DC magnetic filtering cathode vacuum arc plasma source

A cathode vacuum arc and plasma source technology, applied in the direction of plasma, gaseous chemical plating, coating, etc., can solve the problems of reducing the strength of the filtering magnetic field, affecting the stability of the arc discharge, and poor filtering effect of large particles. The effect of improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

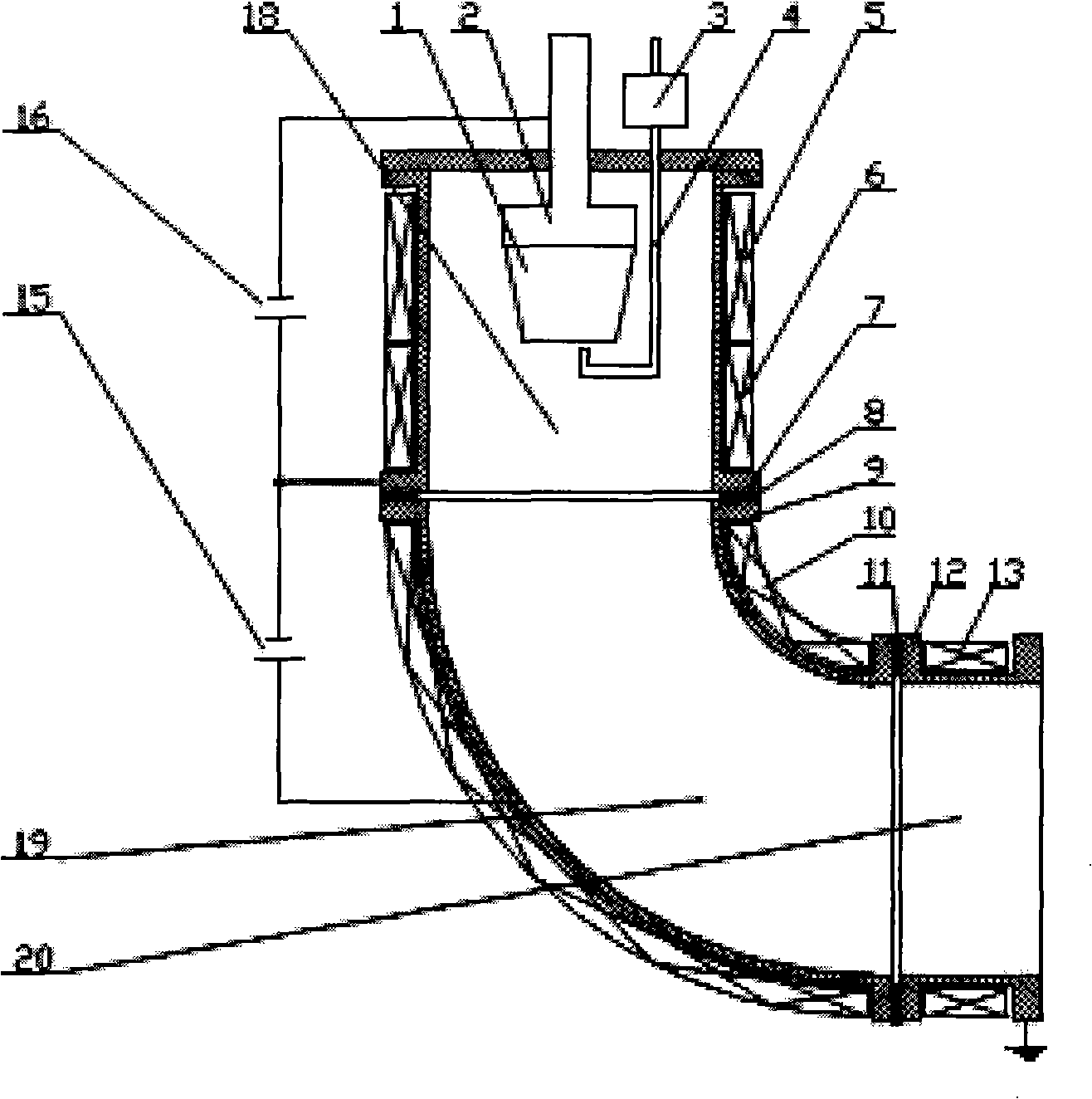

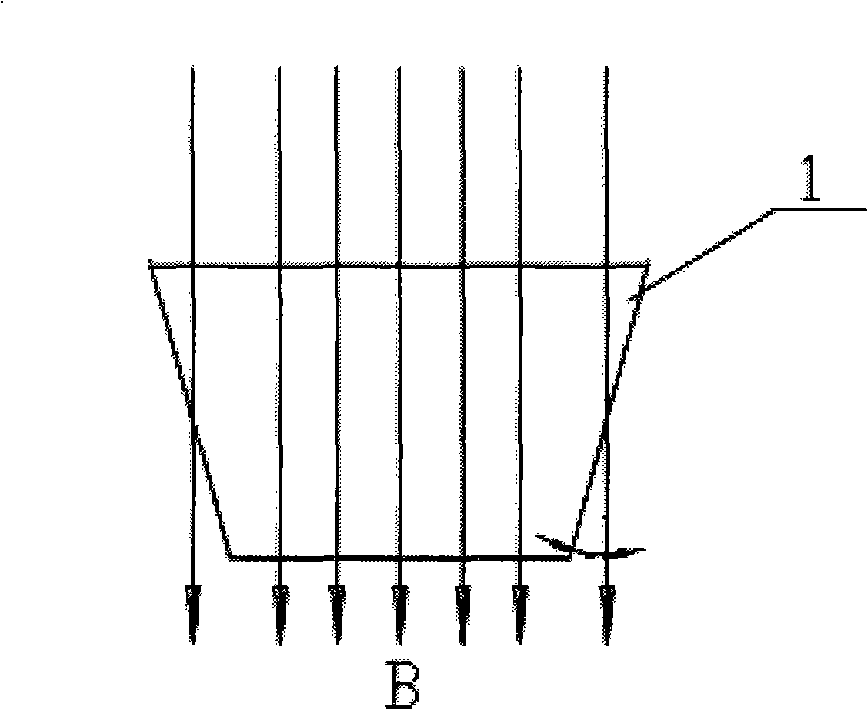

[0021] Such as Figure 1 to Figure 2 As shown, the water-cooled anode cylinder 7 is provided with a truncated-conical cathode 1 installed on the cathode water-cooled seat 2, a trigger pin 4 connected with the trigger wire package 3, and stable wires are respectively wound up and down on the outside of the water-cooled anode cylinder 7. The arc coil 5 and the focusing coil 6, the deflection coil 10 is wound outside the water-cooled filter elbow 9, the lead-out coil 13 is wound outside the water-cooled lead-out straight pipe 12, and the arc discharge is connected between the water-cooled anode cylinder 7 and the cathode water-cooled seat 2 A power supply 16, a positive bias power supply 15 is connected between the water-cooled filter elbow 9 and the water-cooled anode cylinder 7

specific Embodiment approach 2

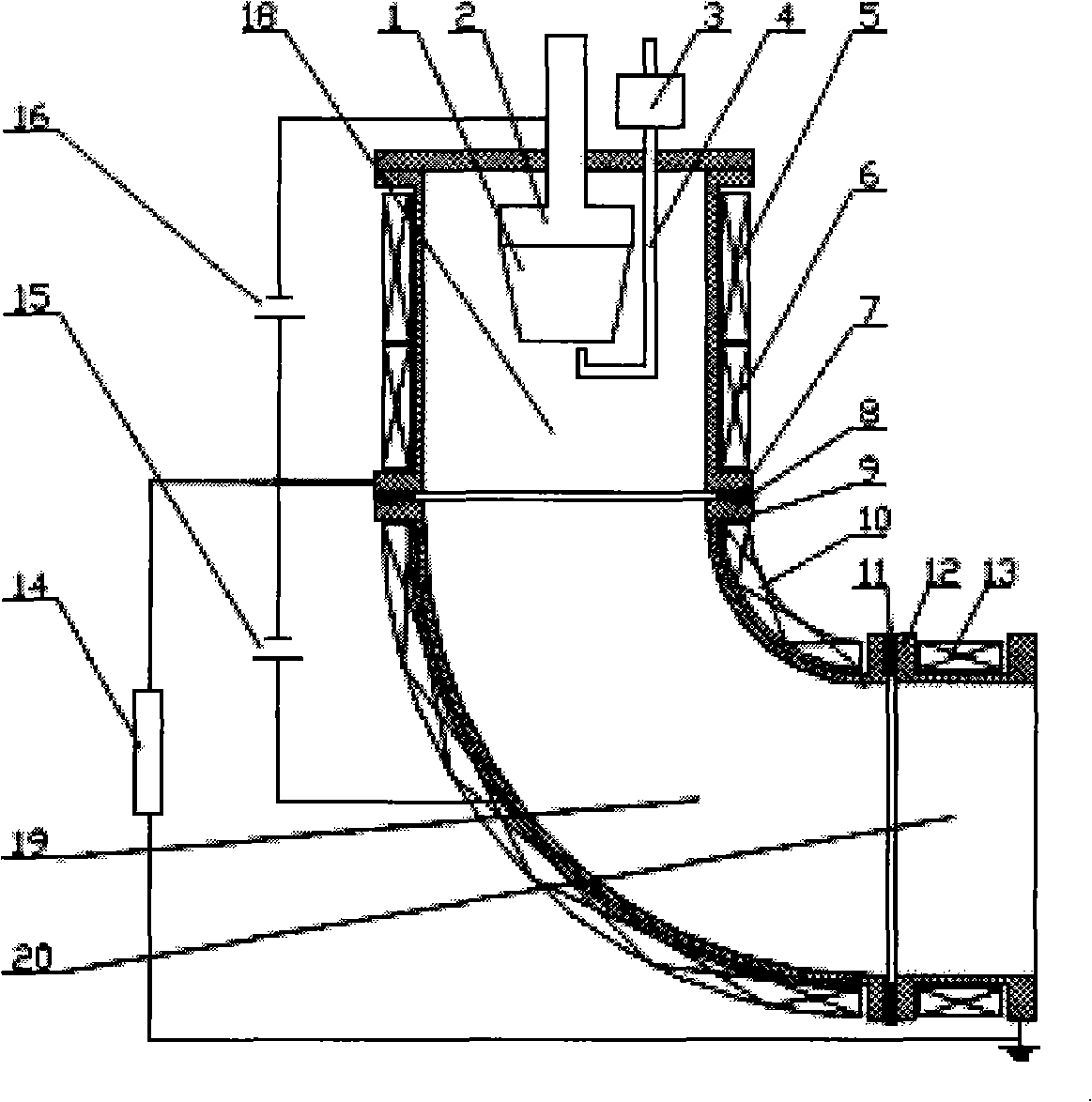

[0022] Such as image 3 As shown, on the basis of Embodiment 1, a resistor 14 is connected between the water-cooled anode cylinder 7 and the water-cooled straight pipe 12,

specific Embodiment approach 3

[0023] Such as Figure 4 As shown, on the basis of Embodiment 1, an air supply pipe 17 is added at the top of the water-cooled anode cylinder 7, and Ar, N 2 、C 2 h 2 Wait for the working gas to be sent into the plasma generation area 18, so that the working gas also participates in the plasma discharge,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com