Through hole electroplating process for printed circuit board

A printed circuit board and through-hole electroplating technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of insufficient copper thickness in the hole, poor through-hole, uneven copper thickness from top to bottom, etc., to improve the electroplating effect, The effect of reducing plating time and increasing plating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

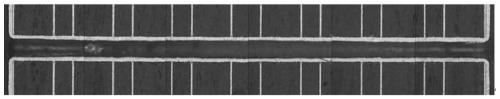

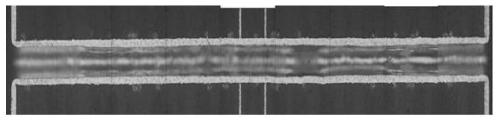

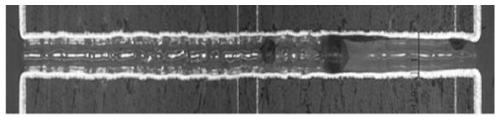

Image

Examples

Embodiment 1

[0056] Test sample: 10mm printed circuit board, the diameter of the through hole is 0.3mm.

[0057] Degreasing: Use the acid degreasing agent model 717 of MacDermid Technology (Suzhou) Co., Ltd. to degrease the printed circuit board. The operating temperature of degreasing is 54 ° C and the time is 3 minutes.

[0058] The operating concentration of the degreasing agent is 12%, and the solvent is deionized water.

[0059] Water washing: the printed circuit board was washed with flowing deionized water and mechanical shaking, the operating temperature of water washing was 25° C., and the washing time was 3 minutes.

[0060] It can be understood that the function of water washing is mainly to remove the acid degreaser on the printed circuit board, so as not to contaminate the subsequent potion.

[0061] Pre-soaking: the printed circuit board is pre-soaked using 10% sulfuric acid solution combined with a mechanical shaking and filtration circulation system. The operating temperat...

Embodiment 2

[0074] Test sample: 4.5mm printed circuit board with a through hole diameter of 0.2mm.

[0075] Degreasing: Use the acid degreasing agent model 717 of MacDermid Technology (Suzhou) Co., Ltd. to degrease the printed circuit board. The operating temperature of degreasing is 54 ° C and the time is 3 minutes.

[0076] The operating concentration of the degreasing agent is 12%, and the solvent is deionized water.

[0077] Water washing: the printed circuit board was washed with flowing deionized water and mechanical shaking, the operating temperature of water washing was 25° C., and the washing time was 3 minutes.

[0078] It can be understood that the function of water washing is mainly to remove the acid degreaser on the printed circuit board, so as to avoid subsequent contamination of subsequent potions.

[0079] Pre-soaking: the printed circuit board is pre-soaked using 10% sulfuric acid solution combined with a mechanical shaking and filtration circulation system. The operati...

Embodiment 3

[0093] Test sample: 4.5mm printed circuit board, the hole diameter of the through hole is 0.25mm.

[0094] Degreasing: Use the acid degreasing agent model 717 of MacDermid Technology (Suzhou) Co., Ltd. to degrease the printed circuit board. The operating temperature of degreasing is 54 ° C and the time is 3 minutes.

[0095] The operating concentration of the degreasing agent is 12%, and the solvent is deionized water.

[0096] Water washing: the printed circuit board was washed with flowing deionized water and mechanical shaking, the operating temperature of water washing was 25° C., and the washing time was 3 minutes.

[0097] It can be understood that the function of water washing is mainly to remove the acid degreaser on the printed circuit board, so as to avoid subsequent contamination of subsequent potions.

[0098] Pre-soaking: the printed circuit board is pre-soaked using 10% sulfuric acid solution combined with a mechanical shaking and filtration circulation system. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com