Car air-conditioner evaporator refrigerating agent flow control system

A refrigerant flow rate and evaporator technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as excessive evaporator overheating, compressor liquid shock, affecting system stability and comfort, etc., to achieve Improve heat transfer efficiency, ensure stability, and avoid overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

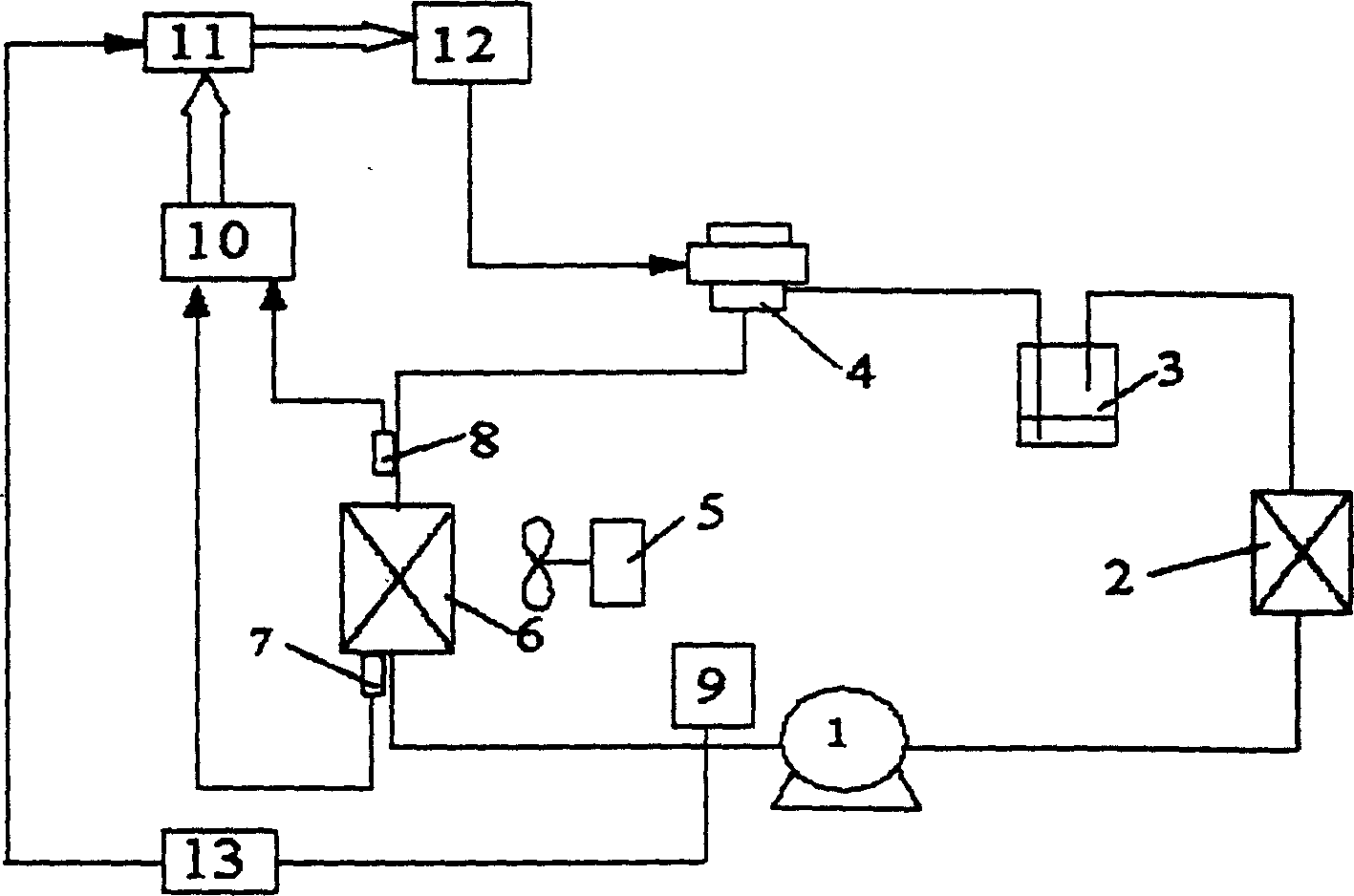

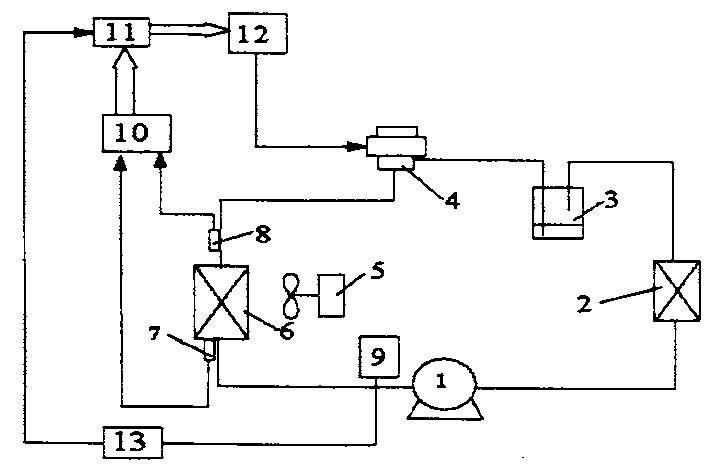

[0007] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings

[0008] Such as figure 1 As shown, the present invention mainly includes: compressor 1, condenser 2, liquid receiver 3, electronic expansion valve 4, evaporator fan 5, evaporator 6, evaporator outlet temperature sensor 7, evaporator inlet temperature sensor 8, compression Engine speed sensor 9, AD conversion module 10, controller 11, electronic expansion valve drive circuit 12, feedforward compensation link 13. The outlet of compressor 1 is connected to the inlet of condenser 2, the outlet of condenser 2 is connected to the inlet of liquid accumulator 3, the outlet of liquid accumulator 3 is connected to the inlet of electronic expansion valve 4, the outlet of electronic expansion valve 4 is connected to the inlet of evaporation The inlet of the evaporator 6 is connected, and the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com