Solution and method for cyanide-free alkaline bright barrel copper plating

A barrel plating and alkaline technology, applied in the field of electrochemical surface science and engineering, can solve the problems of inconvenient operation, charging into the tank, poor brightness, etc., and achieve the effects of good bonding force, time saving and time shortening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

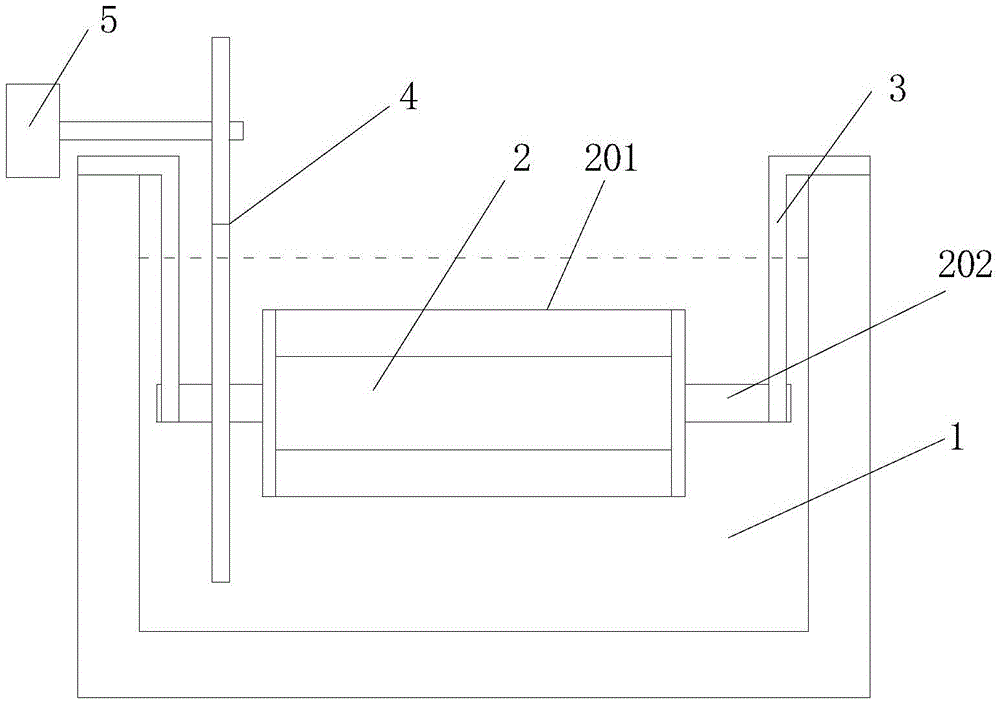

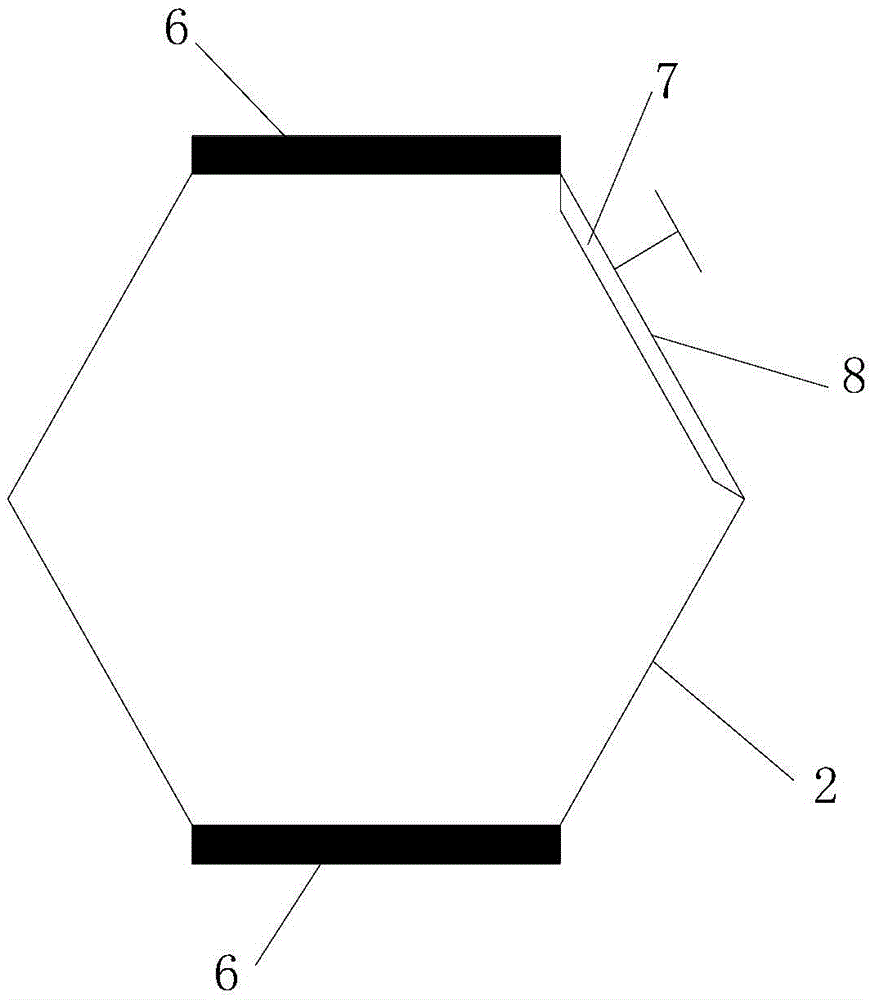

[0056] An ultrasonic roller such as figure 1 with figure 2 As shown, it includes a processing tank 1, a drum 2, a connecting piece 3, a transmission mechanism 4, a motor 5, an ultrasonic plate 6 and an ultrasonic generator. The drum 2 is suspended in the processing tank 1 through a connecting The transmission mechanism 4 is connected with the motor 5, the ultrasonic plate 6 is installed on the side wall of the drum 5, and the ultrasonic plate 6 is connected with the ultrasonic generator. Specifically, after the ultrasonic plate 6 is installed on the side wall of the drum, the ultrasonic plate 6 directly becomes the side wall plate of the drum 5, and there is no barrier between the inner cavity of the drum 5, that is, the ultrasonic plate 6 replaces the side wall plate of the drum . In actual work, after the workpiece to be cleaned is put into the drum 2, the drum 2 is suspended in the processing tank 1 through the connecting piece 3, and the cleaning solution in the process...

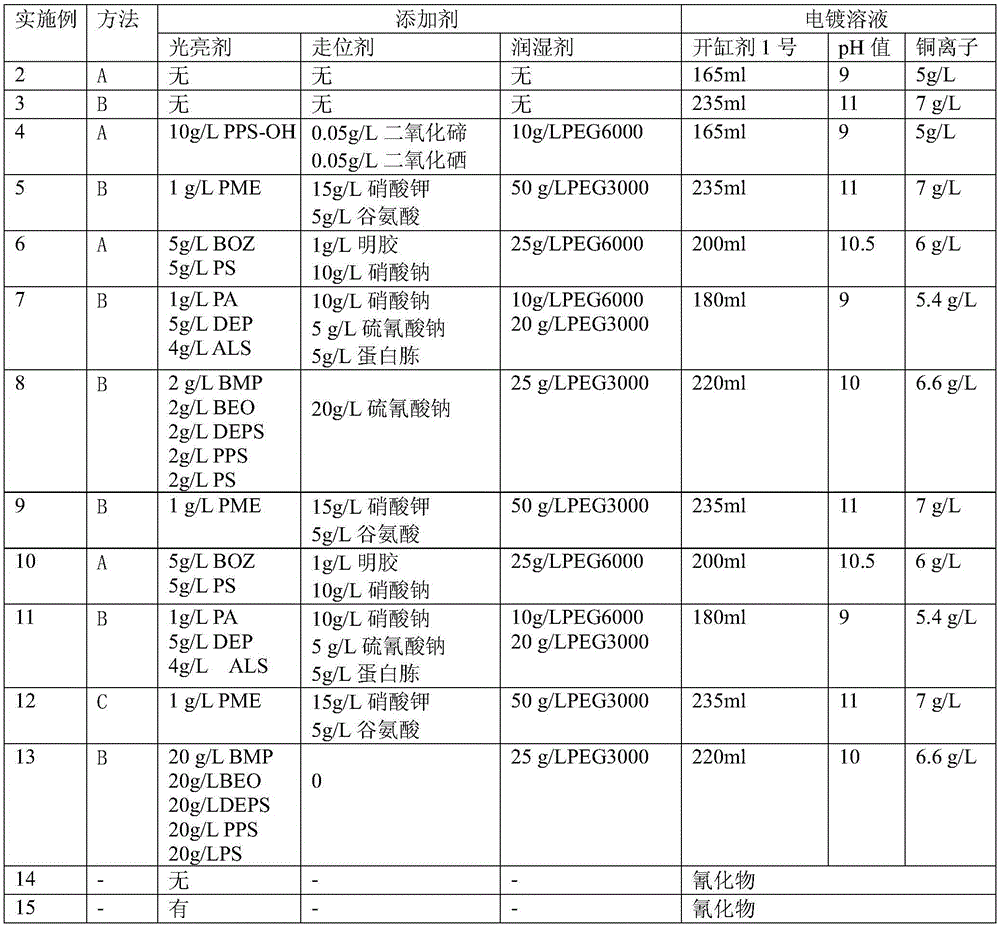

Embodiment 2~15

[0065] 1, the preparation process of a kind of solution of cyanide-free alkaline bright barrel plating copper is as follows:

[0066] ① Dissolving the brightener in pure water to prepare a brightener solution;

[0067] ②Dissolve the displacement agent in pure water to prepare a displacement agent solution;

[0068] ③ Dissolving the wetting agent in pure water to prepare a wetting agent solution;

[0069] ④ Mix the brightener solution, the positioning agent solution and the wetting agent solution according to the volume ratio to obtain the additive;

[0070] ⑤ The amount of BH-582 cylinder starter No. 1 and 300ml of BH-582 cylinder starter No. 2 is calculated based on the content of copper ions in the final system of the cyanide-free alkaline bright barrel copper plating solution being 5-7g / L. The concentration of the solution is 10ml, the pH value is adjusted to 9-11 with a pH regulator (sulfuric acid and sodium hydroxide), and finally the volume is set to 1L with pure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com