Rotary type automatic discharge electroplating rolling barrel

A technology for automatic unloading and electroplating barrels, applied in the electrolysis process, electrolytic components, etc., can solve the problems affecting the smooth automatic continuous operation of barrel plating production lines, increase labor costs for barrel covers, and increase maintenance costs for plating solutions. Electrochemical efficiency, simple structure, effect of reducing plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

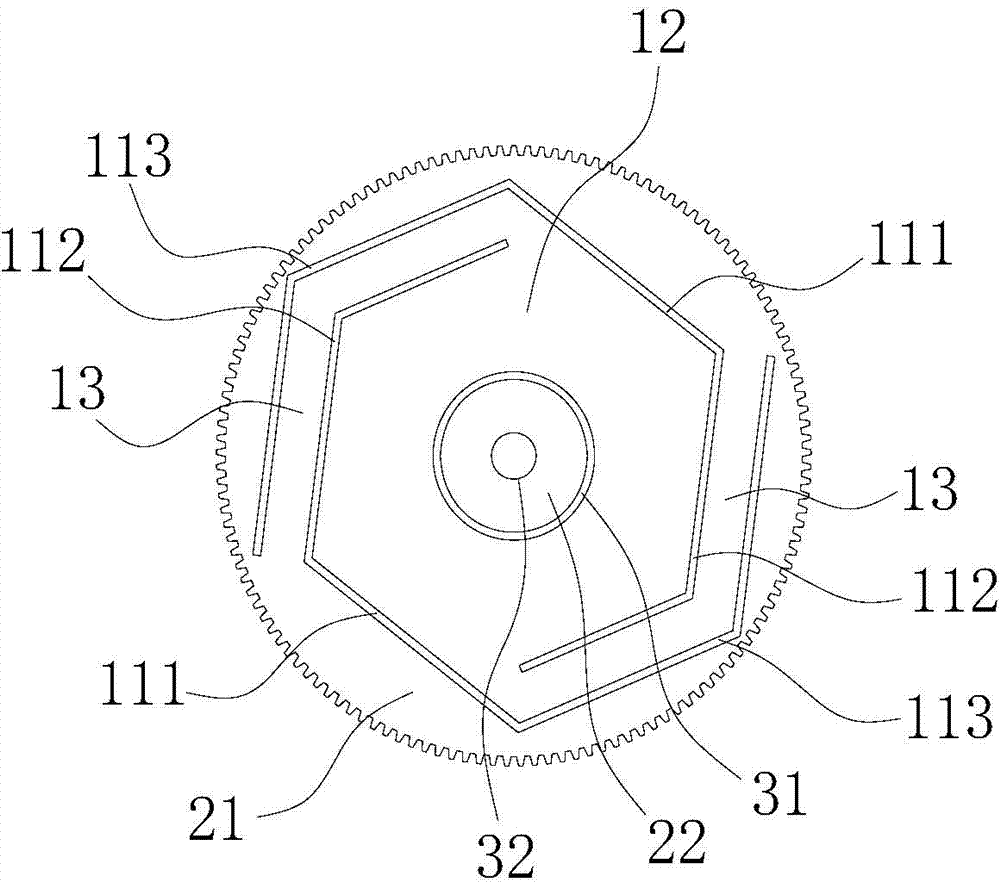

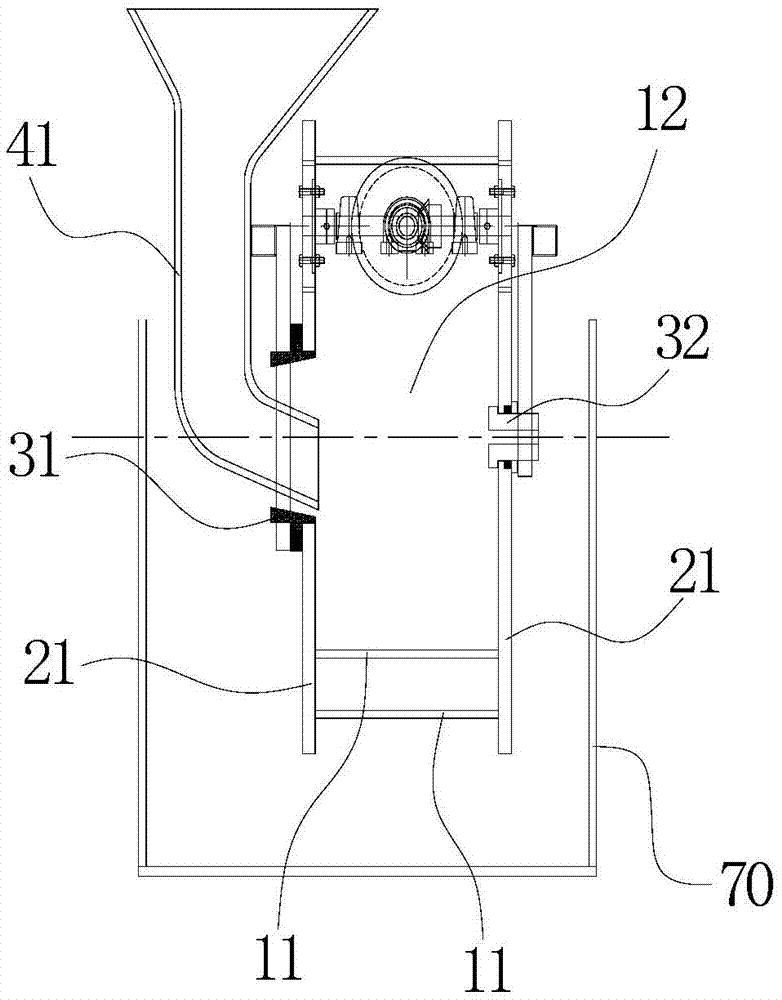

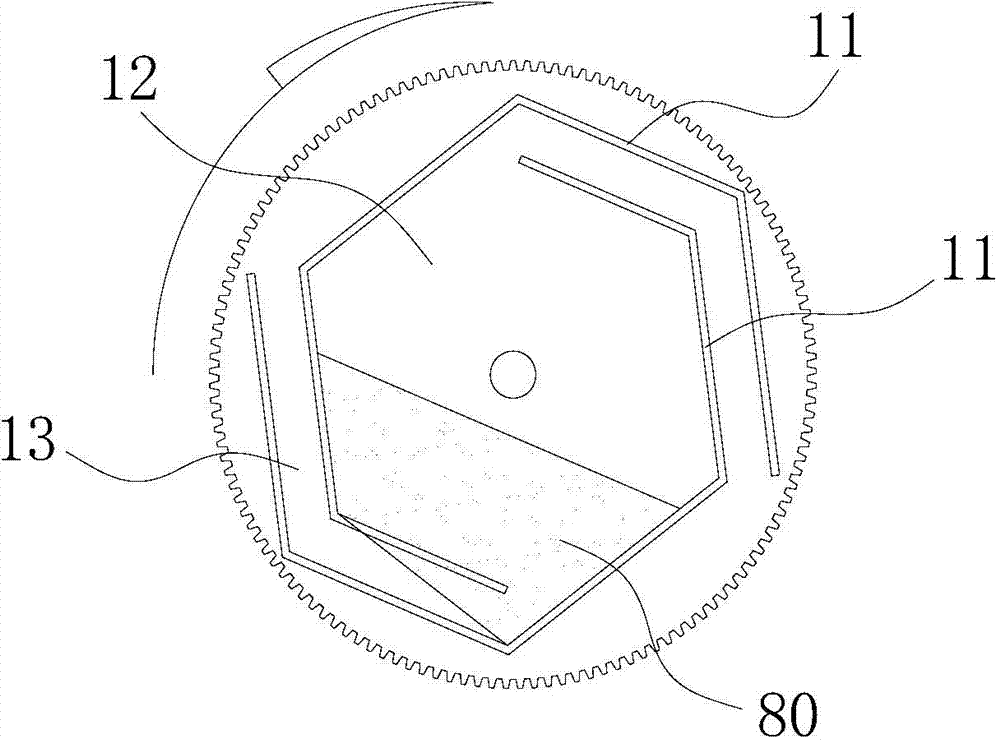

[0025] see figure 1 and figure 2 , the present invention discloses a rotary automatic unloading electroplating barrel, which includes a barrel body, a barrel cover and a rotating shaft. The barrel body is composed of two baffles 11 with a C-shaped cross-section and an opening. Each baffle 11 each includes a bottom wall 111 opposite to its opening, an inner side wall 112 and an outer side wall 113 respectively connected to both sides of the bottom wall 111. The directions facing each other are misaligned, and the electroplating cavity 12 is formed between the bottom wall 111 and the inner side wall 112 of the two baffle plates 11, and the discharge material is formed between the inner side wall 112 of one baffle plate 11 and the outer side wall 113 of the other baffle plate 11. Groove 13, discharge groove 13 communicates with electroplating cavity 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com