Rice processing and polishing process

A paddy and craft technology, which is applied in the field of paddy processing and polishing technology, can solve the problems of increased production cost, insufficient paddy luster, high broken grain rate, etc., and achieve the effect of increasing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

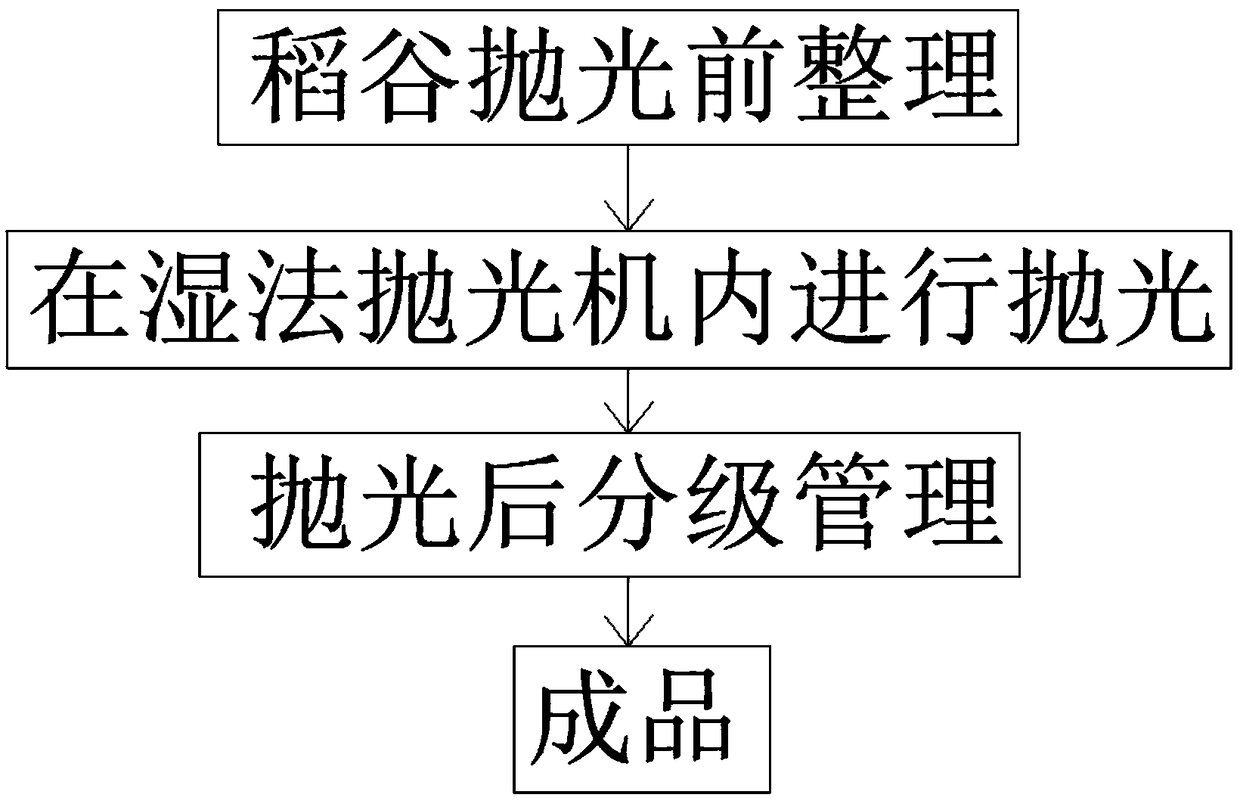

[0048] Such as figure 1 Shown, a kind of paddy processing polishing process, described concrete steps are as follows:

[0049] (1) Finishing before rice polishing: pick out the rice with more broken pieces, select the rice with less broken pieces and pour them into the polishing machine;

[0050] (2), polishing in the wet polishing machine: the rice is polished in the polishing chamber by means of water;

[0051] (3) Grading management after polishing: divide the rice into first, second and third grades;

[0052] (4) Finished product: pack the first-grade, second-grade and third-grade paddy separately.

[0053] In step (2), the wet polishing machine uses water to spray atomized water at high pressure: that is, an air compressor is used to generate atomized water, so that a thin water film is formed on the surface of the rice.

[0054] Step (2) When the wet polishing machine is polishing, the pressure of the polishing chamber is 50Mpa, and the pressure of the polishing chamb...

Embodiment 2

[0060] Such as figure 1 Shown, a kind of paddy processing polishing process, described concrete steps are as follows:

[0061] (1) Finishing before rice polishing: pick out the rice with more broken pieces, select the rice with less broken pieces and pour them into the polishing machine;

[0062] (2), polishing in the wet polishing machine: the rice is polished in the polishing chamber by means of water;

[0063] (3) Grading management after polishing: divide the rice into first, second and third grades;

[0064] (4) Finished product: pack the first-grade, second-grade and third-grade paddy separately.

[0065] In step (2), the wet polishing machine uses water to spray atomized water at high pressure: that is, an air compressor is used to generate atomized water, so that a thin water film is formed on the surface of the rice.

[0066] Step (2) When the wet polishing machine is polishing, the pressure of the polishing chamber is 40Mpa, and the pressure of the polishing chamb...

Embodiment 3

[0072] Such as figure 1 Shown, a kind of paddy processing polishing process, described concrete steps are as follows:

[0073] (1) Finishing before rice polishing: pick out the rice with more broken pieces, select the rice with less broken pieces and pour them into the polishing machine;

[0074] (2), polishing in the wet polishing machine: the rice is polished in the polishing chamber by means of water;

[0075] (3) Grading management after polishing: divide the rice into first, second and third grades;

[0076] (4) Finished product: pack the first-grade, second-grade and third-grade paddy separately.

[0077] In step (2), the wet polishing machine uses water to spray atomized water at high pressure: that is, an air compressor is used to generate atomized water, so that a thin water film is formed on the surface of the rice.

[0078] Step (2) When the wet polishing machine is polishing, the pressure of the polishing chamber is 60Mpa, and the pressure of the polishing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com