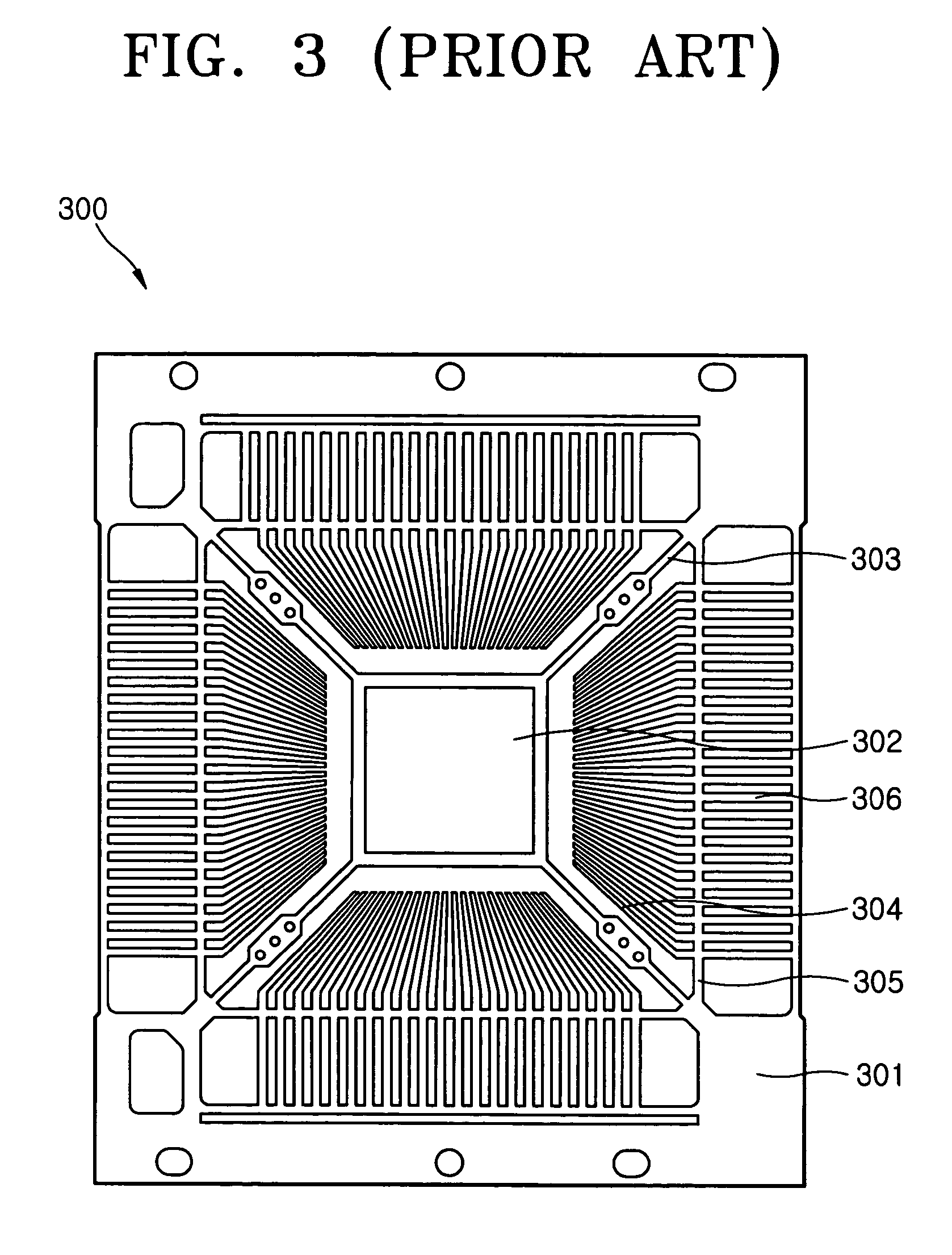

Patents

Literature

105results about How to "Shorten plating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printed circuit board and electrocoppering process thereof

ActiveCN104499021AFill levelImprove uniformityPrinted circuit manufactureProduction lineCopper plating

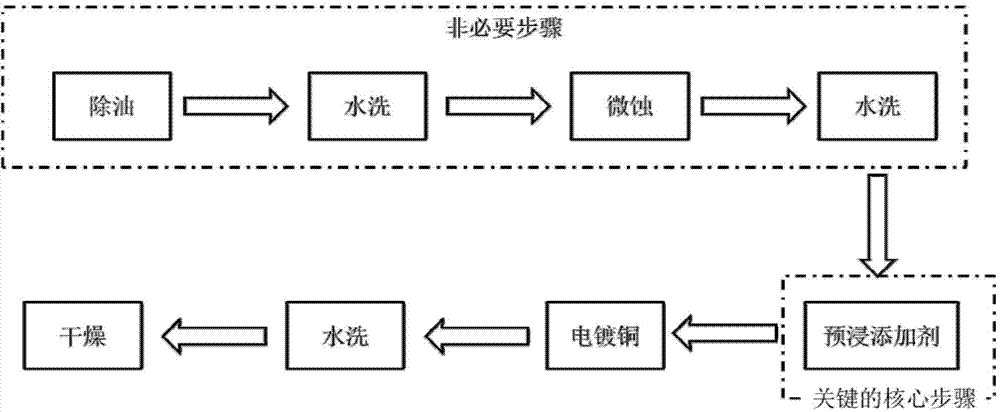

The invention discloses a printed circuit board and an electrocoppering process of the printed circuit board. The printed circuit board comprises a micro blind hole or a micro through hole. The electrocoppering process comprises a pre-treatment step, an electrocoppering step and a post-treatment step. The electrocoppering process is characterized in that a preimpregnation step is further arranged between the pre-treatment step and the electrocoppering step, wherein a first preimpregnation slot and / or a second preimpregnation slot are contained in the preimpregnation step. According to the process disclosed by the invention, high-uniform coatings can be obtained on plating articles with different plate thicknesses / aperture ratios, so that the copper layer uniformity of the through hole of the printed circuit board can be improved, the copper layer thickness of the surface can be effectively reduced, and the TP value can be improved; when the process is applied to filling of the blind hole, the blind hole further can be quickly filled and flattened, so that the electroplating time is shortened and the electroplating copper is saved. The method does not modify existing electrocoppering production line, neither has special requirements on an electroplating additive formula and has very good operability.

Owner:GUANGDONG GUANGHUA SCI TECH

Copper foil having uniform thickness and methods for manufacturing the copper foil

ActiveUS9711799B1Shorten plating timeMany timesPrinted circuit aspectsElectrode carriers/collectorsMetallurgyCopper foil

The present disclosure relates to an improved electrodeposited copper foil having uniform thickness and methods for manufacturing the electrodeposited copper foil. The electrodeposited copper foil typically has one to four interfacial lines through the cross-sectional area of the foil and a weight deviation less than 2.0%. The disclosure also relates to a process for making the electrodeposited copper foil that includes the addition of one or more insulative masks to the surface of a dimensionally stable anode. The insulative mask is cut to correspond to areas of variation in electrodeposited copper foil, such that the mask causes interferences with the electrodeposition process to even out the variation.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

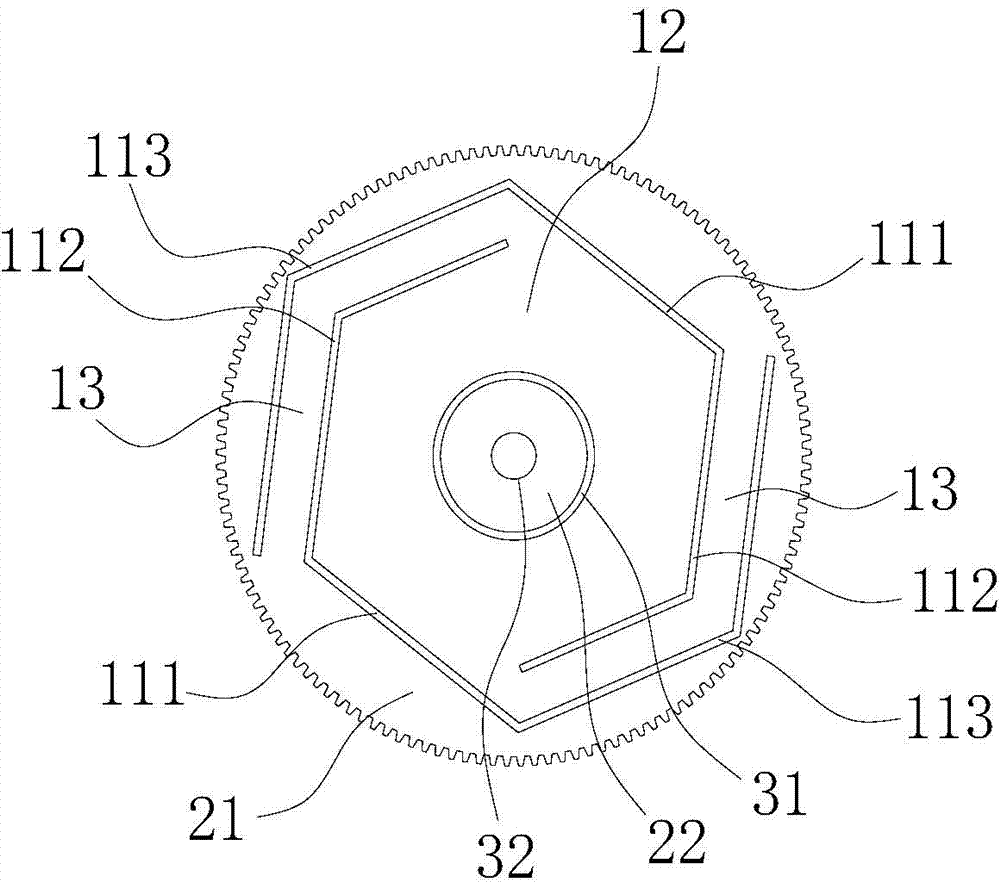

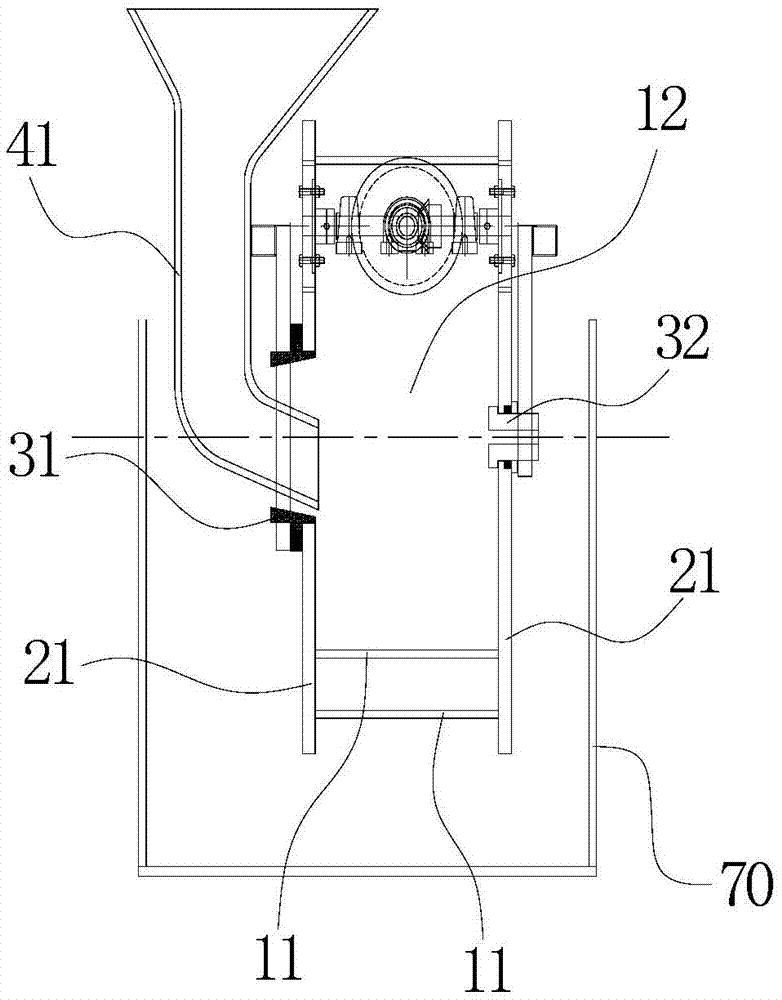

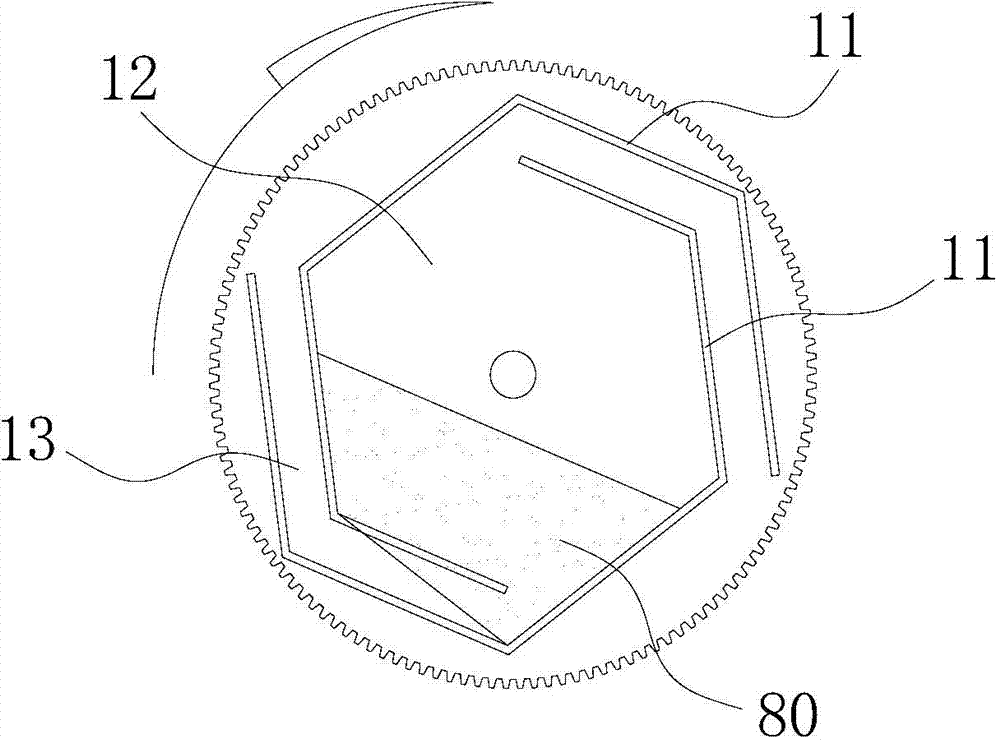

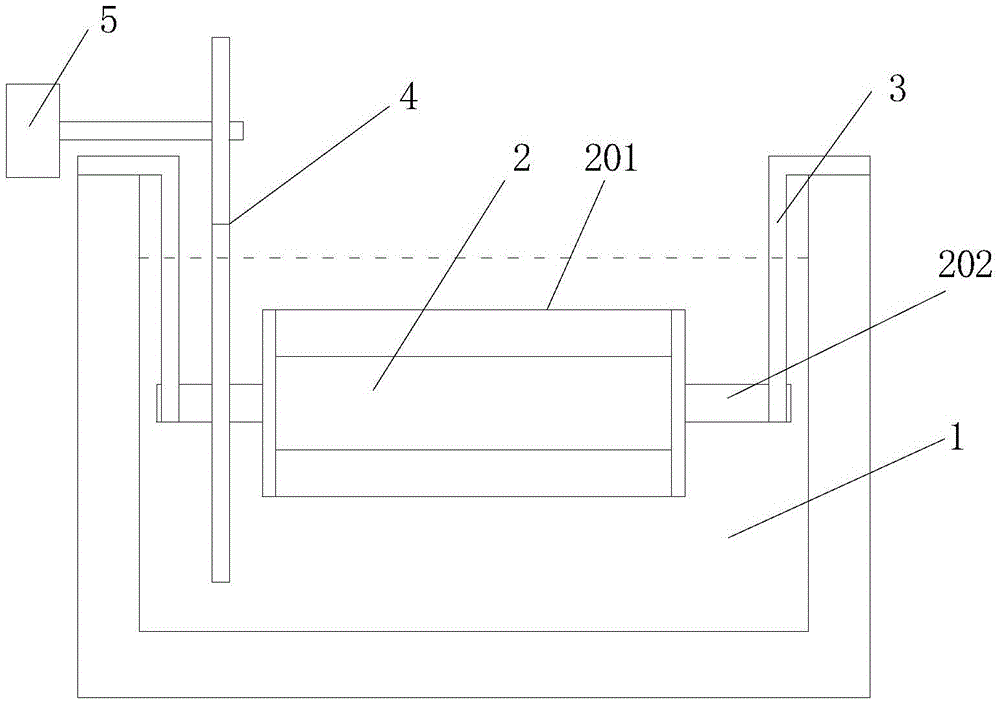

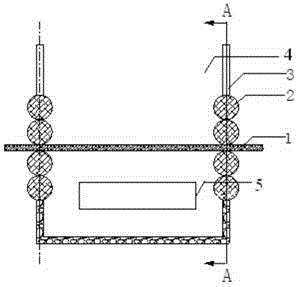

Rotary type automatic discharge electroplating rolling barrel

InactiveCN103498187AImprove electrochemical performanceShorten plating timeElectrolysis componentsEngineeringElectroplating

The invention discloses a rotary type automatic discharge electroplating rolling barrel which comprises a barrel body, a barrel cover and a rotating shaft, wherein the barrel body comprises two baffle plates with C-shaped sections and openings; each baffle plate comprises a bottom wall, an inner side wall and an outer side wall; the bottom wall is opposite to the opening of the baffle plate; the inner side wall and the outer side wall are respectively connected to both sides of the bottom wall; the two baffle plates are mutually jogged in such a way that the openings are just opposite, the two baffle plates are mutually staggered in a direction perpendicular to a direction which is just opposite to the openings of the two baffle plates; electroplating cavities are formed between the bottom walls and inner side walls of the two baffle plates; a discharge chute is formed between the inner side wall of one baffle plate and the outer side wall of the other baffle plate, and the discharge chute is communicated with the electroplating cavity. According to the invention, the barrel body is designed into a structure that the two baffle plates with C-shaped sections are mutually jogged, so that the electroplating and the automatic discharge function can be realized, and the electroplating production continuity can be ensured. The rotary type automatic discharge electroplating rolling barrel disclosed by the invention is simple in structure and convenient to clean and farthest reduces the cross contamination of chemical raw materials among procedures.

Owner:中山市瀚成电镀设备有限公司

Pyrophosphate copper plating used as grounding electroplate liquid for cyanogen-free copper plating

The invention discloses a strike bath solution with pyrophosphate plating copper as the cyanide-free copper, which contains a make-up agent and rehydration salt; the make-up agent contains the following raw materials: potassium pyrophosphate, copper pyrophosphate, ammonium citrate, sorbol, sulfosalt, phenyl carboxylate, dextrin, alkyl thiourea and nitrogen heterocyclic; the rehydration salt is as supplementation of all raw materials in the make-up agent during the plating process; the invention does not contain harmful substances, such as cyanidum, heavey metal, etc and is in compliance with EU RoHS Directive (2002 / 95 / EC) with stable bath solution and wide cathode current density range, and the plating layer prepared by the invention is fine, even and in a semi-bright state; and the make-up is conducted with original solution, supplementation is conducted with single rehydration salt, which is convenient in operation and simple in management; the plating layer is well adhesive to the matrix, with good straggling capability and covering capability. The invention is applicable in pre-plating of iron materials, zinc alloys, aluminum alloys and copper alloys, as well as barrel plating and suspension plating, with the waste water easy to dispose, which will not bring the secondary pollution.

Owner:江门市瑞期精细化学工程有限公司

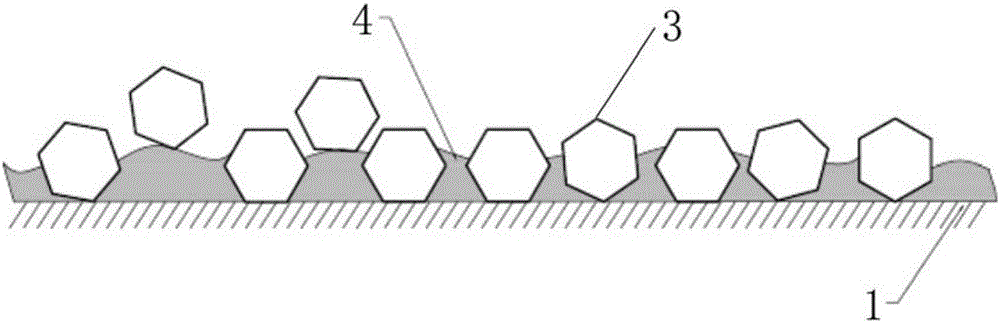

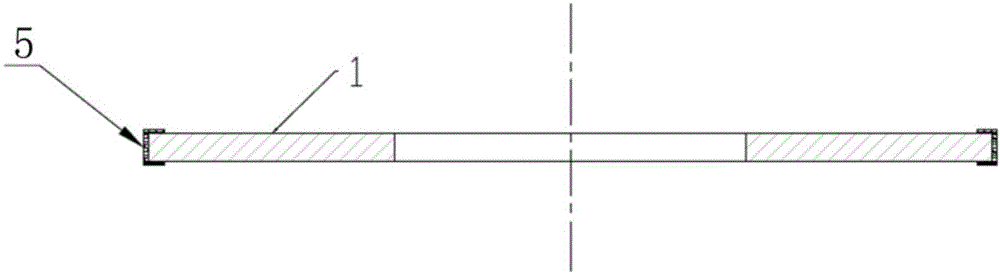

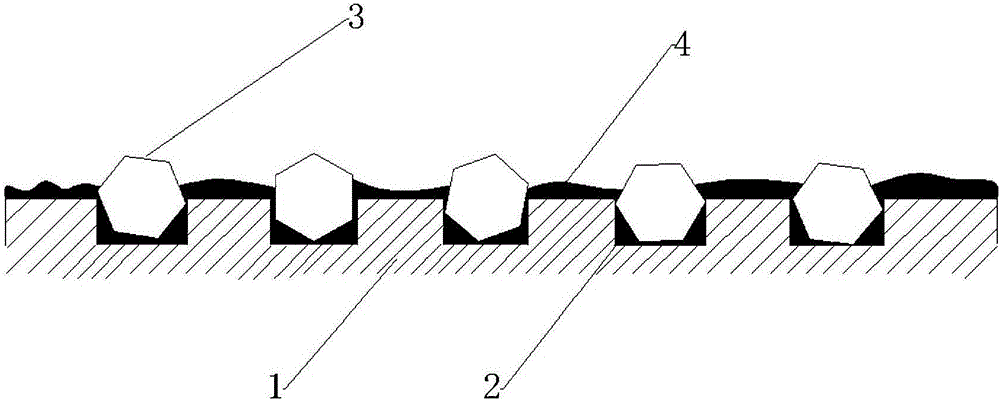

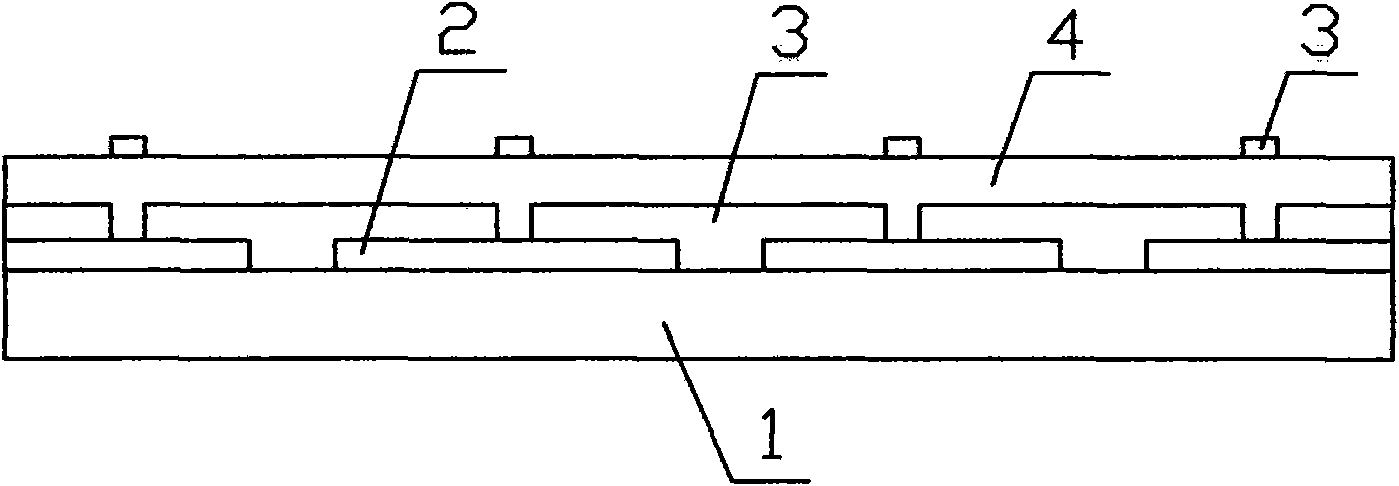

Method for preparing electroplated diamond grinding wheel with orderly arranged abrasive materials

InactiveCN105154958AImprove gripExtended service lifeElectrolytic coatingsLiquid/solution decomposition chemical coatingChemical platingElectroplating

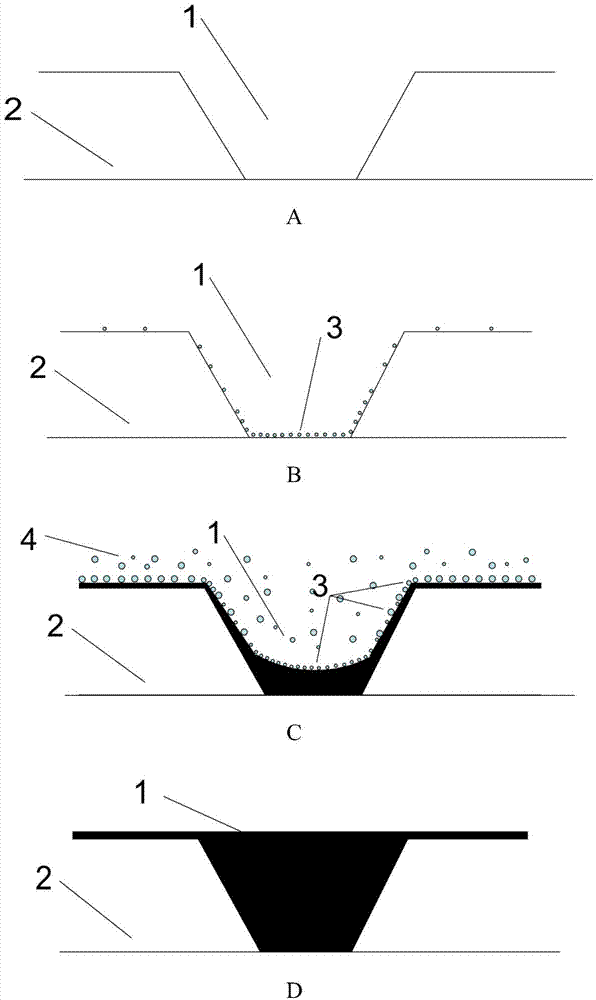

The invention discloses a method for preparing an electroplated diamond grinding wheel with orderly arranged abrasive materials. The method comprises the following steps of forming orderly arranged blind holes in the surface of a grinding wheel substrate to obtain a processed substrate; subjecting the processed substrate to chemical plating to deposit a metal pre-plating layer on the bottoms and the side walls of the blind holes to obtain a pre-plated substrate; placing the diamond abrasive materials on the surface of the pre-plated substrate and carrying out rolling to embed the lower parts of the abrasive materials into the blind holes, so as to obtain a sanded substrate; activating the sanded substrate and electroplating the sanded substrate to deposit metal plating layers on the surface of the grinding wheel substrate and in the blind holes, thereby finally obtaining the electroplated diamond grinding wheel. According to the invention, the diamond abrasive materials can be regularly and orderly arranged on the surface of the grinding wheel substrate; the holding force of the plating layer to the diamond abrasive materials in the electroplating consolidation step is reinforced; the holding force of the diamond grinding wheel to the abrasive materials is strong; the service life is long; the abrasive materials are regularly and orderly arranged on the surface of the grinding wheel substrate; and the grinding quality and the grinding efficiency are increased. Compared with diamond abrasive materials of a same particle size, the abrasive materials in the invention are advantaged in that the electroplating time is shortened by 20-50% than that in the traditional technique, and the uniformity of the electroplating layer is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

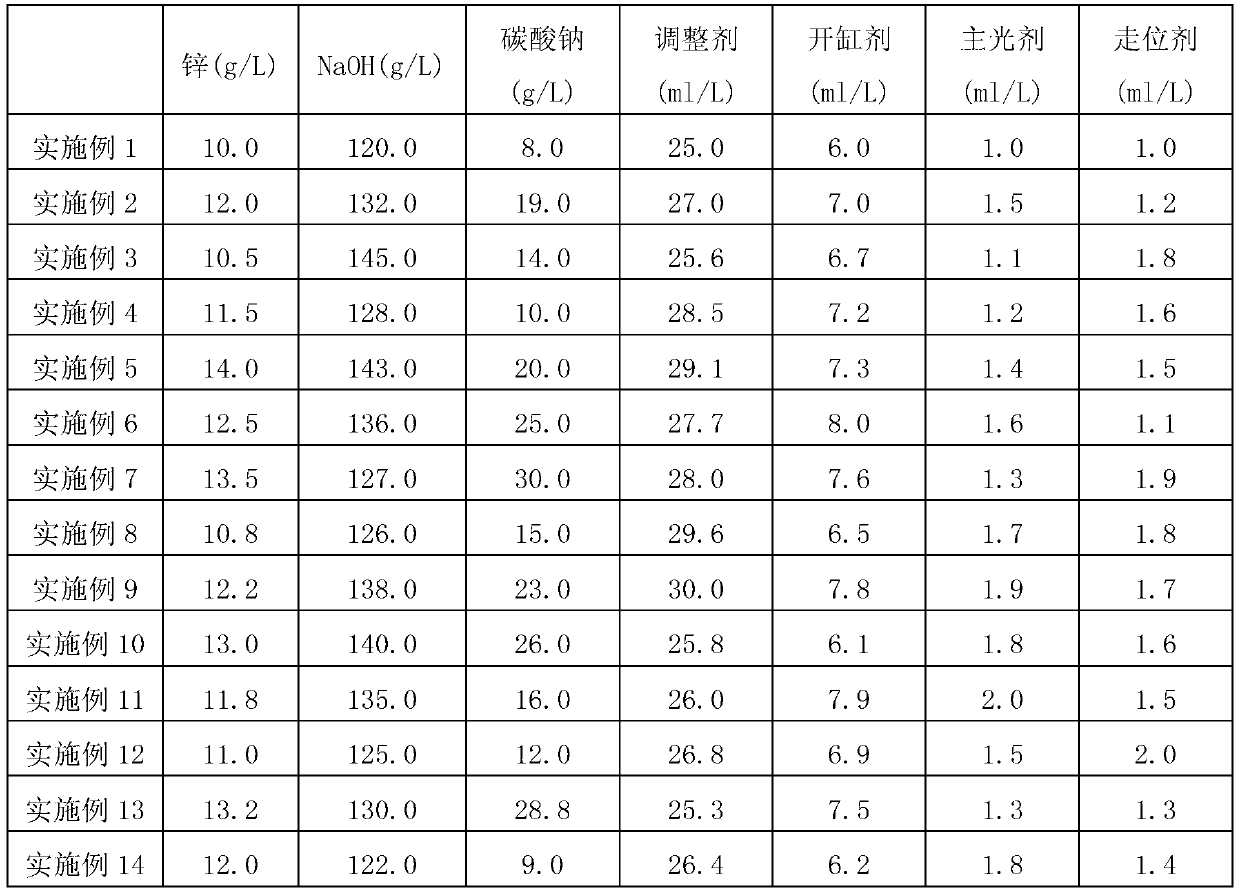

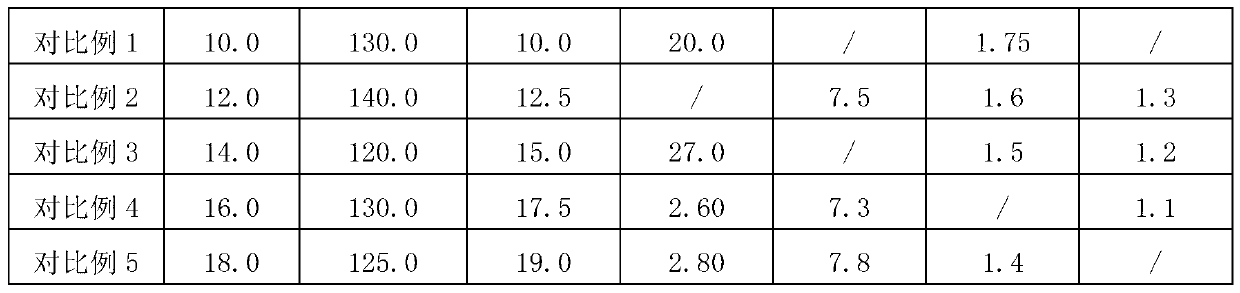

Electroplating solution, preparation method thereof and galvanization technique utilizing electroplating solution

The invention discloses an electroplating solution which mainly comprises an aqueous solution consists of the following substances: zinc, sodium hydroxide, sodium carbonate, a regulating agent, a plating bath solution, a secondary brightener and a bright-throwing power additive. According to the invention, some additives are added into the electroplating solution to adjust the proper zinc ion concentration and the current density, so that the electroplating solution has perfect throwing power; therefore, the electroplating solution has rather good current efficiency, throwing power and covering power. Thus a coating made of the electroplating solution has a better physical property and is more shiny, more full, more uniform and more exquisite with strong binding capability. The invention also discloses a preparation method of the electroplating solution and a galvanization technique using the electroplating solution.

Owner:江西博泉化学有限公司

Ionic liquid electrolyte and method for preparing bright aluminum coating by use of ionic liquid electrolyte

The invention provides an ionic liquid electrolyte and a method for preparing a bright aluminum coating by use of the ionic liquid electrolyte, and mainly aims at solving the problems of inappropriate viscosity, electrical conductivity and the like of the existing ionic liquid for preparing the bright aluminum coating. The electrolyte is composed of an ionic liquid, an anhydrous aluminum halide salt and auxiliaries, wherein the molar ratio of the ionic liquid to the anhydrous aluminum halide salt is 1: (1.5-2.0), and the molar ratio of the ionic liquid to the auxiliaries is 1: (0.1-4). The method for preparing the bright aluminum coating by use of the ionic liquid electrolyte comprises the following steps: firstly, putting an electrolyzer in a nitrogen or argon environment atmosphere without water or oxygen under normal pressure, adding the ionic liquid electrolyte, and performing electrolysis under the conditions of an electrolysis temperature of 10-30 DEG C, the current density of 1-10A / dm<2> and regulated electrolyzer pressure, thereby obtaining the bright luster aluminum coating. After the auxiliaries are added to the ionic liquid electrolyte for preparing the bright aluminum coating, the electrolyzer pressure is reduced and the viscosity and the electrical conductivity of the ionic liquid are improved, and therefore, the electrolytic deposited bright aluminum coating is obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electroplating and vapor deposition composite protection method for neodymium-iron-boron magnet

InactiveCN103173763ABlock Corrosion PathsCorrosion path overcomeVacuum evaporation coatingSputtering coatingGas phaseRare earth

The invention discloses an electroplating and vapor deposition composite protection method for a neodymium-iron-boron magnet. The method comprises the steps of: pretreating the neodymium-iron-boron magnet, carrying out vapor deposition treatment on the pretreated neodymium-iron-boron magnet, and carrying out surface electroplating treatment on the neodymium-iron-boron magnet obtained from the vapor deposition treatment. The protection method disclosed by the invention has the advantages that the vapor deposition film layer formed beforehand closes the cellular structure on the surface of the neodymium-iron-boron magnet and does not cause damage on the neodymium-iron-boron magnet to lead magnetic performance reduction, and therefore, heavy rare earth metals such as dysprosium and terbium or the strategic metal cobalt can be rarely added or not added in the material formulation of the neodymium-iron-boron magnet, so that scarce resources are saved, simultaneously, the vapor deposition film layer can block the subsequent corrosion path on the neodymium-iron-boron magnet caused by an electroplating solution, and can also overcome the pore defect of an electroplated coating so that an external environment cannot contact with the neodymium-iron-boron magnet through the pores of the electroplated coating, and the corrosion resistance of the neodymium-iron-boron magnet is improved through the double protection of the vapor deposition film layer and the electroplated coating.

Owner:NINGBO YUNSHENG +3

New method for manufacturing interconnected copper pillars among plurality of layers of circuit boards

InactiveCN102118923AFirmly connectedImprove performanceMultilayer circuit manufacturePrinted element electric connection formationLight sensingCopper plating

The invention relates to a new method for manufacturing interconnected copper pillars among a plurality of layers of circuit boards, comprising the following steps: 1, coating or laminating a permanent photosensitive layer on the inner-layer circuit boards, and exposing the parts needing to be electroplated with the copper pillars after light sensitivity and developing; 2, through chemically plating copper, leading copper layers to reach the height needed by the copper pillars; 3, coating or laminating a temporary light-sensitive layer, and remaining the light-sensitive layer for protecting the light-sensitive layer of the copper pillars after light sensing and developing; 4, obtaining the copper pillars for interconnection needing among the layers by etching; 5, removing the temporary light-sensitive layer; 6, obtaining new copper layers by chemically plating copper plating and electroplating copper for thickening after surface treatment; and 7, manufacturing an outer-layer circuit on the new copper layers. Compared with the prior art, in the new method, large-area and large-current copper plating is adopted so as to omit electroplating a nickel layer, save the electroplating time and improve the efficiency; and the connection among the copper pillars and copper layers is firm, so that the performance of the plurality of layers of the circuit boards is more stable and reliable and the circuit boards have practicability.

Owner:王利平

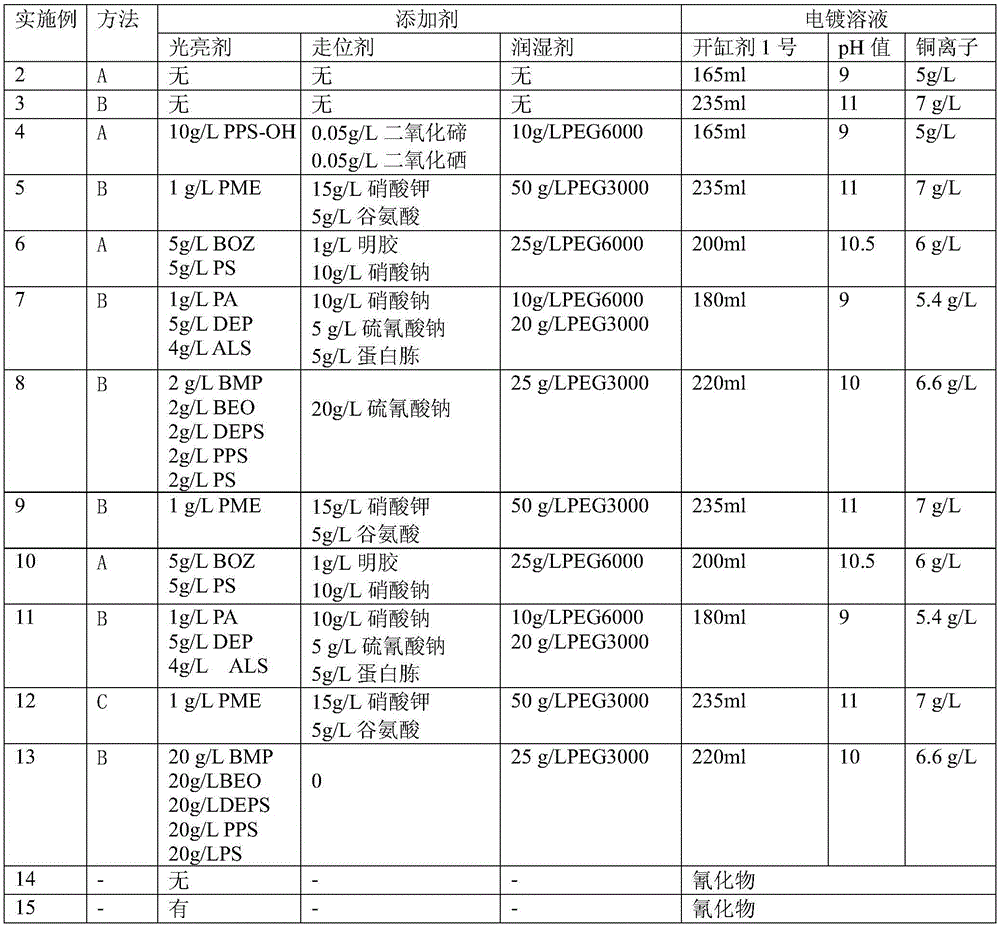

Solution and method for cyanide-free alkaline bright barrel copper plating

The invention discloses a solution and a method for cyanide-free alkaline bright barrel copper plating. The solution comprises a No.1 BH-582 plating bath solution, 300 ml / L of a No.2 BH-582 plating bath solution, 10 ml / L of an additive and a pH value regulator, wherein the addition amount of the No.1 BH-582 plating bath solutions is calculated in such a manner that the content of copper ions in a final system is 5-7 g / L after the No.1 BH-582 plating bath solution and the No.2 BH-582 plating bath solution are matched, and the usage amount of the pH value regulators is based on the condition that the pH of the final system is kept between 9 and 11; the additive comprises a brightener, a bath change agent and a wetting agent in the volume ratio being 1:(1-3):1. The method for cyanide-free alkaline bright barrel copper plating adopts the solution for barrel copper plating and comprises steps as follows: pretreatment of an iron-based blank, activation, water washing and then cyanide-free alkaline bright barrel copper plating. On the basis that the binding force between plating and a matrix is guaranteed, the solution and the method can replace a cyanide system for pre-plating, and environment-friendly and clean production is realized.

Owner:GUANGZHOU HONWAY TECH CORP

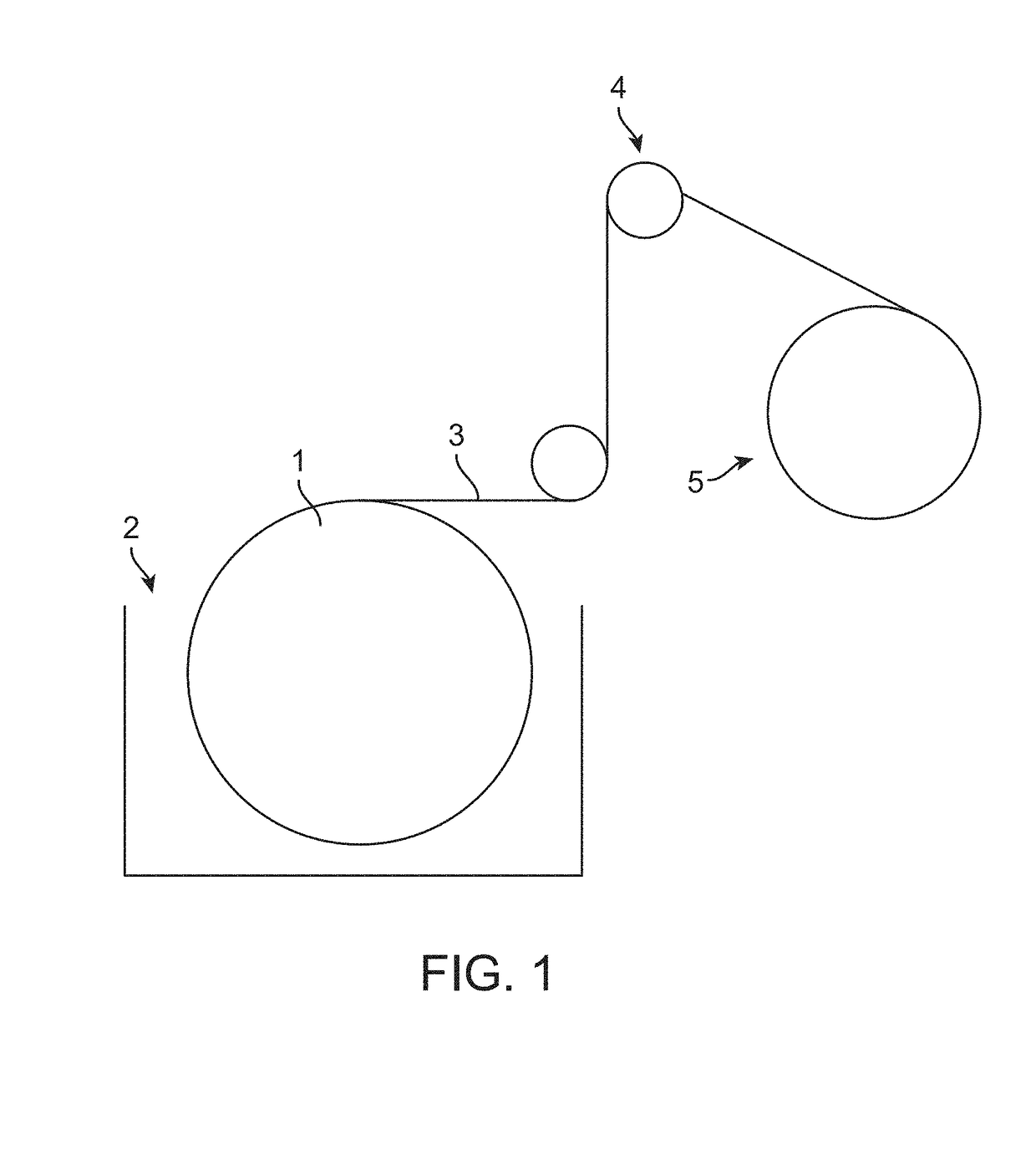

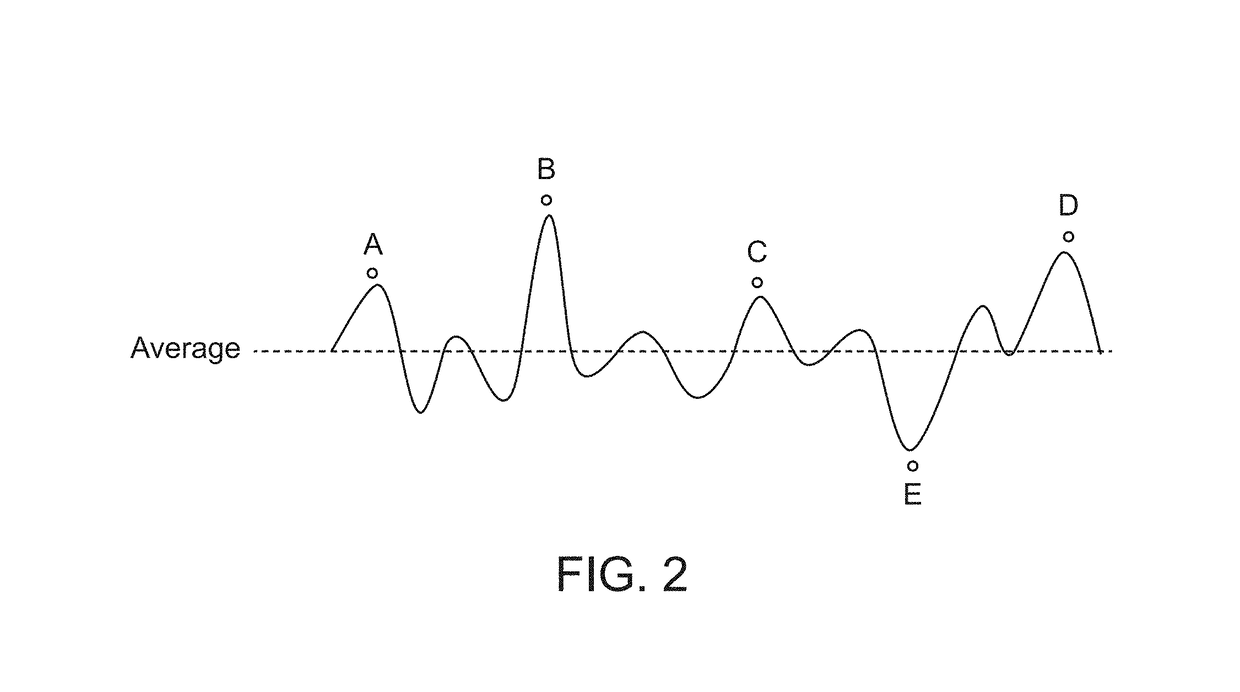

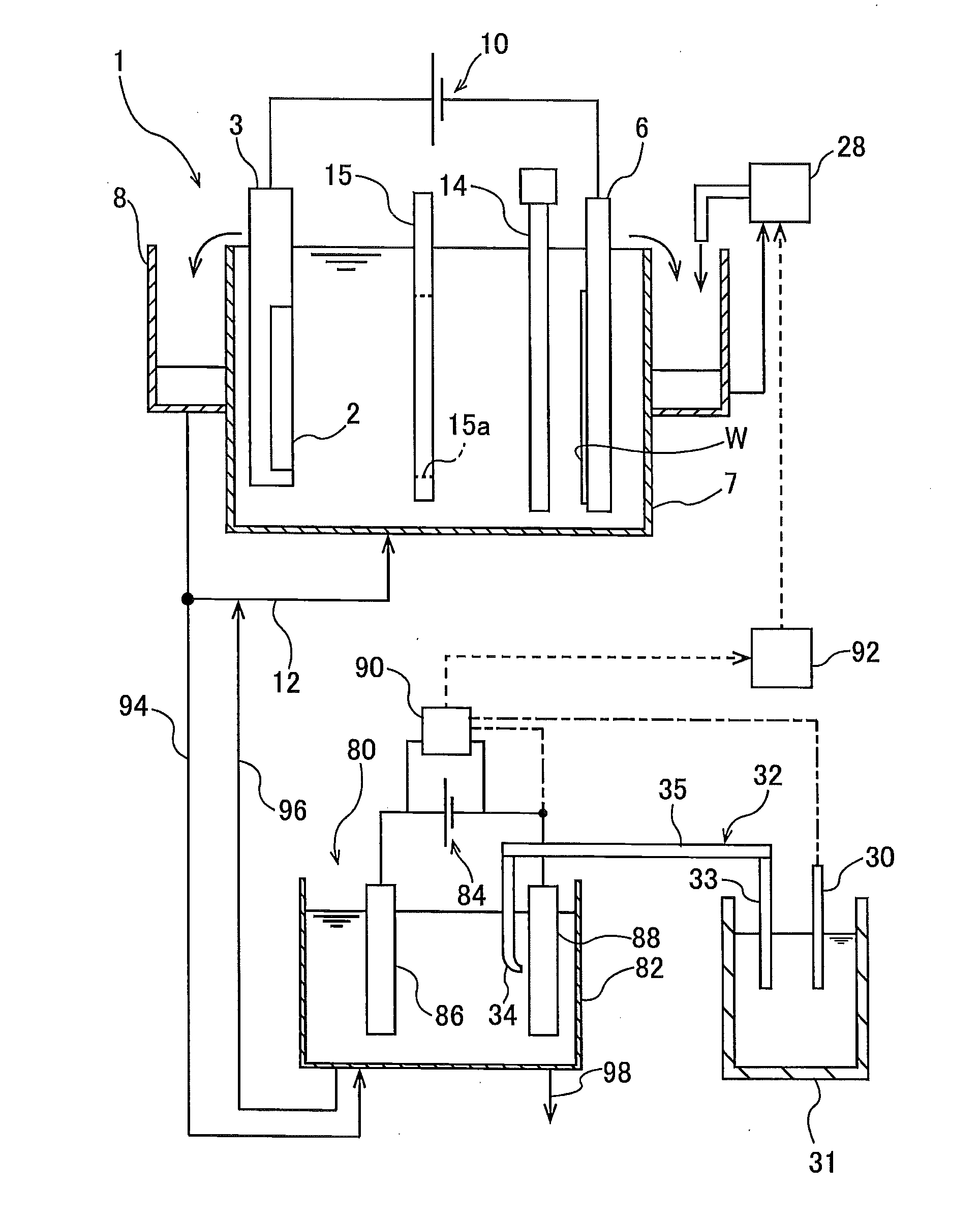

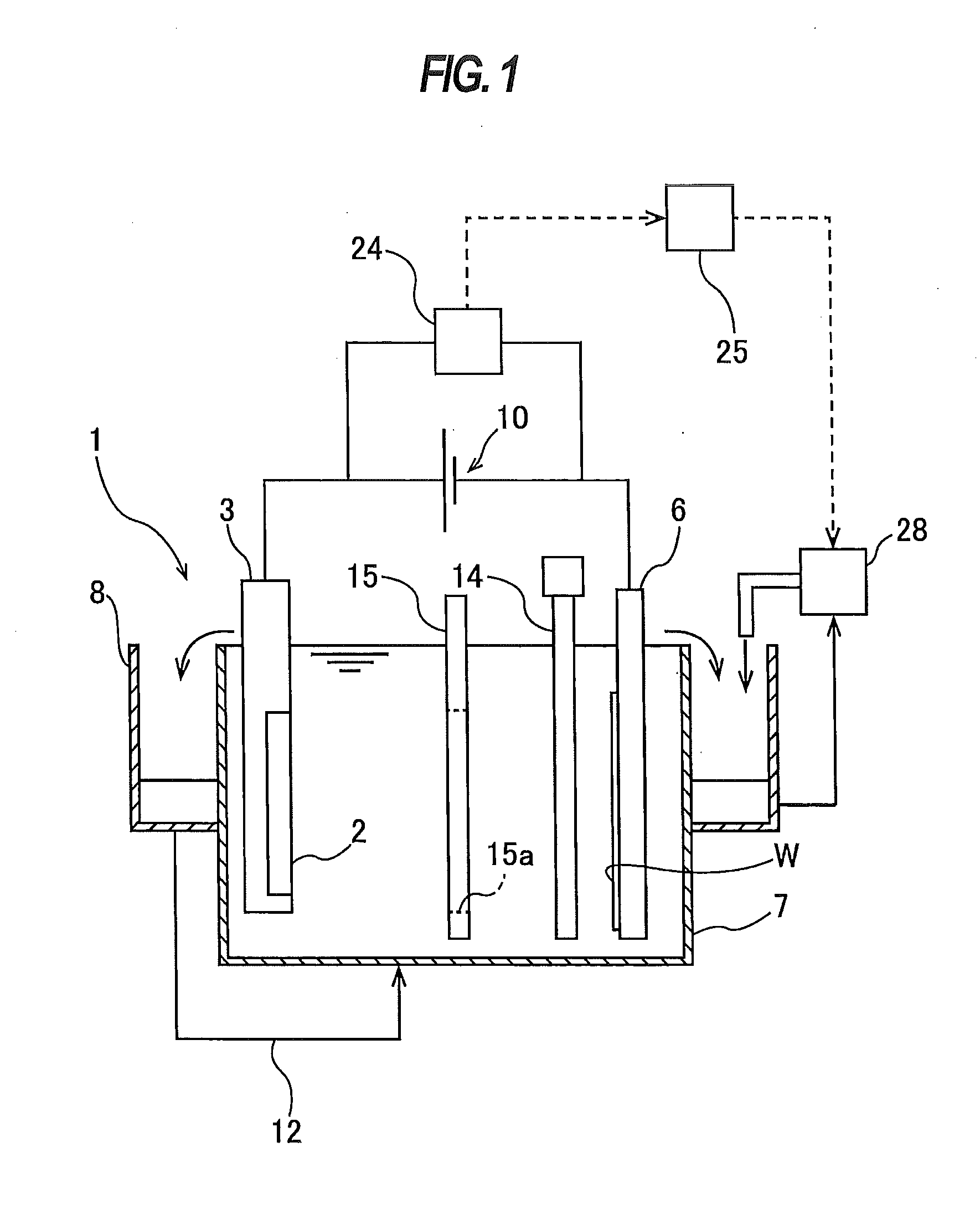

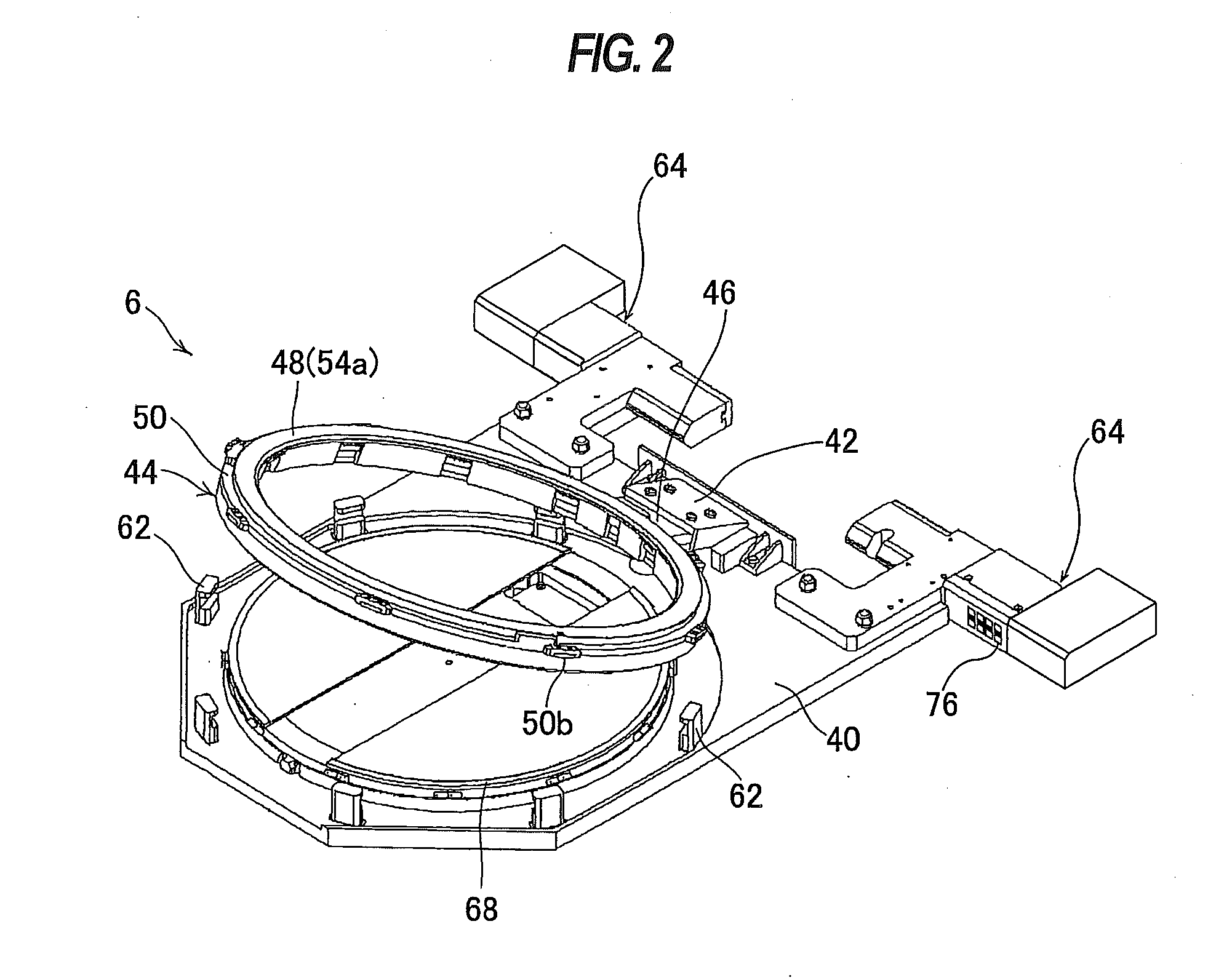

Plating method and plating apparatus

ActiveUS20150203983A1Uniform characteristicPlating time be shortenCellsMachining electric circuitsEngineeringMetal

A plating method capable of controlling a concentration of an additive within a proper range during plating of a substrate is disclosed. The plating method includes: disposing an anode and a substrate, having a via-hole formed in a surface thereof, so as to face each other in a plating solution containing an additive; applying a voltage between the anode and the substrate for filling the via-hole with metal; measuring the voltage applied to the substrate; calculating an amount of change in the voltage per predetermined time; and adjusting a concentration of the additive in the plating solution to keep the amount of change in the voltage within a predetermined control range.

Owner:EBARA CORP

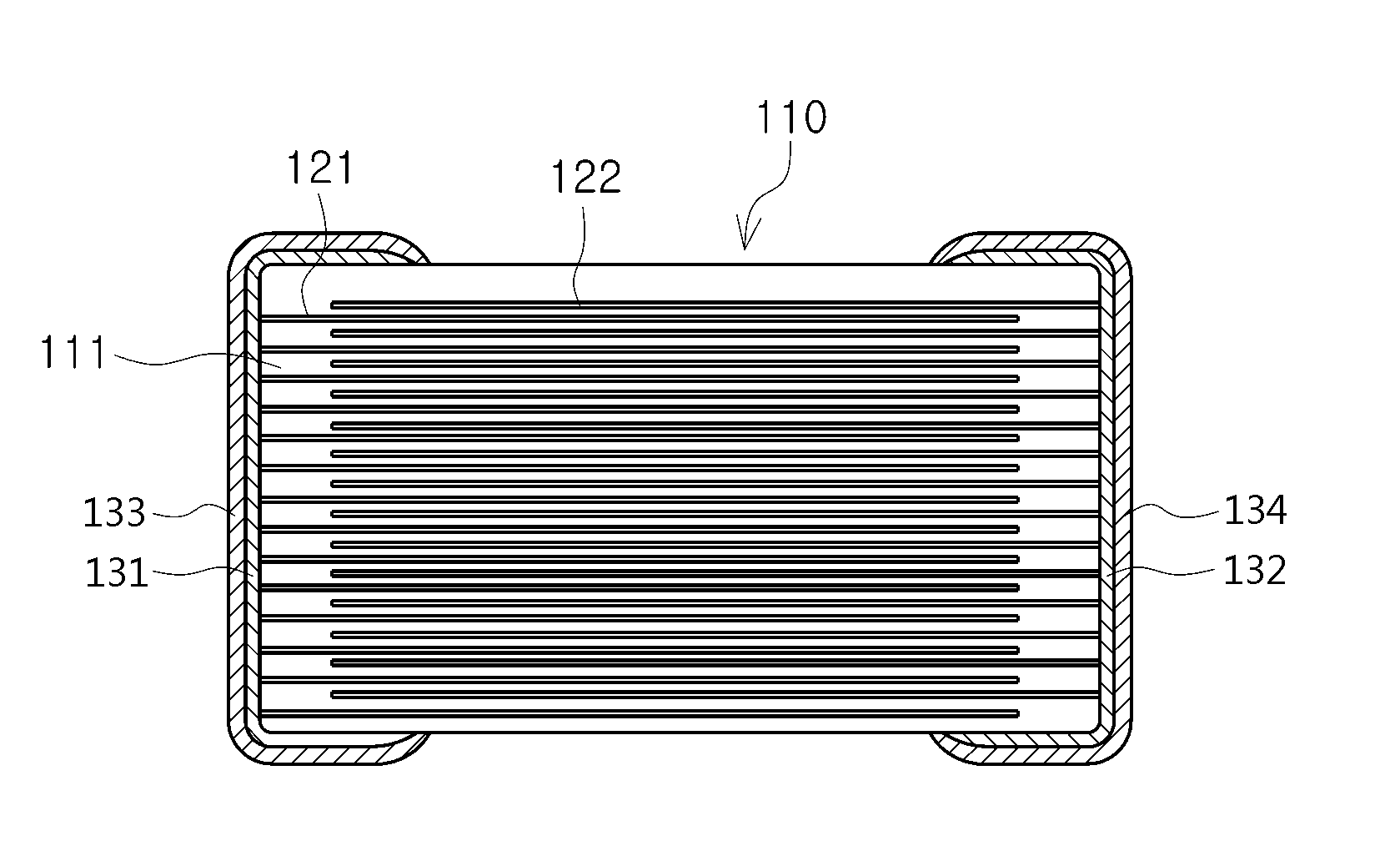

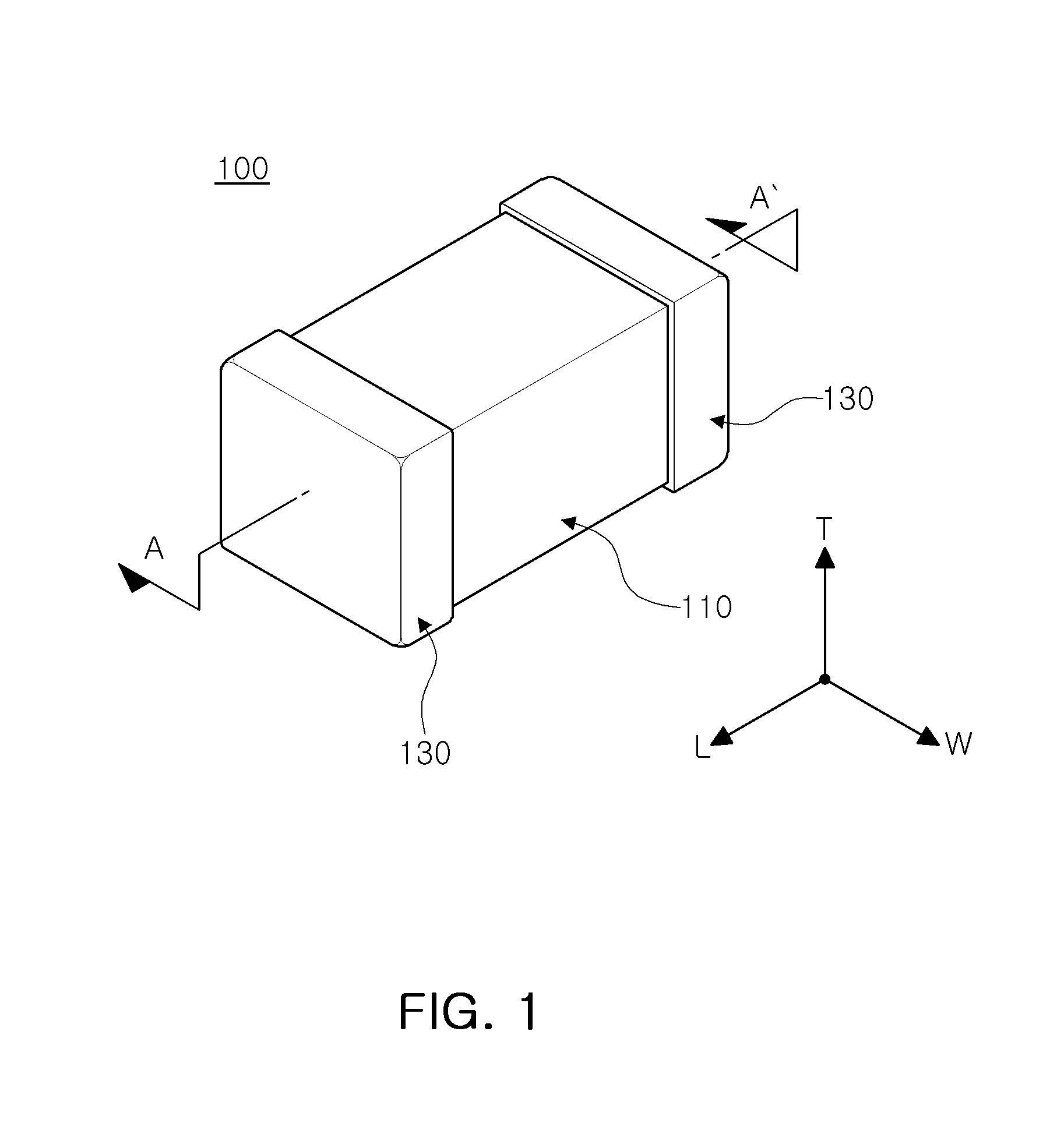

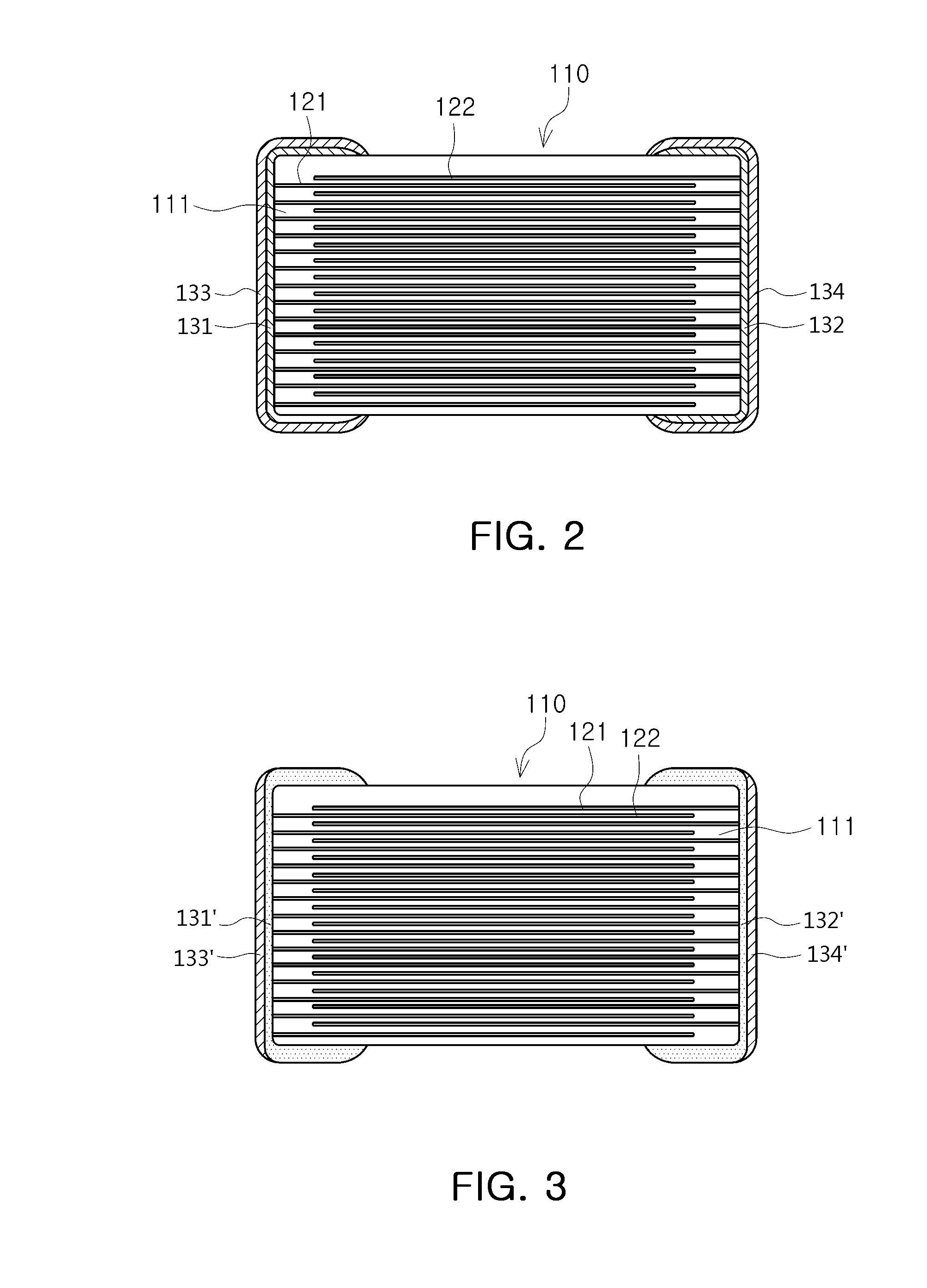

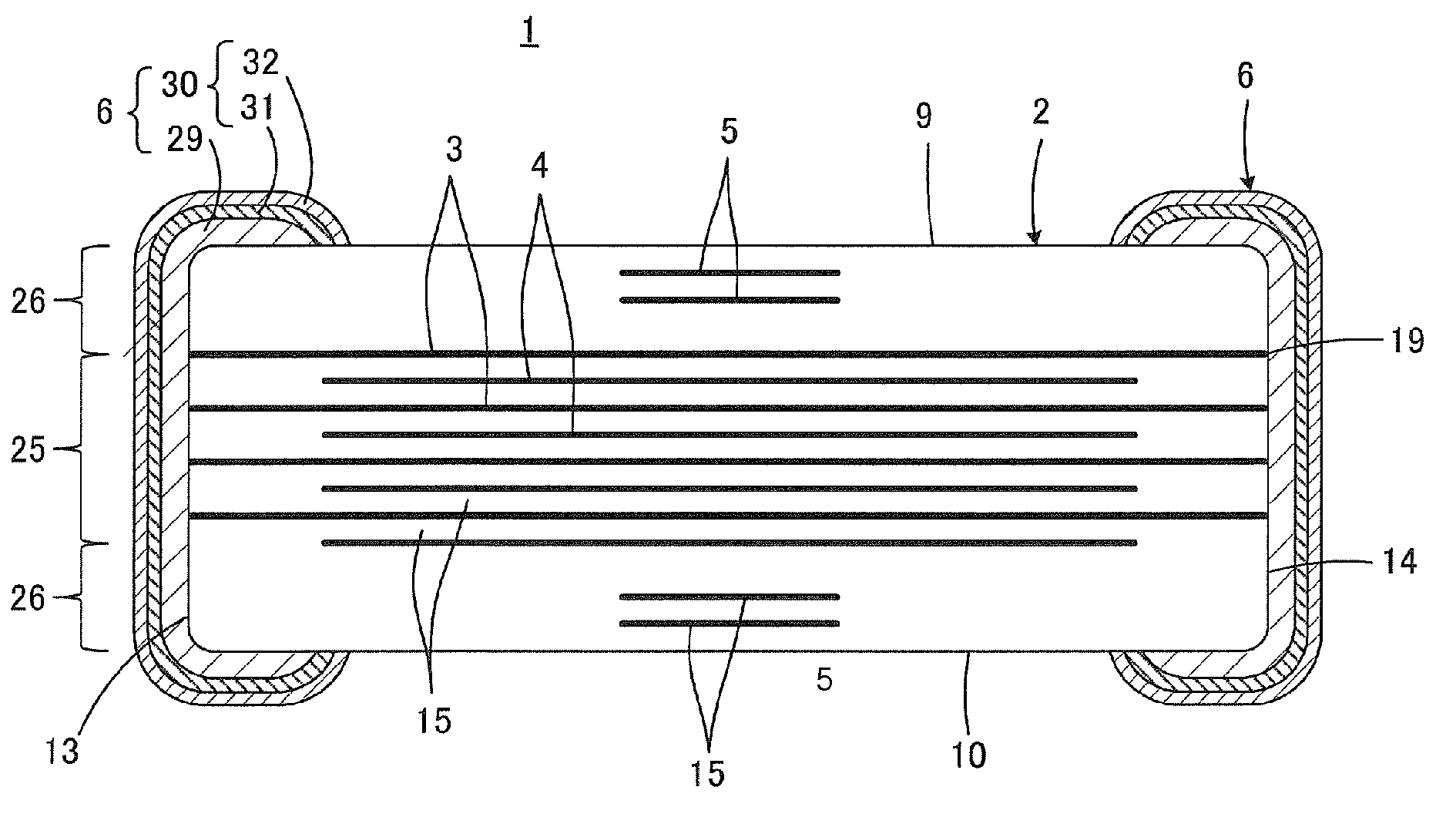

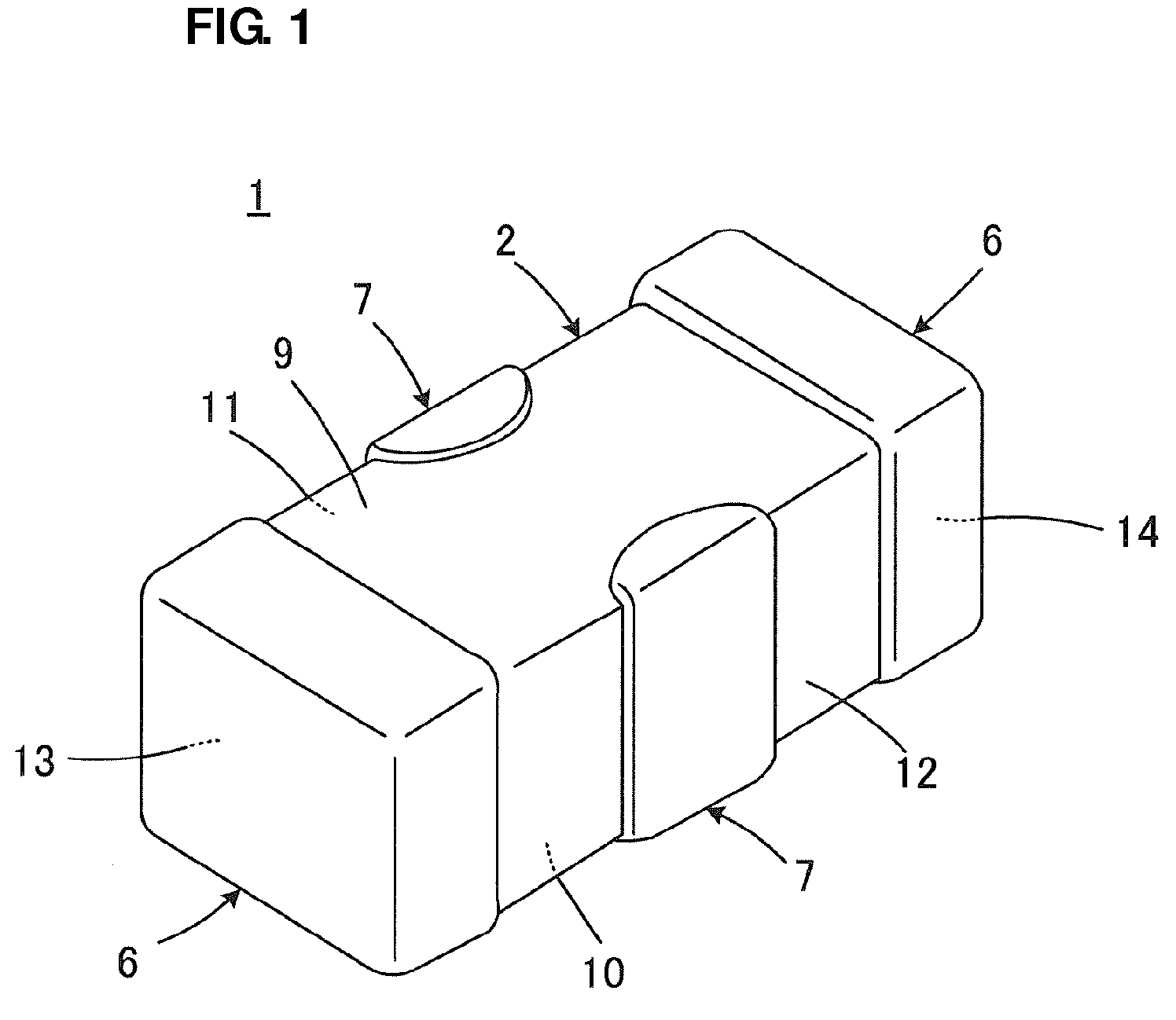

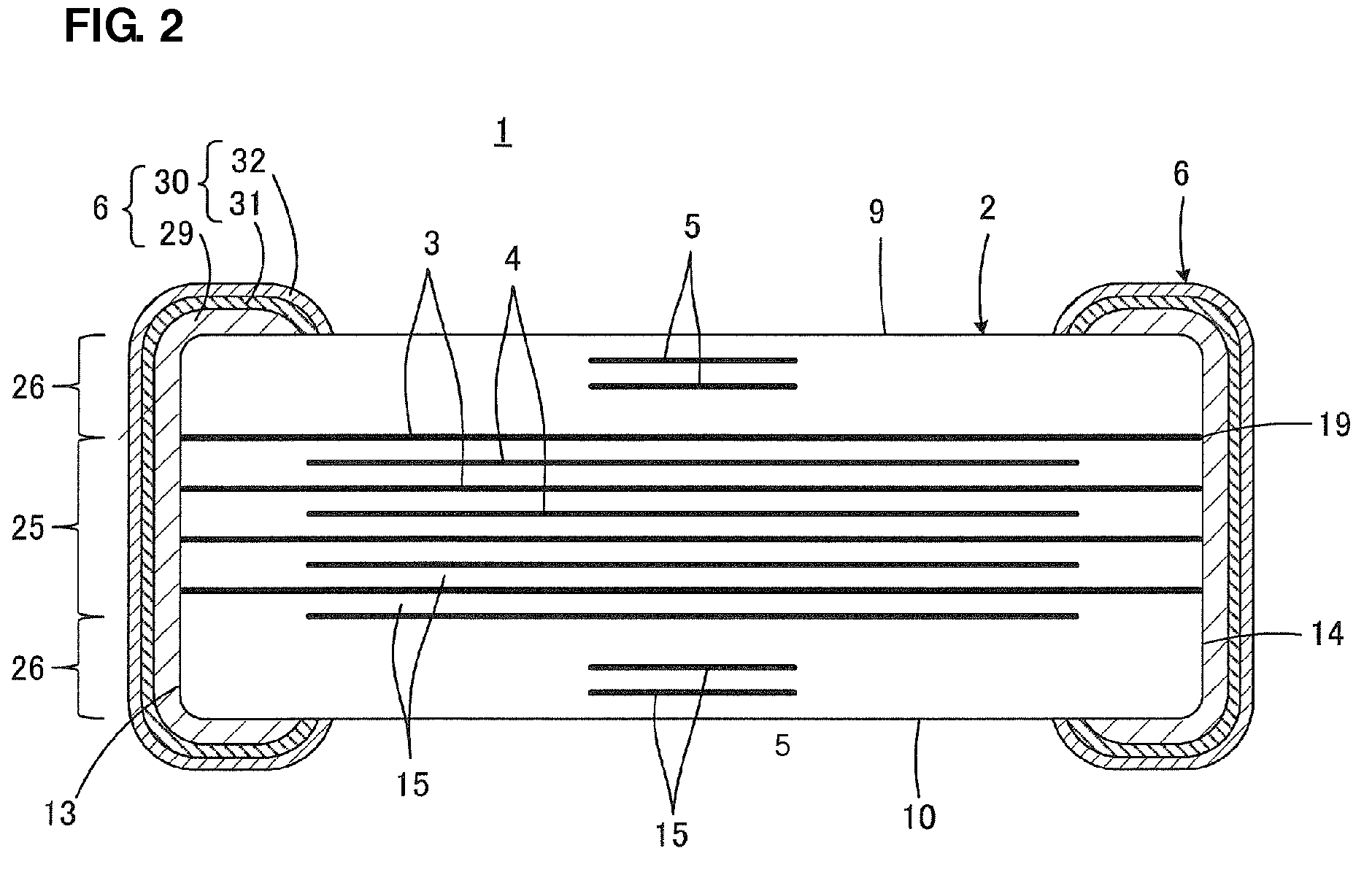

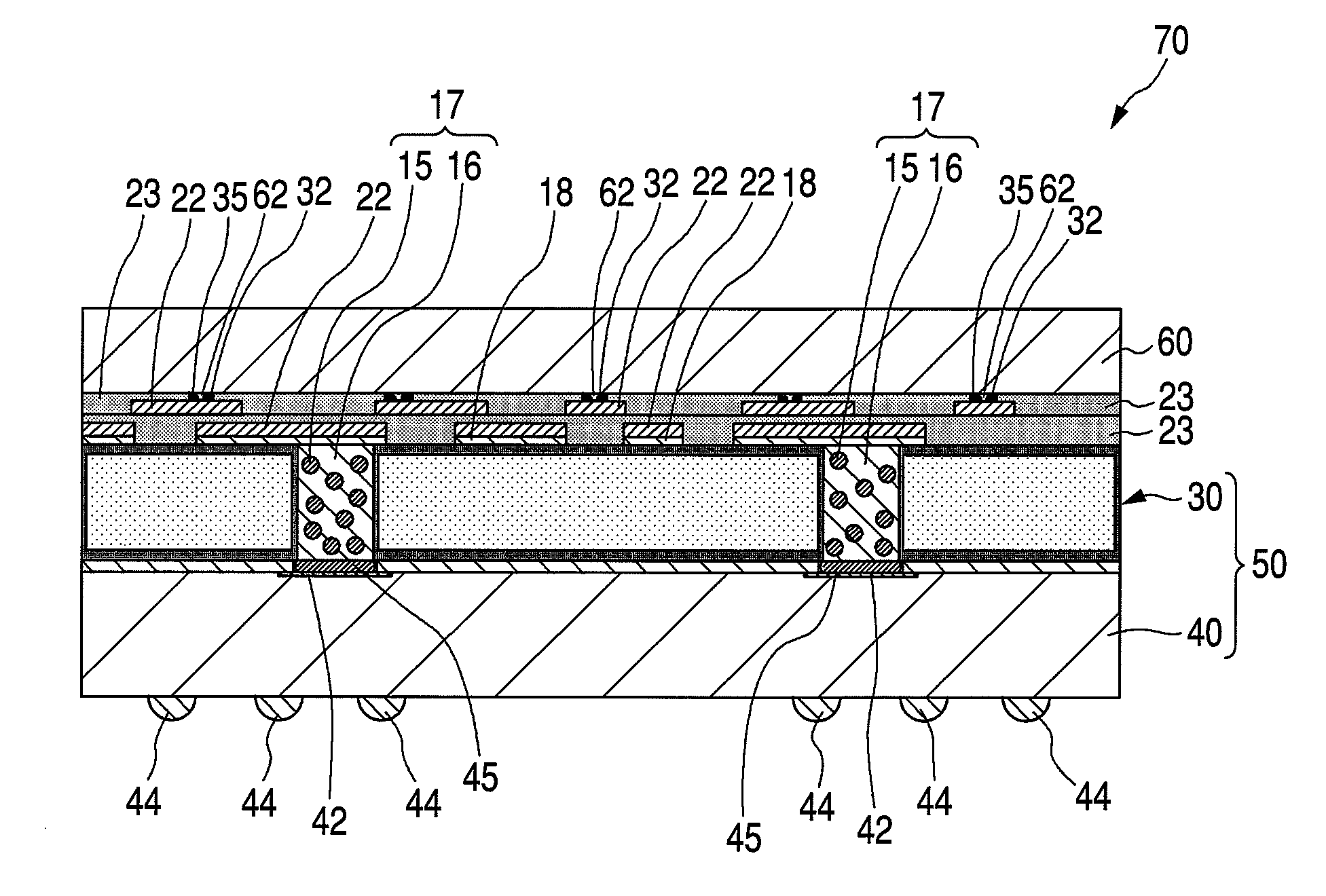

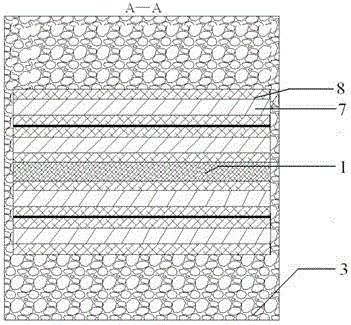

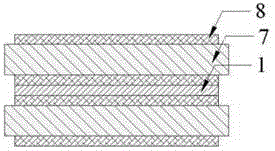

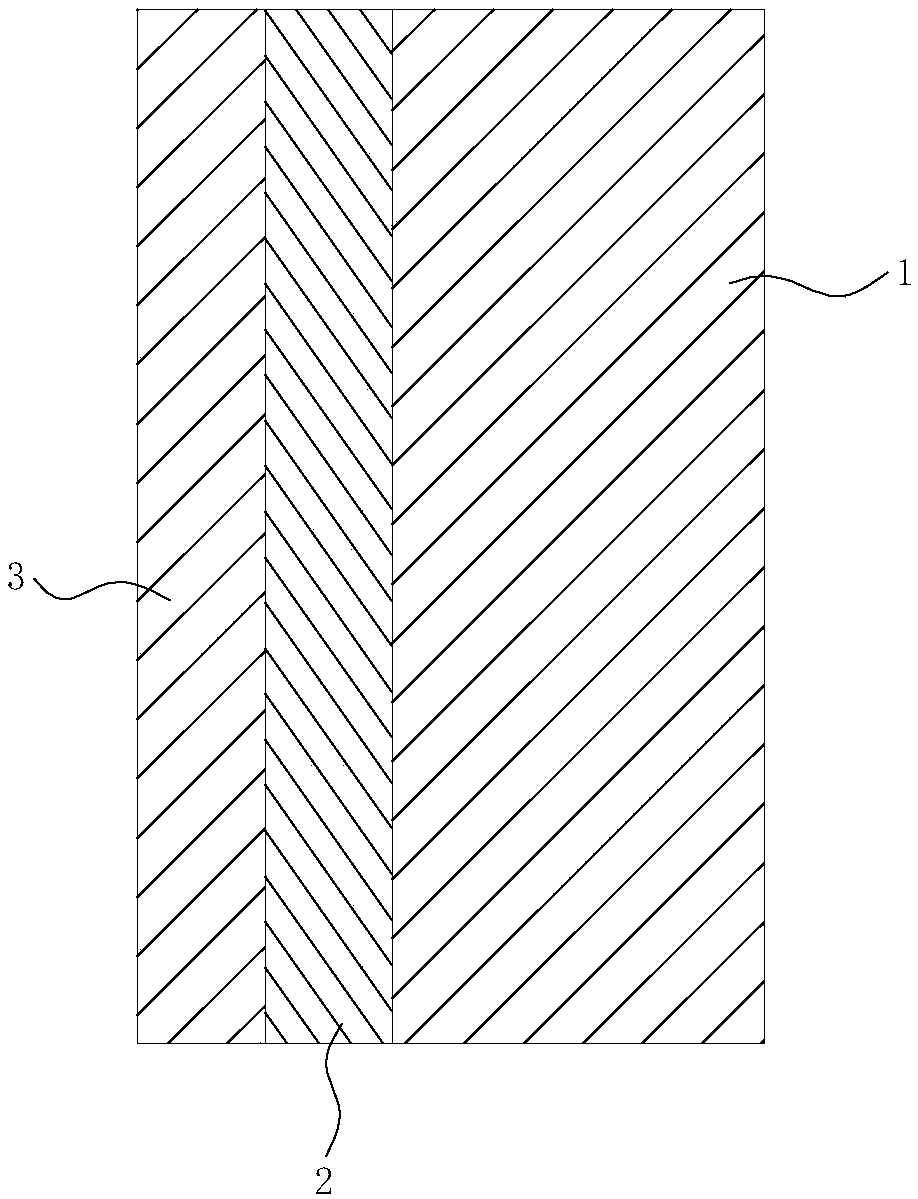

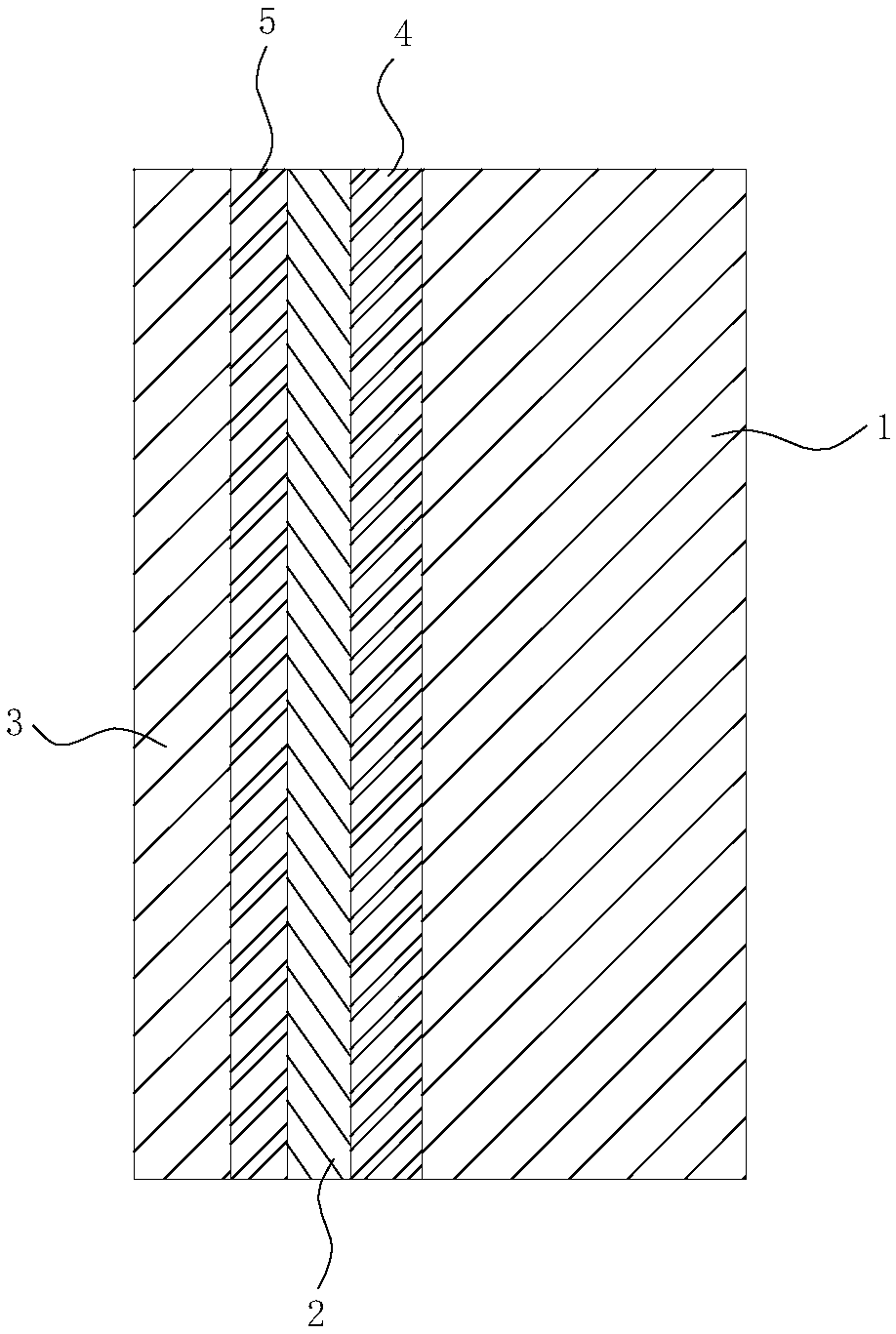

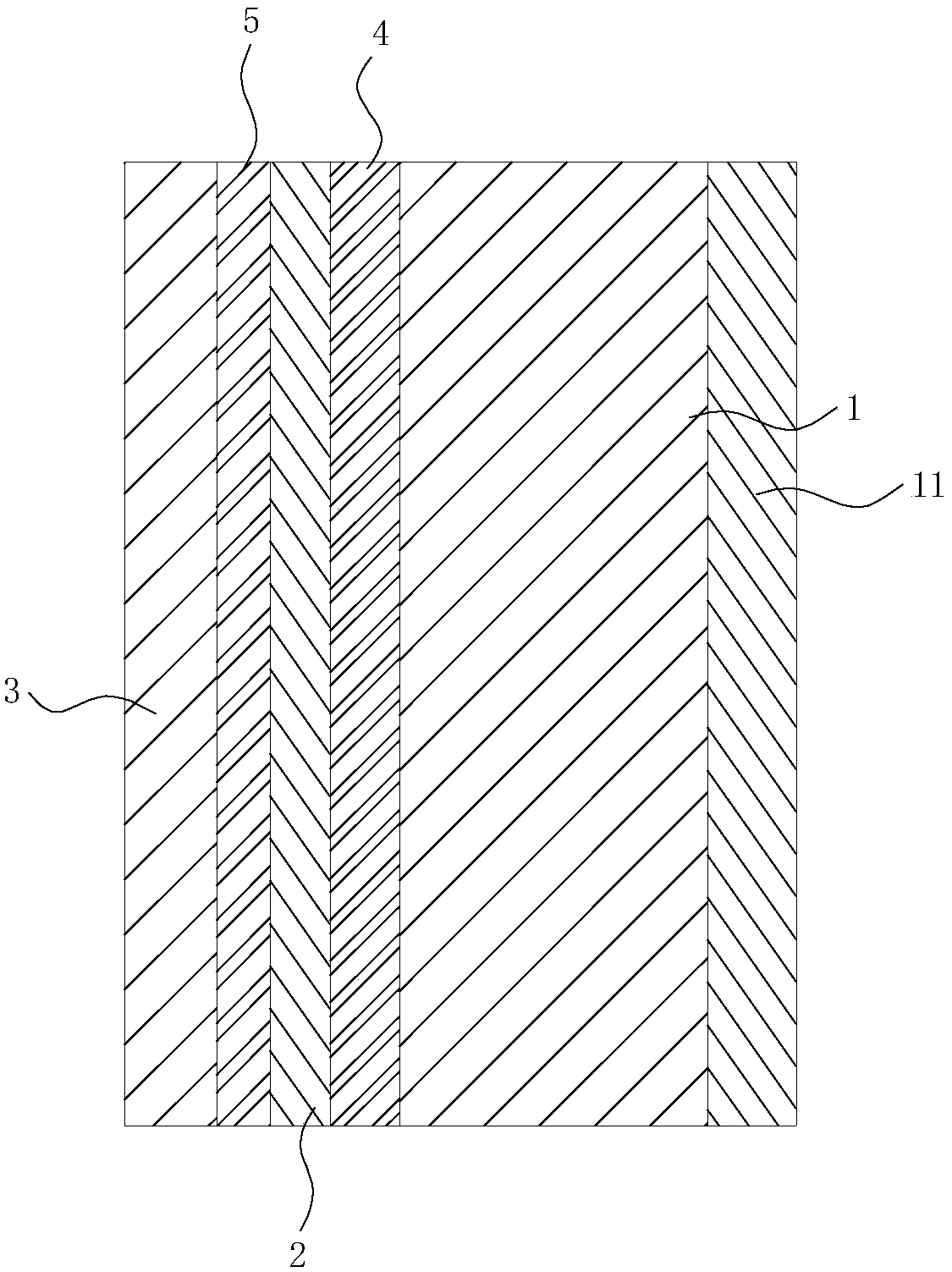

Multilayered ceramic electronic component and manufacturing method of the same

InactiveUS20140022691A1Inhibit the generation of cracksImprove reliabilityFixed capacitor dielectricStacked capacitorsConductive pasteElectronic component

There is provided a multilayered ceramic electronic component including: a ceramic body in which a plurality of dielectric layers are multilayered; a plurality of first and second internal electrode layers formed on at least one surfaces of the dielectric layers and alternately exposed through both ends of the ceramic body in a length direction thereof; first and second adhesive layers formed on both ends of the ceramic body, electrically connected the exposed first and second internal electrodes and formed of a conductive paste; and first and second external electrode layers formed on surfaces of the first and second adhesive layers and formed of a glass-free conductive paste.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

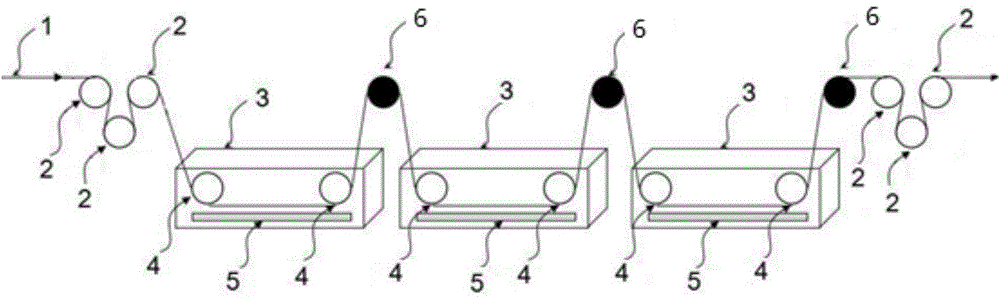

Continuous metal electroplating method and device for carbon fiber tows

The invention provides a continuous metal electroplating method for carbon fiber tows. According to the method, after cleaning treatment by a surfactant solution, a carbon fiber is used as a cathode and plated metal is used as an anode for electroplating, and then cleaning, drying and tow winding are carried out. The continuous metal electroplating method provided by the invention has the advantages of high safety, good deoxidation effect, less investment, high convenience in operation and low operating cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Multilayer ceramic electronic component

ActiveUS8675341B2Improve efficiencyShorten plating timeFixed capacitor electrodesFixed capacitor dielectricElectricityElectrical conductor

Owner:MURATA MFG CO LTD

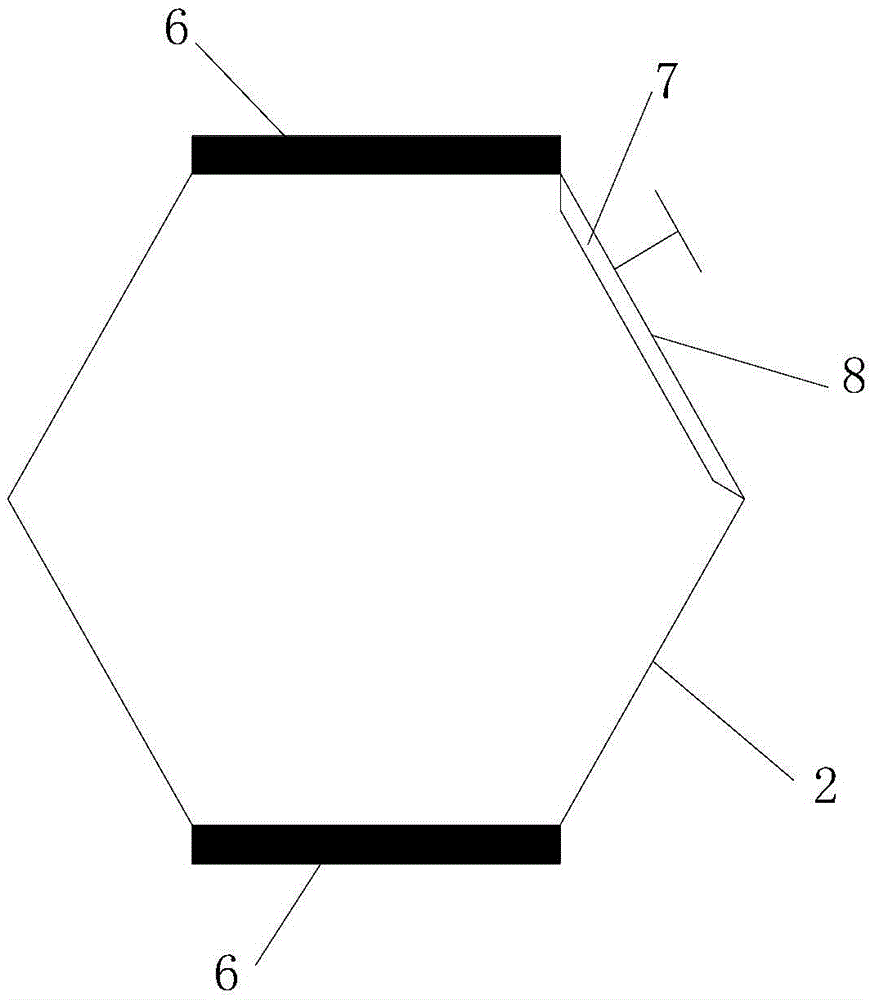

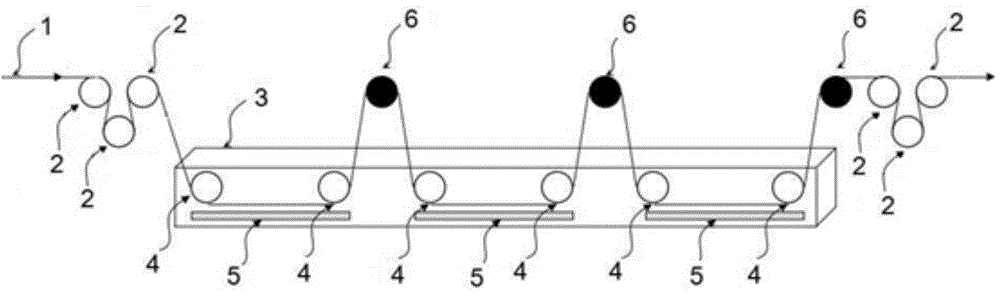

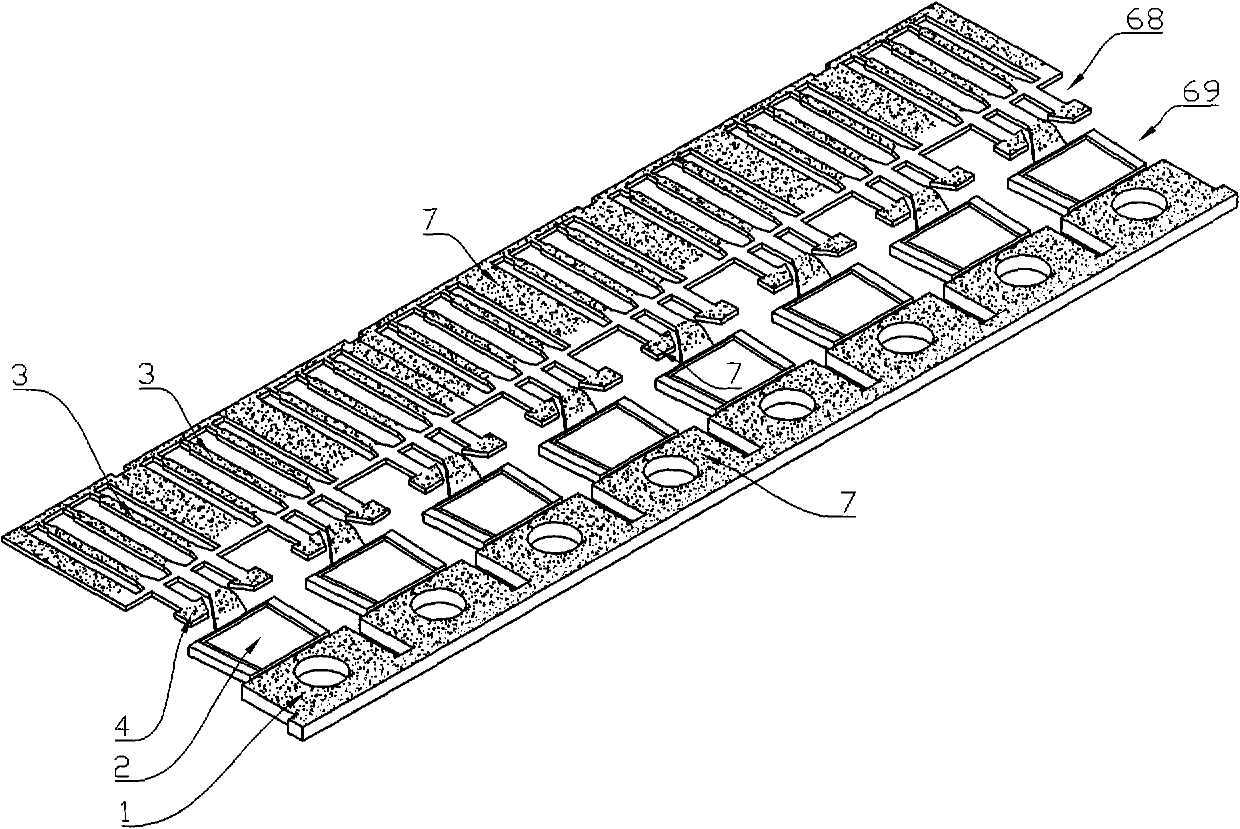

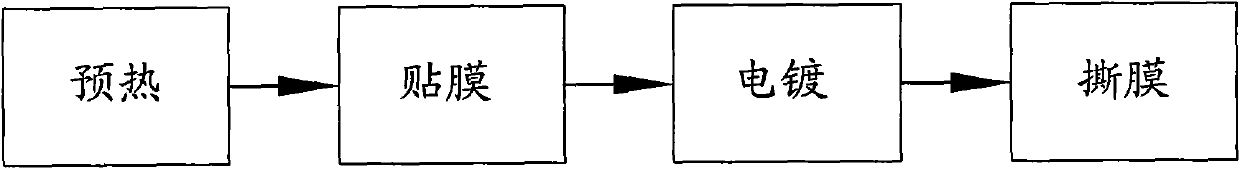

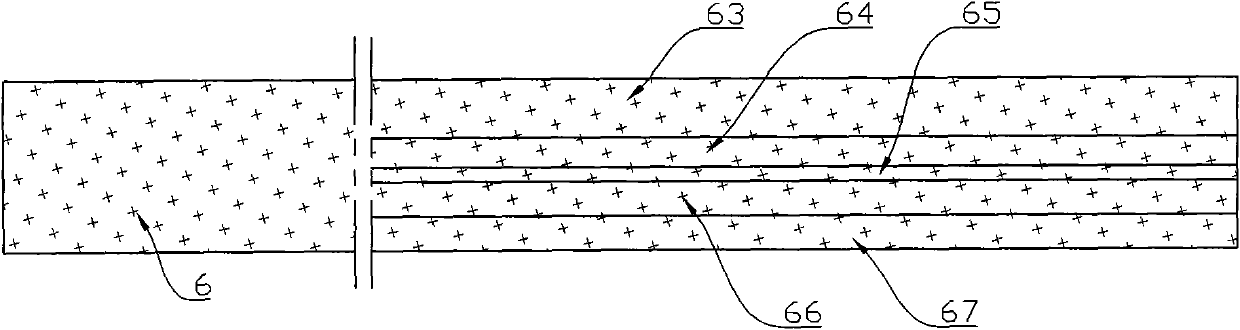

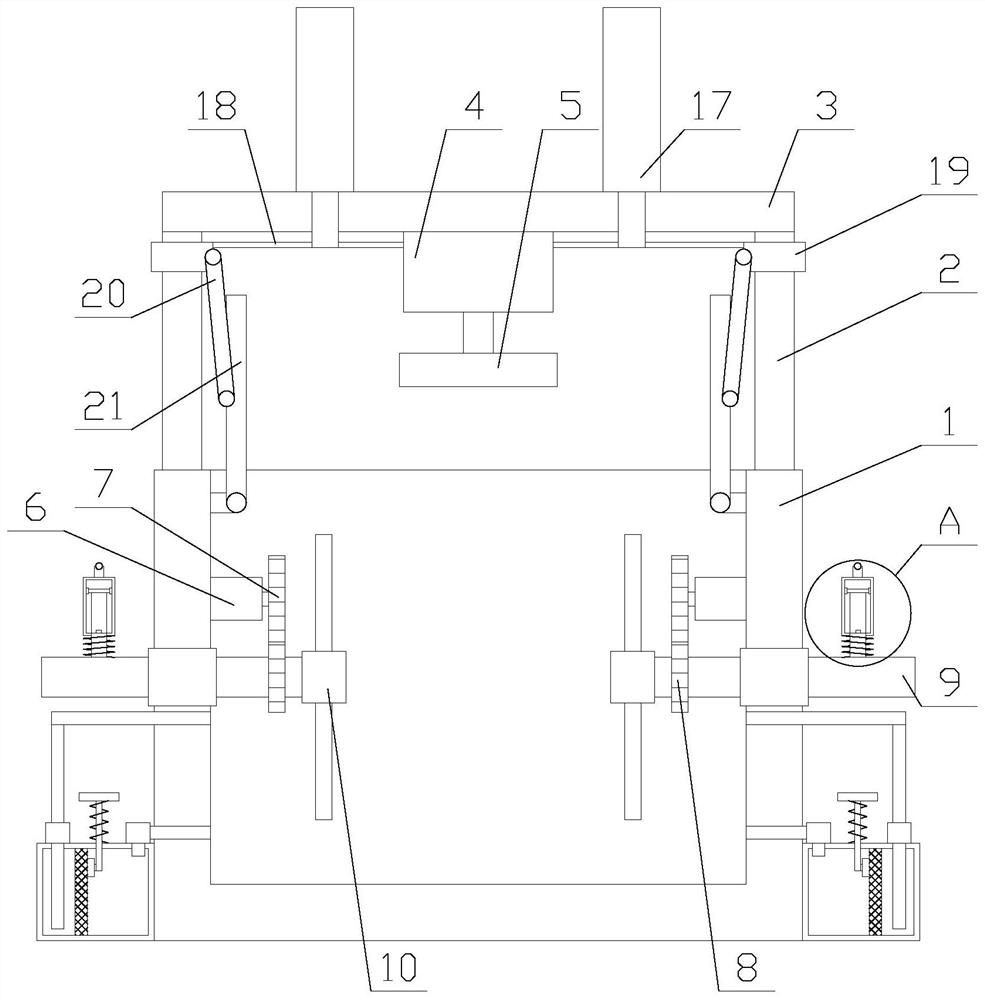

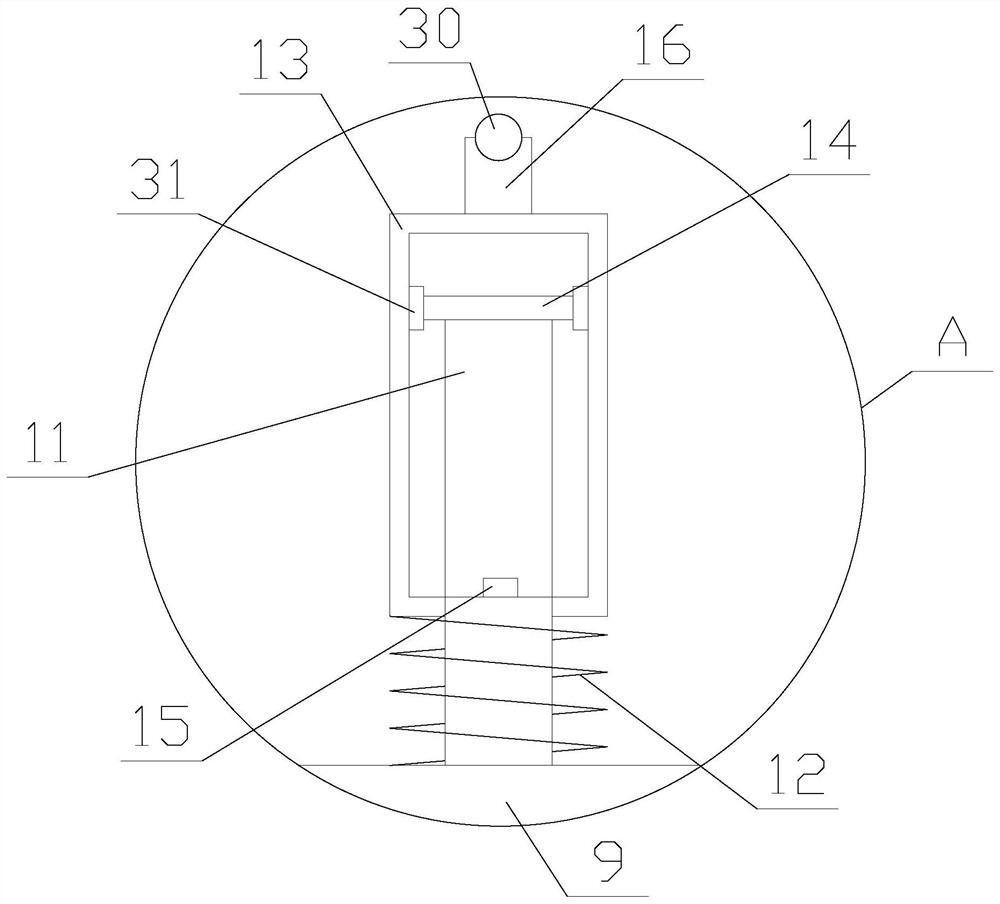

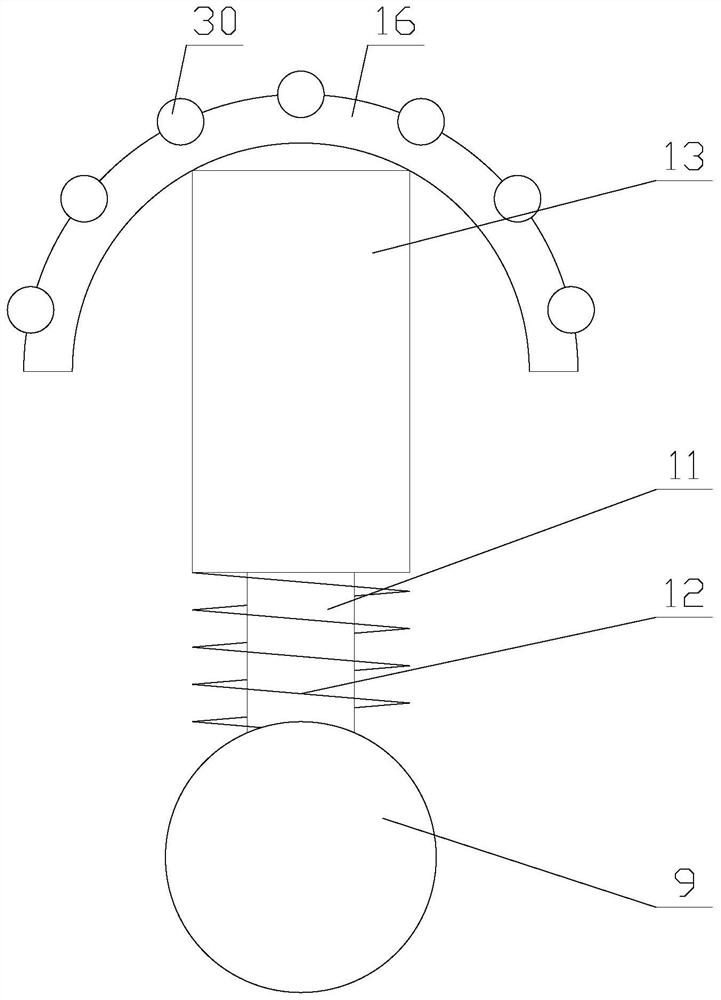

Membrane sticking electroplating process for lead frame and special device thereof

The invention discloses a membrane sticking electroplating process for a lead frame and a special device thereof, which overcome the defects of low efficiency and indistinct outlines of electroplating areas in the conventional electroplating process for the lead frames. The membrane sticking electroplating process comprises the following steps of: performing preheating, membrane sticking, electroplating and dyestripping on a traveled lead frame substrate belt. The membrane sticking process comprises the following steps of: cutting a mucous membrane belt to form a plurality of protective membranes, sorting the protective membranes and laminating the protective membranes which are needed to be adhered to the lead frame substrate belt by using a pair of compression rollers. The membrane sticking electroplating special device for the lead frame comprises a preheating device, a membrane sticking device, an electroplating device and a dyestripping which are connected sequentially, wherein the membrane sticking device comprises a pair of the same membrane sticking machines which are arranged on both sides of the lead frame substrate belt; and a machine frame of each membrane sticking machine is provided with a wheel disc, a plurality of traction rollers, a cutting die, a guide die, a carrier roller and a pair of compression rollers. By the membrane sticking electroplating process, a production process which is performed by electroplating and pressing and is used for the lead frame and a special device thereof are provided for the society, so the continuity of production is improved greatly, and the outlines of electroplating areas are distinct and accurate.

Owner:NINGBO HUALONG ELECTRONICS

Through hole electroplating process for printed circuit board

InactiveCN111519218AOptimizing Plating WaveformsImprove the plating effectCellsPrinted circuit boardIndustrial engineering

The invention discloses a through hole electroplating process for a printed circuit board. The through hole electroplating process comprises the steps of deoiling: stains and oxide layers on a coppersurface of the printed circuit board before electroplating are removed by using an acidic degreasing agent, wherein the deoiling is operated under the temperature of 43-54 DEG C for 3-5 minutes; rinsing: the printed circuit board subjected to the treatment of the degreasing agent is rinsed by adopting flowing deionized water to match with mechanical swinging, wherein the rinsing is operated underthe temperature of 20-28 DEG C for 2-4 minutes; pre-soaking: pre-cleaning is carried out on the printed circuit board before electroplating by using a dilute sulfuric acid solution in cooperation withmechanical swinging and a filtering circulating system, wherein the concentration of the dilute sulfuric acid solution is 10%, and the pre-soaking is operated under the temperature of 20-28 DEG C for1-3 minutes; and electroplating: the printed circuit board is electroplated by utilizing electroplating chemicals, the filtering circulating system, mechanical swinging and jet flow, wherein the electroplating is operated under the temperature of 23-26 DEG C, and the electroplating chemicals comprise an electroplating base solution and an electroplating additive. The through hole electroplating process for the printed circuit board is characterized in that the electroplating time can be shortened to the maximum extent, and the production efficiency can be improved.

Owner:麦德美科技(苏州)有限公司

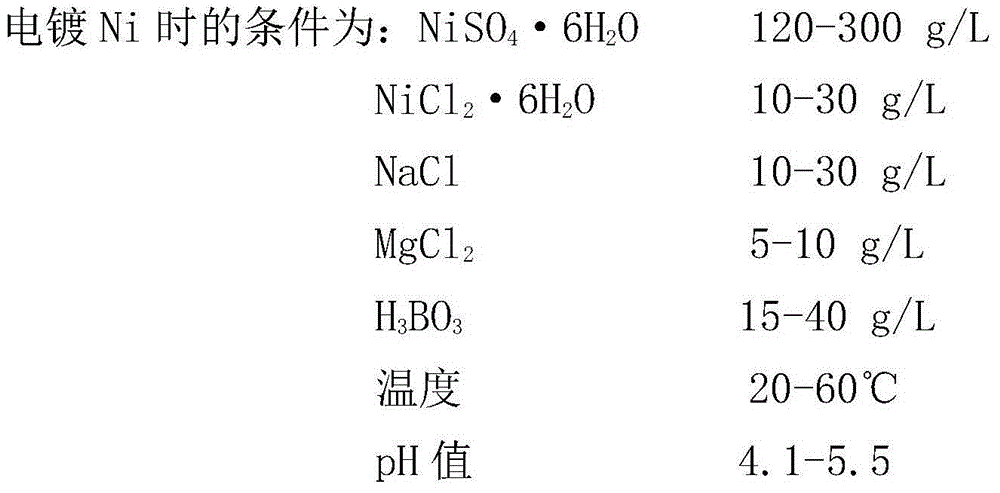

Anti-nitridation process for copper-tin composite plating

The invention discloses an anti-nitridation process for copper-tin composite plating, which comprises the following steps: deoiling and cleaning a workpiece, and then performing weak corrosion treatment on the workpiece with sulfuric acid; performing anodic cleaning on the workpiece, wherein the workpiece subjected to anodic cleaning needs to be taken out of the tank while electrified; performing nickel preplating: keeping the workpiece non-electrified and placing the workpiece in an electroplating solution for 2-4 minutes before nickel preplating, then preplating nickel for 1 mu m, and plating dark nickel for 1-2 mu m; performing activating treatment on the workpiece with sulfuric acid; and performing copper cyanideless electroplating, plating dark tin on the surface of the copper-electroplated layer of the workpiece, and finally performing stabilizing treatment. According to the electroplating process disclosed by the invention, the workpiece can similarly achieve the purpose of preventing nitridation, carburization and cyanogen infiltration in case of a thinner copper-plated layer, thus reducing the thickness of the copper-plated layer, reducing the copper consumption, shortening the electroplating time and improving the electroplating efficiency.

Owner:GUIZHOU HONGLIN MACHINERY

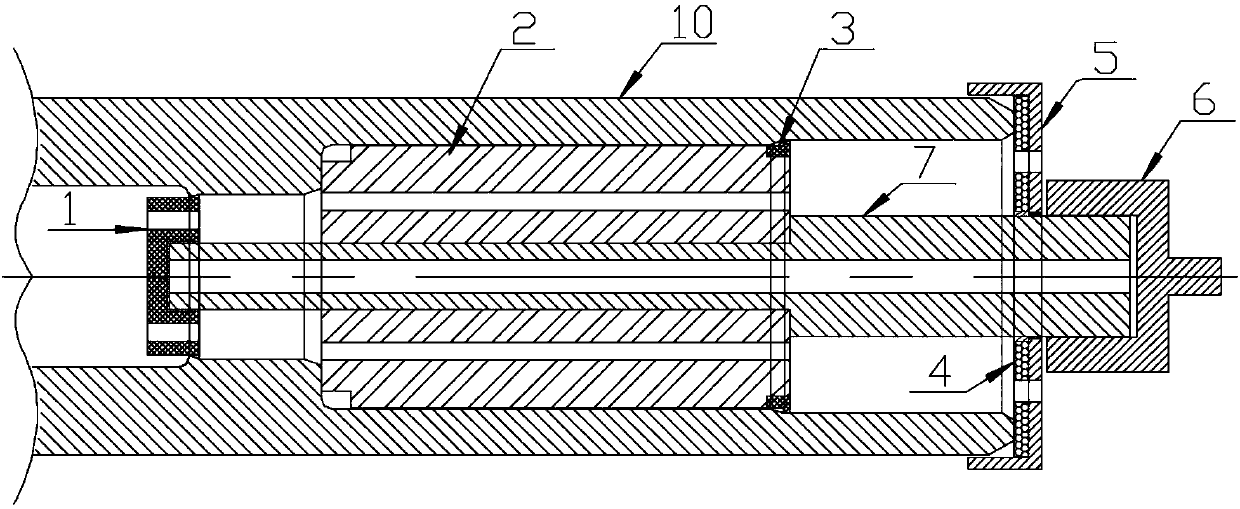

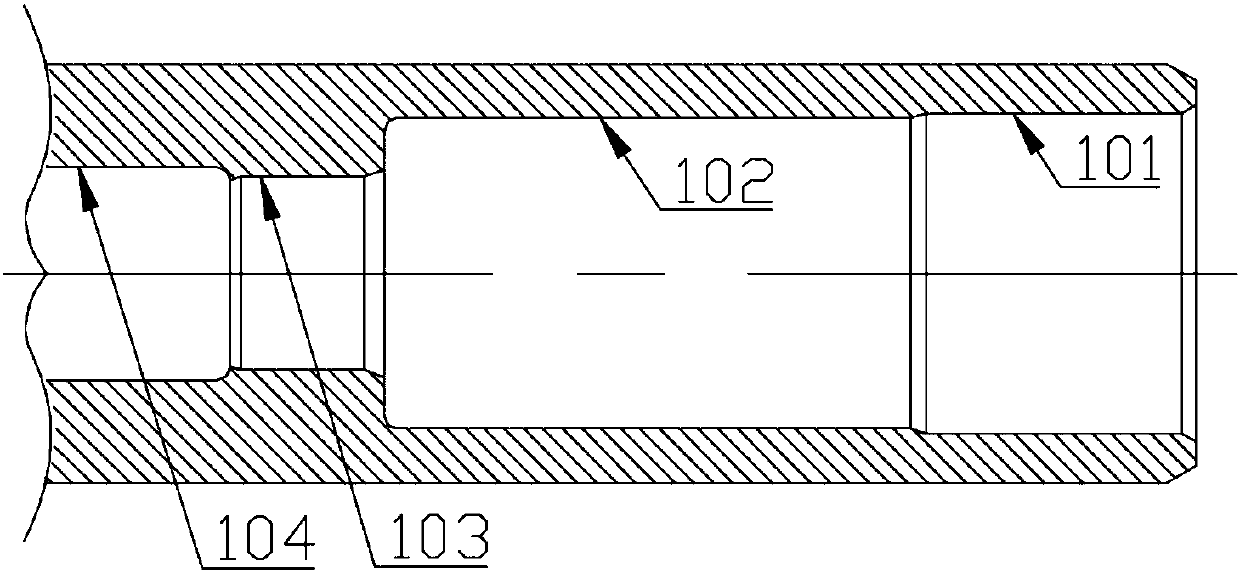

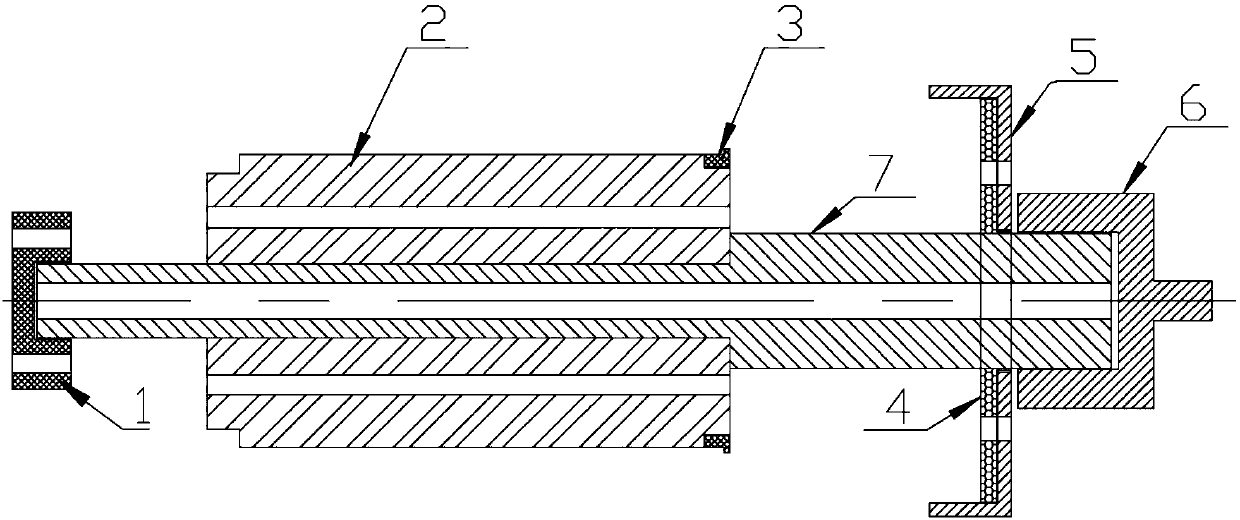

Inner hole electroplating device

ActiveCN107620097AShorten plating timeUniform coating thicknessElectrolysis componentsEngineeringMetallic materials

The invention discloses an inner hole electroplating device. The inner hole electroplating device comprises an anode rod and a protective sleeve, wherein the protective sleeve is arranged on the anoderod in a sleeving manner; a workpiece is arranged on the anode rod and the protective sleeve in a sleeving manner; the protective sleeve is arranged corresponding to the non-electroplated sections ofan inner hole in the workpiece; a gap is formed between the electroplated sections of the inner hole in the workpiece and the anode rod; a metal lining is arranged at the other end of the outer surface of the protective sleeve; a first gasket and a second gasket which are arranged with metal nuts in an overlapping manner are arranged at one end of the anode rod; the first gasket is made of a metal material; the second gasket is made of an insulating material; and the first gasket and the metal lining exert the cathode protective function in the electroplating process. By adoption of the innerhole electroplating device disclosed by the invention, a plurality of discontinuous sections of the inner hole can be electroplated at a time, thereby shortening the electroplating time; the thickness of an electroplated layer is uniform and consistent, thereby lowering the consumption of an electroplating material; and the edge quality of the electroplated layer is improved.

Owner:LANDING GEAR ADVANCED MFG

Method for electroplating silver on surface of printed circuit board through pulse current

The invention discloses a method for electroplating silver on the surface of a printed circuit board through pulse current. The method is low in cost, simple in process and controllable. The method comprises the steps of (1) preparing electroplate liquid containing silver salt and (2) carrying out the silver plating process. In the step (1), silver cyanide, sodium cyanide and sodium hydroxide are used as main salt, dimethylamine-borane and thiourea serve as supporting electrolytes, and an inorganic molten salt plating solution system is prepared. In the step (2), the silver plating process comprises the steps of grinding of the surface of the printed circuit board, chemical oil removal, water flushing, brush polishing, etching activation, pulse silver plating, washing and drying, wherein the pulse silver plating process is that electroplating is carried out at the temperature of 50-60 DEG C, and reverse pulse electroplating is adopted; pulse parameters are that forward current is 5-15 A, reverse current is 15 A, forward pulse time is 18-108 ms, reverse pulse time is 2 ms, and electroplating time is 60 min. The method can be applied to the field of metal materials.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

Electroplating equipment with impurity removal function

The invention relates to electroplating equipment with an impurity removal function. The electroplating equipment comprises a main body, a supporting plate, a lifting device, a lifting plate and two supporting columns, and further comprises a stirring mechanism and two impurity removal mechanisms; the stirring mechanism comprises a protection assembly and two stirring assemblies, and each stirringassembly comprises a first bearing, a rotating shaft, a paddle, a driving unit and a control unit; the protection assembly comprises a connecting ring, two protection units and two air cylinders; each impurity removal mechanism comprises an impurity removal box, a filter screen, a water pumping assembly, a circulating assembly and an impurity removal assembly; and each impurity removal assembly comprises an abutting plate, a second spring, a connecting rod and a scraper blade. According to the electroplating equipment with the impurity removal function, the stirring mechanism can be used forstirring liquid zinc inside the main body, and flow of the liquid zinc is accelerated, so that the galvanizing quality is guaranteed, meanwhile, the electroplating speed can be increased, the electroplating time is shortened, and the working efficiency is improved; and through the impurity removal mechanisms, the function of removing impurities from the liquid zinc is achieved, and reduction of the galvanizing quality due to the excessive impurity content in the liquid zinc is avoided.

Owner:广州市欧伊若科技有限公司

Surface treating method of radio frequency passive module

ActiveCN101311323AFully satisfy the electrical performanceMeet electrical performanceCopper platingComputer module

The invention relates to a surface processing method for a radio frequency passive module, which is to electroplate a ternary alloy layer of copper, tin and zinc on the surface of the module and comprises the steps of pretreatment, preprocessing, pre copper plating, electroplating ternary alloy of copper, tin and zinc and post treatment. The invention adopts the surface processing method of electroplating the ternary alloy of copper, tin and zinc on the surface of the radio frequency passive module, which replaces the traditional silver plating technique. The radio frequency passive module after surface treatment fully satisfies electrical performance of the radio frequency passive module and at the same time reduces cost. Furthermore, the temperature resistance performance and the anti-corrosion performance are greatly improved, thus the service life of the related communication product is prolonged. Compared with the traditional silver plating technique, the steps of electroplating ternary alloy of copper, tin and zinc and post treatment simplify the processing steps, relatively save the electroplating time and also improve the working efficiency.

Owner:SHENZHEN GRENTECH RF COMM LTD

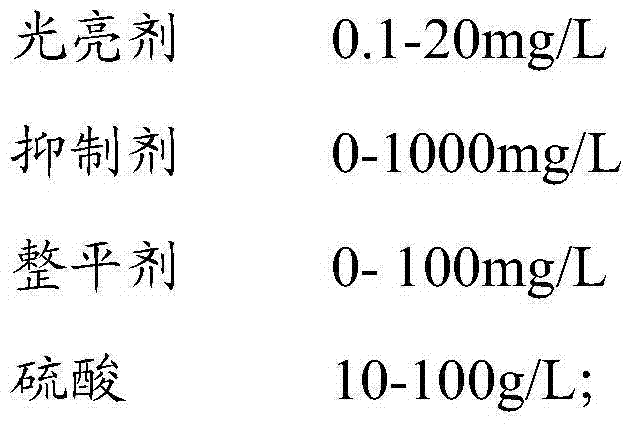

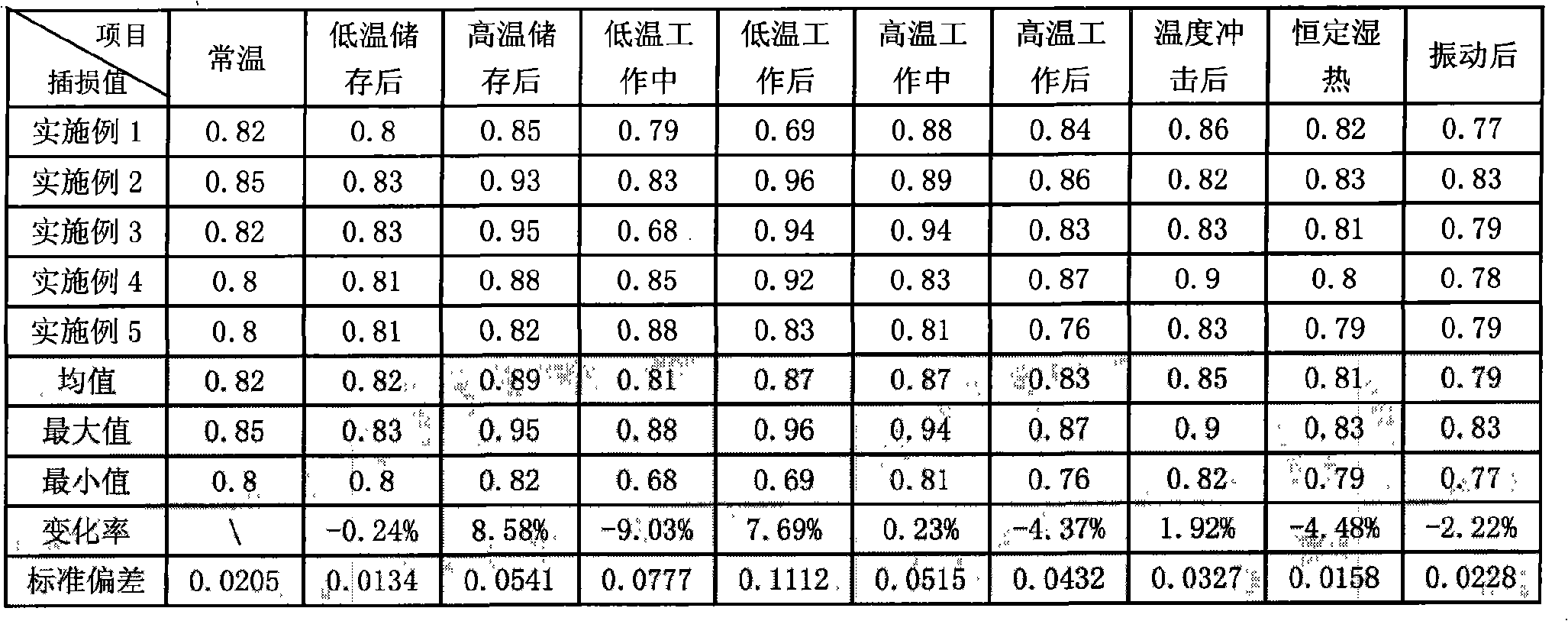

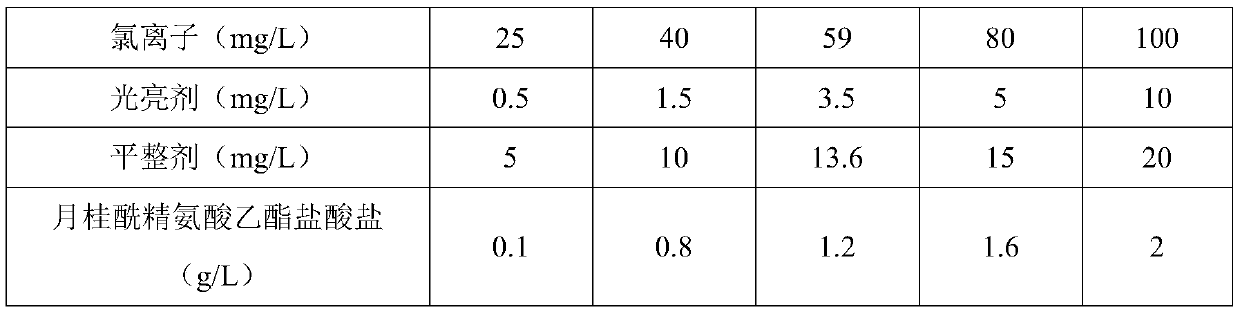

Electrocoppering plating solution and electrocoppering method

The invention belongs to the technical field of electroplating, and particularly relates to an electrocoppering plating solution and an electrocoppering method. The electrocoppering plating solution is composed of copper sulfate pentahydrate, sulfuric acid, chloridions, a brightener, a leveling agent, lauryl L-Arginine ethyl ester dihydrochloride, deionized water and other components. The electrocoppering method comprises the four steps of surface treatment, electrocoppering plating solution preparing, electroplating and drying. By means of the electrocoppering plating solution, electrocoppering can be carried out under the high-density current, a coppered layer of an obtained coppered workpiece is bright and smooth, adhesive force is good, the electroplating time of the low current density under the same condition can be shortened, work efficiency can be improved, and cost can be saved. The formula components of the electrocoppering plating solution are simple, the electrocoppering method is easy to achieve, and industrialization can be achieved easily.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

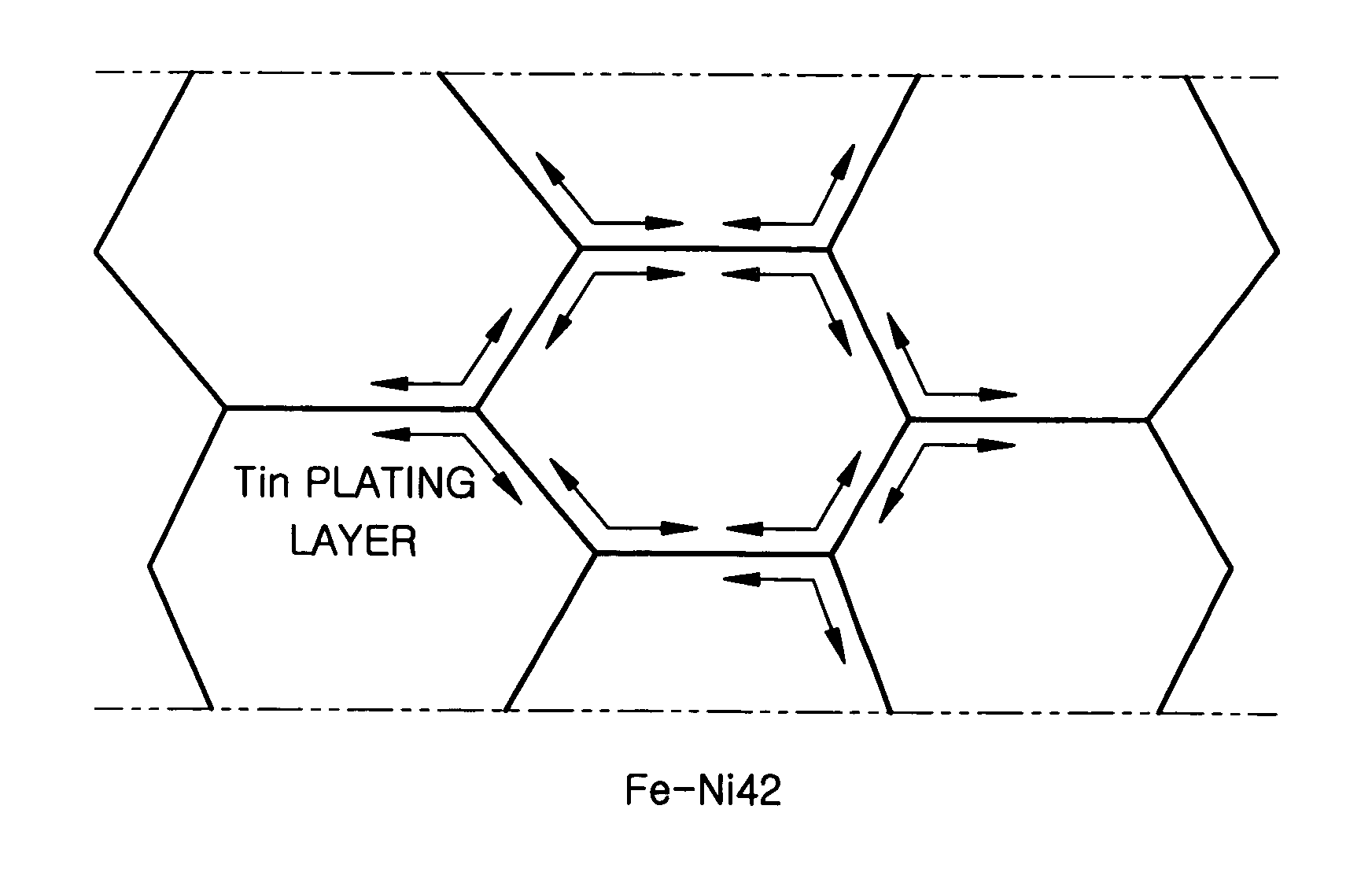

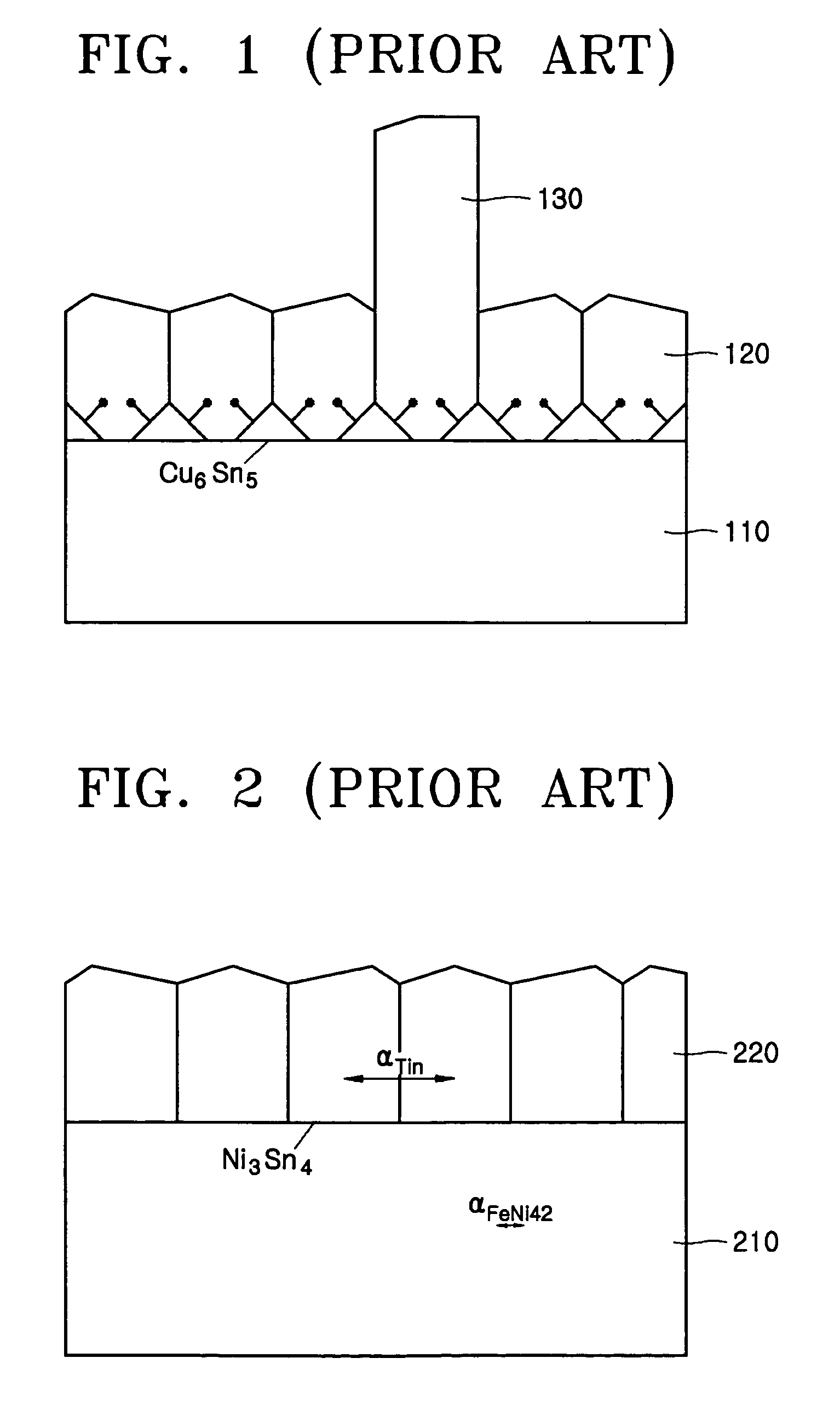

Semiconductor lead frame, semiconductor package having the same, and method of plating the same

InactiveUS7501692B2Minimal formation of whiskerShorten plating timeElectrolytic capacitorsSemiconductor/solid-state device detailsMicrometerSemiconductor package

Provided are a semiconductor lead frame, a semiconductor package having the semiconductor lead frame, and a method of plating the semiconductor lead frame. The method includes preparing a substrate formed of a Fe—Ni alloy (alloy 42), and a plating layer that contains grains less than 1 micrometer in size and is plated on the substrate. The growth of whiskers when a Sn plated layer is formed on a substrate formed of a Fe—Ni alloy (alloy 42) can be suppressed by minimizing the grain size of the Sn plated layer.

Owner:SAMSUNG TECHWIN CO LTD

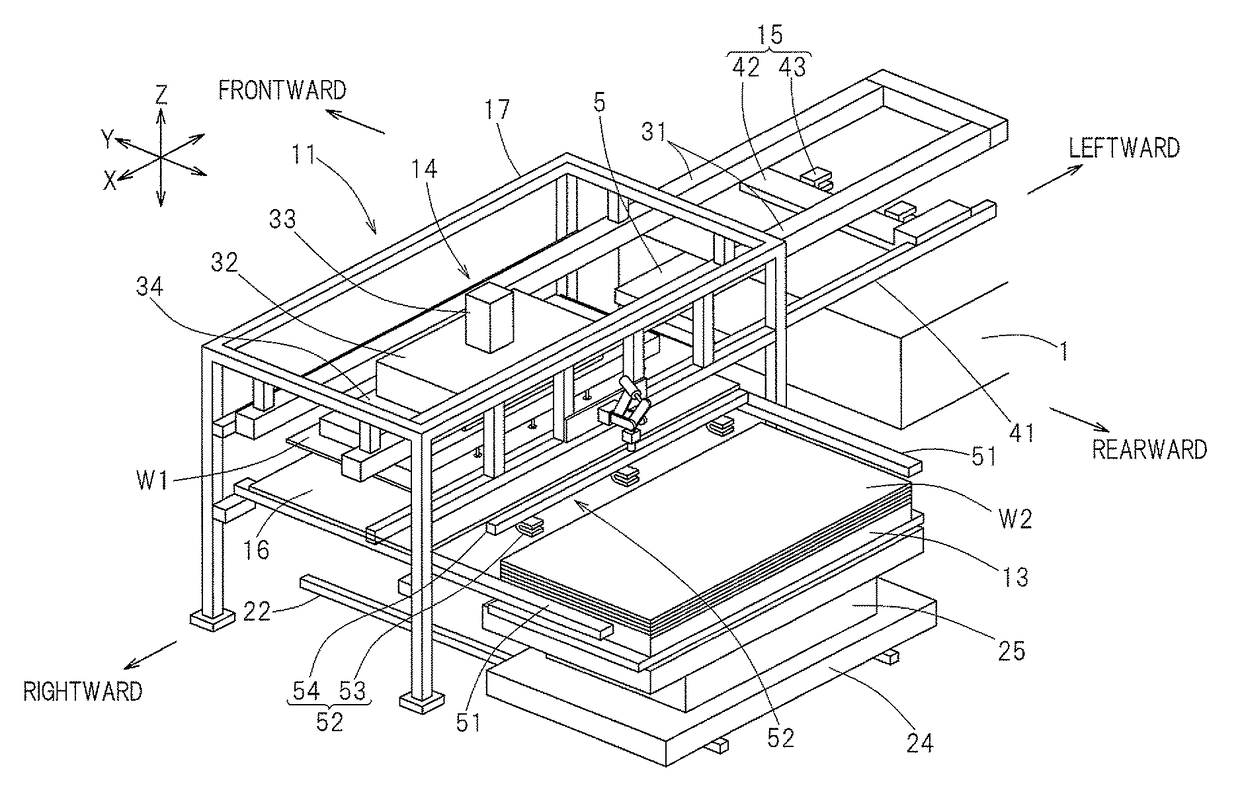

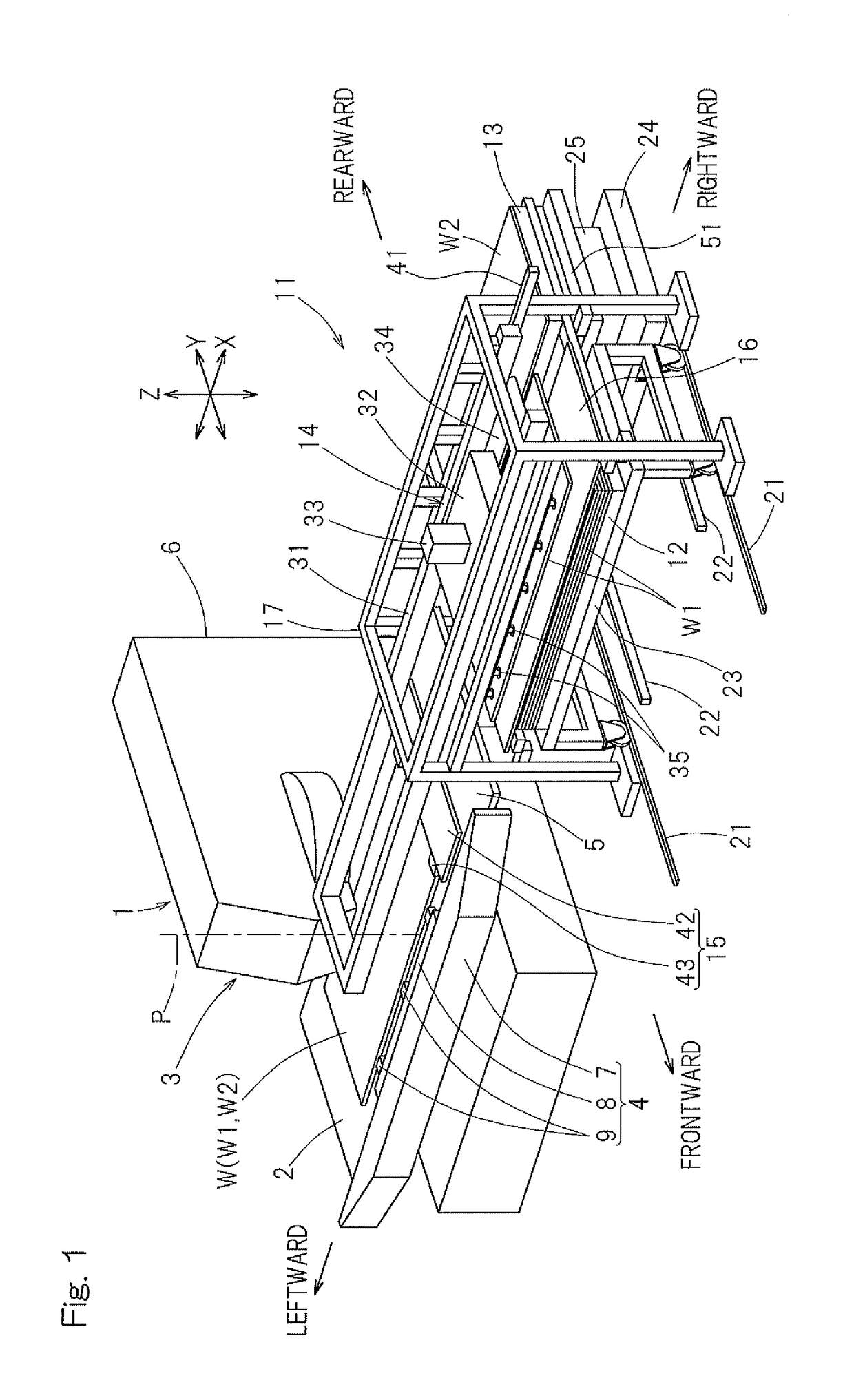

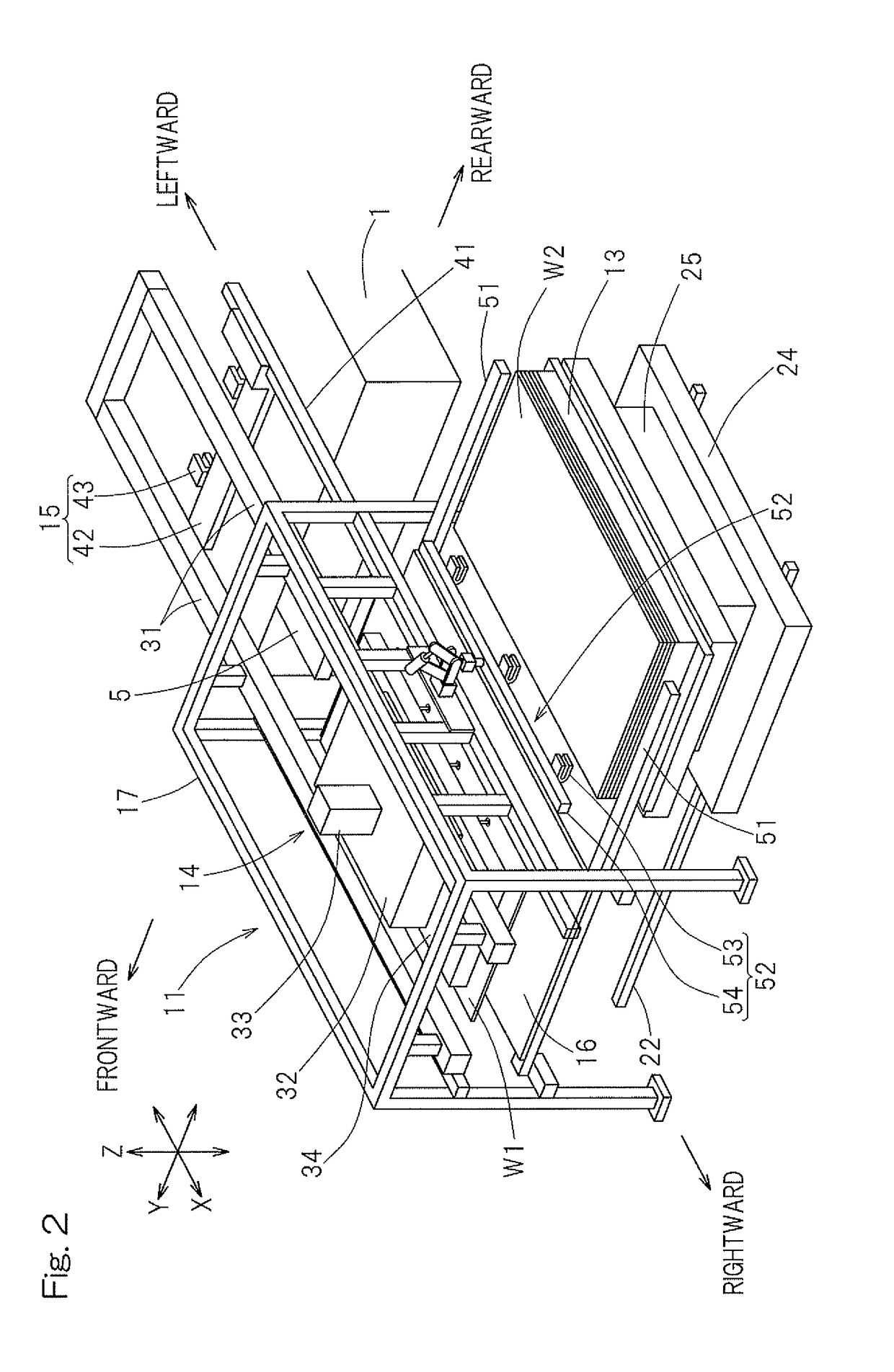

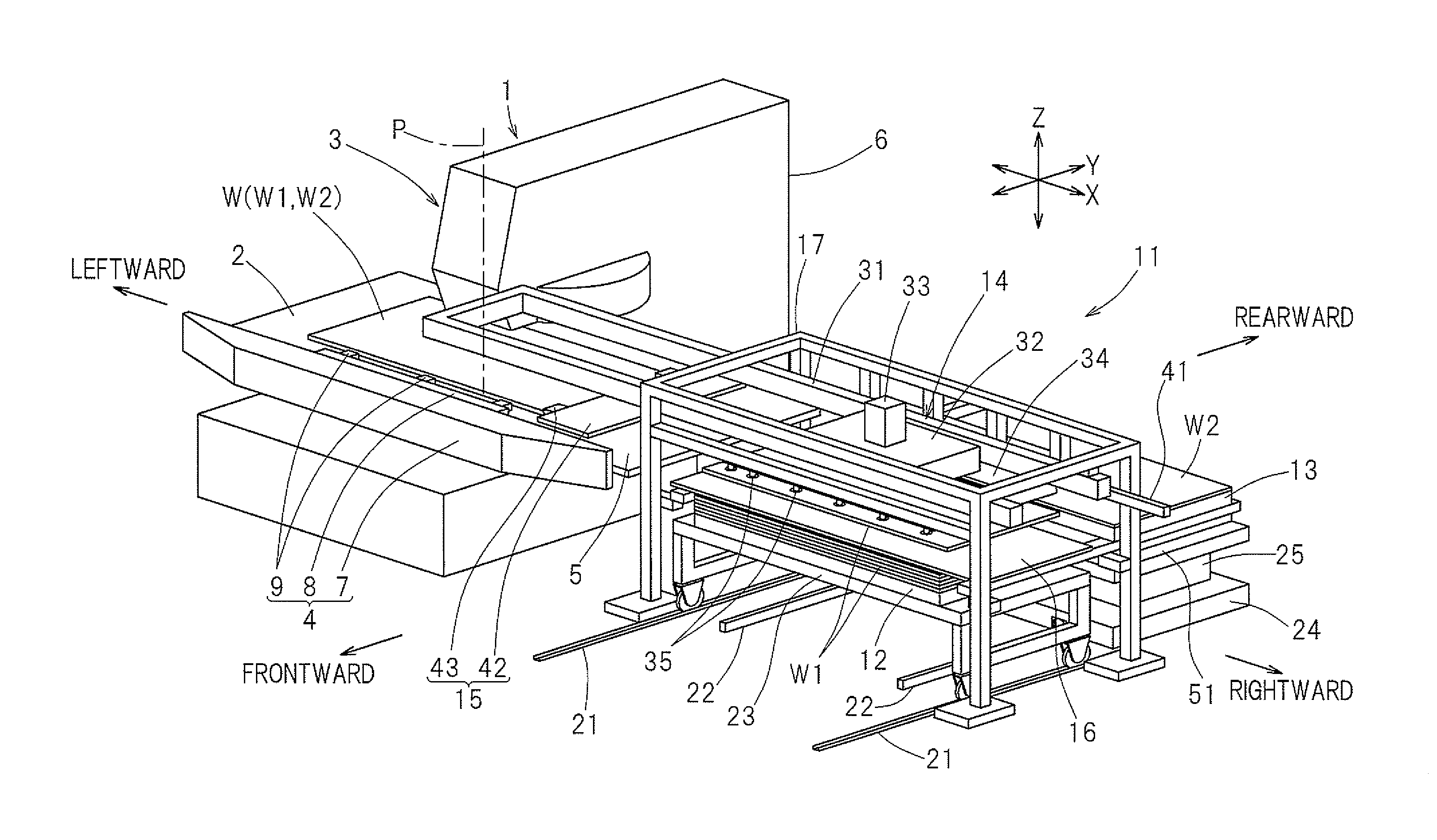

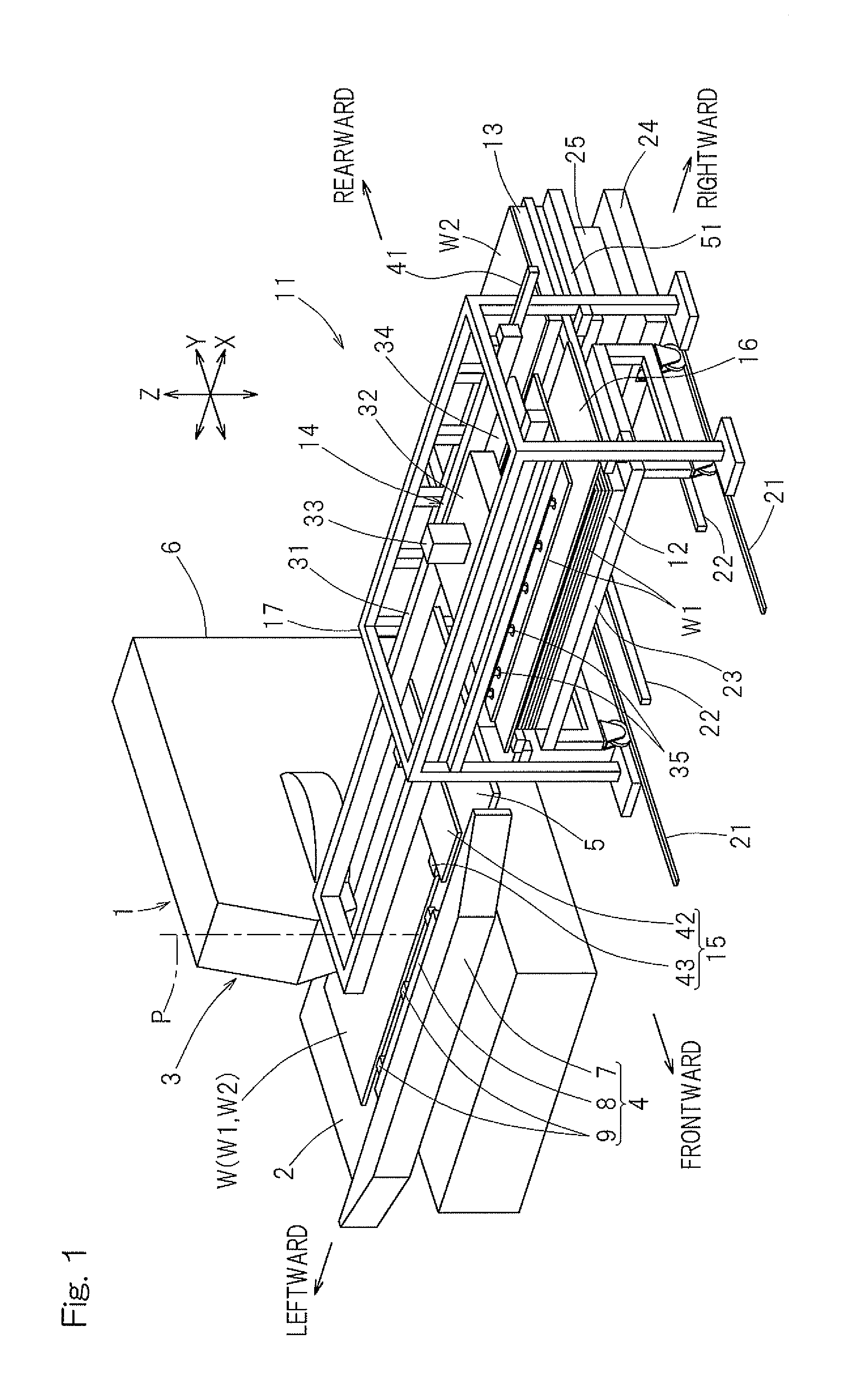

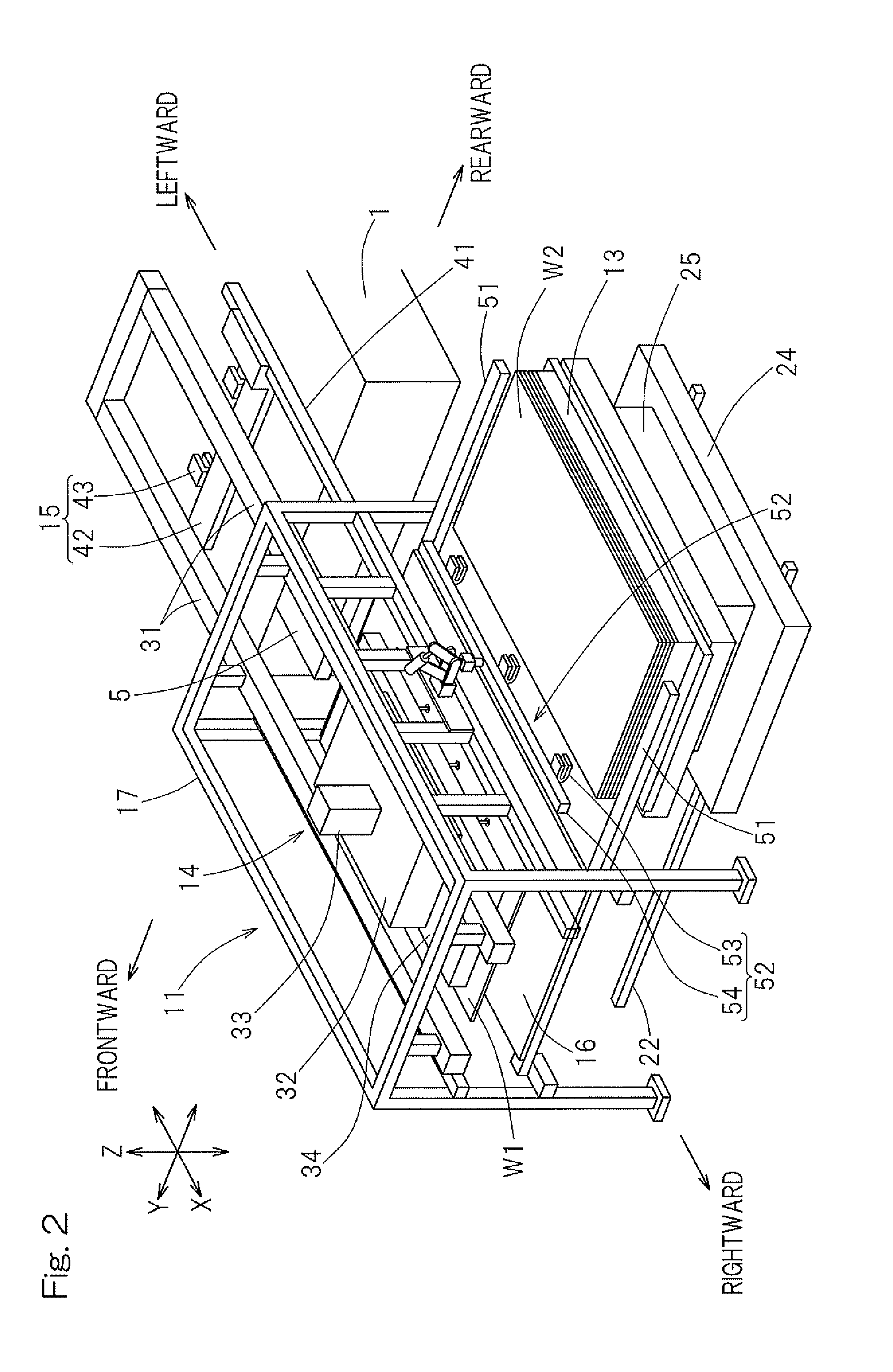

Plate material conveyance apparatus with temporary placement table

ActiveUS9682414B2Shorten cycle timeSpace minimizationMetal-working feeding devicesMetal working apparatusMechanical engineeringEngineering

A plate material conveyance apparatus, disposed next to a plate processing machine, includes an unprocessed plate material placement unit, a processed plate material placement unit, a loader, an unloader and a temporary placement table. The loader reciprocally moves between the unprocessed plate material placement unit and the plate processing machine to deliver an unprocessed plate material onto the plate processing machine. The unloader reciprocally moves in parallel to and below the loader between the unprocessed plate material placement unit and the plate processing machine, and delivers a processed plate material from the plate processing machine to the temporary placement table positioned above the unprocessed plate material placement unit. The temporary placement table slides between the unprocessed plate material placement unit and the plate processing machine, and transfers the processed plate material, received from the unloader, to the processed plate material placement unit.

Owner:MURATA MASCH LTD

Composite electroplating bath containing nano-sized vanadium carbide

InactiveCN105256363AImprove adhesionSolve the problem of increased surface roughnessElectrolytic coatingsStearic acidSaccharin

The invention discloses a composite electroplating bath containing nano-sized vanadium carbide. The composite electroplating bath containing nano-sized vanadium carbide is prepared from, by weight, 500-550 parts of nickel aminosulfonate, 21-25 parts of cobaltous sulfate, 33-38 parts of nickel chloride, 30-35 parts of boric acid, 0.7-0.8 part of lauryl sodium sulfate, 0.4-0.6 part of sodium 1-undecanesulfonate, 4-6 parts of styrene, 0.2-0.3 part of azodiisobutyronitrile, 7-9 parts of the nano-sized vanadium carbide, 0.4-0.5 part of saccharin, 5-6 parts of basalt fibers, 4-5 parts of stearic acid, 2-3 parts of ethylene glycol, 5-6 parts of starch, and a proper amount of deionized water. The composite electroplating bath is environmentally friendly, nontoxic, simple in process and low in cost.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

Method for using Ni-Co-W alloy electroplate liquid to repair nickel-plated combined crystallizer narrow plate in electroplating manner

The invention relates to a method for using Ni-Co-W alloy electroplate liquid to repair a nickel-plated combined crystallizer narrow plate in an electroplating manner and belongs to the technical field of electroplating. The method includes the steps of firstly, preparing electrolyte; secondly, rough machining the narrow plate; thirdly, cleaning the narrow plate; fourthly, electrolyzing the narrow plate; fifthly, electroplating the crystallizer narrow plate. The method has the advantages that the method in novel in concept and well-organized in sequence; nickel alloy is plated on the nickel layer of the lateral edge of the crystallizer narrow plate, electroplating time of the narrow plate can be reduced from five days to three days, lateral edge machining amount is reduced, consumption of cobalt, nickel and power is reduced, work efficiency is increased, and production cost is lowered; wear resistance of the plated layer is increased by using the Ni-Co-W alloy electroplate liquid, and the service life of a crystallizer is prolonged.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

Plate conveyance apparatus and plate processing system using same

ActiveUS20150165508A1Shorten cycle timeSpace minimizationMetal-working feeding devicesMetal working apparatusHandling systemMechanical engineering

A plate material conveyance apparatus, disposed next to a plate processing machine, includes an unprocessed plate material placement unit, a processed plate material placement unit, a loader, an unloader and a temporary placement table. The loader reciprocally moves between the unprocessed plate material placement unit and the plate processing machine to deliver an unprocessed plate material onto the plate processing machine. The unloader reciprocally moves in parallel to and below the loader between the unprocessed plate material placement unit and the plate processing machine, and delivers a processed plate material from the plate processing machine to the temporary placement table positioned above the unprocessed plate material placement unit. The temporary placement table slides between the unprocessed plate material placement unit and the plate processing machine, and transfers the processed plate material, received from the unloader, to the processed plate material placement unit.

Owner:MURATA MASCH LTD

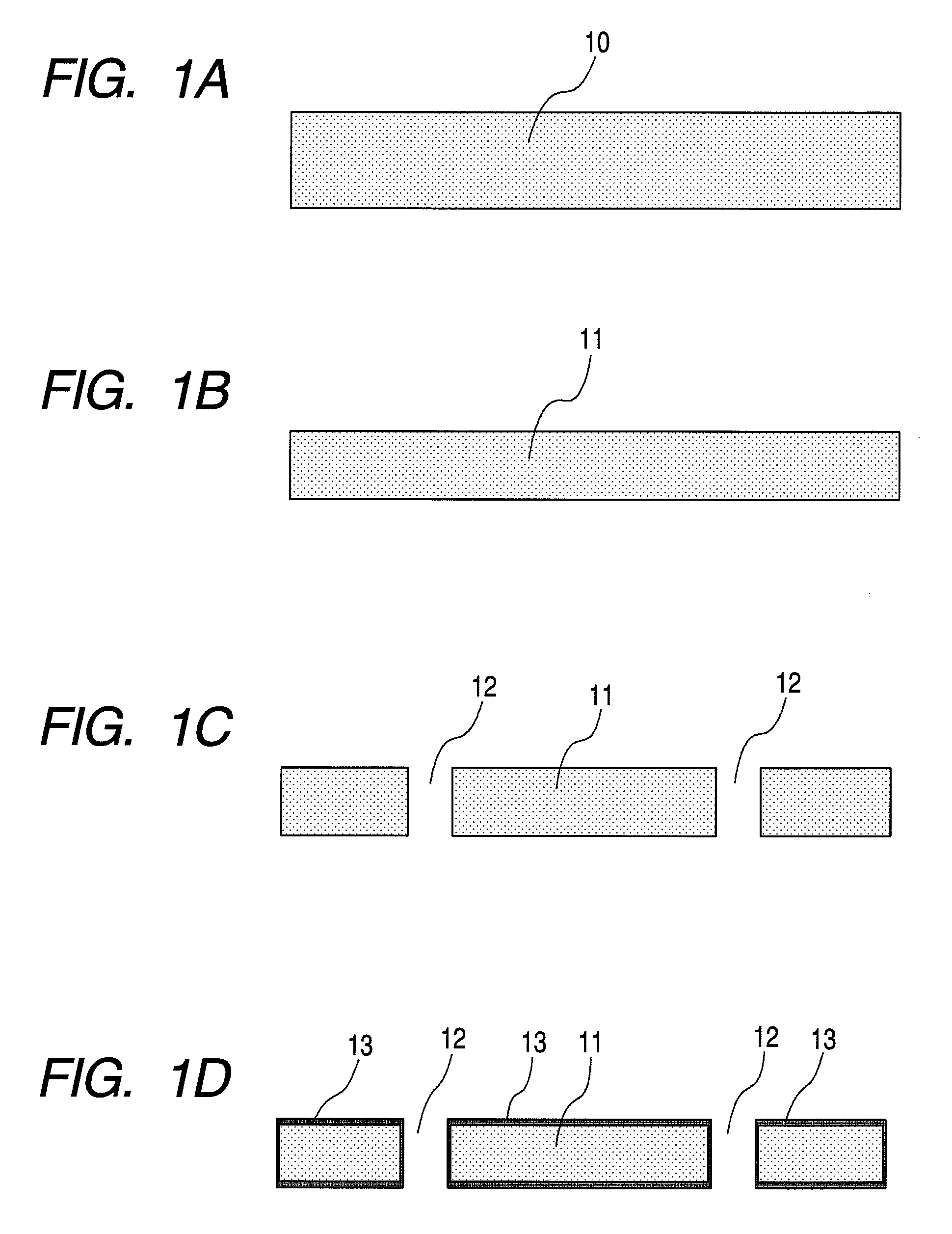

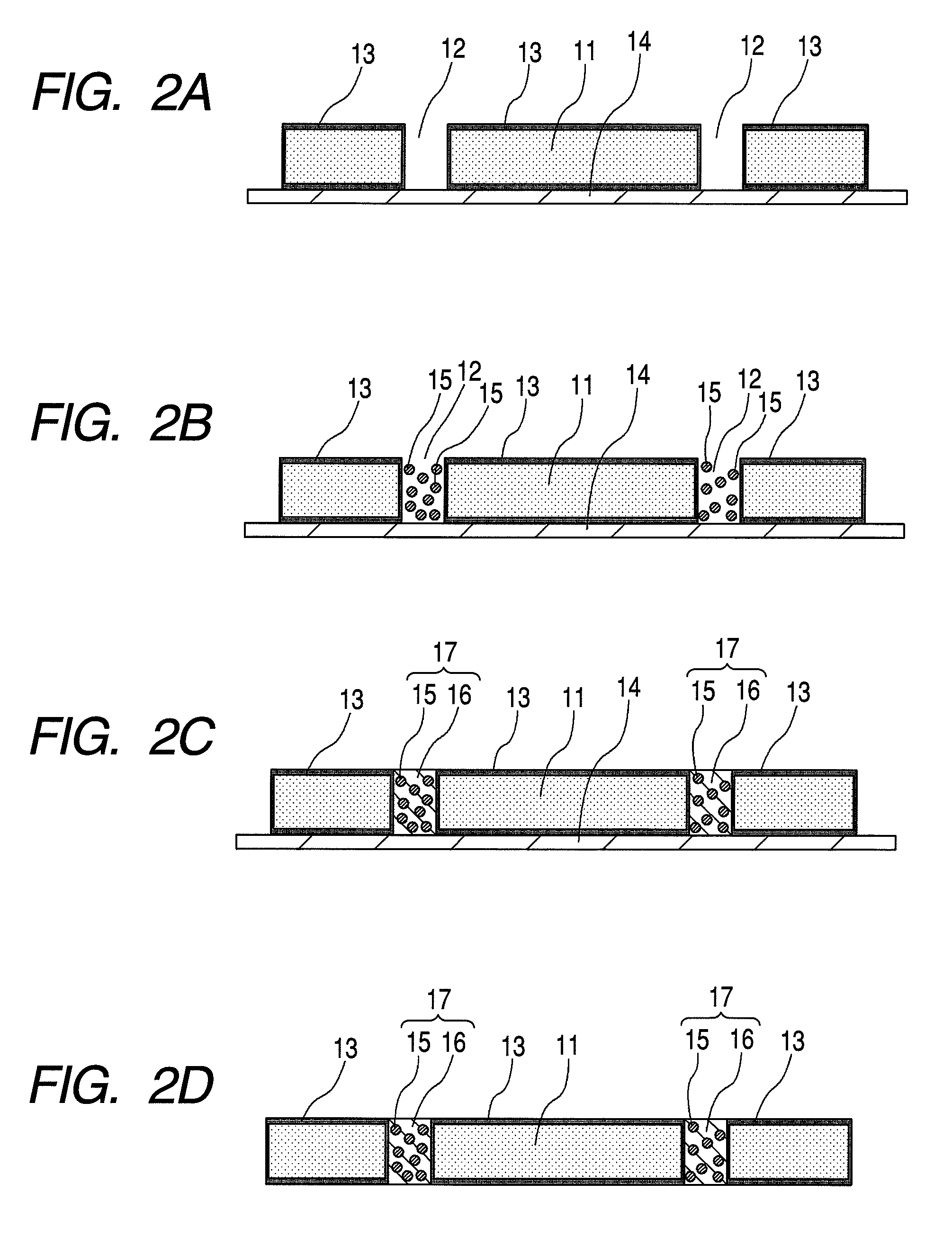

Silicon interposer producing method, silicon interposer and semiconductor device package and semiconductor device incorporating silicon interposer

ActiveUS7851359B2Low thermal expansionLow costSemiconductor/solid-state device detailsSolid-state devicesSilicon interposerConductive materials

A silicon interposer producing method comprising the steps of forming through holes 12 in a silicon wafer 11, forming an oxide coating 13 on the silicon wafer 11, providing a power feeding layer 14 for plating on one of the surfaces of the through holes 12, supplying a low thermal expansion filler 15 having a thermal expansion coefficient lower than the thermal expansion coefficient of the conductive material 16 of through-hole electrodes 17 to the through holes 12, filling the conductive material 16 into the through holes 12 by plating to form the through-hole electrodes 17, and removing the power feeding layer 14 for plating.

Owner:SHINKO ELECTRIC IND CO LTD

A method and electroplating tank for single-sided copper plating of wide-width stainless steel strip

The invention discloses a method for carrying out one-side copper plating on a wide stainless steel band and an electroplating bath. The method comprises the following steps: carrying out oil removal and activation on the pre-plating surface of the stainless steel band of a substrate; carrying out nickel pre-plating and general nickel plating on the activated pre-plating surface of the stainless steel band of the substrate, and carrying out copper plating in an alkaline cyanide-free plating solution; passivating and drying the copper-plated stainless steel band. The improved electroplating bath is adopted in the copper plating process, at least two transmission rotary rollers are hermetically mounted on two groove walls at a transmission inlet and a transmission outlet of the electroplating bath respectively, and the electroplating bath can be used for guaranteeing the liquid level of the bath and preventing a plated layer of the stainless steel band from being scratched and is especially suitable for continuous one-side copper plating of the wide band-shaped stainless steel band. The method is safe, environment-friendly, low in cost and capable of carrying out high-speed one-side copper plating on the wide stainless steel band; the one-side plated layer of the stainless steel band, prepared by the method, is uniform, bright and compact in surface, good in corrosion resistance, high in electric conductivity and excellent in stamping resistance, meets the requirements of electronics and military industry, and can be industrially produced.

Owner:HUNAN YONGSHENG NEW MATERIALS

Nickel-plated steel strip, steel battery case manufactured from the steel strip, and method of manufacturing the steel battery case

PendingCN109301094AAvoid problems prone to cracksRift issues improvedCell component detailsSurface layerAlloy

The invention relates to a nickel-plated steel strip, a steel battery case manufactured from the steel strip, and a method of manufacturing the steel battery case. In the invention, firstly, a pre-nickel-plating layer is formed on the inner surface of the steel strip; then through thermal treatment, a surface layer and a bottom Fe-Ni alloy layer are formed from the inter-permeated pre-nickel-plating layer and a contact surface, a part of the nickel-plating layer being reserved between the surface layer and the bottom Fe-Ni alloy layer, so that a problem that on the steel strip, during a steelcase stamping process, cracks are liable to generate in the plating layer is avoided; the surface layer and the bottom Fe-Ni alloy layer formed through the thermal treatment have compact structure, sothat not only is excellent anticorrosive performance achieved, but also the combining force between the Fe-Ni alloy layer and the Fe substrate is far higher than that between the plating layer and the Fe substrate in the prior art, so that by improving the combining force between the plating layer and the Fe substrate, the problem of forming cracks in the plating layer during the steel case stamping process is greatly solved, thus solving liquid leakage during long time storage of the battery. In addition, a part of the nickel-plating layer is reserved, thus preventing iron from dissolving out from the Fe-Ni alloy layer.

Owner:宁波堇山新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com