Long-ageing reusable plating assistant agent for zinc-aluminum-magnesium alloy for hot dipping

A hot-dip galvanizing and aluminum-magnesium alloy technology, which is applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of short effective time of plating flux, non-reusable, poor bonding strength, etc. Achieve the effect of promoting environmental protection characteristics, reducing hazards, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Hot-dip galvanizing-22% aluminum-2% magnesium alloy plating formulation, the components are as follows:

[0032] ZnCl 2 25%; KF2%; CaCl 2 5%; AgCl4.5%; non-alkali SP binary composite flooding and dispersing agent 2% (a mixture of propylene glycol methyl ether acetate and methoxy propionate, mass ratio 1:1); composite surfactant 0.1% (six A mixture of methyldisilazane and sodium polyoxypropylene ether chain hydrophobic sulfonate, the mass ratio is 1:1), and the rest is water.

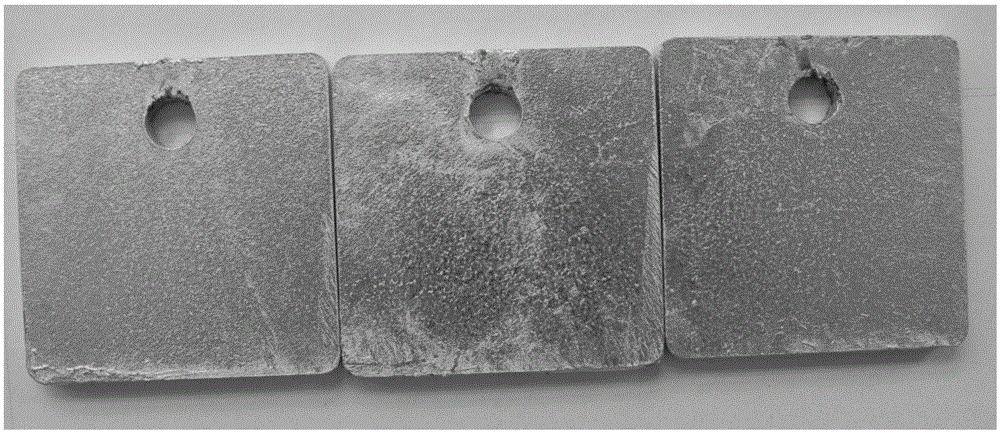

[0033] After degreasing, pickling, and alkali cleaning, the iron and steel substrate is immersed in the plating flux described at 65°C at a speed of 10m / min, dried at 120°C, and then hot-dipped in a zinc-aluminum-magnesium alloy solution for 0.4 min, after cooling, the surface of the iron and steel substrate has no missing plating, the coating is uniform, and the finish is good (attached figure 1 shown). The thickness of the coating is about 75-125μm. The results of the neutral salt spray test...

Embodiment 2

[0035] Hot-dip galvanizing-20% aluminum-2.5% magnesium alloy plating formulation, the components are as follows:

[0036] ZnCl 2 28%; KF6%; CaCl 2 8%; AgCl6.0%; non-alkali SP binary composite flooding and dispersing agent 2.5% (a mixture of propylene glycol methyl ether acetate and methoxy propionate, mass ratio 1:2); composite surfactant 3.5% (six A mixture of methyldisilazane and sodium polyoxypropylene ether chain hydrophobic sulfonate, the mass ratio is 1:2), and the rest is water.

[0037] After degreasing, pickling, and alkali cleaning, the iron and steel substrate is immersed in the plating flux described at 65°C at a speed of 10m / min, dried at 120°C, and then hot-dipped in a zinc-aluminum-magnesium alloy solution for 0.4 min, after cooling, the surface of the iron and steel substrate has no missing plating, the coating is uniform, and the finish is good. The thickness of the coating is about 85-120μm, and the results of the neutral salt spray test show that the time...

Embodiment 3

[0039] Hot-dip galvanizing-15% aluminum-3% magnesium alloy coating formulation, the components are as follows:

[0040] ZnCl 2 28%; KF6%; CaCl 2 10%; AgCl6.5%; non-alkali SP binary composite flooding and dispersing agent 2.5% (a mixture of propylene glycol methyl ether acetate and methoxy propionate, mass ratio 2:1); composite surfactant 0.3% (six A mixture of methyldisilazane and sodium polyoxypropylene ether chain hydrophobic sulfonate, the mass ratio is 1:1), and the rest is water.

[0041] After degreasing, pickling, and alkali cleaning, the iron and steel substrate is immersed in the plating flux described at 85°C at a speed of 12m / min, dried at 100°C, and then hot-dipped in a zinc-aluminum-magnesium alloy solution for 0.6 min, after cooling, the surface of the iron and steel substrate has no missing plating, the coating is uniform, and the finish is good. The thickness of the coating is about 90-140μm. The results of the neutral salt spray test show that the time for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com