Patents

Literature

1395results about How to "Avoid overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

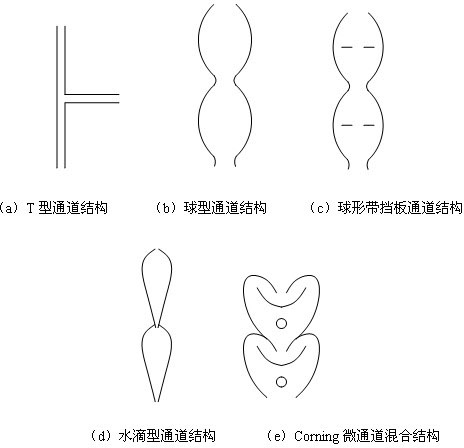

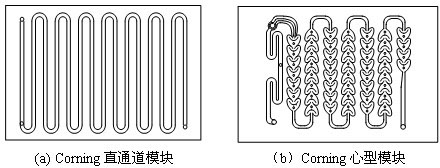

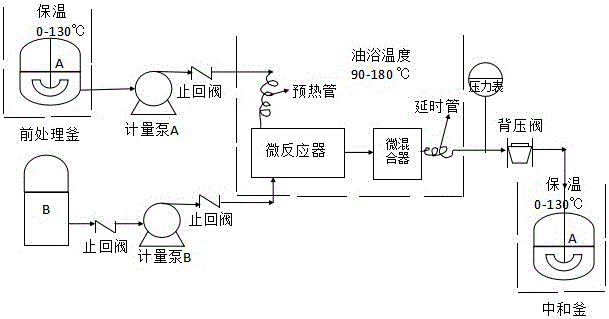

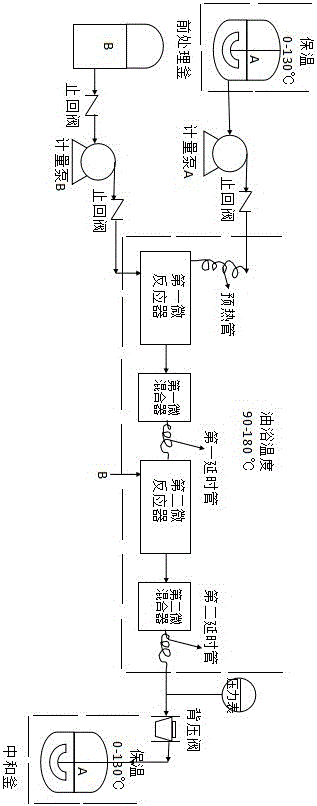

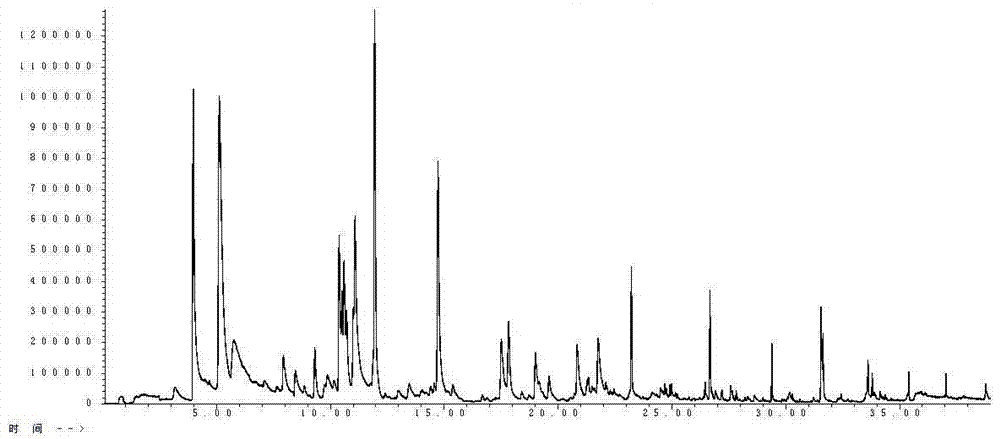

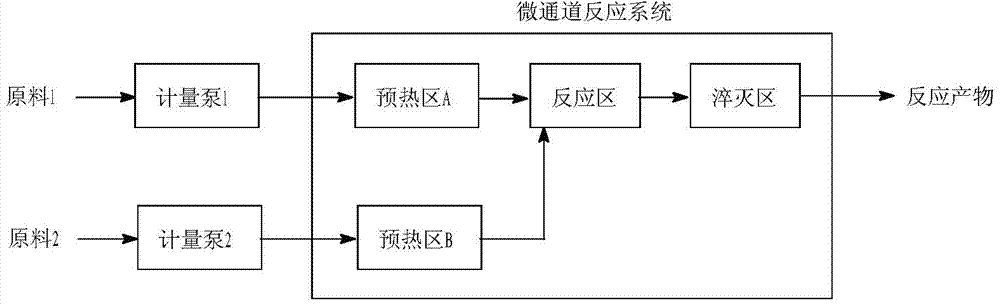

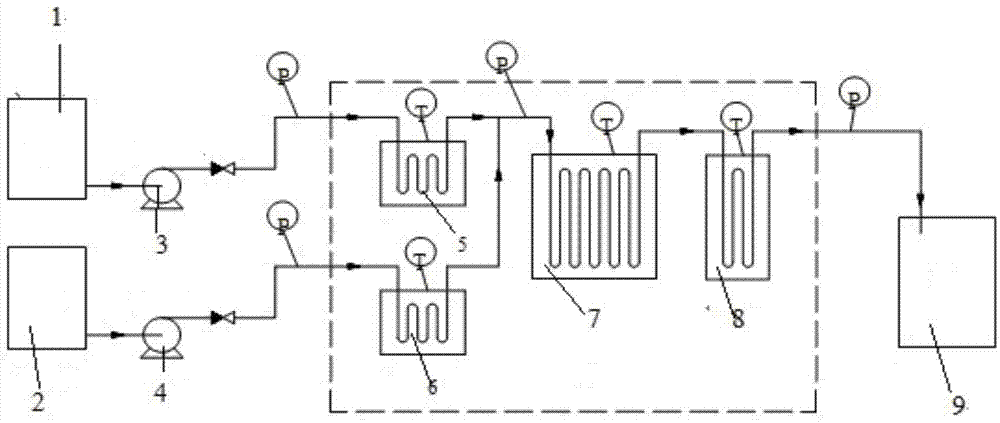

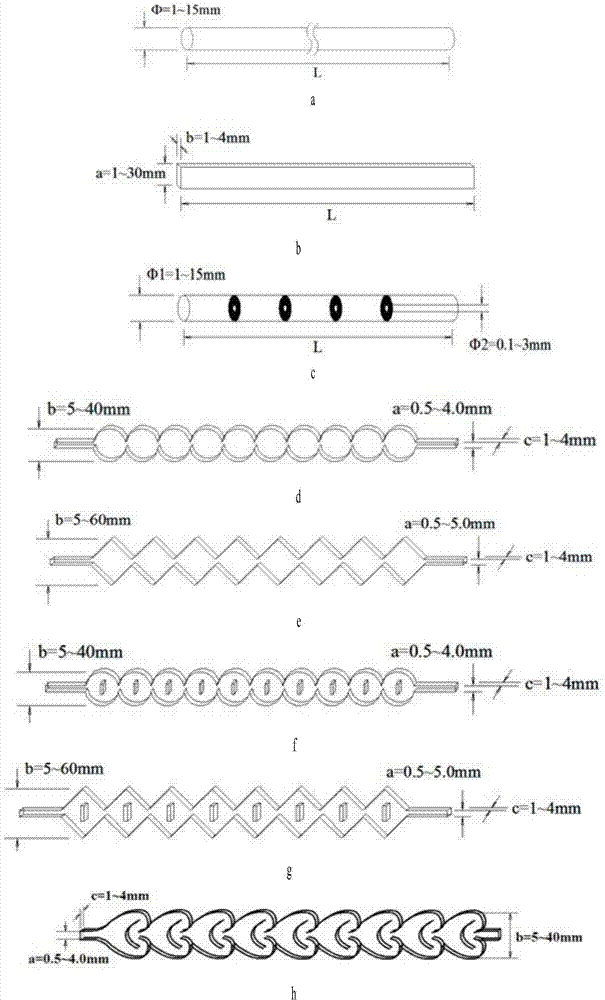

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

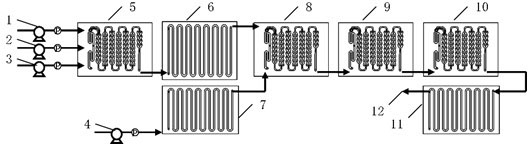

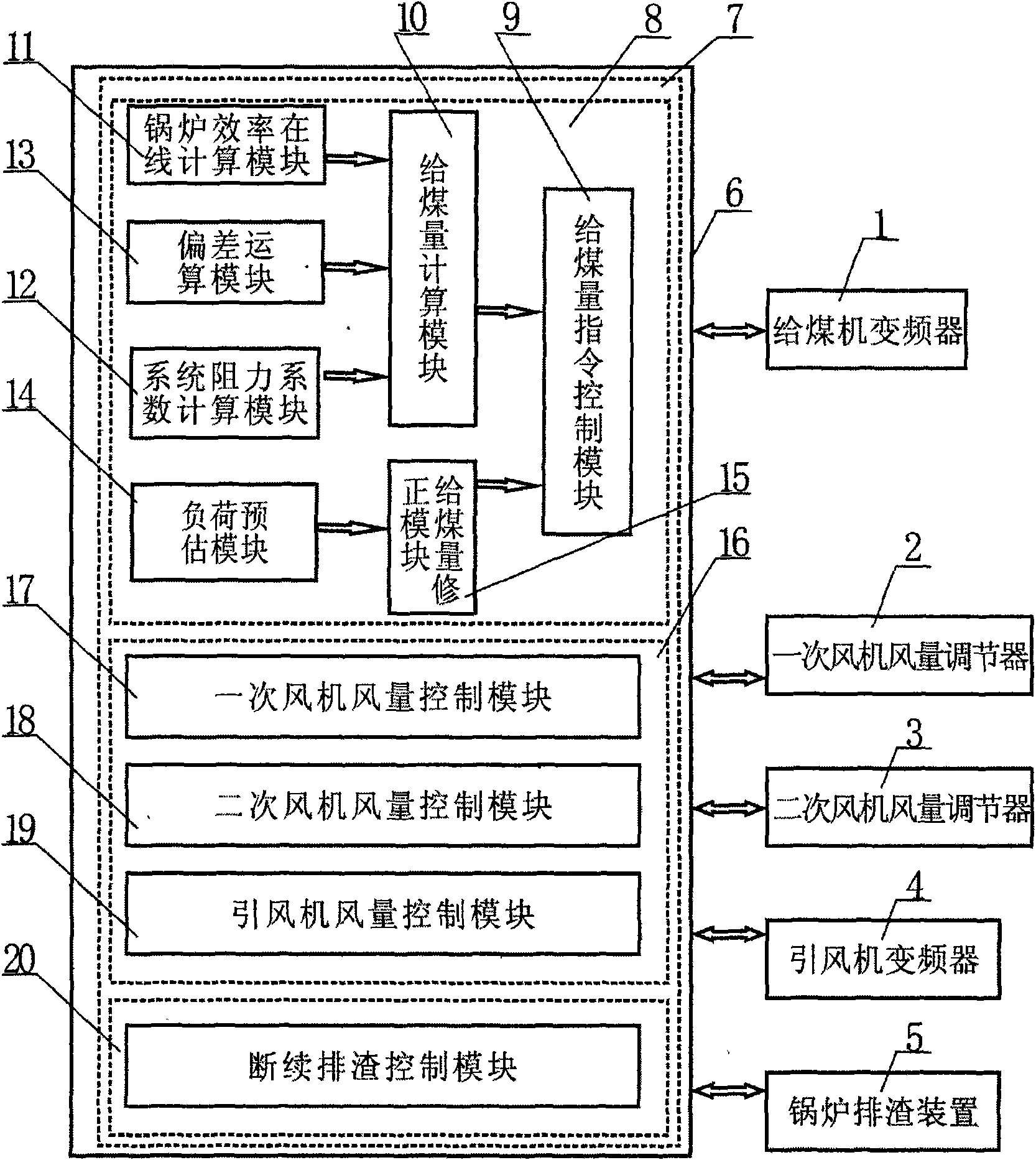

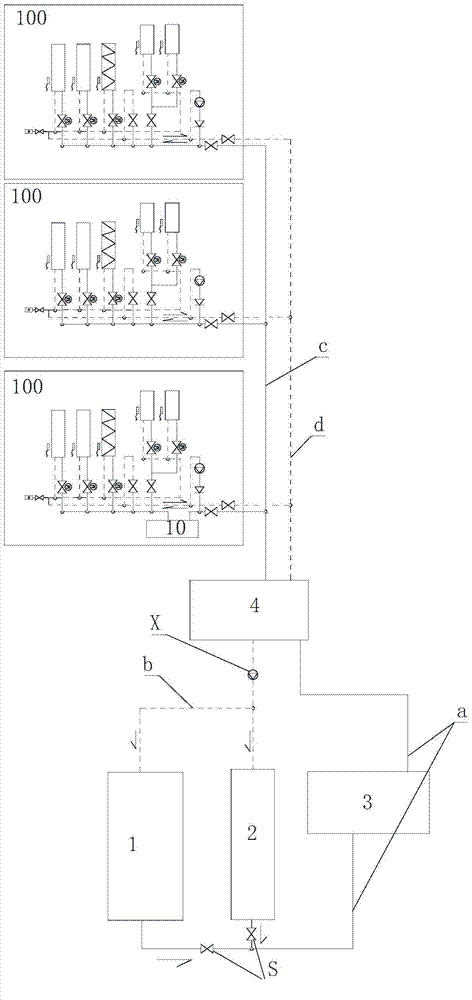

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

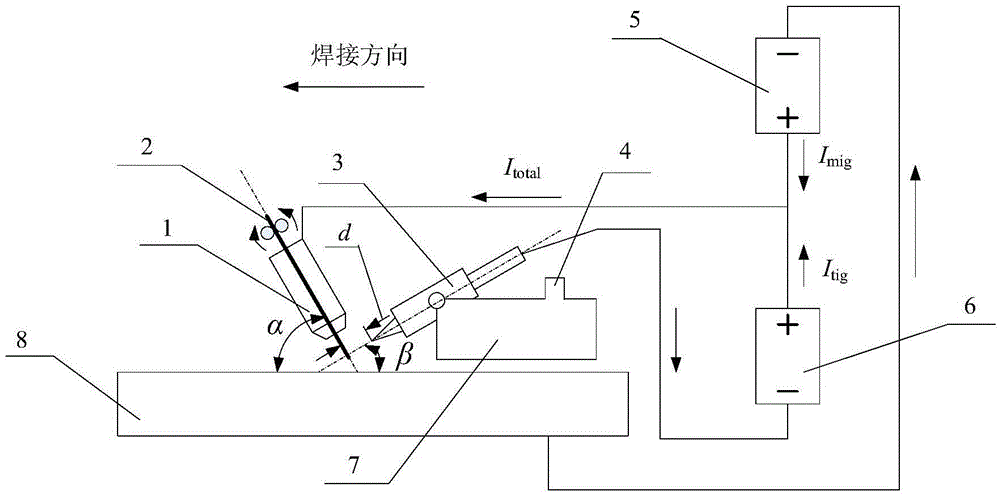

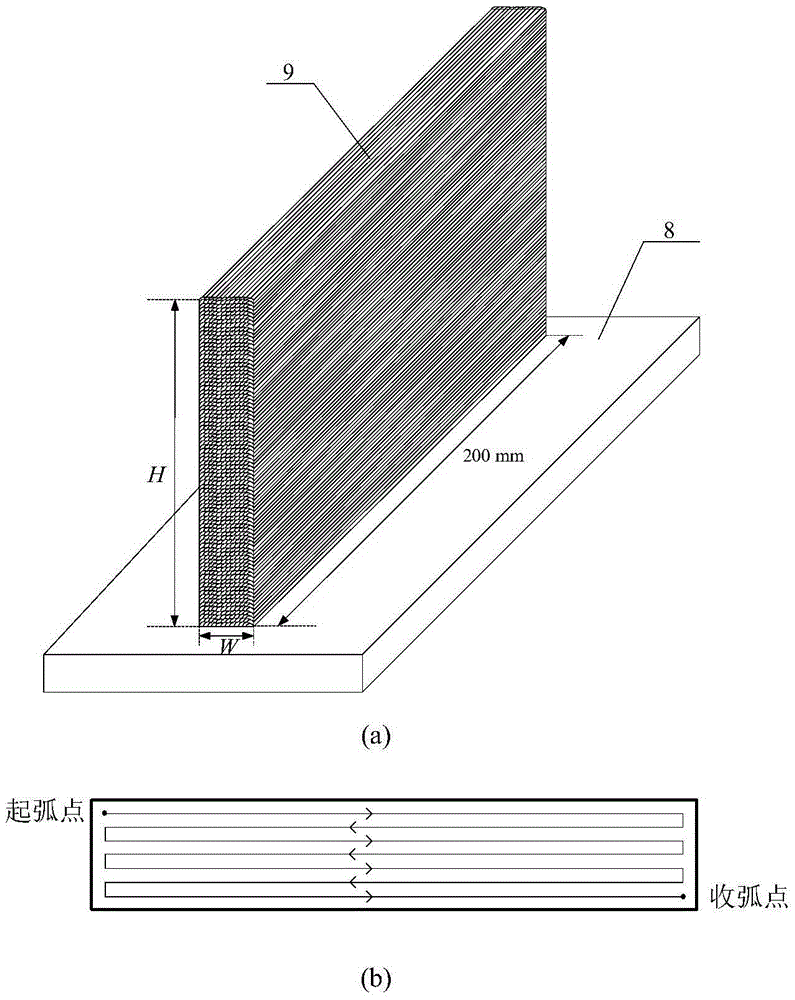

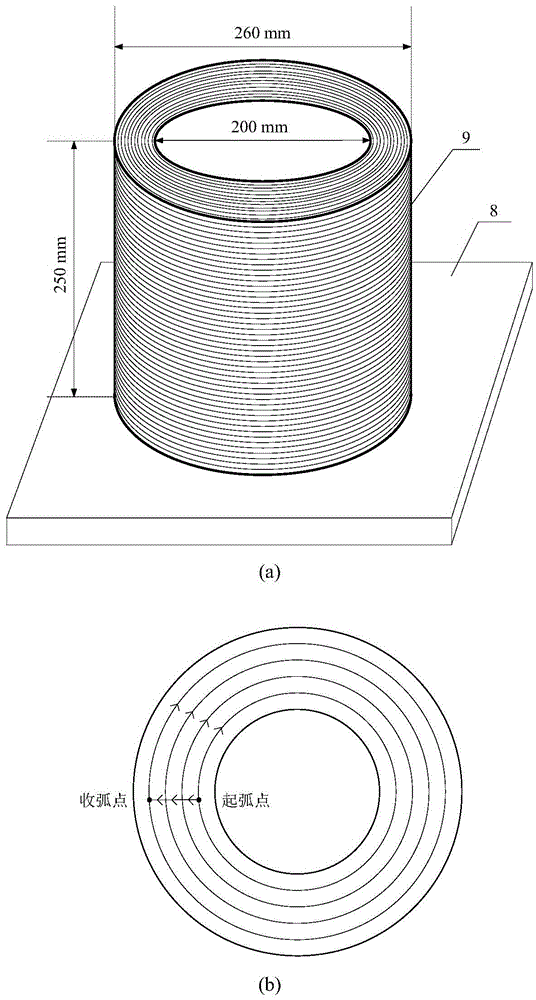

Material increase manufacturing method for titanium alloy shape part by using double-arc hybrid heat source

InactiveCN105458470AImprove deposition rate and welding speedAvoid overheatingArc welding apparatusWelding/soldering/cutting articlesElectric arcPower flow

The invention relates to a material increase manufacturing method for a titanium alloy shape part by using a double-arc hybrid heat source. The method comprises the following steps: MIG welding and TIG welding are originally combed, a welding wire as a melting electrode is sent out by an MIG welding gun and is subjected to surfacing on a base plate; an MIG power anode is connected with a TIG power anode, and an MIG power cathode is connected with the base plate, the MIG welding gun is connected with the MIG power anode, and a TIG welding gun is connected with a TIG power cathode; the MIG welding gun is in the front, and the TIG welding gun is in the back; the current of the welding wire is shunted through a TIG welding circuit, so that the current passing through the welding wire is large, and the current passing through a weldment is small. After the base plate completes a first surfacing layer, a hybrid welding gun is increased by a story height, and a second layer of shape part is welded; the above process is repeated, so that the titanium alloy shape part is formed by overlaying plurality of surfacing layer. The method has the advantages of being high in metal deposition rate, high in welding speed, less in weldment heat input, good in structural and mechanical properties of the shape part and low in cost and solves the problems of lager heat input, low welding speed, poor welding quality and low efficiency during material increase manufacturing of the traditional titanium alloy single TIG arc wire feeding.

Owner:JIANGSU UNIV OF SCI & TECH

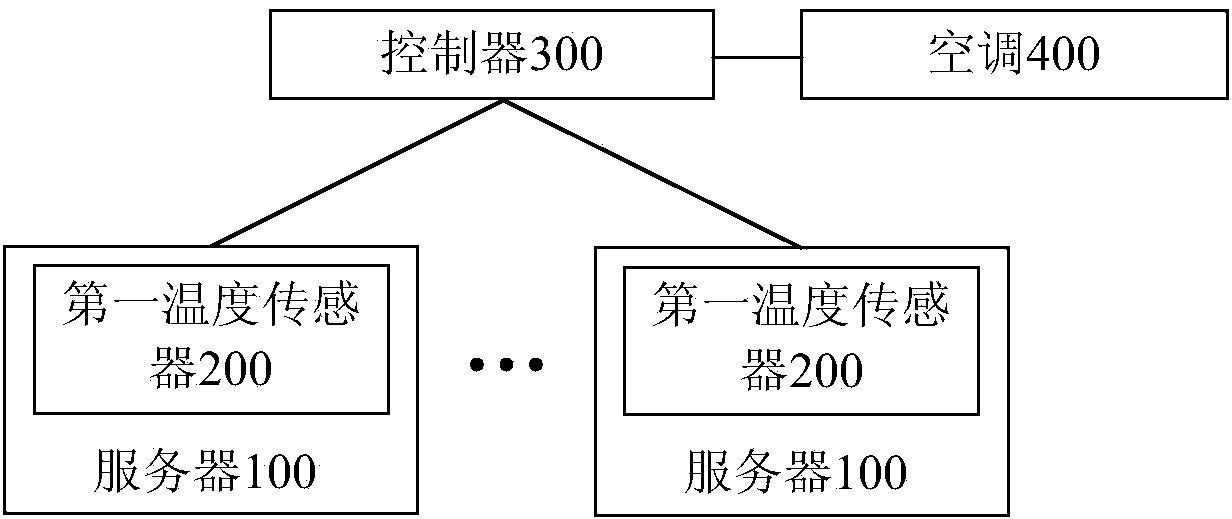

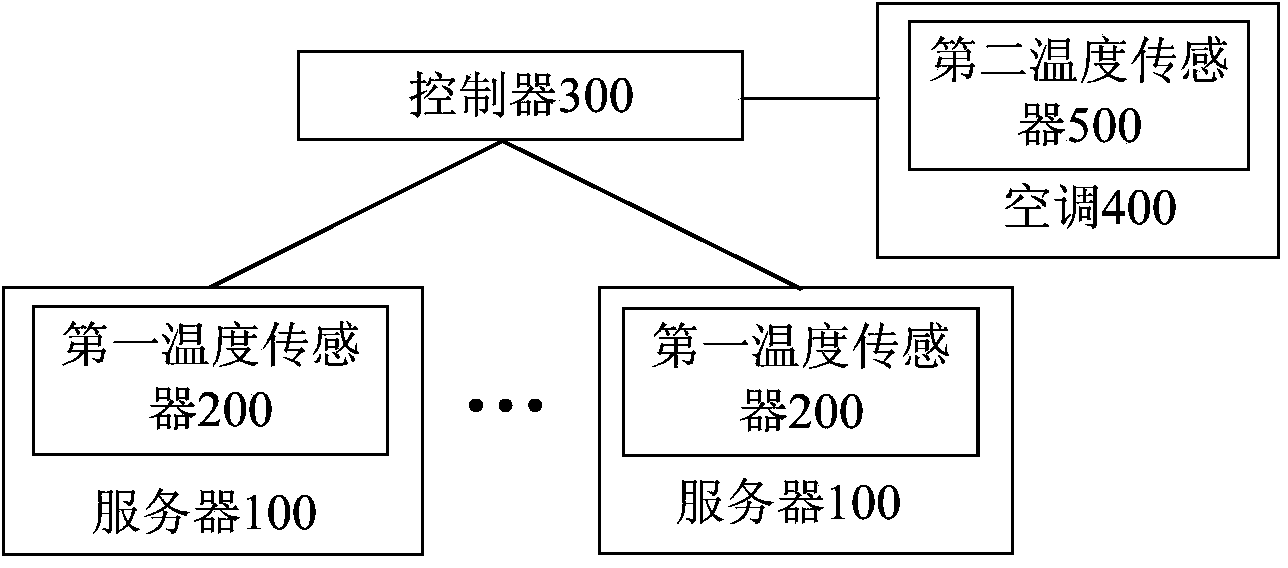

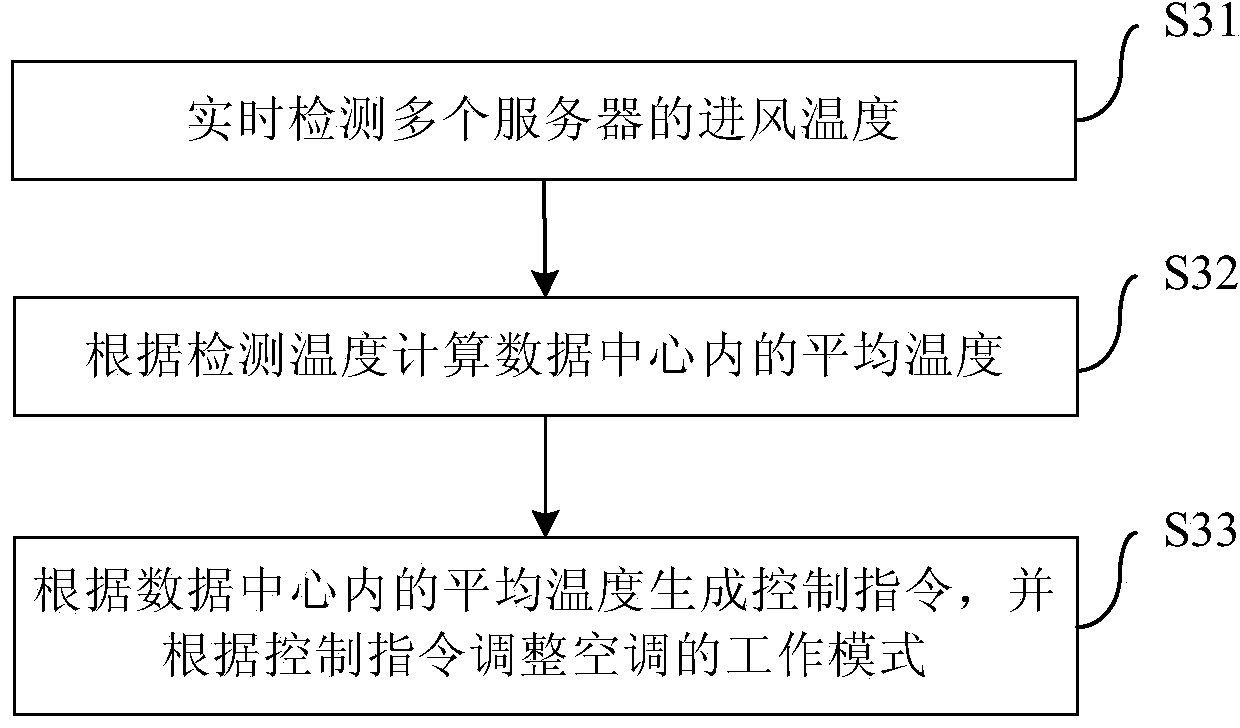

Refrigeration control system and method for data center

ActiveCN103644632ALow failure rateAvoid interventionProgramme controlMechanical apparatusInlet temperatureEngineering

The invention provides a refrigeration control system and method for a data center. The system comprises a plurality of servers, a plurality of first temperature sensors, a controller and an air conditioner, wherein the plurality of first temperature sensors are mounted at air inlets of the plurality of servers and used for detecting air inlet temperatures of the plurality of servers in real time; the controller is used for receiving the detection temperatures sent by the plurality of first temperature sensors, calculating an average temperature in a data center according to the detection temperatures, and generating a control command according to the average temperature in the data center; and the air conditioner is sued for receiving the control command sent by the controller, and adjusting the working mode according to the control command. According to the system provided by the embodiment of the invention, on the premise that the cooling requirement safety of the servers is met, excessive refrigeration caused by an excessively cautious refrigeration control strategy as well as overheating of local servers caused by an excessively radical refrigeration control strategy can be avoided, and the refrigeration energy consumption and service failure rate are reduced greatly.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

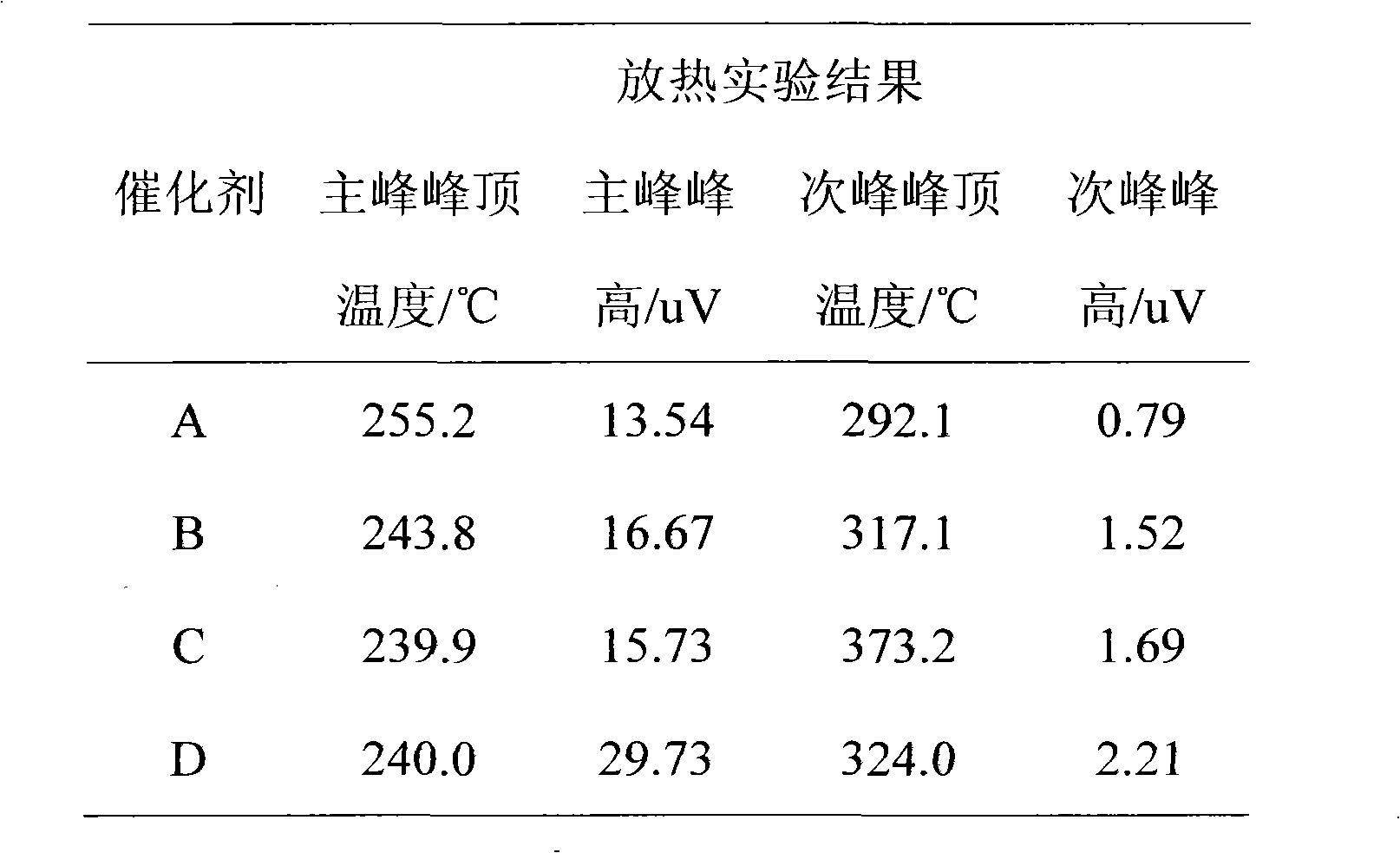

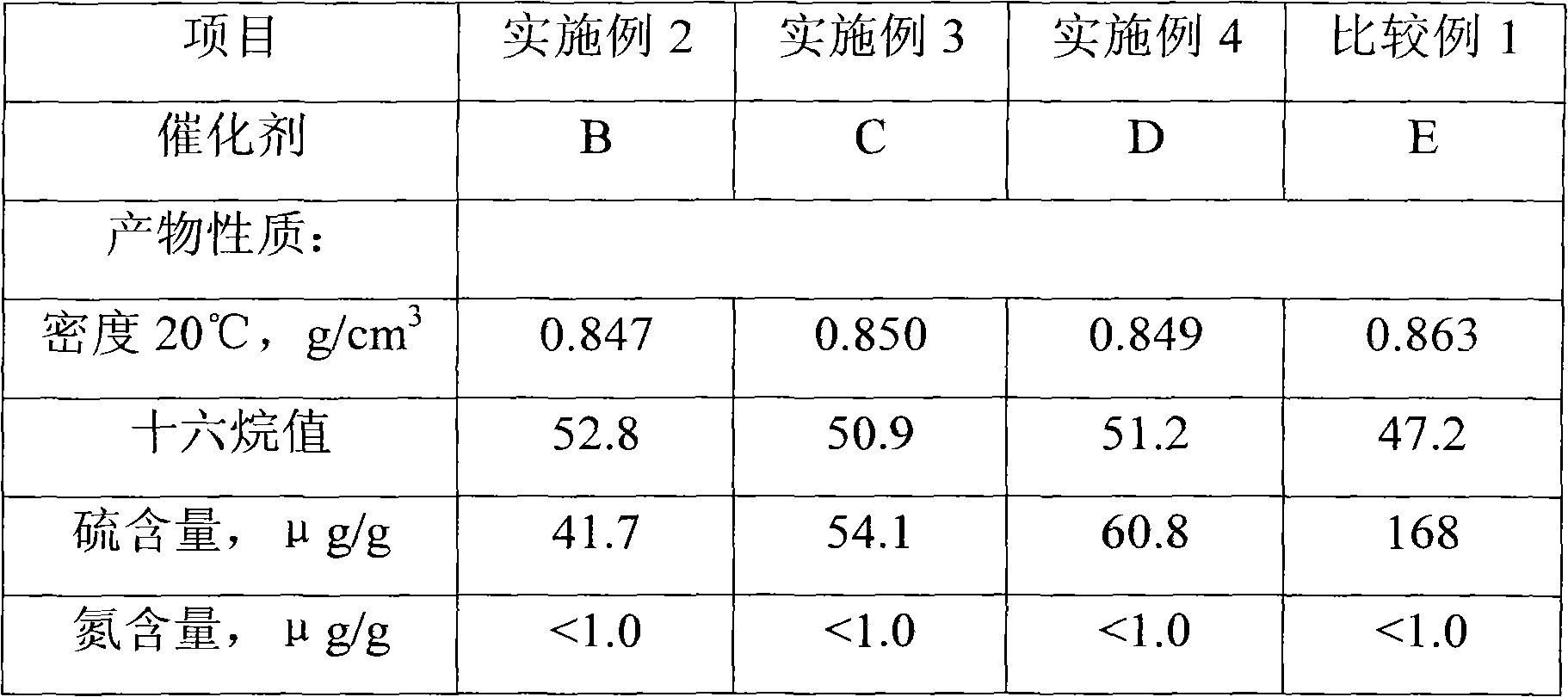

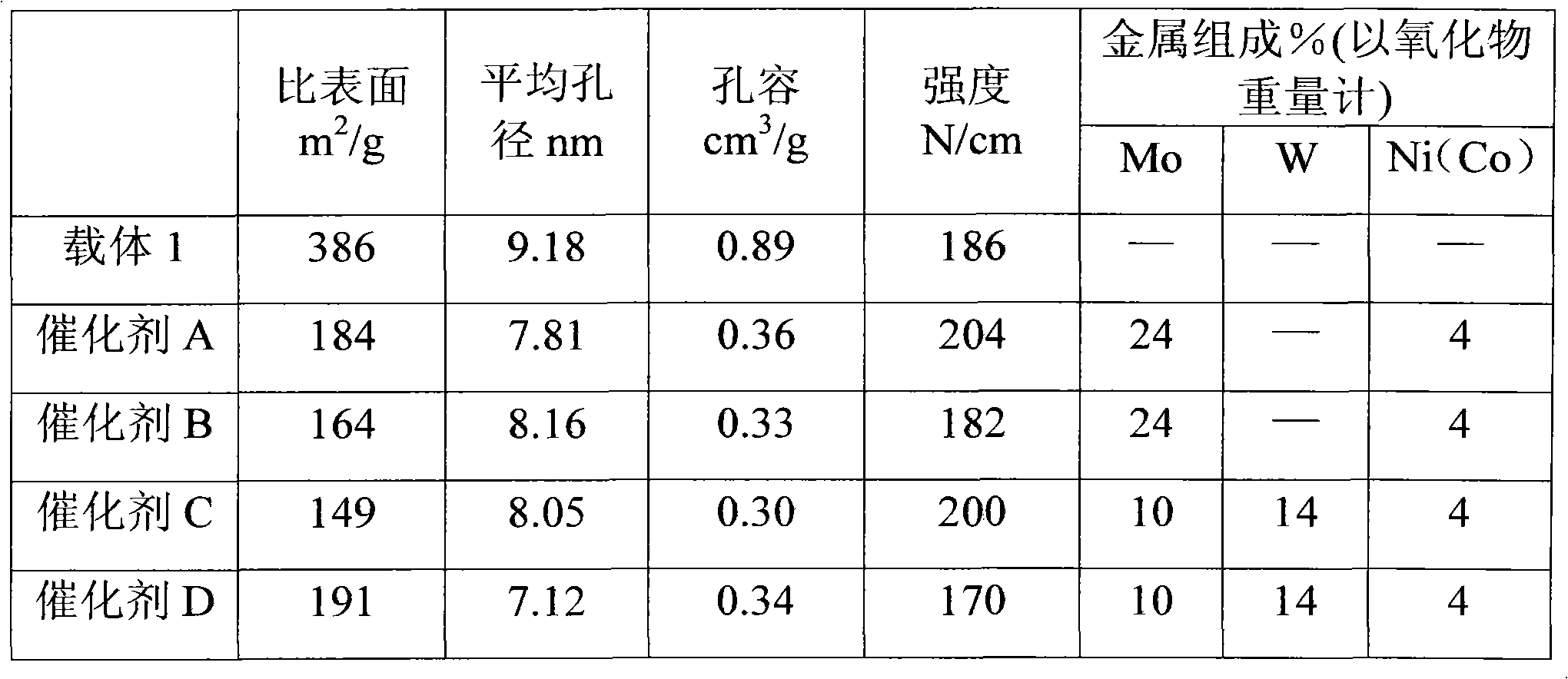

Preparation method of vulcanized catalyst

ActiveCN102039147AReduce manufacturing costSimple production processPhysical/chemical process catalystsActive phasePetroleum

The invention relates to a preparation method of a vulcanized catalyst, comprising the following steps: dipping a required catalyst carrier by a dipping solution, and drying to obtain the vulcanized catalyst, wherein the dipping solution contains a sulfide precursor of metal Mo or W, an inorganic salt of Ni or Co and an organic auxiliary. The auxiliary is added into the dipping solution, thereby reducing the phenomenon of centralized heat emission during the start working procedure. The method in the invention has simple preparation process, inert gas protection is not required during the preparation procedure, category-II active phases with high catalytic activity are easy to form, and the usability of the catalyst is high. The catalyst prepared according to the method in the invention is suitable for the preparation of petroleum fraction hydrogenation catalysts, and the hydrogenation activity of the catalyst prepared by the method is higher than that of a conventional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

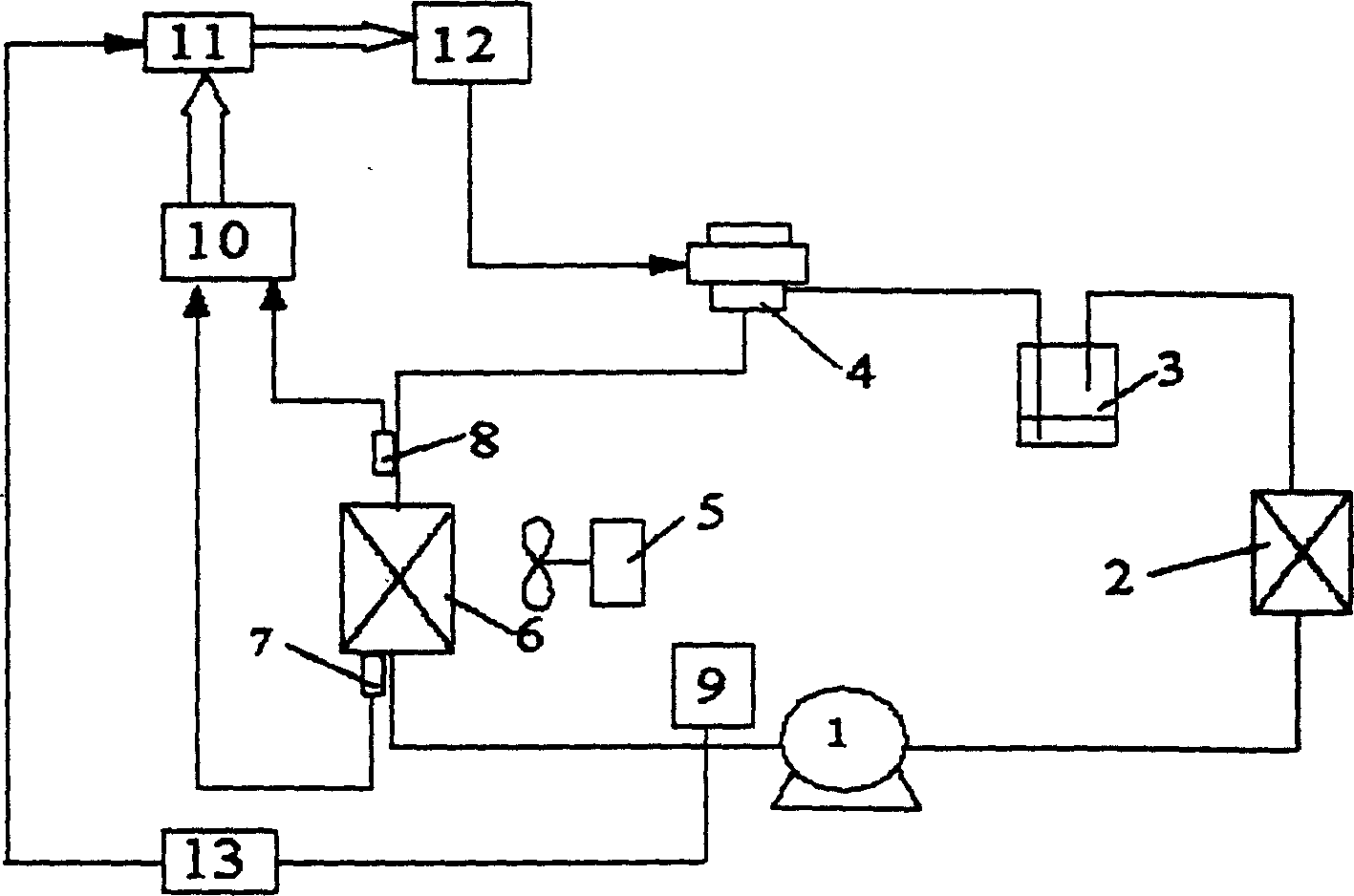

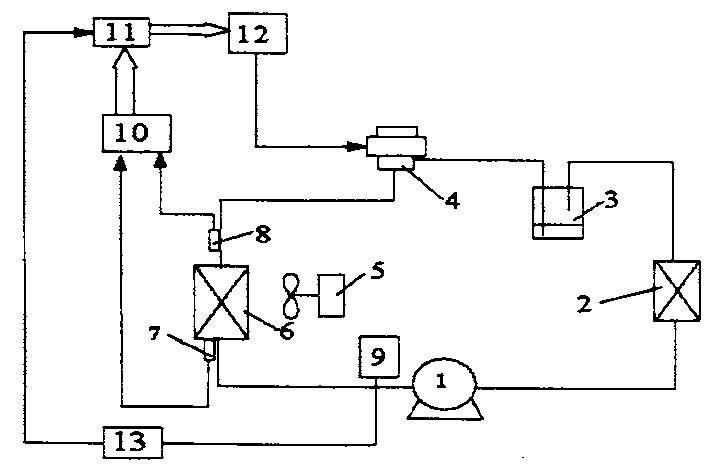

Car air-conditioner evaporator refrigerating agent flow control system

InactiveCN1477355AImprove heat transfer efficiencyAvoid overheatingAir-treating devicesVehicle heating/cooling devicesEvaporatorEngineering

The car air-conditioner refrigerant flow control system adopts the electronic expansion valve as refrigerant flow regulating mechanism. The inlet and outlet of the evaporator are equipped with temp. sensors for respectively measuring the temp. of inlet and outlet of evaporator, and the sum of the difference of both two temp. and correction value of overheating degree of the pressure drop in the evaporator can be used as actual overheating degree of evaporator, and the deviation of the actual overheating degree and set overheating degree can be used as overheating degree feedback signal of theevaporator and fed into the controller, at the same time the rotating speed of the compressor as feedforward signal also can be fed into the controller.

Owner:SHANGHAI JIAO TONG UNIV

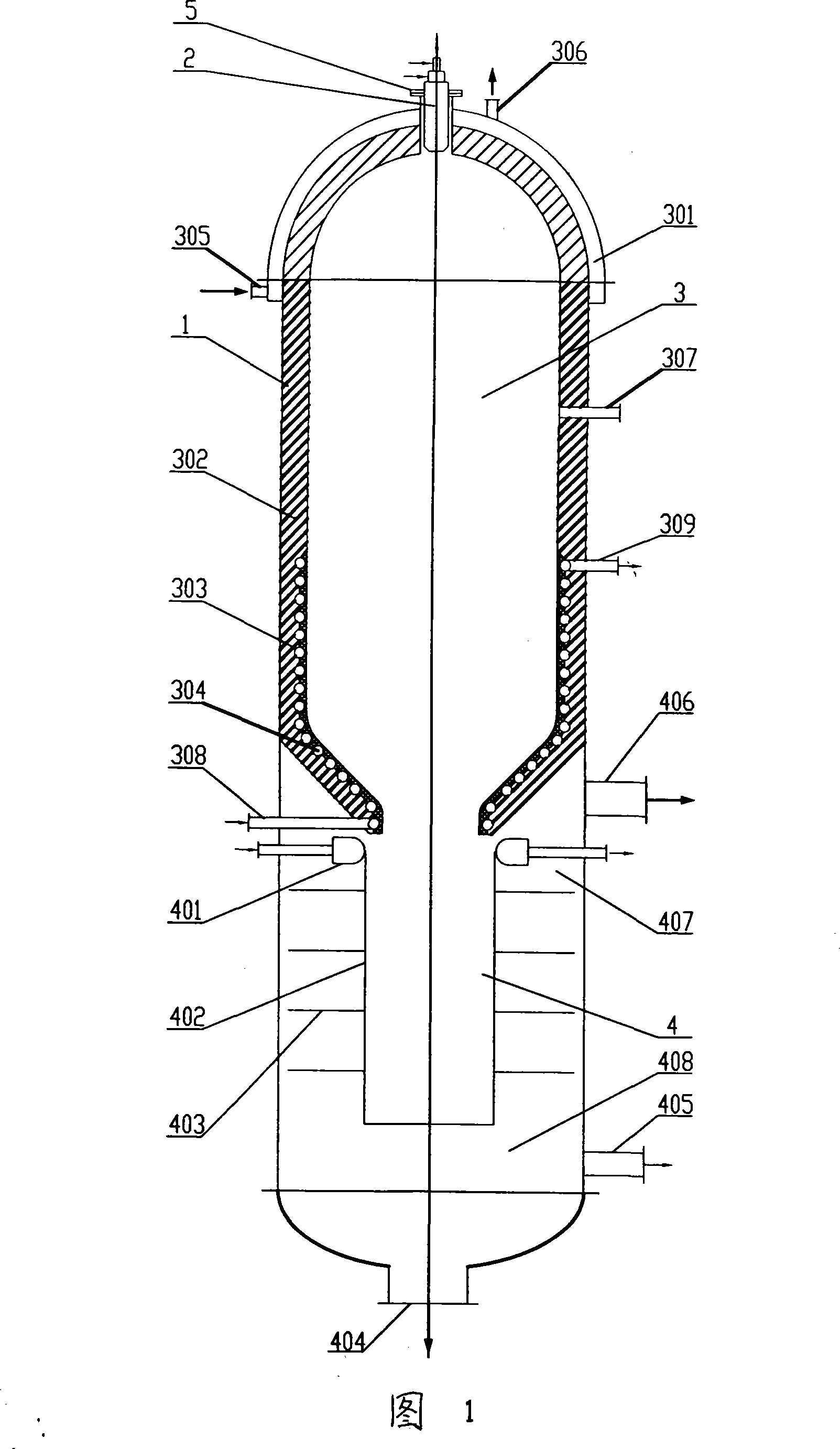

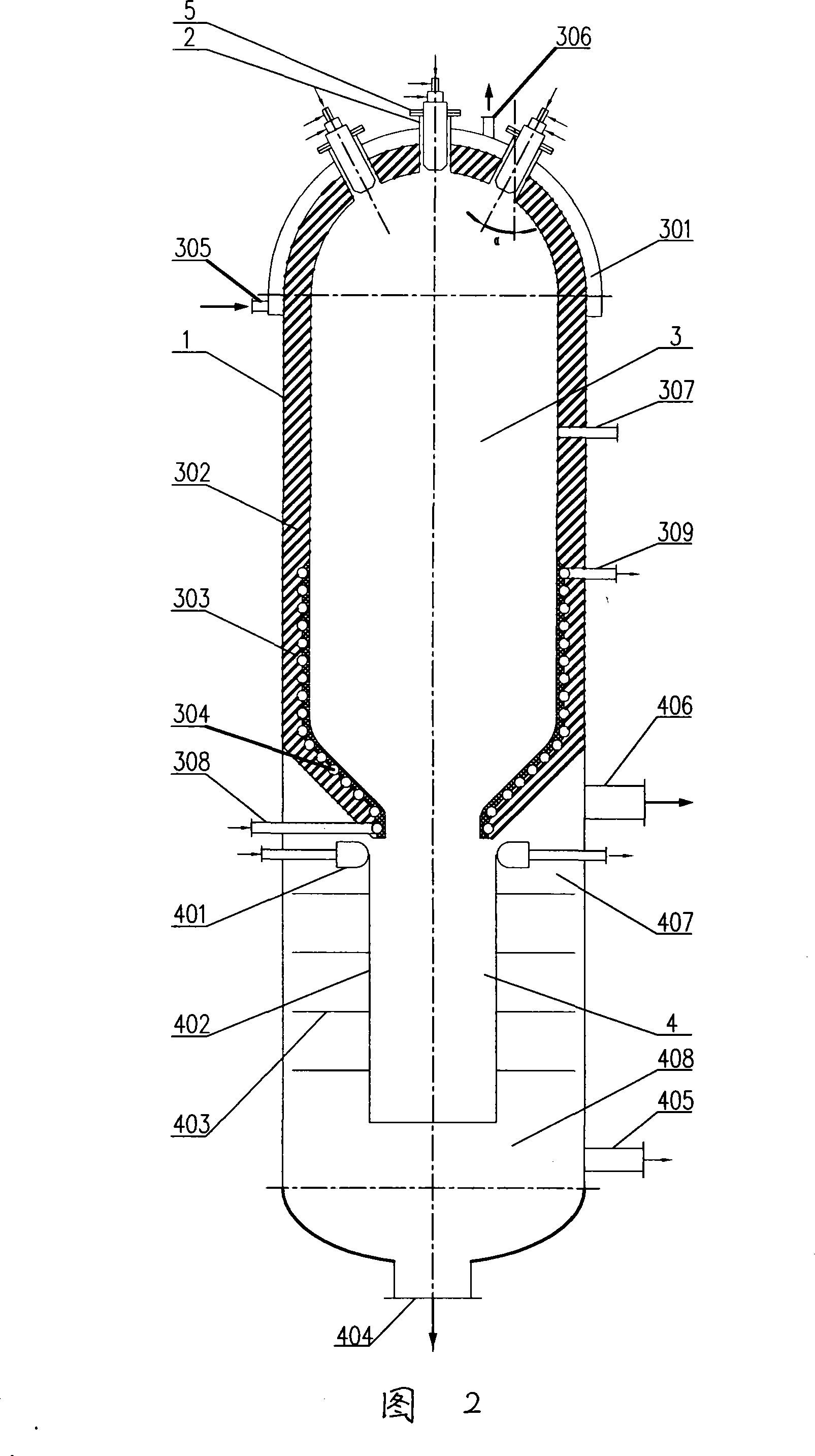

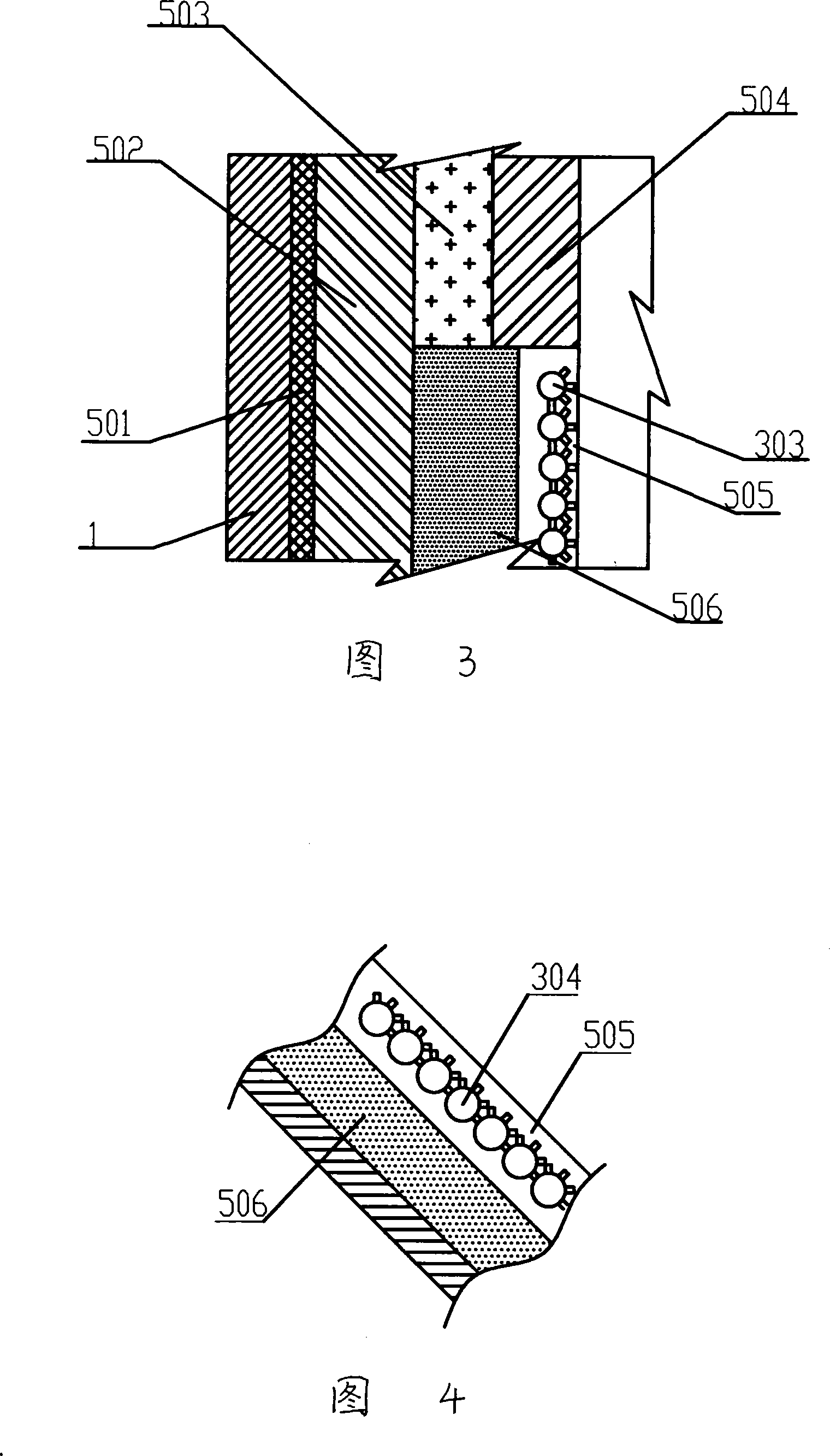

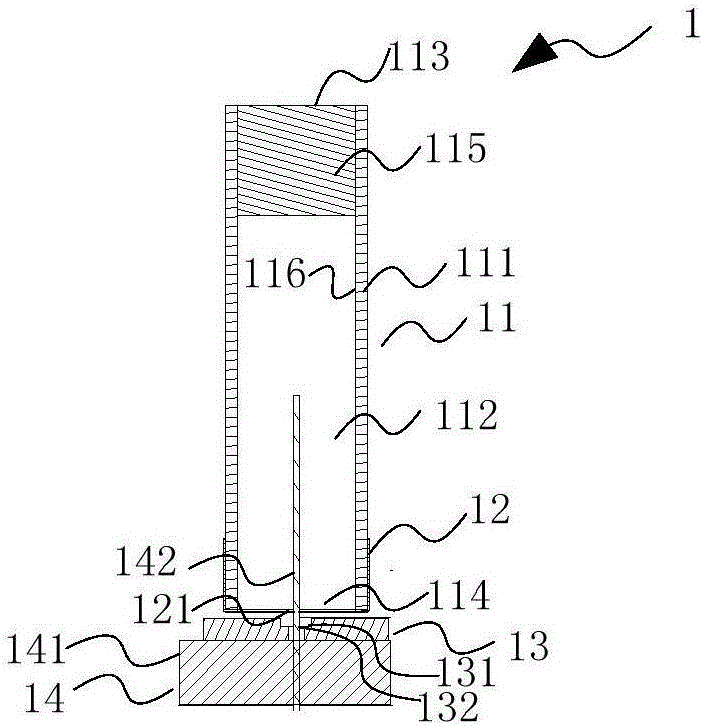

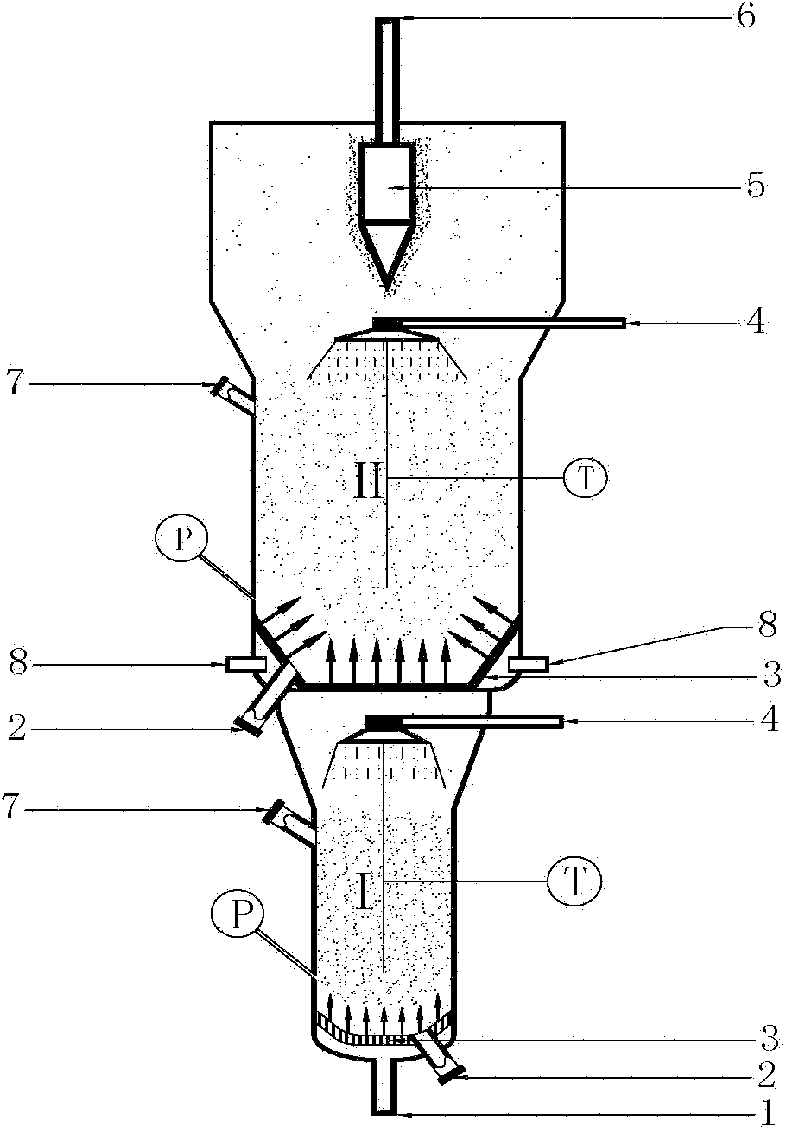

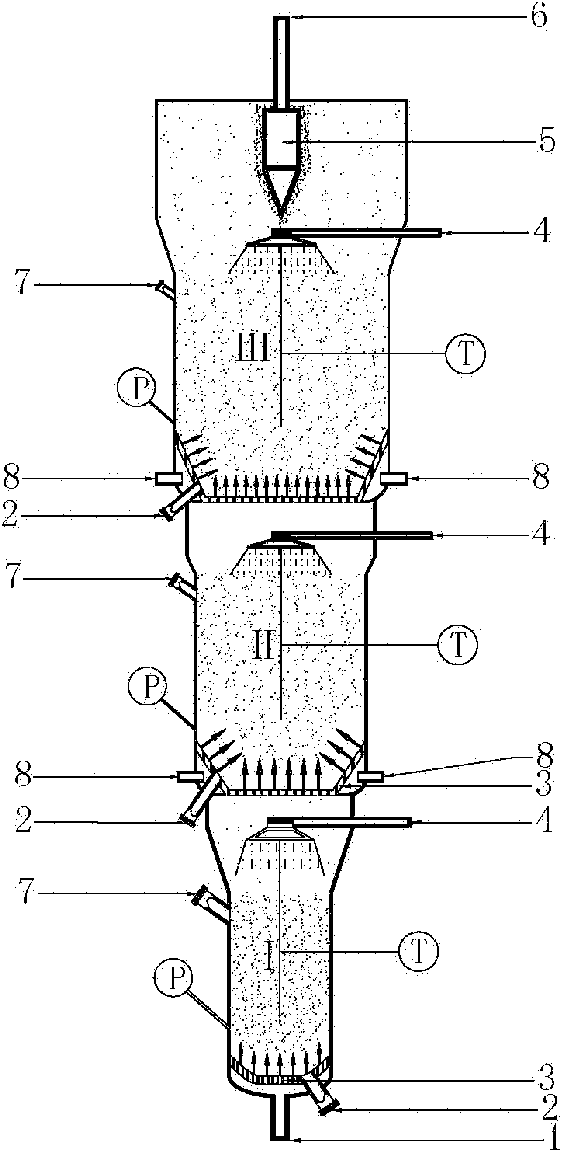

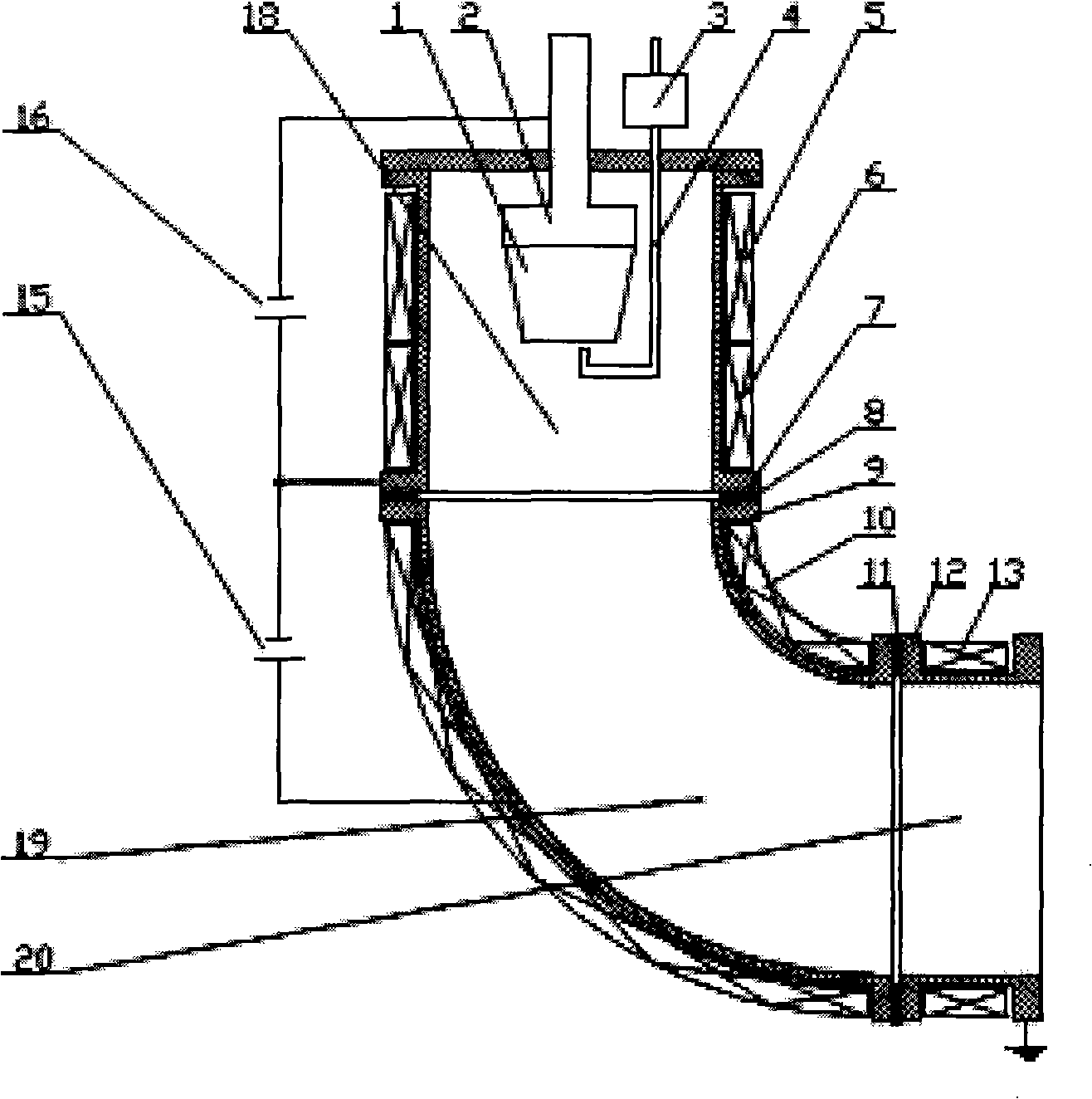

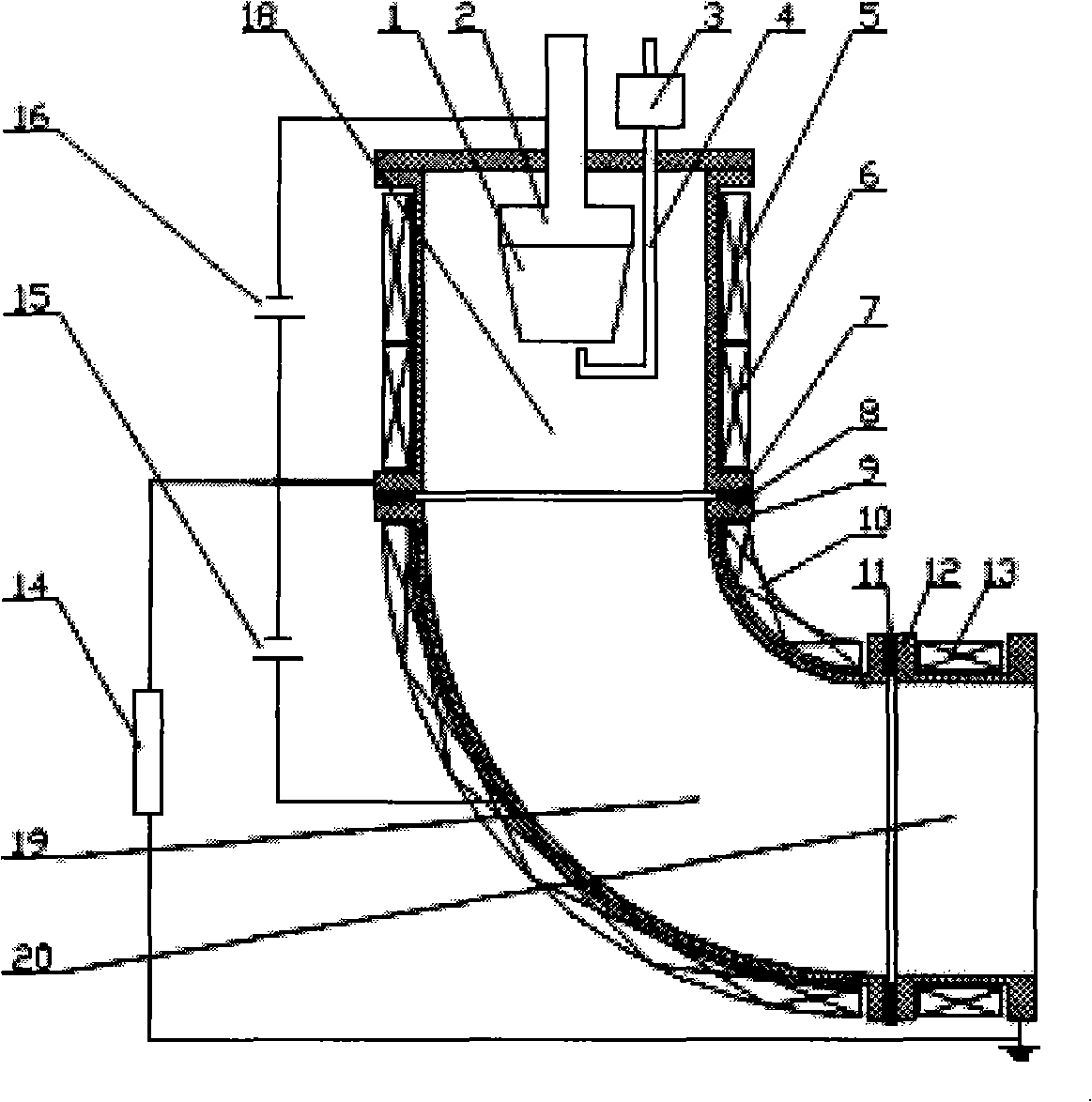

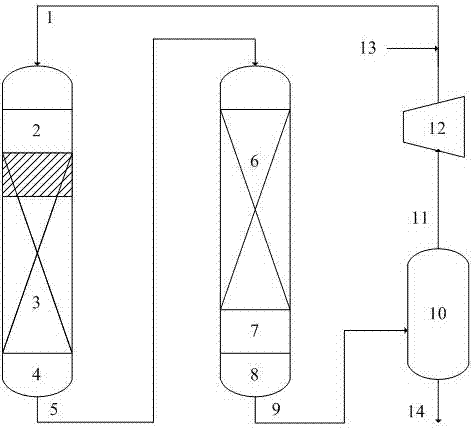

Non-catalytic partial oxidation gasification furnace of inferior raw material

ActiveCN101245263AAvoid overheatingExtended operating cycleHydrogenGranular/pulverulent flues gasificationSyngasSlag

The invention relates to a gasification furnace used for preparing synthesis gas, in particular to a multi-jet vertical airflow bed. An oxidative gasification furnace for non-catalytic parts of inferior raw materials comprises that at least a jet (2) on the top part of a gasification reaction chamber (3) which is communicated with a chilling washing chamber (4) and is characterized in that the gasification reaction chamber (3) is arranged on the upper part of the gasification furnace while the chilling washing chamber (4) is arranged at the lower part of the gasification furnace; the gasification reaction chamber (3) and the chilling washing chamber (4) share a pressure bearing cylinder (1). The gasification furnace has the advantages of avoiding the excessive temperature of the upper part of the gasification reaction chamber and also prolonging the service life of a part at a slag export region of the lower part of the gasification reaction chamber.

Owner:CHINA PETROCHEMICAL CORP +3

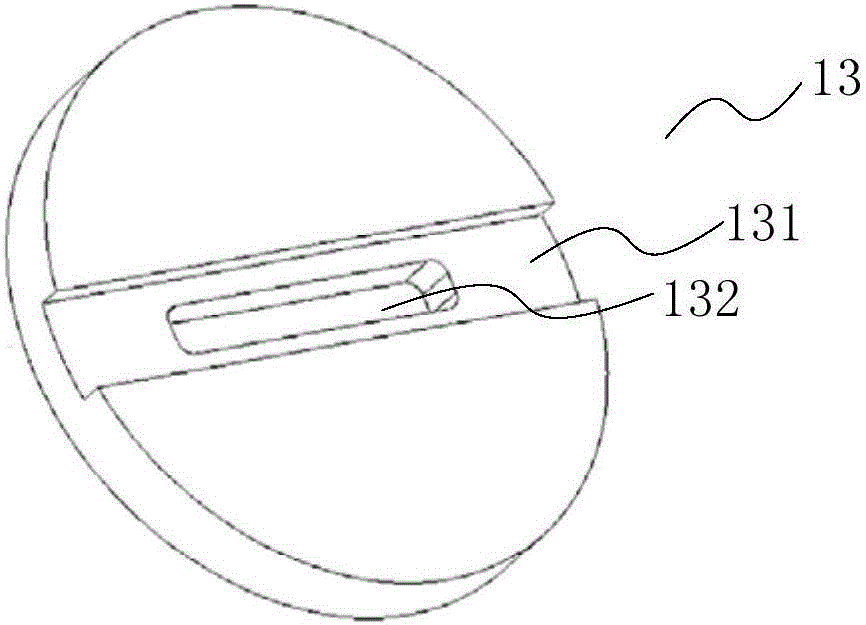

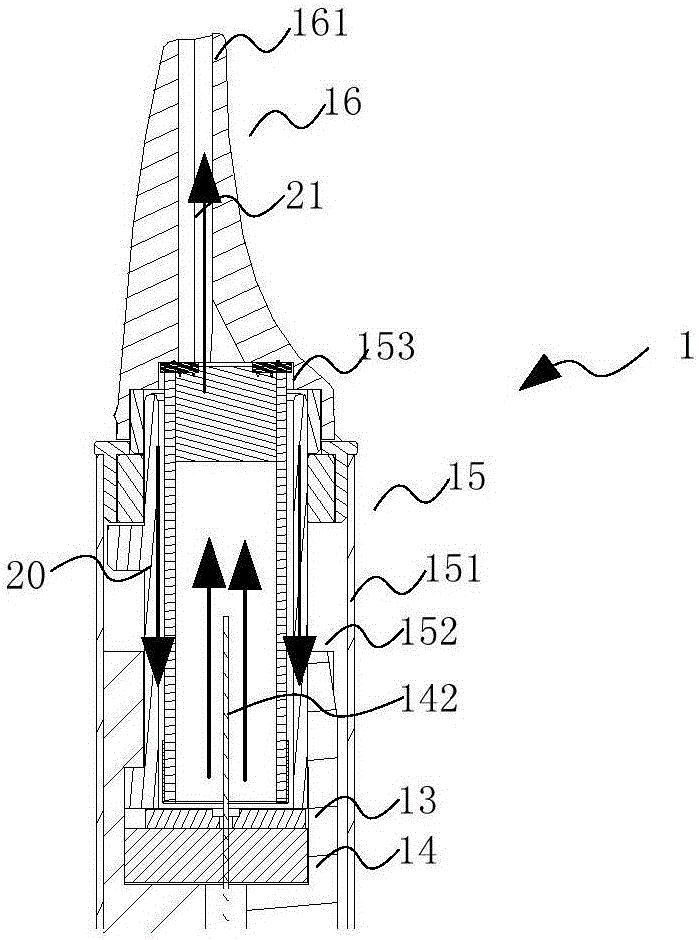

Aerial fog generating device and use method thereof

The invention provides an aerial fog generating device and a use method thereof. The aerial fog generating device comprises a cavity, a sealing cap, an air diversion device and a heater, wherein the cavity is provided with a cavity shell and a cavity accommodating space formed by the cavity shell, the cavity accommodating space is used for accommodating a medium to be heated, and the top of the cavity is provided with filter cotton; the sealing cap is arranged at the bottom of the cavity to seal the bottom of the cavity, and the bottom of the sealing cap forms a penetrating part; the air diversion device is arranged below the sealing cap, and is provided with a diversion trench and a diversion hole, and the diversion hole is arranged corresponding to the penetrating part; the heater comprises a heater bottom cover and a heating ceramic piece, the heater bottom cover is arranged below the air diversion device, and the heating ceramic piece is fixed on the heater bottom cover, passes through the diversion hole and penetrates through the penetrating part so as to be arranged in the cavity accommodating space in a penetrating manner. According to the aerial fog generating device provided by the invention, the heating is uniform, the efficiency is high, the phenomenon that the temperature of the heating ceramic piece is too high can be avoided, and an airflow guiding device adopted can also increase the quantity of aerial fog generated.

Owner:SHANGHAI TOBACCO GRP CO LTD

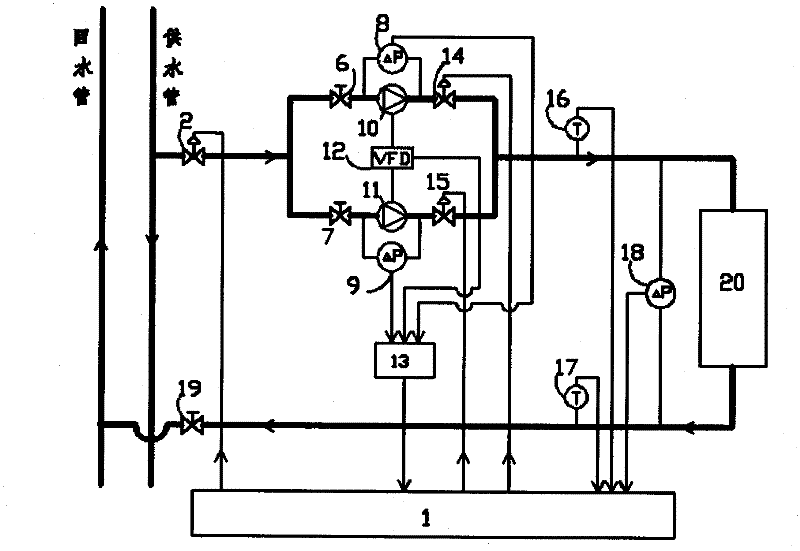

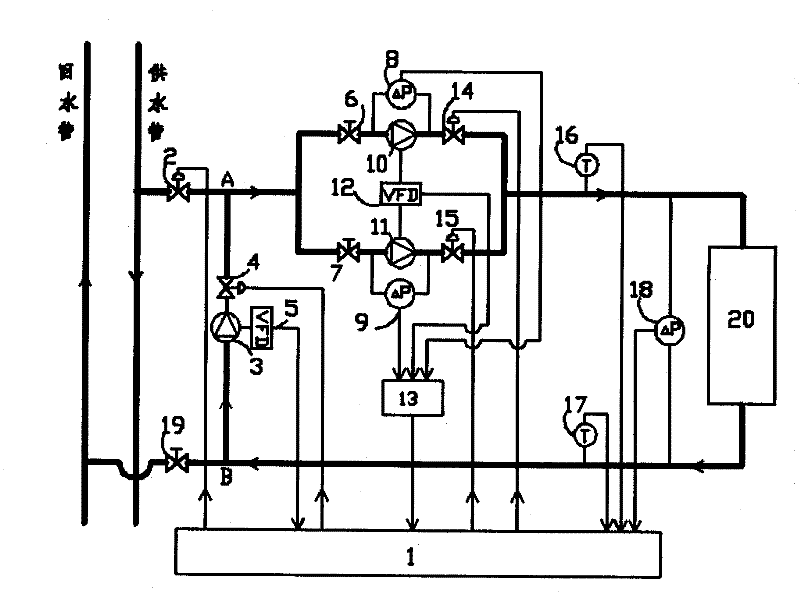

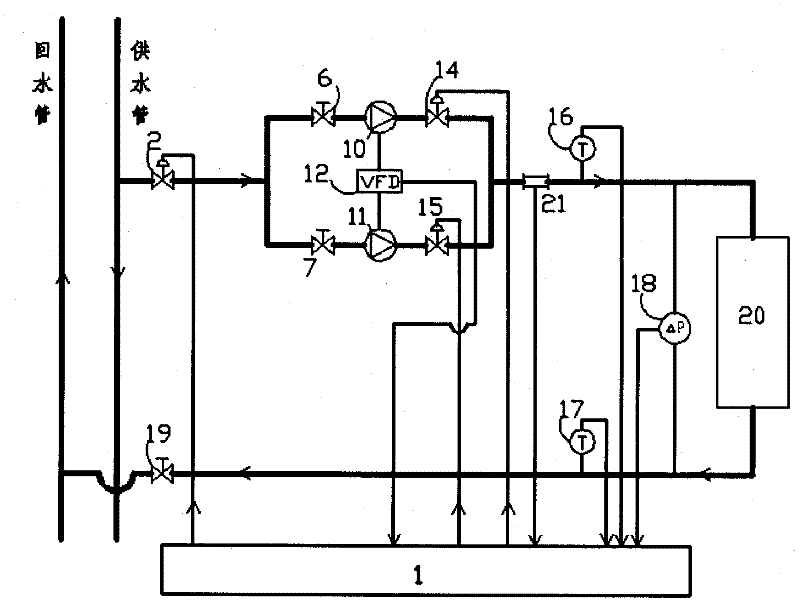

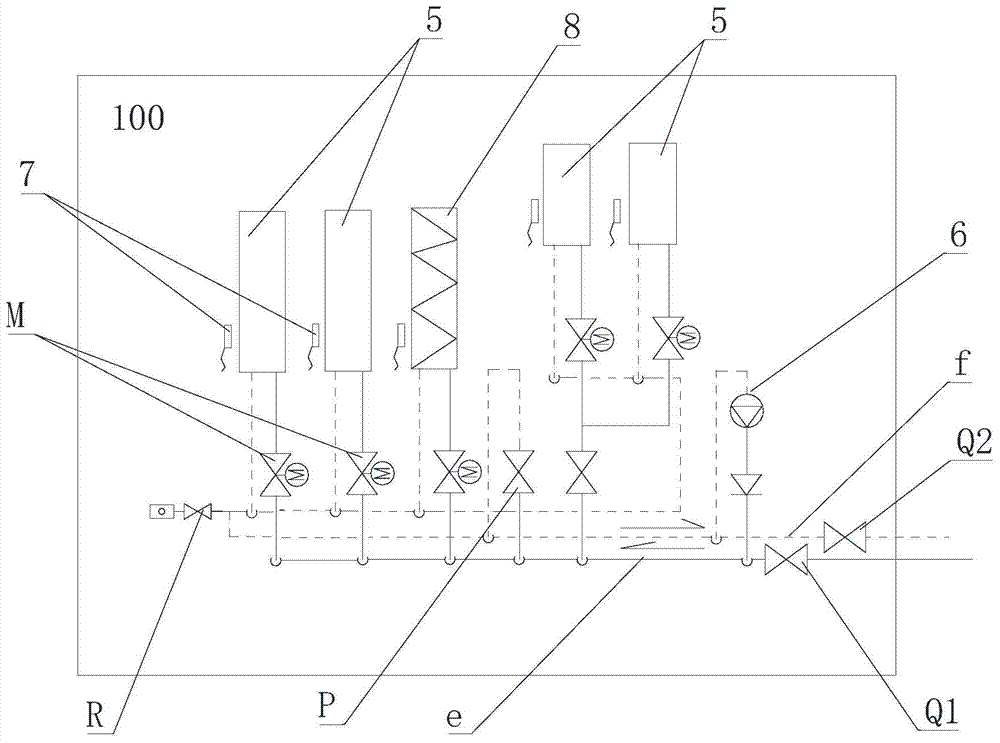

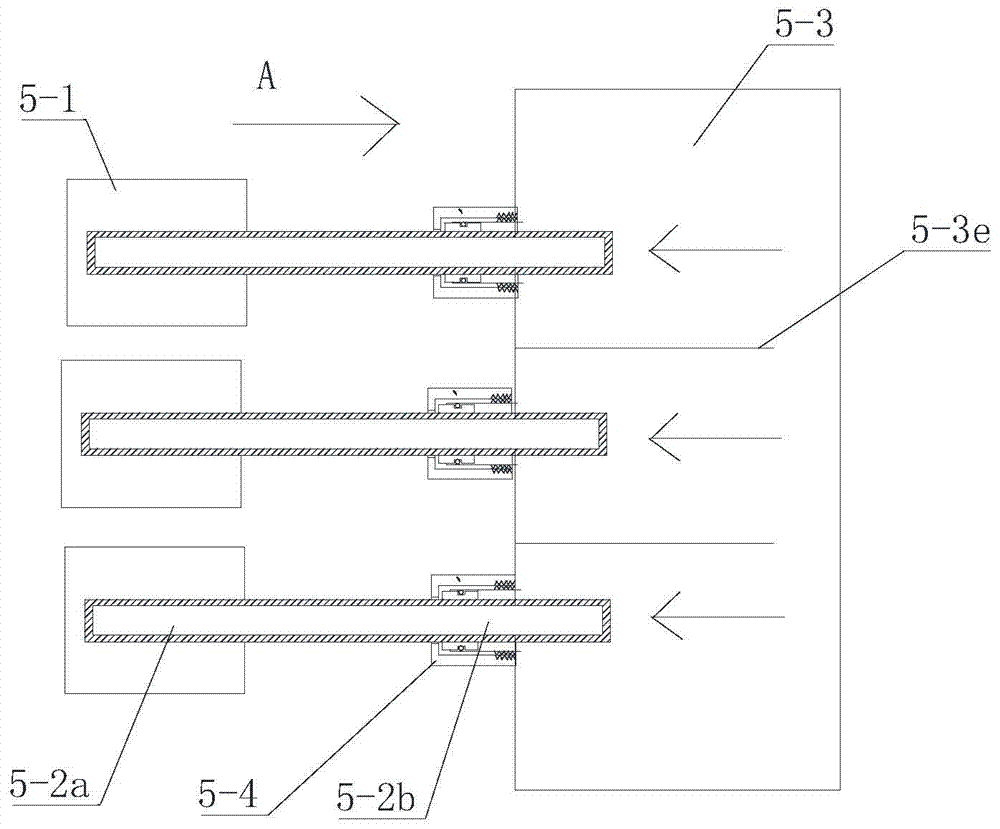

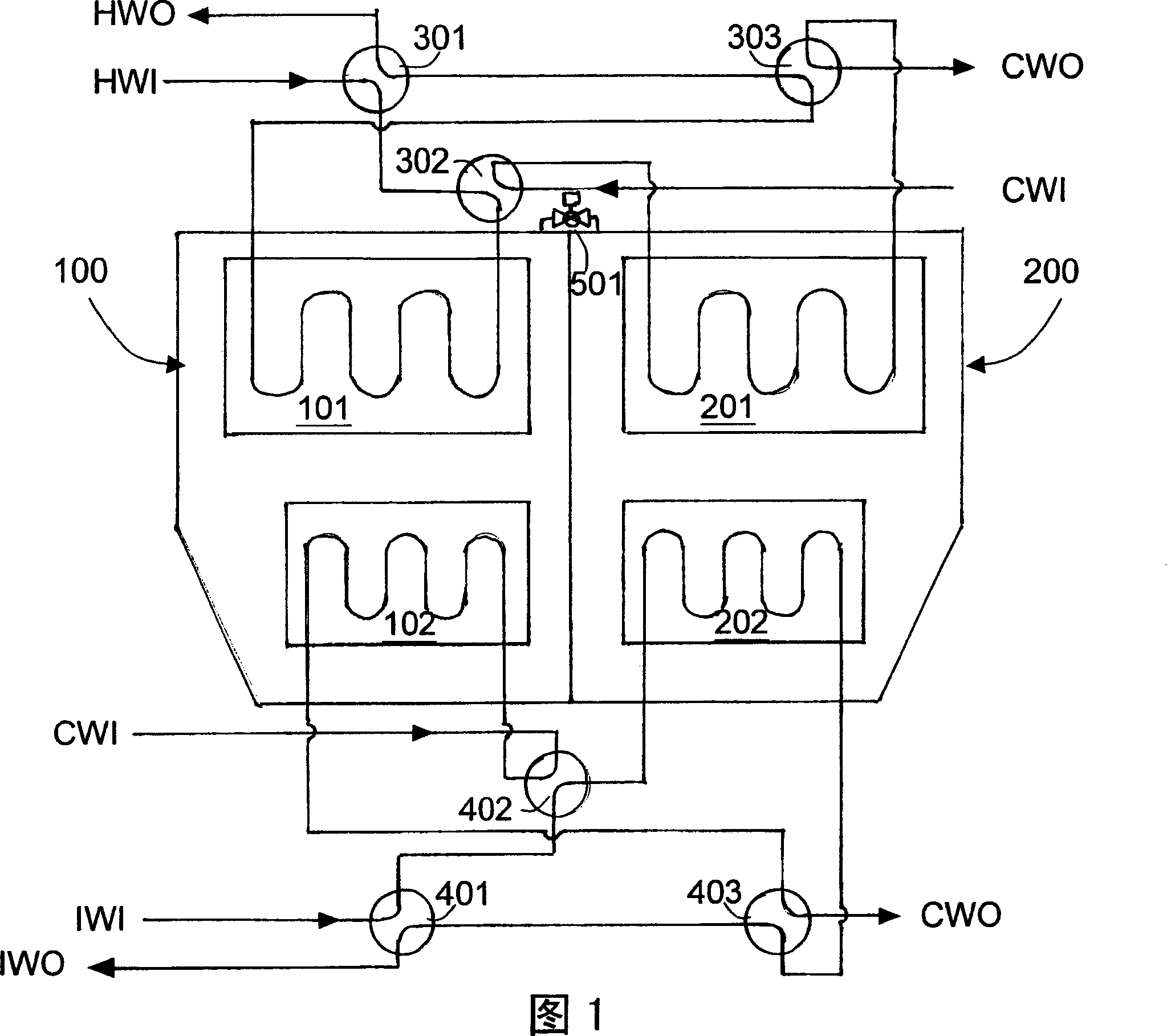

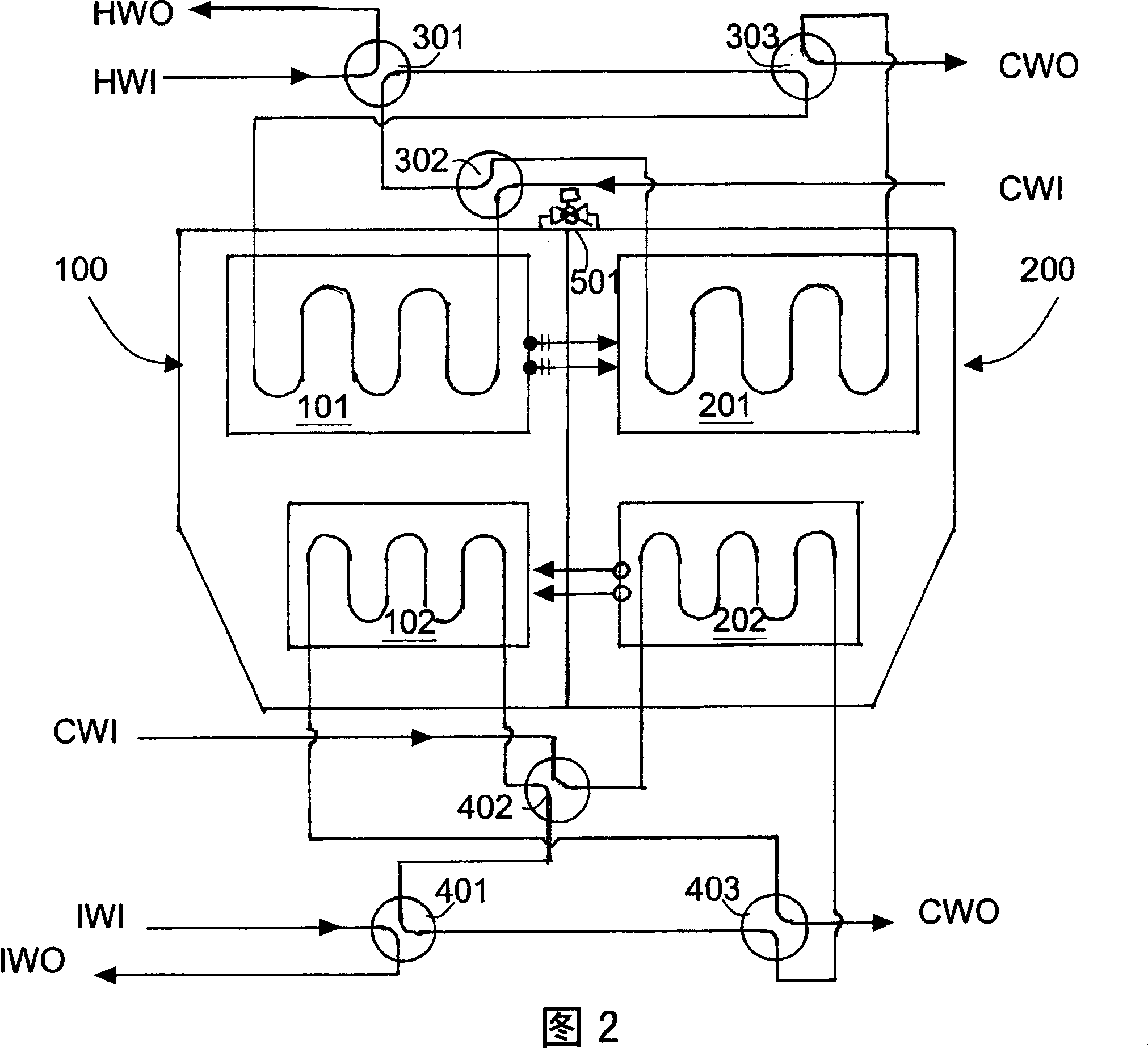

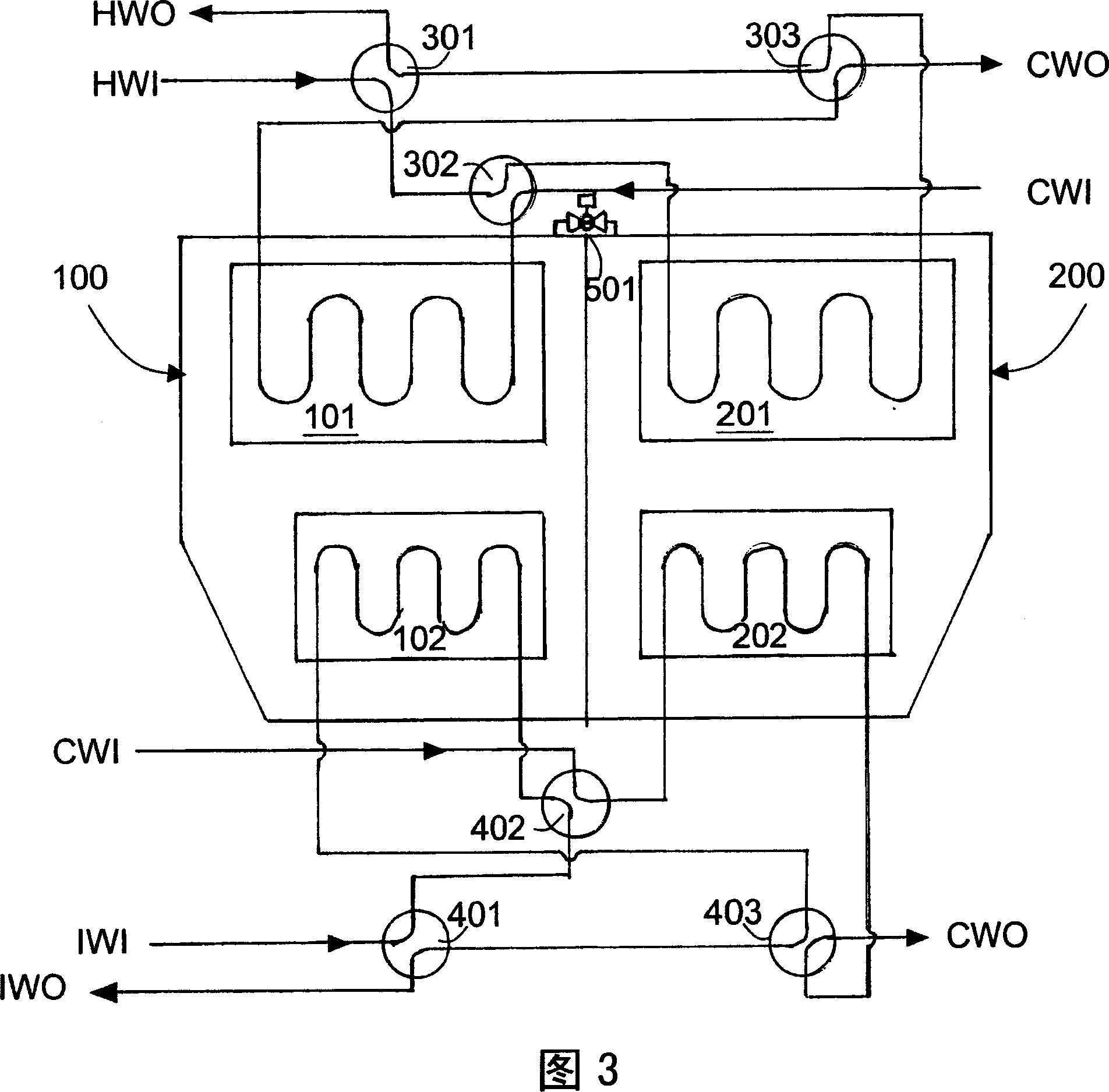

Energy control system and control method for heating and cooling water circulation

InactiveCN102269444APrevent overcoolingAvoid overheatingSpace heating and ventilation detailsRefrigeration safety arrangementThermal energyEnergy control

An energy control system and control method for heating and cooling water circulation, relating to the control of a multi-user heating and cooling system and its corresponding water pump system with or without adjustment function in its terminal devices. It effectively solves the problems of heat energy waste and energy waste generated by water pump circulation. The present invention consists of heat source water supply and return pipelines, water pumps, VFD frequency converters, flowmeters, electric regulating valves, differential pressure sensors, temperature sensors, user terminals, and related control logic that can monitor the performance of the water pumps, start / stop the water pumps, and adjust the frequency of the water pumps. The controller composition. The implementation of the present invention can control the indoor temperature very well, improve the indoor comfort, avoid the overall overcooling or overheating phenomenon in the building room; and can reduce the waste of heat energy by 30%; reduce the energy waste of the circulating water pump by 70%-90% %.

Owner:HARBIN INST OF TECH

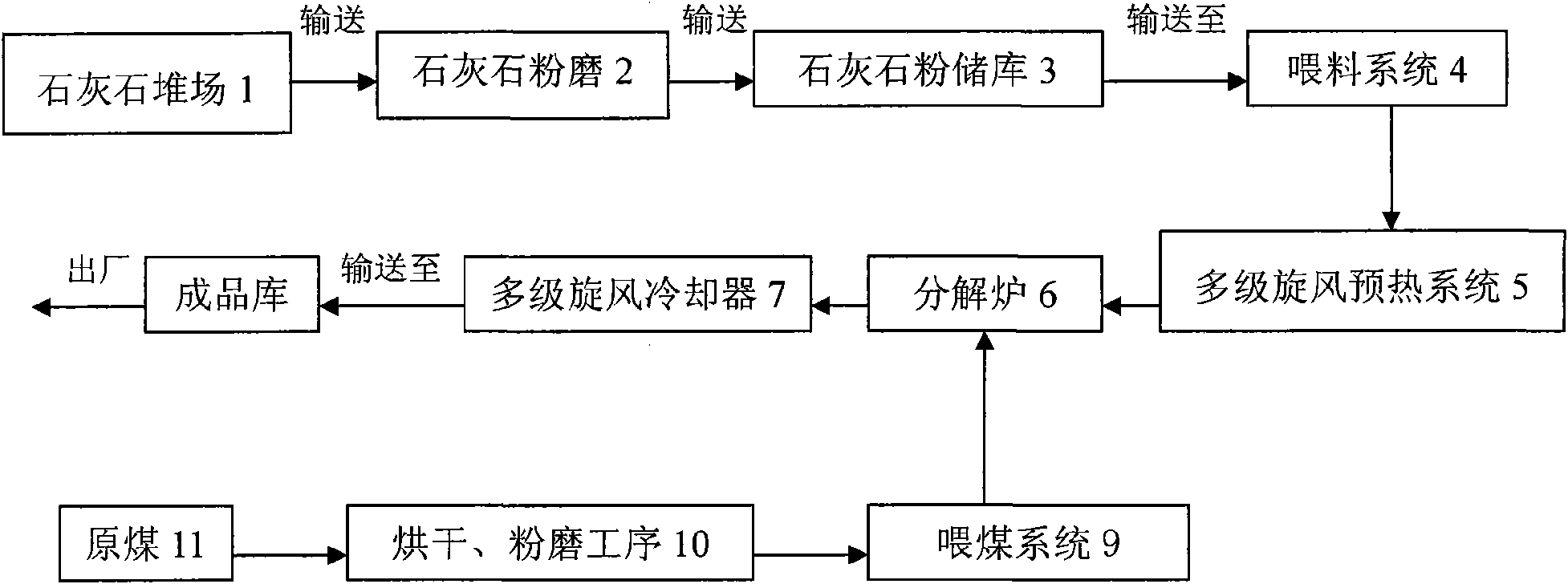

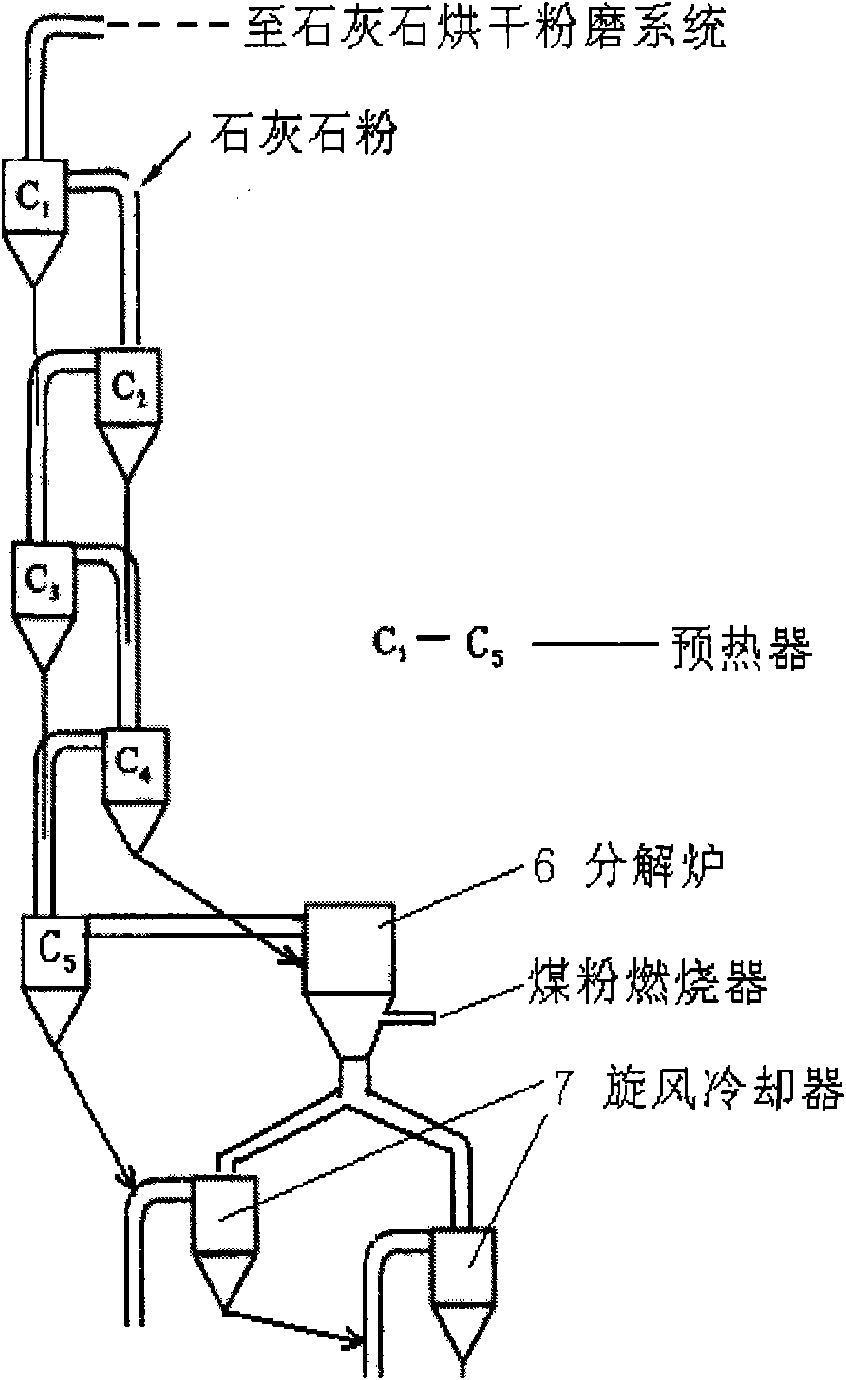

Calcination process of active lime

The invention discloses a calcination process of active lime. The calcination process adopts a preheating-suspension calcination device comprising a multi-stage cyclone preheating system, a decomposing furnace and a multi-stage cyclone cooler. The calcination process is characterized in that limestone powder which is broken and homogenized into blocks is ground into fine powder, the fine powder is placed in a storage tank for homogenization, then preheated by the multi-stage cyclone preheating system and sent to the decomposing furnace for calcination, thereby preparing the active lime, and the active lime is further cooled by the multi-stage cyclone cooler for obtaining the active lime; wherein the main control temperature of the decomposing furnace is 850-950 DEG C; and the calcination time is 3-5 seconds. The calcination process utilizes the preheating-suspension calcination reaction method for calcining the active lime, and fuel can use low-grade fuel-biluminous coal. Compared with the traditional process, the calcination time is short, the effective utilization rate of the lime product is high, the product quality is stable, the energy consumption is low, and a production region has no environmental pollution; meanwhile, the calcined active lime is the fine powder, the use is very convenient, and the range of applications is broader in comparison with the active lime calcined by the traditional process, thereby being conductive to promotion and implementation.

Owner:BEIJING LIULIHE CEMENT

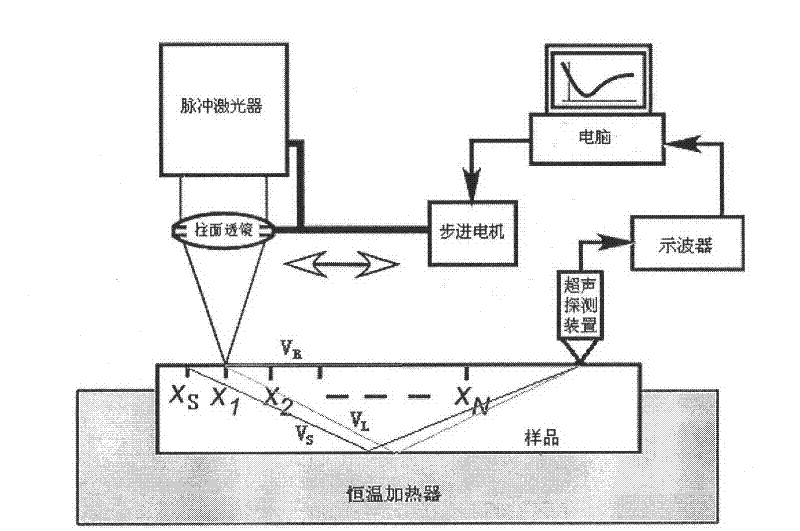

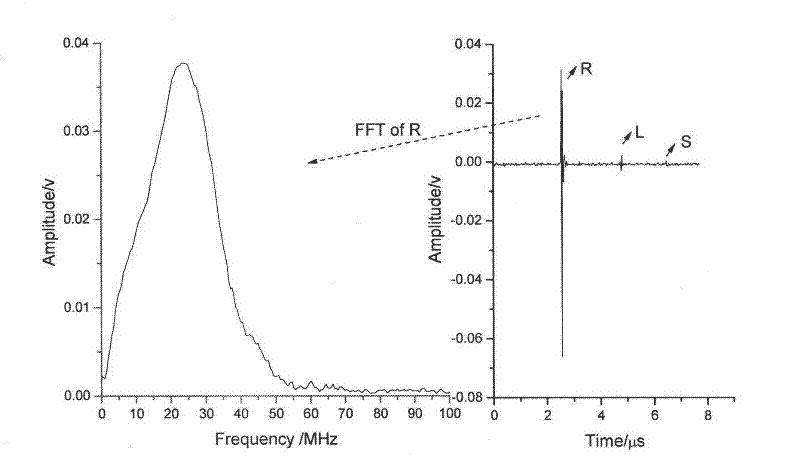

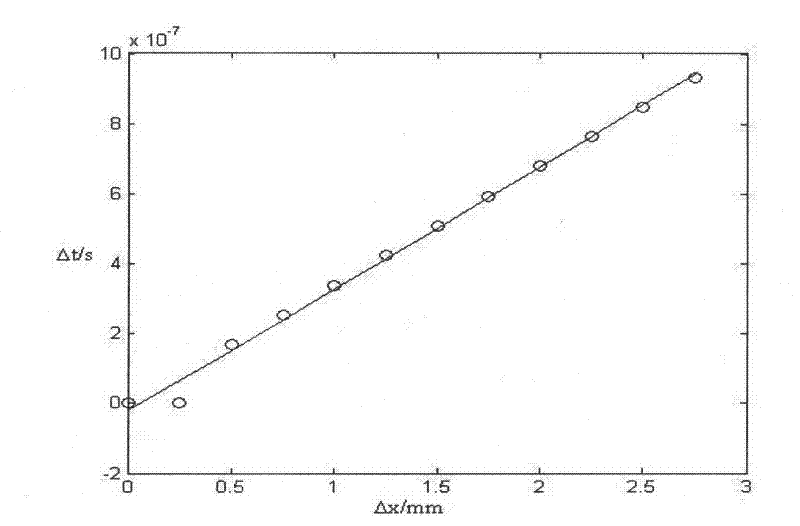

Laser Ultrasonic Determination Method of Metal Third-Order Elastic Constant

InactiveCN102297898AAvoid overheatingAvoid axial length changesAnalysing solids using sonic/ultrasonic/infrasonic wavesCorrelation functionStressed state

The invention discloses a method for utilizing a laser ultrasonic wave to precisely measure a third order elastic constant of metal. The method comprises the following steps: respectively measuring wave velocities of a longitudinal wave, a transverse wave and a surface wave excited by a laser under stress-free state and stress state; utilizing the wave velocities of the longitudinal wave, the transverse wave and the surface wave measured under stress-free state to calculate a second order elastic constant and a density of metal according to a sonic elasticity theory and a Rayleigh equation; utilizing the ultrasonic wave velocities of the longitudinal wave, the transverse wave and the surface wave measured under stress state to introduce an equivalent second order elastic constant and an independently measured linear coefficient of thermal expansion; and lastly, calculating the third order elastic constant according to the sonic elasticity theory. According to the method, a pulse laser source is utilized to excite a sound surface wave, non-contact exciting is performed under a thermal elastic system and an overheated phenomenon of materials is avoided, so as to realize nondestructive measurement. A large amount of sound surface wave data spread for different distances is collected and a correlation function is utilized to calculate a wave velocity of the sound surface wave and a spread distance of sound wave, thereby greatly reducing error of arriving time value of the sound surface wave and promoting the measuring precision of a sound wave velocity.

Owner:NANJING UNIV OF SCI & TECH

Automobile antifreeze

ActiveCN101698793AHigh flash pointNot easy to catch fireHeat-exchange elementsAutomotive engineeringAntifreeze

The invention relates to an automobile antifreeze which comprises the following components by weight percent: 90-96% of alcohols, 1%-5% of water, 0%-0.5% of pigments and 3%-7% of additives. Compared with the prior art, the automobile antifreeze has strong corrosion resistance and can effectively prevent the scale formation, and the automobile antifreeze further has excellent protection performance for any material of a cooling part of an engine and excellent performances of anti-freezing in winter, anti-boiling in summer, anti-scale and anti-corrosion all over the year and the like and can effectively protect a water cooling system of an automobile, prolong the service life of the water cooling system of the automobile, reduce the cost, simultaneously have the environmental protection advantage and achieve the requirements of British standard BS6580:1992.

Owner:SHANGHAI DELIAN CHEM

Method for producing alkoxylate through microchannel reactor

The invention relates to a method for producing alkoxylate through a microchannel reactor, and discloses a method for continuously performing alkoxylation reaction in a microreactor. According to the invention, initiator potassium alcoholate in which low molecules (the low molecules herein are mainly water and methanol) are removed and epoxide enter a microreactor, a delay line and a mixer in a liquid-phase form to perform liquid-liquid reaction, the purpose of sufficient mass transfer and heat transfer is achieved, and the liquid-liquid reaction is realized by increasing the pressure of the reaction system and adding a counterbalance valve. Compared with the alkoxylation reaction in the prior art, the method can effectively solve the heat transfer problem of such reaction, realizes fast and uniform mixing and constant reaction temperature, avoids the temperature runaway phenomenon and reduces the side reaction; the process is continuous flow reaction, and the reaction time is shortened to a few minutes, thus obviously improving the reaction efficiency and production efficiency; and the microreactor hardly has scale-up effect and is high in safety performance, thus being suitable for industrial production.

Owner:YANGZHOU SPED CHEM

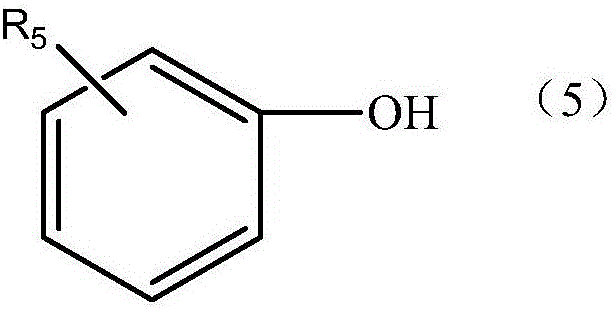

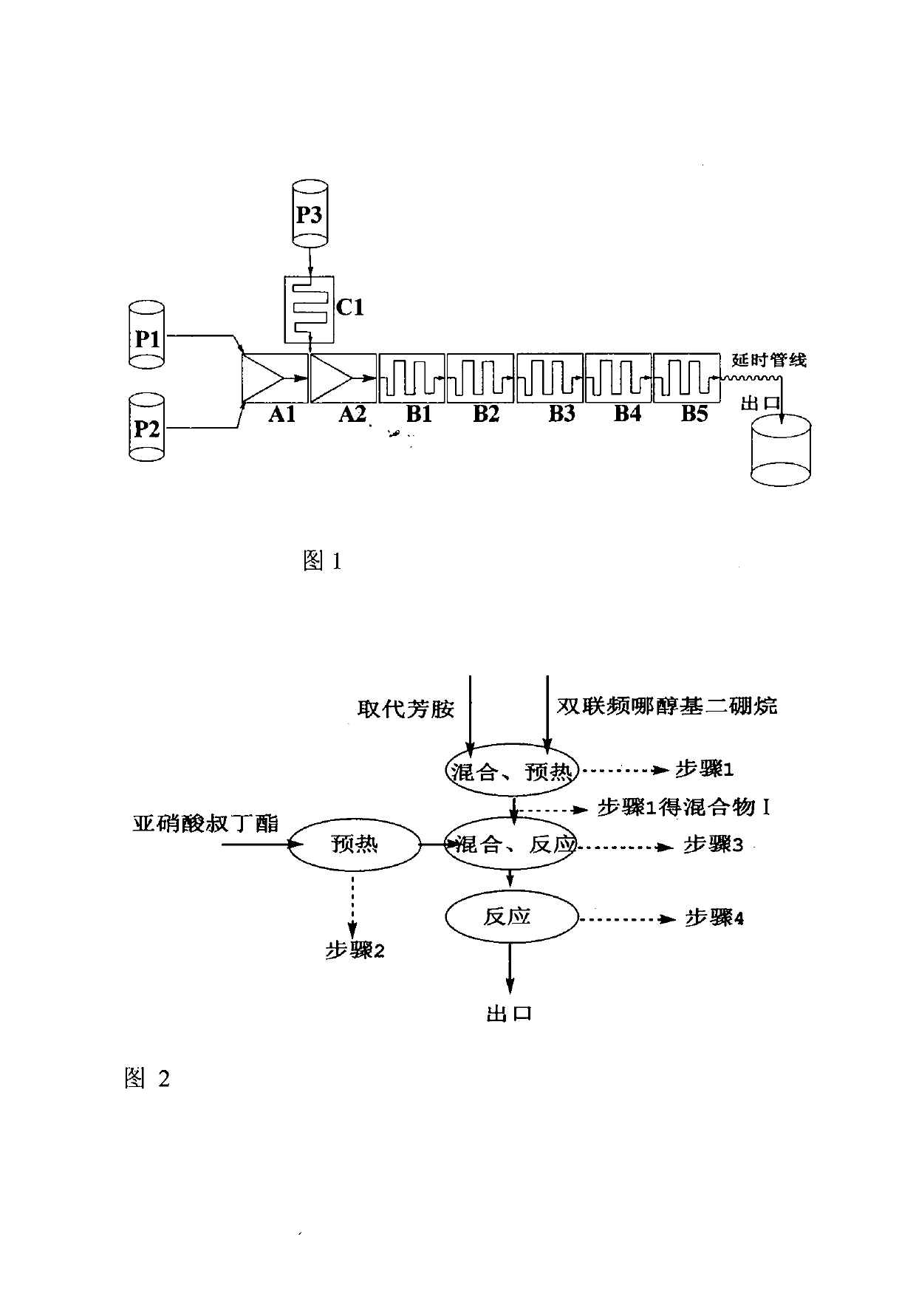

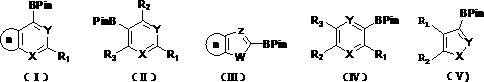

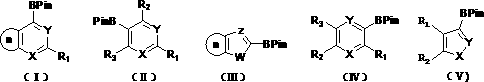

Method for continuously synthesizing arylboronic acid ester by utilizing microreactor

InactiveCN103275112ADegree of reductionShort reaction timeGroup 3/13 element organic compoundsOrganic synthesisN-butyl nitrite

The invention relates to a method for continuously synthesizing arylboronic acid ester by utilizing a microreactor, which belongs to the technical field of green organic synthesis application. The method comprises the following steps of: preheating substituted arylamine, tert-butyl nitrite, bisdiborane in a continuous-flow micro-channel reactor system by using substituted arylamine, acetonitrile, tert-butyl nitrite and bisdiborane as starting materials; and mixing the substituted arylamine with the bisdiborane and then reacting the obtained mixture with the tert-butyl nitrite, wherein in the reaction, the molar ratio of the substituted arylamine to the bisdiborane is (1:0.5)-(1:1.25), the molar ratio of the substituted arylamine to isoamyl nitrite is (1:1.1)-(1:1.5), the reaction temperature is 60 DEG C-120 DEG C, the reaction time is 50 seconds-3600 seconds, and the effective conversion ratio of the substituted arylamine is 50%-90%. The continuous-flow microreactor, which is capable of strengthening the mixing effect, the mass transfer effect and the heat transfer effect, is especially suitable for carrying out homogeneous reaction of the method. Moreover, the method has the characteristics of stable temperature control, safe process and less waste material.

Owner:JINAN SHAOYUAN MEDICAL TECH

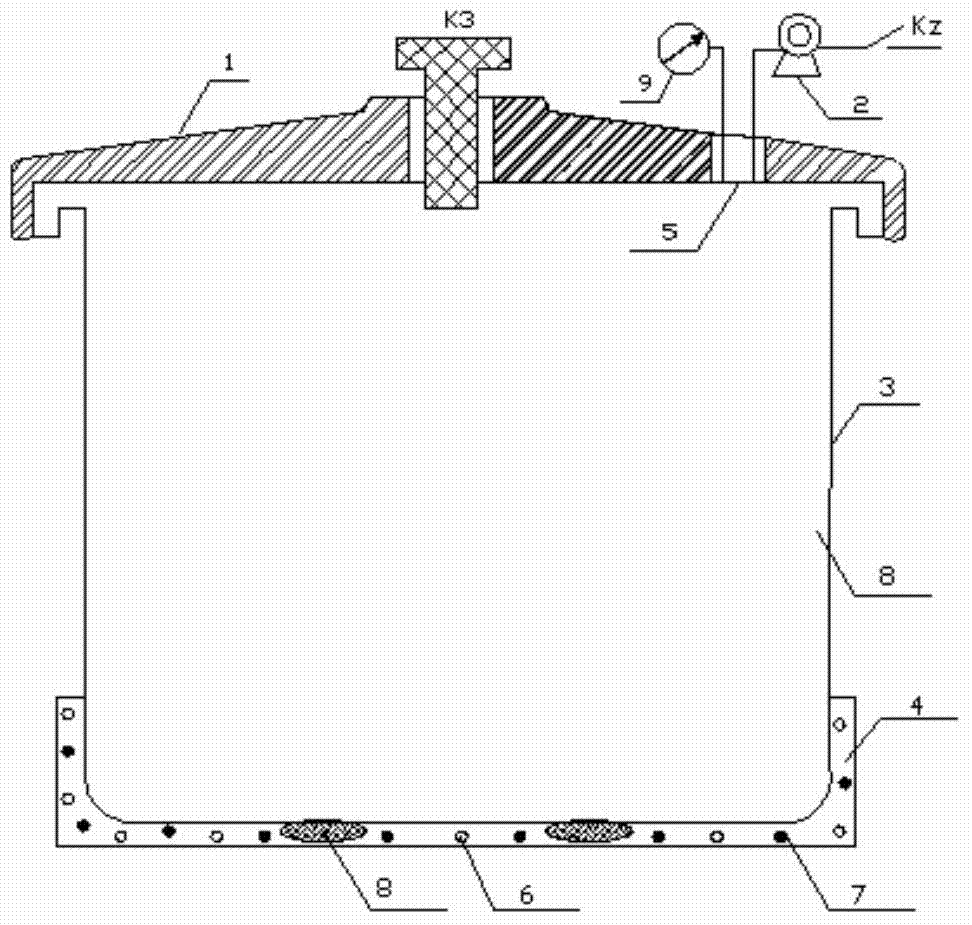

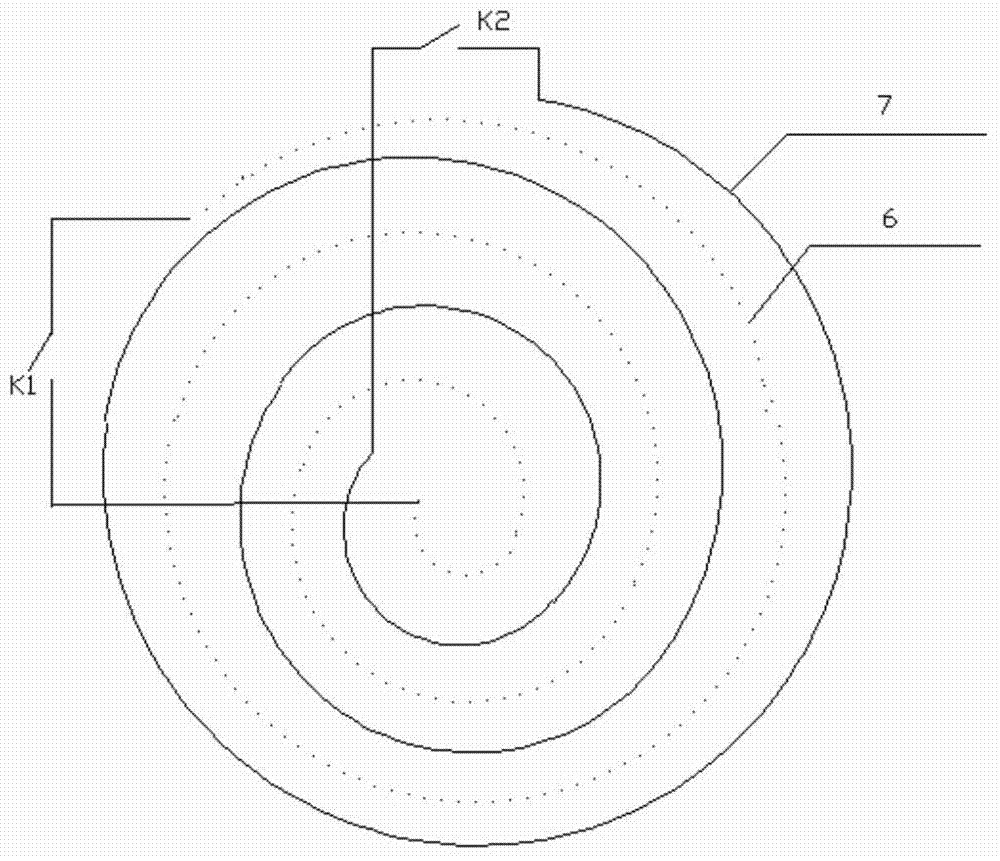

Food cooker with temperature pressure control and cooking method

The invention discloses a food cooker with a temperature pressure control. The food cooker comprises a pot body, wherein the bottom part of the pot body is provided with an interlayer, and a heating channel and a cooling channel which are aligned at intervals are arranged in the interlayer; the heating channel is heated and stopped heating through a switch K1, and the cooling channel is cooled and stopped cooling through a switch K2. The food cooker further comprises a sealing spot cover; an air suction opening towards the pot body and a vacuum opening used for vacuumizing are arranged on the sealing spot cover; the air suction opening is opened and closed under the controlling of an air suction valve K3, and a vacuum opening is connected with a vacuum pump through a vacuum pump switch Kz. The invention further discloses a cooking method by means of the food cooker with the temperature pressure control. Compared with an ordinary electric heating spot, the vacuum device is employed, thus the tasty is quick and the food quality is good. By employing a special standard cooking curve and a cooking controller, the good food taste is guaranteed. After adopting the cooling device, the overheat phenomenon can be avoided.

Owner:HUAZHONG AGRI UNIV

Cooling system of cabinet

ActiveCN104735959AGuaranteed working temperatureAvoid overheatingCooling/ventilation/heating modificationsLiquid storage tankEngineering

A cooling system of a cabinet comprises an outer circulating system and an inner circulating system. The outer circulating system comprises a cold source, a liquid storage tank and an outer circulating pump, and a working medium inlet pipe and a working medium outlet pipe of the outer circulating system are connected with a middle heat exchanger. The inner circulating system comprises a cabinet inner circulating sub-system, a working medium inlet pipe of the inner circulating system and a working medium outlet pipe of the inner circulating system. The cabinet inner circulating sub-system comprises liquid-cooling radiators, a cabinet inner work medium inlet connected with the working medium inlet pipe of the inner circulating system through an inlet check valve, a cabinet inner working medium return pipe connected with a working medium return pipe of the inner circulating system through an outlet check valve, and an air-cooling radiator. The air-cooling radiator is connected with the cabinet inner working medium inlet pipe and the cabinet inner working medium return pipe, a flow proportion adjusting valve is arranged between the air-cooling radiator and the cabinet inner working medium inlet pipe, the liquid-cooling radiators are connected with the cabinet inner working medium inlet pipe and the cabinet inner working medium return pipe, and a flow proportion adjusting valve is arranged between each liquid-cooling radiator and the cabinet inner working medium inlet pipe. The cooling system has the advantages of being high in cooling efficiency and capable of saving energy.

Owner:SHENZHEN ENVICOOL TECH

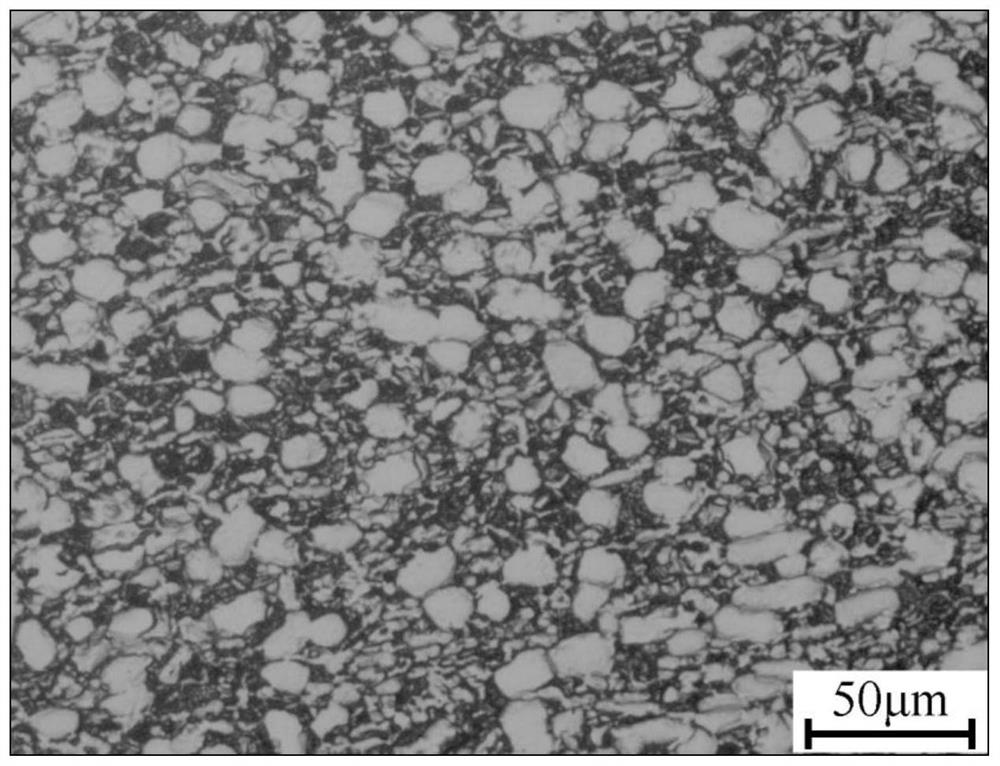

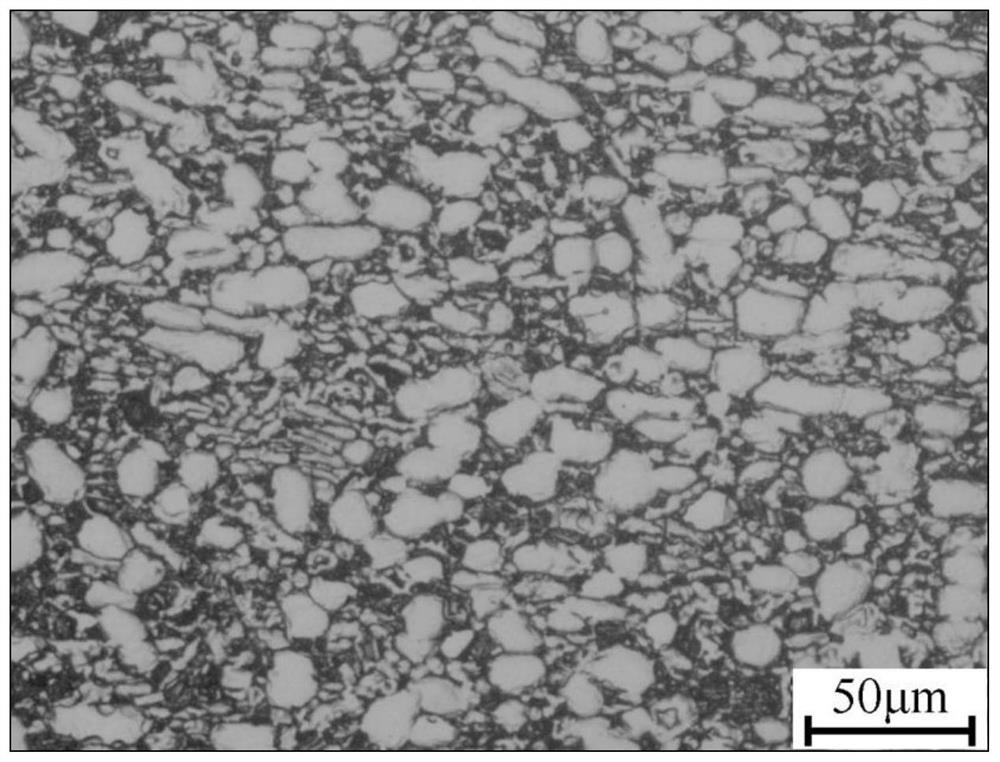

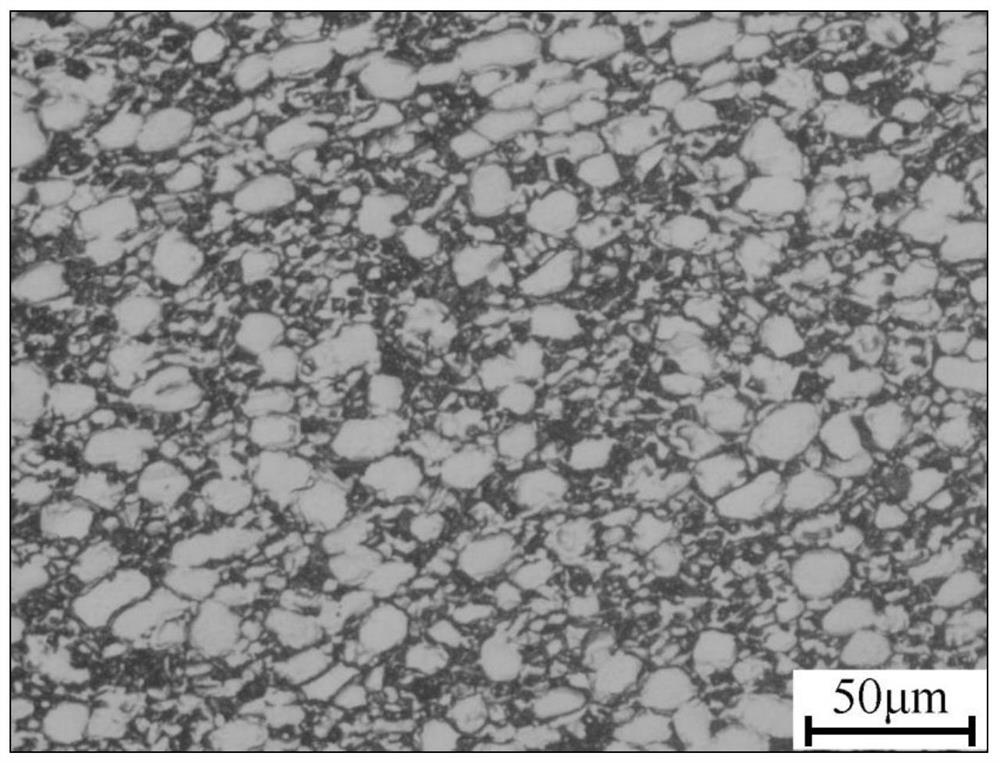

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

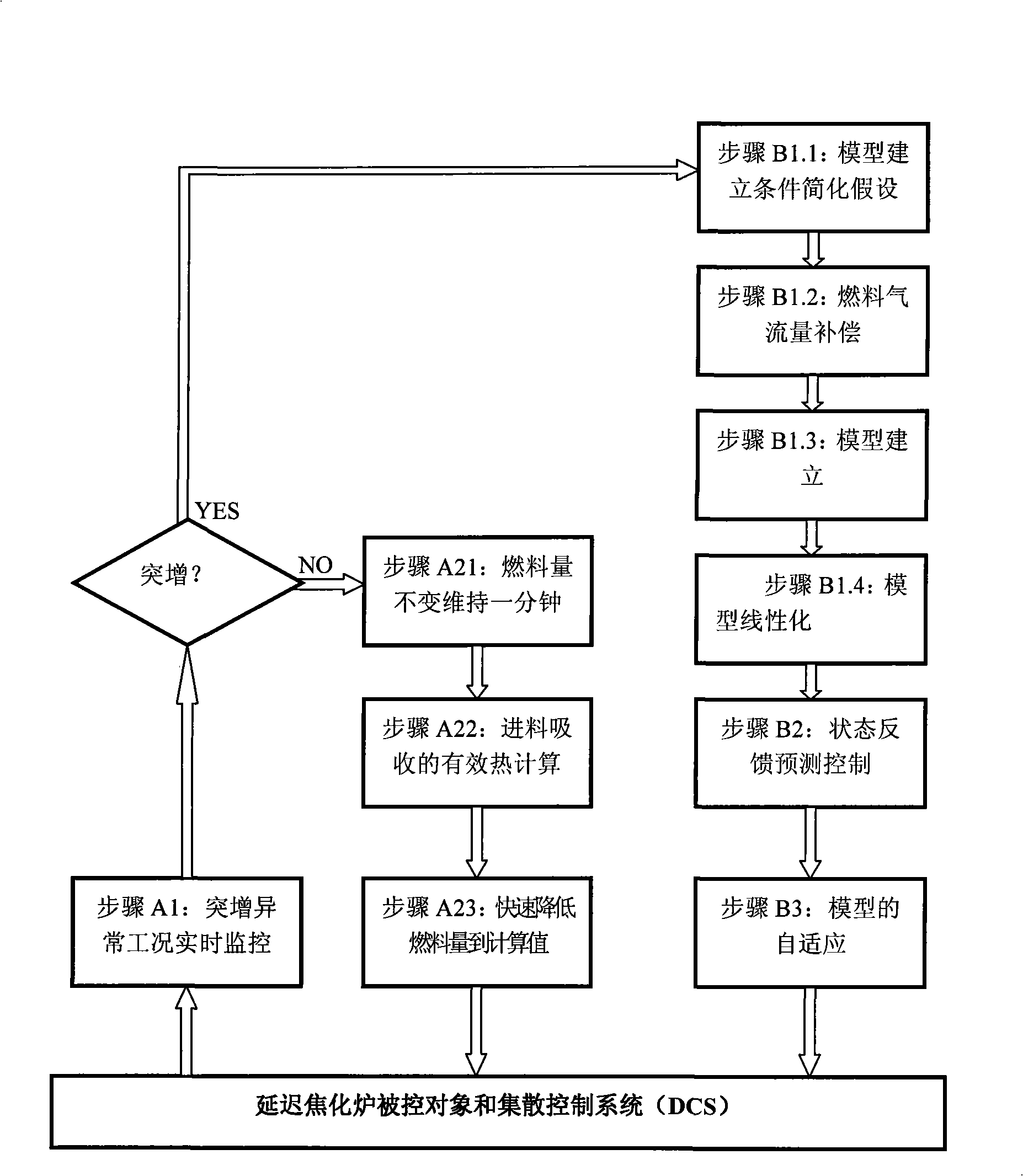

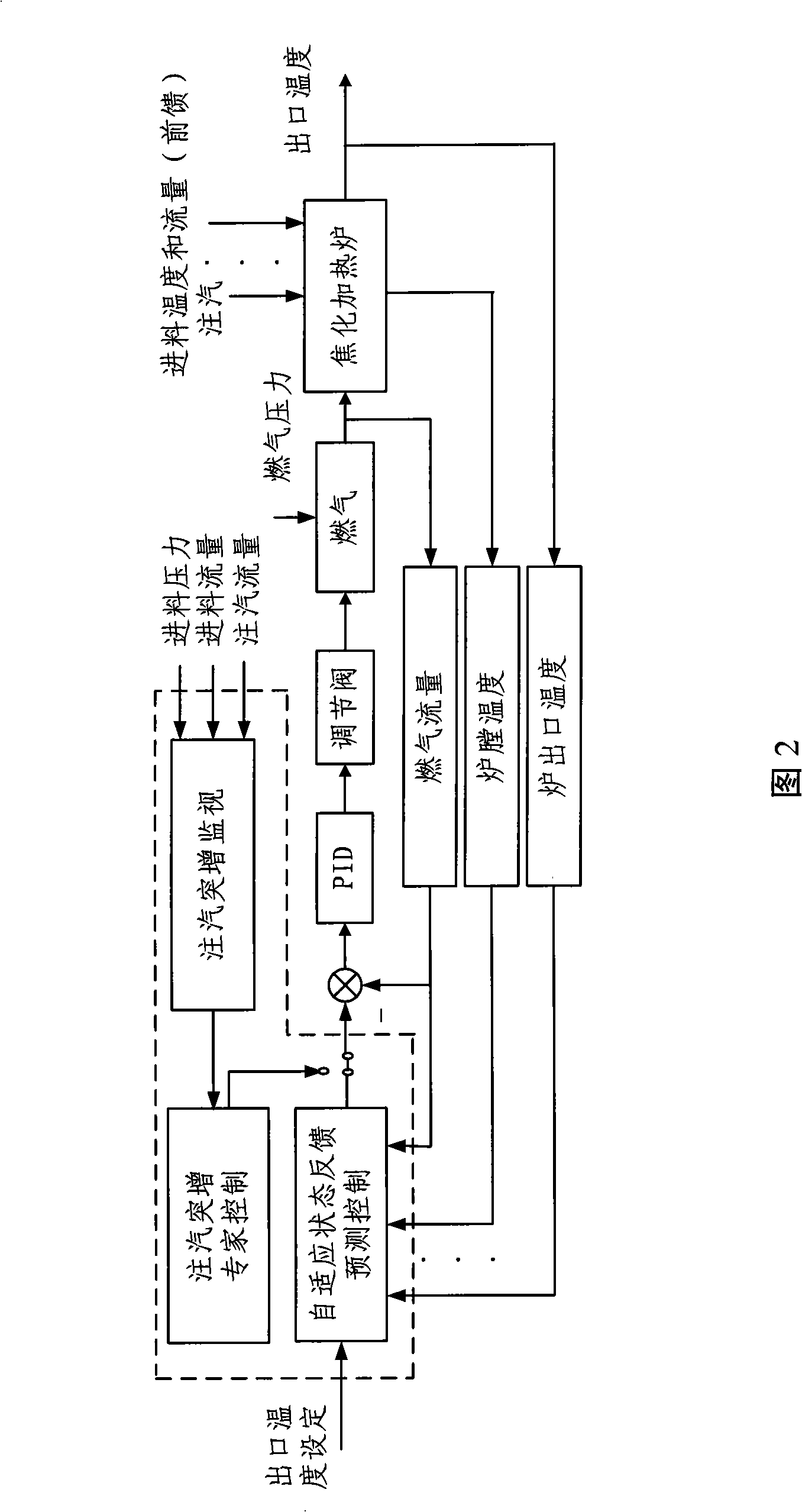

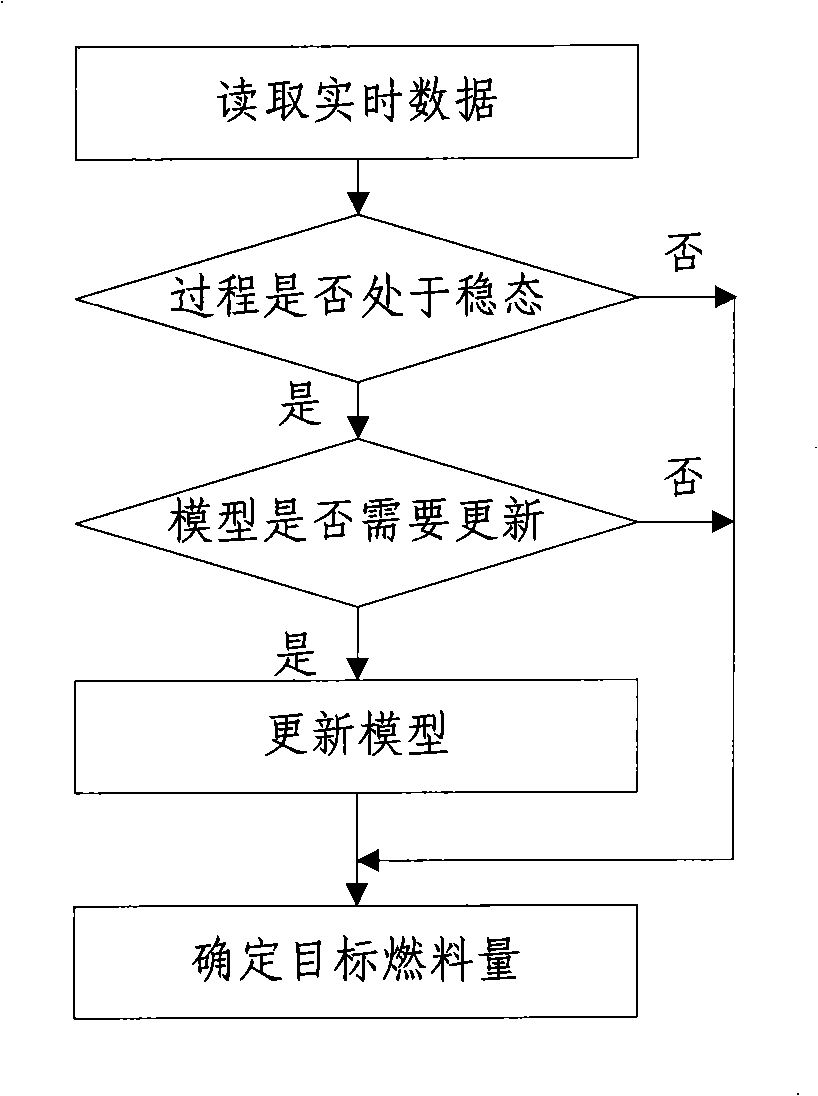

Control method for delay coking stove

InactiveCN101256400AAvoid overheatingImprove anti-interference abilityThermal non-catalytic crackingProgramme controlEngineeringHeat balance

The invention discloses a control method for a delayed coking furnace, comprising: measuring a steam injection quantity, a feeding quantity and a feeding pressure; judging whether the injection quantity has sudden increase abnormal working condition, according to the measured steam injection quantity, feeding quantity and feeding pressure; measuring the temperatures of a hearth and a tube wall, if the sudden increase abnormal working condition occurs; determining an objective fuel quantity, according to the hearth temperature, the feeding quantity and the tube wall temperature; and adjusting the fuel quantity of the delayed coking furnace to the objective fuel quantity. By a state feedback prediction control scheme of real states, the anti-interference ability is effectively improved. Directed at the process characteristic change caused by load change and coking, the variation of a working point is judged on line, model self-adaptation is carried out, and the rate of putting into operation is increased. Directed at great inverse response of an outlet temperature caused by sudden increase of steam injection quantity, expert control is performed based on heat balance calculation, which can effectively prevent the outlet temperature from exceeding, and improving the operation cycle of devices.

Owner:TSINGHUA UNIV

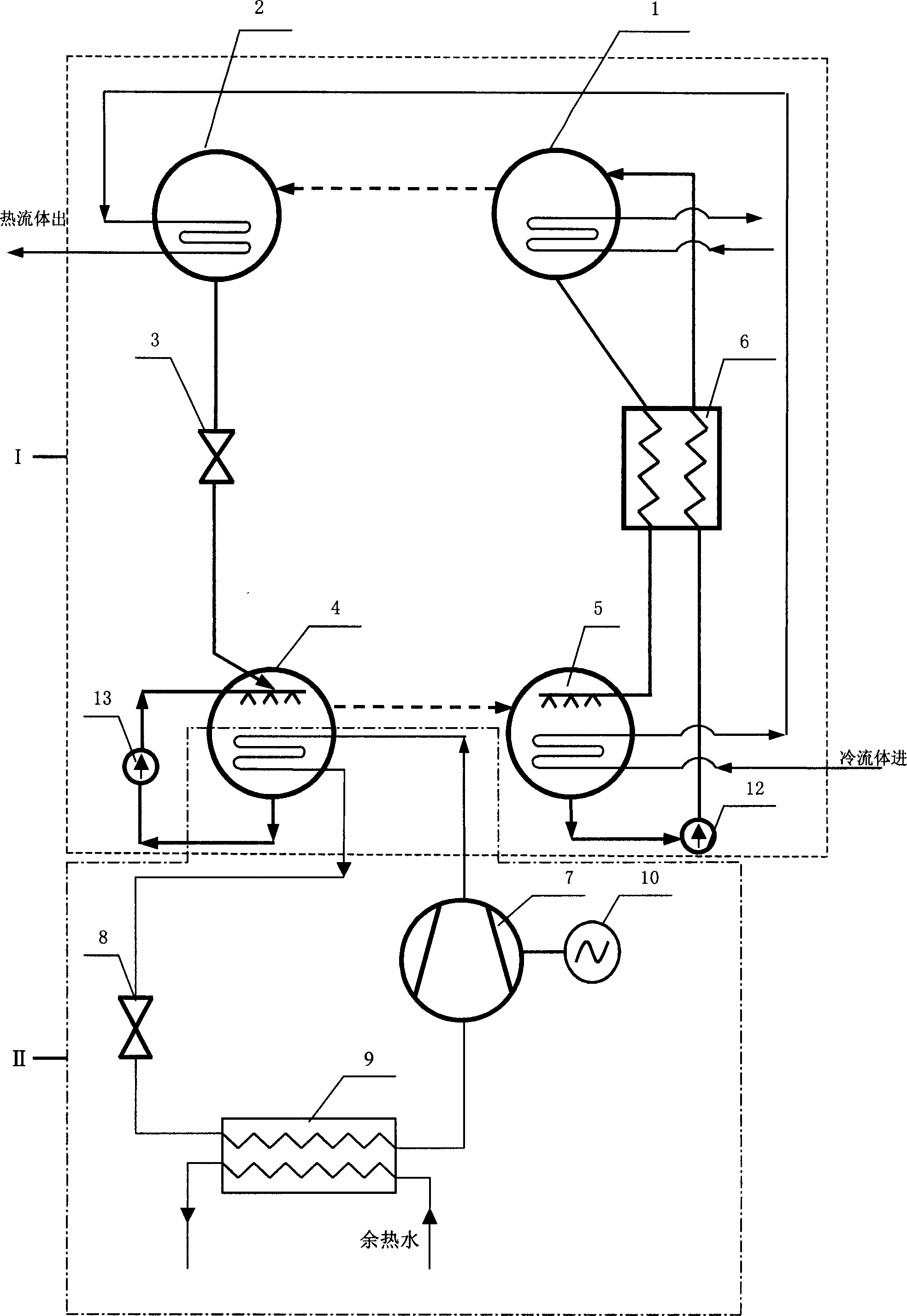

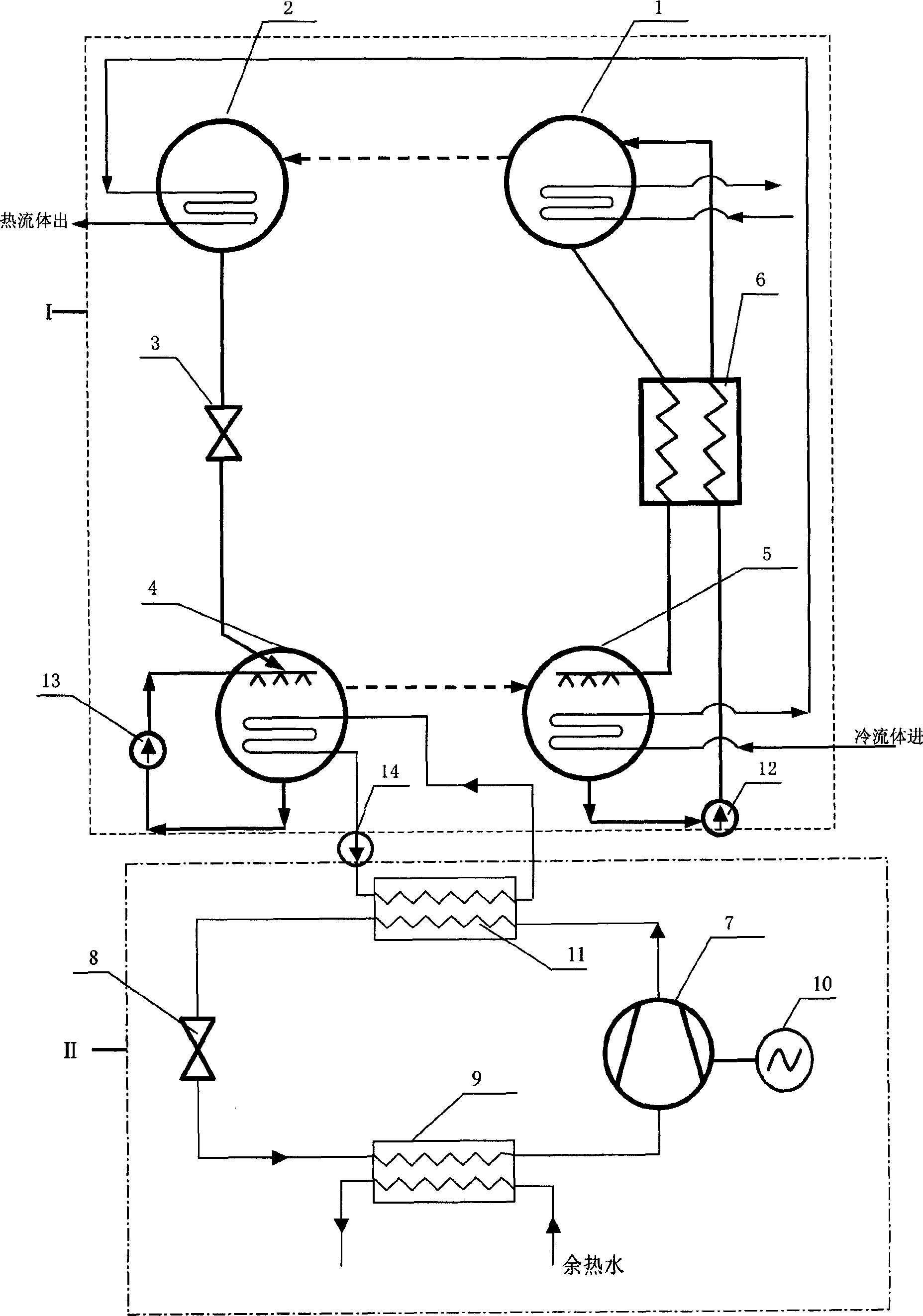

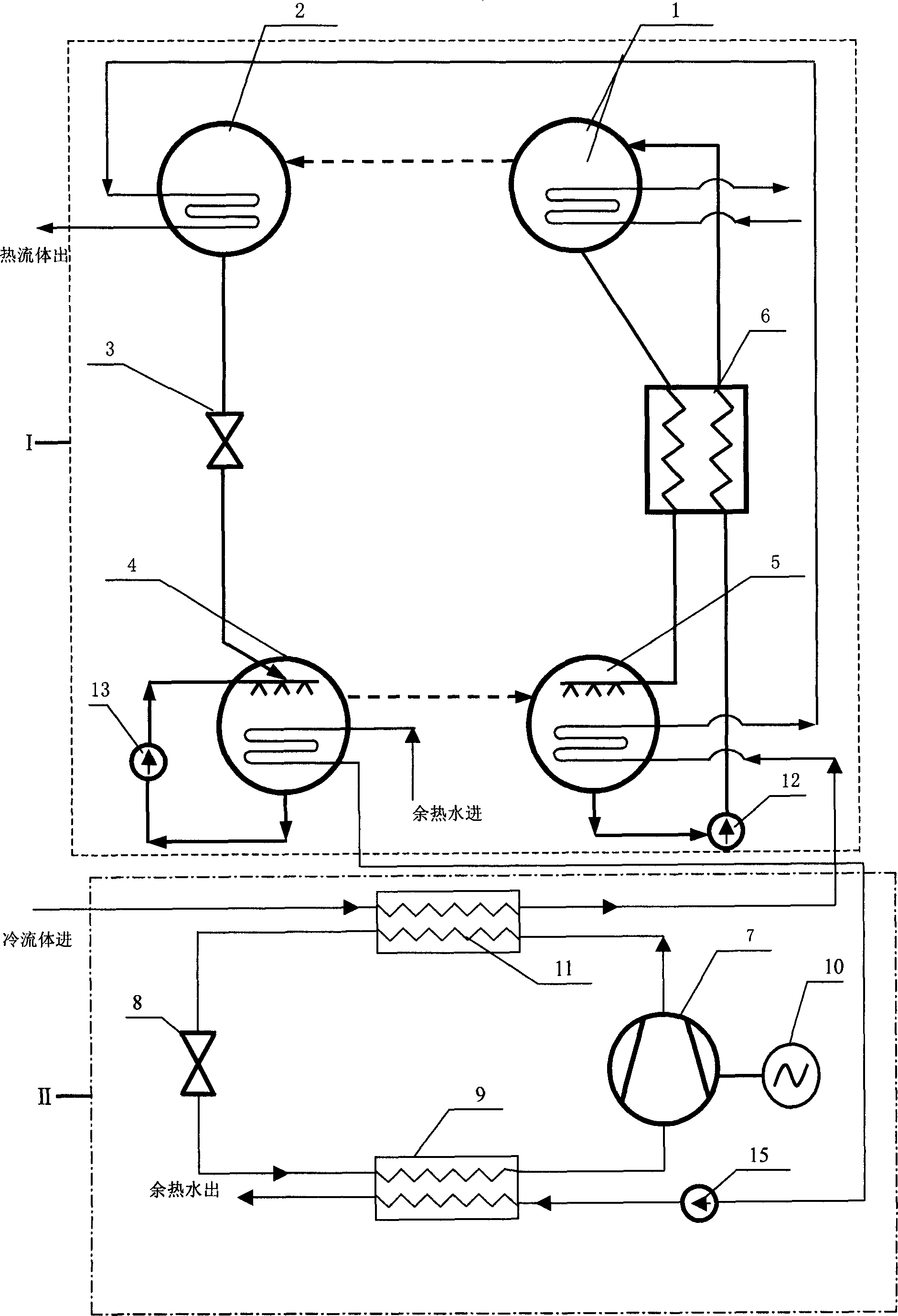

Solid adsorptive refrigerator

ActiveCN1982809AAvoid overheatingSolve the problem of water increase (decrease)Climate change adaptationEnergy efficient heating/coolingWater sourceEnergy recovery

A solid adsorption type refrigerating plant uses a hot-water source and a cold-water source as a by-pass control in the heat recovery and cold-energy recovery process to make it not enter the adsorption bed and the condenser / evaporator, in order to solve the problem of increasing (decreasing) the water yield at the water source end. An additional mass recovery device is used for accelerating and balancing pressure, so as to make further increasement on the refrigerating ability.

Owner:IND TECH RES INST

Operation-starting method of sulfurized hydrogenation catalyst

ActiveCN102041051AReduce manufacturing costSimple production processCatalyst activation/preparationHydrocarbon oils treatmentHydrogenation reactionReaction temperature

The invention relates to an operation-starting method of a sulfurized hydrogenation catalyst. The method comprises the following steps: putting the sulfurized hydrogenation catalyst into a reactor; then pumping inert gases to replace the air in the reactor and pipes in front of and at the back of the reactor and gradually raising the temperature to the activation temperature; and pumping hydrogen to replace the inert gases, adjusting the pressure and temperature to the reaction pressure and temperature after the airflow is stable and putting raw oil to begin hydrogenation. The method overcomes the defects of high preparation cost, long presulfurization time and high operation cost of the conventional oxidized catalysts. The method has the following advantages: the catalyst prepared by the method dispenses with presulfurization and has simple preparation process and operation-starting method; concentrated heat release during operation starting can be suppressed by adopting the inert gases to activate the catalyst; the method is suitable for preparing catalysts for hydrogenation of petroleum fractions; and the hydrogenation activity of the catalyst prepared by the method is superior to that of the conventional catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

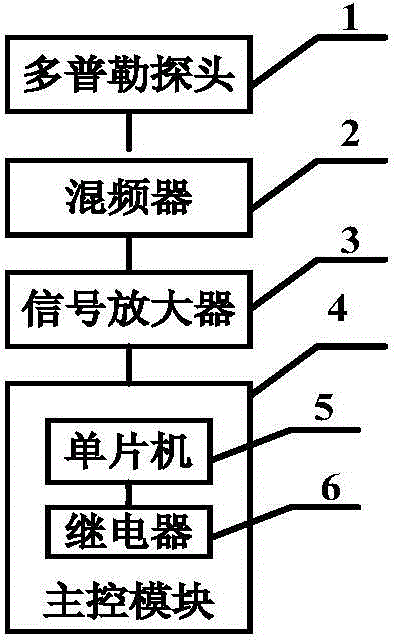

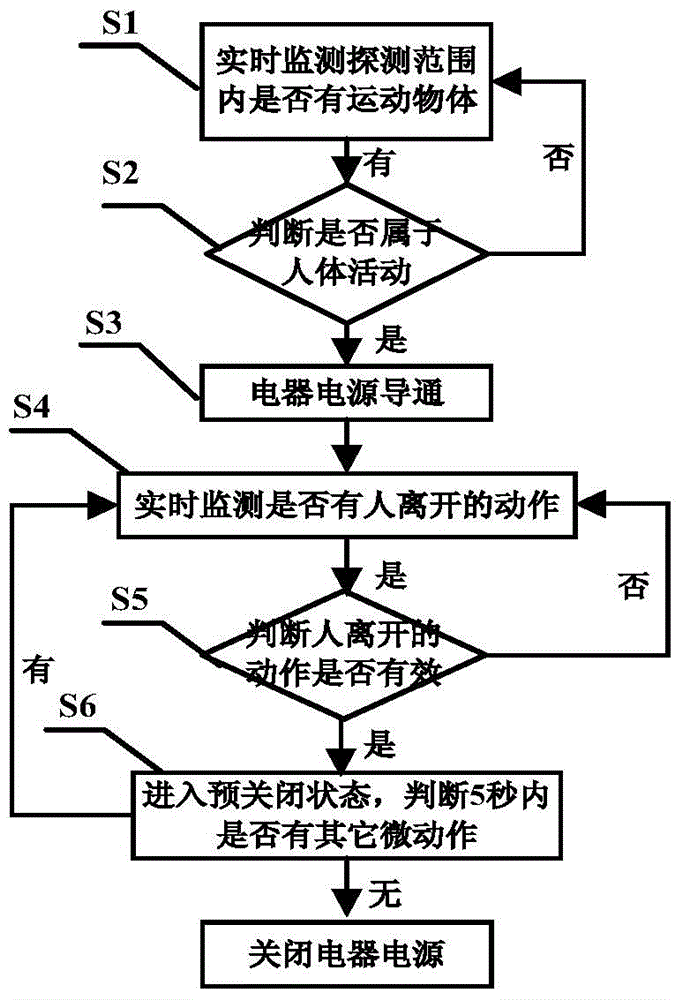

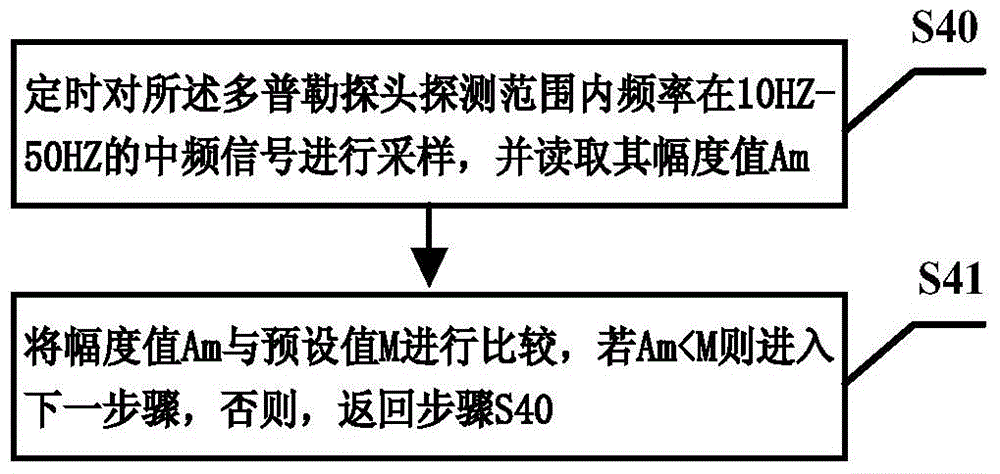

Microwave induction control method and microwave induction control device

ActiveCN104678828AExtended service lifeSolve problems that are prone to electric shock hazardsProgramme controlComputer controlHuman bodyElectricity

The invention discloses a microwave induction control method and a microwave induction control device and relates to the technical field of application of microwave sensors. According to the method, an action system for judging whether persons enter or leave the scene or not is established by using the Doppler effect through the microwave induction control device; a switch of a power supply of an electrical appliance is controlled by identifying the action that human bodies enter or leave the scene; the microwave induction control device adopted by the method can be arranged inside the electrical appliance, so that the electrical appliance adopts a closed structure, and moisture resistance and electric shock prevention can be realized. In addition, according to the method, the action whether the human bodies leave or not can be identified, and the power supply of the electrical appliance is automatically closed when the human bodies leave the detection range and no person exist in the detection range. Besides, the device is low in power consumption; when the device is installed on the electrical appliance for use, the standby power consumption of the electrical appliance can be greatly reduced, and further the aims of saving energy and electricity are achieved.

Owner:感仁科技(深圳)有限公司

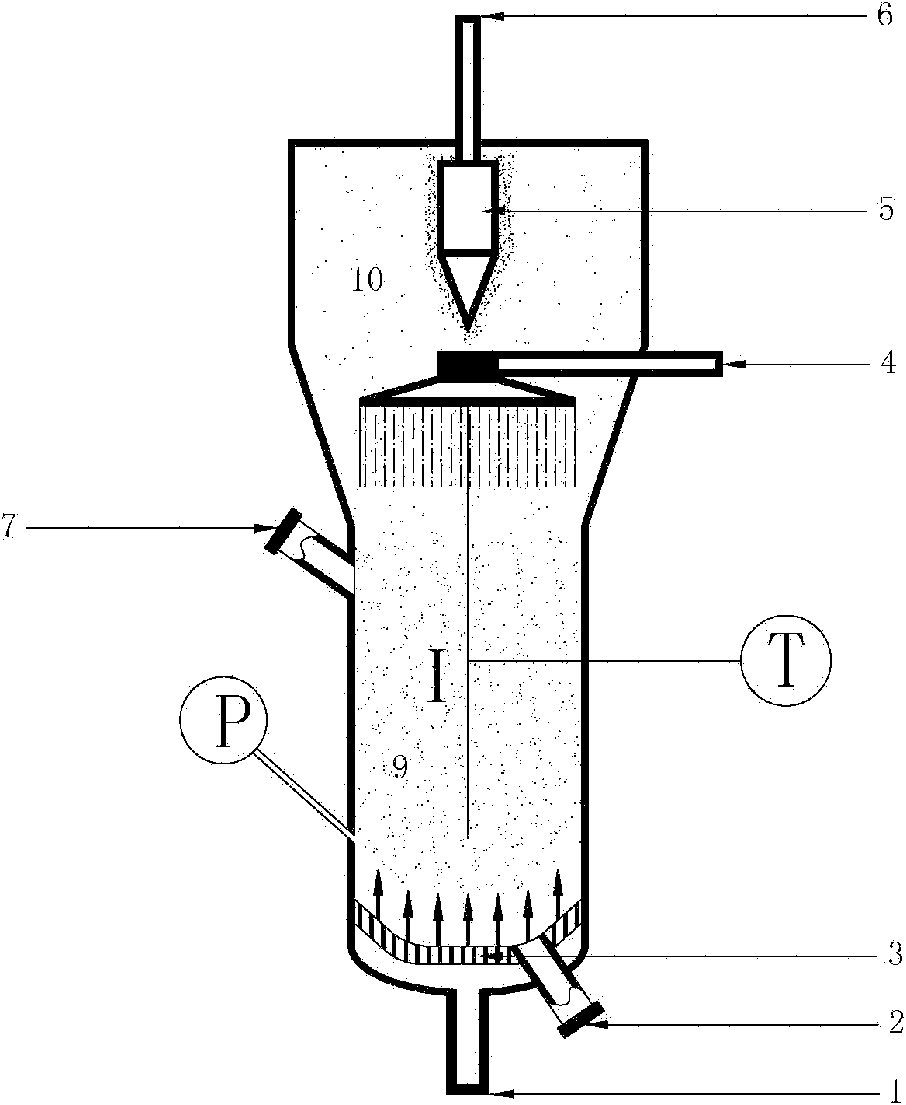

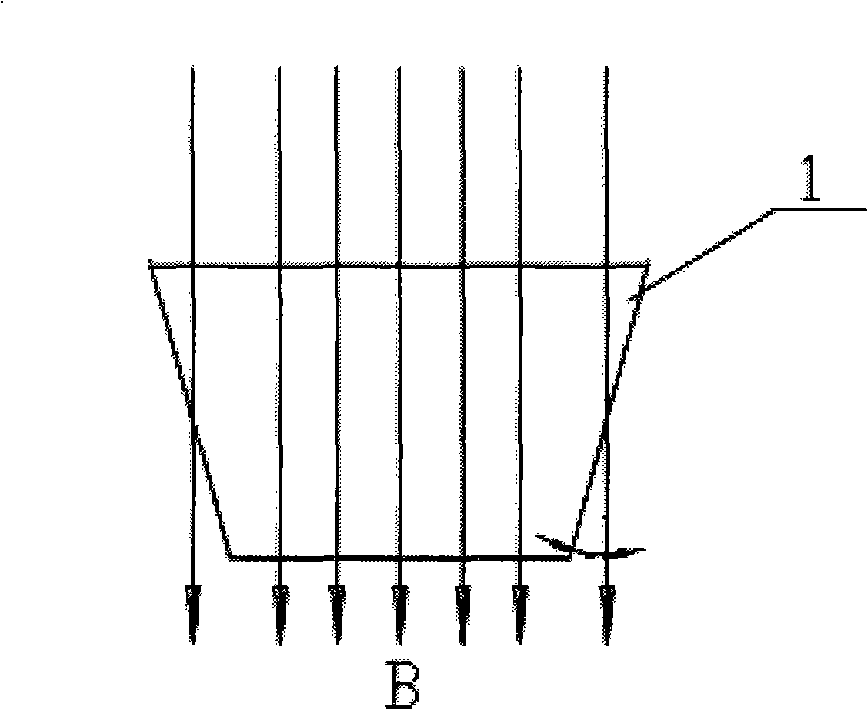

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Monolithic multi-way valve body casting piece casting method

ActiveCN105903910ADefect control such as sticky sandAvoid overheatingFoundry mouldsFoundry coresCasting defectLinearity

The invention discloses a monolithic multi-way valve body casting piece casting method which comprises the following steps: preparing a core preparing mold, and checking and cleaning the mold; preparing a main core by mold sand, and after the shape of the main core is finalized, spraying a mold release agent, and demolding; preparing small cores, and drilling exhaust holes in the small cores; finishing to remove burrs on the main core and the small cores, and removing a transition jet nozzle on the main core; fixing the main core by a sand core bonding preparation tooling, firstly assembling the small core at one side, and then assembling the small core at the other side; mounting the assembled sand core into a shell body; and casting a valve body: performing a pouring process at two sides of a side thin gate at the same time, using an exothermic riser with the diameter of 120 mm and the height of 220 mm, and placing special cold iron at the bottom face of the shell body. The monolithic multi-way valve body casting piece casted by the casting method has the advantages that the linearity of a main valve hole casting blank is controlled to be less than or equal to 1.0 mm, and the valve hole linearity is ensured; the casting piece pore shrinkage, shrinkage porosity, internal gas holes and other casting defects, especially defects of micropores in the casting piece, are solved; and the compactness of the internal structure is improved.

Owner:南通华东油压科技有限公司

Charging method adopting USB interfaces

InactiveCN101771178AReduce thermal power consumptionAvoid overheatingBatteries circuit arrangementsSecondary cells charging/dischargingCharge voltageElectricity

The invention discloses a charging method adopting USB interfaces, which is characterized in that after detecting voltage input on the power pins of the USB interfaces, a charge control module firstly detects the data pin signals of the USB interfaces and then sets different charge current for the batteries according to the difference of the data pin signals; if detecting that the two data wires of the USB interfaces are at high level, the charge control module sets high current for charging the batteries, or the charge control module sets low current for charging the batteries; the USB interfaces employ voltage of 4.5-5.6V. In the method, under the same low charge voltage, whether the inserted power supply is from the computer or the travel charger is judged by recognizing the data pin signals of the USB interfaces, thus setting different charge current for the batteries, solving the problem that the existing travel chargers have big current and big voltage when charging and reducing the heat power consumption during charging.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

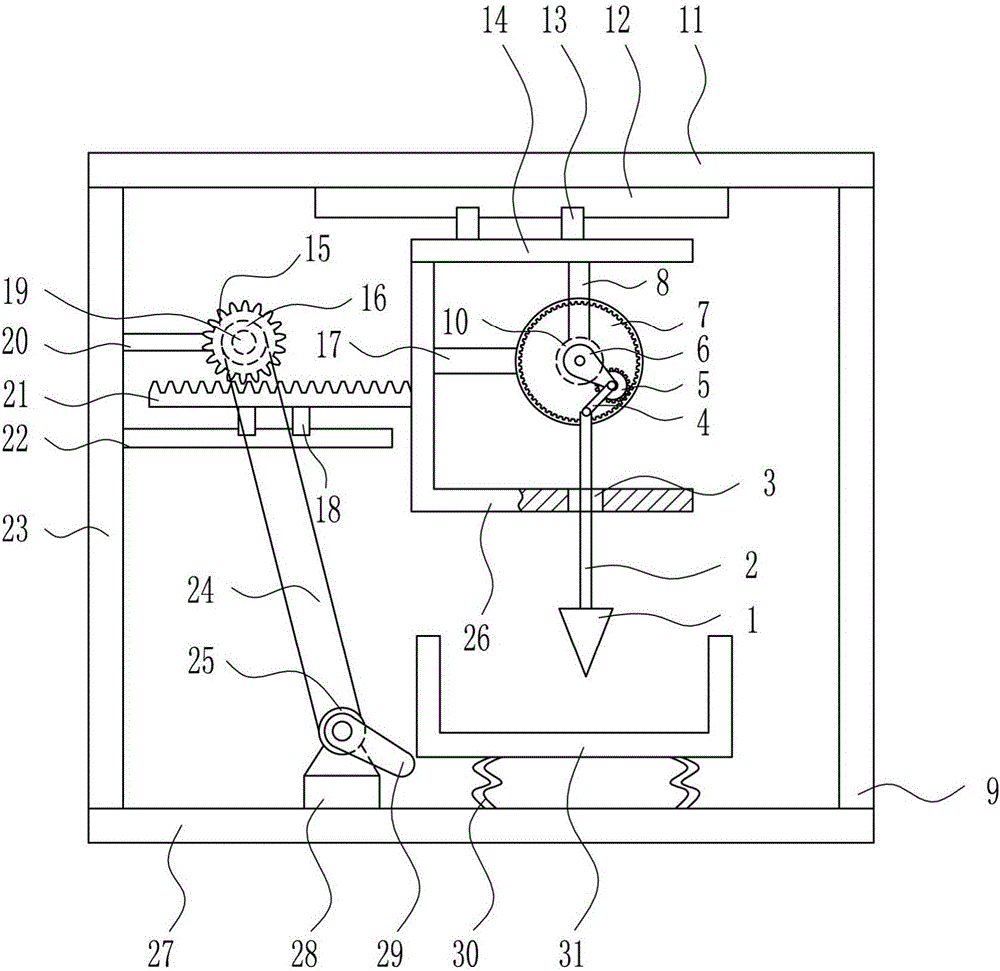

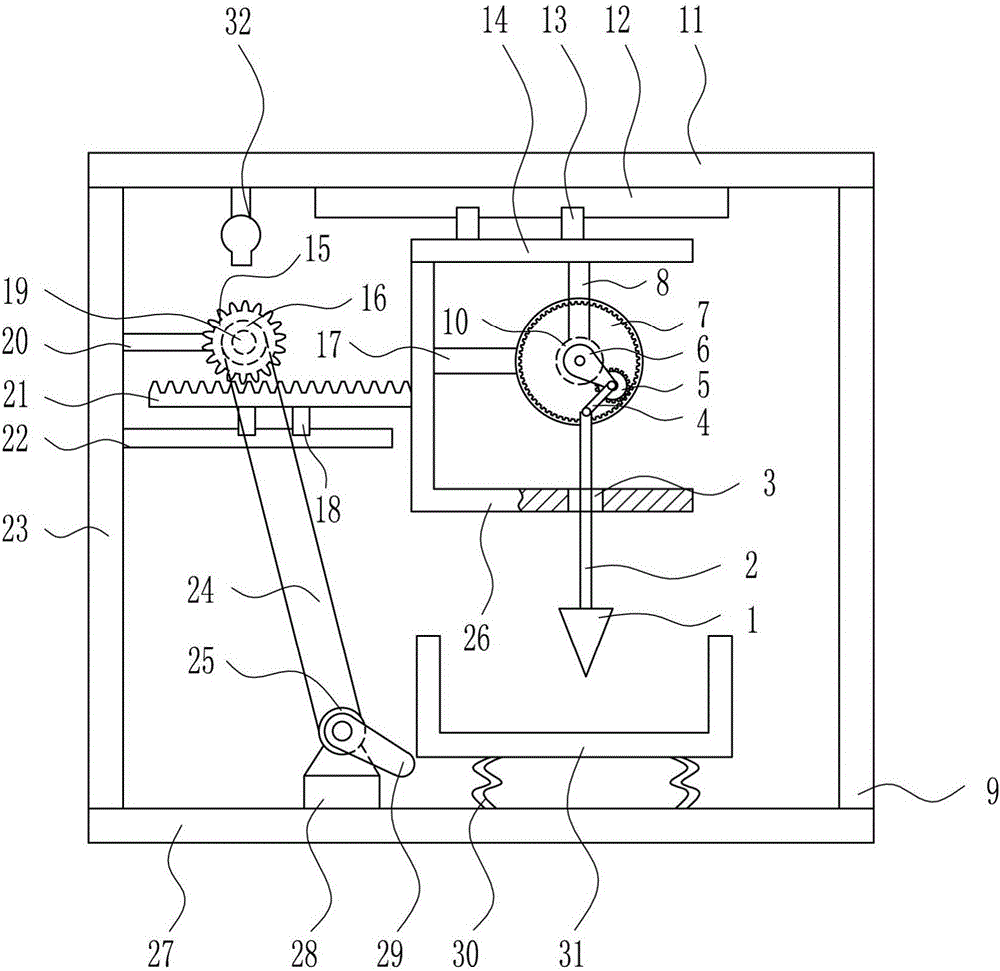

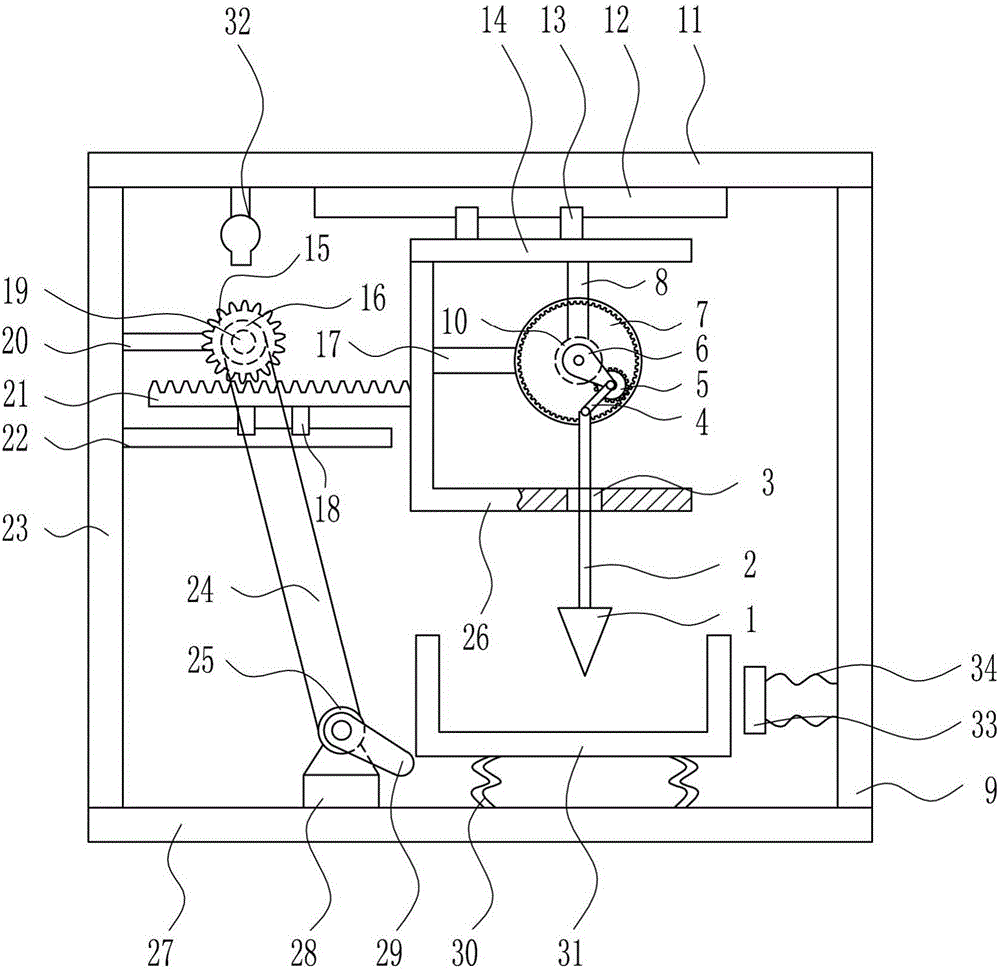

Rapid waste plastic shredding device for food production

ActiveCN106239774AAvoid overheatingExtended service lifePlastic recyclingGrain treatmentsPulleyWaste management

The invention relates to a waste plastic shredding device, in particular to a rapid waste plastic shredding device for food production and aims to provide the rapid waste plastic shredding device for food production which is thorough in shredding, convenient to operate and high in shredding speed. The rapid waste plastic shredding device for food production comprises a cutter, a lifting rod, a first connecting rod, a planetary gear, a crank, a gear ring, a second connecting rod, a right rack, a first motor, a top plate, a first sliding rail, a first sliding block and the like; a left rack and a mounting base are arranged on the left side of top of a bottom plate; the mounting base is positioned on the right side of the left rack; and a small belt pulley is mounted on the mounting base. The rapid waste plastic shredding device for food production realizes the effects of thorough shredding, convenience in operation and high shredding speed and plays the important roles in realizing an excellent shredding effect, improving the working efficiency and realizing high safety.

Owner:江苏通发环保科技有限公司

DC magnetic filtering cathode vacuum arc plasma source

ActiveCN101321427AImprove output efficiencyReduce lossesElectric discharge tubesChemical vapor deposition coatingPhysicsPositive bias

The invention belongs to a plasma source, particularly claims a DC magnetic filtered cathode vacuum arc plasma source. The plasma source is characterized in that a positive bias power supply reduces the loss of the plasma effectively, improves the output efficiency, restrains and stabilizes cathode arc discharging in the cathode head face by using the included angle of the axial magnetic field and the conical cathode inclined plane, so that the invention can work under high vacuum, and the evenness of the plasma entering the vacuum cavity is improved; a resistor can be connected between the water cooling anode cylinder and the water cooling leading-out straight tube, the low plasma output efficiency and the over heat phenomenon of the water cooling leading-out straight tube due to direct grounding of the anode are avoided, thus further improving the output efficiency of the plasma; an air tube can be applied to inflating working gas in the plasma generating area, to participate in plasma discharging, such a method is helpful for depositing high-quality reaction membrane on the work pieces.

Owner:SOUTHWESTERN INST OF PHYSICS

Operation method of vulcanized catalyst

ActiveCN102041050AReduce manufacturing costSimple production processPhysical/chemical process catalystsHydrocarbon oils treatmentHydrogenation reactionOxidation state

The invention relates to an operation method of a vulcanized catalyst, which comprises steps of loading the vulcanized catalyst into a reactor, introducing inert gas to replace air in the reactor and air in pipes in front of and behind the reactor, gradually raising the temperature to the activation temperature, switching hydrogen, adjusting pressure and temperature to reaction pressure and reaction temperature after airflow is stable, and introducing raw oil to carry out hydrogenation reaction, wherein a sulfide precursor containing metal Mo or W, Ni or Co, and a catalyst carrier required by the dipping of the dipping solution of an organic assistant are adopted by the vulcanized catalyst, and can be dried to obtain the vulcanized catalyst. The operation method solves the disadvantages of high preparation cost, long prevulcanization time and high operating cost of the traditional oxidation state catalyst. The catalyst prepared by the method does not need to be pre-vulcanized, and the preparation process and the operation method are simple, and are suitable for preparing the petroleum distillate hydrogenation catalyst. The hydrogenation activity of the catalyst prepared by the operation method is better than that of the traditional catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment

InactiveCN103539770AShort reaction timeImprove reaction efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsCyclohexanoneAcetic anhydride

The invention relates to a continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment, belonging to the technical field of organic synthesis. The method takes cyclohexanone as initial reaction raw material and peracetic acid generated in the reaction of hydrogen peroxide and acetic anhydride as an oxidizing agent, and the processes such as peroxy acid preparation, cyclohexanone oxidation and the like are continuously completed in a microchannel reactor system. The continuous reaction technological method effectively controls the temperature in the reaction process, is high in safety, does not need an additional solvent, catalyst and stabilizing agent, is beneficial to separation and purification of caprolactone, and enables the high-yield continuous production of the epsilon-caprolactone to be possible; the microchannel reaction equipment provided by the invention highly meets the requirements of the reaction technology. The conversion rate of the cyclohexanone reaches 50-95%, and the selectivity of the epsilon-caprolactone is 80-100%.

Owner:CHANGZHOU UNIV

Second-active-center-containing catalyst hydrogenation apparatus startup method

ActiveCN106947527AImprove usage activityConvenience and Economic PathwayTreatment with hydrotreatment processesProduct gasChemistry

The present invention discloses a startup sulfurization method of a hydrocracking apparatus. According to the present invention, with the grading use of the ex-situ presulfided catalyst, the hydrogenation catalyst containing the second active center is pre-protected with the hydrogen sulfide gas produced in the heating process while a certain auxiliary gas can be selectively injected according to different preparation methods of the second active center catalysts, such that the wet startup is converted into the dry startup; and the activity of the catalyst can be improved with the method of the present invention, and the method is suitable for the sulfurization startup process of the hydrogenation catalyst containing the second active center.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com