface, easy to remove, and tightly combined. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

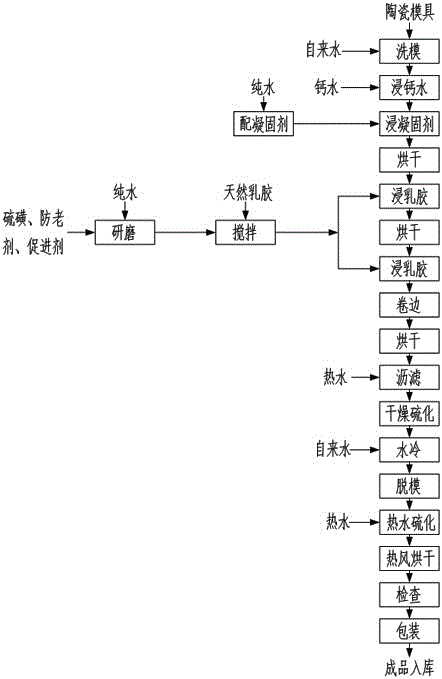

[0032] like figure 1 The production method of shown latex gloves comprises the steps:

[0033] Step 1, wash the mold, wash the ceramic mold with clean water.

[0034] Step 2, soaking in calcium water, immersing the ceramic mold in calcium water, so that calcium ions are evenly distributed on the surface of the ceramic mold; in this application, calcium water is an aqueous solution of calcium chloride, a release agent, and a surfactant, and the concentration of calcium ions depends on the The concentration of latex gloves produced, the greater the concentration of calcium ions, the greater the thickness of the latex gloves produced, the smaller the concentration of calcium ions, the smaller the thickness of latex gloves produced, according to specific configuration.

[0035] Step 2.1, prepare coagulant, add calcium chloride, release agent, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com