Yoke product and preparation method thereof

A product and technology of yoke, applied in mechanical equipment, coating, hot-dip plating process, etc., can solve problems such as poor adhesion, zinc layer peeling, etc., achieve good wettability, high coating performance, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The objects and functions of the present invention and methods for achieving the objects and functions will be clarified below by referring to the exemplary embodiments.

[0022] In the present invention, the yoke product is prepared by a method comprising the following steps: roll forging billet → forging forming → magnetic particle inspection → mechanical processing → hot-dip galvanizing; and the steps do not include quenching and tempering treatment.

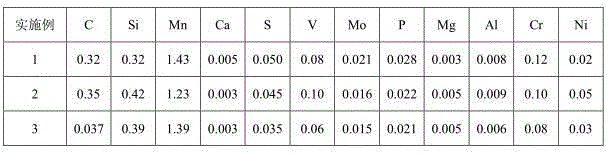

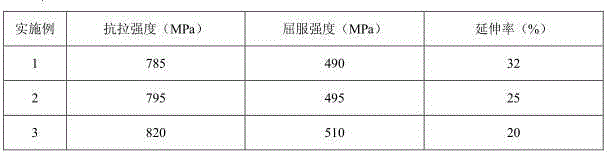

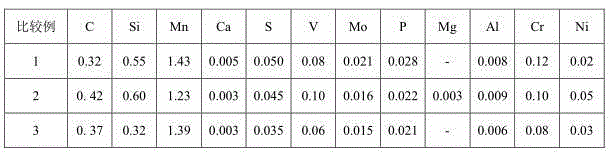

[0023] Among them, the material used in the yoke product is non-quenched and tempered free-cutting steel, and its element composition and weight percentage are: C: 0.32~0.39wt%, Si: 0.30~0.50wt%, Mn: 1.00~1.50wt%, S: 0.035~0.050 wt%, Ca: 0.002~0.005 wt%, Mg: 0.002~0.005 wt%, V: 0.06~0.13 wt%, Mo: 0.015~0.025wt%, P≤0.035wt%, Cr≤0.30wt% %, Ni≤0.30wt%, Cu≤0.25wt%, Al≤0.01wt%, Nb≤0.01wt%, Ti≤0.01wt%, the balance is Fe and unavoidable impurities. The non-quenched and tempered free-cutting steel is smelted in an electric fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com