Patents

Literature

79 results about "Change agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for user network behavioural based anomaly detection

InactiveUS20070245420A1Memory loss protectionError detection/correctionApplication softwareBehavioural analysis

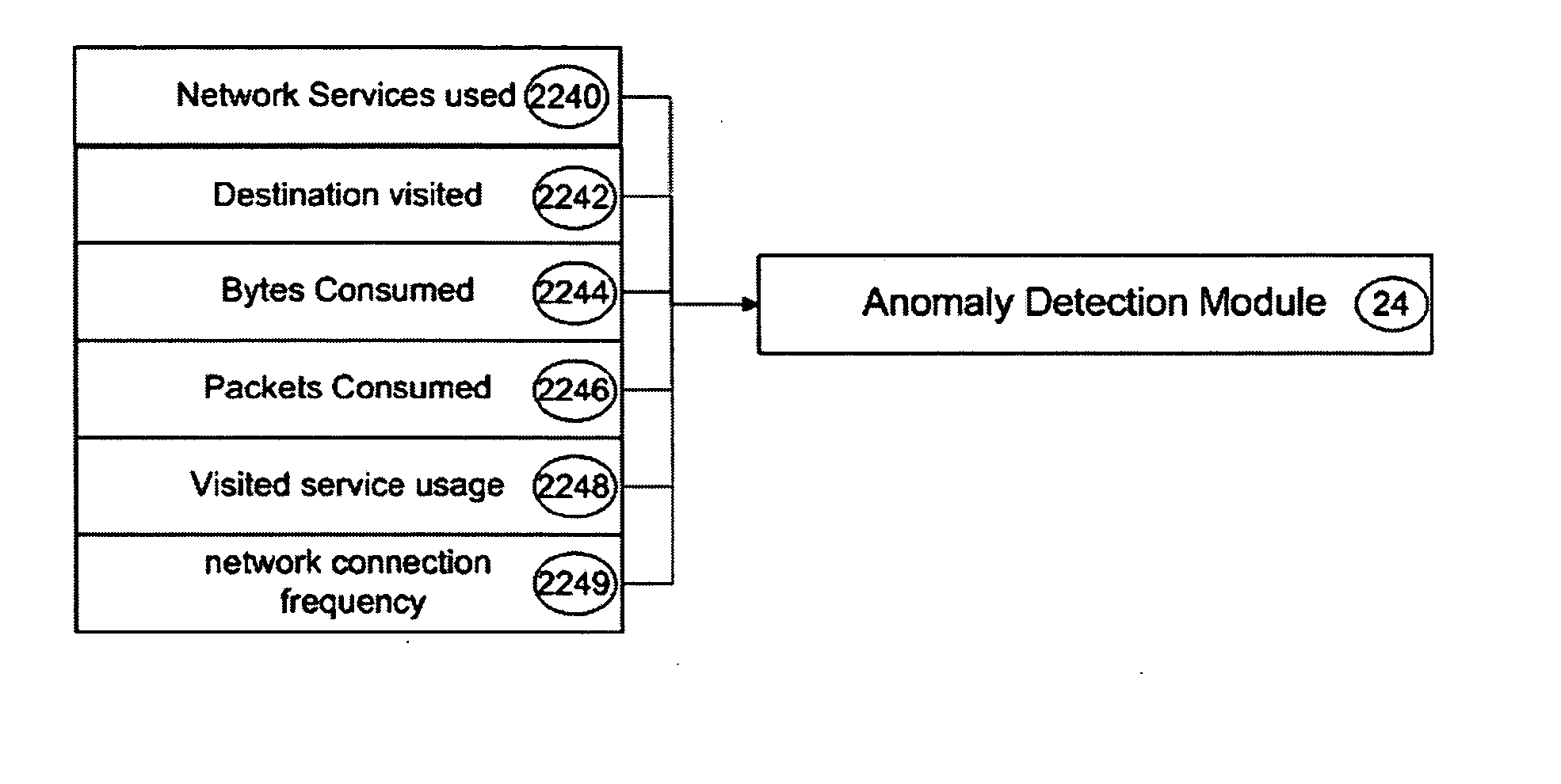

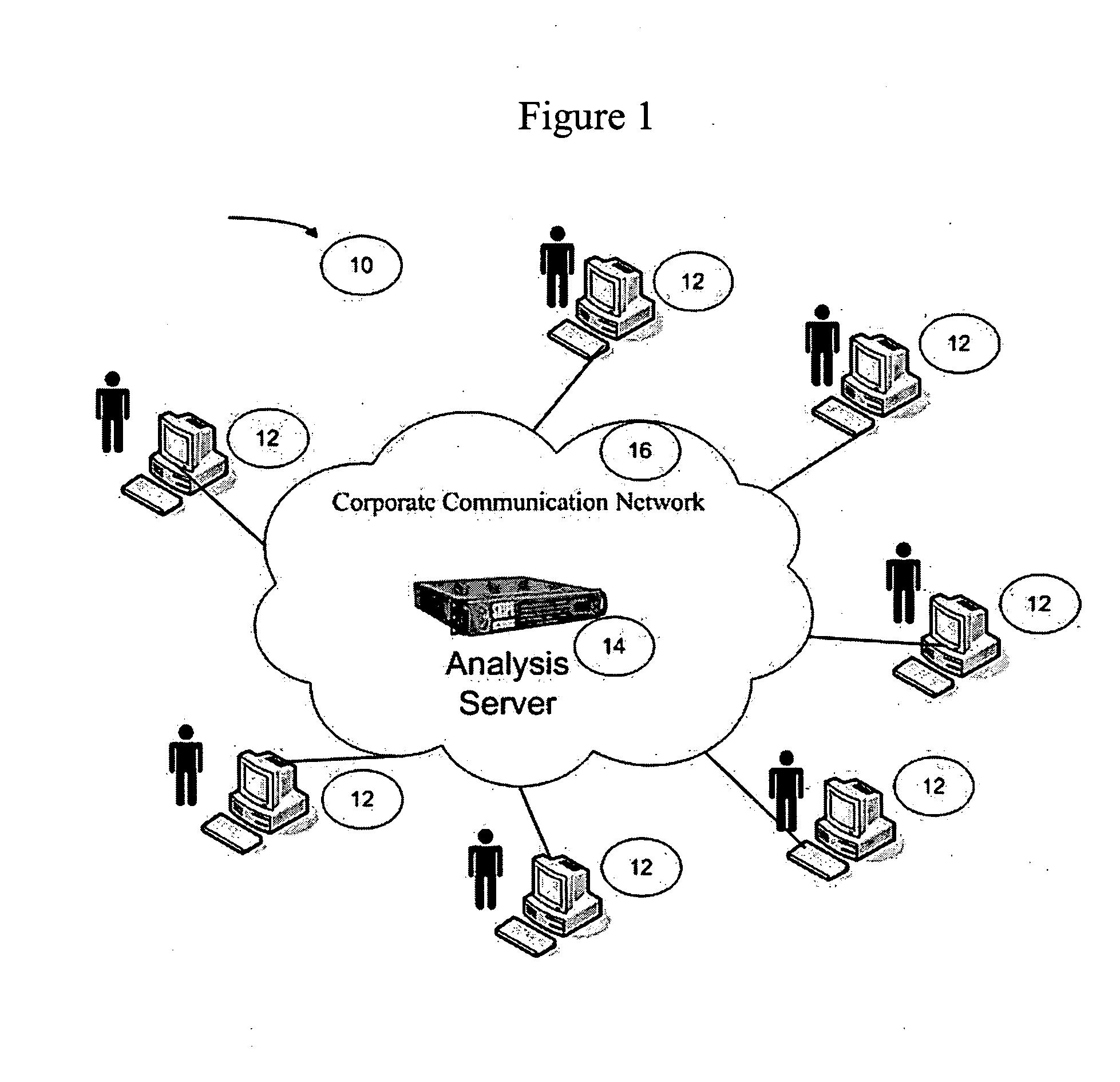

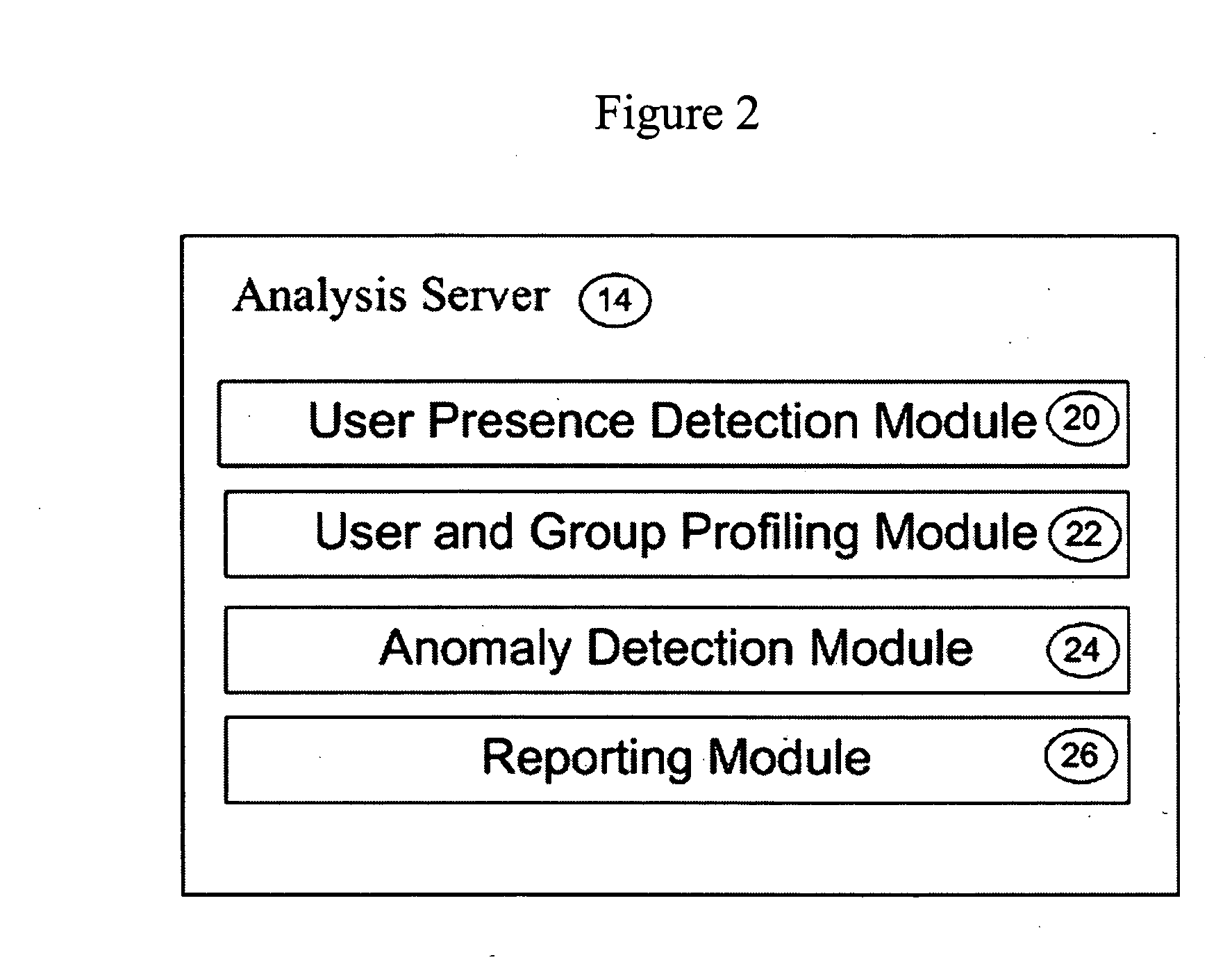

A baseline can be defined using specific attributes of the network traffic. Using the established baseline, deviation can then be measured to detect anomaly on the network. The accuracy of the baseline is the most important criterion of any effective network anomaly detection technique. In a local area network (LAN) environment, the attributes change very frequently by many change agents; for example, new entities, such as users, application, and network-enabled devices, added to and removed from the LAN environment. The invention provides an improved method of establishing a baseline for network anomaly detection based on user's behaviour profiling. A user behaviour profiling is a distinct network usage pattern pertaining to a specific individual user operating on the LAN environment. No two users profiling would be the same. A group of users that have similar network usage attributes can be extrapolated using data mining technique to establish a group profiling baseline to detect network usage anomaly. By combining user and group profiling, a network anomaly detection system can measure subtle shift in network usage and as a result separate good user's network usage behaviour from the bad one. Using the said technique, a lower rate of false positives of network anomaly can be created that is suitable to operate in a highly dynamic LAN environment.

Owner:YONG YUH MING +1

Wet wipe dispensing system

Owner:KIMBERLY-CLARK WORLDWIDE INC

Neutral silicone fire-retardent sealing glue and its preparing method

InactiveCN1438289AImprove fire performanceNot corrosiveOther chemical processesAdhesivesCross-linkChemical reaction

The invention is a neutral silicone fireproof sealing gum and the making method. It adds alpha, omiga-dihydroxy polysiloxane 10-90 shares, filling 90-100 shares and flame resistting agent 10-90 shares to vacuum kneader, then at the temperature of 80-150 deg.C and the vacuum of -0.06-0.095 MPa, dehydrates and mixes for 60-100 minutes, and then moves to high-speed disperse blending kettle; at room temperature, adds silicon alkyl cross-linking agent 1-10 shares, touch-changing agent 1-10 shares, tackifier 1-10 shares, catalytic curing agent 0.1-5 shares and plasticizer 1-10 shares to the blending kettle to mix, and at the vacuum of -0.06-0.095 MPa and the speed of 100-600 rpm, and makes chemical reaction for 30-180 minutes to get the sealing gum. The main technical indexes: pendent degree according to GB / T 13477, zero, extrusion according to GB16776, 2.3-2.8 and flame retardance according to GB / T2048-1996, FV-zero level.

Owner:CHENGDU GUIBAO SCI & TECH

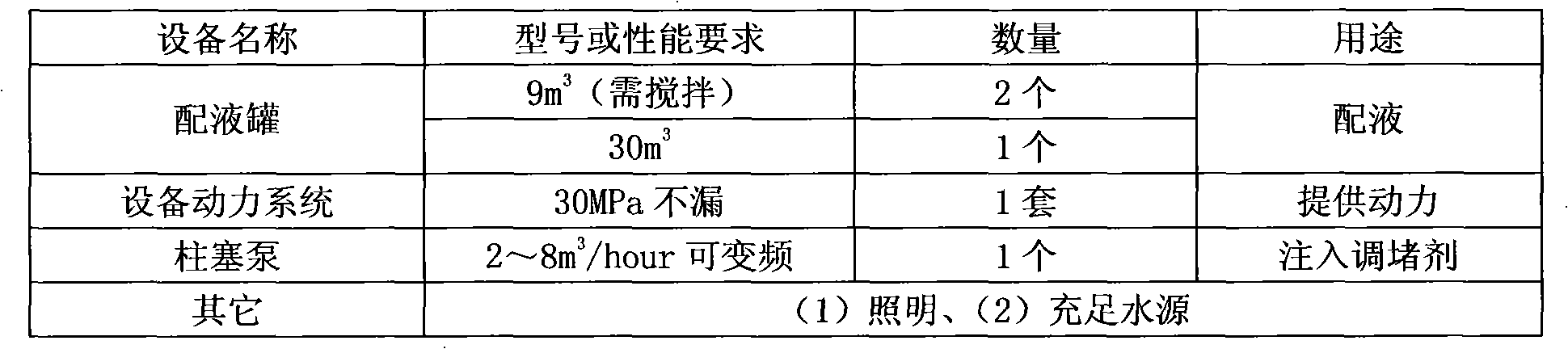

Deep profile control method for fractured oil reservoir

The invention relates to a deep profile control method for a fractured oil reservoir. By the method, the recovery ratio of crude oil can be increased. Four sections of plugs are provided for plugging different types of fluid-channeling channels, wherein in the first section of plug, a high-strength solidification system is used for plugging fracture; in the second section of plug, inorganic gel is used for plugging microfracture or large pores; in the third section of plug, a water drive flow direction changing agent and weak gel are used for further filling the fracture and the pores so as to displace residual oil in the pores; and in the fourth section of plug: a strong gel YQY plugging agent is used for plugging the fracture near the wellbore. By the method, the problem that the oil well is flooded by water caused by the fracture of the fractured oil reservoir water injection well can be effectively solved; the water absorption condition of a storage layer is changed; the utilization ratio of the injected water is increased; the swept volume is enlarged; and the oil displacement efficiency is improved finally.

Owner:PETROCHINA CO LTD

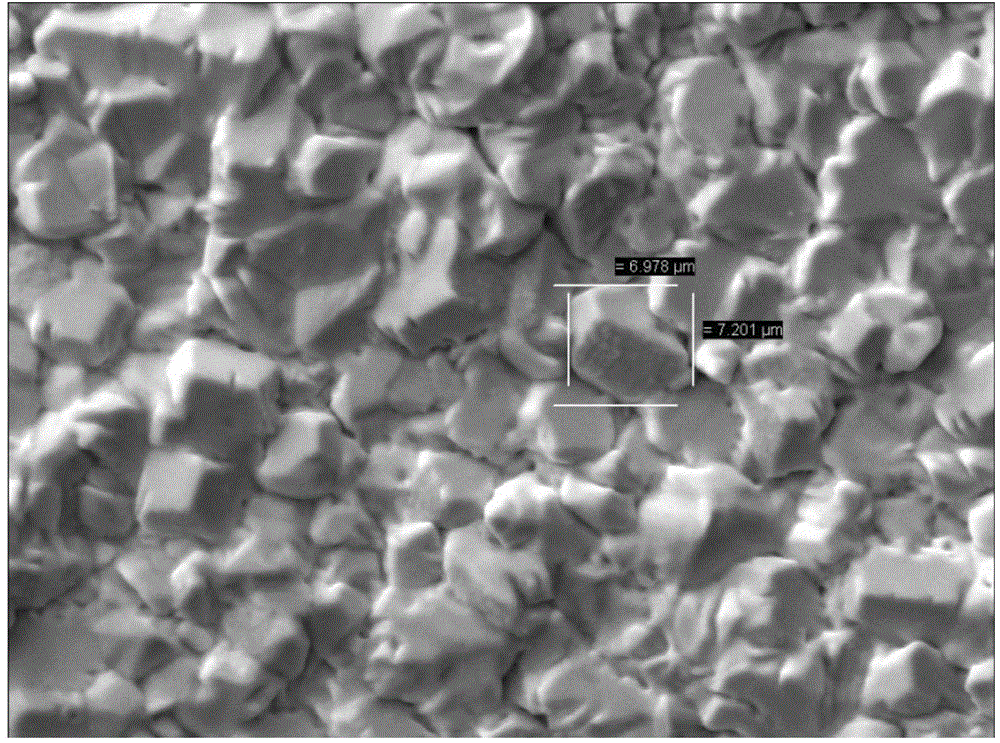

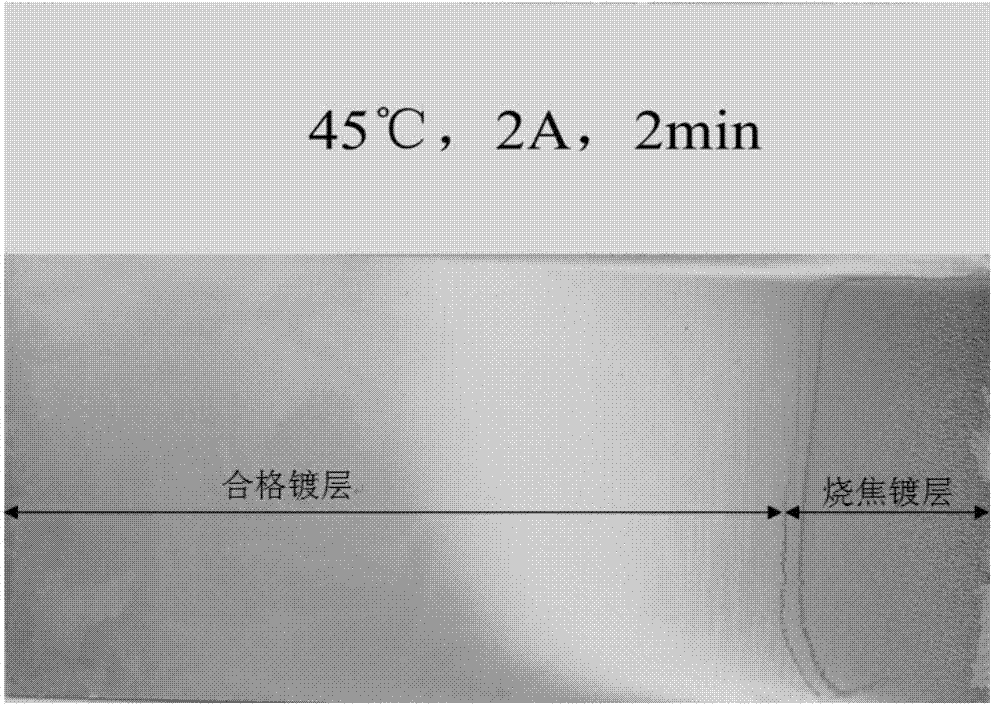

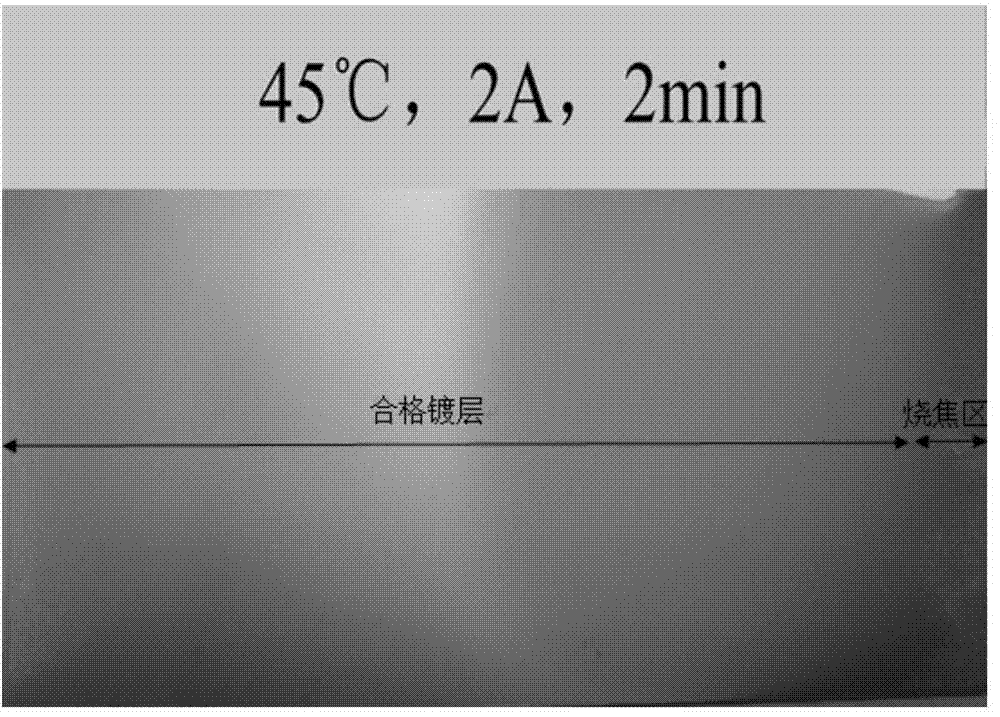

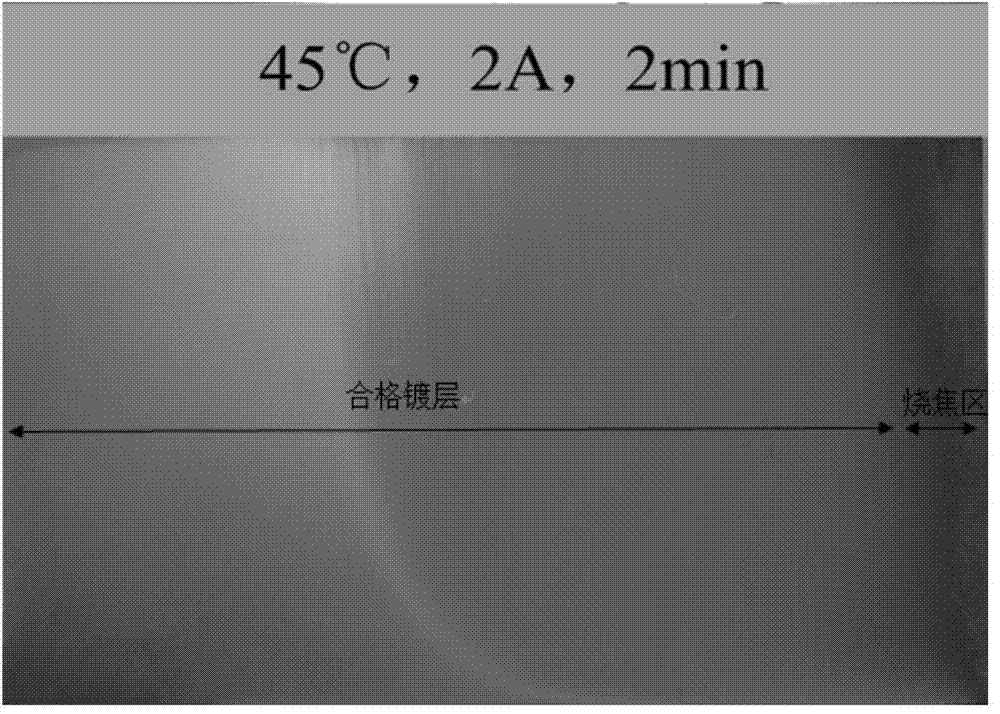

Multi-functional half-white brightness tin-plated additive

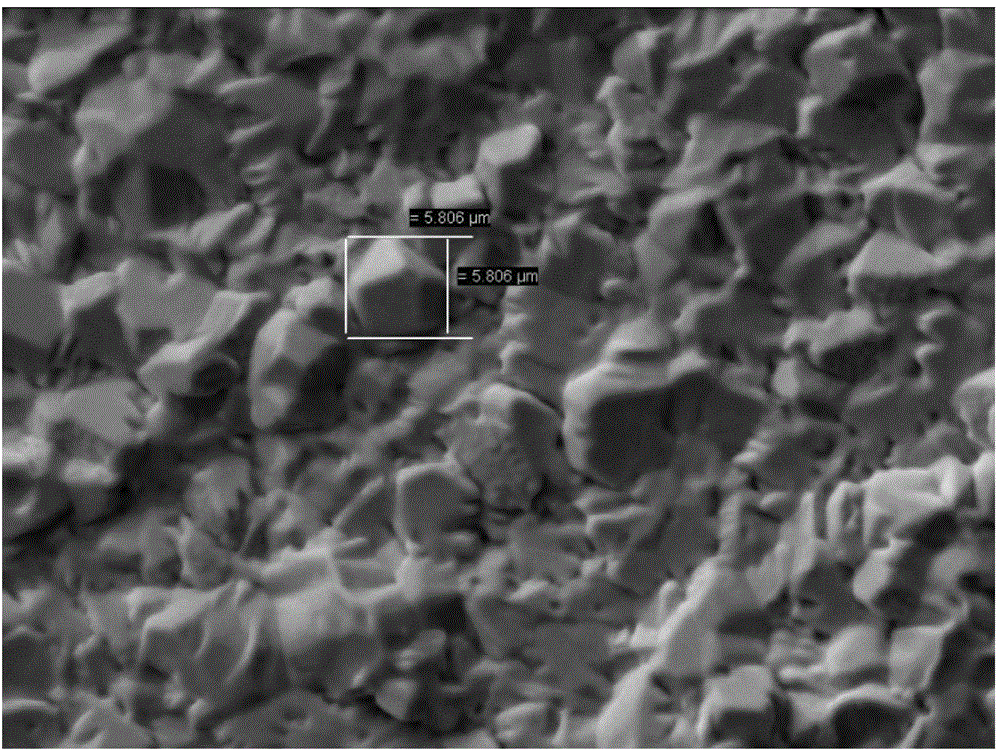

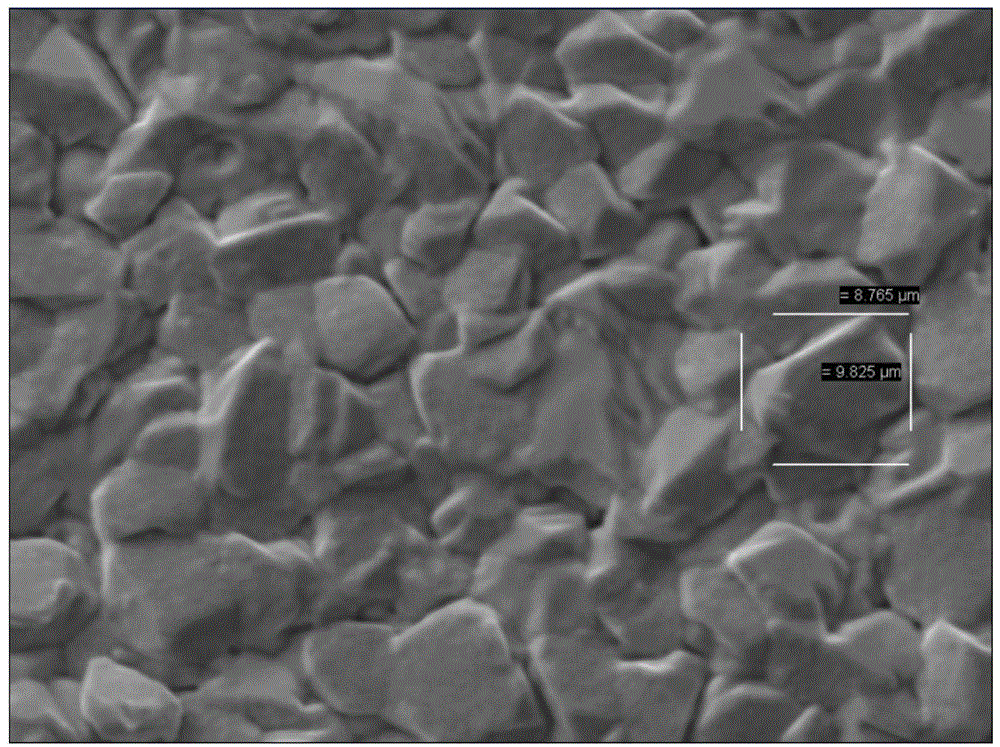

The invention provides a multi-functional half-white brightness tin-plated additive which comprises the following components in parts by weight: 0.1-3 parts of a main brightener, 5-15 parts of a dispersing agent, 0.1-3 parts of a stabilizing agent, 0.1-2 parts of a leveling agent, 0.1-3 parts of a change agent, 0.1-2 parts of a low-foam wetting agent, 1-5 parts of an anti-crystal whisker agent, 0.05-0.5 part of a flocculating agent, 40-55 parts of an aqueous organic solvent, 0.1-2 parts of a functional auxiliary, 0.1-2 parts of acid and 25-40 parts of water. The multi-functional half-white brightness tin-plated additive has good dispersive capacity and coverage capacity, can enable the plating layer thickness to reach 3 micrometers or more, is fine, smooth and compact in crystal grains and has high bonding strength with a matrix; according to the multi-functional half-white brightness tin-plated additive, the performance of a plating layer can be obviously improved, the cost of a plating solution is low, and the electroplating liquid has wide operating temperature range and cathode current density range; the tin plating layer is compact is surface structure, high in white brightness and strong in bonding strength and has excellent weldability and oxidation resistance.

Owner:苏州禾川化学技术服务有限公司

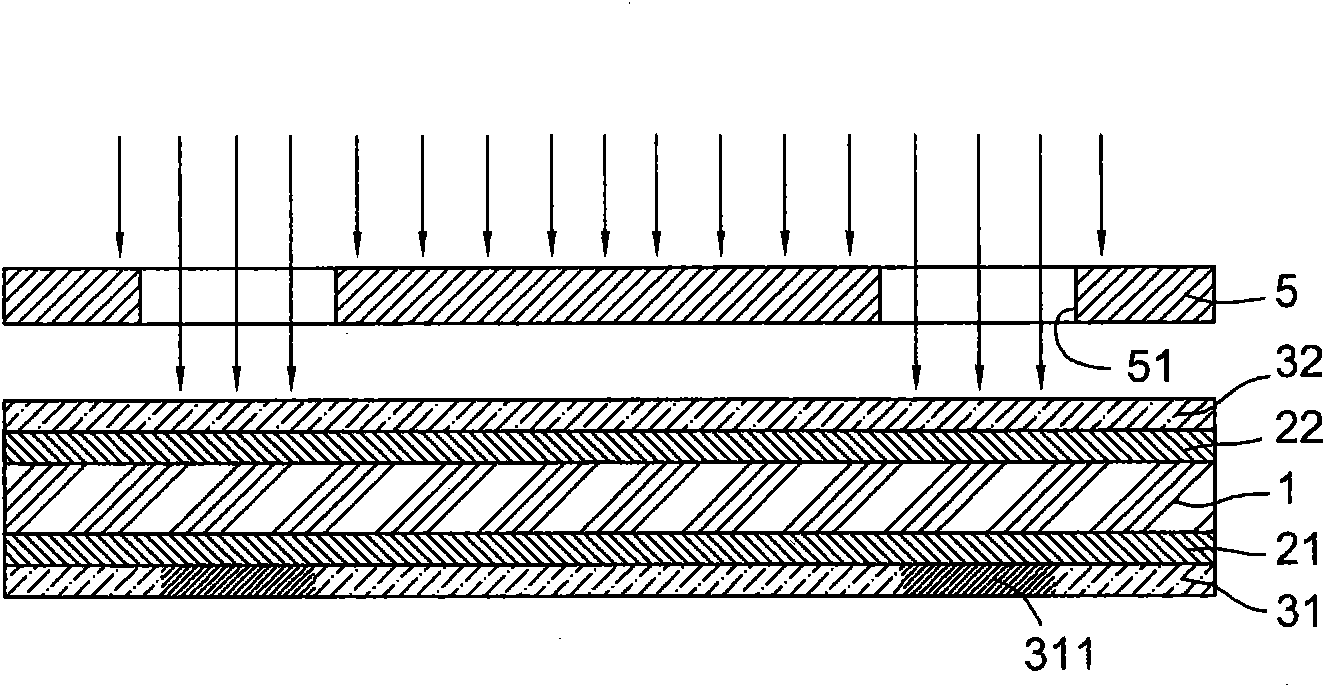

Method for producing transparent substrate double-sided conductive film of touch control circuit

InactiveCN101561729ASimplify the placement processSave man hoursSemiconductor/solid-state device manufacturingInput/output processes for data processingControl circuitElectrically conductive

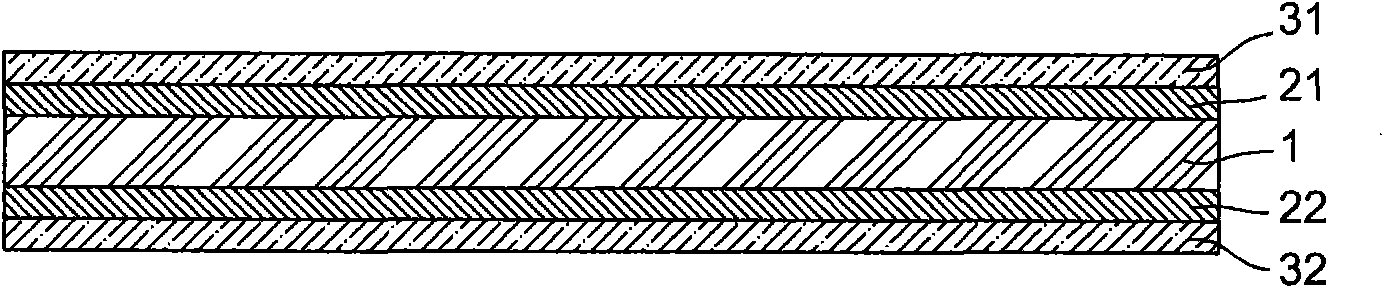

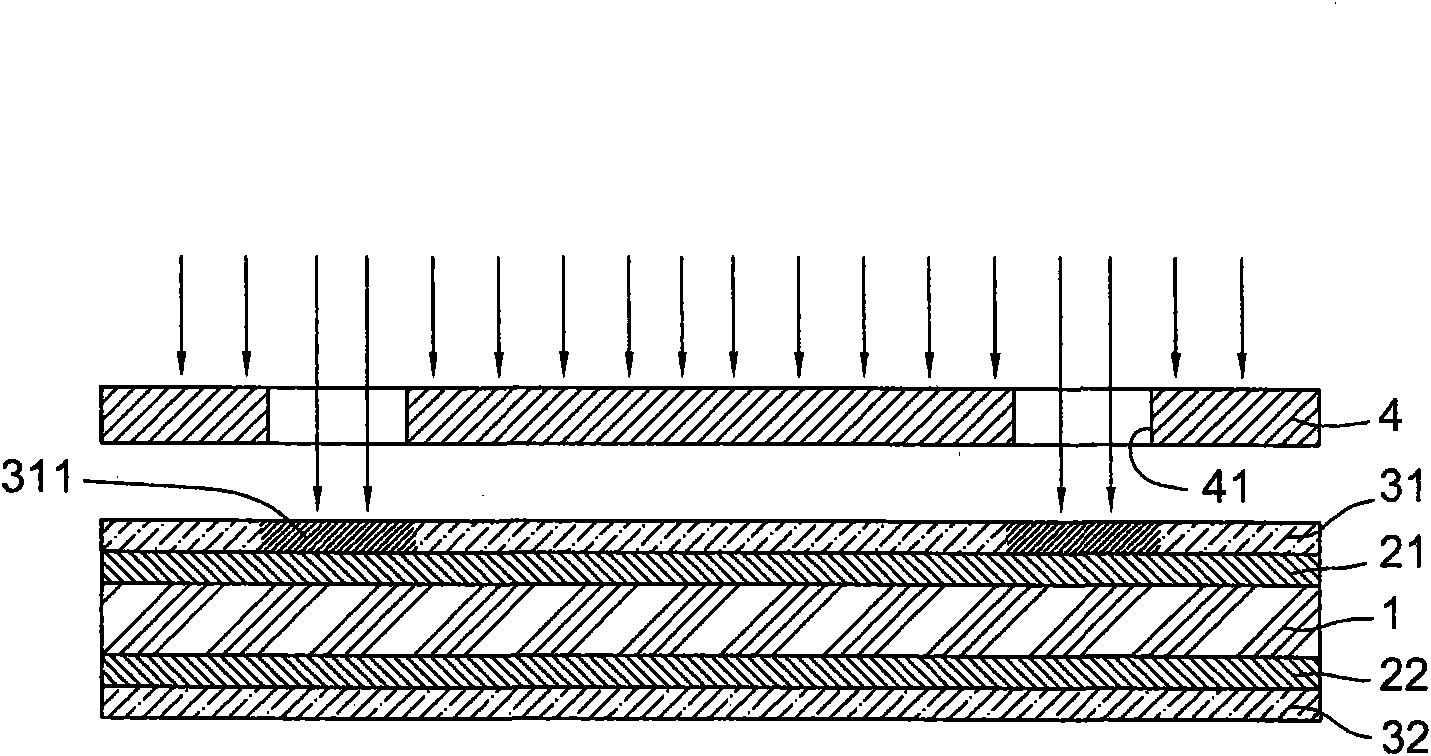

The invention discloses a method for producing a transparent substrate double-sided conductive film of a touch control circuit, comprising the following steps: attaching a first photoresistive layer with photosensitive colour-changing agent on a fist conductive substrate layer of a first surface of a transparent substrate and attaching a second photoresistive layer on a second conductive substrate of a second surface of the transparent substrate; exposing the first photoresistive layer to enable the first photoresistive layer to receive the exposure area to form a circuit pattern with identification colors; exposing the second photoresistive layer by utilizing the circuit pattern of the first exposing as the contraposition reference of the exposure of the second photoresistive layer; developing and etching the double sides of the transparent substrate to enable the first conductive substrate layer to form a first conductive film of a touch control circuit, and forming a second conductive film of the touch control circuit on the second conductive substrate layer. The invention simplifies the laying procedures of the touch control circuit, thereby having the advantages of reduction of labor hour and reduction of cost.

Owner:TPK LENS SOLUTIONS INC

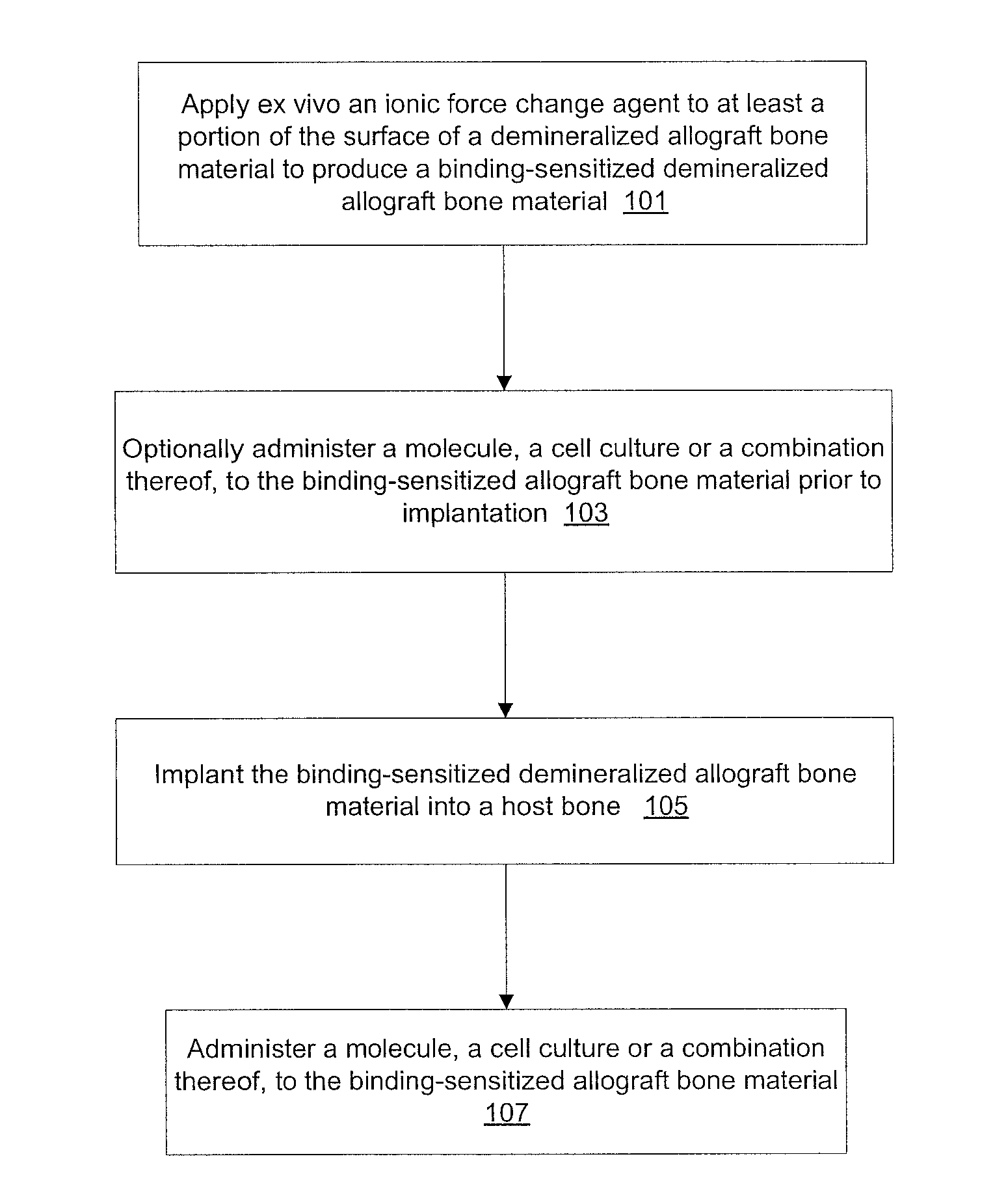

Modification of reactivity of bone constructs

A method of enhancing the binding of growth factors and cell cultures to a demineralized allograft bone material which includes applying ex vivo an effective quantity of an ionic force change agent to at least a portion of the surface of a demineralized allograft bone material to produce a binding-sensitized demineralized allograft bone material and implanting the binding-sensitized demineralized allograft bone material into a host bone. The ionic force change agent may include at least one of enzymes, pressure, chemicals, heat, sheer force, oxygen plasma, supercritical nitrogen, supercritical carbon, supercritical water or a combination thereof. A molecule, a cell culture, or a combination thereof is administered to the binding-sensitized demineralized allograft bone material.

Owner:WARSAW ORTHOPEDIC INC

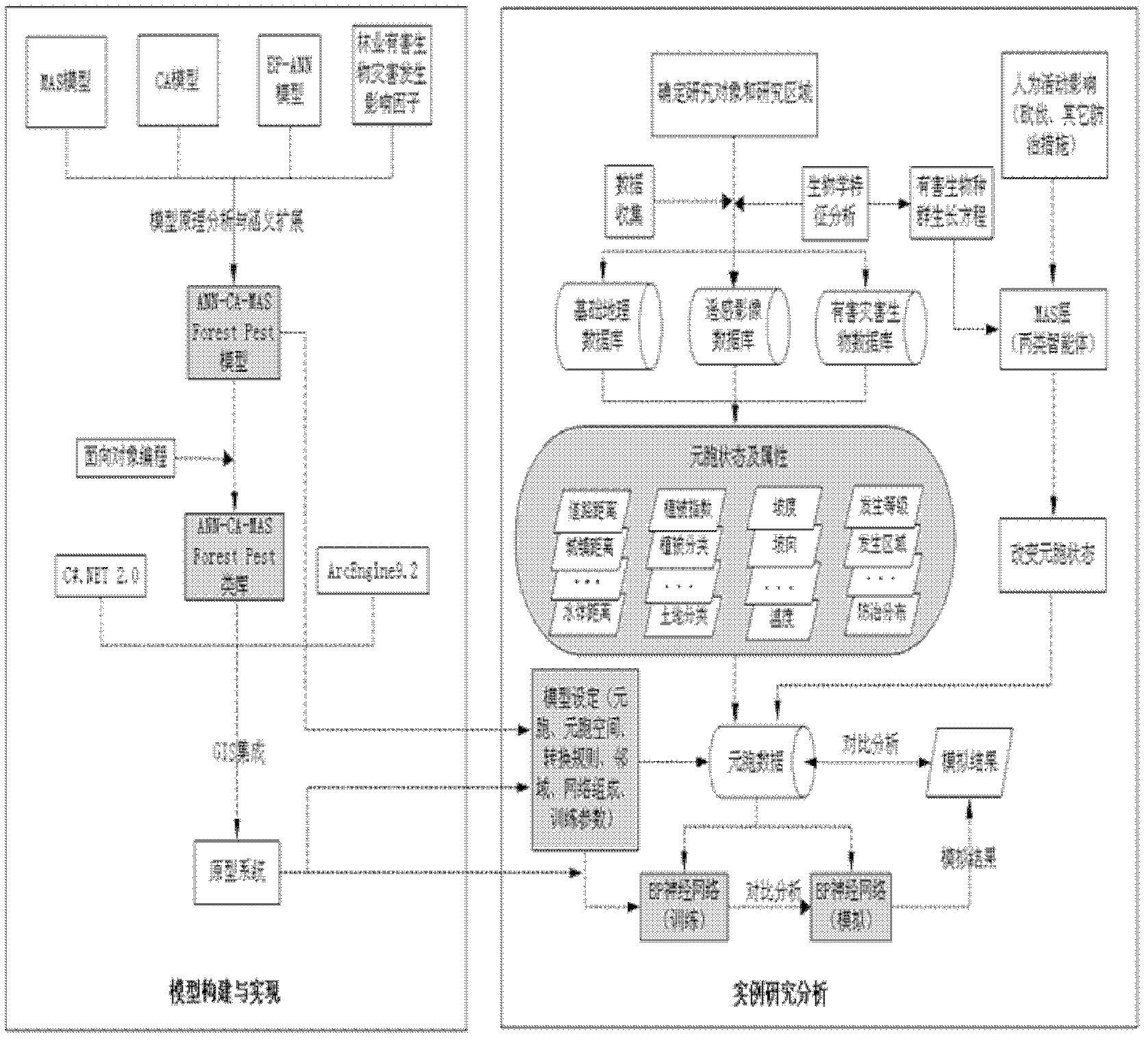

System and method for predicting forest pest disaster

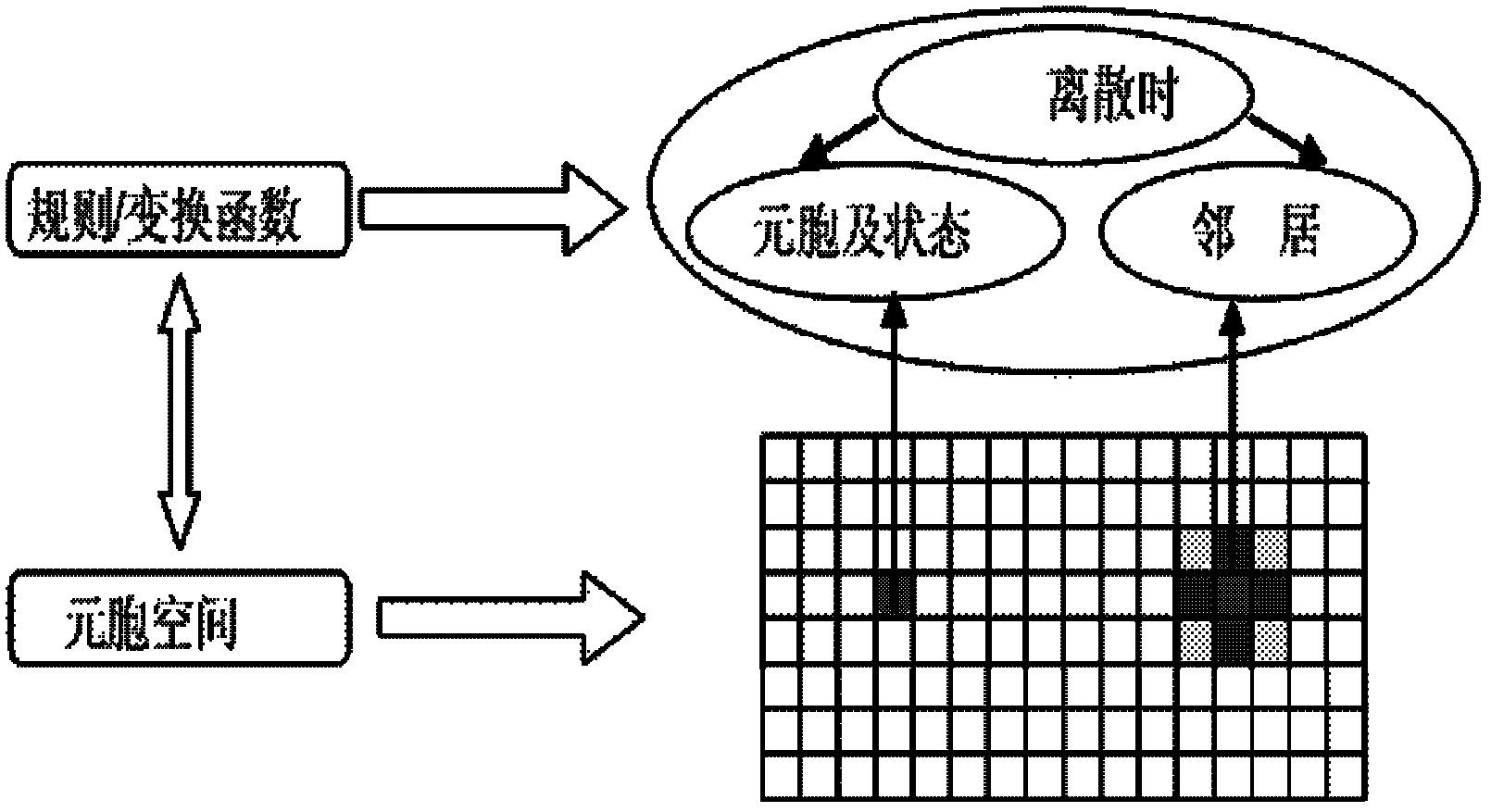

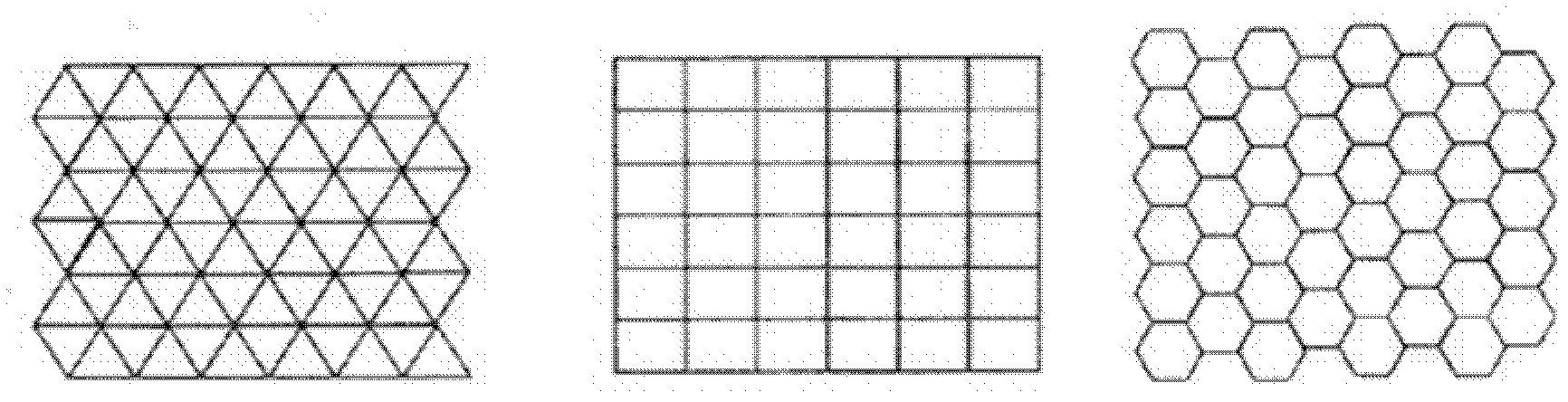

The invention discloses a system and a method for predicting a forest pest disaster. The system mainly comprises a forest pest disaster prediction model module, wherein the forest pest disaster prediction model module comprises a geographical cellular automata model, an artificial neural network model and a multi-agent model; each cell in the geographical cellular automata model represents a geographical area and has a cell state which is used for representing disaster degree and one or more cell attributes which are used for representing disaster influence factors; a state conversion rule is acquired by training the artificial neural network model; the input of the artificial neural network model is the disaster influence factors, and the output of the artificial neural network model is the disaster degree; the multi-agent model comprises a human activity influence agent which is used for representing influence of human activity on the cell state, and a pest population change agent which is used for representing the dynamic evolution process of a pest population; and analysis results of the agents are integrated with the current cell state to obtain the updated current cell state.

Owner:BEIJING FORESTRY UNIVERSITY

Composite profile control system and construction method for plugging by using composite profile control system

InactiveCN106947451AAvoid pollutionImprove injection abilityFluid removalDrilling compositionCross-linkParticle injection

The invention relates to a composite profile control system, which comprises a high-strength cross-linked polymer profile control agent, a water displacement flowing direction change agent, a compound flocculation profile control agent and an oil displacement agent. According to the present invention, in order to improve the profile control effect and prolong the profile control lasting period, by considering the synergetic effect among the plugging agents, the plugging agents are subjected to cross injection in slugs; and by following the combined principle of plugging, controlling and displacement, the high-strength cross-linked polymer profile control agent capable of improving the swept volume and the displacement efficiency, the water displacement flowing direction change agent capable of improving the lasting period and the compound flocculation profile control agent are used and are subjected to alternating injection, and then the oil displacement agent is injected, such that the profile control and displacement requirements of the oil reservoir deep part can be met, the oil reservoirs having different permeabilities can be met, different profile control purposes and different process requirements can be met, the shear resistance and the swelling are improved, the cost is reduced, the strength and the temperature resistance are improved, and the particle injection and the injection depth are improved.

Owner:河南易发石油工程技术有限公司

Plating solution for high-speed electrotinning

Owner:HARBIN INST OF TECH

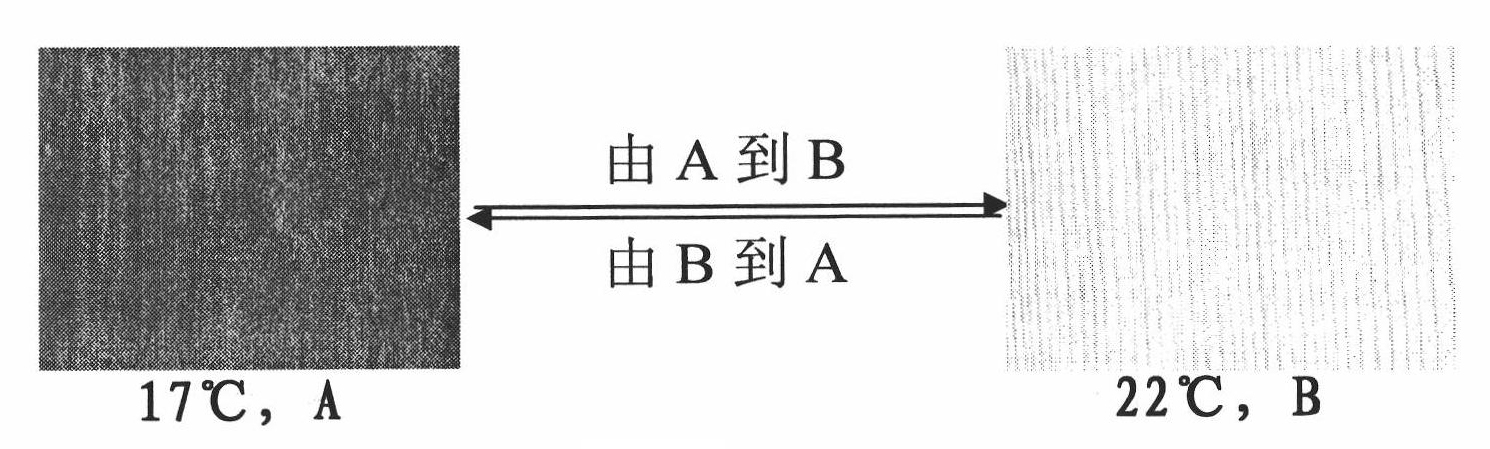

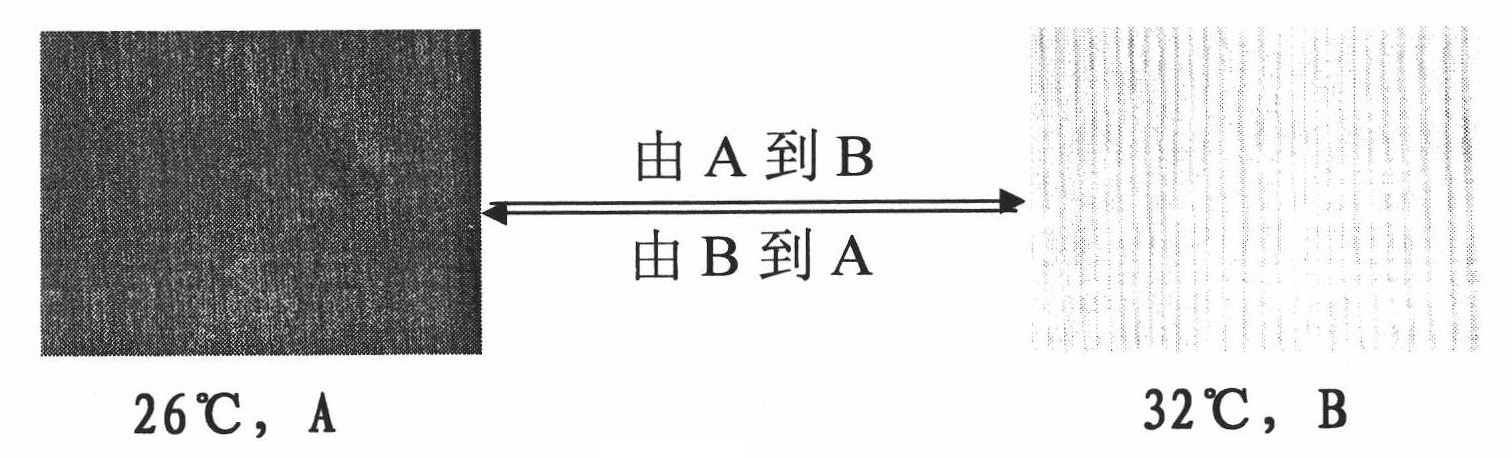

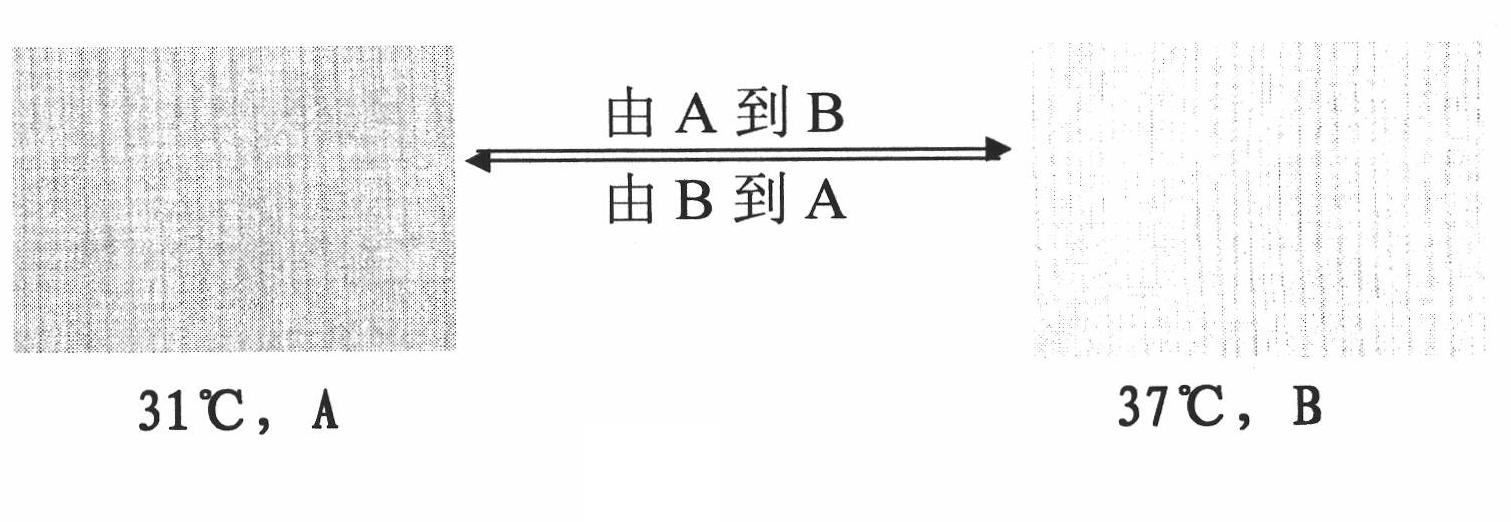

Temperature-sensitive reversible color wooden material and manufacturing method thereof

InactiveCN101817192AImprove color changing performanceHigh sensitivity to discolorationCoating impregnationCoatingsAdditive ingredientColor changes

The invention discloses a temperature-sensitive reversible color wooden material and a manufacturing method thereof. The surface of the temperature-sensitive reversible color wooden material is provided with a temperature-sensitive reversible color functional layer; the functional layer is formed by dipping temperature colour-changing agent into the wooden material from the surface and remaining the agent in the pore of wooden material; the temperature-sensitive reversible color functional layer can be reversibly changed into another color from one color along with the change of temperature in a preset temperature zone. The wooden material of the invention can be used as wooden structure material and can be used as wooden facing material. The invention also discloses a special temperature colour-changing agent which mainly comprises procrypsis agent, colour-developing agent and solvent, wherein the procrypsis agent determines color change, the colour-developing agent determines color change shade, and the solvent determines color change temperature; the proportion of three ingredients is adjusted to control color, color change degree and color change temperature zone of temperature colour-changing wooden material.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Ink for laser imaging

ActiveUS20160168407A1Good laser imaging efficacyNegligible impactVacuum evaporation coatingSputtering coatingRare-earth elementAlkaline earth metal

In a first aspect, the invention provides an ink formulation comprising: (a) a near infrared absorbing system comprising a compound of the formula M1W1.6O6, wherein M1 is one or more elements selected from the group consisting of H, He, alkali metals such as Li, Na, K, Rb, Cs, alkaline earth metals such as Be, Mg, Ca, Sr, Ba, rare-earth elements, Zr, Cr, Mn, Fe, Ru, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, AL Ga, in, Tl, Si, Ge, Sn, Pb, Sb, B, F, P, S, Se, Br, Te, Ti, Nb, V, Mo, Ta, Re, Hf, Os, Bi and I, or ammonium; (b) a colour change agent; and (c) a binder. The invention also provides alternative ink formulations for laser marking, a method of forming an image using the ink formulations and a substrate coated with the ink formulation of the invention. Ink formulations according to the invention have been found to have good laser imaging efficacy, and an essentially negligible impact on the background colour of the coating.

Owner:DATALASE

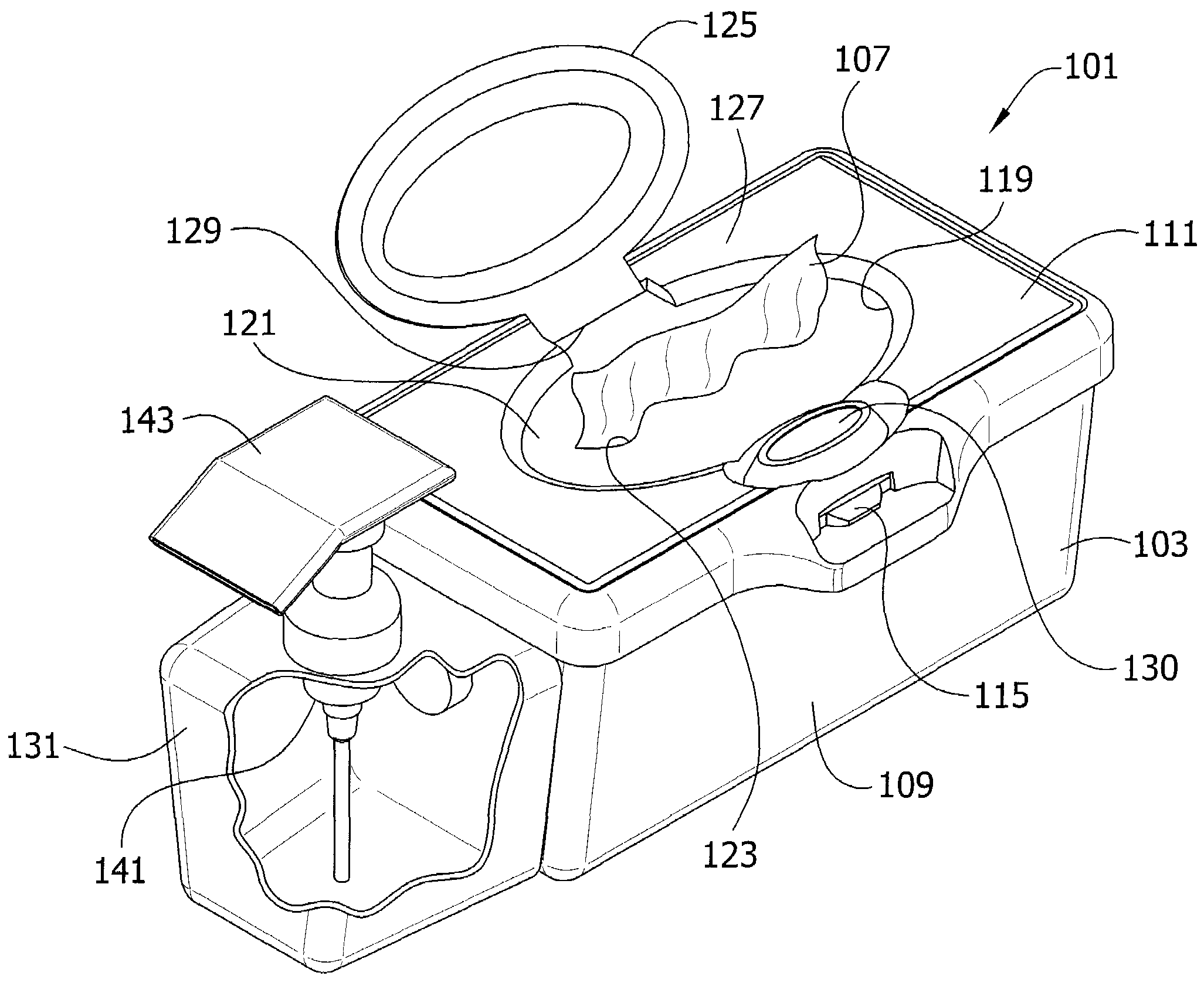

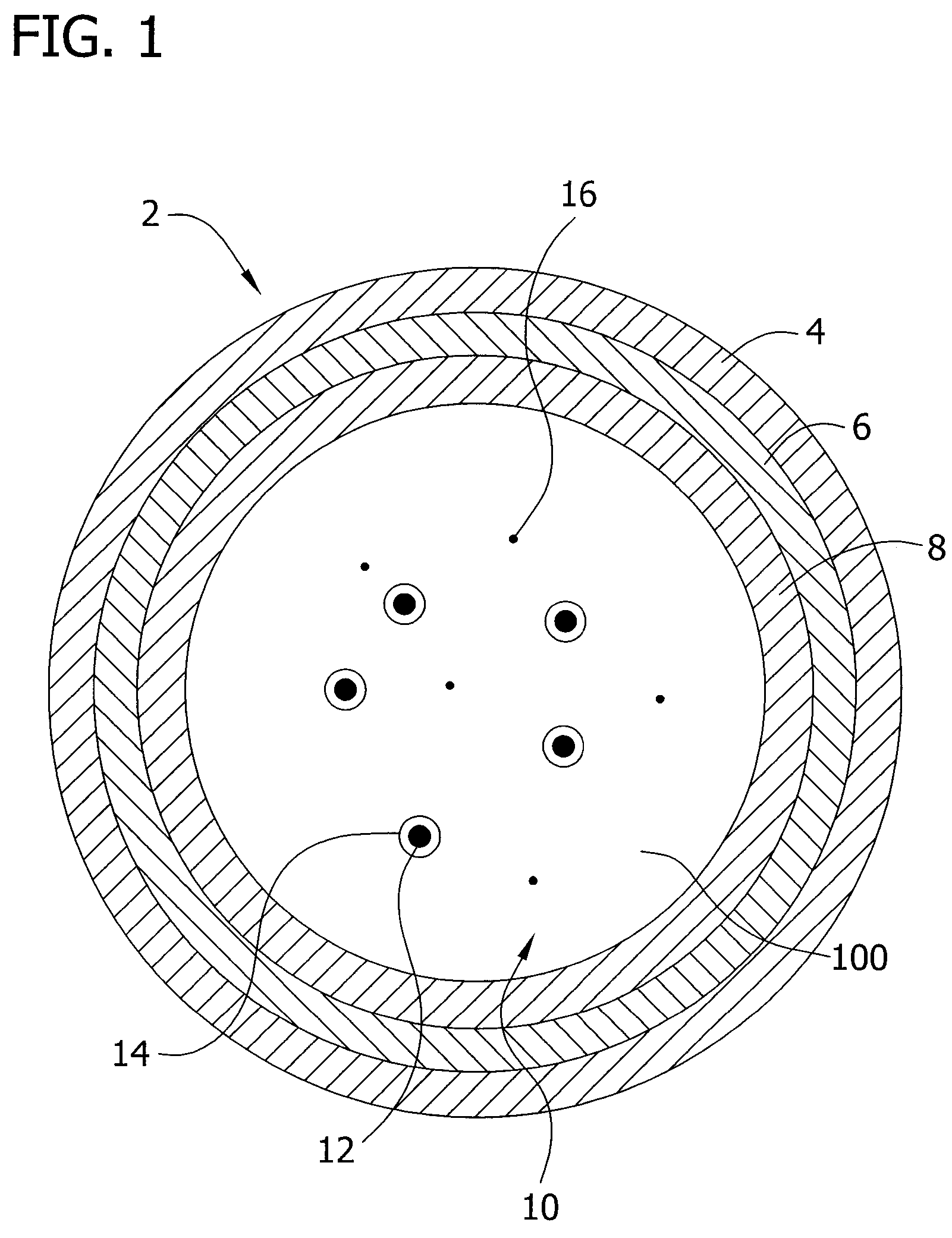

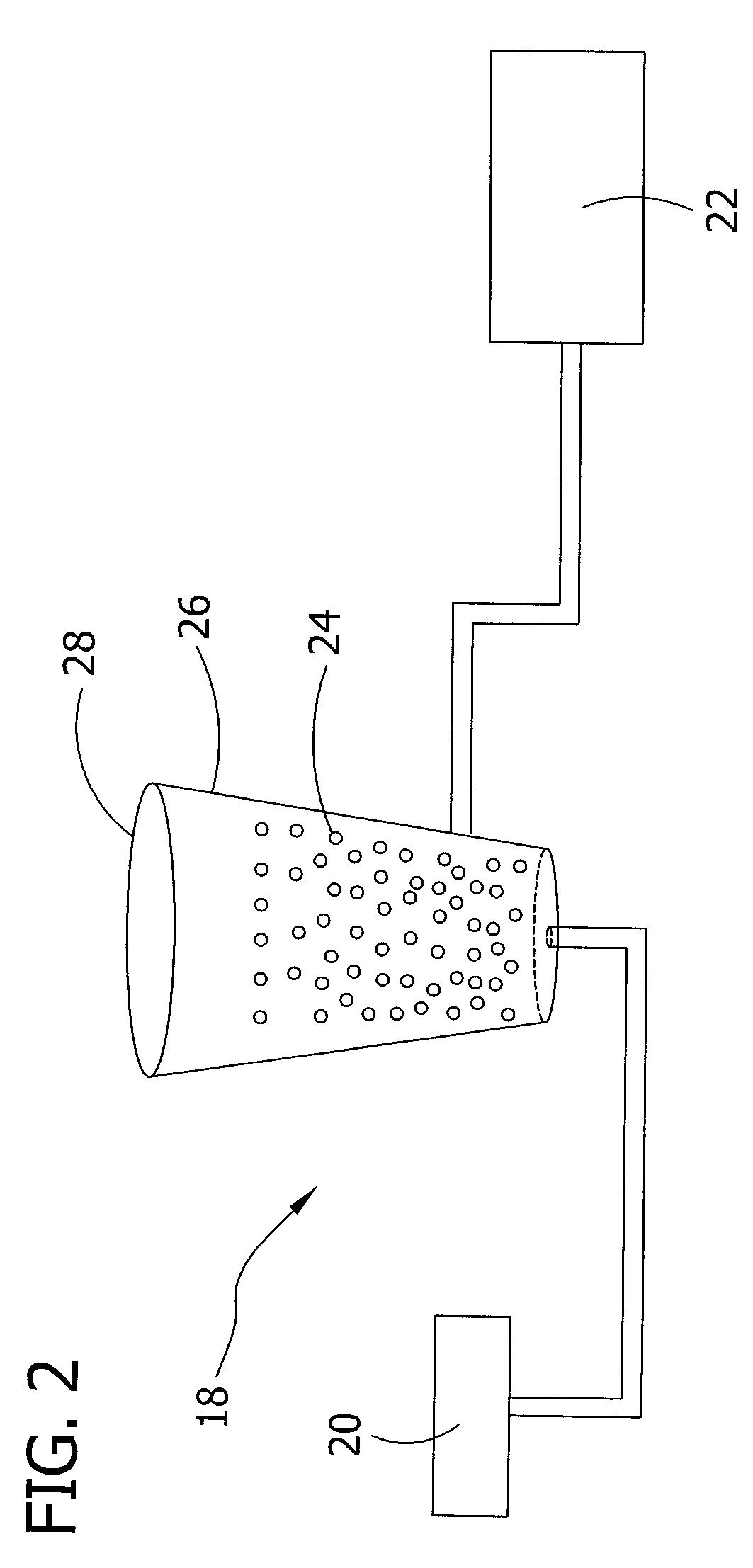

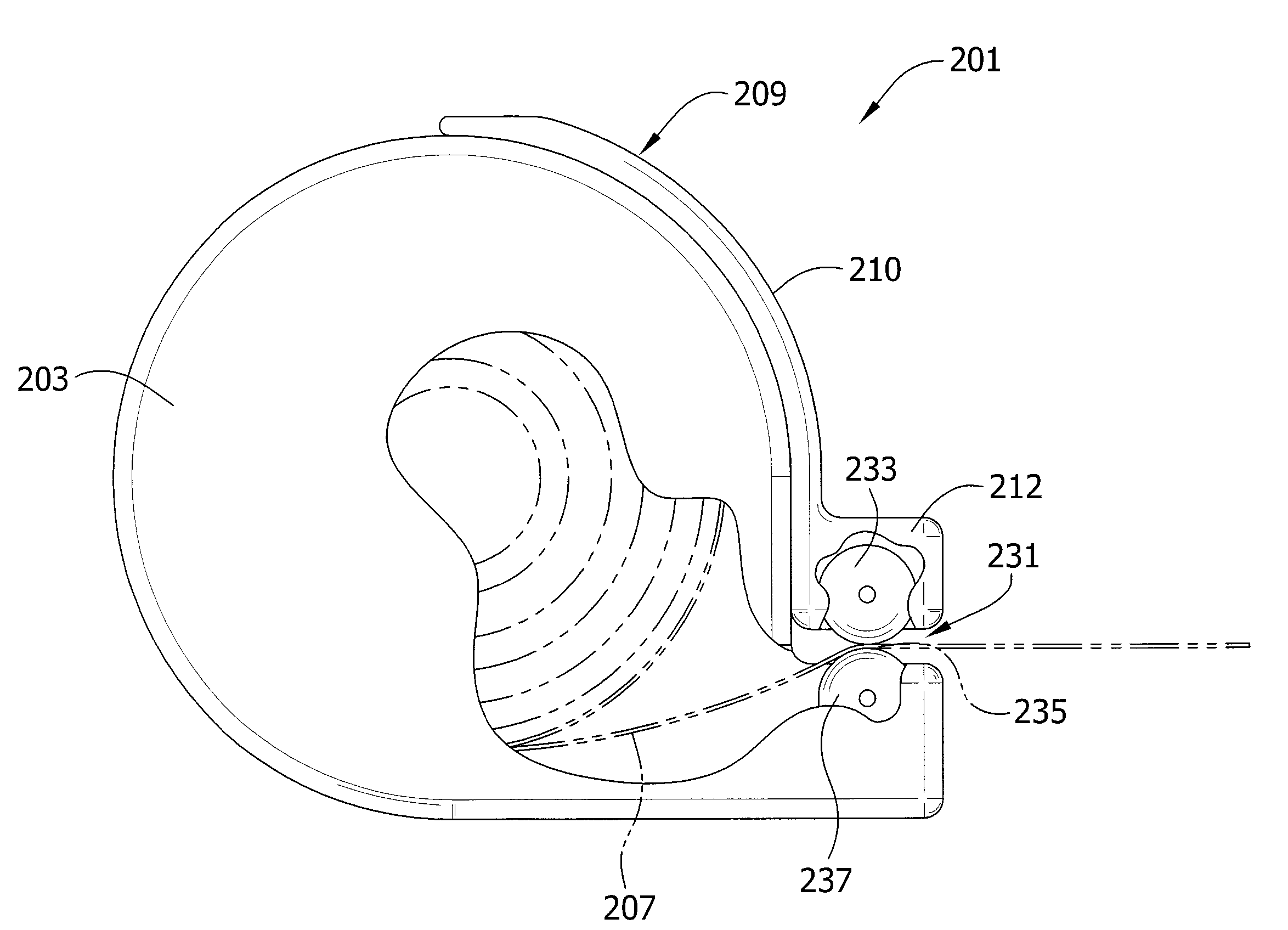

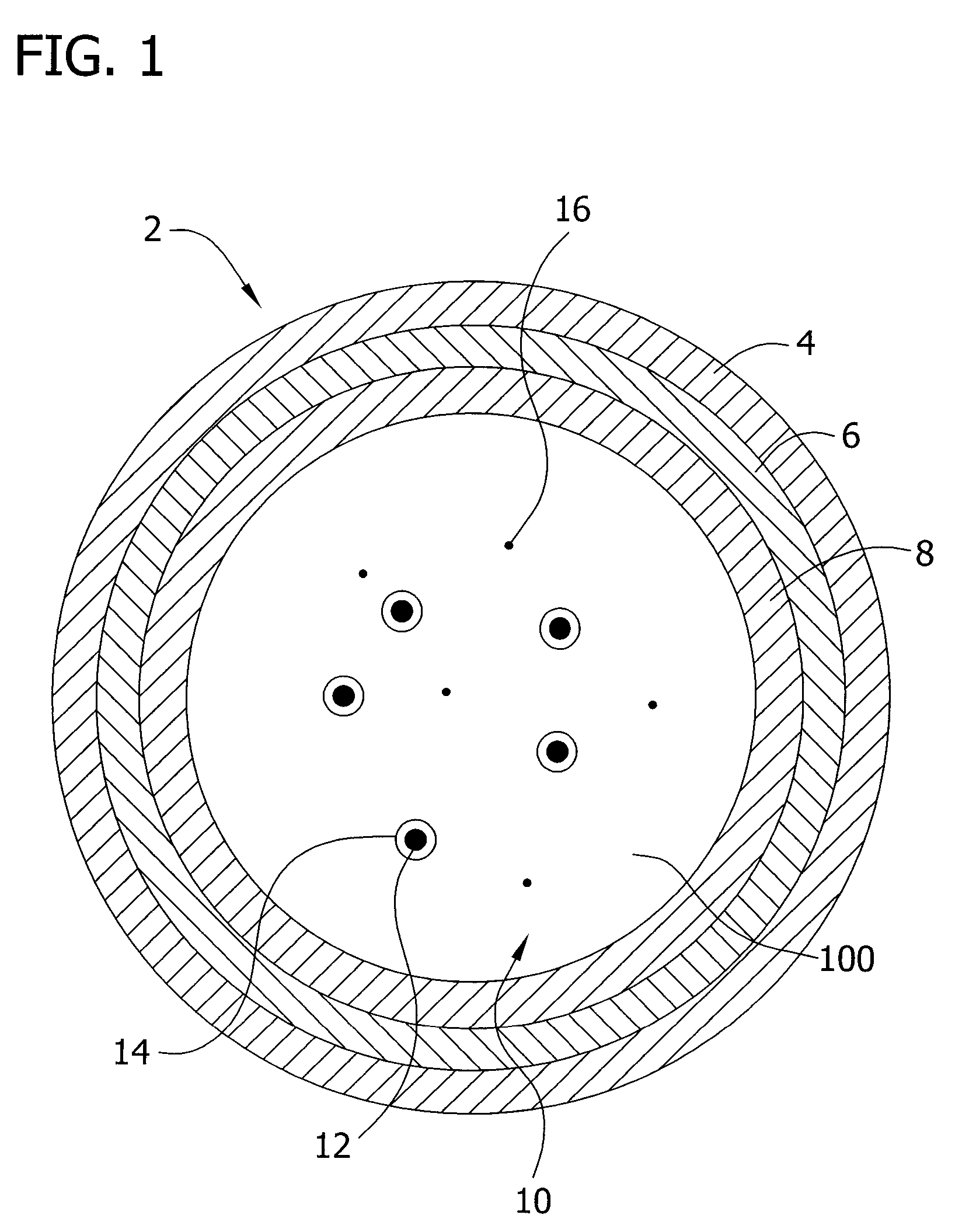

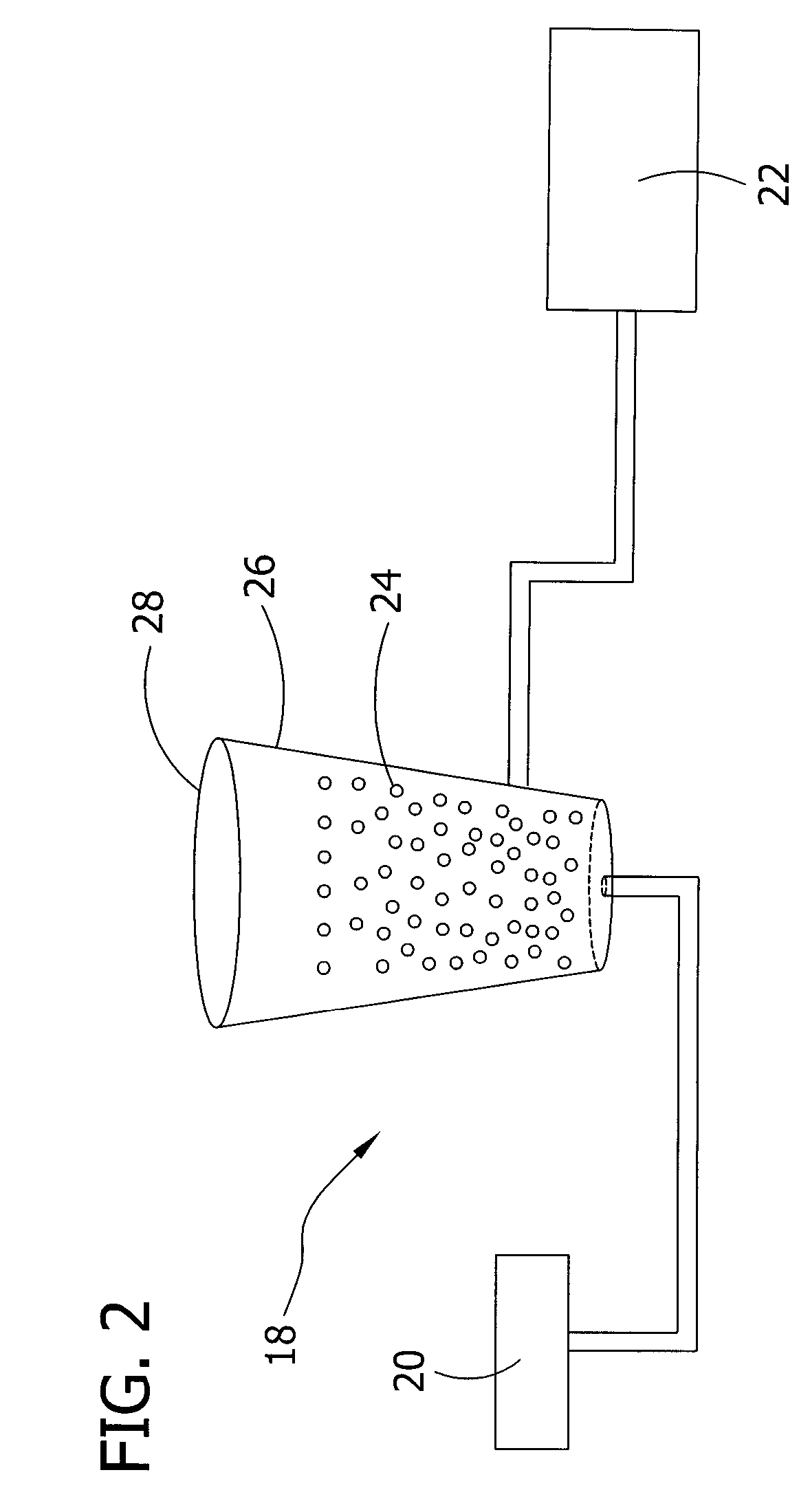

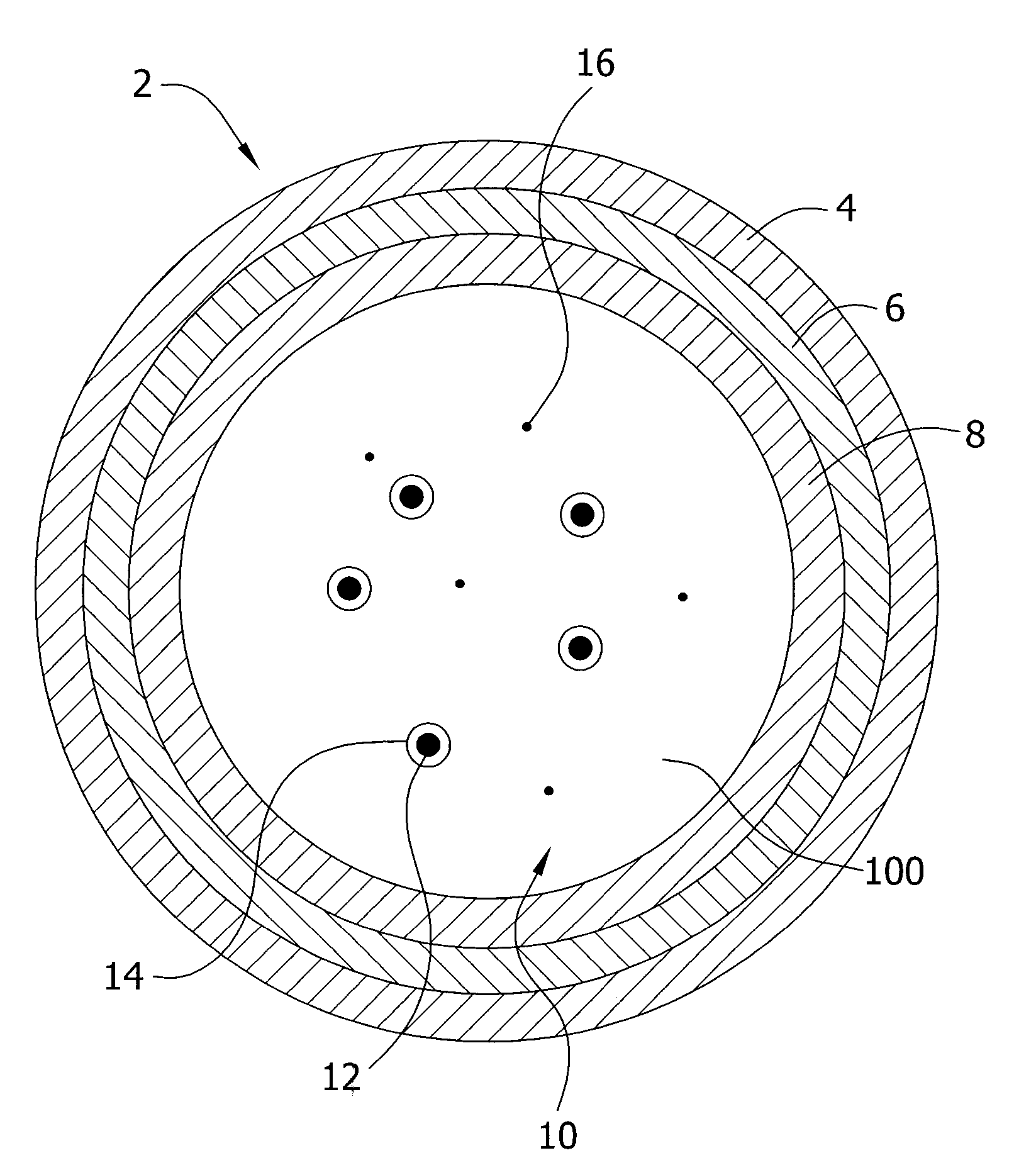

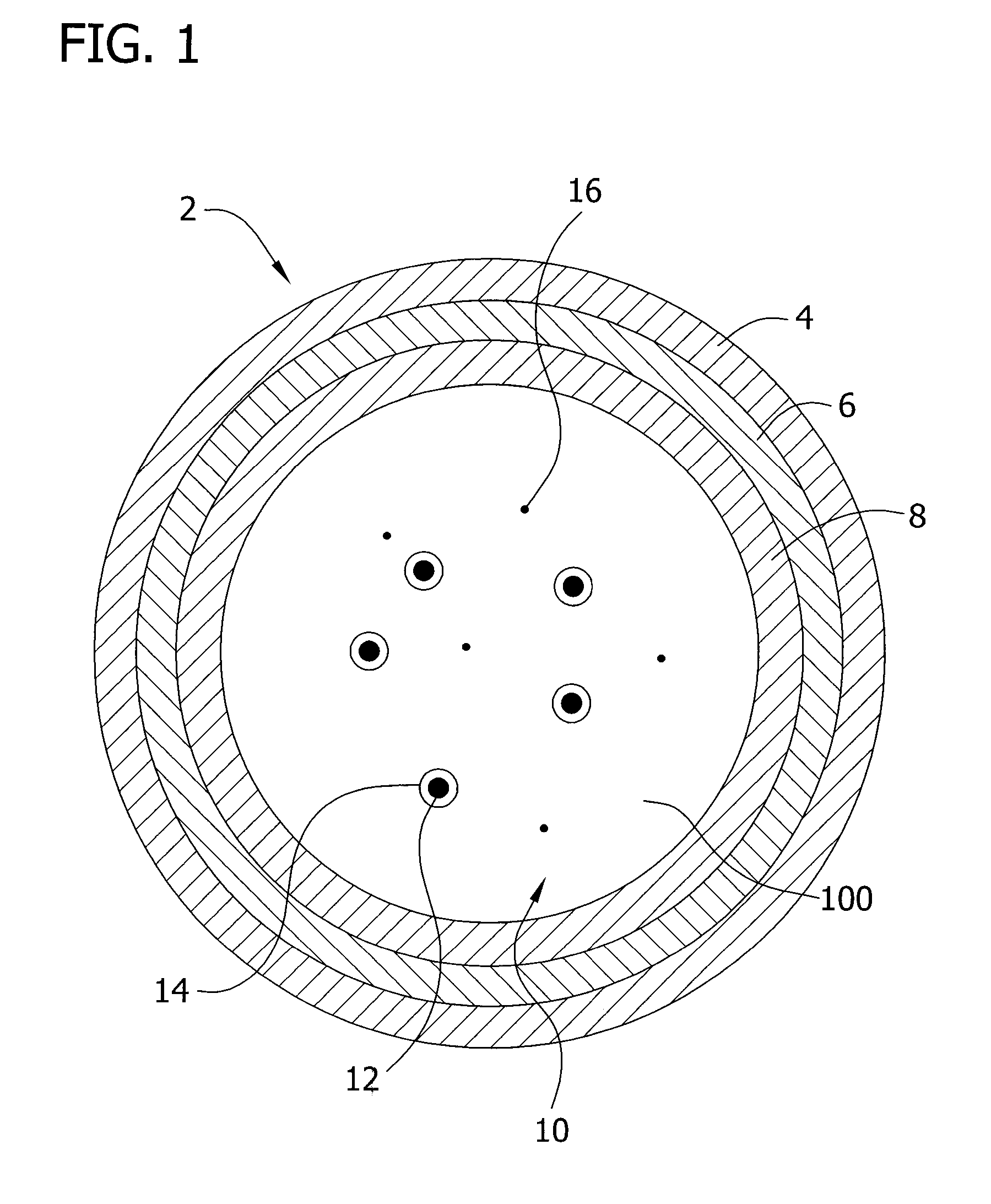

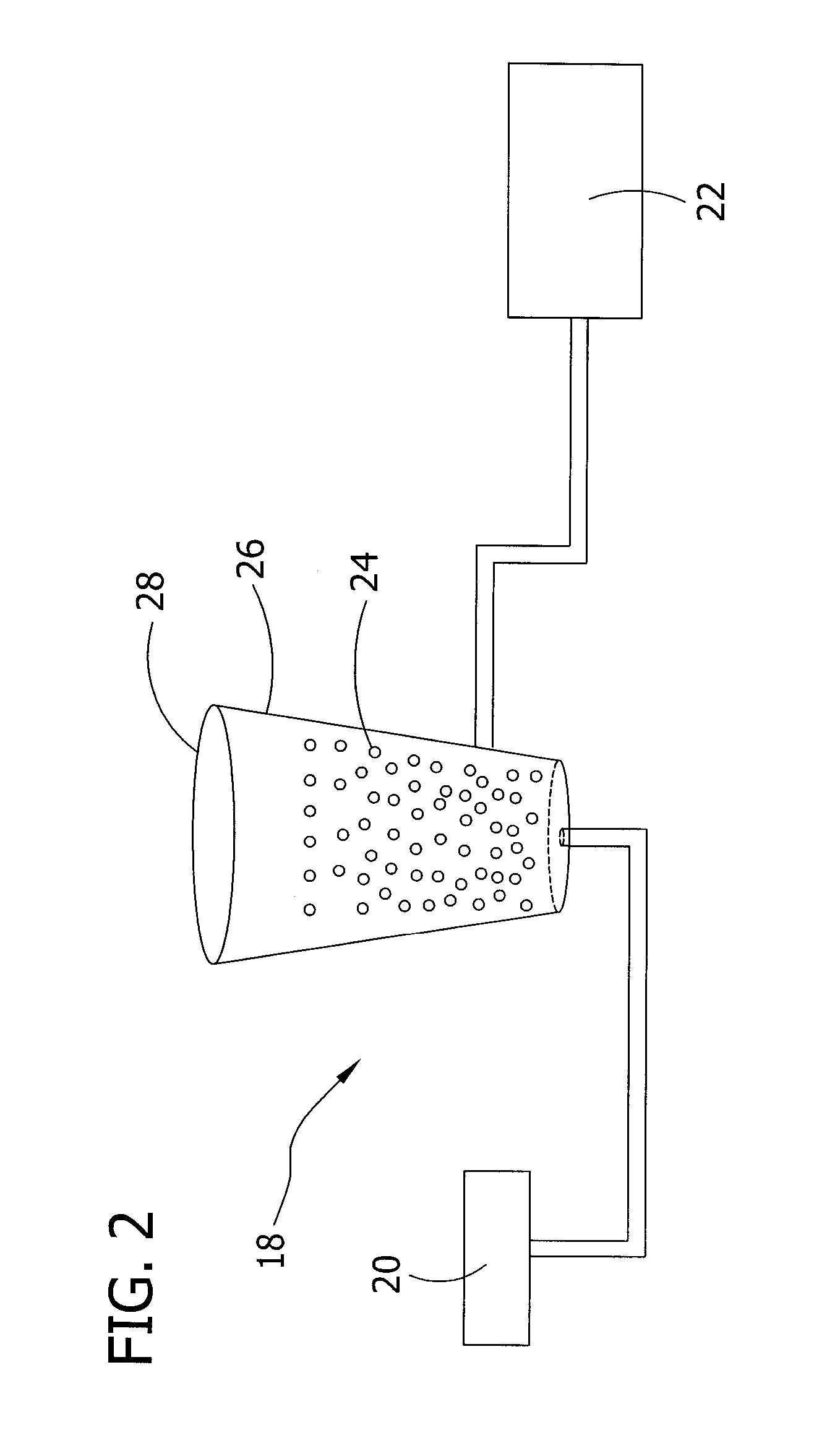

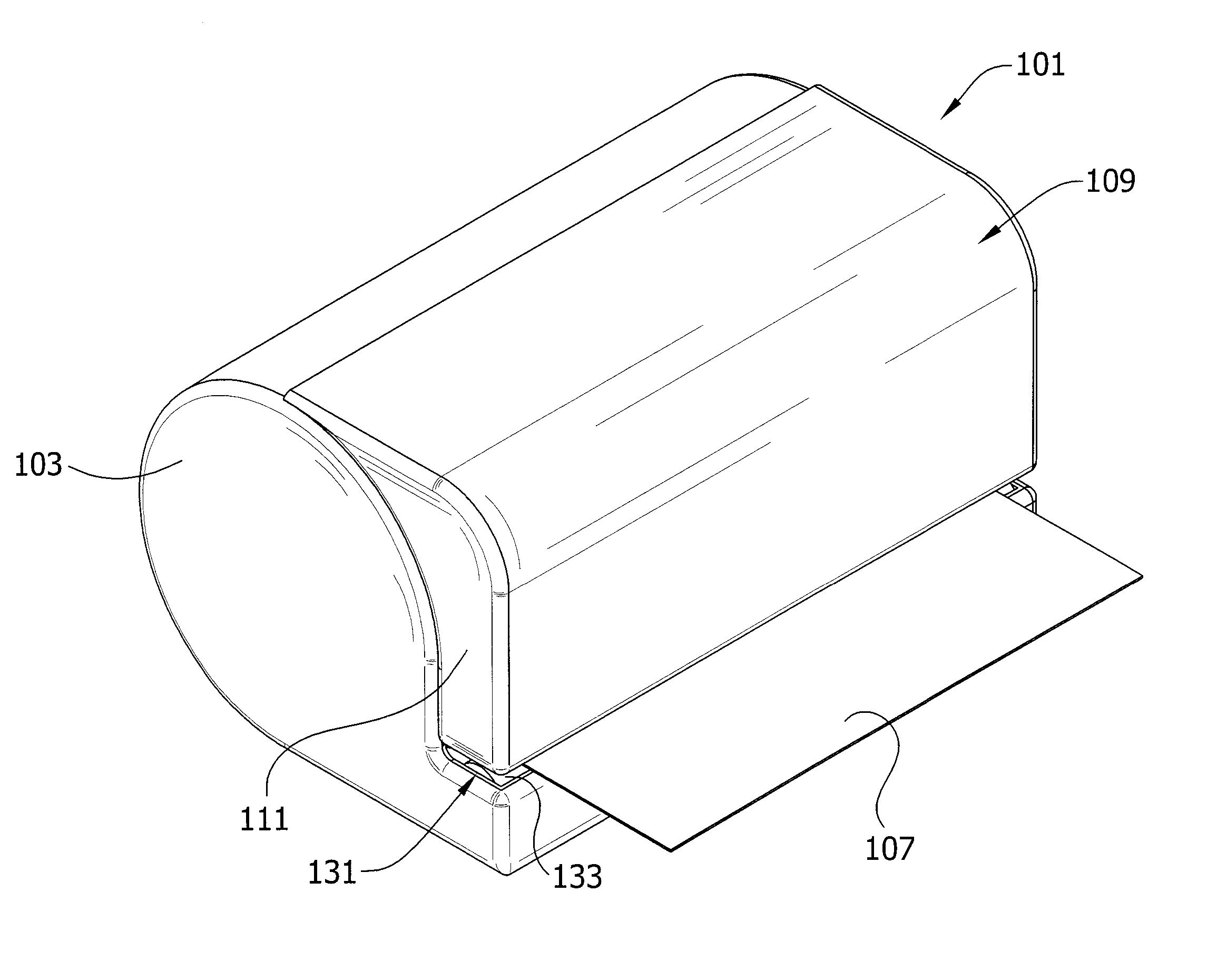

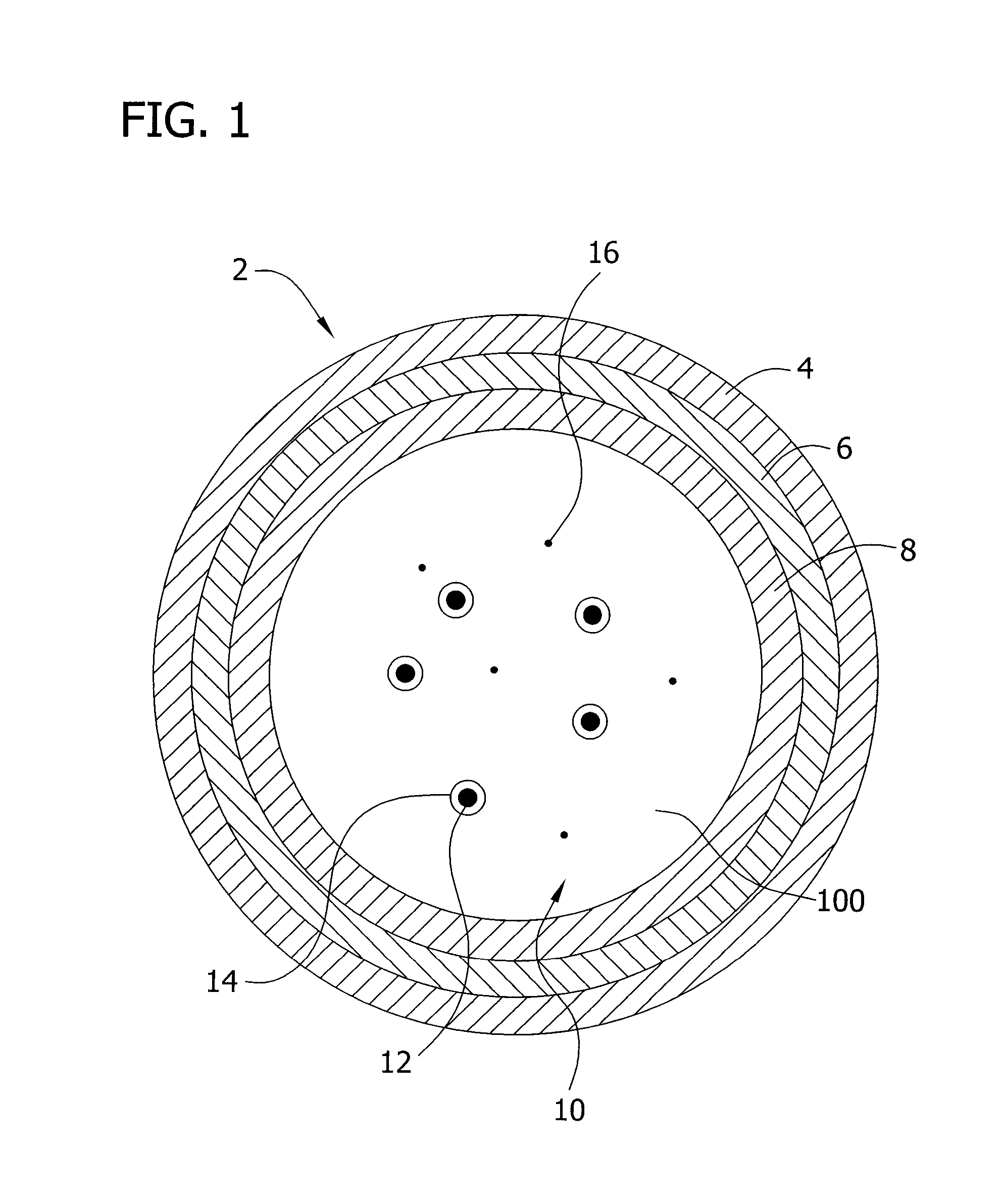

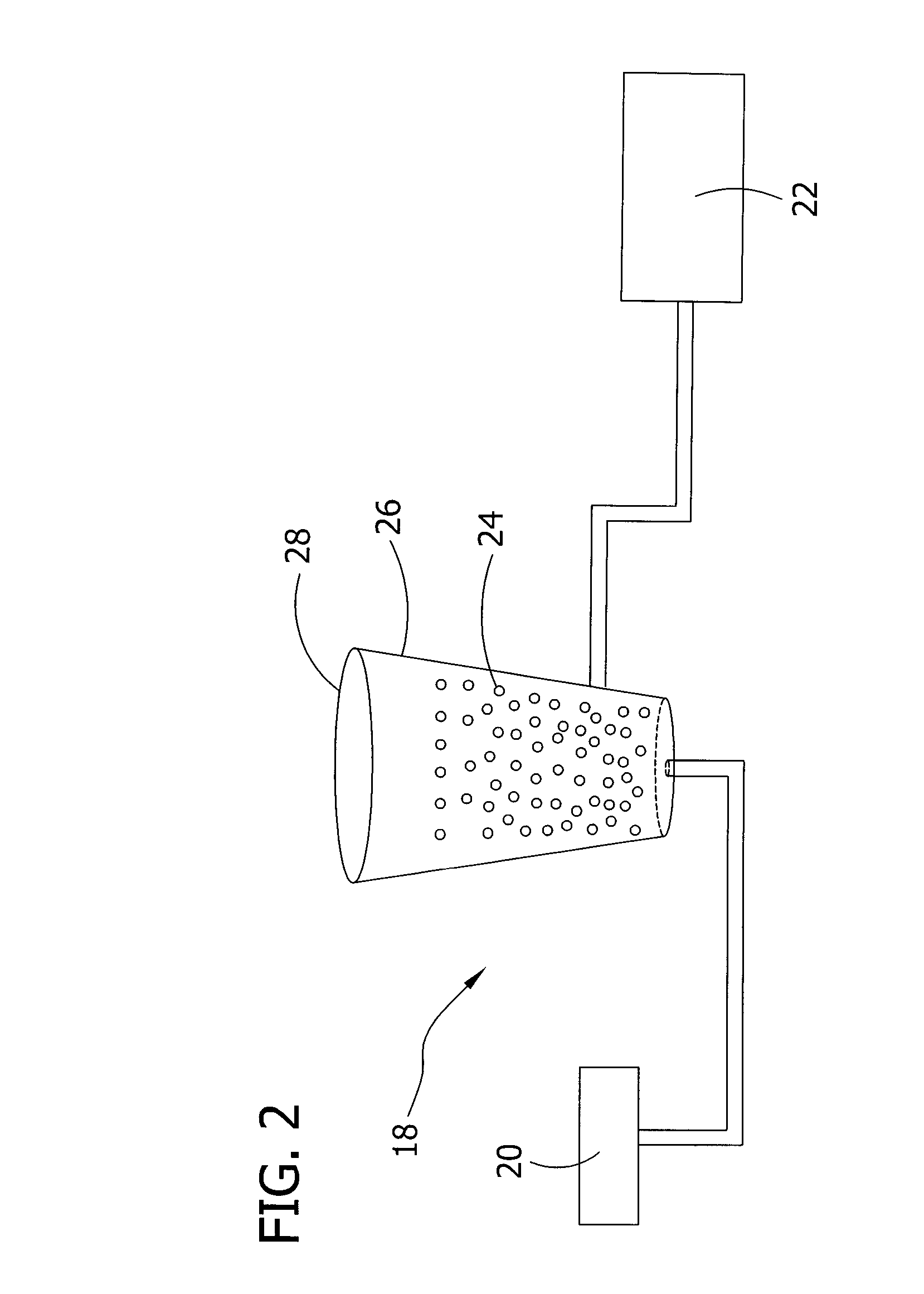

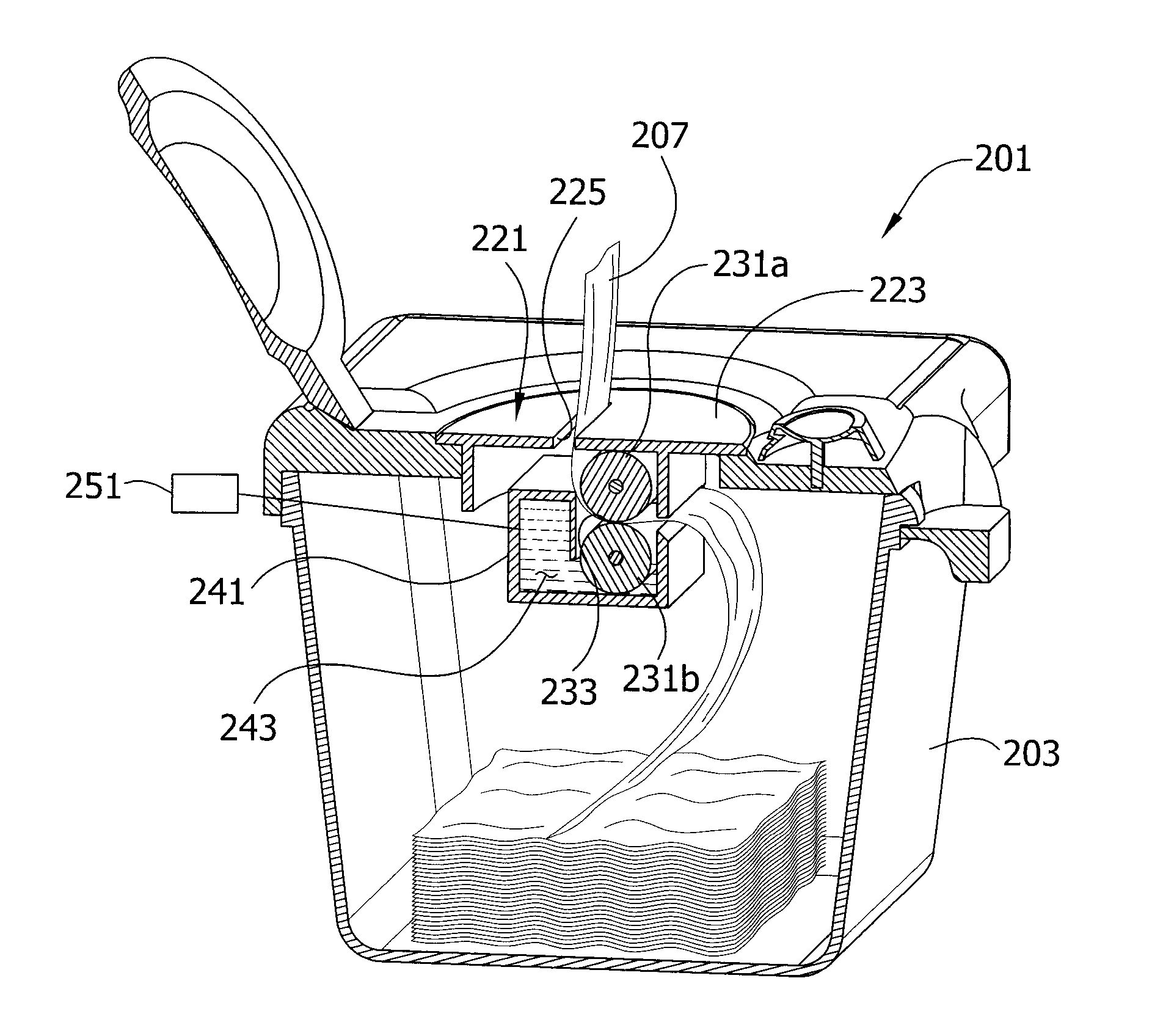

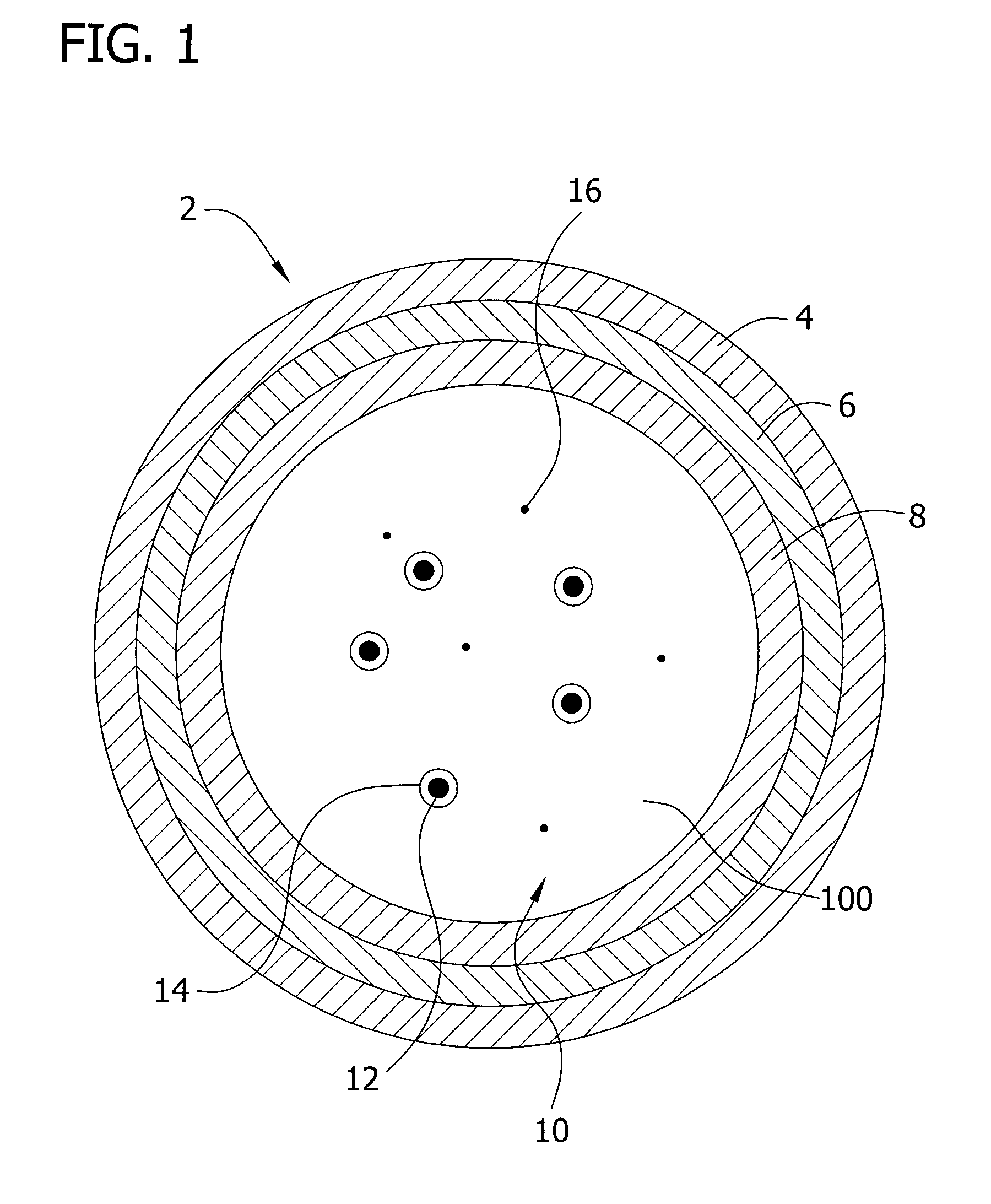

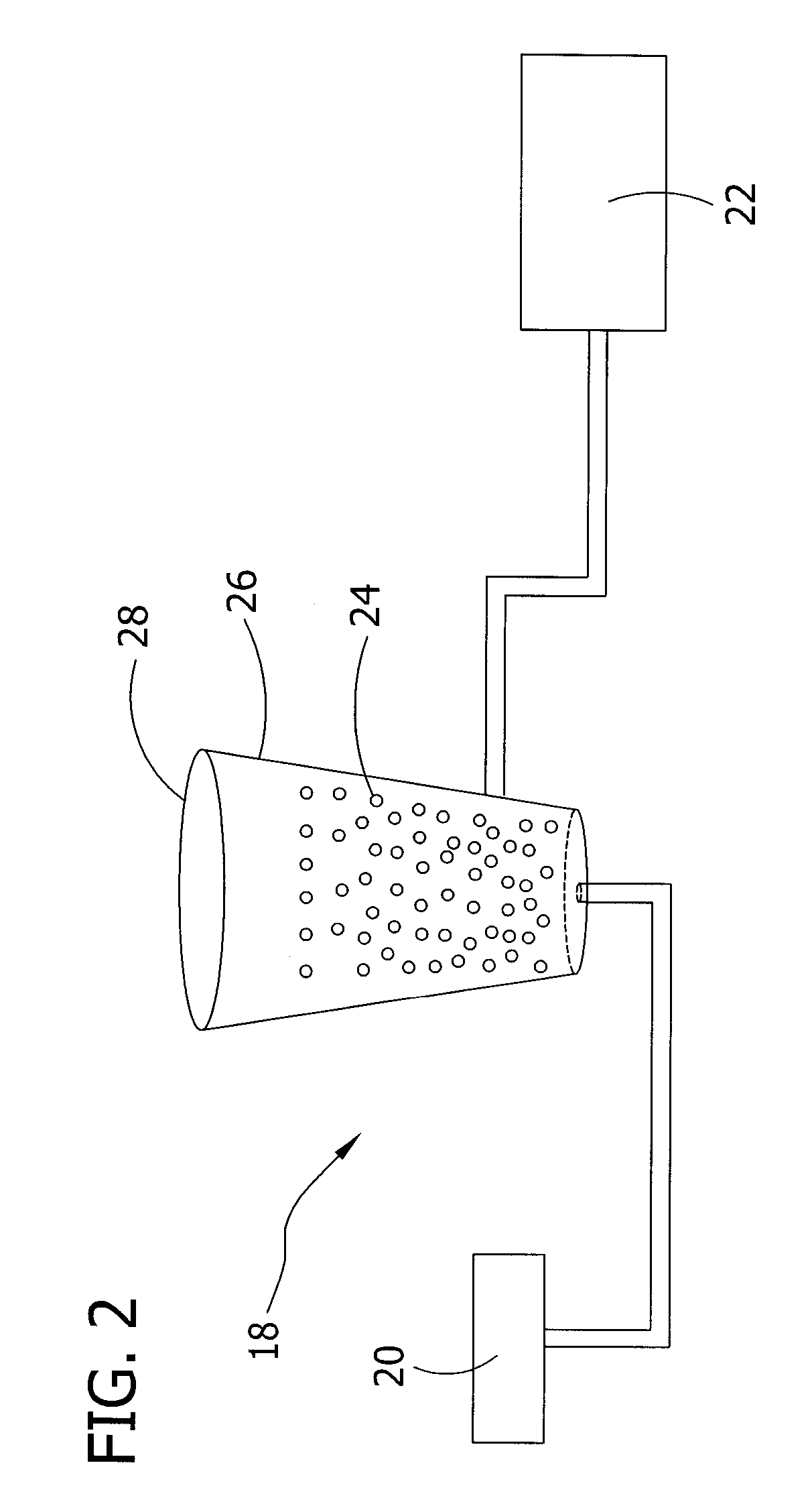

Wet wipe dispensing system for dispensing warm wet wipes

InactiveUS7654412B2Promote ruptureImprove responseRacksLighting and heating apparatusDelivery vehicleWet wipe

In a dispensing system and process for dispensing a warm wet wipe, a wet has an aqueous solution and microencapsulated delivery vehicles including a temperature change agent capable of generating a temperature change upon contact with the aqueous solution. An activating device facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from a wet wipe container to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm wet wipe. In another embodiment the wet wipe in the container has an aqueous solution. A lotion having the microencapsulated delivery vehicles is disposed in a lotion container free from contact with the wet wipe. An applicator in communication with the lotion is operable to apply the lotion to the wet wipe while the wet wipe is disposed at least in part within the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Dispensing system for dispensing warm wet wipes

In a dispensing system for dispensing wet wipes, a wet wipe has an aqueous solution and microencapsulated delivery vehicles including a temperature agent, and is disposed in a wet wipe container. A cartridge is held in assembly with the wet wipe container and has an activating device that facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from the dispensing system to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm or cooled wet wipe. In another embodiment, the wet wipe has an aqueous solution and a lotion having the microencapsulated heat delivery vehicles disposed in the cartridge free from contact with the wet wipe. The cartridge also has an applicator that is operable to apply the lotion to the wet wipe as the wet wipe is removed from the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

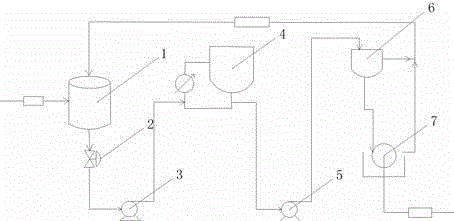

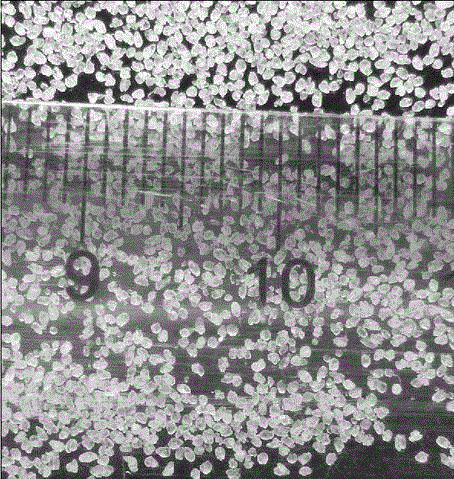

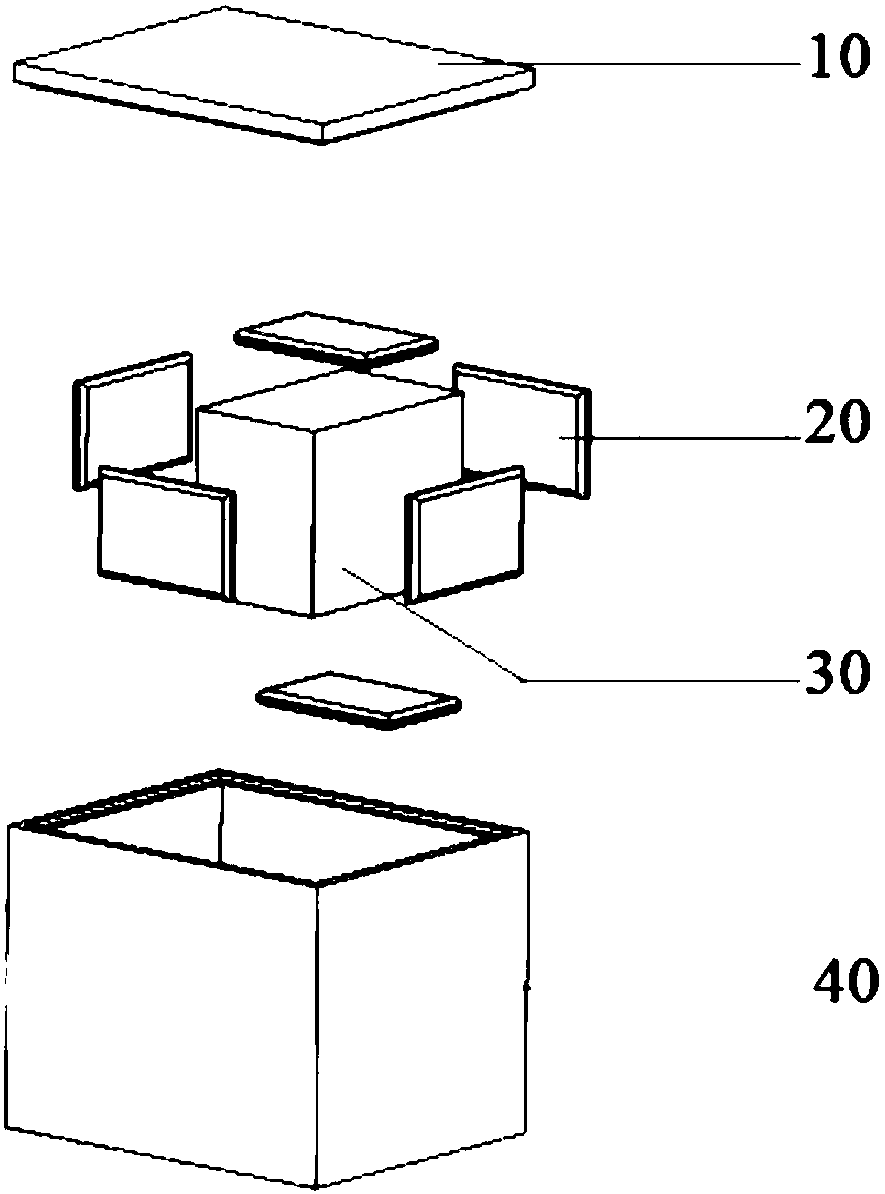

Large-granular boric acid, continuously cooling recrystallization preparation process and continuously cooling recrystallization preparation method thereof

InactiveCN105236439AIncrease surface tensionSolve technical problemsBoron-oxygen compoundsCentrifugationGranularity

The invention discloses large-granular boric acid, a continuously cooling recrystallization preparation process and a continuously cooling recrystallization preparation method thereof. The process includes the steps of: mixing boron-containing waste water or a powdery boric acid crude product with deionzied water according to mass ratio of (10-35):100; adding 10-1000 ppm of a surface tension change agent to obtain a mixture; increasing the temperature of the mixture with stirring until the raw materials are dissolved completely; performing primary temperature reduction, when the temperature is reduced to be higher than a crystal forming point by 1-3 DEG C, adding a boric acid crystal seed being 0.1-0.3 mm in granularity and performing secondary temperature reduction to 10-20 DEG C to prepare continuously-crystallized mother liquid; performing cyclic crystallization, centrifugation and washing to the mother liquid at 50-90 DEG C; and finally drying the crystals to obtain the large-granular boric acid product, wherein the cyclic crystallization is controlled within 2-8 h. The process is stable and is free of any crystal floatation problem. The large-granular boric acid is 0.6-1.2 mm in granularity, is high in purity, is mono-dispersed, is good in flowability and is free of blocking in storage and transportation.

Owner:CHENGDU CHENGDE CHEM TECH

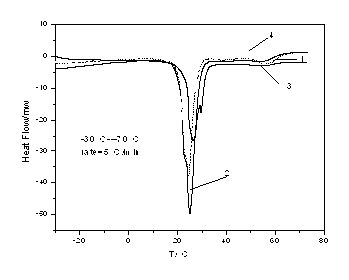

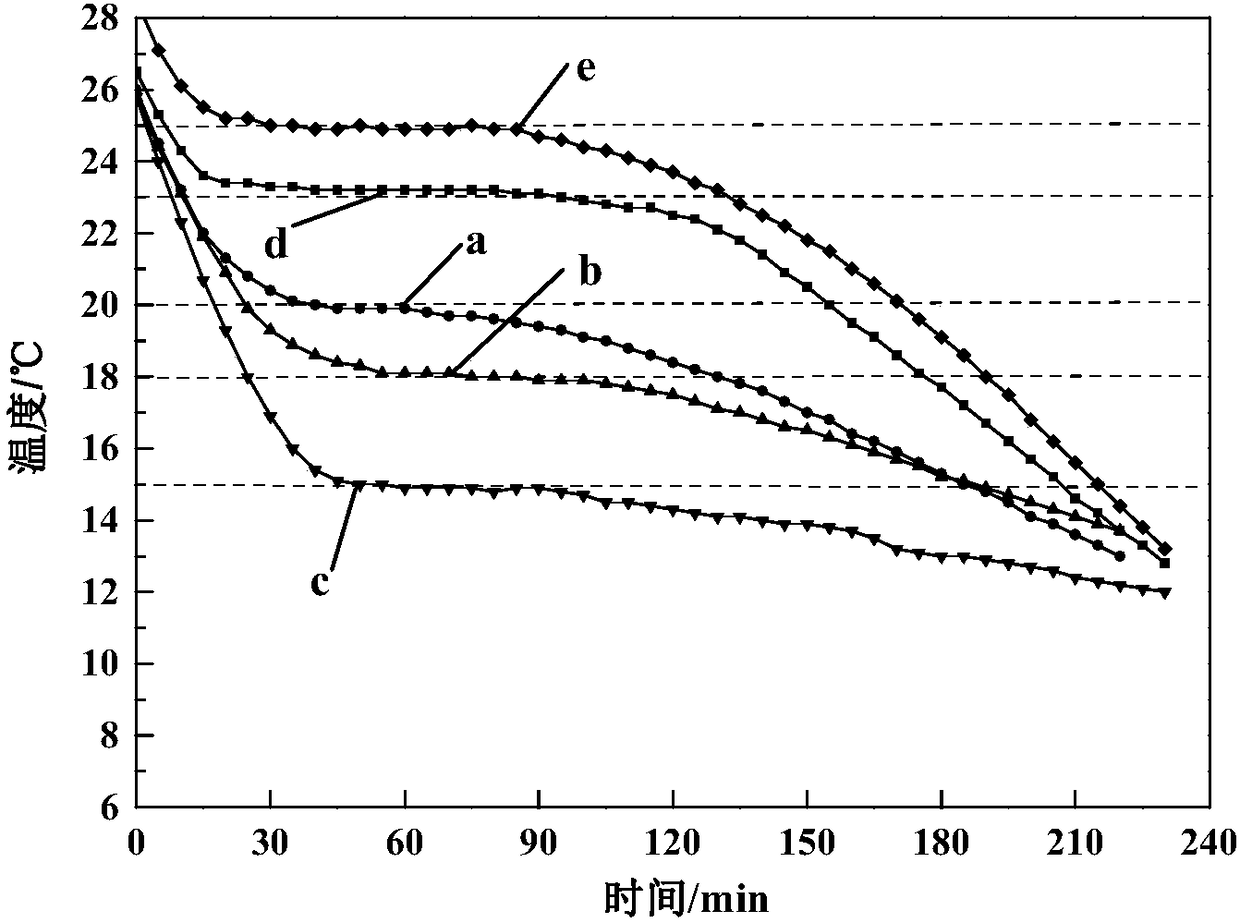

Preparation method of alkanol self-temperature control phase change material

InactiveCN103194183ALarge latent heat of phase changeLow costHeat-exchange elementsPhase change enthalpyParaffin wax

The invention discloses a preparation method of a phase change material. The preparation method is that dodecanol serving as a main phase change agent and paraffin serving as a secondary phase change agent are adopted for preparing a low-temperature phase change material. The low-temperature phase change material has phase change temperature about 22 DEG C, is relatively high in phase change enthalpy value which is about 180J / g, has stable performance, excellent phase change reversibility and little change in size during the phase change, and is safe, nontoxic and non-corrosive.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Modification of chemical forces of bone constructs

The present invention relates to a method for enhancing ingrowth of host bone comprising: modifying a bone graft structure to provide an ionic gradient to produce a modified bone graft structure; and implanting the modified bone graft structure. The present invention also relates to a method of enhancing the binding of growth factors and cell cultures to a bone graft structure comprising: applying ex vivo an effective quantity of an ionic force change agent to the surface of a bone graft structure to produce a binding-sensitized bone graft structure; implanting said binding-sensitized bone graft structure into a host bone; and administering to said binding-sensitized bone graft structure a molecule, a cell culture or a combination thereof.

Owner:MEDTRONIC INC +1

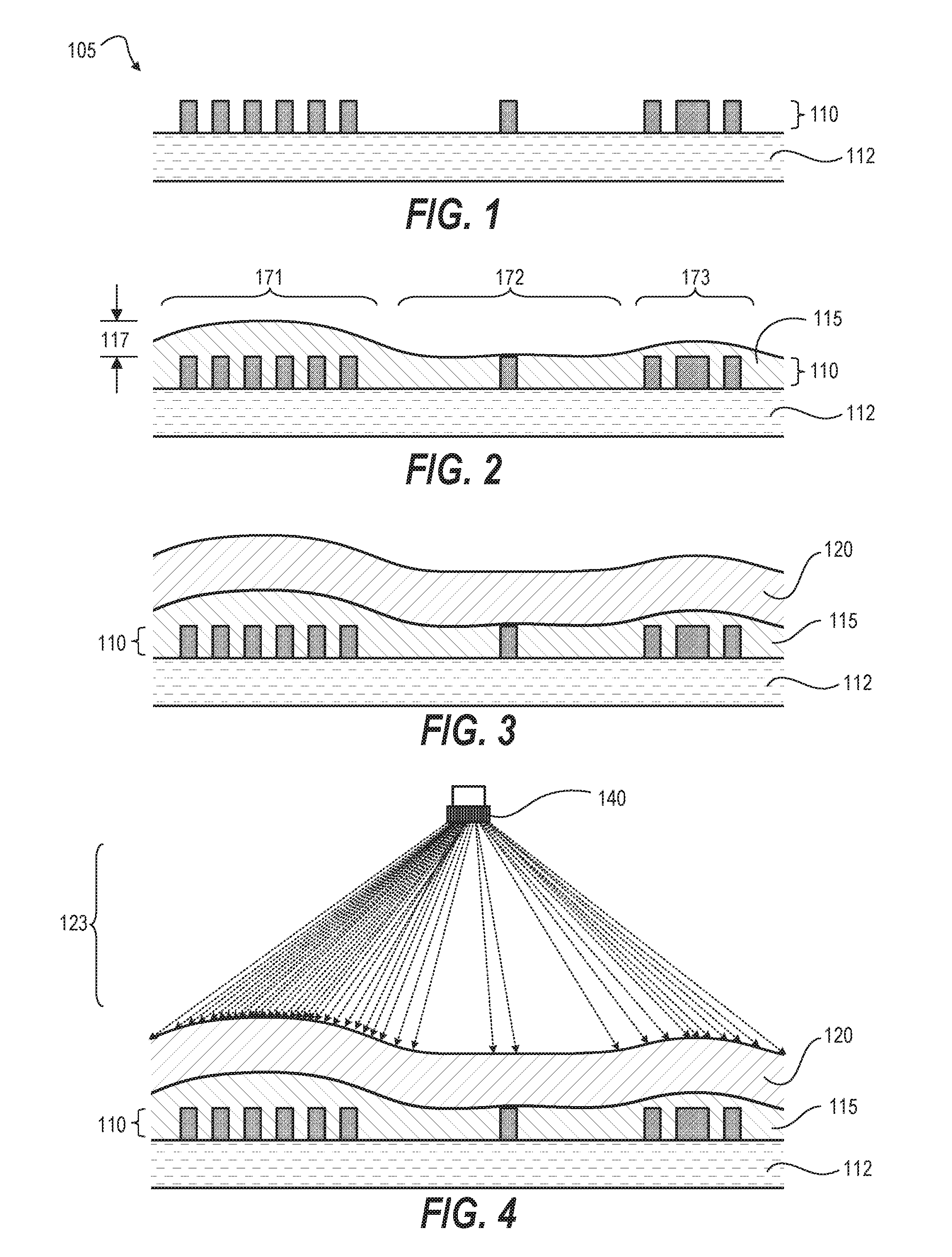

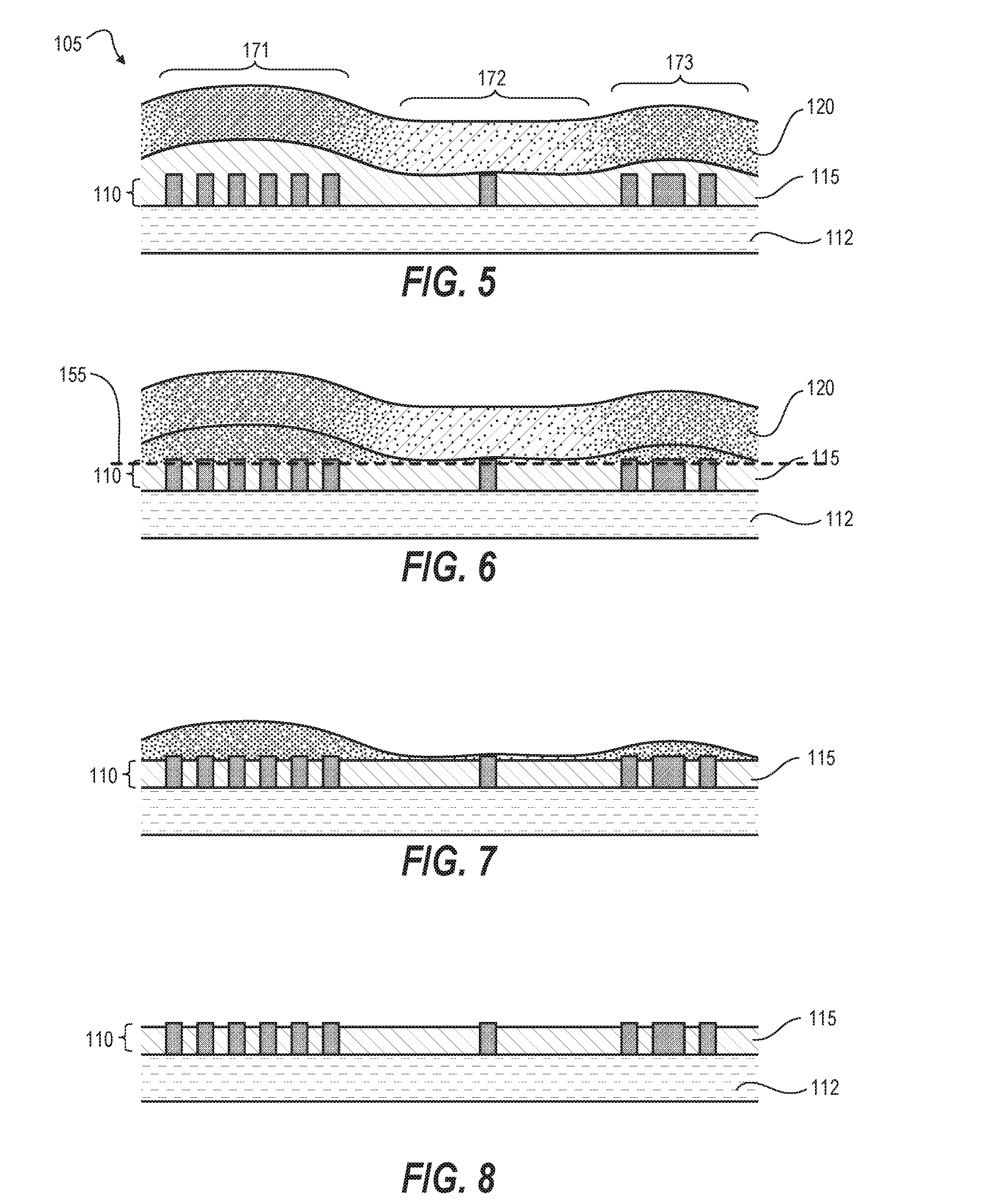

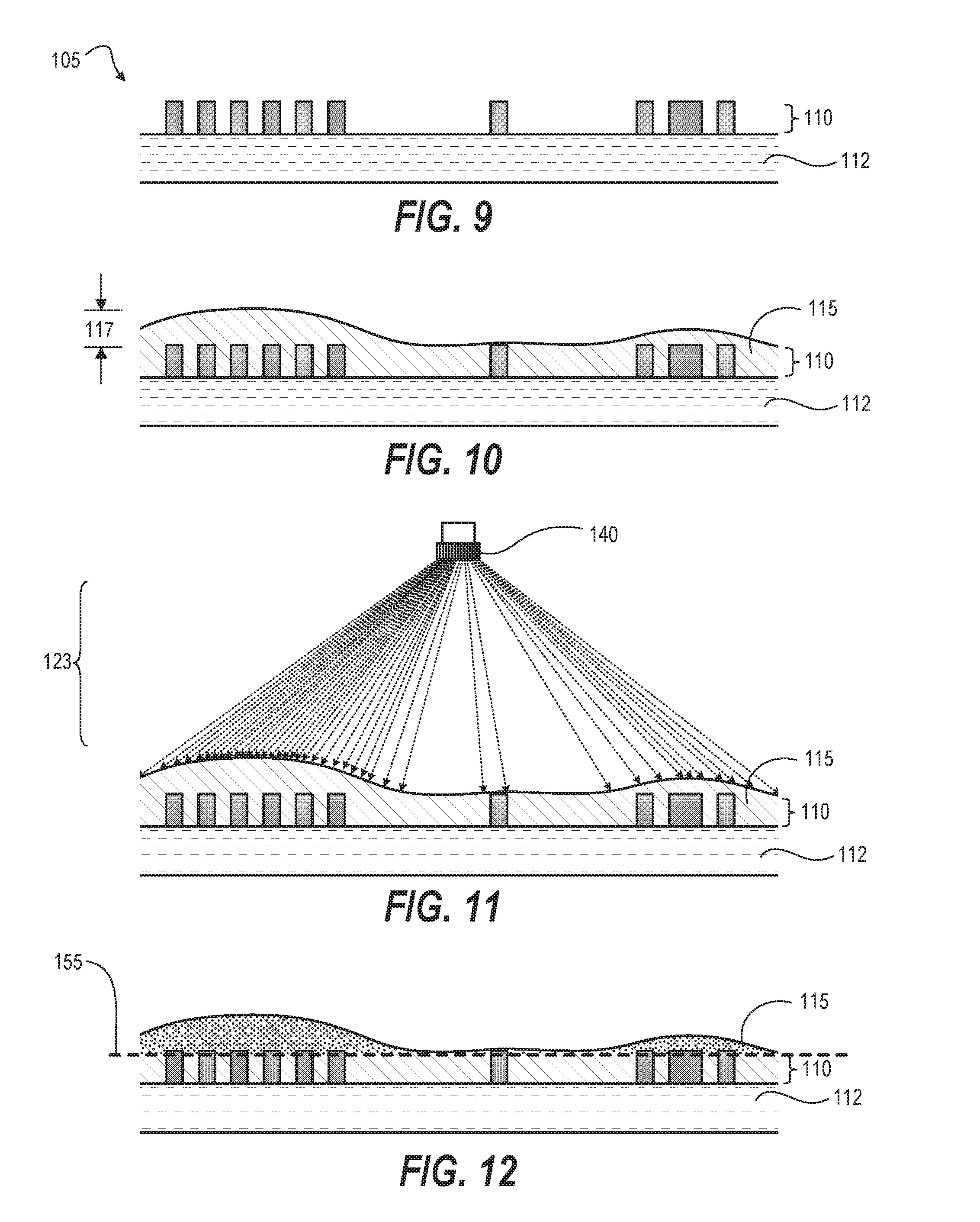

System and Method for Planarizing a Substrate

ActiveUS20160300726A1Highly accurateHighly controllableSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusSolubilityPhysics

Techniques include providing selective or differential planarization such that different regions of a substrate can have different amounts of material removed. In general, methods herein use photo-reactive generator compounds to generate solubility-changing agents. A specific pattern of light is projected onto a substrate containing such photo-reactive generator compounds to create different concentrations of solubility-changing agent(s) at specific locations across a substrate. As generated solubility-changing agents are diffused into an underlying layer, these concentration differences then control an amount (height or depth) of material removed from a given film or layer at specific spatial locations on the substrate.

Owner:TOKYO ELECTRON LTD

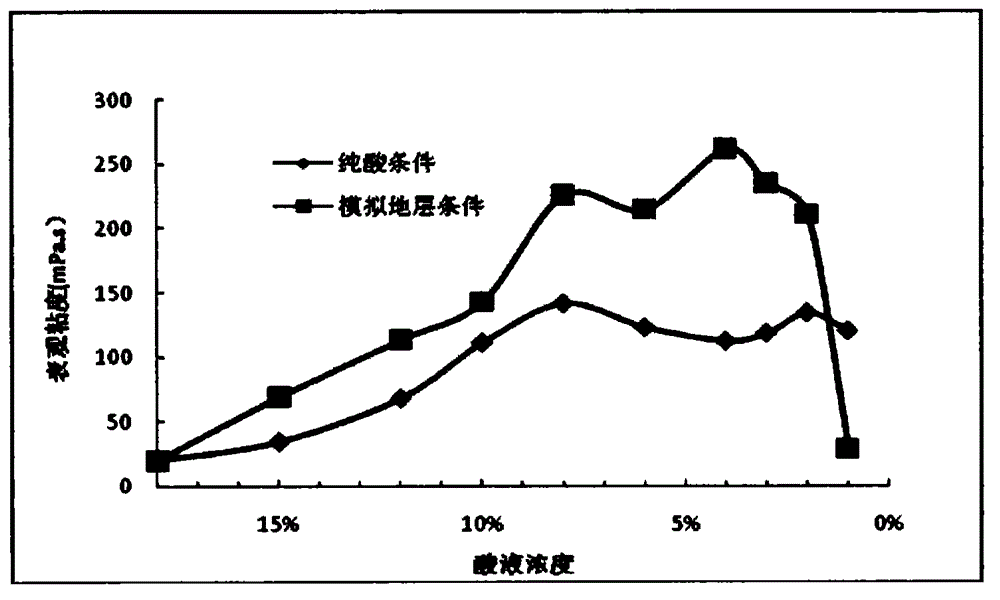

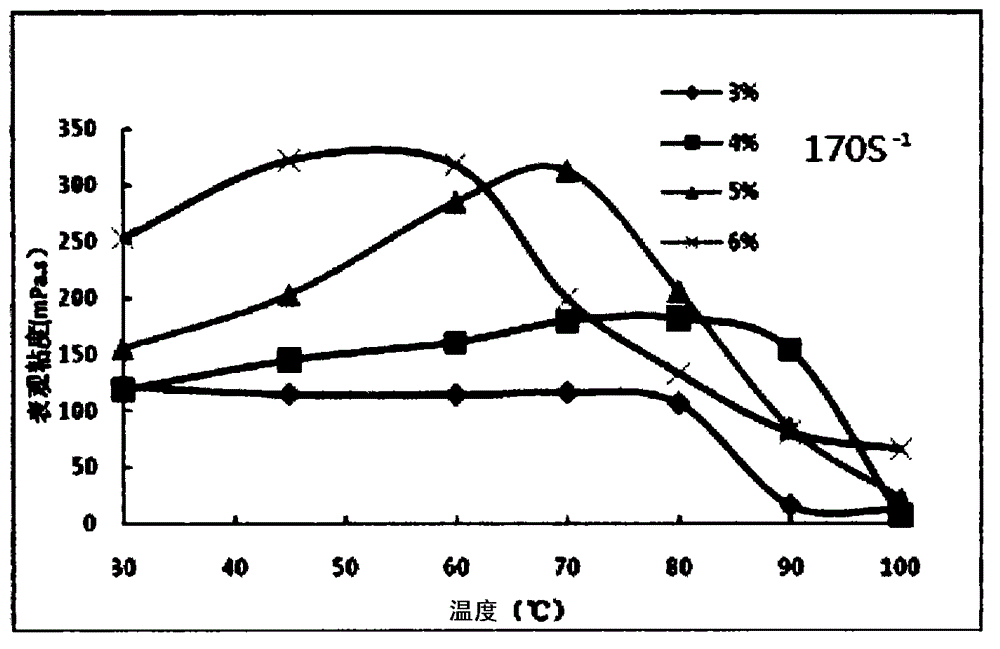

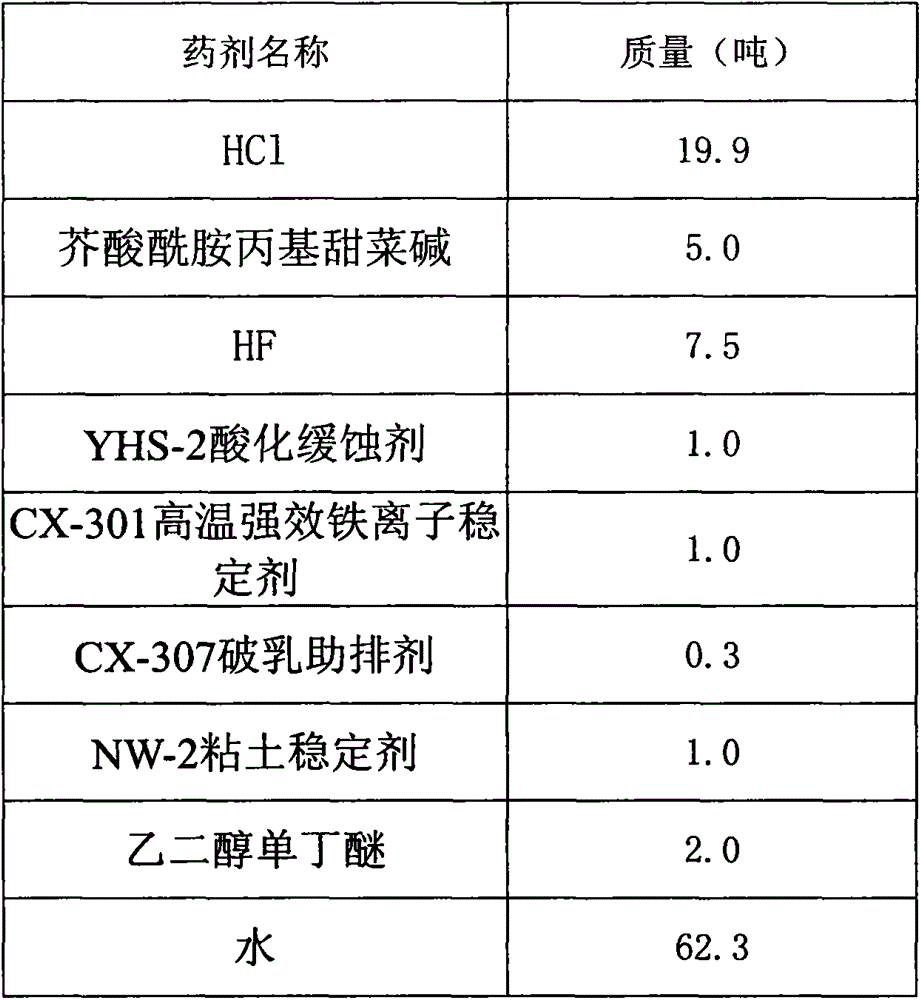

Variable-viscosity acid liquid used for acidifying processing

InactiveCN104479656ASlow reaction rateEvenly distributedDrilling compositionHydrofluoric acidSolvent

A variable-viscosity acid liquid is composed of the following compositions in percent by weight: 19.9-25.0% of hydrochloric acid, 1.0-7.5% of hydrofluoric acid, 5-7% of a viscosity-changing agent, 1-2% of an acidifying corrosion inhibitor, 0.1-0.5% of an ferric-ion stabilizing agent, 0.3-0.4% of a demulsification cleanup additive, 1-1.5% of a clay stabilizing agent, 1-2% of an acidifying mutual solvent, and the balance water. The invention provides the variable-viscosity acid liquid, and the variable-viscosity acid liquid has self-diverting flow-dividing effect and is capable of realizing general acidifying and uniform acid distribution.

Owner:SOUTHWEST PETROLEUM UNIV

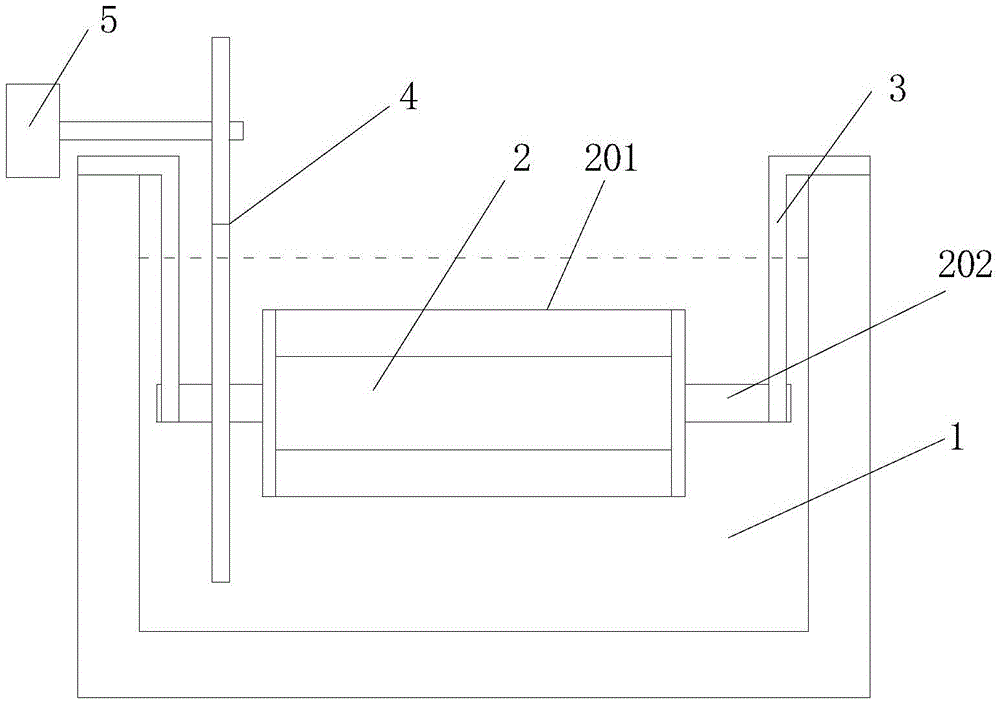

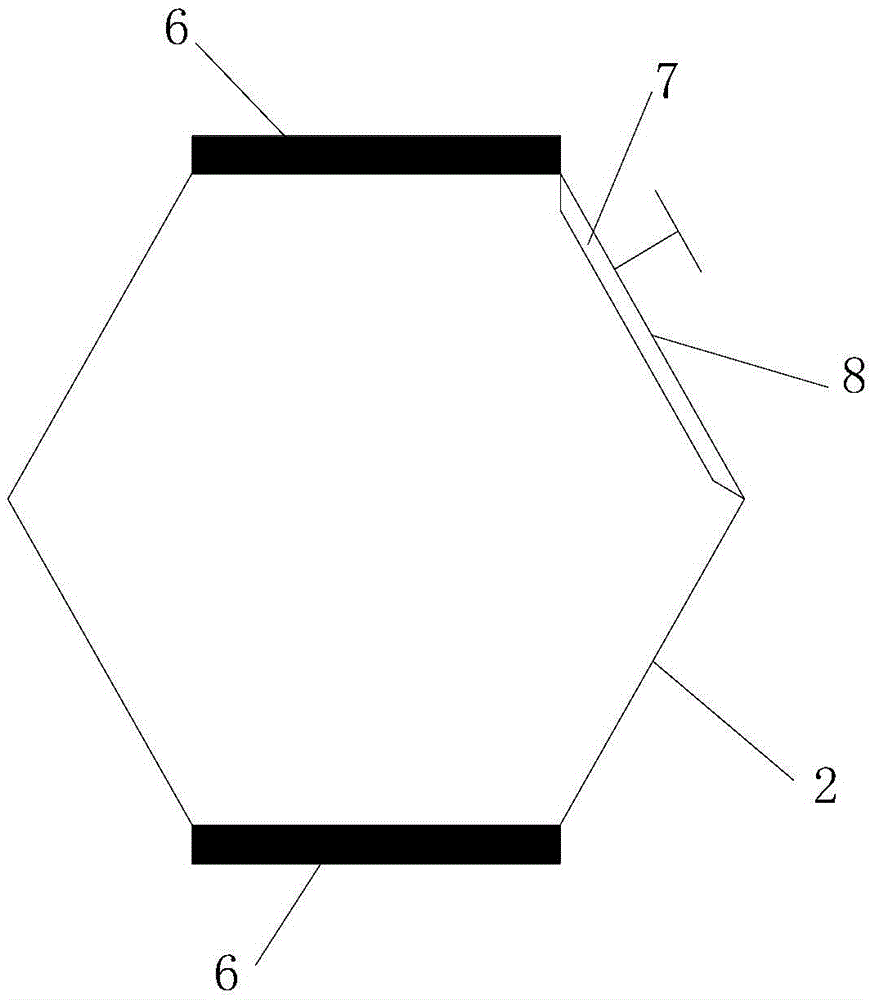

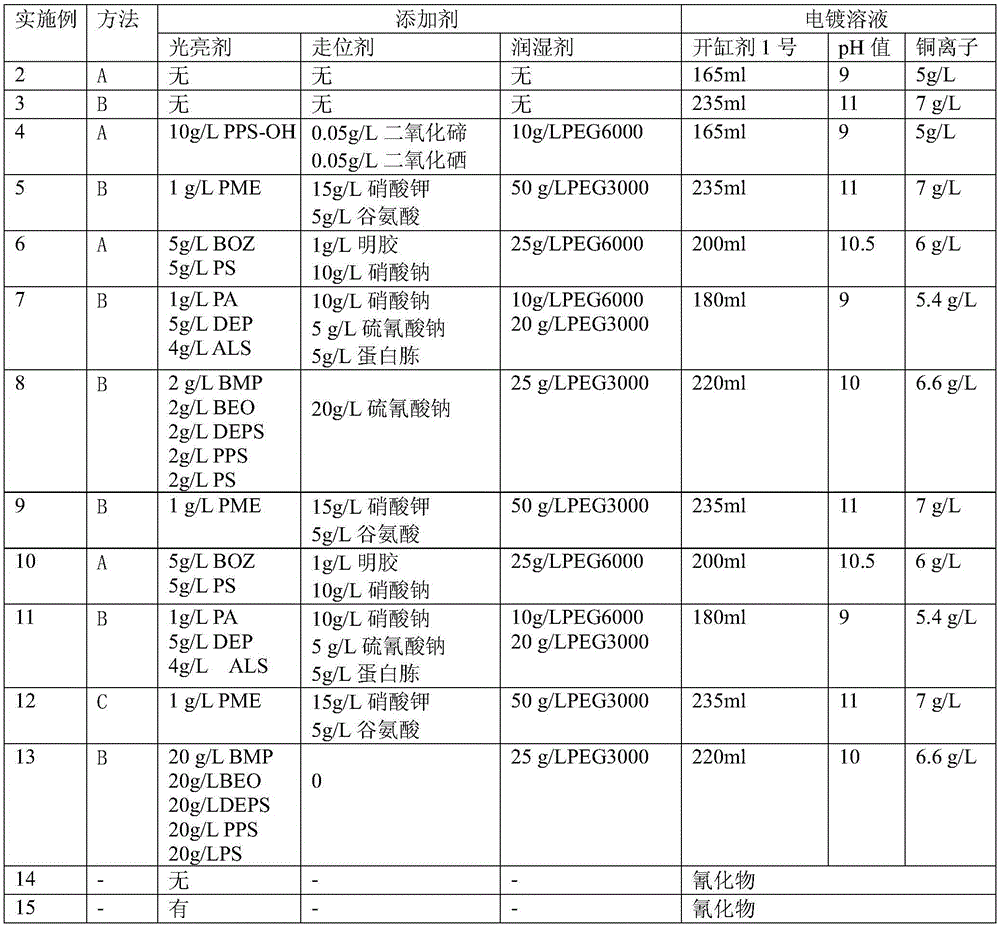

Solution and method for cyanide-free alkaline bright barrel copper plating

The invention discloses a solution and a method for cyanide-free alkaline bright barrel copper plating. The solution comprises a No.1 BH-582 plating bath solution, 300 ml / L of a No.2 BH-582 plating bath solution, 10 ml / L of an additive and a pH value regulator, wherein the addition amount of the No.1 BH-582 plating bath solutions is calculated in such a manner that the content of copper ions in a final system is 5-7 g / L after the No.1 BH-582 plating bath solution and the No.2 BH-582 plating bath solution are matched, and the usage amount of the pH value regulators is based on the condition that the pH of the final system is kept between 9 and 11; the additive comprises a brightener, a bath change agent and a wetting agent in the volume ratio being 1:(1-3):1. The method for cyanide-free alkaline bright barrel copper plating adopts the solution for barrel copper plating and comprises steps as follows: pretreatment of an iron-based blank, activation, water washing and then cyanide-free alkaline bright barrel copper plating. On the basis that the binding force between plating and a matrix is guaranteed, the solution and the method can replace a cyanide system for pre-plating, and environment-friendly and clean production is realized.

Owner:GUANGZHOU HONWAY TECH CORP

Wet wipe dispensing system for dispensing warm wet wipes

InactiveUS20080087680A1Promote ruptureImprove responseRacksLighting and heating apparatusDelivery vehicleWet wipe

In a dispensing system and process for dispensing a warm wet wipe, a wet has an aqueous solution and microencapsulated delivery vehicles including a temperature change agent capable of generating a temperature change upon contact with the aqueous solution. An activating device facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from a wet wipe container to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm wet wipe. In another embodiment the wet wipe in the container has an aqueous solution. A lotion having the microencapsulated delivery vehicles is disposed in a lotion container free from contact with the wet wipe. An applicator in communication with the lotion is operable to apply the lotion to the wet wipe while the wet wipe is disposed at least in part within the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Dispensing system for dispensing warm wet wipes

In a dispensing system for dispensing wet wipes, a wet wipe has an aqueous solution and microencapsulated delivery vehicles including a temperature agent, and is disposed in a wet wipe container. A cartridge is held in assembly with the wet wipe container and has an activating device that facilitates rupturing of the microencapsulated delivery vehicles as the wet wipe is removed from the dispensing system to allow contact between the temperature change agent and the aqueous solution of the wet wipe to thereby dispense a warm or cooled wet wipe. In another embodiment, the wet wipe has an aqueous solution and a lotion having the microencapsulated heat delivery vehicles disposed in the cartridge free from contact with the wet wipe. The cartridge also has an applicator that is operable to apply the lotion to the wet wipe as the wet wipe is removed from the wet wipe container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Gel phase-change material as well as preparation method and application method thereof

ActiveCN108300418ANot corrosivePrevent overcoolingDomestic cooling apparatusLighting and heating apparatusCold chainSodium sulfate

The invention discloses a gel phase-change material. The gel phase-change material is prepared from components in percentage by mass as follows: 35%-39% of sodium sulfate, 2.8%-8.5% of sodium chloride, 0.5%-2.5% of ammonium chloride, 2.5%-4% of a thickening agent, 3.0%-3.3% of borax, 0.1%-0.2% of a crystal form changing agent, 1%-1.8% of white carbon black and the balance of pure water. The gel phase-change material is adjustable at the temperature of 15-25 DEG C, is non-toxic, odorless, non-corrosive and gelatinous and has shape plasticity, the problems of supercooling, phase separation and liquid phase leakage of a traditional aqueous phase-change material are solved, furthermore, the gel phase-change material is higher in latent heat of phase change, long in cold insulation time and lowin cost, adopts a simple preparation process and can be widely applied to cold-chain transportation of products such as red wine, chocolate and the like at the storage and transportation temperatureof 15-25 DEG C.

Owner:SOLEE WUHAN SCI & TECH

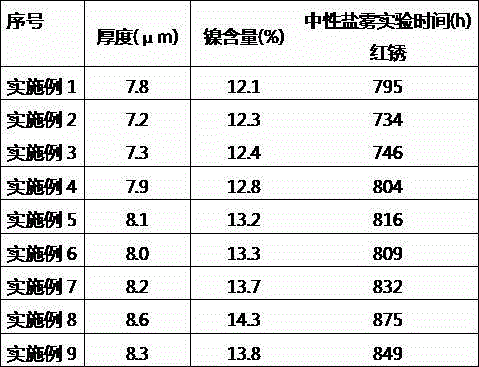

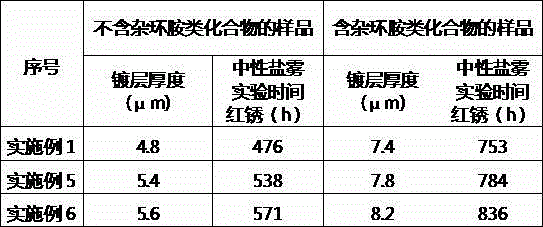

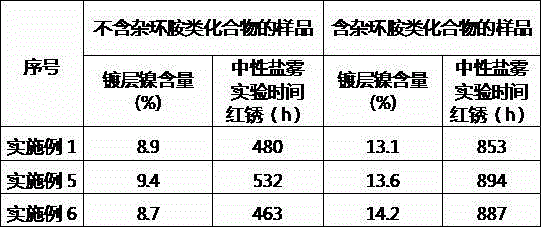

High corrosion resistance zinc-nickel alloy electroplating additive with weak acidity to neutrality and electroplating liquid

ActiveCN104651888AImprove anti-corrosion performanceRelaxed working conditions for electroplatingNickel alloyChloride

The invention discloses a high corrosion resistance zinc-nickel alloy electroplating additive with weak acidity to neutrality and an electroplating liquid. The high corrosion resistance zinc-nickel alloy electroplating additive comprises the following components in parts by volume: 60-90 parts of a complexing agent, 15-25 parts of brightener, and 1-5 parts of a change agent. The electroplating liquid prepared from the additive consists of 150-220g / L of potassium chloride, 35-70g / L of potassium acetate, 50-75g / L of zinc chloride, 55-80g / L of nickel chloride, 60-90ml / L of a complexing agent, 15-25ml / L of a brightener, 1-5ml / L of a change agent and the balance of water. The high corrosion resistance zinc-nickel alloy electroplating additive disclosed by the invention is free of boric acid and ammonium chloride, the current efficiency of the high corrosion resistance zinc-nickel alloy electroplating additive is as high as 95%, as the basic liquid is free of boric acid, the pH value is relatively high and can be stabilized to be 5.5-7, the nickel content of a layer formed by electroplating with the electroplating liquid with the additive is stabilized to be within 10-15%, and the electroplated layer is stable in gamma crystal phase and excellent in anti-corrosion property.

Owner:武汉风帆电化科技股份有限公司

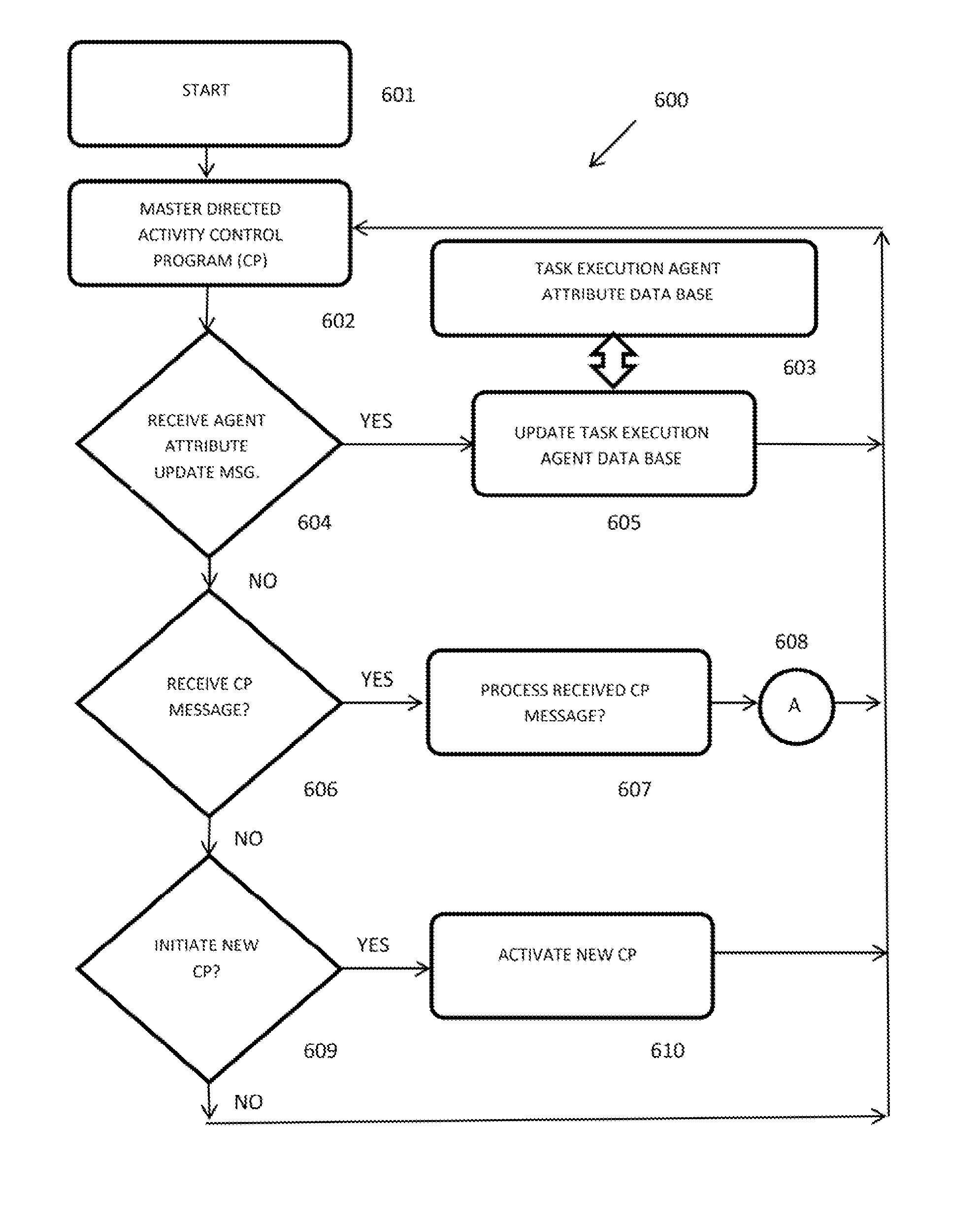

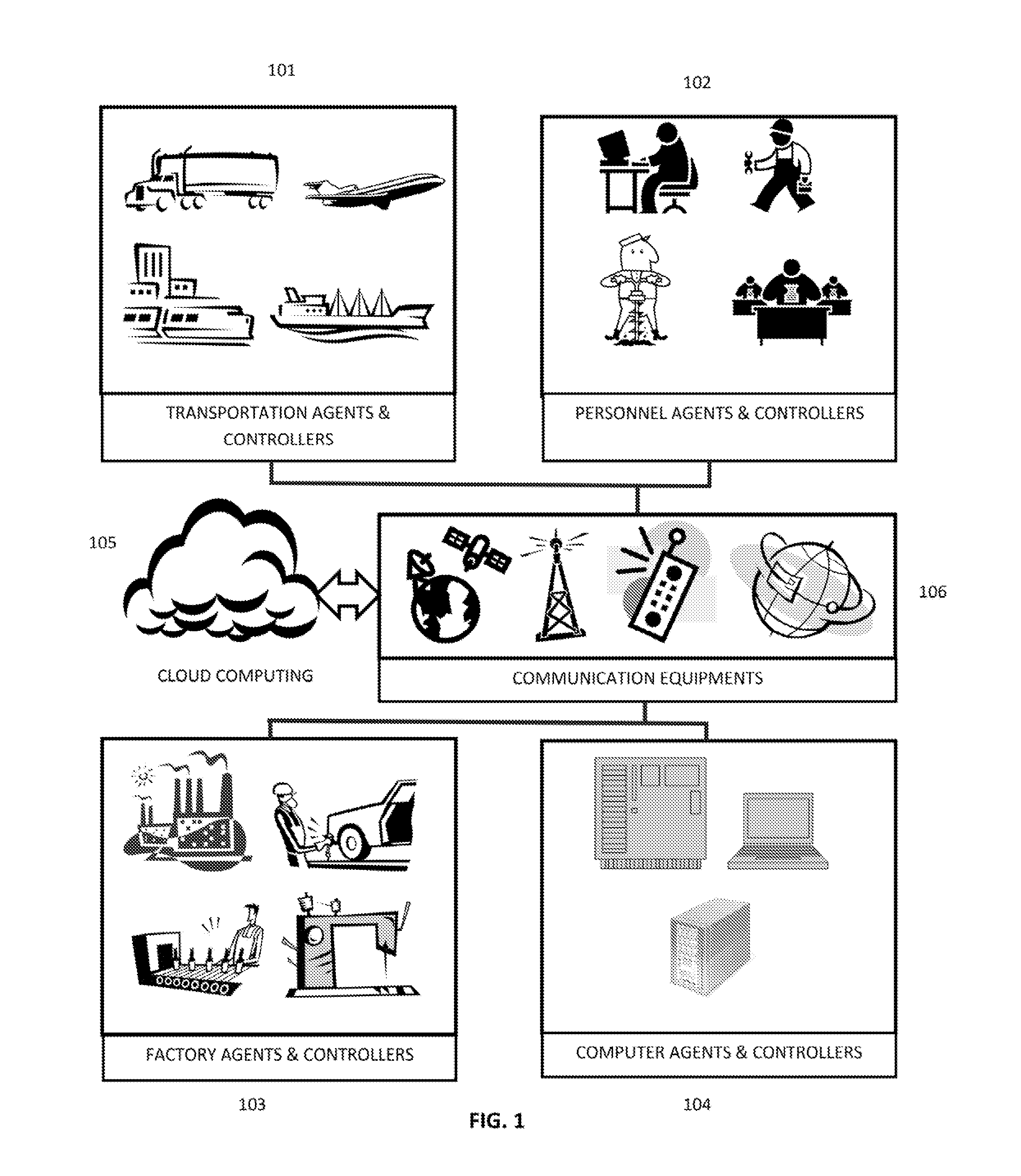

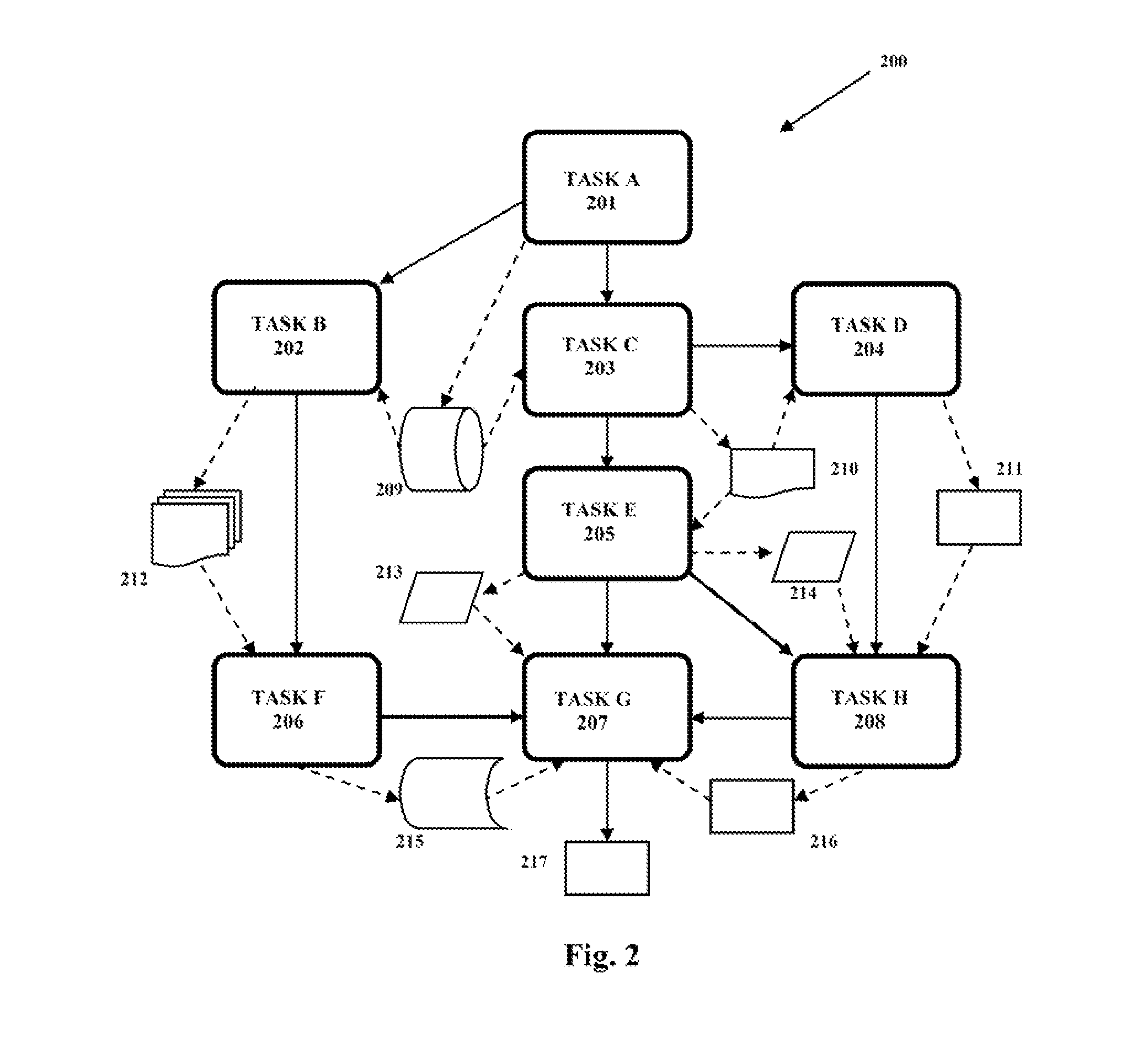

Distributed activity control systems and methods

ActiveUS9477519B2Program initiation/switchingKnowledge representationControl systemExecution control

Owner:PEDERSEN ROBERT D

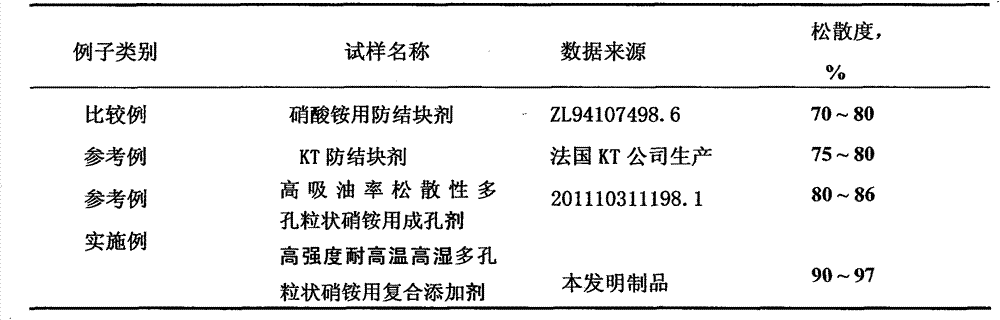

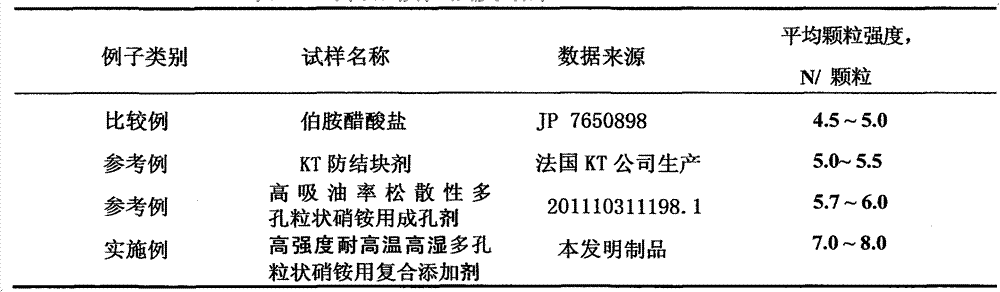

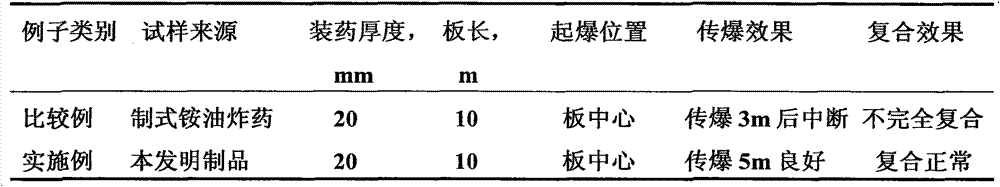

Composite additive for high-strength high temperature and high moisture resisting porous granular nitramine

InactiveCN103113173AWon't clogProduction and use safetyNon-explosive/non-thermic compositionsPrillAnticaking agent

The invention relates to a waterborne composite additive which can improve the physical properties of porous granular nitramine. The composite additive is characterized by consisting of internally added full water soluble powder and an ointment-shaped outer wrapping agent. The internally added full water soluble powder consists of an enhancer, an anti-crystal change agent, a diffusant and the like. The ointment-shaped outer wrapping agent consists of a water repellent, an anti-crystal change agent, an enhancer and the like. The composition additive is provided by the invention to overcome the deficiencies of additive for porous granular nitramine researched by predecessors that the porous granular nitramine product is low in strength, easy to block in high temperature and moist environments, more foam in production process of powder aqueous liquor, high cost due to imported raw materials and the like in actual use. The composite additive has the characteristics that not only is high-strength porous granular nitramine prepared, but also the product can be stored for three months in high temperature and moist environments, and the shatter value is maintained at 90%. The composite additive provided by the invention can be further used as an effective anti-blocking agent for preparing a high nitrogen nitryl compound fertilizer. The fortified concentration of the composite additive provided by the invention is 0.10-0.12%.

Owner:太原海力丰科技发展有限公司

Ink for laser imaging

Ink formulations and methods of using the same in laser-imaging are provided. An ink formulation can comprise a graphene-based component, a colour change agent, a binder, and a solvent. Substrates, coatings, and articles comprising a graphene-based component are also provided, and laser marking can be brought about by an ablation or direct charring process.

Owner:DATALASE

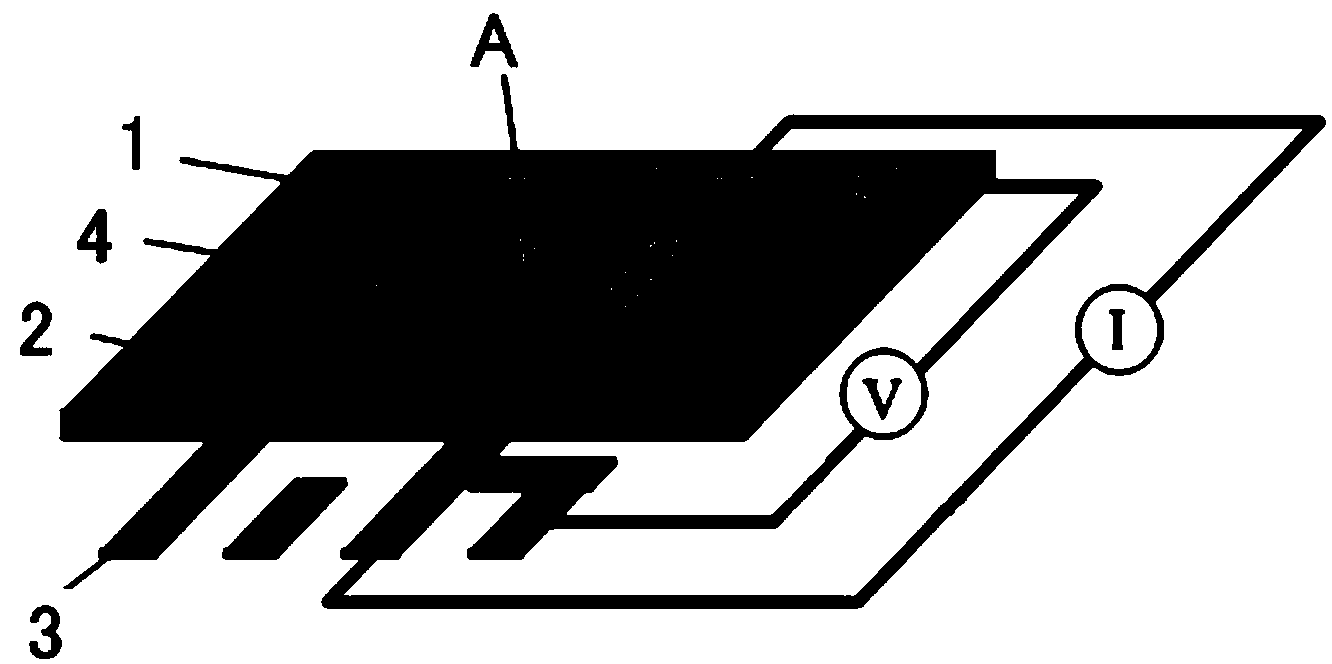

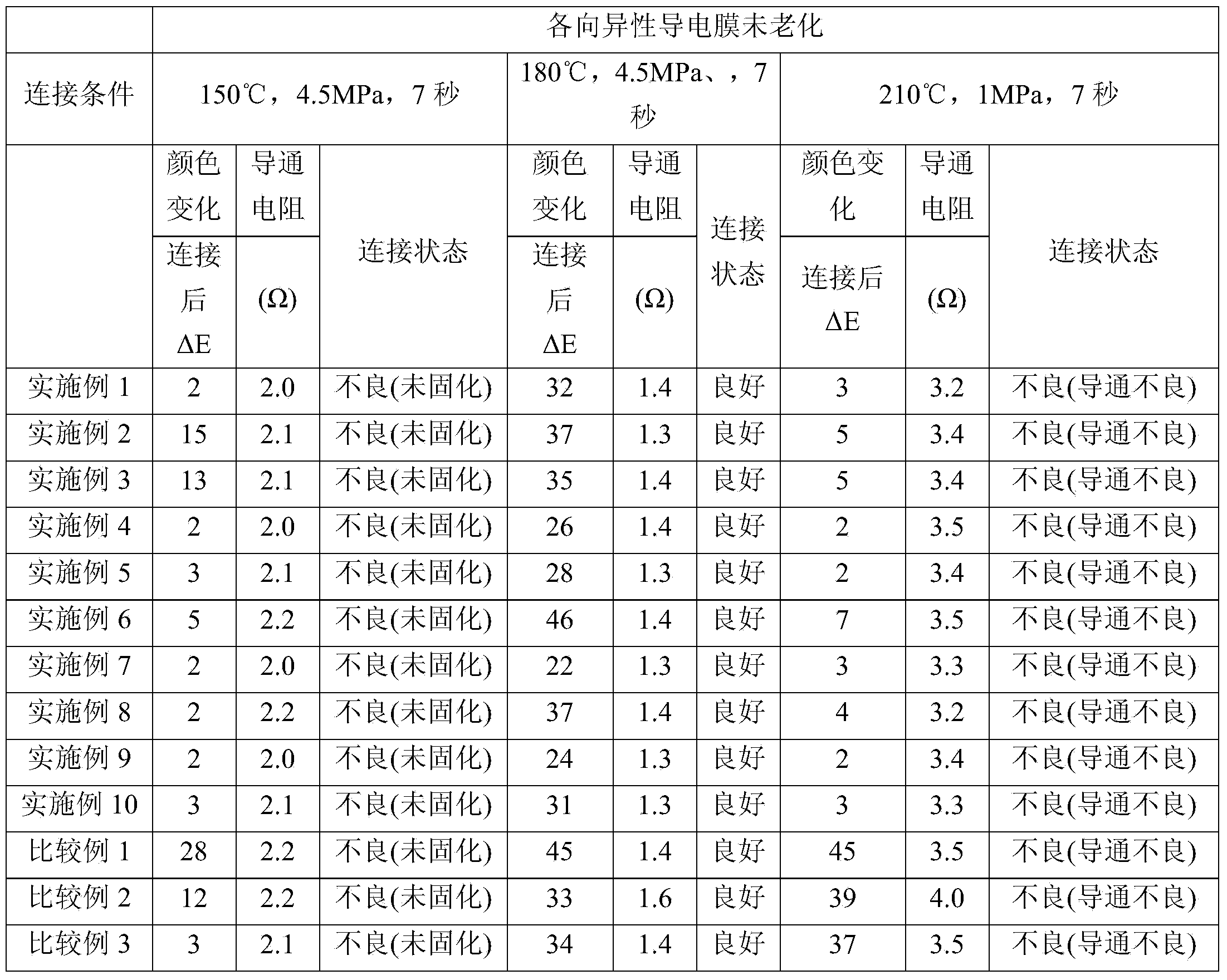

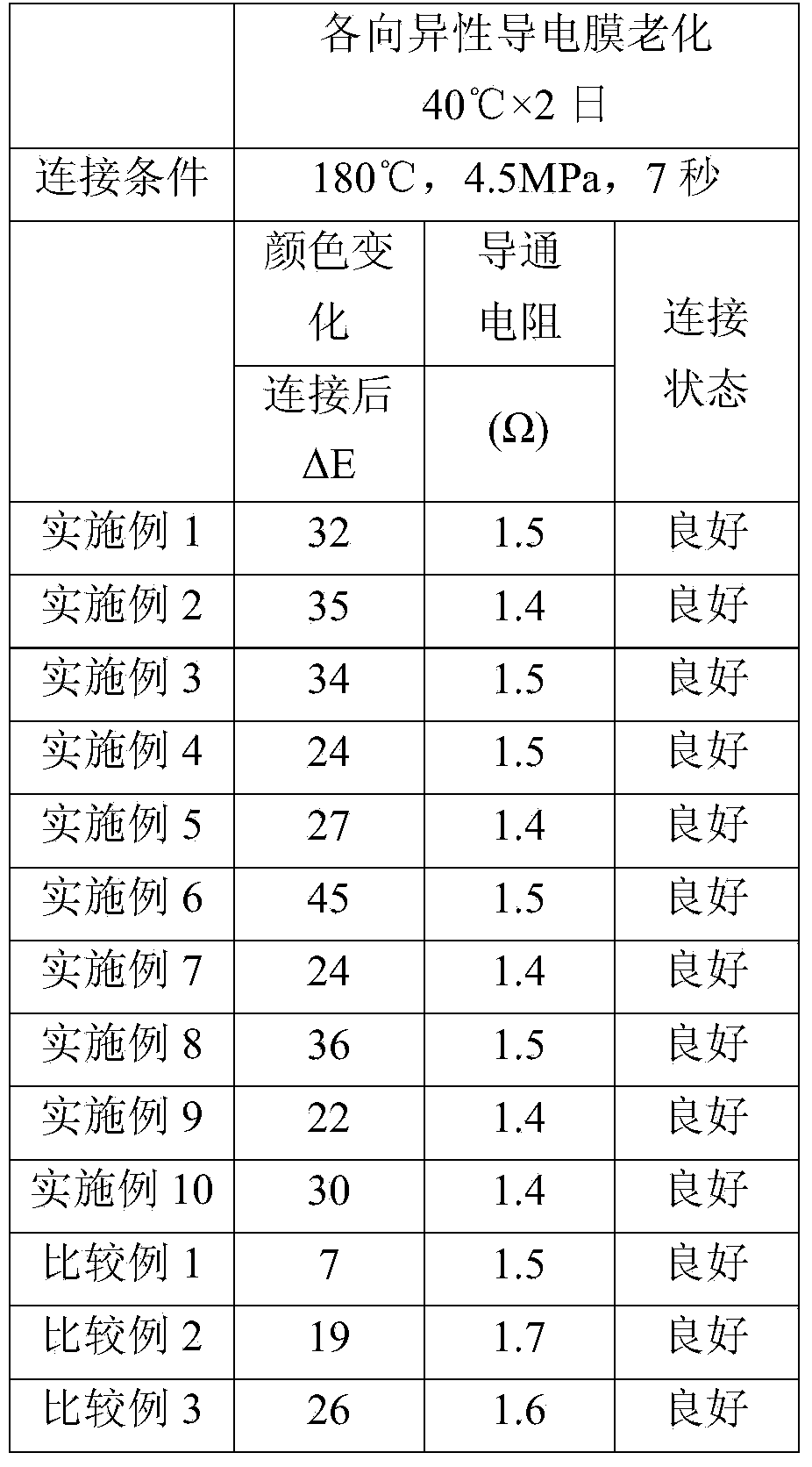

Anisotropic conductive film, connecting method, and joined body

InactiveCN104109491AImprove stabilityGood connection statusPrinted circuit assemblingLine/current collector detailsAnisotropic conductive filmEngineering

An anisotropic conductive film allowing anisotropic conductive connection between terminals of a first circuit part and terminals of a second circuit part comprises a first layer containing film forming resin and a second layer containing film forming resin. At least one of the first layer and the second layer contains conductive particles. One of the first layer and the second layer contains leuco dye and the other contains a hue change agent which interacts with the leuco dye to make the hue of the anisotropic conductive film change.

Owner:DEXERIALS CORP

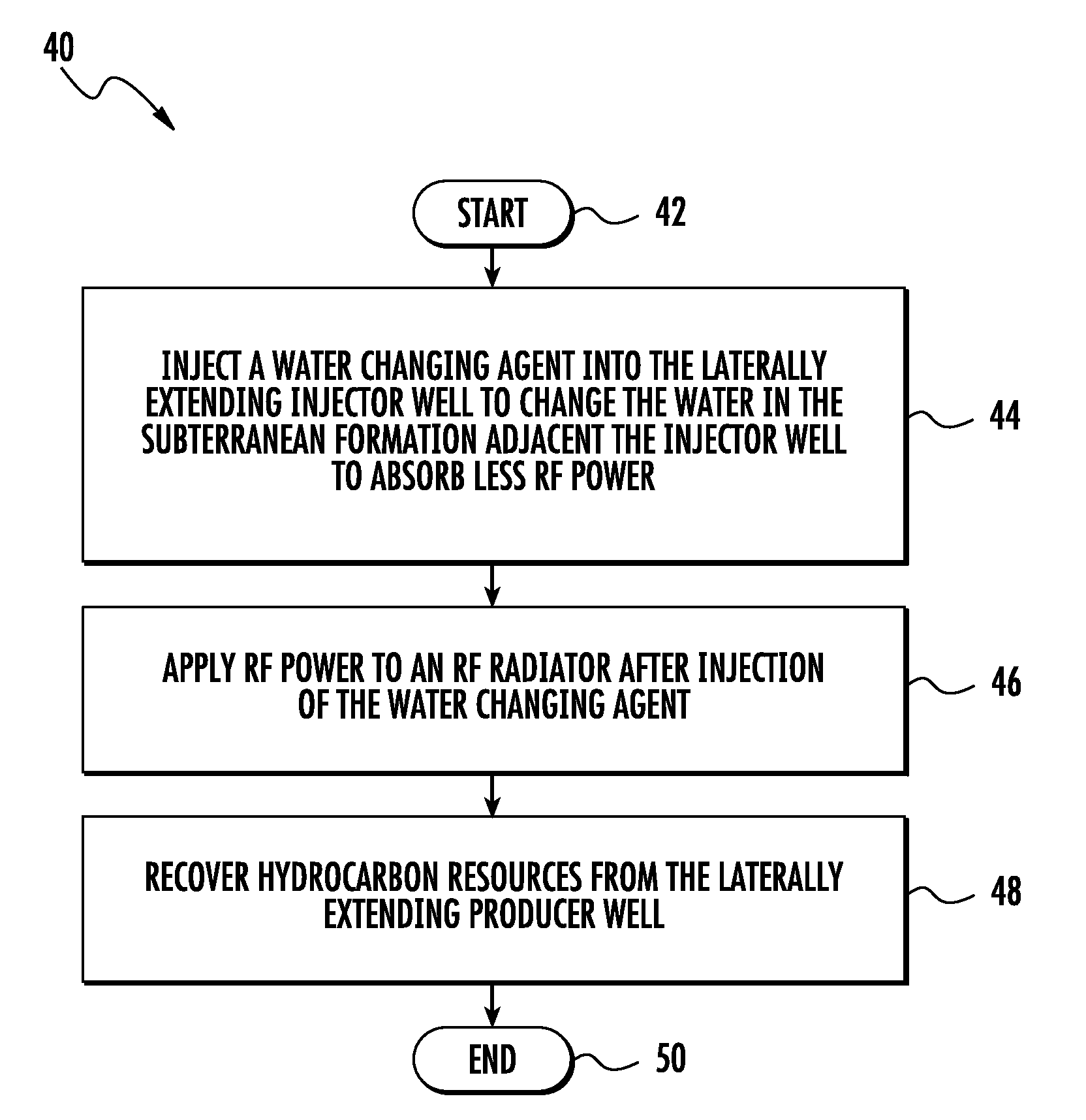

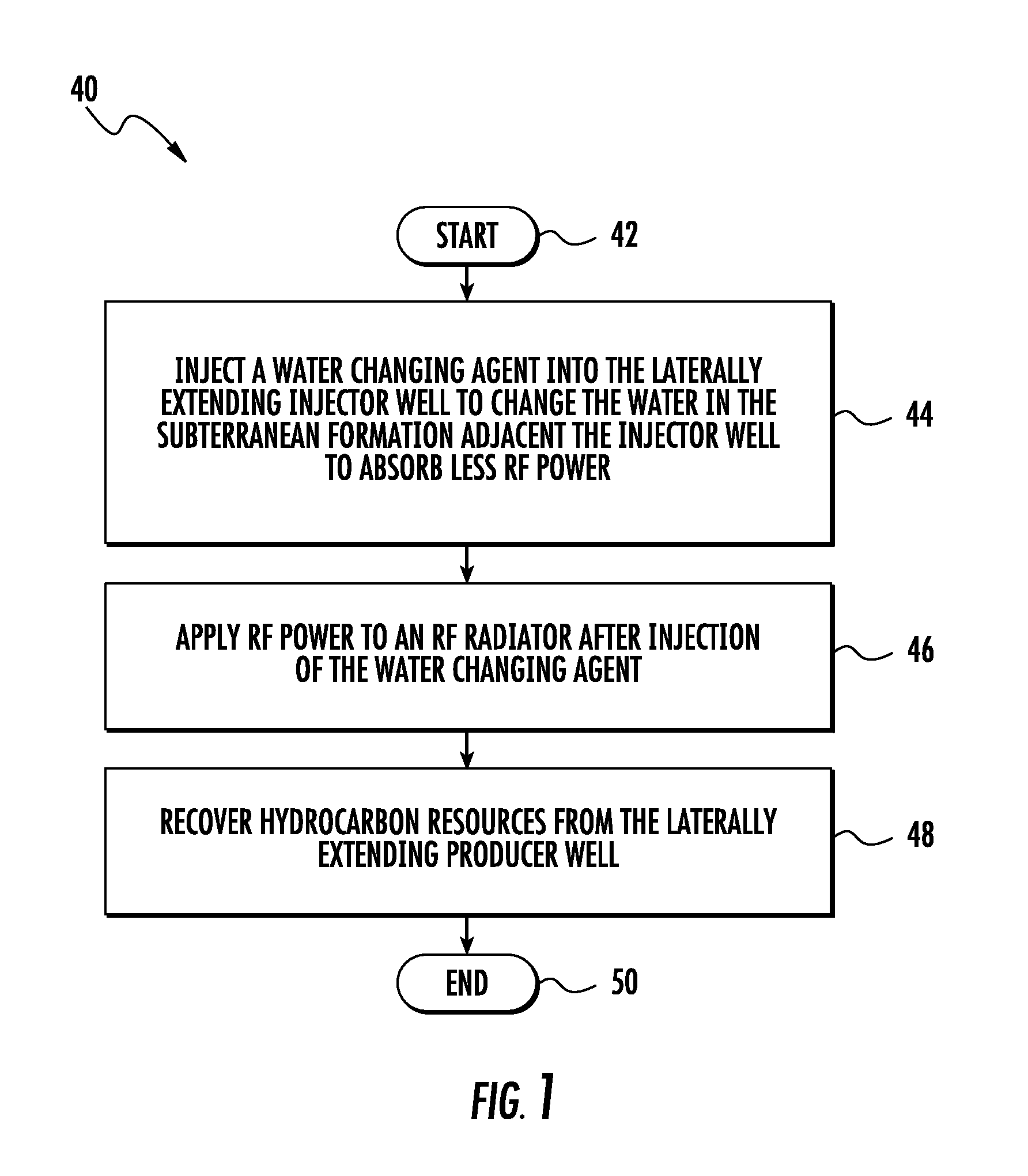

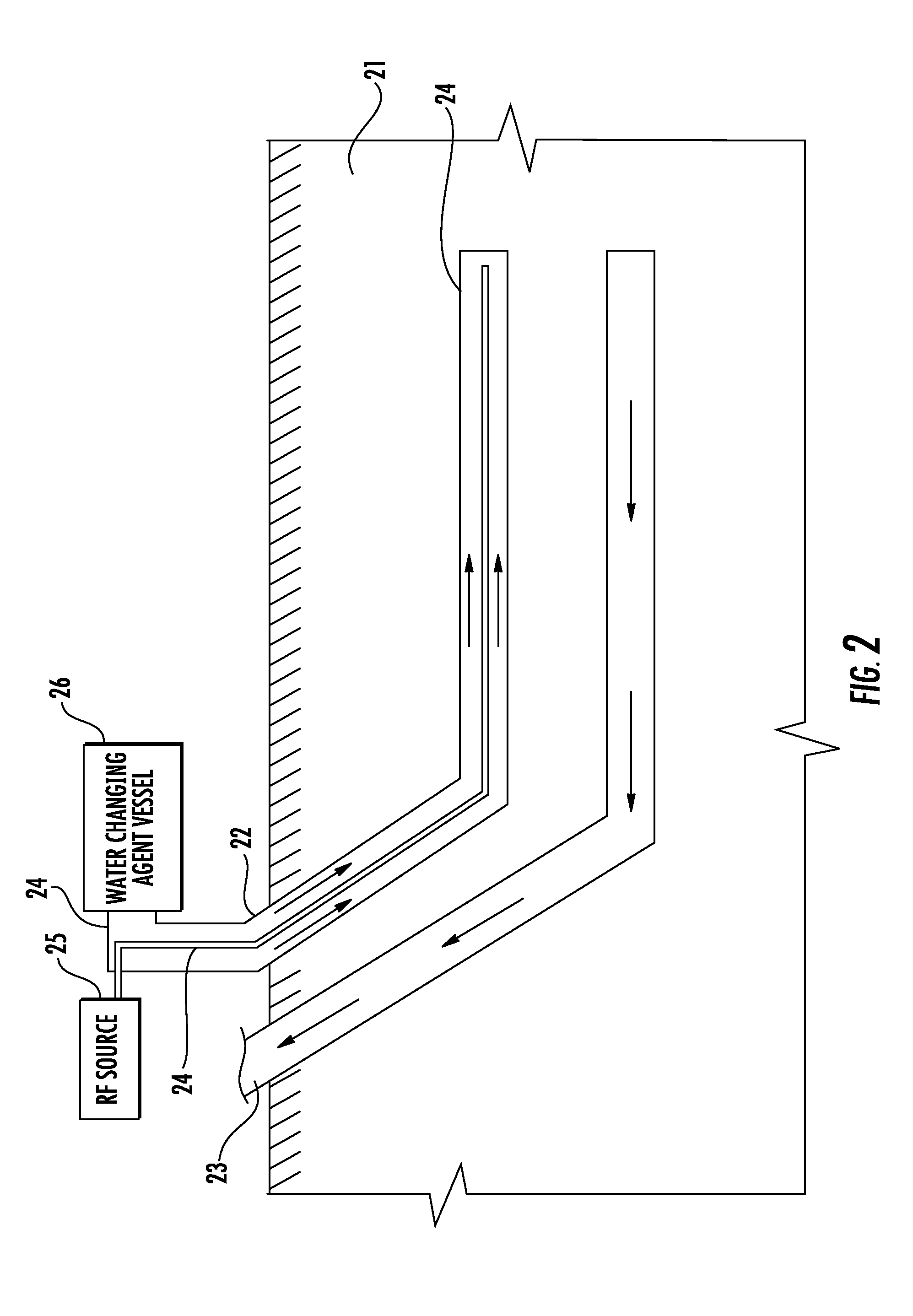

Method for hydrocarbon recovery using a water changing or driving agent with RF heating

A method of processing a hydrocarbon resource in a subterranean formation including a laterally extending injector well, a laterally extending producer well below the laterally extending injector well, and water within the subterranean formation, may include injecting a water changing agent into the laterally extending injector well to change the water in the subterranean formation adjacent the injector well to absorb less RF power. The method may also include applying RF power to an RF radiator within the injector well after injection of the water changing agent, and recovering hydrocarbon resources from the laterally extending producer well. In another embodiment, the method may include injecting a water driving agent into the laterally extending injector well.

Owner:HARRIS CORP

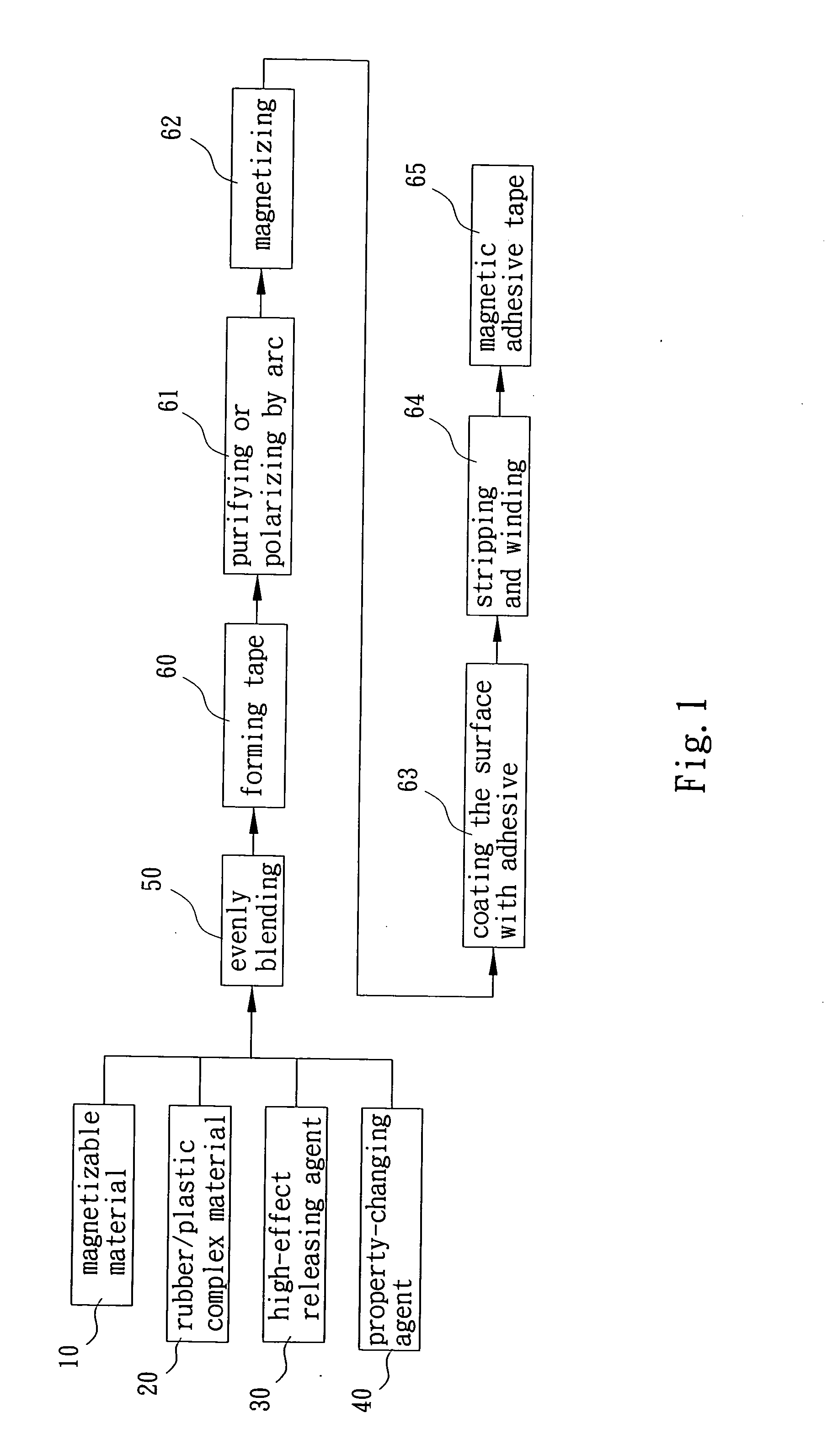

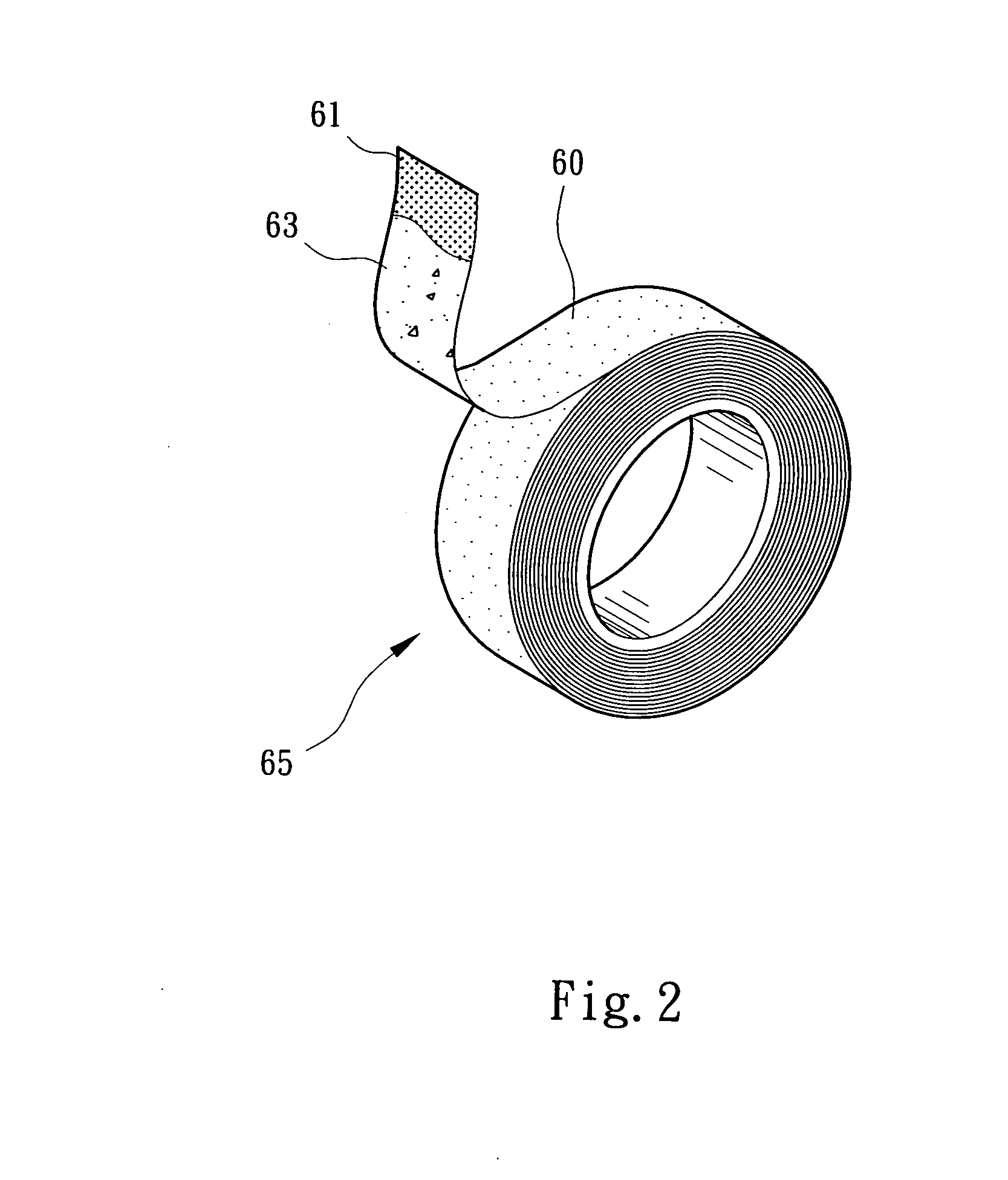

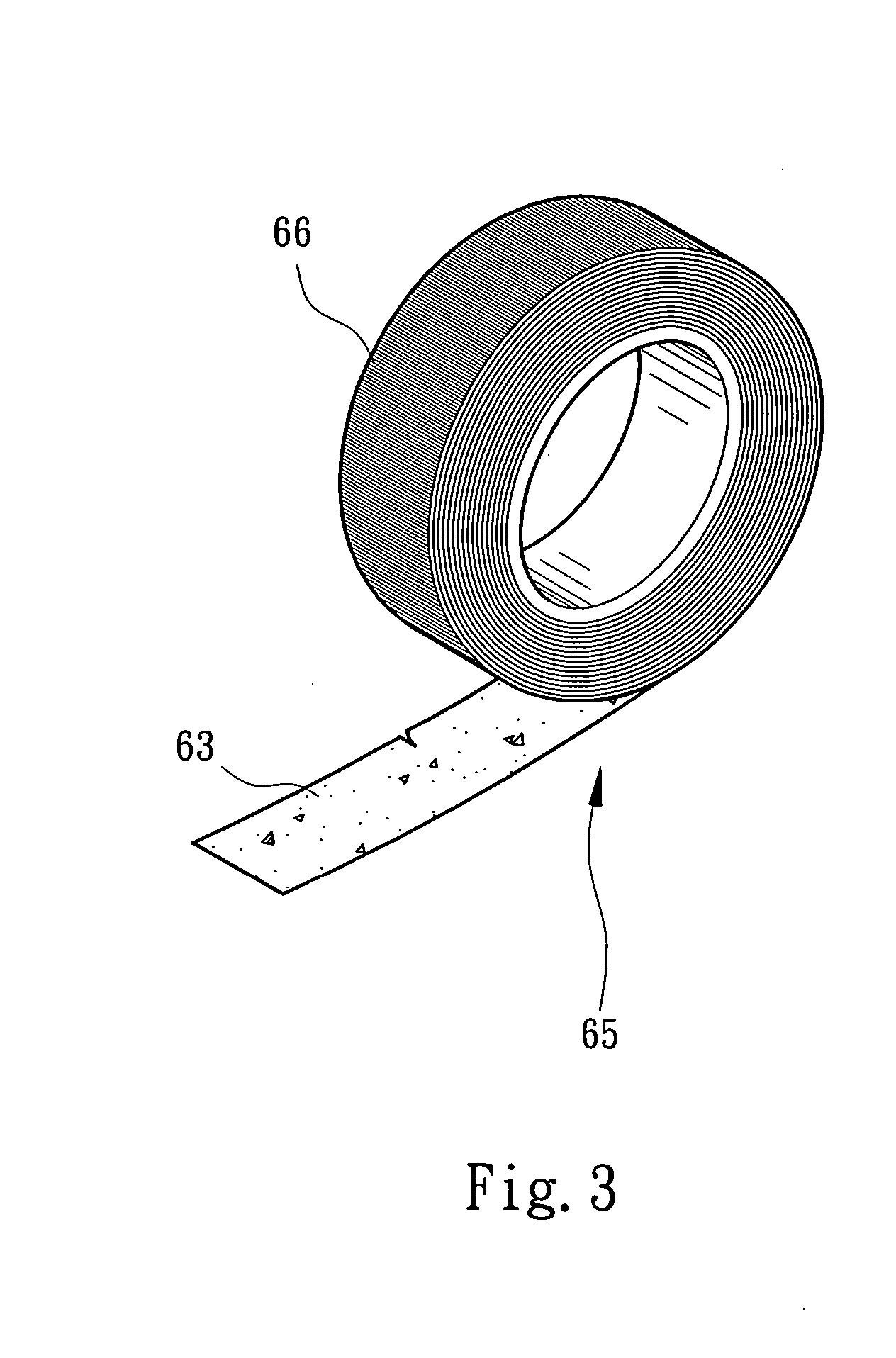

Magnetic adhesive tape and a method for manufacturing the magnetic adhesive tape

InactiveUS20060234046A1Improve adhesionThe production process is simpleFilm/foil adhesivesMagnetic materialsAdhesiveBiomedical engineering

A magnetic adhesive tape and a method for manufacturing the magnetic adhesive tape. A high-effect releasing agent and a property-changing agent are added into a soft magnetic material and blended with each other to form a strip-like soft magnetic substrate with releasable surface. One face of the substrate is purified or roughened and coated with a high-effect adhesive layer. The substrate is wound on a reel. An outer end of the wound substrate can be drawn out segment by segment for use.

Owner:WU HUNG CHIH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com