Cigarette tow with phase change heat absorption function and preparation method of cigarette tow

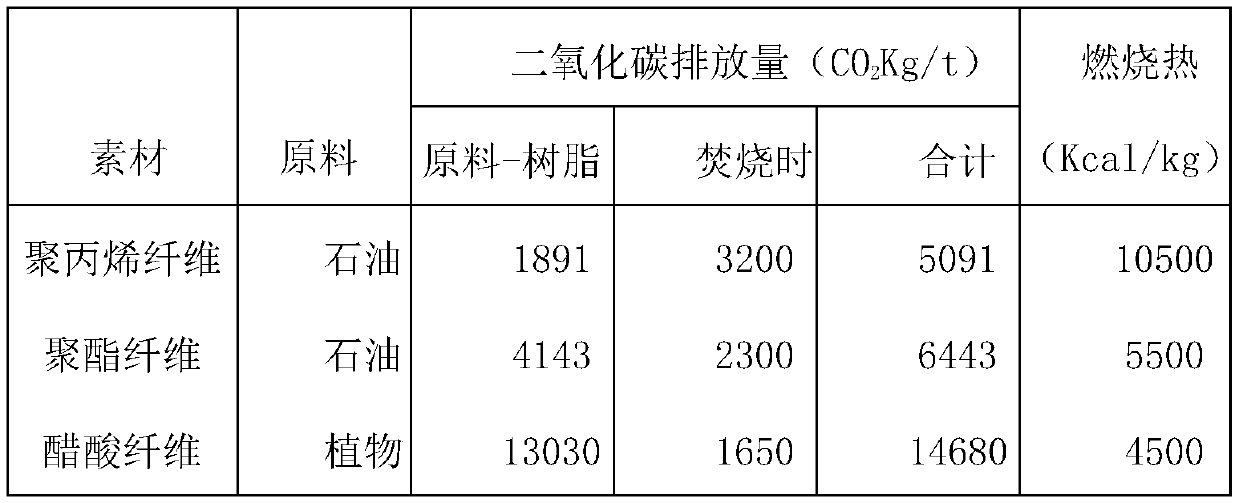

A phase change and functional technology, applied in rayon manufacturing, hollow filament manufacturing, fire-retardant and flame-retardant filament manufacturing, etc., can solve the problem of unsatisfactory cooling effect of flue gas, achieve large latent heat of phase change, and improve contact exchange. Specific surface, the effect of reducing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a tobacco tow with a phase-change endothermic function, specifically comprising the following steps:

[0031] (1) Dry the food fiber grade polylactic acid at 70°C for 4h, add microcapsules containing phase change agent after drying the slices, melt in the screw extruder, set the temperature of the screw feeding section to 180°C and the temperature of the compression section to 202 ℃, the temperature of the metering section is 197 ℃; the microcapsule core is prepared by filling the zeolite with phase change paraffin; the capsule wall is prepared by polyacrylic resin;

[0032] (2) spinning the melted fiber-grade polylactic acid at a spinning temperature of 190° C., passing through a spinneret with a special-shaped hollow and multiple shapes, wherein the shape of the spinneret holes in the spinneret is a combination of Y-type and C-type, Make the molten polylactic acid flow through the hollow special-shaped hollow spinneret orifice and spray; and coo...

Embodiment 2

[0037] A method for preparing a tobacco tow with a phase-change endothermic function, specifically comprising the following steps:

[0038] (1) Dry the food fiber grade polylactic acid at 85°C for 3 hours, add microcapsules containing phase change agent after drying the slices, and melt them in the screw extruder. Set the temperature of the screw feeding section to 185°C and the temperature of the compression section to 205°C ℃, the temperature of the metering section is 200 ℃; the microcapsule core is prepared by filling the activated carbon with polyethylene glycol; the capsule wall is prepared by polyurethane resin;

[0039] (2) Spinning the melted fiber-grade polylactic acid at a spinning temperature of 210° C. through a spinneret with a special-shaped hollow and multiple shapes, wherein the shape of the spinneret holes in the spinneret is a combination of double arcs and shapes. , so that the molten polylactic acid flows through the hollow special-shaped hollow spinneret ...

Embodiment 3

[0044] A method for preparing a tobacco tow with a phase-change endothermic function, specifically comprising the following steps:

[0045] (1) Dry the food fiber grade polylactic acid at 100 °C for 2 hours, add microcapsules containing phase change agent after drying the slices, and melt them in the screw extruder. Set the temperature of the screw feeding section to 190 °C and the temperature of the compression section to 208 °C ℃, the temperature of the metering section is 203 ℃; the microcapsule core is prepared by filling fatty acid in silicate; the capsule wall is prepared by polyester resin;

[0046] (2) Spinning the melted fiber-grade polylactic acid at a spinning temperature of 220° C., passing through a spinneret with a special-shaped hollow and multiple shapes, wherein the shape of the spinneret holes in the spinneret is a combination of Y-shaped and double-arc shapes. , so that the molten polylactic acid flows through the hollow special-shaped hollow spinneret and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com