Printed circuit board and electrocoppering process thereof

A printed circuit board and copper electroplating technology, which is applied in the fields of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of great difficulty in breakthrough and little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

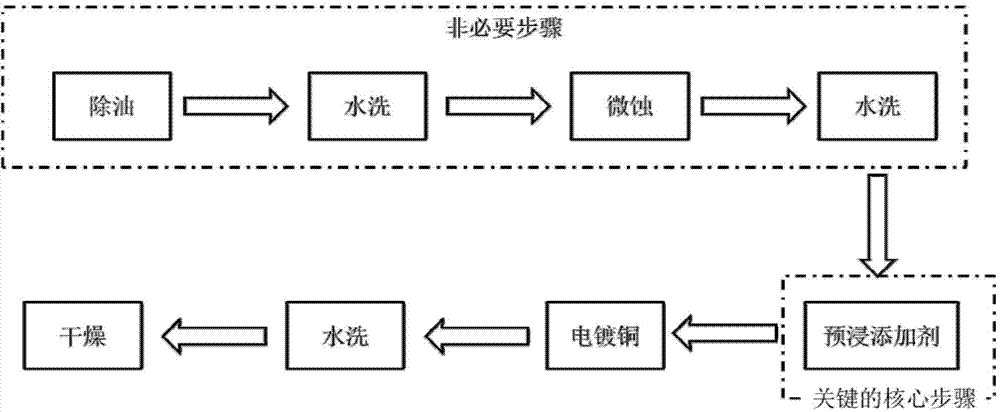

Method used

Image

Examples

Embodiment 1

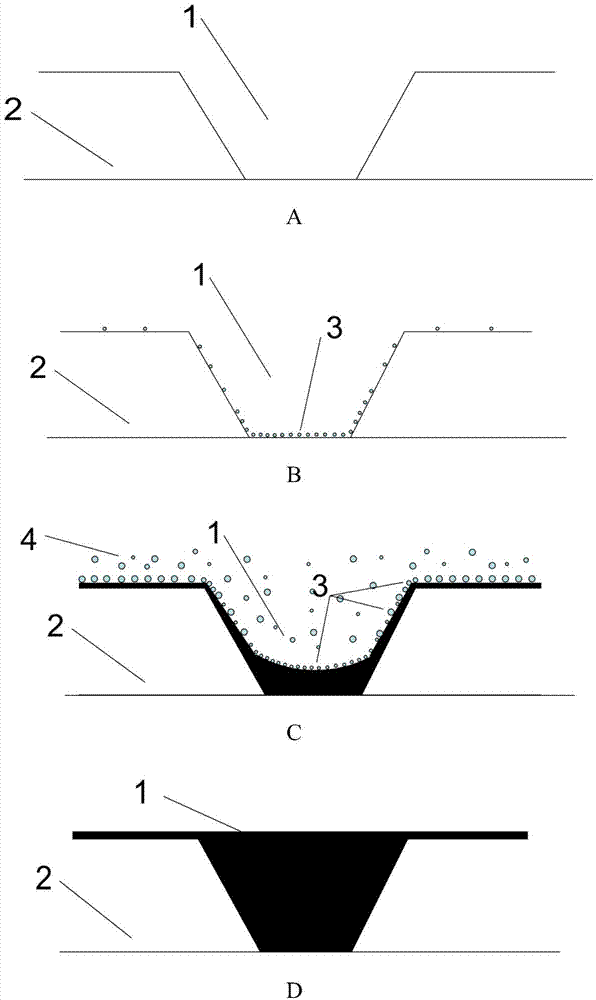

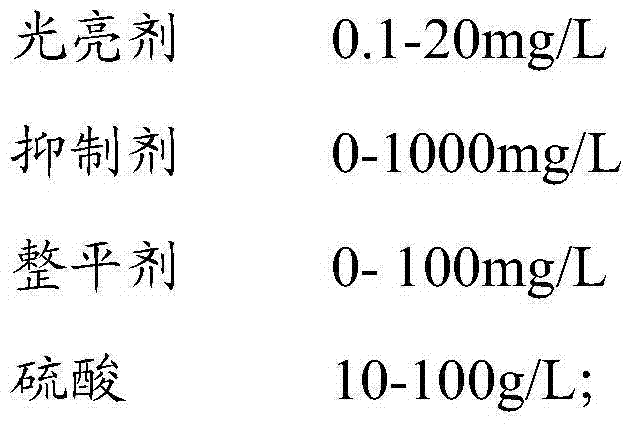

[0059] Use the method of laser ablation to make micro-blind holes with a diameter of 100 μm and an insulating layer thickness of 75 μm. After desmearing, surface adjustment, catalytic activation and electroless copper plating, pre-dip 5% by volume sulfuric acid aqueous solution for 1 min. Put it directly into the electroplating tank for electroplating. The components of the electroplating solution are:

[0060] Copper sulfate pentahydrate: 200g / L

[0061] Sulfuric acid: 60g / L

[0063] Hole filling brightener: 0.8mg / L

[0064] Pore filling inhibitor: 30mg / L

[0065] Hole filling and leveling agent: 6mg / L

[0066] Deionized water: balance

[0067] The electroplating current 1.5A / dm 3 , the electroplating temperature is 25°C, turn on the left and right swing and inflate, and the time is 60min. The thickness of the coating and the results of filling blind holes obtained in this embodiment are shown in Table 1.

Embodiment 2

[0069] Use the method of laser ablation to make micro-blind holes with a diameter of 100 μm and an insulating layer thickness of 75 μm. After desmearing, surface adjustment, catalytic activation and electroless copper plating, pre-dip 5% by volume sulfuric acid aqueous solution for 1 min. Then pre-plate a copper layer with a thickness of 5 microns in the pre-plating tank. After one week of storage, take out the plate and go through acid degreasing, cleaning, micro-etching, and then pre-soak 5% sulfuric acid aqueous solution for 1 min, and then directly put it into the electroplating tank. Perform electroplating.

[0070] The components of the pre-plating tank solution are:

[0071] Copper sulfate pentahydrate: 200g / L

[0072] Sulfuric acid: 60g / L

[0074] Pore filling inhibitor: 15mg / L

[0075] Deionized water: balance

[0076] The components of the electroplating solution are:

[0077] Copper sulfate pentahydrate: 200g / L

[0078] Sulfuri...

Embodiment 3

[0086] Use a mechanical numerical control machine to drill a through hole with a diameter of 0.25mm on the printed circuit copper clad substrate. The plate is Shengyi 36 / 1.6FR-4 double-sided copper clad sheet material, and the thickness to diameter ratio of the through hole is 6:1. After desmearing, surface adjustment, catalytic activation and electroless copper plating, it is pre-soaked in 5% by volume sulfuric acid aqueous solution for 1 min, and then directly put into the electroplating tank for electroplating.

[0087] The components of the electroplating solution are:

[0088] Copper sulfate pentahydrate: 70g / L

[0089] Sulfuric acid: 240g / L

[0091] VCP brightener: 0.4mg / L

[0092] VCP inhibitor: 8mg / L

[0093] VCP leveling agent: 2mg / L

[0094] Deionized water: balance

[0095] The electroplating current 3.0A / dm 3 , the electroplating temperature is 25°C, turn on the left and right swing and inflate, and the time is 50min. The analy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com